Effect of Steam and Smoke Cooking Processes on Web-Foot Octopus (Amphioctopus sp.) Home Meal Replacement Product

Abstract

:1. Introduction

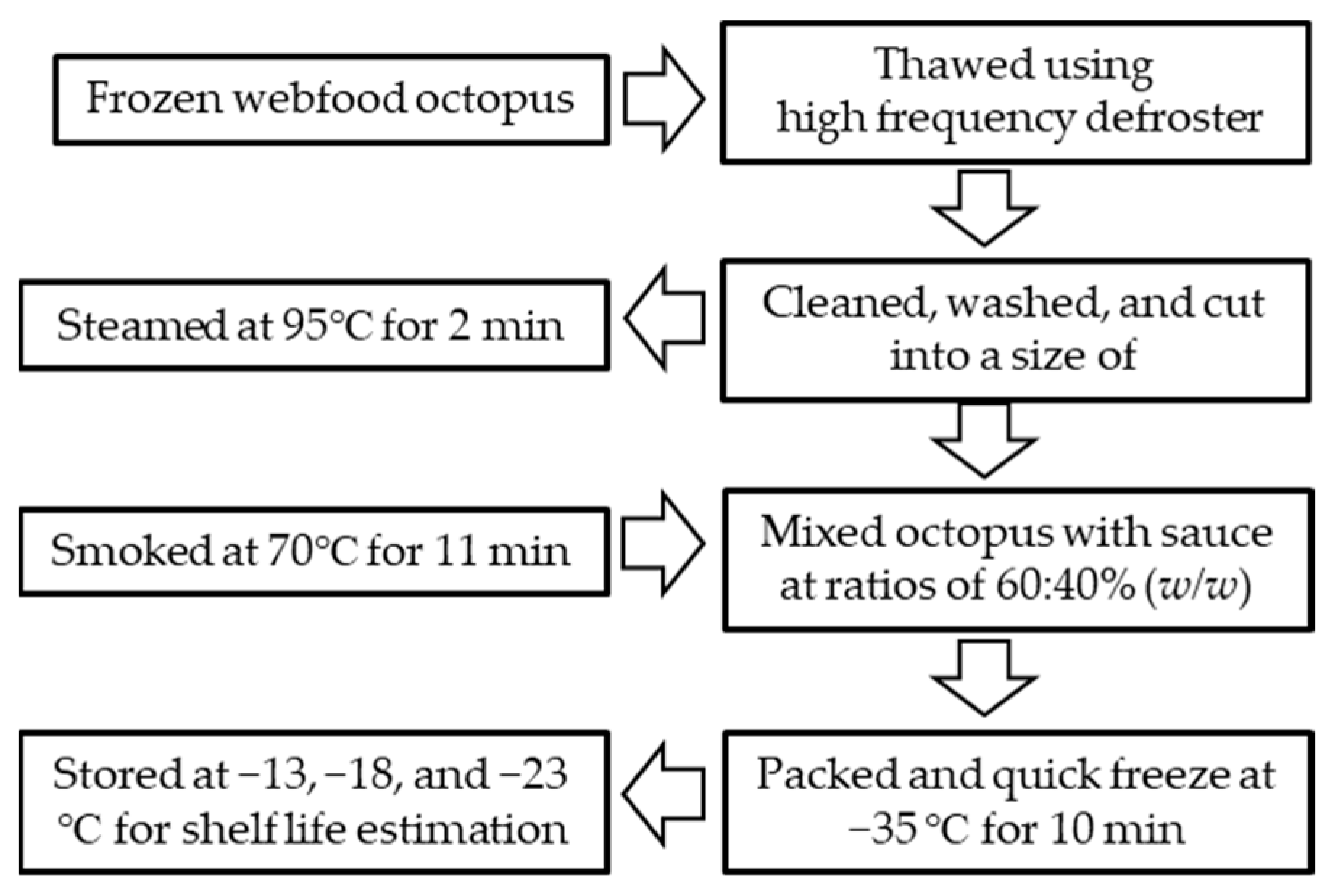

2. Materials and Methods

2.1. Preparation of Raw Materials

2.2. Steaming and Smoking Processes

2.3. Preparing Test HMR Products

2.4. Sensory Evaluation

2.5. Physicochemical Analysis

2.5.1. pH

2.5.2. Volatile Basic Nitrogen

2.5.3. Thiobarbituric Acid-Reactive Substances

2.6. Nutritional Quality Analysis

2.7. Microbial Analysis

2.8. Shelf-Life Analysis

2.9. Statistical Analysis

3. Results and Discussion

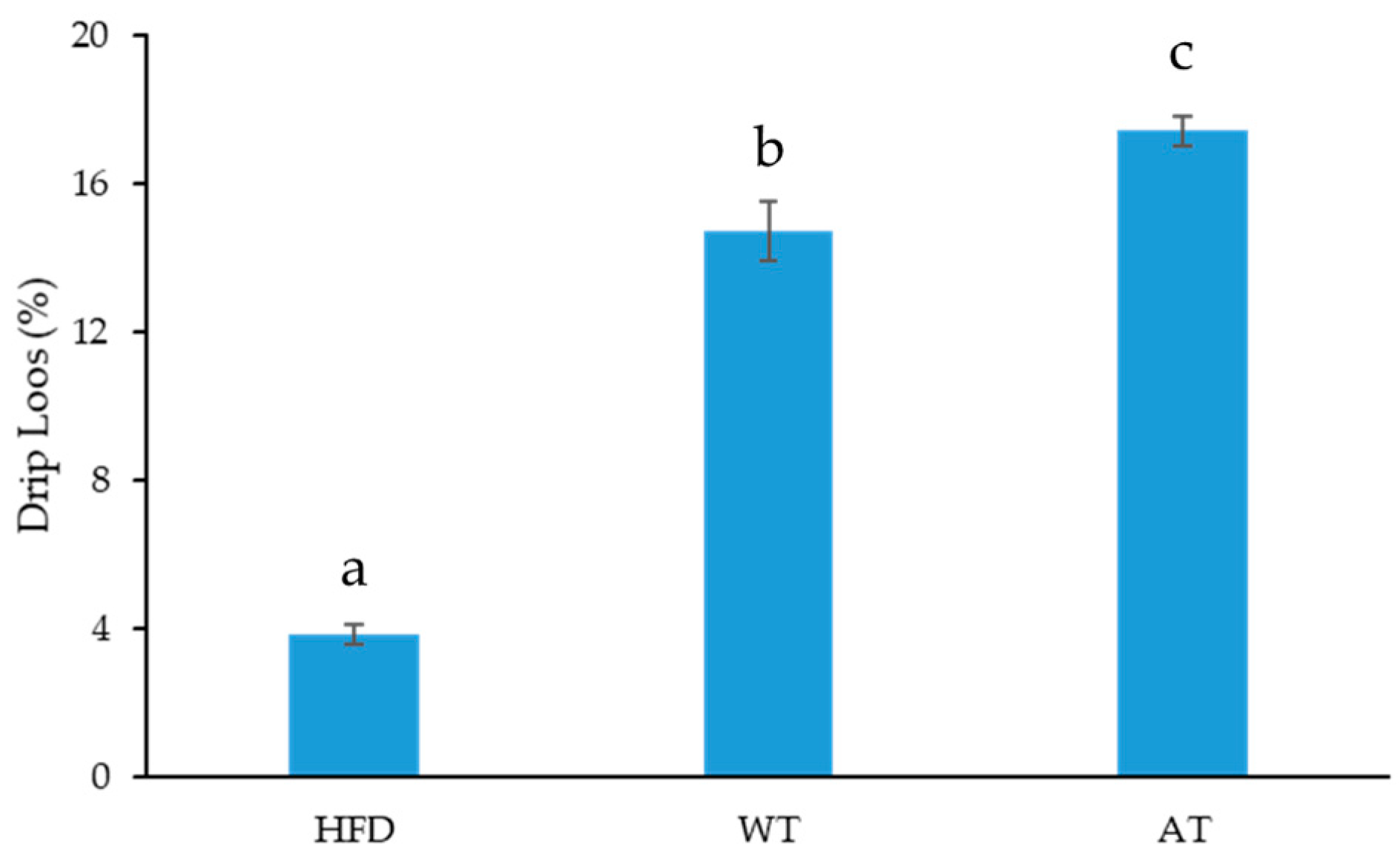

3.1. Drip Loss

