Effect of Humidity-Controlled Dehydration on Microbial Growth and Quality Characteristics of Fresh Wet Noodles

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of the Fresh Wet Noodles (FWN)

2.3. Humidity-Controlled Dehydration (HCD)

2.4. Determination of Bacterial Content

2.5. Color Measurement of the HCD Noodles

2.6. Determination of the Degree of Gelatinization

2.7. Cooking and Textural Properties of the Fresh Wet Noodles

2.7.1. Cooking Loss and Water Absorption Index

2.7.2. Textural Properties

2.8. Sensory Evaluation

2.9. Scanning Electron Microscopy

2.10. Statistical Analysis

3. Results and Discussion

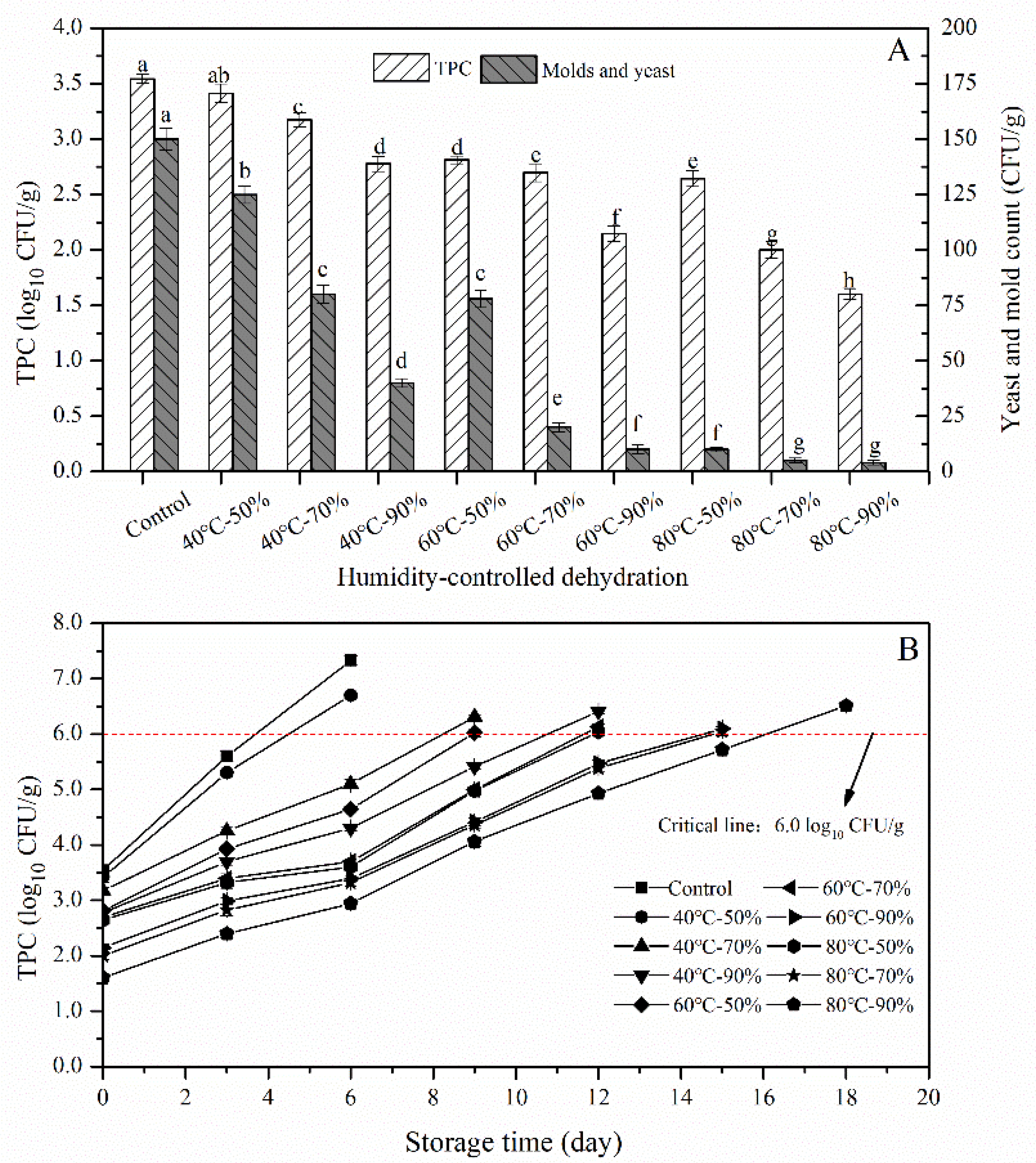

3.1. Microbial Analysis of HCD Fresh Wet Noodles

