Quality of Frozen Hake Fillets in the Portuguese Retail Market: A Case Study of Inadequate Practices in the European Frozen White Fish Market

Abstract

1. Introduction

2. Materials and Methods

2.1. Raw Material, Processing, and Sampling

2.1.1. Market Study

2.1.2. Chemicals and Reagents

2.2. Analytical Determinations

2.2.1. Physical Analysis

2.2.2. Biochemical Analysis

2.2.3. Hake Fillets Species Identification

2.2.4. Microbiology Analysis

2.2.5. Sensory Analysis

2.3. Statistical Analysis

3. Results and Discussion

3.1. Hake Fillets Species Identification

3.2. Net Weight, Glaze Ice, Thaw-Drip, Cook Loss, and Water-Holding Capacity (Raw and Cook)

3.3. pH

3.4. Soluble Protein, Soluble/Total Protein Percentage, and Thaw-Drip Protein

3.5. Total Volatile Basic Nitrogen

3.6. Total Phosphates and Free Polyphosphates

3.7. Citrates

3.8. Microbiology Analysis

3.9. Packaging Analysis

3.10. Sensory Analysis

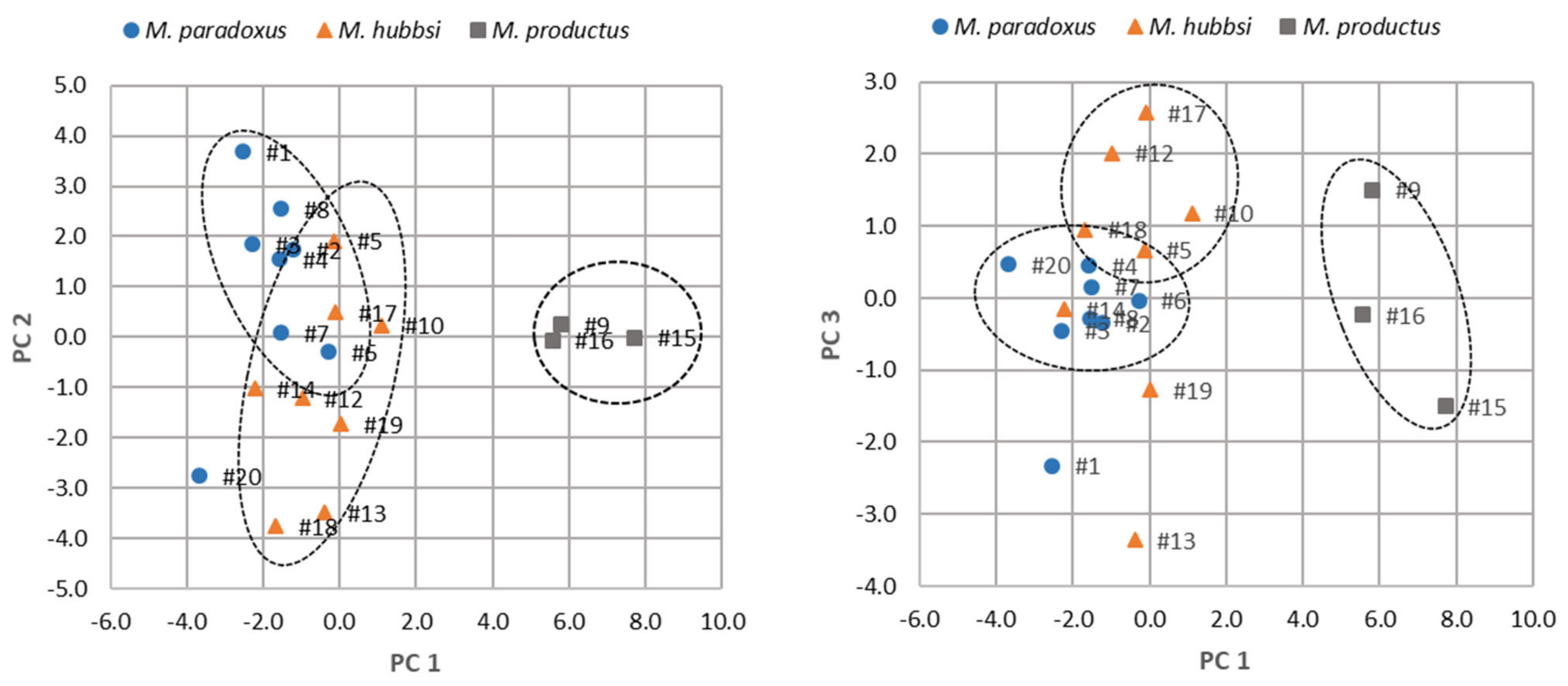

3.11. Relationship between Quality Control Parameters Indices—Multivariate Analysis

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- FAO. The State of World Fisheries and Aquaculture 2018—Meeting the Sustainable Development Goals; FAO: Rome, Italy, 2018. [Google Scholar]

- EUMOFA. EUMOFA’s Annual Report Offers A Comprehensive Analysis At EU-Level of All Market Dimensions of Fisheries and Aquaculture Products. Luxembourg. 2019. Available online: https://www.eumofa.eu/documents/20178/314856/EN_The+EU+fish+market_2019.pdf (accessed on 8 January 2020).

- AIPCE-CEP. EU Fish Processors and Traders Association and European Federation of National Organizations of Importers and Exporters of Fish, Finfish Study 2018. EU Fish Processors and Traders Association, Brussels, Nov. 2018. Available online: https://www.aipce-cep.org/wp-content/uploads/2018/12/Finfish-Study-2018-compressed.pdf (accessed on 10 January 2020).

- Laurenti, G. Fish and Fishery Products: World Apparent Consumption Statistics Based on Food Balance Sheets 1961–2007; Food and Agriculture of the United Nations: Rome, Italy, 2010. [Google Scholar]

- Vanhonacker, F.; Pieniak, Z.; Verbeke, W. European consumer perceptions and barriers for fresh, frozen, preserved and ready-meal fish products. Br. Food J. 2013, 115, 508–525. [Google Scholar] [CrossRef]

- Owen, H.; Carpenter, G. Fish Dependence—2018 Update. The Reliance of the EU on Fish from Elsewhere; New Economics Foundation: London, UK, 2018. [Google Scholar]

- Almeida, C.; Karadzic, V.; Vaz, S. The seafood market in Portugal: Driving forces and consequences. Mar. Policy 2015, 61, 87–94. [Google Scholar] [CrossRef]

- Nunes, M.L.; Bandarra, N.M.; Oliveira, L.; Batista, I.; Calhau, M.A. Composition and nutritional value of fishery products consumed in Portugal. In Seafood Research from Fish to Dish. Quality, Safety and Processing of Wild and Farmed Fish; Luten, J.B., Jacobsen, C., Bekaert, K., Sæbø, A., Oehlenschläger, J., Eds.; Wageningen Academic Publishers: Wageningen, The Netherlands, 2006; pp. 477–487. [Google Scholar]

- Johnston, W.A.; Nicholson, F.J.; Roger, A.; Stroud, G.D. Freezing and Refrigerated Storage in Fisheries; FAO Fisheries Technical Paper. No. 340FAO: Rome, Italy, 1994; 143p. [Google Scholar]

- Moody, M.W. Fish Processing. In Encyclopedia of Food Sciences and Nutrition, 2nd ed.; Trugo, L., Finglas, P.M., Eds.; Academic Press: Cambridge, MA, USA, 2003; pp. 2453–2457. [Google Scholar] [CrossRef]

- Samples, S. The effects of storage and preservation technologies on the quality of fish products: A review. J. Food Process. Preserv. 2015, 39, 1206–1215. [Google Scholar] [CrossRef]