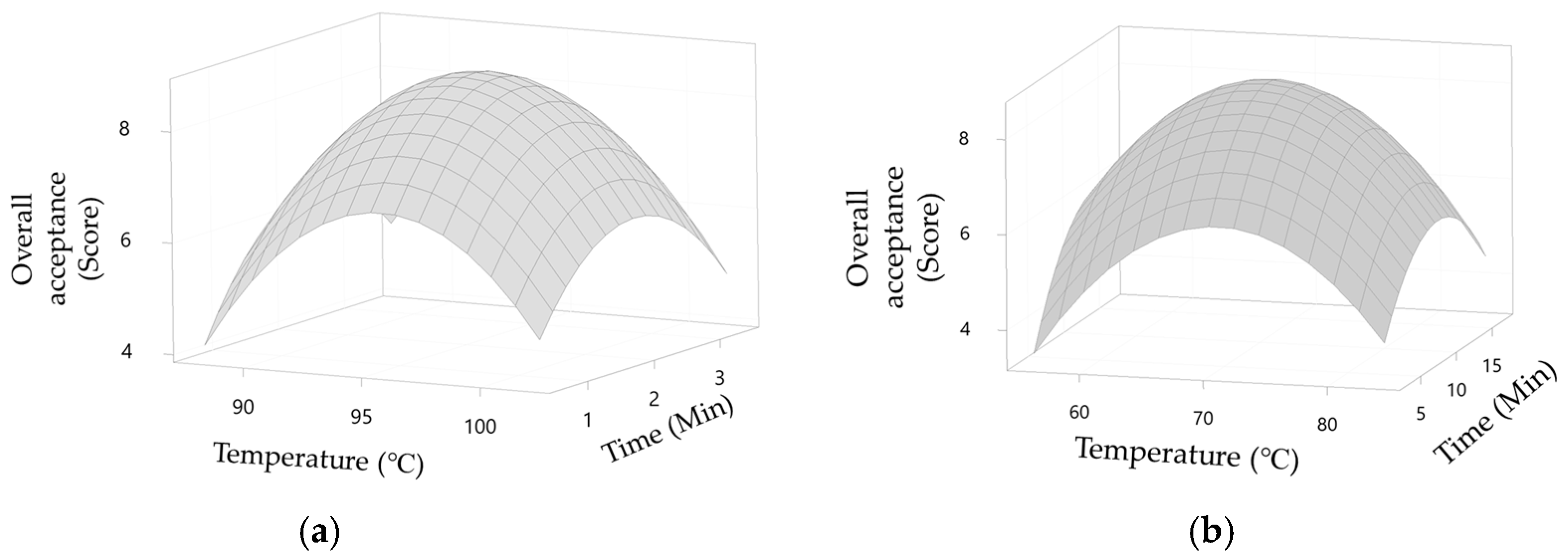

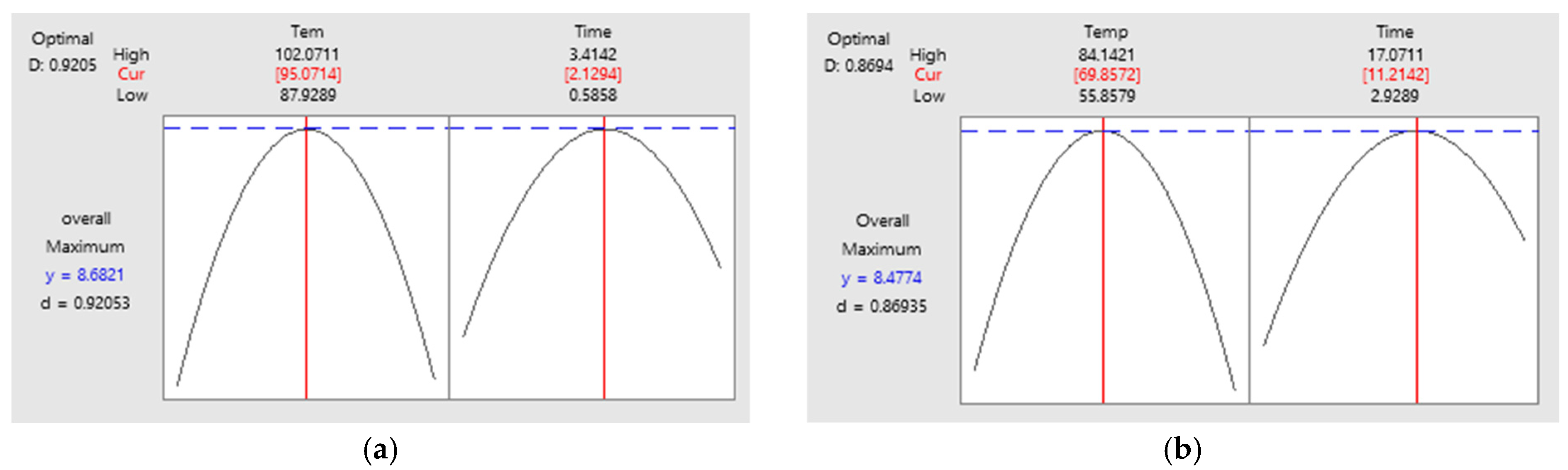

3.2. Optimal Conditions for Steaming and Smoking

3.3. Effects of Steam and Smoke on Physicochemical Properties of Web-Foot Octopus

3.4. Sensory Evaluation of test HMR Product

3.5. Nutritional Composition of Test HMR Product

3.6. Shelf-Life Estimation

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ahn, A.K.; Choe, Y.C.; Cho, H.B. Types of Home Meal Replacement and Determinants of Consumption in South Korea. Agribus. Inf. Manag. 2014, 6, 1–12. [Google Scholar] [CrossRef] [Green Version]

- Tirtawijaya, G.; Kim, S.R.; Cho, W.H.; Sohn, J.H.; Kim, J.-S.; Choi, J.-S. Development of a Home Meal Replacement Product Containing Braised Mackerel (Scomber japonicus) with Radish (Raphanus sativus). Foods 2021, 10, 1135. [Google Scholar] [CrossRef] [PubMed]

- Tirtawijaya, G.; Lee, M.-J.; Negara, B.F.S.P.; Cho, W.-H.; Sohn, J.-H.; Kim, J.-S.; Choi, J.-S. Effects of Vacuum Frying on the Preparation of Ready-to-Heat Batter-Fried and Sauced Chub Mackerel (Scomber japonicus). Foods 2021, 10, 1962. [Google Scholar] [CrossRef] [PubMed]

- Negara, B.F.S.P.; Lee, M.-J.; Tirtawijaya, G.; Cho, W.-H.; Sohn, J.-H.; Kim, J.-S.; Choi, J.-S. Application of Deep, Vacuum, and Air Frying Methods to Fry Chub Mackerel (Scomber japonicus). Processes 2021, 9, 1225. [Google Scholar] [CrossRef]