3.1.1. Initial Bacterial Content

3.1.2. Microbial Growth during Storage

3.2. Quality Analysis of HCD Fresh Wet Noodles

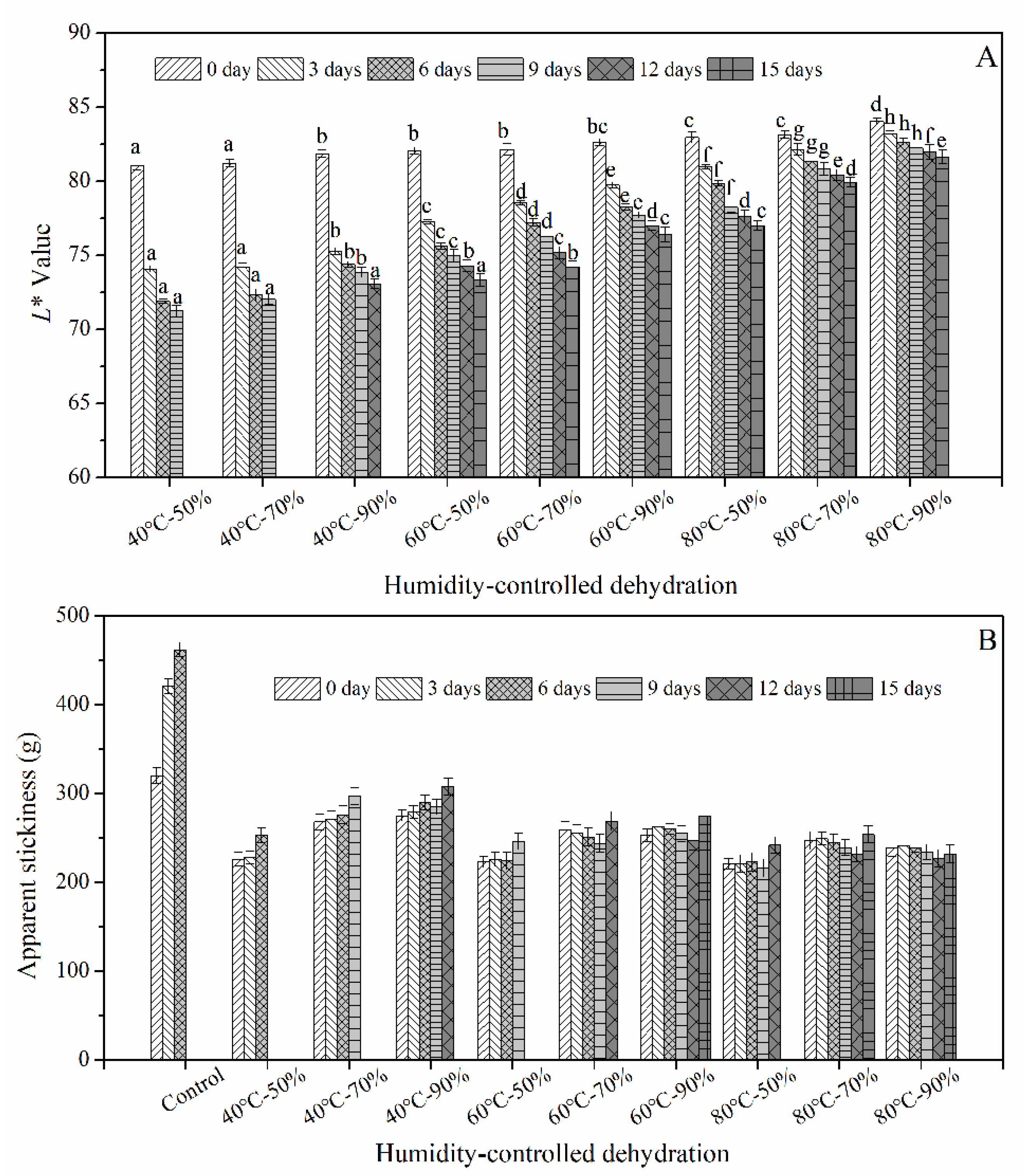

3.2.1. Color Changes

3.2.2. Apparent Stickiness

3.2.3. Degree of Gelatinization

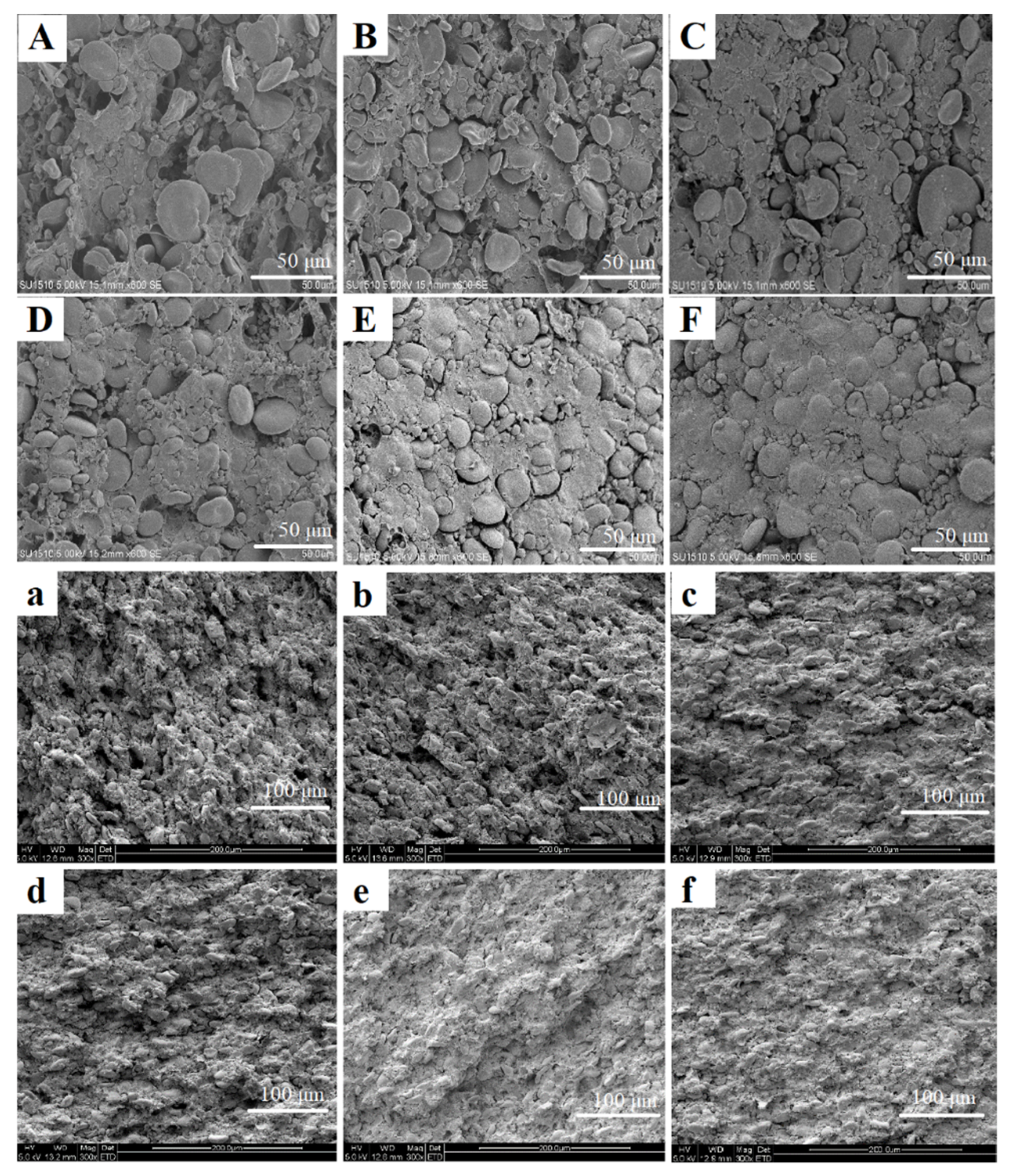

3.2.4. Microstructure

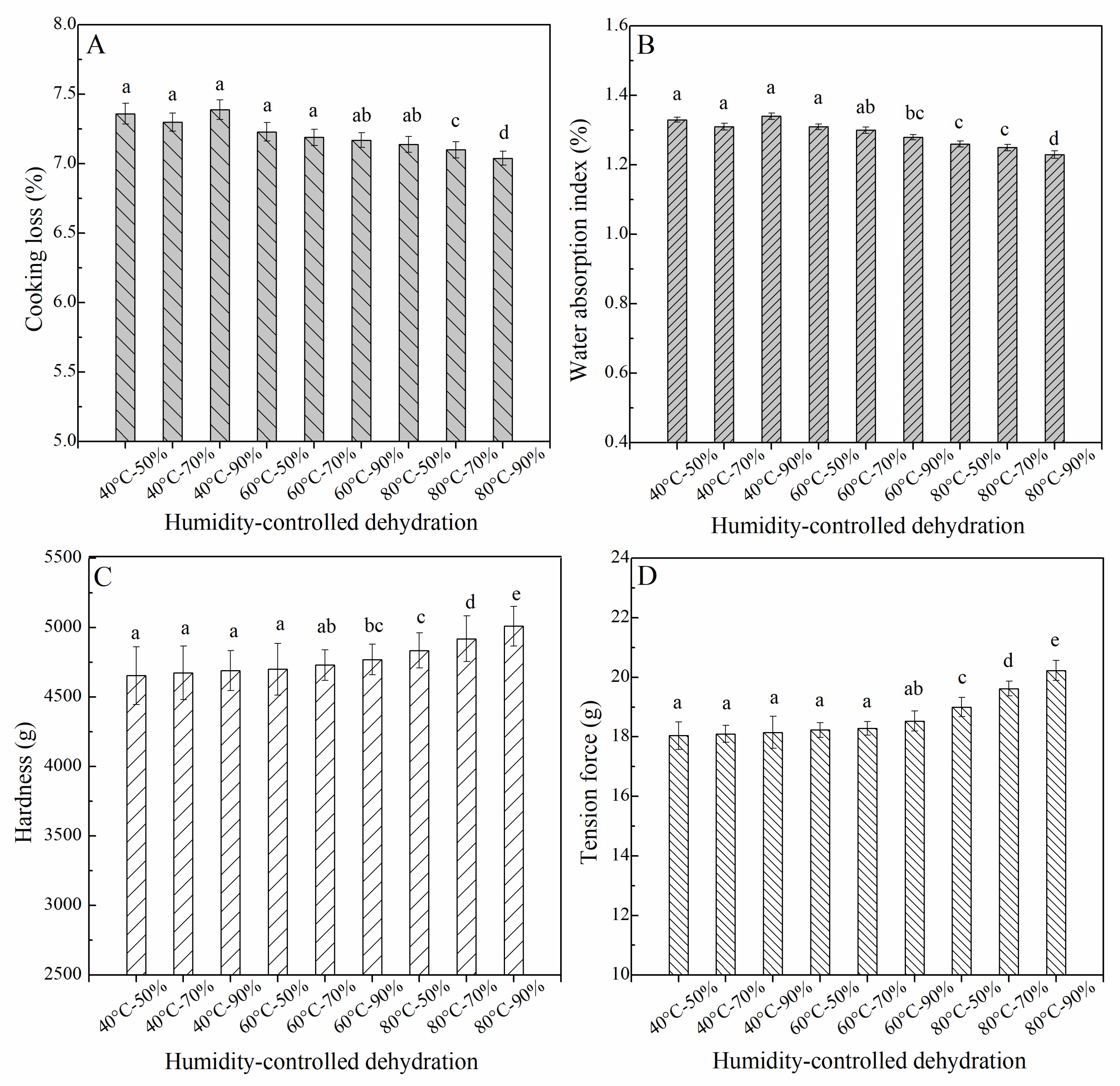

3.3. Cooking and Texture Properties of the HCD Fresh Wet Noodles

3.4. Sensory Evaluation of HCD Fresh Wet Noodles

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Chen, Y.; Chen, G.; Wei, R.; Zhang, Y.; Li, S. Quality characteristics of fresh wet noodles treated with nonthermal plasma sterilization. Food Chem. 2019, 297, 124900. [Google Scholar] [CrossRef]