- Sikorski, Z.; Olley, J.; Kostuch, S. Protein changes in frozen fish. Crit. Rev. Food Sci. Technol. 1976, 8, 97–129. [Google Scholar] [CrossRef]

- Mills, A. Measuring changes that occur during frozen storage of fish: A review. Int. J. Food Sci. Technol. 1975, 10, 483–496. [Google Scholar] [CrossRef]

- Haard, N.F. Biochemical Reactions in Fish Muscle During Frozen Storage. In Seafood Science and Technology; Bligh, E.G., Ed.; Fishing News Books: Oxford, UK, 1992; pp. 176–209. [Google Scholar]

- Careche, M.; Mazo, M.L.; Fernández-Martin, F. Extractability and thermal stability of frozen hake (Merluccius merluccius) fillets stored at −10 and −30 °C. J. Sci. Food Agric. 2002, 82, 1791–1799. [Google Scholar] [CrossRef]

- Shenouda, S.Y.K. Theories of protein denaturation during frozen storage of fish flesh. Adv. Food Res. 1980, 26, 275–311. [Google Scholar]

- Nakazawa, N.; Okazaki, E. Recent research on factors influencing the quality of frozen seafood. Fish. Sci. 2020, 86, 231–244. [Google Scholar] [CrossRef]

- Rustad, T. Muscle chemistry and the quality of wild and farmed cod. In Quality Assurance in the Fish Industry; Huss, H.H., Jakobsen, M., Liston, J., Eds.; Elsevier Science Publishers: Amsterdam, The Netherlands, 1992; pp. 19–27. [Google Scholar]

- Nygard, T. Liquid losses from Atlantic Cod (Gadus morhua) during heat treatment. Master’s Thesis, University of Stavanger, Stavanger, Norway, 2019. [Google Scholar]

- Eskin, N.A.M. Biochemical changes in raw foods: Meat and fish. In Biochemistry of Foods, 2nd ed.; Eskin, M., Ed.; Academic Press, Inc.: London, UK, 1990; pp. 3–68. [Google Scholar]

- Gonçalves, A.A. The pH of the seafood meat: A problem that deserves to be clarified. MOJ Food Process. Technol. 2017, 4, 25–26. [Google Scholar] [CrossRef]

- Oehlenschläger, J. Evaluation of some well-established and some underrated indices for the determination of freshness and/or spoilage of ice stored wet fish. In Quality Assurance in the Fish Industry; Huss, H.H., Jakobsen, M., Liston, J., Eds.; Elsevier Science Publishers: Amsterdam, The Netherlands, 1992; pp. 339–350. [Google Scholar]

- Etienne, M. Volatile Amines as Criteria for Chemical Quality Assessment. European Project 63—Valid Ifremer, Nantes. 2005, pp. 1–22. Available online: https://archimer.ifremer.fr/doc/2005/rapport-6486.pdf (accessed on 16 December 2020).

- European Commission. Regulation (EU) No 1169/2011 of the European Parliament and of the Council of 25 October 2011 on the provision of food information to consumers, amending Regulations (EC) No 1924/2006 and (EC) No 1925/2006 of the European Parliament and of the Council. Off. J. Eur. Union 2011, L 304, 18–63. [Google Scholar]

- International Institute of Refrigeration. Recommendations for the Processing and Handling of Frozen Foods. Recommendations pour la Préparation et la Distribution des Aliments Congelés, 4th ed.; International Institute of Refrigeration: Paris, France, 2006. [Google Scholar]

- World Food Logistics Organization. Frozen Foods Handling & Storage; WFLO Commodity Storage Manual; World Food Logistics Organization, 2008; Available online: https://www.gcca.org/resources/industry-topics/commodity-storage-handling/commodity-storage-manual (accessed on 28 October 2020).

- European Commission. Regulation (EC) No 853/2004 of the European Parliament and of the Council of 29 April 2004 laying down specific hygiene rules for food of animal origin. Off. J. Eur. Union 2004, L 139, 55–205. [Google Scholar]

- European Commission Commission Regulation (EC) No 2074/2005 of 5 December 2005 laying down implementing measures for certain products under Regulation (EC) No 853/2004 of the European Parliament and of the Council and for the organisation of official controls. Off. J. Eur. Union 2005, L 338, 27–59.

- European Commission. Commission Regulation (EC) No 2073/2005 of 15 November 2005 on microbiological criteria for foodstuffs. Off. J. Eur. Union 2005, L 338, 1–26. [Google Scholar]

- ICMSF International Commission on Microbiological Specifications for Foods. Sampling plans for fish and shellfish. In ICMSF, Microorganisms in foods. Sampling for microbiological analysis: Principles and scientific applications, 2nd ed.; University of Toronto Press: Toronto, ON, Canada, 1986; Volume 2, pp. 181–196. [Google Scholar]

- Sciortino, J.A.; Ravikumar, R. Fishery Harbour Manual on the Prevention of Pollution. Madras, India, Bay of Bengal Programme. 1999, BOBP/MAG/22. Available online: http://books.google.com/books?id=WF3bAAAAMAAJ (accessed on 16 January 2021).

- SEAFISH. Review of Polyphosphates as Additives and Testing Methods for Them in Scallops and Prawns. Campden BRI Report: BC-REP-125846-01. 2012. Available online: https://www.seafish.org/document/?id=7cf5af51-1499-47aa-b578-9346f26a95f7 (accessed on 16 December 2020).

- Bour, N.J.S.; Soullier, B.A.; Zemel, M.B. Effect of level and form of phosphorus and level of calcium intake on zinc, iron and copper bioavailability in man. Nutr. Res. 1984, 4, 371–379. [Google Scholar] [CrossRef]

- Ritz, E.; Hahn, K.; Ketteler, M.; Kuhlmann, M.K.; Mann, J. Phosphate additives in food—A health risk. Dtsch. Arztebl Int. 2012, 49–55. [Google Scholar]

- European Commission. Regulation (EC) No 1333/2008 of the European Parliament and of the Council of 16 December 2008 on food additives. Off. J. Eur. Union 2008, L 354, 16–33. [Google Scholar]

- European Commission. Regulation (EU) No 1379/2013 of the European Parliament and of the Council of 11 December 2013 on the common organization of the markets in fishery and aquaculture products. Off. J. Eur. Union 2013, L 354, 1–21. [Google Scholar]

- Decreto Lei. Decreto-Lei n.° 37/2004, Diário da República n.°48/2004, Série I-A de 2004-02-26, Ministério da Agricultura, Desenvolvimento Rural e Pescas, 2004, 37, 1006–1009. Available online: https://data.dre.pt/eli/dec-lei/37/2004/02/26/p/dre/pt/html (accessed on 20 April 2020).

- Anonym. Teste a pescada congelada (Test to frozen hake). Deco Proteste 1999, 131, 14–19.

- Anonym. Pescada congelada (Frozen hake). Deco Proteste 2009, 300, 29–32.