- Negara, B.; Kim, S.; Sohn, J.; Kim, J.-S.; Choi, J.-S. Application of high-frequency defrosting, superheated steam, and quick-freezing treatments to improve the quality of seafood home meal replacement products consisting of the Adductor Muscle of Pen Shells and Common Squid Meat. Appl. Sci. 2021, 11, 2926. [Google Scholar] [CrossRef]

- Cho, W.-H.; Yoon, S.-J.; Choi, J.-S. Optimization of Texture-Modified Yellowfin Sole (Pleuronectes aspera) by Enzymatic Treatment and Superheated Steam Treating to Improve Quality Characteristics. Processes 2021, 9, 763. [Google Scholar] [CrossRef]

- Ozogul, Y.; Duysak, O.; Ozogul, F.; Özkütük, A.S.; Türeli, C. Seasonal effects in the nutritional quality of the body structural tissue of cephalopods. Food Chem. 2008, 108, 847–852. [Google Scholar] [CrossRef]

- Food and Agriculture Organization of the United Nations. The State of World Fisheries and Aquaculture 2018—Meeting the Sustainable Development Goals; FAO: Rome, Italy, 2018; Available online: http://www.fao. org/3/i9540en/i9540en.pdf (accessed on 15 September 2021).

- Hamada, S.; Terashima, S.; Hirayama, S.; Wada, R.; Ura, H.; Nakamura, S. Comparison of the food chemical properties of fish meat roasted by superheated steam heating and propane-gas combustion heating. Natl. Fish. Univ. Res. Rep. 2006, 55, 1–11. [Google Scholar]

- Idrus, N.F.M.; Zzaman, W.; Yang, T.A.; Easa, A.M.; Sharifudin, M.S.; Noorakmar, B.W.; Jahurul, M.H.A. Effect of superheated-steam roasting on physicochemical properties of peanut (Arachis hypogea) oil. Food Sci. Biotechnol. 2017, 26, 911–920. [Google Scholar] [CrossRef]

- Alfy, A.; Kiran, B.V.; Jeevitha, G.C.; Hebbar, H.U. Recent developments in superheated steam processing of foods—A review. Crit. Rev. Food Sci. Nutr. 2014, 56, 2191–2208. [Google Scholar] [CrossRef]

- Franco, M.L.R.D.S.; Viegas, E.M.M.; Kronka, S.N.; Vidotti, R.M.; Assano, M.; Gasparino, E. Effects of hot and cold smoking processes on organoleptic properties, yield and composition of matrinxa fillet. Rev. Bras. Zootec. 2010, 39, 695–700. [Google Scholar] [CrossRef] [Green Version]

- Salaudeen, M.M.; Osibona, A.O. Impact of smoking techniques and storage conditions on microbial safety and stability of catfish (Clarias gariepinus). Ife J. Sci. 2018, 20, 345–353. [Google Scholar] [CrossRef]

- Colakoglu, F.A.; Ormanci, H.B.; Cakir, F. Effect of marination and smoking on lipid and fatty acid composition of thornback ray (Raja clavata) and spiny dogfish (Squalus acanthias). Eur. Food Res. Technol. 2011, 232, 1069–1075. [Google Scholar] [CrossRef]

- Kauffman, R.G.; Eikelenboom, G.; van der Wal, P.G.; Merkus, G.; Zaar, M. The use of filter paper to estimate drip loss of porcine musculature. Meat Sci. 1986, 18, 191–200. [Google Scholar] [CrossRef]

- Li, M.; Wang, W.; Fang, W.; Li, Y. Inhibitory effects of chitosan coating combined with organic acids on Listeria monocytogenes in refrigerated ready-to-eat shrimps. J. Food Prot. 2013, 76, 1377–1383. [Google Scholar] [CrossRef]

- Peiretti, P.G.; Medana, C.; Visentin, S.; Giancotti, V.; Zunino, V.; Meineri, G. Determination of carnosine, anserine, homocarnosine, pentosidine and thiobarbituric acid reactive substances contents in meat from different animal species. Food Chem. 2011, 126, 1939–1947. [Google Scholar] [CrossRef] [PubMed]

- Association of Official Analytical Chemist. Official Methods of Analysis; Horwitz, W., Ed.; AOAC International: Washington, DC, USA, 2000. [Google Scholar]

- Venugopal, V. Seafood Processing Adding Value through Quick Freezing, Retortable Packaging, and Cook-Chilling; Taylor & Francis: New York, NY, USA, 2006; p. 485. [Google Scholar]

- Alizadeh, E.; Chapleau, N.; De Lamballerie, M.; LeBail, A. Effects of freezing and thawing processes on the quality of Atlantic salmon (Salmo salar) fillets. J. Food Sci. 2007, 72, 279–284. [Google Scholar] [CrossRef]

- Gokoglu, N.; Yerlikaya, P.; Cengiz, E. Effects of cooking methods on the proximate composition and mineral contents of rainbow trout (Oncorhynchus mykiss). Food Chem. 2004, 84, 19–22. [Google Scholar] [CrossRef]

- Otto, G.; Roehe, R.; Looft, H.; Thoelking, L.; Kalm, E. Comparison of different methods for determination of drip loss and their relationships to meat quality and carcass characteristics in pigs. Meat Sci. 2004, 68, 401–409. [Google Scholar] [CrossRef]

