Development of an Artificial Neural Network Utilizing Particle Swarm Optimization for Modeling the Spray Drying of Coconut Milk

Abstract

:1. Introduction

2. Materials and Methods

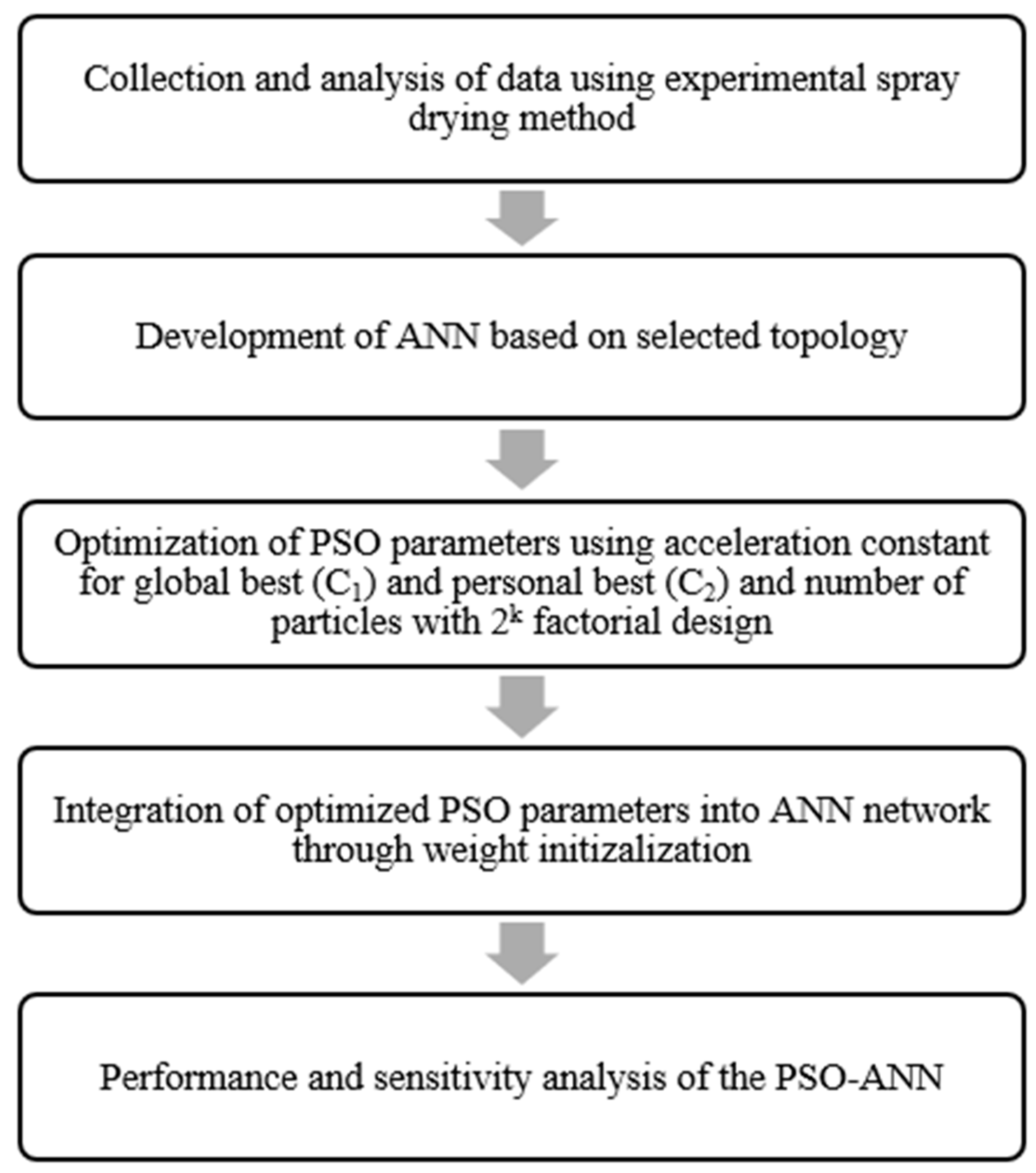

2.1. Framework Study

2.2. Coconut Milk Powder Production

2.3. Moisture Content

2.4. Surface Free Fat

2.5. Outlet Temperature

2.6. Development of Artificial Neural Network

2.7. PSO Algorithm Development