- Bremmer, A.H. Toward Practical Definitions of Quality for Food Science. Crit. Rev. Food Sci. Nut. 2000, 40, 83–90. [Google Scholar] [CrossRef] [PubMed]

- FAO/WHO. Method for the Determination of Net Content of Frozen Fish Blocks Covered by Glaze—Annex B. In Standard for Quick Frozen Blocks of Fish Fillet, Minced Fish Flesh and Mixtures; Fish and Fishery Products; Codex Stan 165-1989-Rev1-1995. Joint FAO/WHO Food Standards, Programme Codex Alimentarius commission: Rome, Italy, 2001; Volume 9A, pp. 17–18. [Google Scholar]

- Sánchez-González, J.; Carmona, P.; Moreno, P.; Borderías, J.; Sánchez-Alonso, I.; Rodríguez-Casado, A.; Careche, M. Protein and water structural changes in fish surimi during gelation as revealed by isotopic H/D exchange and Raman spectroscopy. Food Chem. 2008, 106, 56–64. [Google Scholar] [CrossRef]

- AOAC. Official Methods of Analysis of the Association of Official Analytical Communities International, 18th ed.; AOAC: Washington, DC, USA, 2005. [Google Scholar]

- Saint-Denis, T.; Goupy, J. Optimization of a nitrogen analyser based on the Dumas method. Anal. Chim. Acta 2004, 51, 191–198. [Google Scholar] [CrossRef]

- Cobb, B.F., III; Alaniz, I.; Thompson, C.A., Jr. Biochemical and microbial studies on shrimp: Volatile nitrogen and amino nitrogen analysis. J. Food Sci. 1973, 38, 431–436. [Google Scholar] [CrossRef]

- Woyewoda, A.D.; Shaw, S.J.; Ke, P.J.; Burns, B.G. Recommended Laboratory Methods for Assessment of Fish Quality. Can. Tech. Rep. Fish. Aquat. Sci. 1986, 1448, 156. [Google Scholar]

- ISO. ISO 13730: Meat and Meat Products—Determination of Total Phosphorus Content—Spectrometric Method; Technical Committee TC 34/SC 6; ISO: Geneva, Switzerland, 1996. [Google Scholar]

- Lourenço, H.M.; Anacleto, P.; Afonso, C.; Martins, M.F.; Carvalho, M.L.; Lino, A.R.; Nunes, M.L. Chemical characterisation of Nephrops norvegicus from Portuguese coast. J. Sci. Food Agr. 2009, 89, 2572–2580. [Google Scholar] [CrossRef]

- Dafflon, O.; Scheurer, L.; Gobet, H.; Bosset, J.O. Polyphosphate determination in seafood and processed cheese using high performance anion exchange chromatography after phosphatase inhibition using microwave heat shock. Mitt. Lebensm. Hyg. 2003, 94, 127–135. [Google Scholar]

- Nguyen, M.V.; Jonsson, J.O.; Thorkelsson, G.; Arason, S.; Gudmundsdottir, A.; Thorarinsdottir, K.A. Quantitative and qualitative changes in added phosphates in cod (Gadus morhua) during salting, storage and rehydration. LWT Food Sci. Technol. 2012, 47, 126–132. [Google Scholar] [CrossRef]

- Ivanova, N.V.; Zemlak, T.S.; Hanner, R.H.; Hebert, P.D.N. Universal primer cocktails for fish DNA barcoding. Mol. Ecol. 2007, 7, 544–548. [Google Scholar] [CrossRef]

- Kumar, S.; Stecher, G.; Tamura, K. MEGA7: Molecular Evolutionary Genetics Analysis version 7.0 for bigger datasets. Mol. Biol. Evol. 2016, 33, 1870–1874. [Google Scholar] [CrossRef]

- ISO 7218:2007/AMD 1:2013. Microbiology of Food and Animal Feeding Stuffs—General Requirements and Guidance for Microbiological Examinations—Amendment 1. Available online: https://www.iso.org/standard/52204.html (accessed on 20 April 2020).

- ISO 6887-3:2017. Microbiology of the Food Chain—Preparation of Test Samples, Initial Suspension and Decimal Dilutions for Microbiological Examination—Part 3: Specific Rules for The Preparation of Fish and Fishery Products. Available online: https://www.iso.org/standard/63337.html (accessed on 20 April 2020).

- ISO 6887-1:2017. Microbiology of the Food Chain—Preparation of Test Samples, Initial Suspension and Decimal Dilutions for Microbiological Examination—Part 1: General Rules for the Preparation of the Initial Suspension and Decimal Dilutions. Available online: https://www.iso.org/standard/63335.html (accessed on 20 April 2020).

- ISO 4833-1:2013. Microbiology of the Food Chain—Horizontal Method for the Enumeration of Microorganisms—Part 1: Colony Count at 30 °C by the Pour Plate Technique. Available online: https://www.iso.org/standard/53728.html (accessed on 20 April 2020).

- ISO 21527-1:2008. Microbiology of Food and Animal Feeding Stuffs—Horizontal Method for the Enumeration of Yeasts and Moulds—Part 1: Colony Count Technique in Products with Water Activity Greater Than 0,95. Available online: https://www.iso.org/standard/38275.html (accessed on 20 April 2020).

- ISO 6888-1:1999. Microbiology of Food and Animal Feeding Stuffs—Horizontal Method for the Enumeration of Coagulase-Positive Staphylococci (Staphylococcus Aureus and Other Species)—Part 1: Technique Using Baird-Parker Agar Medium. Available online: https://www.iso.org/standard/23036.html (accessed on 20 April 2020).

- Meilgaard, M.; Civille, G.V.; Carr, B.T. Sensory Evaluation Techniques, 3rd ed.; CRC Press LLC: Boca Raton, FL, USA, 1999; p. 387. [Google Scholar]

- Mariani, S.; Griffiths, A.M.; Velasco, A.; Kappel, K.; Jérôme, M.; Perez-Martin, R.I.; Schröder, U.; Verrez-Bagnis, V.; Silva, H.; Vandamme, S.G.; et al. Low mislabeling rates indicate marked improvements in European seafood market operations. Front. Ecol. Environ. 2016, 13, 536–540. [Google Scholar] [CrossRef]

- Di Pinto, A.; Di Pinto, P.; Terio, V.; Bozzo, G.; Bonerba, E.; Ceci, E.; Tantillo, G. DNA barcoding for detecting market substitution in salted cod fillets and battered cod chunks. Food Chem. 2013, 141, 1757–1762. [Google Scholar] [CrossRef] [PubMed]

- Lloris, D.; Matallanas, J.; Oliver, P. Hakes of the World (Family Merlucciidae): An Annotated and Illustrated Catalogue of Hake Species Known to Date; Food and Agriculture Organization of the United Nations: Rome, Italy, 2005; ISBN 978-92-5-104984-6. [Google Scholar]

- Harris, D.J.; Rosado, D.; Xavier, R. DNA Barcoding Reveals Extensive Mislabeling in Seafood Sold in Portuguese Supermarkets. J. Aquat. Food Prod. T. 2016, 25, 1375–1380. [Google Scholar] [CrossRef]

- Mendes, R.; Silva, H. Control of seafood labeling in Portugal. Relatórios Científicos e Técnicos do IPMA. 2015, 4, 1–25. Available online: https://www.ipma.pt/export/sites/ipma/bin/docs/publicacoes/ipma/rct-ipma-sd-4.pdf (accessed on 16 December 2020).

- Seafish. Product Integrity. Report FS94_07_16. Origin Way, Europarc, Grimsby. 2016. Available online: https://www.seafish.org/media/publications/FS94_07_16_Glazing_REV.pdf (accessed on 16 July 2020).

- Ciarlo, B.S.; Boeri, R.L.; Giannini, D.H. Storage life of frozen blocks of Patagonian hake (Merluccius hubbsi) filleted and minced. J. Food Sci. 1985, 50, 723–726. [Google Scholar] [CrossRef]

- Miyauchi, D.; Spinelli, J.; Dassow, J.A. Factor affecting drip. Fish. Ind. Res. 1963, 2, 13–19. [Google Scholar]

- Duun, A.S. Superchilling of muscle food storage stability and quality aspects of salmon (Salmo salar), cod (Gadus morhua) and pork. Ph.D. Thesis, Dep. Biotechnology, NTNU, Trondheim, Trondheim, Norway, 2008. Available online: https://ntnuopen.ntnu.no/ntnu-xmlui/handle/11250/244472 (accessed on 16 December 2020).

