Measurement of Food Losses in a Hungarian Dairy Processing Plant

Abstract

1. Introduction

- Is it possible to quantify, and if so, to what extent (in milk equivalent) the amount of food loss in milk processing?

- At which production stage does the greatest amount of food loss in milk processing occur?

- How can we reduce the amount of food loss in milk processing?

2. Materials and Methods

Flw Standard Requirements & Description of the Analysed Company’s Inventory

- 1.

- Base FLW accounting and reporting on the principles of relevance, completeness, consistency, transparency, and accuracy.

- ▹

- Relevance: Milk processing was evaluated to identify relevant hotspots, where milk and dairy product losses and waste were higher than expected and therefore could be reduced.

- ▹

- Completeness: From factory gate (intake of raw milk from transport vehicle) to cooling and storage within the plant.

- ▹

- Consistency: Two on-site visits combined with expert interviews. Data was ensured by production management.

- ▹

- Transparency: In the case of liquid milk, yoghurt, sour cream, and kefir, destinations and quantity of losses were reported transparently by experts. In the case of cheese products, no access was allowed. The name of the analysed dairy company is withheld at the request of the management.

- ▹

- Accuracy: depends on how the measurement is performed (Table 1). Liquid milk product (ESL) loss estimations are more accurate than for yoghurt, sour cream, and kefir.

- 2.

- Account for and report the physical amount of FLW expressed as weight.

- 3.

- Define and report on the scope of the FLW inventory (see FLW Standard for additional details).Timeframe: Data reported for January 2018 and January 2019.Material type: Food (inedible parts were not included)Destinations: When water is mixed with milk, sewer/wastewater treatment was considered as milk loss and waste. Clean water or other losses were not currently the subject of our research.Boundary:

- ▹

- Food category: dairy products (General Standard for Food Additives (GSFA) 01.0): liquid milk, sour cream, yoghurt, kefir.

- ▹

- Lifecycle stage: From factory gate (intake of raw milk from transport vehicle) to cooling and storage within the plant (ISIC code: 1050—manufacture of dairy products)

- ▹

- Geography: Hungary, UN country code 348

- ▹

- Organization: One Southern Trans-Danubian dairy factory (ltd).

Related issues: Weight of packaging and water are excluded. - 4.

- Describe the quantification method(s) used. If existing studies or data are used, identify the source and scope.Surveys (visits and interviews):

- ▹

- January 2018: identification of processing stages and loss data was ensured (Table 2). Whole plant visit and senior and junior production manager interviews.

- ▹

- January 2019: revision of loss data from January 2018 (no significant change was reported). Partial plant visit and senior and junior production manager interviews.