2.8. Optimization of PSO Parameters

2.9. PSO Integration into ANN Development

2.10. Cost Function

2.11. Performance Comparison of ANN and PSO–ANN

2.12. ANOVA Statistical Analysis

2.13. Sensitivity Analysis

3. Results and Discussion

3.1. Development of ANN with K-Fold Cross Validation

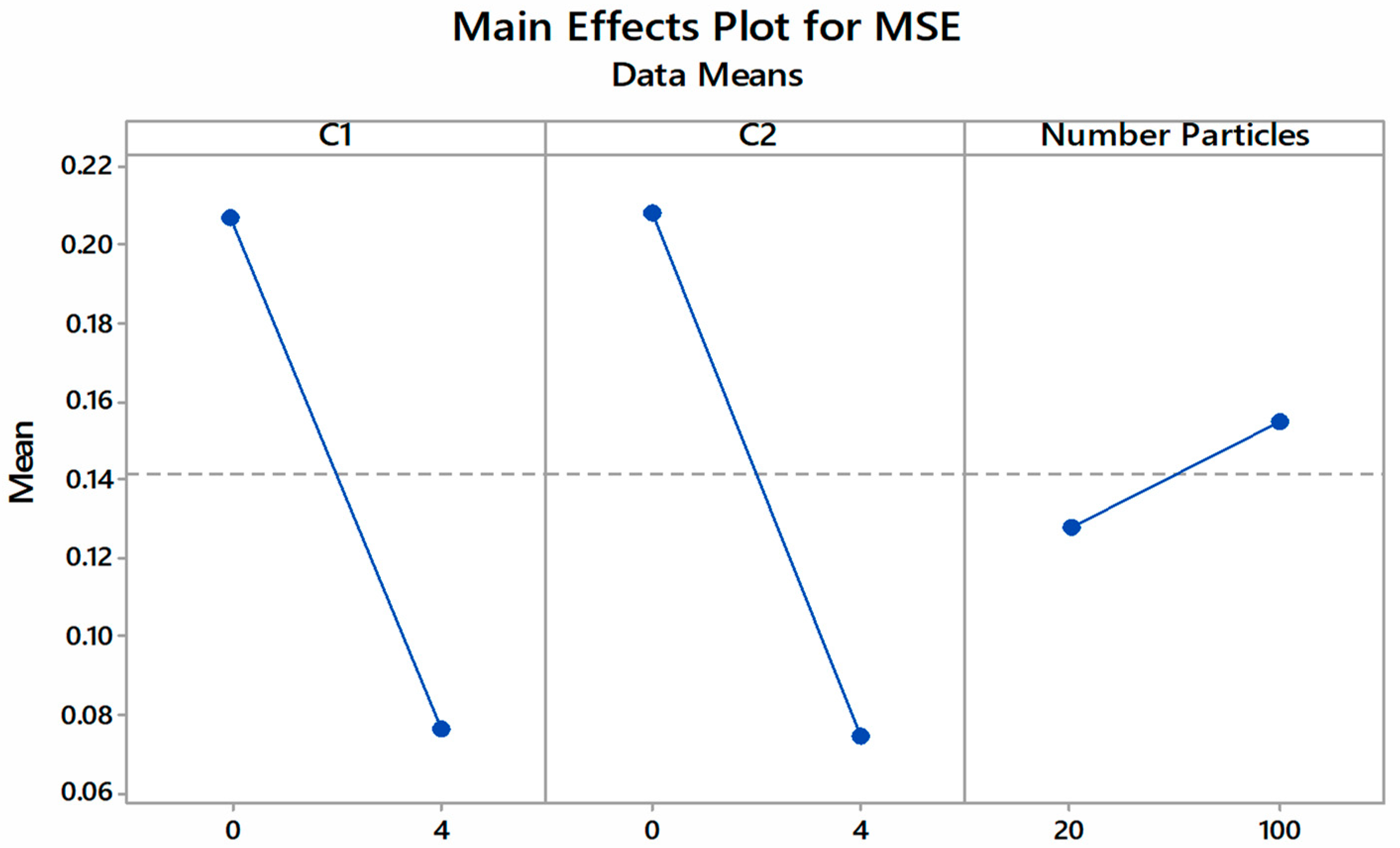

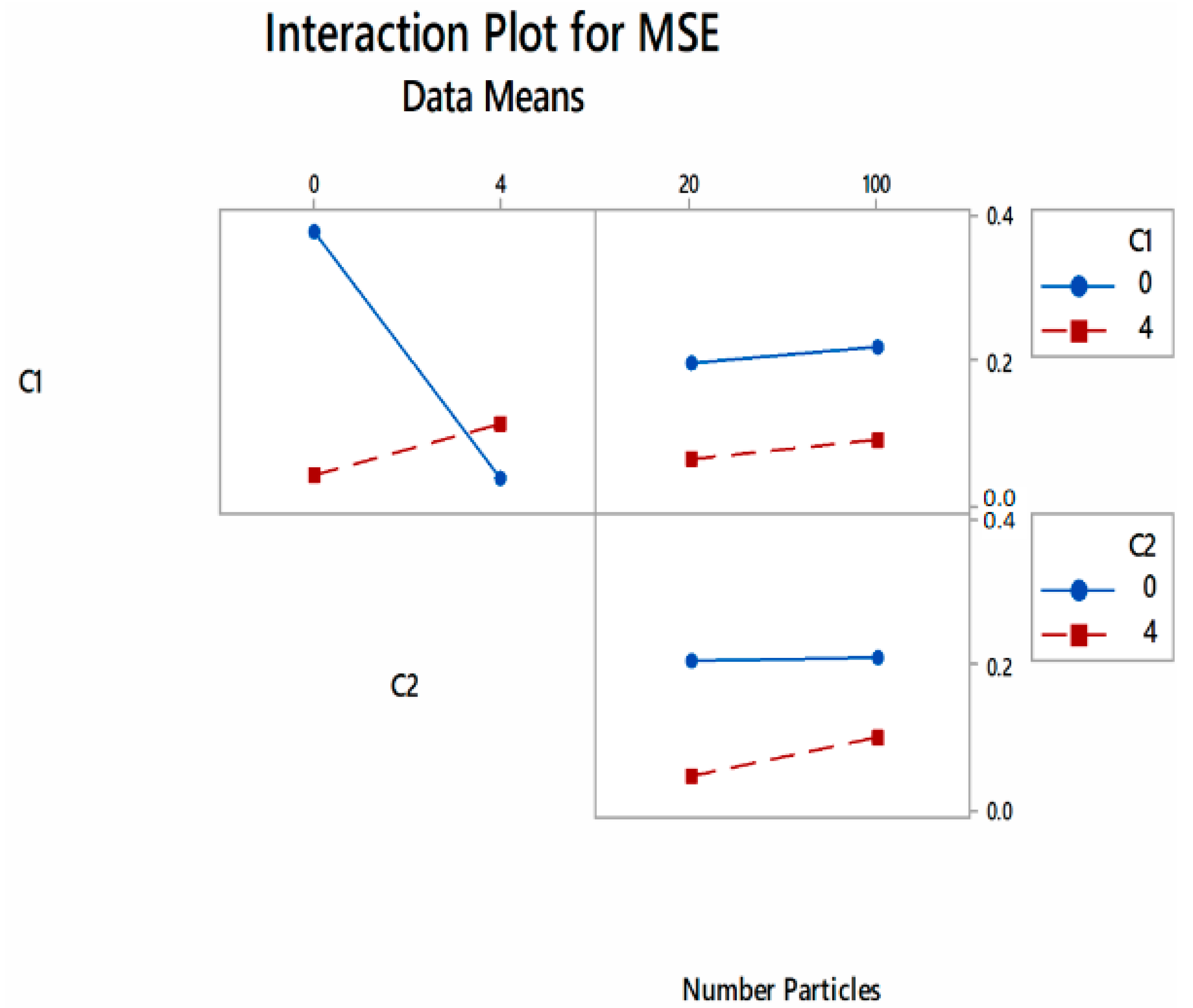

3.2. Design of Experiments and Validation Optimization of PSO Parameters

3.3. Effect of PSO Parameters on Fitness Value and Optimization Process

3.4. Validity of PSO Parameters

3.5. Development of PSO–ANN

3.6. Sensitivity Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Straatsma, J.; Van Houwelingen, G.; Steenbergen, A.E.; De Jong, P. Spray Drying of Food Products: 1. Simulation Model. J. Food Eng. 1999, 42, 67–72. [Google Scholar] [CrossRef]