- Chefs Resources. Chefs Resources. Hake Fish, Culinary Profile for Hake. Chefs Resources Inc ©. 2020. Available online: https://chefs-resources.com/?s=hake (accessed on 16 December 2020).

- Herrero, A.M.; Carmona, P.; Garcia, M.L.; Solas, M.T.; Careche, M. Ultrastructural changes and structure and mobility of myowater in frozen-stored hake (Merluccius merluccius L.) muscle: Relationship with functionality and texture. J. Agric. Food Chem. 2005, 53, 2558–2566. [Google Scholar] [CrossRef]

- Haque, M.A.; Timilsena, Y.P.; Adhikari, B. Food Proteins, Structure, and Function. Reference Module in Food Science; Elsevier: Amsterdam, The Netherlands, 2016. [Google Scholar] [CrossRef]

- Miyauchi, D.; Spinelli, J.; Dassow, J.A. Drip formation in fish: No. 3-Composition of drip from defrosted Pacific cod fillets. Fish. Industrial Res. 1965, 2, 65. [Google Scholar]

- Sigurgisladottir, S.; Ingvarsdottir, H.; Torrissen, O.; Cardinal, M.; Hafsteinsson, H. Effects of freezing/thawing on the microstructure and the texture of smoked Atlantic salmon (Salmo salar). Food Res. Int. 2000, 33, 857–865. [Google Scholar] [CrossRef]

- Trout, G.R. Techniques for measuring water-binding capacity in muscle foods–A review of methodology. Meat Sci. 1988, 23, 235–252. [Google Scholar] [CrossRef]

- Sánchez-Alonso, I.; Martinez, I.; Sánchez-Valencia, J.; Careche, M. Estimation of freezing storage time and quality changes in hake (Merluccius merluccius, L.) by low field NMR. Food Chem. 2012, 135, 1626–1634. [Google Scholar] [CrossRef]

- Sánchez-Valencia, J.; Sánchez-Alonso, I.; Martinez, I.; Careche, M. Estimation of frozen storage time or temperature by kinetic modeling of the Kramer shear resistance and water holding capacity (WHC) of hake (Merluccius merluccius, L.) muscle. J. Food Eng. 2014, 120, 37–43. [Google Scholar] [CrossRef]

- Simeonidou, S.; Govaris, A.; Vareltzis, K. Effect of frozen storage on the quality of whole fish and fillets of horse mackerel (Trachurus trachurus) and mediterranean hake (Merluccius mediterraneus). Z. Lebensm. Unters. Forsch. A 1997, 204, 405–410. [Google Scholar] [CrossRef]

- Aitken, A.; Connell, J.J. Fish. In Effects of Heating on Foodstuffs; Priestley, R.J., Ed.; Applied Science Publishers: London, UK, 1979; pp. 219–253. [Google Scholar]

- Jenkelunas, P.J.; Li-Chan, E.C.Y. Production and assessment of Pacific hake (Merluccius productus) hydrolysates as cryoprotectants for frozen fish mince. Food Chem. 2018, 239, 535–543. [Google Scholar] [CrossRef] [PubMed]

- Hurtado, J.L.; Montero, P.; Borderias, A.J. Extension of shelf life of chilled hake (Merluccius capensis) by high pressure. Food Sci. Tech. Int. 2000, 6, 243–249. [Google Scholar] [CrossRef]

- Cheong, B.C. Utilization of Pacific Hake (Merluccius productus) in Thermally Processed Products. Master’s Thesis, Department of Food Science, The University of British Columbia, Vancouver, BC, Canada, 1985. [Google Scholar]

- Ofstad, R.; Kidman, S.; Myklebust, R.; Hermansson, A.M. Liquid holding capacity and structural-changes during heating of fish muscle—Cod (Gadus morhua) and Salmon (Salmo salar). Food Struct. 1993, 12, 163–174. [Google Scholar]

- Aman, M.B. Effect of cooking and preservation methods on the water holding capacity (WHC) of mullet fish in relation with changes occurred in muscle proteins. Z. Lebensm. Unters. Forsch. 1983, 177, 345–347. [Google Scholar] [CrossRef]

- Patashnik, M.; Groninger, H.S.; Barnett, H.; Kudo, G.; Koury, B. Pacific whiting, Merluccius productus: I: Abnormal muscle texture caused by Myxosporidan-induced proteolysis. Mar. Fish. Rev. 1982, 44, 1–12. [Google Scholar]

- Torry Research Station. Yield and Nutritional Value of the Commercially More Important Fish Species; (No. 309); Food and Agriculture Organization: Quebec City, QC, Canada, 1989. [Google Scholar]

- Hsu, C.K.; Kolbe, E.; Morrisey, M.T.; Chung, Y.C. Protein Denaturation of Frozen Pacific Whiting (Merluccius productus) Fillets. J. Food Sci. 1993, 58, 1055–1056, 1075. [Google Scholar] [CrossRef]

- De Koning, A.J.; Mol, T.H. Quantitative quality test for frozen fish: Soluble protein and free fatty acid content as quality criteria for hake (Merluccius capensis) stored at −18 °C. J. Sci. Food Agric. 1991, 54, 440–458. [Google Scholar] [CrossRef]

- Sotelo, C.; Aubourg, S.P.; Perez-Martin, R.I.; Gallardo, J.M. Protein denaturation in frozen stored hake (Merluccius merluccius L.) muscle: The role of formaldehyde. Food Chem. 1994, 50, 267–275. [Google Scholar] [CrossRef]

- Babbit, J.K.; Crawford, D.L.; Law, D.K. Decomposition of trimethylamine oxide and changes in protein extractability during frozen storage of minced and intact hake (Merluccius productus) muscle. J. Agr. Food Chem. 1972, 20, 1052–1054. [Google Scholar] [CrossRef]

- Kaale, L.D.; Eikevik, T.M.; Rustad, T.; Nordtvedt, T.M. Changes in water holding capacity and drip loss of Atlantic salmon (Salmo salar) muscle during superchilled storage. LWT—Food Sci. Technol. 2014, 55, 528–535. [Google Scholar] [CrossRef]

- Conrad, J.W.; Barneti, H.J.; Teeny, F.M.; Nelson, R.W. Observations from a preservation and processing study on Atka mackerel, Pleurogrammus monopterygius. Mar. Fish. Rev. 1985, 47, 73–77. [Google Scholar]

- Teixeira, B.; Vieira, H.; Lourenço, H.; Gonçalves, S.; Martins, M.F.; Mendes, R. Control of phosphate levels in seafood products from the Portuguese market: Is there a need for concern? J. Food Compost. Anal. 2017, 62, 94–102. [Google Scholar] [CrossRef]

- Vlieg, P.; Lee, J.; Grace, N.D. Elemental concentration of marine and freshwater finfish, and shellfish from New Zealand waters. J. Food Compos. Anal. 1991, 4, 136–147. [Google Scholar] [CrossRef]

- INSA, Tabela da composição de alimentos (Table of food composition), Instituto Nacional de Saúde Dr. Ricardo Jorge, V 4.1—2019. Available online: http://portfir.insa.pt/no (accessed on 28 October 2020).