- Li, M.; Zhu, K.-X.; Sun, Q.-J.; Amza, T.; Guo, X.-N.; Zhou, H.-M. Quality characteristics, structural changes, and storage stability of semi-dried noodles induced by moderate dehydration: Understanding the quality changes in semi-dried noodles. Food Chem. 2016, 194, 797–804. [Google Scholar] [CrossRef]

- Li, M.; Ma, M.; Zhu, K.X.; Guo, X.N.; Zhou, H.M. Delineating the physico-chemical, structural, and water characteristic changes during the deterioration of fresh noodles: Understanding the deterioration mechanisms of fresh noodles. Food Chem. 2017, 216, 374–381. [Google Scholar] [CrossRef]

- Ma, M.; Han, C.-W.; Li, M.; Song, X.-Q.; Sun, Q.-J.; Zhu, K.-X. Inhibiting effect of low-molecular weight polyols on the physico-chemical and structural deteriorations of gluten protein during storage of fresh noodles. Food Chem. 2019, 287, 11–19. [Google Scholar] [CrossRef]

- Tsiraki, M.I.; Karam, L.; Abiad, M.G.; Yehia, H.M.; Savvaidis, I.N. Use of natural antimicrobials to improve the quality characteristics of fresh “Phyllo”—A dough-based wheat product—Shelf life assessment. Food Microbiol. 2017, 62, 153–159. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y.; Zhang, Y.; Jiang, L.; Chen, G.; Yu, J.; Li, S.; Chen, Y. Moisture molecule migration and quality changes of fresh wet noodles dehydrated by cold plasma treatment. Food Chem. 2020, 328, 127053. [Google Scholar] [CrossRef] [PubMed]

- Zhu, K.-X.; Dai, X.; Guo, X.; Peng, W.; Zhou, H.-M. Retarding effects of organic acids, hydrocolloids and microwave treatment on the discoloration of green tea fresh noodles. LWT Food Sci. Technol. 2014, 55, 176–182. [Google Scholar] [CrossRef]

- Hou, G.G.; Otsubo, S.; Okusu, H.; Shen, L. Noodle Processing Technology. In Asian Noodles: Science, Technology, and Processing; John Wiley & Sons, Inc: Hoboken, NJ, USA, 2010; pp. 106–107. [Google Scholar]

- Del Nobile, M.; Di Benedetto, N.; Suriano, N.; Conte, A.; Lamacchia, C.; Corbo, M.; Sinigaglia, M. Use of natural compounds to improve the microbial stability of Amaranth-based homemade fresh pasta. Food Microbiol. 2009, 26, 151–156. [Google Scholar] [CrossRef] [PubMed]

