Solar Cookers and Dryers: Environmental Sustainability and Nutraceutical Content in Food Processing

Abstract

1. Introduction

2. The History of Solar Cookers and Dryers

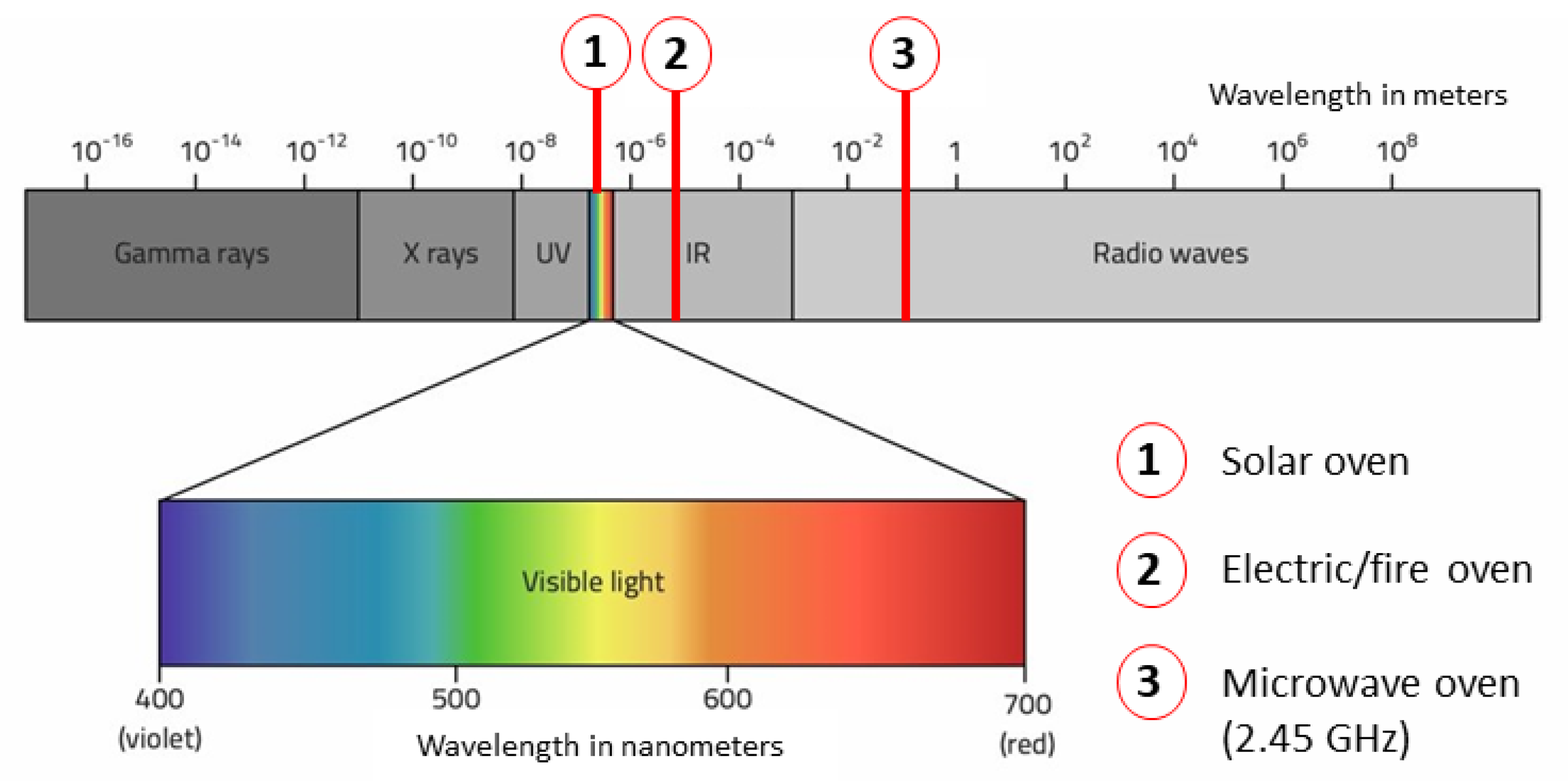

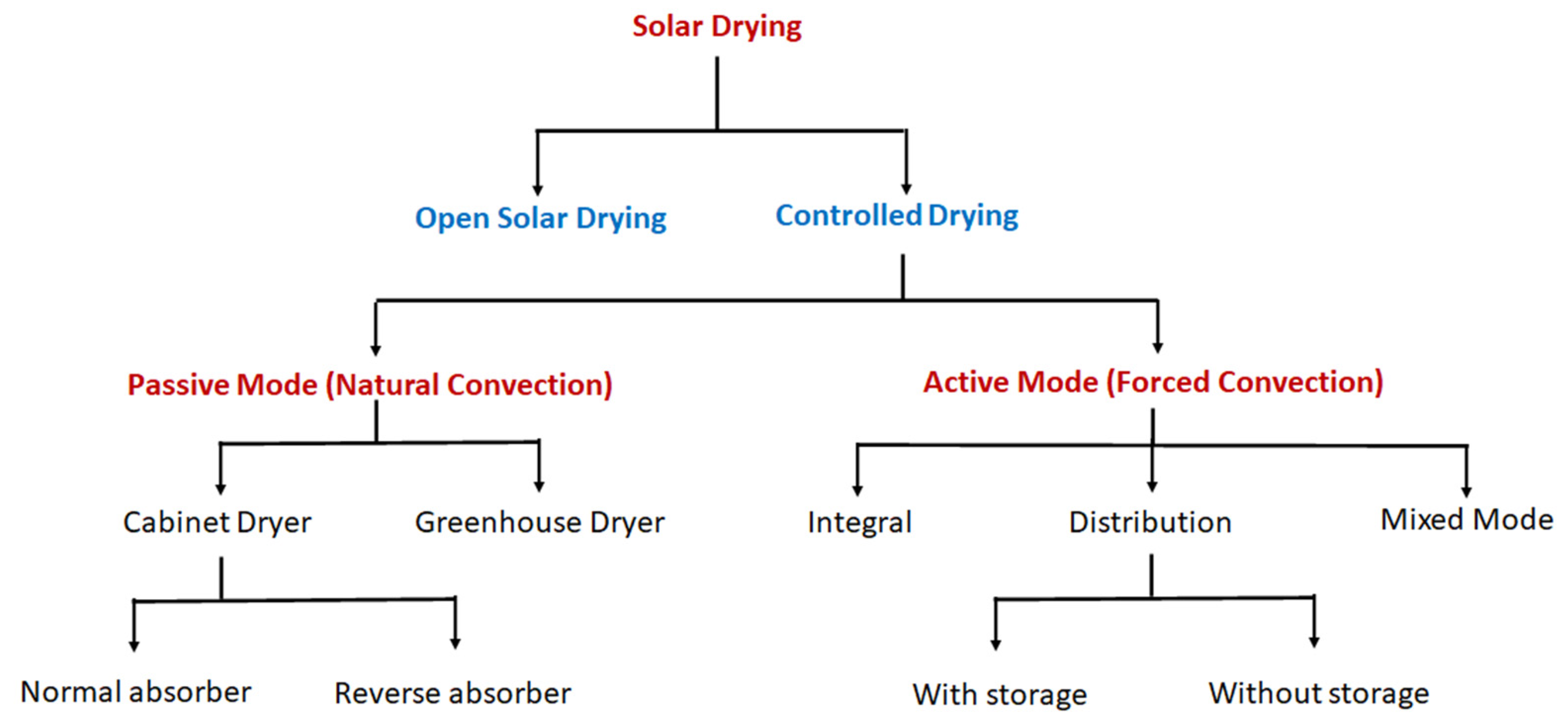

3. Solar Cooker and Dryer: Classifications

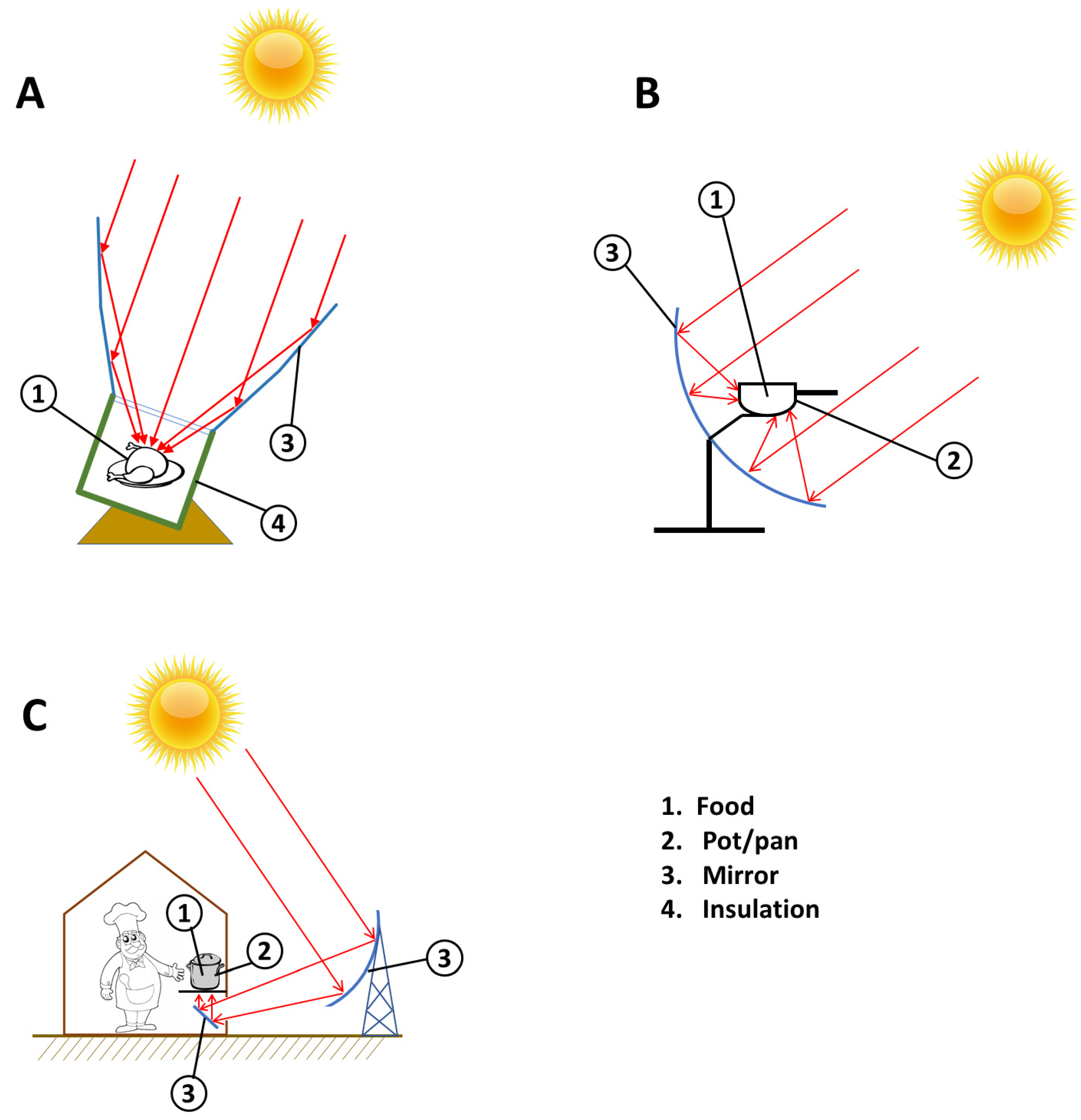