- Bisenius, S.; Ludmann, M.; Neuhaus, H.; Effkemann, S.; Heemken, O.; Bartelt, E.; Haunhorst, E.; Kehrenberg, C. The impact of food additives on the chemical composition in cod (Gadus morhua): A comparative study. J. Consum. Prot. Food S. 2019, 14, 329–339. [Google Scholar] [CrossRef]

- Manthey-Karl, M.; Lehmann, I.; Ostermeyer, U.; Schröder, U. Natural Chemical Composition of Commercial Fish Species: Characterisation of Pangasius, Wild and Farmed Turbot and Barramundi. Foods 2016, 5, 58. [Google Scholar] [CrossRef]

- KLB. Kantonales Laboratorium Bern (Swiss State Laboratory of the Canton Bern). In Jahresbericht 2005; Annual Report; Kantonales Laboratorium: Bern, Switzerland, 2005. (In German) [Google Scholar]

- KLB. Kantonales Laboratorium Bern (Swiss State Laboratory of the Canton Bern). In Jahresbericht 2006; Annual Report; Kantonales Laboratorium: Bern, Switzerland, 2006. (In German) [Google Scholar]

- Fonnesbech, V.B.; Venkateswaran, K.; Atomi, M.; Gram, L. Identification of Shewanella baltica as the most important H2S-producing species during iced storage of Danish marine fish. Appl. Environ. Microbiol. 2005, 71, 6689–6697. [Google Scholar] [CrossRef]

- Gram, L.; Huss, H.H. Microbiological spoilage of fish and fish products. Int. J. Food Microbiol. 1996, 33, 121–137. [Google Scholar] [CrossRef]

- McDonell, J.J. Excellence in Seafood. Hake. 2020. Available online: http://www.jjmcdonnell.com/products/Hake (accessed on 7 July 2020).

- Amerine, M.A.; Pangborn, M.; Roessler, E.B. Principles of Sensory Evaluation of Food, 1st ed.; Anson, M.L., Mrak, E.M., Chichester, C.O., Eds.; Academic Press: New York, NY, USA, 1965; 612p. [Google Scholar]

- Kramer, A.; Twigg, B.A. Fundamentals of Quality Control for the Food Industry; AVI Publishing Co: Westport, CT, USA, 1970; p. 512. [Google Scholar]

| Sample | Labeled Net Weight (kg) | Labeled Species | Capture Area | Freezing Date | Best Before | Storage Days * | Labeled Ingredients |

|---|---|---|---|---|---|---|---|

| 1 | 400 | Merluccius capensis/paradoxus | Southeast Atlantic | 16 November 2017 | 10.2019 | 315 | - |

| 2 | 400 | Merluccius capensis/paradoxus | Southeast Atlantic | 06 September 2017 | 12.2019 | 385 | Fillets of Cape hake |

| 3 | 400 | Merluccius capensis/paradoxus | Southeast Atlantic | 10 July 2018 | 01.2020 | 81 | - |

| 4 | 400 | Merluccius capensis/paradoxus | Southeast Atlantic (FAO 47) | 23 July 2018 | 01.2020 | 68 | Shallow-water Cape hake/Deep-water Cape hake |

| 5 | 400 | Merluccius capensis | Southeast Atlantic | 02 May 2018 | 05.2020 | 149 | Fillet, water |

| 6 | 400 | Merluccius capensis/paradoxus | Southeast Atlantic (FAO 47) | 01 February 2018 | 02.2020 | 240 | Cape hake |

| 7 | 400 | Merluccius capensis/paradoxus | Southeast Atlantic | 08 August 2018 | 02.2020 | 53 | - |

| 8 | 600 | Merluccius capensis/paradoxus | Southeast Atlantic (FAO 47) | 28 November 2017 | 01.2020 | 303 | Cape hake |

| 9 | 600 | Merluccius productus | Northeast Pacific | 05 November 2017 | 11.2019 | 326 | - |

| 10 | 600 | Merluccius hubbsi | Southwest Atlantic (FAO 41) | 01 June 2016 | 05.2019 | 840 | Argentine hake, fish |

| 11 | 800 | Merluccius hubbsi | Southwest Atlantic | 20 July 2017 | 07.2019 | 431 | - |

| 12 | 662 | Merluccius hubbsi | Southwest Atlantic | 16 December 2018 ** | 02.2020 | 285 | Hake, water |

| 13 | 400 | Merluccius hubbsi | Southwest Atlantic | 21 September 2017 | 09.2019 | 370 | - |

| 14 | 800 | Merluccius hubbsi | Southwest Atlantic | 03 September 2018 | 09.2020 | 28 | - |

| 15 | 800 | Merluccius productus | Northeast Pacific (FAO 67) | 12 October 2016 | 10.2018 | 709 | Hake, water |

| 16 | 800 | Merluccius productus | Northeast Pacific (FAO 67) | 18 August 2017 | 05.2020 | 403 | Hake, E451, water |

| 17 | 1000 | Merluccius hubbsi | Southwest Atlantic (FAO 41) | 01 July 2017 | 01.2020 | 450 | Fish |

| 18 | 750 | Merluccius hubbsi | Southwest Atlantic (FAO 41) | 02 April 2018 | 05.2019 | 179 | Fish, E330 and sugars |

| 19 | 900 | Merluccius hubbsi | Southwest Atlantic | 06 August 2017 | 08.2019 | 415 | Fish |

| 20 | 700 | Merluccius capensis | Southeast Atlantic | 05 February 2018 | 07.2019 | 236 | Fillets, water |

| Sample | Labeled Species | Sequence (GenBank) | Identified Species (n = 3) | Conformity (C/NC) * |

|---|---|---|---|---|

| 1 | Merluccius capensis/paradoxus | KP975790 | Merluccius paradoxus | C |

| 2 | Merluccius capensis/paradoxus | KP975790 | Merluccius paradoxus | C |

| 3 | Merluccius capensis/paradoxus | KP975790 | Merluccius paradoxus | C |

| 4 | Merluccius capensis/paradoxus | KP975790 | Merluccius paradoxus | C |

| 5 | Merluccius capensis | EU074469 | Merluccius hubbsi | NC |

| 6 | Merluccius capensis/paradoxus | KP975790 | Merluccius paradoxus | C |

| 7 | Merluccius capensis/paradoxus | KP975790 | Merluccius paradoxus | C |

| 8 | Merluccius capensis/paradoxus | KP975790 | Merluccius paradoxus | C |

| 9 | Merluccius productus | FJ164843 | Merluccius productus | C |

| 10 | Merluccius hubbsi | EU074469 | Merluccius hubbsi | C |

| 11 | Merluccius hubbsi | KX119441 | Gadus chalcogrammus | NC |

| 12 | Merluccius hubbsi | EU074469 | Merluccius hubbsi | C |

| 13 | Merluccius hubbsi | EU074469 | Merluccius hubbsi | C |

| 14 | Merluccius hubbsi | EU074469 | Merluccius hubbsi | C |

| 15 | Merluccius productus | FJ164843 | Merluccius productus | C |

| 16 | Merluccius productus | FJ164843 | Merluccius productus | C |

| 17 | Merluccius hubbsi | EU074469 | Merluccius hubbsi | C |

| 18 | Merluccius hubbsi | EU074469 | Merluccius hubbsi | C |

| 19 | Merluccius hubbsi | EU074469 | Merluccius hubbsi | C |

| 20 | Merluccius capensis | KP975790 | Merluccius paradoxus | NC |

| Sample | Corrected Net Weight (g) * | Net Weight Difference (%) | Glaze Ice (%) * | Thaw Drip Loss (%) | WHC–Raw (%) | Cook Loss (%) | WHC–Cook (%) |

|---|---|---|---|---|---|---|---|

| 1 | 402.1 ± 5.7 | 0.5 ± 1.4 | 7.6 ± 0.9 | 4.9 ± 3.1 | 68.2 ± 2.4 | 15.3 ± 0.7 | 61.6 ± 0.3 |

| 2 | 409.5 ± 13.1 | 2.4 ± 3.3 | 14.3 ± 1.8 | 1.2 ± 1.1 | 56.0 ± 0.6 | 17.3 ± 3.1 | 58.2 ± 0.1 |

| 3 | 397.5 ± 6.1 | −0.6 ± 1.5 | 13.2 ± 1.0 | 4.6 ± 1.0 | 60.1 ± 1.1 | 17.3 ± 1.3 | 60.0 ± 0.9 |