- ▹

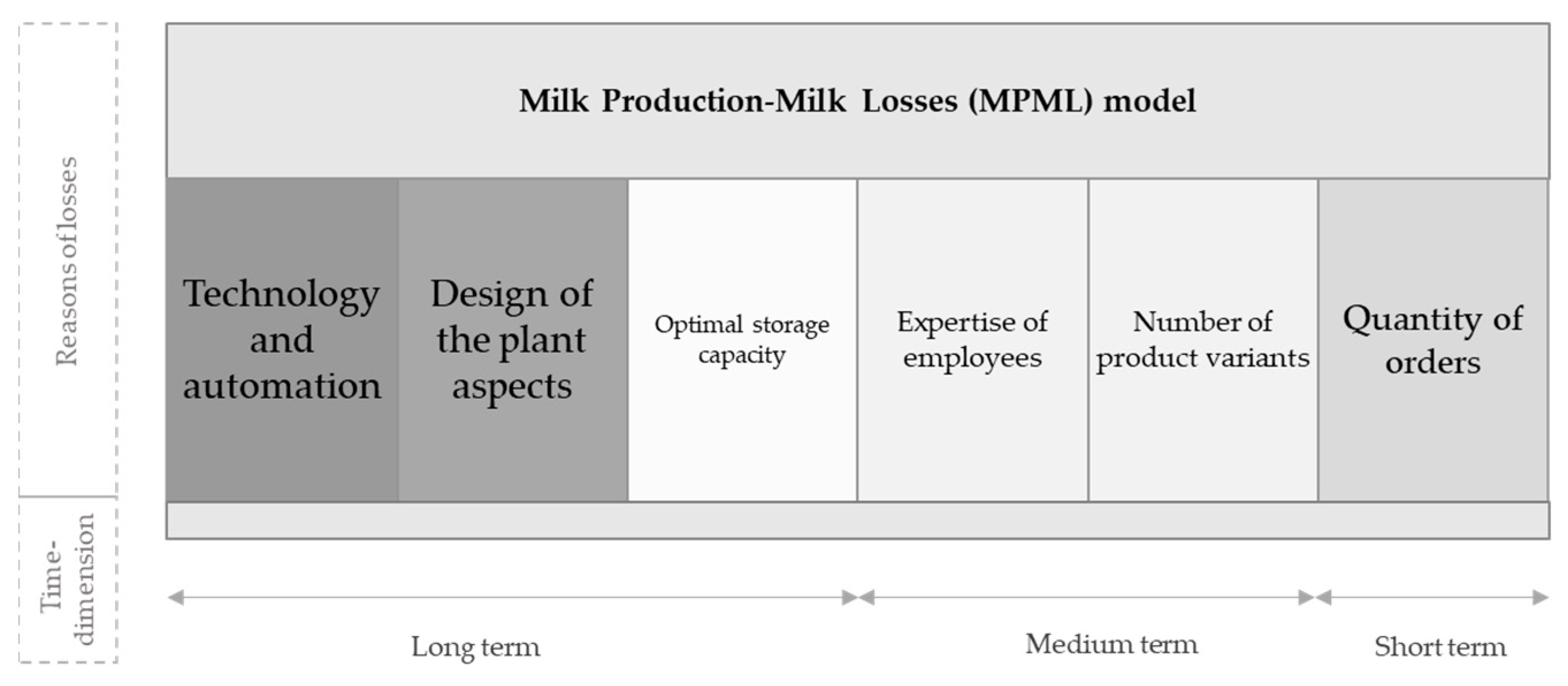

- March 2020: finalization of identified reasons of milk loss (Figure 3). Senior production manager online interview.

- 5.

- If sampling and scaling of data are undertaken, describe the approach and calculation used, as well as the period of time over which sample data are collected (including start and end dates)

- 6.

- Provide a qualitative description and/or quantitative assessment of the uncertainty around FLW inventory results.

- 7.

- If assurance of the FLW inventory is undertaken (which may include peer review, verification, validation, quality assurance, quality control, and audit), create an assurance statement.

- 8.

- If tracking the amount of FLW and/or setting an FLW reduction target, select a base year, identify the scope of the target, and recalculate the base year FLW inventory when necessary.

3. Results and Discussion

4. Conclusions

- use the highest possible level of automation (A)

- remove water from the pipes with nitrogen (A)

- rationalization of length and slope of pipes (B)

- fulfilment of order quantity that meets the criteria of the company’s economies of scale (F)

- employ a skilled workforce in manufacturing and keep fluctuation as low as possible (D)

- optimization of production also in case of taste transitions (E)

- development of storage capacity adapted to daily production capacity (C)

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

References

- FAO. Global Initiative on Food Loss and Waste; Food and Agriculture Organization of the United Nations: Rome, Italy, 2017; pp. 1–64. Available online: http://www.fao.org/3/a-i7657e.pdf (accessed on 15 January 2019).

- Hall, K.D.; Guo, J.; Dore, M.; Chow, C.C. The Progressive Increase of Food Waste in America and Its Environmental Impact. PLoS ONE 2009, 4, e7940. [Google Scholar] [CrossRef] [PubMed]

- United Nations. The Sustainable Development Goals Report; Department of Economic and Social Affairs: New York, NY, USA, 2019; ISBN 978-92-1-101403-7. Available online: https://unstats.un.org/sdgs/report/2019/The-Sustainable-Development-Goals-Report-2019.pdf (accessed on 22 February 2020).