- Bai, Y.-P.; Guo, X.-N.; Zhu, K.-X.; Zhou, H.-M. Shelf-life extension of semi-dried buckwheat noodles by the combination of aqueous ozone treatment and modified atmosphere packaging. Food Chem. 2017, 237, 553–560. [Google Scholar] [CrossRef] [PubMed]

- Li, M.; Zhu, K.; Guo, X.; Peng, W.; Zhou, H. Effect of water activity (aw) and irradiation on the shelf-life of fresh noodles. Innov. Food Sci. Emerg. Technol. 2011, 12, 526–530. [Google Scholar] [CrossRef]

- Chau, T.T.; Kao, K.C.; Blank, G.; Madrid, F. Microwave plasmas for low-temperature dry sterilization. Biomaterials 1996, 17, 1273–1277. [Google Scholar] [CrossRef]

- Inazu, T.; Iwasaki, K.-I.; Furuta, T. Effect of Temperature and Relative Humidity on Drying Kinetics of Fresh Japanese Noodle (Udon). LWT Food Sci. Technol. 2002, 35, 649–655. [Google Scholar] [CrossRef]

- Villeneuve, S.; Gélinas, P. Drying kinetics of whole durum wheat pasta according to temperature and relative humidity. LWT Food Sci. Technol. 2007, 40, 465–471. [Google Scholar] [CrossRef]

- Piwińska, M.; Wyrwisz, J.; Kurek, M.A.; Wierzbicka, A. Effect of drying methods on the physical properties of durum wheat pasta. CyTA J. Food 2016, 14, 523–528. [Google Scholar] [CrossRef] [Green Version]

- Xiang, Z.; Ye, F.; Zhou, Y.; Wang, L.; Zhao, G. Performance and mechanism of an innovative humidity-controlled hot-air drying method for concentrated starch gels: A case of sweet potato starch noodles. Food Chem. 2018, 269, 193–201. [Google Scholar] [CrossRef]

- GB/T 4789.2, Code of National Food Safety Standard of China. Food Microbiological Examination: Aerobic Plate Count; The State Food and Drug Administration: Beijing, China, 2016. [Google Scholar]

- GB/T 4789.15, Code of National Food Safety Standard of China. Food Microbiological Examination: Mold and Yeast Count; The State Food and Drug Administration: Beijing, China, 2016. [Google Scholar]

- Wootton, M.; Weeden, D.; Munk, N. A rapid method for the estimation of starch gelatinization in processed foods. Food Technol. 1971, 23, 612–615. [Google Scholar]

- American Association of Cereal Chemists. AACC Method 66-50. AACC International Approved Methods, 10th ed.; AACC International: St. Paul, MN, USA, 2000. [Google Scholar]

- Wu, J.; Corke, H. Quality of dried white salted noodles affected by microbial transglutaminase. J. Sci. Food Agric. 2005, 85, 2587–2594. [Google Scholar] [CrossRef]

- Costa, C.; Lucera, A.; Mastromatteo, M.; Conte, A.; Del Nobile, M.A. Shelf life extension of durum semolina-based fresh pasta. Int. J. Food Sci. Technol. 2010, 45, 1545–1551. [Google Scholar] [CrossRef]

- Fechner, K.; Dreymann, N.; Schimkowiak, S.; Czerny, C.-P.; Teitzel, J. Efficacy of dairy on-farm high-temperature, short-time pasteurization of milk on the viability of Mycobacterium avium ssp. paratuberculosis. J. Dairy Sci. 2019, 102, 11280–11290. [Google Scholar] [CrossRef] [PubMed]

- Giribaldi, M.; Coscia, A.; Peila, C.; Antoniazzi, S.; Lamberti, C.; Ortoffi, M.; Moro, G.E.; Bertino, E.; Civera, T.; Cavallarin, L. Pasteurization of human milk by a benchtop High-Temperature Short-Time device. Innov. Food Sci. Emerg. Technol. 2016, 36, 228–233. [Google Scholar] [CrossRef]