- Oakley, D.E. Spray Dryer Modeling in Theory and Practice. Dry. Technol. 2004, 22, 1371–1402. [Google Scholar] [CrossRef]

- Naik, A.; Venu, G.V.; Prakash, M.; Raghavarao, K.S.M.S. Dehydration of Coconut Skim Milk and Evaluation of Functional Properties. CYTA-J. Food 2014, 12, 227–234. [Google Scholar] [CrossRef] [Green Version]

- Chiewchan, N.; Phungamngoen, C.; Siriwattanayothin, S. Effect of Homogenizing Pressure and Sterilizing Condition on Quality of Canned High Fat Coconut Milk. J. Food Eng. 2006, 73, 38–44. [Google Scholar] [CrossRef]

- Santana, A.A.; Martin, L.G.P.; de Oliveira, R.A.; Kurozawa, L.E.; Park, K.J. Spray Drying of Babassu Coconut Milk Using Different Carrier Agents. Dry. Technol. 2017, 35, 76–87. [Google Scholar] [CrossRef]

- Fatimah, F.; Gugule, S.; Tallei, T. Characteristic Of Coconut Milk Powder Made By Variation Of Coconut-Water Ratio, Concentration Of Tween And Guar Gum. J. Appl. Sci. Res. 2017, 13, 34–44. [Google Scholar]

- Santana, A.A.; de Oliveira, R.A.; Pinedo, A.A.; Kurozawa, L.E.; Park, K.J. Microencapsulation of Babassu Coconut Milk. Food Sci. Technol. 2013, 33, 737–744. [Google Scholar] [CrossRef] [Green Version]

- Avila, E.L.; Rodríguez, M.C.; Velásquez, H.J.C. Influence of Maltodextrin and Spray Drying Process Conditions on Sugarcane Juice Powder Quality. Rev. Fac. Nac. Agron. Medellín 2015, 68, 7509–7520. [Google Scholar] [CrossRef]

- Huang, Y.; Kangas, L.J.; Rasco, B.A. Applications of Artificial Neural Networks (ANNs) in Food Science. Crit. Rev. Food Sci. Nutr. 2007, 47, 113–126. [Google Scholar] [CrossRef]

- Aghbashlo, M.; Hosseinpour, S.; Mujumdar, A.S. Application of Artificial Neural Networks (ANNs) in Drying Technology: A Comprehensive Review. Dry. Technol. 2015, 33, 1397–1462. [Google Scholar] [CrossRef]

- Guiné, R.P.F. The Use of Artificial Neural Networks (ANN) in Food Process Engineering. ETP Int. J. Food Eng. 2019, 15–21. [Google Scholar] [CrossRef]

- Keshani, S.; Daud, W.R.W.; Woo, M.W.; Talib, M.Z.M.; Chuah, A.L.; Russly, A.R. Artificial Neural Network Modeling of the Deposition Rate of Lactose Powder in Spray Dryers. Dry. Technol. 2012, 30, 386–397. [Google Scholar] [CrossRef]

- Olunloyo, V.O.S.; Ibidapo, T.A.; Dinrifo, R.R. Neural Network-Based Electronic Nose for Cocoa Beans Quality Assessment. Agric. Eng. Int. CIGR J. 2011, 13, 4. [Google Scholar]

- Golpour, I.; Chayjan, R.A.; Parian, J.A.; Khazaei, J. Prediction of Paddy Moisture Content during Thin Layer Drying Using Machine Vision and Artificial Neural Networks. J. Agric. Sci. Technol. 2015, 17, 287–298. [Google Scholar]

- Chegini, G.R.; Khazaei, J.; Ghobadian, B.; Goudarzi, A.M. Prediction of Process and Product Parameters in an Orange Juice Spray Dryer Using Artificial Neural Networks. J. Food Eng. 2008, 84, 534–543. [Google Scholar] [CrossRef]