- Beggs, K.L.H.; Bowers, J.A.; Brown, D. Sensory and physical characteristics of reduced-fat turkey frankfurters with modified corn starch and water. J. Food Sci. 1997, 62, 1240–1244. [Google Scholar] [CrossRef]

- Pappa, I.C.; Bloukas, J.G.; Arvanitoyannis, I.S. Optimisation of salt, olive oil and pectin for low-fat frankfurters produced by replacing pork backfat with olive oil. Meat Sci. 2000, 56, 81–88. [Google Scholar] [CrossRef]

- Sutikno, L.A.; Bashir, K.M.I.; Kim, H.; Park, Y.; Won, N.E.; An, J.H.; Jeon, J.H.; Yoon, S.J.; Park, S.M.; Sohn, J.H.; et al. Improvement in Physicochemical, Microbial, and Sensory Properties of Common Squid (Todarodes pacificus) by Superheated Steam Roasting in Combination with Smoking Treatment. J. Food Qual. 2019, 2019, 8721725. [Google Scholar] [CrossRef]

- Mohibbullah, M.; Won, N.E.; Jeon, J.H.; An, J.H.; Park, Y.; Kim, H.; Bashir, K.M.I.; Park, S.M.; Kim, Y.S.; Yoon, S.J.; et al. Effect of superheated steam roasting with hot smoking treatment on improving physicochemical properties of the adductor muscle of pen shell (Atrina pectinate). Food Sci. Nutr. 2018, 6, 1317–1327. [Google Scholar] [CrossRef]

- Yildiz, P.O. Effect of essential oils and packaging on hot smoked rainbow trout during storage. J. Food Process. Preserv. 2015, 39, 806–815. [Google Scholar] [CrossRef]

- Chen, H.Z.; Zhang, M.; Bhandari, B.; Yang, C.H. Development of a novel colorimetric food package label for monitoring lean pork freshness. LWT Food Sci. Technol. 2019, 99, 43–49. [Google Scholar] [CrossRef] [Green Version]

- Howgate, P. A critical review of total volatile bases and trimethylamine as indices of freshness of fish. Part 1. Determination. Electron. J. Environ. Agric. Food Chem. 2010, 9, 29–57. [Google Scholar]

- Servillo, L.; D’onofrio, N.; Giovane, A.; Casale, R.; Cautela, D.; Castaldo, D.; Iannaccone, F.; Neglia, G.; Campanile, G.; Balestrieri, M.L. Ruminant meat and milk contain delta-valerobetaine, another precursor of trimethylamine N-oxide (TMAO) like gamma-butyrobetaine. Food Chem. 2018, 260, 193–199. [Google Scholar] [CrossRef]

- Samples, S. The effects of storage and preservation technologies on the quality of fish products: A review. J. Food Process. Preserv. 2014, 39, 1206–1215. [Google Scholar] [CrossRef]

- Hergenreder, J.; Hosch, J.J.; Varnold, K.A.; Haack, A.L. Effects of freezing and thawing rates on tenderness and sensory quality of beef subprimals. J. Anim. Sci. 2013, 91, 483–490. [Google Scholar] [CrossRef]

- Reid, D.S. Overview of physical/chemical aspects of freezing. In Quality in Frozen Food, 1st ed.; Erickson, M.C., Hung, Y., Eds.; Springer: New York, NY, USA, 1997; pp. 10–28. [Google Scholar]

- George, R.M. Freezing system. In Quality in Frozen Food, 1st ed.; Erickson, M.C., Hung, Y., Eds.; Springer: New York, NY, USA, 1997; pp. 3–9. [Google Scholar]

- Leygonie, C.; Britz, T.J.; Hoffman, L.C. Impact of freezing and thawing on the quality of meat. Meat Sci. 2012, 91, 93–98. [Google Scholar] [CrossRef]

- Li, F.F.; Wang, B.; Liu, Q.; Chen, Q.; Zhang, H.W.; Xia, X.F.; Kong, B.H. Changes in myofibrillar protein gel quality of porcine longissimus muscle induced by its stuctural modification under different thawing methods. Meat Sci. 2019, 147, 108–115. [Google Scholar] [CrossRef] [PubMed]

- Wang, B.; Du, X.; Kong, B.; Liu, Q.; Li, F.; Pan, N.; Xia, X.; Zhang, D. Effect of ultrasound thawing, vacuum thawing, and microwave thawing on gelling properties of protein from porcine longissimus dorsi. Ultrason. Sonochem. 2019, 64, 104860. [Google Scholar] [CrossRef] [PubMed]

- Mouritsen, O.G.; Styrbæk, K. Cephalopod Gastronomy—A Promise for the Future. Front. Commun. 2018, 3, 38. [Google Scholar] [CrossRef]

- Murthy, W.S.; Singh, S.N. Nutritional requirements for human adaptation in extreme environments. Proc. Indian Natn Sci. Acad. 2003, 69, 485–506. [Google Scholar]