- Esbelin, J.; Santos, T.; Hébraud, M. Desiccation: An environmental and food industry stress that bacteria commonly face. Food Microbiol. 2018, 69, 82–88. [Google Scholar] [CrossRef]

- Zhang, S.; Zhang, L.; Lan, R.; Zhou, X.; Kou, X.; Wang, S. Thermal inactivation of Aspergillus flavus in peanut kernels as influenced by temperature, water activity and heating rate. Food Microbiol. 2018, 76, 237–244. [Google Scholar] [CrossRef]

- Güler, S.; Köksel, H.; Ng, P. Effects of industrial pasta drying temperatures on starch properties and pasta quality. Food Res. Int. 2002, 35, 421–427. [Google Scholar] [CrossRef]

- Wagner, M.; Morel, M.-H.; Bonicel, J.; Cuq, B. Mechanisms of heat-mediated aggregation of wheat gluten protein upon pasta processing. J. Agric. Food Chem. 2011, 59, 3146–3154. [Google Scholar] [CrossRef]

- Baiano, A.; Conte, A.; Del Nobile, M. Influence of drying temperature on the spaghetti cooking quality. J. Food Eng. 2006, 76, 341–347. [Google Scholar] [CrossRef]

| HCD | Final Moisture Content (%) | Gelatinization Degree (%) | Yeasts and Molds Count at Different Storage Time (CFU/g) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Temperature (°C) | RH (%) | Time (min) | 0 day | 3 days | 6 days | 9 days | 12 days | 15 days | 18 days | ||

| Control | 34.00 ± 0.15 a | 23.14 ± 0.74 a | 150 | 2000 | 5000 | - | - | - | - | ||

| 40 | 50 | 6 | 30.18 ± 0.20 a | 23.46 ± 0.65 a | 125 | 1450 | 3800 | - | - | - | - |

| 70 | 12 | 30.36 ± 0.19 a | 23.63 ± 0.71 a | 80 | 350 | 1750 | 3200 | - | - | - | |

| 90 | 32 | 30.27 ± 0.20 a | 23.81 ± 0.47 a | 42 | 200 | 1280 | 2200 | - | - | - | |

| 60 | 50 | 5 | 30.21 ± 0.22 a | 24.66 ± 0.62 ab | 78 | 190 | 1120 | 2000 | - | - | - |

| 70 | 10 | 30.33 ± 0.17 a | 25.71 ± 0.38 b | 20 | 25 | 65 | 310 | 1550 | - | - | |

| 90 | 23 | 30.25 ± 0.21 a | 27.33 ± 0.41 c | 10 | 10 | 10 | 20 | 20 | 400 | - | |

| 80 | 50 | 3 | 30.38 ± 0.16 a | 31.39 ± 0.42 d | 10 | 10 | 10 | 15 | 350 | 1800 | - |

| 70 | 7 | 30.29 ± 0.24 a | 32.04 ± 0.53 de | <10 | <10 | <10 | <10 | <10 | <10 | 20 | |

| 90 | 18 | 30.25 ± 0.23 a | 33.83 ± 0.55 e | <10 | <10 | <10 | <10 | <10 | <10 | 20 | |

| HCD | Value of Sensory Evaluation | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Uncooked Noodles | Cooked Noodle Samples | ||||||||

| Color | Appearance | Chewiness | Elasticity | Adhesiveness | Smoothness | Flavor | Overall Acceptability | Total Score | |

| Control | 9.70 ± 0.13 a | 9.69 ± 0.19 a | 18.79 ± 0.18 a | 23.42 ± 0.23 a | 13.72 ± 0.18 a | 4.27 ± 0.18 a | 4.71 ± 0.14 a | 9.18 ± 0.15 a | 93.48 |

| 40 °C-50% | 9.83 ± 0.16 a | 9.06 ± 0.19 b | 17.20 ± 0.15 c | 21.28 ± 0.20 c | 13.70 ± 0.17 a | 4.24 ± 0.21 a | 4.46 ± 0.27 a | 8.59 ± 0.18 b | 88.36 |