| 4 | 419.2 ± 6.8 | 4.8 ± 1.7 | 12.5 ± 1.3 | 3.1 ± 1.9 | 54.0 ± 1.5 | 21.5 ± 2.6 | 58.0 ± 1.7 |

| 5 | 418.0 ± 15.2 | 4.5 ± 3.8 | 10.0 ± 0.7 | 2.1 ± 2.0 | 53.0 ± 2.2 | 15.1 ± 3.1 | 55.6 ± 0.2 |

| 6 | 413.3 ± 15.0 | 3.3 ± 3.7 | 13.4 ± 1.5 | 5.2 ± 1.6 | 50.5 ± 2.2 | 17.3 ± 3.5 | 56.9 ± 1.6 |

| 7 | 411.4 ± 11.5 | 2.9 ± 2.9 | 14.9 ± 1.8 | 8.9 ± 2.3 | 54.0 ± 0.4 | 20.8 ± 3.1 | 58.8 ± 0.1 |

| 8 | 643.8 ± 7.3 | 7.3 ± 1.2 | 5.8 ± 0.6 | 4.7 ± 2.5 | 56.2 ± 2.2 | 16.9 ± 1.4 | 59.9 ± 0.2 |

| 9 | 601.1 ± 11.0 | 0.2 ± 1.8 | 19.3 ± 1.5 | 25.1 ± 0.9 | 51.5 ± 1.0 | 17.2 ± 2.2 | 52.4 ± 2.1 |

| 10 | 629.6 ± 25.4 | 4.9 ± 4.2 | 7.7 ± 1.6 | 7.5 ± 4.0 | 49.0 ± 0.7 | 14.9 ± 1.2 | 55.3 ± 0.7 |

| 12 | 559.8 ± 14.6 | −15.4 ± 2.2 | 25.2 ± 1.9 | 5.4 ± 3.7 | 54.0 ± 1.6 | 13.3 ± 4.1 | 56.5 ± 0.0 |

| 13 | 381.7 ± 13.3 | −4.6 ± 3.3 | 18.3 ± 3.0 | 2.4 ± 1.0 | 48.5 ± 1.2 | 14.8 ± 4.1 | 61.6 ± 1.1 |

| 14 | 793.6 ± 29.2 | −0.8 ± 3.6 | 17.0 ± 2.0 | 2.4 ± 3.2 | 50.3 ± 1.9 | 19.6 ± 1.3 | 60.2 ± 0.9 |

| 15 | 723.5 ± 26.6 | −9.6 ± 3.3 | 23.0 ± 3.2 | 16.8 ± 4.2 | 51.0 ± 0.6 | 19.3 ± 3.9 | 55.5 ± 1.0 |

| 16 | 756.9 ± 20.5 | −5.4 ± 2.6 | 28.3 ± 1.8 | 22.6 ± 2.2 | 54.0 ± 1.5 | 15.8 ± 2.0 | 58.0 ± 0.4 |

| 17 | 1034.3 ± 32.8 | 3.4 ± 3.3 | 12.1 ± 0.6 | 3.0 ± 1.3 | 50.5 ± 1.1 | 15.0 ± 1.0 | 54.4 ± 0.0 |

| 18 | 714.1 ± 49.3 | −4.8 ± 6.6 | 32.9 ± 3.8 | 4.9 ± 5.1 | 50.5 ± 1.2 | 17.6 ± 0.6 | 59.6 ± 0.7 |

| 19 | 916.3 ± 20.6 | 1.8 ± 2.3 | 12.1 ± 1.9 | 6.3 ± 2.4 | 49.1 ± 0.4 | 20.2 ± 2.1 | 59.2 ± 1.2 |

| 20 | 746.6 ± 26.2 | 6.7 ± 3.7 | 27.8 ± 2.2 | 7.5 ± 3.2 | 54.5 ± 1.0 | 22.9 ± 2.3 | 60.0 ± 0.6 |

| Sample | Moisture (%) | Protein (%) | M/P Ratio | pH | TVB-N (mg/100 g) | Soluble Protein (g/100 g) | Soluble/Total Protein (%) | Thaw Drip Loss Protein (g/100 mL) |

|---|---|---|---|---|---|---|---|---|

| 1 | 79.7 ± 0.0 | 19.5 ± 0.7 | 4.1 | 6.73 ± 0.03 | 9.3 ± 1.1 | 13.2 ± 0.0 | 67.5 ± 0.1 | 12.7 ± 0.2 |

| 2 | 80.7 ± 0.3 | 17.3 ± 0.7 | 4.7 | 6.73 ± 0.02 | 11.7 ± 1.4 | 12.4 ± 0.3 | 71.5 ± 1.5 | 46.2 ± 0.5 |

| 3 | 79.1 ± 0.0 | 18.2 ± 0.3 | 4.4 | 6.58 ± 0.00 | 11.6 ± 1.4 | 12.4 ± 0.0 | 68.5 ± 0.2 | 16.9 ± 0.3 |

| 4 | 80.0 ± 0.6 | 17.2 ± 0.4 | 4.6 | 6.74 ± 0.04 | 16.2 ± 1.9 | 12.4 ± 0.1 | 72.2 ± 0.5 | 21.7 ± 0.1 |

| 5 | 80.8 ± 0.4 | 17.7 ± 0.7 | 4.6 | 6.84 ± 0.05 | 12.5 ± 1.5 | 12.0 ± 0.0 | 67.8 ± 0.2 | 21.9 ± 0.2 |

| 6 | 80.6 ± 0.0 | 17.9 ± 0.2 | 4.5 | 6.70 ± 0.03 | 14.3 ± 1.7 | 11.8 ± 0.1 | 65.9 ± 0.6 | 13.0 ± 0.3 |

| 7 | 78.9 ± 0.4 | 18.2 ± 0.4 | 4.3 | 6.57 ± 0.00 | 10.7 ± 1.3 | 11.8 ± 0.0 | 64.7 ± 0.2 | 10.2 ± 0.2 |

| 8 | 80.7 ± 0.0 | 17.8 ± 0.2 | 4.5 | 6.74 ± 0.04 | 11.3 ± 1.4 | 12.6 ± 0.3 | 70.7 ± 1.6 | 9.1 ± 0.3 |

| 9 | 83.0 ± 0.3 | 15.5 ± 0.3 | 5.4 | 7.02 ± 0.02 | 11.6 ± 1.4 | 9.8 ± 0.0 | 63.4 ± 0.1 | 3.9 ± 0.1 |

| 10 | 79.4 ± 0.9 | 17.0 ± 0.2 | 4.7 | 6.77 ± 0.02 | 11.9 ± 1.4 | 11.7 ± 0.2 | 68.8 ± 0.9 | 7.2 ± 0.0 |

| 12 | 79.6 ± 0.4 | 17.4 ± 0.3 | 4.6 | 6.85 ± 0.00 | 14.9 ± 1.8 | 11.6 ± 0.3 | 66.3 ± 1.6 | 14.5 ± 0.0 |

| 13 | 81.3 ± 0.1 | 17.9 ± 0.4 | 4.6 | 6.94 ± 0.00 | 23.5 ± 2.8 | 11.0 ± 0.1 | 61.4 ± 0.8 | 31.7 ± 0.2 |

| 14 | 78.7 ± 0.1 | 18.1 ± 0.0 | 4.4 | 6.85 ± 0.01 | 17.0 ± 2.0 | 11.7 ± 0.3 | 64.7 ± 1.5 | 24.6 ± 0.3 |