- Li, X.; Rezaei, R.; Li, P.; Wu, G. Composition of amino acids in feed ingredients for animal diets. Amino Acids 2011, 40, 1159–1168. [Google Scholar] [CrossRef]

- Li, P.; Wu, G. Composition of amino acids and related nitrogenous nutrients in feedstuffs for animal diets. Amino Acids 2020, 52, 523–542. [Google Scholar] [CrossRef] [Green Version]

- Calder, P.C.; Yaqoob, P. Glutamine and the immune system. Amino Acids 1999, 17, 227–241. [Google Scholar] [CrossRef] [PubMed]

- Takahashi, T.; Eri, T.; Ram, B.S.; Meester, F.D.; Wilczynska, A.; Wilson, D.; Juneja, L.R. Essential and non-essential amino acids in relation to glutamate. Open Nutraceuticals J. 2011, 4, 205–212. [Google Scholar] [CrossRef]

- Akram, M.; Asif, H.M.; Uzair, M.; Akhtar, N.; Madni, A.; Shah, S.M.A.; Hasan, Z.U.; Ullah, A. Amino acids: A review article. J. Med. Plant. Res. 2011, 5, 3997–4000. [Google Scholar]

- Sarower, M.G.; Hasanuzzaman, A.F.M.; Biswas, B.; Abe, H. Taste producing components in fish and fisheries products: A review. Int. J. Food Ferment. Technol. 2012, 2, 113–121. [Google Scholar]

- Swanson, D.; Block, R.; Mousa, S.A. Omega-3 fatty acids EPA and DHA: Health benefits throughout life. Adv. Nutr. 2012, 3, 1–7. [Google Scholar] [CrossRef]

- Simopoulos, A.P. The Importance of the Omega-6/Omega-3 Fatty Acid Ratio in Cardiovascular Disease and Other Chronic Diseases. Exp. Biol. Med. 2008, 233, 674–688. [Google Scholar] [CrossRef]

- Benjakul, S.; Bauer, F. Biochemical and physicochemical changes in catfish (Silurusglanis linne) muscle as influenced by different freeze-thaw cycles. Food Chem. 2001, 72, 207–217. [Google Scholar] [CrossRef]

- Ertbjerg, P.; Puolanne, E. Muscle structure, sarcomere length and influences on meat quality: A review. Meat Sci. 2017, 132, 139–152. [Google Scholar] [CrossRef] [Green Version]

- Ngapo, T.M.; Babare, I.H.; Reynolds, J.; Mawson, R.F. Freezing rate and frozen storage effects on the ultrastructure of samples of pork. Meat Sci. 1999, 53, 159–168. [Google Scholar] [CrossRef]

- Martino, M.N.; Otero, L.; Sanz, P.D.; Zaritzky, N.E. Size and location of ice crystals in pork frozen by high-pressure-assisted freezing as compared to classical methods. Meat Sci. 1998, 50, 303–313. [Google Scholar] [CrossRef] [Green Version]

- Jiang, Q.; Nakazawa, N.; Hu, Y.; Osako, K.; Okazaki, E. Micro-structural modification and its effect on the quality attributes of frozen-thawed bigeye tuna (Thunnus obesus) meat during salting. LWT 2019, 100, 213–219. [Google Scholar] [CrossRef]

- Hanzawa, R.; Fukuda, Y. Improvement of quality by new loin feezing tuna. Refrigeration 2006, 81, 204–207. [Google Scholar]

- Miguéis, S.; Santos, C.; Saraiva, C.; Esteves, A. Evaluation of ready to eat sashimi in northern Portugal restaurants. Food Control 2015, 47, 32–36. [Google Scholar] [CrossRef]

- Lee, D.H.; Kang, D.M.; Park, S.K.; Jeong, M.C.; Kang, M.G.; Jo, D.M.; Lee, J.H.; Lee, D.E.; Sim, Y.A.; Jeong, G.J.; et al. Shelf-life extension of Raw Oyster Crassostrea gigas by depuration process. Korean J. Fish. Aquat. Sci. 2020, 53, 842–850. [Google Scholar]

| No. | Ingredients | (%) |

|---|---|---|

| 1. | Corn syrup | 8.22 |

| 2. | Fermented anchovy sauce | 1.93 |

| 3. | Garlic powder | 3.22 |

| 4. | Gochujang | 3.22 |

| 5. | Korean beef stock | 0.64 |

| 6. | Monosodium glutamate | 0.32 |

| 7. | Oligosaccharide | 4.83 |

| 8. | Pepper | 0.06 |

| 9. | Purified water | 45.12 |

| 10. | Red pepper powder | 16.11 |

| 11. | Soy sauce | 6.45 |

| 12. | Sugar | 9.86 |

| Sensorial Characteristics | Hedonic Scale | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | |

| Aroma | Rancid Extremely | Rancid Very Much | Aromatic Moderately | Aromatic Slightly | Musty | Savoury Moderately | Savoury Slightly | Mild Very Much | Mild Extremely |

| Color | Dislike Extremely | Dislike Very Much | Dislike Moderately | Dislike Slightly | Neither Like nor Dislike | Like Slightly | Like Moderately | Like Very Much | Like Extremely |