- Youssefi, S.; Emam-Djomeh, Z.; Mousavi, S.M. Comparison of Artificial Neural Network (ANN) and Response Surface Methodology (RSM) in the Prediction of Quality Parameters of Spray-Dried Pomegranate Juice. Dry. Technol. 2009, 27, 910–917. [Google Scholar] [CrossRef]

- Przybył, K.; Gawałek, J.; Koszela, K. Application of Artificial Neural Network for the Quality-Based Classification of Spray-Dried Rhubarb Juice Powders. J. Food Sci. Technol. 2020. [Google Scholar] [CrossRef]

- Torrecilla, J.S.; Aragón, J.M.; Palancar, M.C. Optimization of an Artificial Neural Network by Selecting the Training Function. Application to Olive Oil Mills Waste. Ind. Eng. Chem. Res. 2008, 47, 7072–7080. [Google Scholar] [CrossRef]

- Ding, S.; Su, C.; Yu, J. An Optimizing BP Neural Network Algorithm Based on Genetic Algorithm. Artif. Intell. Rev. 2011, 36, 153–162. [Google Scholar] [CrossRef]

- Whitley, D.; Starkweather, T.; Bogart, C. Genetic Algorithms and Neural Networks: Optimizing Connections and Connectivity. Parallel Comput. 1990, 14, 347–361. [Google Scholar] [CrossRef]

- Gorjian, S.; Hashjin, T.T.; Khoshtaghaza, M.H. Designing and Optimizing a Back Propagation Neural Network to Model a Thin-Layer Drying Process. Int. Agrophys. 2011, 25, 13–19. [Google Scholar]

- Jafari, S.M.; Ganje, M.; Dehnad, D.; Ghanbari, V. Mathematical, Fuzzy Logic and Artificial Neural Network Modeling Techniques to Predict Drying Kinetics of Onion. J. Food Process. Preserv. 2016, 40, 329–339. [Google Scholar] [CrossRef]

- Rane, V.A. Particle Swarm Optimization (PSO) Algorithm: Parameters Effect And Analysis. Int. J. Innov. Res. Dev. 2013, 2, 8–16. [Google Scholar]

- Clow, B.; White, T. An Evolutionary Race: A Comparison of Genetic Algorithms and Particle Swarm Optimization Used for Training Neural Networks. In Proceedings of the International Conference on Artificial Intelligence, IC-AI’04, Las Vegas, NV, USA, 21–24 June 2004; Volume 2, pp. 582–588. [Google Scholar]

- How, M.S.; Jones, J.R.; Morgenstern, M.P.; Gray-Stuart, E.; Bronlund, J.E.; Saint-Eve, A.; Trelea, I.C.; Souchon, I. Modelling the role of oral processing on in vivo aroma release of white rice: Conceptual model and experimental validation. LWT 2021, 141, 110918. [Google Scholar] [CrossRef]

- Da Silva Veloso, Y.M.; de Almeida, M.M.; de Alsina, O.L.S.; Leite, M.S. Artificial Neural Network Model for the Flow Regime Recognition in the Drying of Guava Pieces in the Spouted Bed. Chem. Eng. Commun. 2020, 207, 549–558. [Google Scholar] [CrossRef]

- Ming, J.L.K.; Taip, F.S.; Anuar, M.S.; Noor, S.B.M.; Abdullah, Z. Artificial Neural Network Topology Optimization using K-Fold Cross Validation for Spray Drying of Coconut Milk. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2020. [Google Scholar] [CrossRef]

- Ming, J.L.K.; Taip, F.S.; Anuar, M.S.; Noor, S.B.M.; Abdullah, Z. Optimization of Genetic Algorithm Parameter in Hybrid Genetic Algorithm-Neural Network Modelling: Application to Spray Drying of Coconut Milk. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2020; Volume 991. [Google Scholar] [CrossRef]

- Nekkanti, V.; Muniyappan, T.; Karatgi, P.; Hari, M.S.; Marella, S.; Pillai, R. Spray-Drying Process Optimization for Manufacture of Drugcyclodextrin Complex Powder Using Design of Experiments. Drug Dev. Ind. Pharm. 2009, 35, 1219–1229. [Google Scholar] [CrossRef]