| 15 | 82.5 ± 0.4 | 15.5 ± 0.1 | 5.3 | 7.00 ± 0.01 | 7.1 ± 0.9 | 9.7 ± 0.3 | 62.9 ± 2.2 | 4.5 ± 0.1 |

| 16 | 84.1 ± 0.5 | 14.6 ± 0.2 | 5.8 | 7.15 ± 0.03 | 5.3 ± 0.6 | 9.9 ± 0.3 | 67.7 ± 1.9 | 4.6 ± 0.0 |

| 17 | 78.6 ± 0.1 | 17.2 ± 0.3 | 4.6 | 6.86 ± 0.07 | 11.9 ± 1.4 | 12.0 ±0.5 | 69.5 ± 2.7 | 14.2 ± 0.3 |

| 18 | 78.7 ± 1.4 | 17.1 ± 0.0 | 4.6 | 6.95 ± 0.05 | 15.4 ± 1.8 | 10.9 ±0.4 | 63.7 ± 2.5 | 15.1 ± 0.2 |

| 19 | 78.6 ± 0.7 | 18.0 ± 0.6 | 4.4 | 6.88 ± 0.01 | 17.0 ± 2.0 | 11.2 ± 0.2 | 62.6 ± 1.2 | 9.7 ± 0.2 |

| 20 | 78.4 ± 0.4 | 18.6 ± 0.2 | 4.2 | 6.58 ± 0.03 | 18.8 ± 2.3 | 11.1 ± 0.3 | 59.7 ± 1.8 | 13.8 ± 0.2 |

| Total Phosphates | PO4 | P2O7 * | P3O9 * | P3O10 * | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Sample | Fillets (g P2O5/kg) | Thaw Water (g P2O5/L) | Fillets (g P2O5/kg) | Thaw Water (g P2O5/L) | Fillets (g P2O5/kg) | Thaw Water (g P2O5/L) | Fillets (g P2O5/kg) | Thaw Water (g P2O5/L) | Fillets (g P2O5/kg) | Thaw Water (g P2O5/L) |

| 1 | 4.3 ± 0.2 | 3.9 ± 0.1 | 3.5 ± 0.1 | 3.5 ± 0.0 | <LOD | <LOD | <LOD | <LOD | <LOD | <LOD |

| 2 | 4.3 ± 0.1 | 3.5 ± 0.1 | 3.3 ± 0.1 | 3.0 ± 0.1 | <LOD | <LOD | <LOD | <LOD | <LOD | <LOD |

| 3 | 4.2 ± 0.0 | 3.4 ± 0.0 | 3.2 ± 0.0 | 3.1 ± 0.0 | <LOD | <LOD | <LOD | <LOD | <LOD | <LOD |

| 4 | 4.2 ± 0.1 | 3.5 ± 0.1 | 3.2 ± 0.0 | 3.1 ± 0.1 | <LOD | <LOD | <LOD | <LOD | <LOD | <LOD |

| 5 | 4.7 ± 0.1 | 3.7 ± 0.1 | 3.4 ± 0.1 | 3.4 ± 0.0 | <LOD | <LOD | <LOD | <LOD | <LOD | <LOD |

| 6 | 4.2 ± 0.0 | 3.3 ± 0.0 | 3.1 ± 0.0 | 2.9 ± 0.0 | <LOD | <LOD | <LOD | <LOD | <LOD | <LOD |

| 7 | 4.2 ± 0.0 | 3.2 ± 0.0 | 3.2 ± 0.0 | 2.7 ± 0.2 | <LOD | <LOD | <LOD | <LOD | <LOD | <LOD |

| 8 | 4.3 ± 0.0 | 3.4 ± 0.0 | 3.5 ± 0.0 | 3.1 ± 0.1 | <LOD | <LOD | <LOD | <LOD | <LOD | <LOD |

| 9 | 4.8 ± 0.0 | 5.1 ± 0.0 | 3.9 ± 0.3 | 3.3 ± 0.3 | <LOD | <LOQ | <LOD | 1.1 ± 0.0 | <LOD | 0.3 ± 0.1 |

| 10 | 4.3 ± 0.0 | 3.4 ± 0.0 | 3.1 ± 0.2 | 2.9 ± 0.2 | <LOD | <LOD | <LOD | <LOD | <LOD | <LOD |

| 12 | 4.0 ± 0.1 | 2.5 ± 0.0 | 3.0 ± 0.0 | 2.3 ± 0.1 | <LOD | <LOD | <LOD | <LOD | <LOD | <LOD |

| 13 | 3.8 ± 0.1 | 3.4 ± 0.0 | 2.7 ± 0.1 | 2.9 ± 0.1 | <LOD | <LOD | <LOD | <LOD | <LOD | <LOD |

| 14 | 4.1 ± 0.0 | 3.0 ± 0.0 | 3.0 ± 0.2 | 2.7 ± 0.0 | <LOD | <LOD | <LOD | <LOD | <LOD | <LOD |

| 15 | 5.2 ± 0.0 | 4.9 ± 0.0 | 4.6 ± 0.1 | 3.8 ± 0.0 | < LOQ | <LOQ | <LOD | 1.0 ± 0.1 | <LOD | 0.7 ± 0.0 |

| 16 | 4.4 ± 0.0 | 4.6 ± 0.0 | 3.9 ± 0.0 | 3.0 ± 0.0 | <LOD | <LOD | <LOD | 1.1 ± 0.1 | <LOD | <0.04 |

| 17 | 4.3 ± 0.1 | 3.0 ± 0.2 | 3.2 ± 0.0 | 2.6 ± 0.2 | <LOD | <LOD | <LOD | <LOD | <LOD | <LOD |

| 18 | 3.6 ± 0.0 | 2.1 ± 0.0 | 2.6 ± 0.1 | 1.9 ± 0.1 | <LOD | <LOD | <LOD | <LOD | <LOD | <LOD |

| 19 | 4.2 ± 0.1 | 3.4 ± 0.0 | 2.9 ± 0.1 | 3.0 ± 0.0 | <LOD | <LOD | <LOD | <LOD | <LOD | <LOD |

| 20 | 3.6 ± 0.0 | 2.5 ± 0.0 | 2.3 ± 0.0 | 2.2 ± 0.0 | <LOD | <LOD | <LOD | <LOD | <LOD | <LOD |

| Sample | Aerobic Mesophilic 30 °C (cfu/g) | Sulphite Producers (cfu/g) | Total Coliforms (cfu/g) | Escherichia coli (cfu/g) | Yeast and Molds (cfu/g) | Staphylococcus Aureus (cfu/g) | Salmonella (25 g) |

|---|---|---|---|---|---|---|---|

| 1 | 1.2 × 103 | <1.0 ×10 | <1.0 × 10 | <1.0 × 10 | 5.3 × 10 | <1.0 × 10 | Negative |

| 2 | 6.0 × 10 | <1.0 × 10 | <1.0 × 10 | <1.0 × 10 | <1.0 × 10 | <1.0 × 10 | Negative |

| 3 | 5.8 × 103 | <1.0 × 10 | <1.0 × 10 | <1.0 × 10 | <1.0 × 10 | <1.0 × 10 | Negative |

| 4 | 8.6 × 103 | 2.5 × 102 | <4.0 × 10 | <1.0 × 10 | <4.0 × 10 | <1.0 × 10 | Negative |

| 5 | 6.5 × 102 | <1.0 × 10 | <1.0 × 10 | <1.0 × 10 | <4.0 × 10 | <1.0 × 10 | Negative |

| 6 | 1.2 × 103 | <4.0 × 10 | <1.0 × 10 | <1.0 × 10 | <4.0 × 10 | <1.0 × 10 | Negative |

| 7 | 3.0 × 103 | 1.1 × 10 | <1.0 × 10 | <1.0 × 10 | <1.0 × 10 | <1.0 × 10 | Negative |