- Liberti, F.; Pistolesi, V.; Massoli, S.; Bartocci, P.; Bidini Fantozzi, F. i-REXFO LIFE: An innovative business model to reduce food waste. Energy Procedia 2018, 148, 439–446. [Google Scholar] [CrossRef]

- Pató, B.S.G. The effect of climate change on distribution logistics. Int. J. Bus. Insights Transform. 2017, 8, 24–29. [Google Scholar]

- Kovács, Z.; Pató, B.S.G. Impacts of extreme weather in supply chains. Időjárás O. J. Hung. Meteorol. Serv. 2014, 118, 283–291. [Google Scholar]

- Darvasné Ördög, E.; Dudás, G.; Kőrőshegyi, D.; Kulmány, I.; Kürthy, G.; Rné Kocsis, T.; Székelyhidi, K.; Takács, E.; Vajda, Á. Élelmiszer-Veszteségek Keletkezésének Okai, Azok Kezelése és Megítélése a Feldolgozóipari Vállalatok Körében. Agrárgazdasági Könyvek; NAIK Agrárgazdasági Kutatóintézet: Budapest, Hungary, 2019; ISBN 978-963-491-606-2. [Google Scholar]

- Caldeira, C.; De Laurentiis, V.; Corrado, S.; Van Holsteijn, F.; Sala, S. Quantification of food waste per product group along the food supply chain in the European Union: A mass flow analysis. Resour. Conserv. Recycl. 2019, 149, 479–488. [Google Scholar] [CrossRef] [PubMed]

- Monier, V.; Mudgal, S.; Escalon, V.; O’Connor, C.; Gibon, T.; Anderson, G.; Montoux, H. Preparatory. Study on Food Waste Across Eu 27. 2010. Available online: http://ec.europa.eu/environment/archives/eussd/pdf/bio_foodwaste_report.pdf (accessed on 15 January 2019).

- FAO. Global Food Losses and Food Waste–Extent, Causes and Prevention; Food and Agriculture Organization of the United Nations: Rome, Italy, 2011; ISBN 978-92-5-107205-9. Available online: http://www.fao.org/3/mb060e/mb060e.pdf (accessed on 15 January 2019).

- Parfitt, J.; Barthel, M.; Macnaughton, S. Food waste within food supply chains: Quantification and potential for change to 2050. Philos. Trans. R. Soc. B Biol. Sci. 2010, 365, 3065–3081. [Google Scholar] [CrossRef] [PubMed]

- Priefer, C.; Jörissen, J.; Braeutigam, K.-R. Options for Cutting Down on Food Waste. European Parliament; Institute for Technology Assessment and Systems Analysis: Brussels, Belgium, 2013; ISBN 978-92-823-4750-8. [Google Scholar] [CrossRef]

- Östergren, K.; Gustavsson, J.; Bos-Brouwers, H.; Timmermans, T.; Hansen, O.-J.; Moller, H.; Anderson, G.; O’Connor, C.; Soethoudt, H.; Quested, T.; et al. FUSIONS Definitional Framework for Food Waste. Full Report; Göteborg, Sweden, 2014; pp. 1–134. ISBN 978-91-7290-331-9. Available online: https://www.eu-fusions.org/phocadownload/Publications/FUSIONS%20Definitional%20Framework%20for%20Food%20Waste%202014.pdf (accessed on 20 January 2019).

- Kürthy, G. Élelmiszerveszteség a Feldolgozóiparban: Technológiai Szükségszerűség Vagy Felelős Stratégiával, Együttműködéssel Kezelhető kihívás?-Szakmai Előadás és Kapcsolódó Témabeszélgetés; Agrárgazdasági Kutató Intézet Élelmiszerlánc Kutatási Osztály: Budapest, Hungary, 2018. [Google Scholar]

- Themen, D. Reduction of Food Losses and Waste in Europe and Central Asia for Improved Food Security and Agrifood Chain. Available online: http://www.fao.org/3/a-au844e.pdf (accessed on 12 January 2018).

- Varga, J.; Sipiczki, Z. A magyarországi agrárvállalkozások likviditási és jövedelmezőségi helyzetének elemzése a 2005-2014 közötti időszakban. Gazdálkodás 2017, 61, 14–26. [Google Scholar] [CrossRef]

- Fisher, K.; Whittaker, D. Opportunities to Reduce Waste along the Journey of Milk, from Dairy to Home. Waste and Resources Action Programme; Final Report. UK. 2018. Available online: http://www.wrap.org.uk/sites/files/wrap/Report%20-%20Opportunities%20to%20reduce%20waste%20along%20the%20journey%20of%20milk%20PUB%2011.2018.pdf (accessed on 5 March 2019).