- Jones, K.O.; Boizanté, G. Comparison of Genetic Algorithms and Particle Swarm Optimization. In Proceedings of the International Conference on Computer Systems and Technologies—CompSysTech’ 2005; ACM Press: New York, NY, USA, 2005; p. 191. [Google Scholar]

- Khaouane, L.; Si-Moussa, C.; Hanini, S.; Benkortbi, O. Optimization of Culture Conditions for the Production of Pleuromutilin from Pleurotus Mutilus Using a Hybrid Method Based on Central Composite Design, Neural Network, and Particle Swarm Optimization. Biotechnol. Bioprocess Eng. 2012, 17, 1048–1054. [Google Scholar] [CrossRef]

- Shi, Y.; Eberhart, R. A Modified Particle Swarm Optimizer. In Proceedings of the 1998 IEEE International Conference on Evolutionary Computation Proceedings, Anchorage, AK, USA, 4–9 May 1998; pp. 69–73. [Google Scholar]

- Sheela, K.G.; Deepa, S.N. Review on Methods to Fix Number of Hidden Neurons in Neural Networks. Math. Probl. Eng. 2013, 2013. [Google Scholar] [CrossRef] [Green Version]

- Bayram, Ö.A.; Bayram, M.; Tekin, A.R. Spray Drying of Sumac Flavour Using Sodium Chloride, Sucrose, Glucose and Starch as Carriers. J. Food Eng. 2005, 69, 253–260. [Google Scholar] [CrossRef]

- Omwamba, M.; Hu, Q. Antioxidant Capacity and Antioxidative Compounds in Barley (Hordeumvulgare L.) Grain Optimized Using Response Surface Methodology in Hot Air Roasting. Eur. Food Res. Technol. 2009, 229, 907–914. [Google Scholar] [CrossRef]

- Moheno-Barrueta, M.; Tzuc, O.M.; Martínez-Pereyra, G.; Cardoso-Fernández, V.; Rojas-Blanco, L.; Ramírez-Morales, E.; Pérez-Hernández, G.; Bassam, A. Experimental Evaluation and Theoretical Optimization of an Indirect Solar Dryer with Forced Ventilation under Tropical Climate by an Inverse Artificial Neural Network. Appl. Sci. 2021, 11, 7616. [Google Scholar] [CrossRef]

- Alexander, D.L.J.; Tropsha, A.; Winkler, D.A. Beware of R 2: Simple, Unambiguous Assessment of the Prediction Accuracy of QSAR and QSPR Models. J. Chem. Inf. Modeling 2015, 55, 1316–1322. [Google Scholar] [CrossRef] [Green Version]

- Sendrescu, D.; Roman, M. Parameter Identification of Bacterial Growth Bioprocesses Using Particle Swarm Optimization. In Proceedings of the 2013 9th Asian Control Conference (ASCC), Istanbul, Turkey, 23–26 June 2013; Volume 2013, pp. 1–6. [Google Scholar]

- He, Y.; Ma, W.J.; Zhang, J.P. The Parameters Selection of PSO Algorithm Influencing On Performance of Fault Diagnosis. MATEC Web Conf. 2016, 63, 02019. [Google Scholar] [CrossRef]

- Ch, S.; Mathur, S. Particle Swarm Optimization Trained Neural Network for Aquifer Parameter Estimation. KSCE J. Civ. Eng. 2012, 16, 298–307. [Google Scholar] [CrossRef]

- Tran, T.T.A.; Nguyen, H.V.H. Effects of Spray-Drying Temperatures and Carriers on Physical and Antioxidant Properties of Lemongrass Leaf Extract Powder. Beverages 2018, 4, 84. [Google Scholar] [CrossRef] [Green Version]

- Goula, A.M.; Adamopoulos, K.G. Spray Drying of Tomato Pulp in Dehumidified Air: I. The Effect on Product Recovery. J. Food Eng. 2005, 66, 25–34. [Google Scholar] [CrossRef]

- Reineccius, G.A. The Spray Drying of Food Flavors. Dry. Technol. 2004, 22, 1289–1324. [Google Scholar] [CrossRef]