| Flavor | Uncooked | Uncooked Slightly | Brunt Moderately | Brunt Slightly | Fatty | Salty Moderately | Salty Slightly | Tasty Very Much | Tasty Extremely |

| Texture | Hard Extremely | Hard Moderately | Dry Moderately | Dry Slightly | Dry | Soft Slightly | Soft | Chewy Moderately | Chewy |

| Overall acceptance | Dislike Extremely | Dislike Very Much | Dislike Moderately | Dislike Slightly | Neither Like nor Dislike | Like Slightly | Like Moderately | Like Very Much | Like Extremely |

| Treatment | Quadratic Polynomial Model Equations | R2 |

|---|---|---|

| Steam | −421.7 + 8.927X1 + 5.77X2 − 0.04668X12 − 0.7921X22 − 0.0250X1X2 | 98 |

| Smoke | −59.93 + 1.810X1 + 0.951X2 − 0.012708X12 − 0.03217X22 − 0.00333X1X2 | 97 |

| Parameters | Raw Octopus | Steamed-Smoked Octopus |

|---|---|---|

| pH | 7.24 ± 0.1 | 7.38 ± 0.03 |

| VBN (mg%) | 6.32 ± 0.01 | 3.69 ± 0.25 |

| TBARS (mg MDA/kg) | 1.10 ± 0.03 | 1.04 ± 0.01 |

| Sensorial Characteristic | Fresh Product | Quick Freezing | Slow Freezing |

|---|---|---|---|

| Aroma | 8.79 ± 0.05 a | 8.76 ± 0.03 a | 8.74 ± 0.02 a |

| Color | 8.66 ± 0.10 a | 8.64 ± 0.04 a | 8.62 ± 0.09 a |

| Flavor | 8.74 ± 0.05 a | 8.71 ± 0.03 a | 8.69 ± 0.05 a |

| Texture | 8.72 ± 0.04 a | 8.70 ± 0.06 a | 8.31 ± 0.10 b |

| Overall acceptance | 8.63 ± 0.25 a | 8.62 ± 0.06 a | 8.61 ± 0.07 a |

| Parameters | Unit (per 100 g) | Contain |

|---|---|---|

| Calcium | mg | 18 |

| Calories | kcal | 151.6 |

| Carbohydrate | g | 23.7 |

| Cholesterol | g | 0.6 |

| Crude fat | g | 9.7 |

| Crude protein | g | 13.5 |

| Dietary fiber | g | 0.8 |

| Iron | mg | 0.7 |

| Trans fat | g | 2.0 |

| Potassium | g | 0.3 |

| Saturated fat | g | 0.4 |

| Sodium | mg | 8.7 |

| Sugars | g | 13.2 |

| Trans fat | g | - |

| Vitamin D | g | - |

| Amino Acids | g/100 g | % |

|---|---|---|

| Alanine | 0.98 | 6.96 |

| Aspartic acid | 1.59 | 11.29 |

| Cysteine | 0.16 | 1.14 |

| Glutamic acid | 2.44 | 17.33 |

| Glycine | 1.20 | 8.52 |

| Proline | 0.73 | 5.18 |

| Serine | 0.69 | 4.90 |

| Tyrosine | 0.39 | 2.77 |

| Total Non-Essential | 8.18 | 58 |

| Arginine | 0.85 | 6.04 |

| Histidine | 0.29 | 2.06 |

| Isoleucine | 0.69 | 4.90 |

| Leucine | 1.26 | 8.95 |

| Lysine | 0.48 | 3.41 |

| Methionine | 0.27 | 1.92 |

| Phenylalanine | 0.57 | 4.05 |

| Threonine | 0.72 | 5.11 |

| Tryptophan | 0.14 | 0.99 |

| Valine | 0.63 | 4.47 |

| Total Essential | 5.9 | 42 |

| Total Amino Acid | 14.08 | 100 |

| Fatty Acids | % |

|---|---|

| Capric acid | 0.01 |

| Lauric acid | 0.01 |

| Myristic acid | 3.18 |

| Pentadecanoic acid | 0.30 |

| Palmitic acid | 22.12 |

| Magaric acid | 0.10 |

| Stearic acid | 1.68 |

| Arachidic acid | 0.04 |

| Heneicosylic acid | 0.02 |

| Lignoceric acid | 1.67 |

| Myristoleic acid | 0.06 |

| Pentadecenoic acid | 0.05 |

| Palmitoleic acid | 5.33 |

| Magaoleic acid | 0.15 |

| Oleic acid | 16.54 |

| Linoleic acid | 0.28 |

| γ-Linolenic acid | 0.07 |

| Linolenic acid | 0.28 |

| Eicosenoic acid | 2.05 |

| Eicosadienoic acid | 0.20 |

| Dihomoδ-Linoleicacid | 0.06 |

| Eicosatrienoic acid | 0.06 |

| Arachidonic acid | 0.71 |

| Erucic acid | 0.34 |

| DHA | 23.60 |

| EPA | 20.40 |

| ƩSFA | 29.13 |

| ƩPUFA | 46.15 |

| ƩMUFA | 24.72 |

| Ʃ ω3 | 44.34 |

| Ʃ ω6 | 1.81 |

| Temperature (°C) | Day | Overall Acceptance | VBN (mg%) | TBARS (mg MDA/kg) | TBC (log CFU/g) | Salmonella spp. | S. aureus |