- Charad, J.; Lanctuit, H.; Goodwin, L.; Hanson, C.; Leous, J.P.; Robertson, K.; Ahlouwa, S. Nestlé Dairy Factories in Pakistan: Losses Across the Value Chain; The Food Loss & Waste Protocol: Washington, DC, USA, 2017; Available online: http://www.flwprotocol.org/wp-content/uploads/2017/05/FLW_Standard_Case-Study_March-2017_NestlePakistan.pdf (accessed on 10 January 2018).

- Tostivint, C.; De Veron, S.; Jan, O.; Lanctuit, H.; Hutton, Z.V.; Loubière, M. Measuring food waste in a dairy supply chain in Pakistan. J. Clean. Prod. 2017, 145, 221–231. [Google Scholar] [CrossRef]

- Ahmad, T.; Aadil, R.M.; Ahmed, H.; Rahman, U.; Soares, B.C.V.; Souza, S.L.Q.; Pimentel, T.C.; Scudino, H.; Guimarães, J.T.; Esmerino, E.A.; et al. Treatment and utilization of dairy industrial waste: A review. Trends Food Sci. Technol. 2019, 88, 361–372. [Google Scholar] [CrossRef]

- Carawan, R.E.; Jones, V.A. Water and Waste Management Educational Program for Dairy Processing. J. Dairy Sci. 1977, 60, 1192–1197. [Google Scholar] [CrossRef]

- Charad, J.; Erhardt, R.; Orias, N.E.; Larsen, E.; Robertson, K.; Kneller, C. Nestlé’s Milk Losses from Farm Gate to Factory in 30 Countries; The Food Loss & Waste Protocol: Washington, DC, USA, 2019; Available online: https://www.flwprotocol.org/case-studies/nestles-milk-losses-from-farm-gate-to-factory-in-30-countries/ (accessed on 20 November 2019).

- Wesana, J.; Gellynck, X.; Dora, M.K.; Pearce, D.; De Steur, H. Measuring food and nutritional losses through value stream mapping along the dairy value chain in Uganda. Resour. Conserv. Recycl. 2019, 150, 104416. [Google Scholar] [CrossRef]

- Hanson, C.; Lipinski, B.; Robertson, K.; Dias, D.; Gavilan, I.; Gréverath, P.; Ritter, S.; Fonseca, J.; Van Otterdijk, T.; Lomax, J.; et al. Food Loss and Waste Accounting and Reporting Standard; World Resources Institute: Washington, DC, USA, 2016; ISBN 978-1-56973-892-4. Available online: http://flwprotocol.org/wp-content/uploads/2017/05/FLW_Standard_fnal_2016.pdf (accessed on 10 January 2018).

- Hanson, C. Guidance on Interpreting Sustainable Development Goal Target 12.3; World Resources Institute: Washington, DC, USA, 2017; Available online: https://champions123.org/wp-content/uploads/2017/10/champions-12-3-guidance-on-interpreting-sdg-target-12-3.pdf (accessed on 15 January 2019).

- European Commission. COMMISSION REGULATION (EC) No 595/2004 of 30 March 2004 Laying down Detailed Rules for Applying Council Regulation (EC) No 1788/2003 Establishing a Levy in the Milk and Milk Products Sector. 2004. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:02004R0595-20120401&from=HU (accessed on 5 February 2019).

- Food Loss and Waste Accounting and Reporting Standard (FLW). Sample Reporting Template, Version 1.0. 2017. Available online: https://flwprotocol.org/flw-standard/tools-resources/sample-reporting-template/ (accessed on 10 January 2018).

- Rózsa, A.; Tálas, D. Versenyhelyzet-Elemzés a Magyarországi Tejfeldolgozó Szektorban. Gazdálkodás 2014, 58, 519–539. [Google Scholar] [CrossRef]

- Babcsányi, I.; Jacobsen, M.; Gazdag, A.; Deister, U.; Kerpen, J.; Sabo, F.; Prediger, J.; Prechel, S. Útmutató az Elérhető Legjobb Technika Meghatározásához a Tejfeldolgozás Terén; Környezetvédelmi és Vízügyi Minisztérium Környezetgazdálkodási Intézet IPPC Osztálya: Budapest, Hungary, 2005; Available online: https://ippc.kormany.hu/download/c/e9/70000/tej_utmutato.pdf (accessed on 8 March 2019).