- Adhikari, B.; Howes, T.; Bhandari, B.R.; Langrish, T.A.G. Effect of Addition of Proteins on the Production of Amorphous Sucrose Powder through Spray Drying. J. Food Eng. 2009, 94, 144–153. [Google Scholar] [CrossRef] [Green Version]

- Vega, C.; Roos, Y.H. Invited Review: Spray-Dried Dairy and Dairy-like Emulsions—Compositional Considerations. J. Dairy Sci. 2006, 89, 383–401. [Google Scholar] [CrossRef] [Green Version]

| Parameter | Low | High | Significance |

|---|---|---|---|

| Acceleration constant for global best (C1) | 0 | 4 | Stochastic acceleration that pulls the particle towards global best position of the swarm |

| Acceleration constant for personal best (C2) | 0 | 4 | Stochastic acceleration that pulls the particle towards personal best position of the particle |

| Number of Particles | 20 | 100 | The number of particles in the search space |

| PSO Parameters | Average MSE Reading | p-Value | ||

|---|---|---|---|---|

| Acceleration Constant for Global Best (C1) | Acceleration Constant for Personal Best (C2) | Number of Particles | ||

| 4 | 4 | 100 | 0.150 | p < 0.05 |

| 0 | 4 | 100 | 0.045 | p < 0.05 |

| 4 | 0 | 100 | 0.025 | p < 0.05 |

| 0 | 4 | 20 | 0.030 | p < 0.05 |

| 0 | 0 | 20 | 0.357 | p < 0.05 |

| 4 | 0 | 20 | 0.055 | p < 0.05 |

| 4 | 4 | 20 | 0.068 | p < 0.05 |

| 0 | 0 | 100 | 0.394 | p < 0.05 |

| Acceleration Constant for Global Best (C1) | Acceleration Constant for Personal Best (C2) | Number of Particle | |

|---|---|---|---|

| Constraints | 0–4.0 | 0–4.0 | 20–100 |

| Optimized PSO parameter | 4.0 | 0 | 100 |

| Factor | Type | Level | Values | ||

|---|---|---|---|---|---|

| Acceleration Constant for Global Best (C1) | Fixed | 2 | 0.0, 0.4 | ||

| Acceleration Constant for Personal Best (C2) | Fixed | 2 | 0.0, 0.4 | ||

| Number of Particles | Fixed | 2 | 20, 100 | ||

| Analysis of Variance for Fitness Value | |||||

| Source | DF | SS | MS | F | P |

| Acceleration Constant for Global Best (C1) | 1 | 0.0341 | 0.0341 | 1.65 | 0.0151 |

| Acceleration Constant for Personal Best (C2) | 1 | 0.0513 | 0.05123 | 8.24 | 0.0278 |

| Number of Particles | 1 | 0.0033 | 0.0033 | 1.37 | 0.0412 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ming, J.L.K.; Anuar, M.S.; How, M.S.; Noor, S.B.M.; Abdullah, Z.; Taip, F.S. Development of an Artificial Neural Network Utilizing Particle Swarm Optimization for Modeling the Spray Drying of Coconut Milk. Foods 2021, 10, 2708. https://doi.org/10.3390/foods10112708

Ming JLK, Anuar MS, How MS, Noor SBM, Abdullah Z, Taip FS. Development of an Artificial Neural Network Utilizing Particle Swarm Optimization for Modeling the Spray Drying of Coconut Milk. Foods. 2021; 10(11):2708. https://doi.org/10.3390/foods10112708

Chicago/Turabian StyleMing, Jesse Lee Kar, Mohd Shamsul Anuar, Muhammad Syahmeer How, Samsul Bahari Mohd Noor, Zalizawati Abdullah, and Farah Saleena Taip. 2021. "Development of an Artificial Neural Network Utilizing Particle Swarm Optimization for Modeling the Spray Drying of Coconut Milk" Foods 10, no. 11: 2708. https://doi.org/10.3390/foods10112708

APA StyleMing, J. L. K., Anuar, M. S., How, M. S., Noor, S. B. M., Abdullah, Z., & Taip, F. S. (2021). Development of an Artificial Neural Network Utilizing Particle Swarm Optimization for Modeling the Spray Drying of Coconut Milk. Foods, 10(11), 2708. https://doi.org/10.3390/foods10112708