|---|---|---|---|---|---|---|---|

| −13 | 0 | 8.63 ± 0.25 a | 3.70 ± 0.09 a | 1.06 ± 0.03 a | 4.06 ± 0.10 a | - | - |

| 15 | 8.44 ± 0.03 ab | 3.79 ± 0.17 ab | 1.27 ± 0.03 ab | 4.19 ± 0.01 b | - | - | |

| 30 | 8.21 ± 0.02 bc | 3.84 ± 0.16 ab | 1.45 ± 0.05 ab | 4.24 ± 0.02 b | - | - | |

| 45 | 8.00 ± 0.05 c | 3.96 ± 0.21 ab | 1.64 ± 0.04 bc | 4.48 ± 0.02 c | - | - | |

| 60 | 7.60 ± 0.22 d | 4.09 ± 0.27 ab | 1.97 ± 0.04 cd | 4.60 ± 0.02 d | - | - | |

| 75 | 7.47 ± 0.25 d | 4.21 ± 0.23 b | 2.22 ± 0.02 de | 4.75 ± 0.02 e | - | - | |

| 90 | 7.33 ± 0.12 d | 4.39 ± 0.25 b | 2.57 ± 0.05 e | 4.88 ± 0.09 f | - | - | |

| −18 | 0 | 8.63 ± 0.25 a | 3.70 ± 0.09 a | 1.06 ± 0.03 a | 4.06 ± 0.10 a | - | - |

| 15 | 8.61 ± 0.02 a | 3.76 ± 0.01 a | 1.25 ± 0.02 a | 4.09 ± 0.01 a | - | - | |

| 30 | 8.56 ± 0.03 a | 3.79 ± 0.15 a | 1.39 ± 0.03 ab | 4.12 ± 0.02 a | - | - | |

| 45 | 8.53 ± 0.03 a | 3.85 ± 0.23 a | 1.46 ± 0.02 ab | 4.13 ± 0.02 a | - | - | |

| 60 | 8.49 ± 0.01 a | 3.90 ± 0.24 a | 1.49 ± 0.05 ab | 4.18 ± 0.02 b | - | - | |

| 75 | 8.45 ± 0.02 a | 3.95 ± 0.24 a | 1.85 ± 0.04 bc | 4.20 ± 0.01 c | - | - | |

| 90 | 8.40 ± 0.16 a | 3.99 ± 0.23 a | 2.26 ± 0.06 c | 4.22 ± 0.02 d | - | - | |

| −23 | 0 | 8.63 ± 0.25 a | 3.70 ± 0.09 a | 1.06 ± 0.03 a | 4.06 ± 0.10 a | - | - |

| 15 | 8.61 ± 0.04 a | 3.74 ± 0.02 a | 1.15 ± 0.02 a | 4.08 ± 0.02 ab | - | - | |

| 30 | 8.59 ± 0.04 a | 3.77 ± 0.16 a | 1.20 ± 0.09 a | 4.09 ± 0.01 ab | - | - | |

| 45 | 8.57 ± 0.03 a | 3.81 ± 0.18 a | 1.25 ± 0.02 ab | 4.12 ± 0.02 ab | - | - | |

| 60 | 8.55 ± 0.03 a | 3.84 ± 0.18 a | 1.35 ± 0.04 ab | 4.13 ± 0.01 ab | - | - | |

| 75 | 8.53 ± 0.02 a | 3.86 ± 0.18 a | 1.55 ± 0.02 b | 4.15 ± 0.01 ab | - | - | |

| 90 | 8.50 ± 0.16 a | 3.88 ± 0.19 a | 1.90 ± 0.12 c | 4.17 ± 0.01 b | - | - |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Negara, B.F.S.P.; Gong, H.-J.; Lee, M.-J.; Choi, J.-S. Effect of Steam and Smoke Cooking Processes on Web-Foot Octopus (Amphioctopus sp.) Home Meal Replacement Product. Foods 2021, 10, 2825. https://doi.org/10.3390/foods10112825

Negara BFSP, Gong H-J, Lee M-J, Choi J-S. Effect of Steam and Smoke Cooking Processes on Web-Foot Octopus (Amphioctopus sp.) Home Meal Replacement Product. Foods. 2021; 10(11):2825. https://doi.org/10.3390/foods10112825

Chicago/Turabian StyleNegara, Bertoka Fajar Surya Perwira, Hee-Jin Gong, Mi-Jeong Lee, and Jae-Suk Choi. 2021. "Effect of Steam and Smoke Cooking Processes on Web-Foot Octopus (Amphioctopus sp.) Home Meal Replacement Product" Foods 10, no. 11: 2825. https://doi.org/10.3390/foods10112825

APA StyleNegara, B. F. S. P., Gong, H.-J., Lee, M.-J., & Choi, J.-S. (2021). Effect of Steam and Smoke Cooking Processes on Web-Foot Octopus (Amphioctopus sp.) Home Meal Replacement Product. Foods, 10(11), 2825. https://doi.org/10.3390/foods10112825