- Szakály, Z.; Polereczki, Z.; Szigeti, O.; Szente, V. Consumer judgement of nutritional benefits of dairy products. Milchwiss. Milk Sci. Int. 2012, 67, 366–369. [Google Scholar]

- Verma, M.; Plaisier, C.; van Wagenberg, C.P.A.; Achterbosch, T. A Systems Approach to Food Loss and Solutions: Understanding Practices, Causes, and Indicators. Sustainability 2019, 11, 579. [Google Scholar] [CrossRef]

| Processing Stage | Applied Technology | Technological Parameters of Equipment | How to Measure Losses? |

|---|---|---|---|

| Intake of raw milk | Milk collection in a closed system | 1 line 30,000 L/h (pump, plate refrigerator/cooler) 180,000 L of raw milk storage capacity | Digital flow meter |

| Skimming (separator de-sludge) | “Self-emptying” skimmer, automatic fat adjuster | 1 pc 20,000 L/h | Proportionality of operating time and loss per emptying (periodic measurement) |

| Pasteurization | Closed system, operation in accordance with the applicable regulations (automatic control and registration of temperature and pressure values) | 1 pc 20,000 L/h 1 pc 6000 L/h 1 pc 5000 L/h | Digital flow meters, automatic data recording |

| Extended Shelf-Life (ESL) sterile container | Closed system, overpressure (2 bar) | 15,000 L capacity | Digital flow meters, automatic data recording |

| Cheese milk | Automatic fat, manual protein adjustment | Using the available 20,000 L/h pasteurizer and separator equipment | Digital flow meters, automatic data recording. Calculation according to standard from the finished product. |

| Sour cream, Yoghurt, Kefir | Closed system product line | Using the available 20,000 L/h pasteurizer and separator, the 5000 and 6000 L/h pasteurizer, and the homogenizers set up with them | Digital flow meters, automatic data recording, stocking of the finished product. Measuring after cleaning under pressure with a digital scale |

| Products awaiting delivery (Cooling, storage) | Manual and mechanical handling, storage according to First In First Out (FIFO) inventory valuation | Hand and machine forklifts | Measuring and documenting the difference between products taken over from production and sold. |

| Processing Stage | Average Loss Amount | Main Reason of Milk Loss | ||

|---|---|---|---|---|

| Liter, kg/day | Milk Equivalent (kg/day) | |||

| Daily production | Intake of raw milk | 80–100 L | 82.4–103 kg | A,B,C |

| Skimming (separator de-sludge) | - | 378 L = 389.3 kg | A,B | |

| Pasteurization | 180–240 L | 185.4–247.2 kg | A,D | |

| ESL sterile container | 200 L | 126 L = 129.8 kg | A,B,F | |

| Cheese milk | 300–420 L | 262.5–367.5 L = 270.3–378.5 kg | A,B,F | |

| Periodic production | Sour cream | 9.6–12 kg | 24.6–30.7 L = 25.3–31.6 kg | A,B,E,F |

| Yoghurt | 4.8–9.6 kg | 12.3–24.6 L = 12.7–25.3 kg | A,B,E,F | |

| Kefir | negligible | negligible | A,B,F | |

| Products awaiting delivery, storage | milk, sour cream, yoghurt, kefir | 140 L | 144.18 kg | D |

| Total | 1203.4–1406.8 L 1239.4–1448.9 kg (Daily 0.9–1.0%) | |||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tóth, K.; Borbély, C.; Nagy, B.; Szabó-Szentgróti, G.; Szabó-Szentgróti, E. Measurement of Food Losses in a Hungarian Dairy Processing Plant. Foods 2021, 10, 229. https://doi.org/10.3390/foods10020229

Tóth K, Borbély C, Nagy B, Szabó-Szentgróti G, Szabó-Szentgróti E. Measurement of Food Losses in a Hungarian Dairy Processing Plant. Foods. 2021; 10(2):229. https://doi.org/10.3390/foods10020229

Chicago/Turabian StyleTóth, Katalin, Csaba Borbély, Bernadett Nagy, Gábor Szabó-Szentgróti, and Eszter Szabó-Szentgróti. 2021. "Measurement of Food Losses in a Hungarian Dairy Processing Plant" Foods 10, no. 2: 229. https://doi.org/10.3390/foods10020229

APA StyleTóth, K., Borbély, C., Nagy, B., Szabó-Szentgróti, G., & Szabó-Szentgróti, E. (2021). Measurement of Food Losses in a Hungarian Dairy Processing Plant. Foods, 10(2), 229. https://doi.org/10.3390/foods10020229