| 8 | 6.2 × 102 | 1.5 × 102 | <1.0 × 10 | <1.0 × 10 | <4.0 × 10 | <1.0 × 10 | Negative |

| 9 | 4.0 × 10 | <1.0 ×10 | <1.0 × 10 | <1.0 × 10 | 1.6 × 10 | <1.0 × 10 | Negative |

| 10 | 3.6 × 10 | <4.0 × 10 | <1.0 × 10 | <1.0 × 10 | <4.0 × 10 | <1.0 × 10 | Negative |

| 12 | 2.8 × 103 | <4.0 × 10 | <1.0 × 10 | <1.0 × 10 | 4.4 × 102 | <1.0 × 10 | Negative |

| 13 | 6.1 × 103 | <4.0 × 10 | <1.0 × 10 | <1.0 × 10 | <1.0 × 10 | <1.0 × 10 | Negative |

| 14 | 6.2 × 102 | <1.0 × 10 | <1.0 × 10 | <1.0 × 10 | 3.6 × 10 | <1.0 × 10 | Negative |

| 15 | 1.6 × 102 | <1.0 × 10 | <1.0 × 10 | <1.0 × 10 | <4.0 × 10 | <1.0 × 10 | Negative |

| 16 | 4.7 × 102 | <1.0 × 10 | <1.0 × 10 | <1.0 × 10 | <1.0 × 10 | <1.0 × 10 | Negative |

| 17 | 1.4 × 102 | <1.0 × 10 | <1.0 × 10 | <1.0 × 10 | <4.0 × 10 | <1.0 × 10 | Negative |

| 18 | 6.5 × 103 | <4.0 × 10 | <1.0 × 10 | <1.0 × 10 | <4.0 × 10 | <1.0 × 10 | Negative |

| 19 | 5.0 × 104 | <4.0 × 10 | <1.0 × 10 | <1.0 × 10 | 1.7 × 102 | <1.0 × 10 | Negative |

| 20 | 3.5 × 103 | <4.0 × 10 | <4.0 × 10 | <1.0 × 10 | 5.7 × 10 | <1.0 × 10 | Negative |

| SENSORY SCALE | |||||

|---|---|---|---|---|---|

| ATTRIBUTES | Absent (1) | Slight (2) | Moderate (3) | Intense (4) | Very Intense (5) |

| Packaging defects | 89 | 11 | |||

| Size variation * | 21 | 74 | 5 | ||

| Presence of ice | 69 | 26 | 5 | ||

| Dehydration | 69 | 26 | 5 | ||

| Muscle gaps | 42 | 37 | 16 | 5 | |

| Blood stains | 5 | 53 | 31 | 11 | |

| Color (yellow) | 15 | 58 | 11 | 11 | 5 |

| Odor (rancid) | 21 | 37 | 11 | 26 | 5 |

| OVERALL QUALITY | Excellent | Good | Fair | Poor | Bad |

| 5 | 74 | 16 | 5 | ||

| SENSORY SCALE | |||||

|---|---|---|---|---|---|

| NEGATIVE ATTRIBUTES | Very Intense | Intense | Moderate | Slight | Absent |

| Discoloration | 16 | 53 | 31 | ||

| Dehydration | 5 | 21 | 74 | ||

| Rancid odor | 5 | 11 | 63 | 21 | |

| Rancid/bitter flavor | 16 | 32 | 53 | ||

| POSITIVE ATTRIBUTES | Absent | Slight | Moderate | Intense | Very Intense |

| Typical color/appearance | 69 | 31 | |||

| Typical odor | 21 | 69 | 10 | ||

| Typical flavor | 16 | 69 | 15 | ||

| Firmness | 5 | 47 | 48 | ||

| Succulence | 10 | 64 | 26 | ||

| OVERALL QUALITY | Bad | Poor | Fair | Good | Excellent |

| 16 | 47 | 37 | |||

| Parameters | PC 1 | PC 2 | PC 3 |

|---|---|---|---|

| Storage length | 0.57 | −0.02 | −0.05 |

| Glaze ice | 0.24 | −0.70 | 0.14 |

| Moisture | 0.80 | 0.17 | −0.21 |

| Protein | −0.88 | 0.10 | −0.25 |

| M/P ratio | 0.91 | −0.03 | 0.12 |

| Soluble protein | −0.78 | 0.58 | −0.03 |

| Soluble/total protein | −0.14 | 0.75 | 0.26 |

| Thaw drip loss | 0.83 | −0.04 | 0.09 |

| Thaw drip loss protein | −0.47 | −0.00 | −0.22 |

| WHCraw | −0.33 | 0.66 | −0.25 |

| WHCcook | −0.63 | −0.14 | −0.66 |

| WHCtotal | −0.40 | −0.08 | −0.79 |

| TVB-N | −0.53 | −0.62 | −0.16 |

| pH | 0.74 | −0.27 | −0.03 |

| Total phosphates in fillets | 0.76 | 0.55 | −0.02 |

| Total phosphates in thawing waters | 0.81 | 0.43 | −0.26 |

| Orthophosphates in fillets | 0.79 | 0.53 | −0.10 |

| Orthophosphates in thawing waters | 0.49 | 0.66 | −0.47 |

| Overall score of negative descriptors of raw fillets | 0.56 | −0.48 | −0.46 |

| Overall score of negative descriptors of cooked fillets | 0.76 | −0.31 | −0.32 |

| Overall score of positive descriptors of cooked fillets | −0.83 | 0.35 | 0.19 |

| Variables | R | p-value | Estimated Limits * | 95% Confidence Limits |

|---|---|---|---|---|

| M/P ratio vs. overall quality | −0.810 | <0.01 | 4.3 | ± 0.2 |

| Protein vs. overall quality | 0.808 | <0.01 | 18.2% | ± 0.5 |

| Soluble protein vs. overall quality | 0.805 | <0.01 | 12.2% | ± 0.4 |

| pH vs. overall quality | −0.691 | <0.05 | 6.7 | ± 0.1 |

| Thaw drip loss vs. overall quality | −0.657 | <0.05 | 3.4% | ± 3.4 |

| WHCraw vs. overall quality | 0.563 | <0.05 | 55.7% | ± 2.6 |

| WHCcook vs. overall quality | 0.563 | <0.05 | 59.1 % | ± 1.5 |

| Storage length vs. overall quality | −0.556 | <0.05 | 6.8 months | ± 3.9 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mendes, R.; Silva, H.; Oliveira, P.; Oliveira, L.; Teixeira, B. Quality of Frozen Hake Fillets in the Portuguese Retail Market: A Case Study of Inadequate Practices in the European Frozen White Fish Market. Foods 2021, 10, 848. https://doi.org/10.3390/foods10040848

Mendes R, Silva H, Oliveira P, Oliveira L, Teixeira B. Quality of Frozen Hake Fillets in the Portuguese Retail Market: A Case Study of Inadequate Practices in the European Frozen White Fish Market. Foods. 2021; 10(4):848. https://doi.org/10.3390/foods10040848

Chicago/Turabian StyleMendes, Rogério, Helena Silva, Patrícia Oliveira, Luís Oliveira, and Bárbara Teixeira. 2021. "Quality of Frozen Hake Fillets in the Portuguese Retail Market: A Case Study of Inadequate Practices in the European Frozen White Fish Market" Foods 10, no. 4: 848. https://doi.org/10.3390/foods10040848

APA StyleMendes, R., Silva, H., Oliveira, P., Oliveira, L., & Teixeira, B. (2021). Quality of Frozen Hake Fillets in the Portuguese Retail Market: A Case Study of Inadequate Practices in the European Frozen White Fish Market. Foods, 10(4), 848. https://doi.org/10.3390/foods10040848