| 40 °C-70% | 9.79 ± 0.19 a | 9.04 ± 0.17 b | 17.18 ± 0.20 c | 21.55 ± 0.18 c | 13.71 ± 0.20 a | 4.21 ± 0.23 a | 4.44 ± 0.21 a | 8.63 ± 0.22 b | 88.55 |

| 40 °C-90% | 9.78 ± 0.23 a | 9.11 ± 0.22 b | 17.22 ± 0.21 c | 21.49 ± 0.23 c | 13.71 ± 0.22 a | 4.26 ± 0.24 a | 4.17 ± 0.28 b | 8.67 ± 0.24 b | 88.41 |

| 60 °C-50% | 9.49 ± 0.16 b | 9.24 ± 0.24 b | 17.35 ± 0.25 b | 22.27 ± 0.24 b | 13.71 ± 0.18 a | 4.23 ± 0.26 a | 4.05 ± 0.20 b | 8.78 ± 0.15 b | 89.12 |

| 60 °C-70% | 9.42 ± 0.22 b | 9.30 ± 0.29 a | 17.47 ± 0.23 b | 22.11 ± 0.19 b | 13.69 ± 0.24 a | 4.22 ± 0.18 a | 3.94 ± 0.21 b | 8.84 ± 0.27 a | 88.99 |

| 60 °C-90% | 9.43 ± 0.17 b | 9.37 ± 0.26 a | 17.45 ± 0.18 b | 22.30 ± 0.21 b | 13.70 ± 0.17 a | 4.29 ± 0.25 a | 3.90 ± 0.23 b | 8.88 ± 0.27 a | 89.32 |

| 80 °C-50% | 9.48 ± 0.28 ab | 9.41 ± 0.20 a | 17.56 ± 0.17 b | 22.05 ± 0.24 b | 13.73 ± 0.16 a | 4.25 ± 0.26 a | 3.95 ± 0.17 b | 8.81 ± 0.21 a | 89.24 |

| 80 °C-70% | 9.43 ± 0.17 b | 9.39 ± 0.30 a | 17.62 ± 0.19 b | 22.25 ± 0.26 b | 13.71 ± 0.25 a | 4.25 ± 0.18 a | 3.91 ± 0.18 b | 8.92 ± 0.19 a | 89.48 |

| 80 °C-90% | 9.41 ± 0.16 b | 9.42 ± 0.18 a | 17.09 ± 0.20 c | 22.18 ± 0.28 b | 13.69 ± 0.15 a | 4.29 ± 0.26 a | 3.86 ± 0.16 b | 8.62 ± 0.23 b | 88.56 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xing, J.-J.; Jiang, D.-H.; Yang, Z.; Guo, X.-N.; Zhu, K.-X. Effect of Humidity-Controlled Dehydration on Microbial Growth and Quality Characteristics of Fresh Wet Noodles. Foods 2021, 10, 844. https://doi.org/10.3390/foods10040844

Xing J-J, Jiang D-H, Yang Z, Guo X-N, Zhu K-X. Effect of Humidity-Controlled Dehydration on Microbial Growth and Quality Characteristics of Fresh Wet Noodles. Foods. 2021; 10(4):844. https://doi.org/10.3390/foods10040844

Chicago/Turabian StyleXing, Jun-Jie, Dong-Hui Jiang, Zhen Yang, Xiao-Na Guo, and Ke-Xue Zhu. 2021. "Effect of Humidity-Controlled Dehydration on Microbial Growth and Quality Characteristics of Fresh Wet Noodles" Foods 10, no. 4: 844. https://doi.org/10.3390/foods10040844

APA StyleXing, J.-J., Jiang, D.-H., Yang, Z., Guo, X.-N., & Zhu, K.-X. (2021). Effect of Humidity-Controlled Dehydration on Microbial Growth and Quality Characteristics of Fresh Wet Noodles. Foods, 10(4), 844. https://doi.org/10.3390/foods10040844