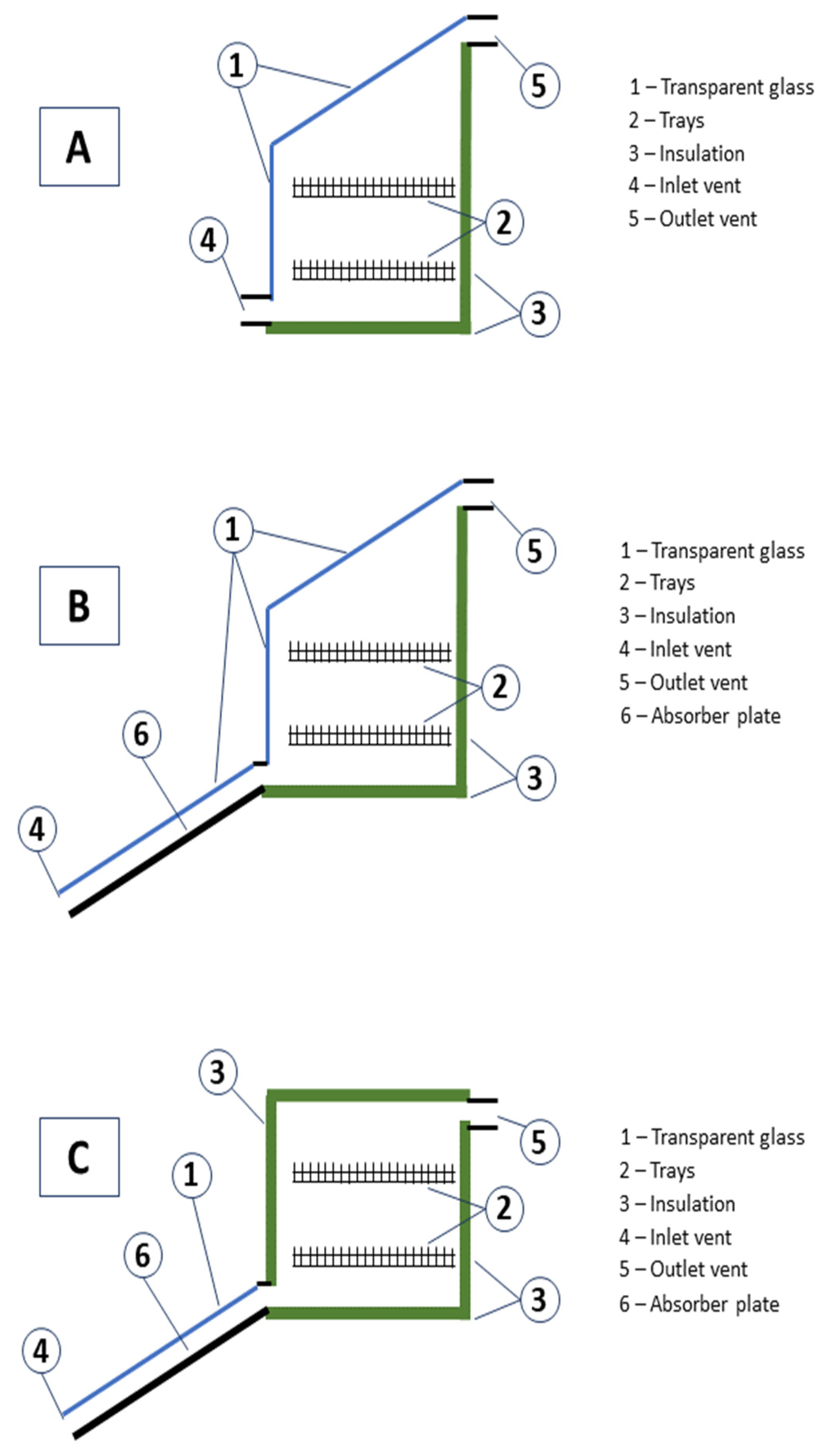

- indirect transfer of the sun’s energy to the food (Figure 3B,C). Here we will always have at least a pot or pan or stovetop in the middle. Mirrors take the form of a parabola and the receiver is in the focus. Energy is concentrated on the pot and then the pot will soon transfer it to the food. With this approach the cooking will depend only on the temperature of the pot and the food will have the same treatment as in conventional cooking with the heat source placed below the pot.

- direct light into the food. With this approach the sunlight is concentrated into the food, and the cooking process depends either on sunlight or heat (Figure 3A).Within type (1) it is important to underline the advantages for the approach, as in Figure 3C where the sunlight is focused below a stovetop, through a second reflection. The position of the focus is far from the parabola and the receiver is completely separated from the capturing system. This approach gives two advantages: (a) we can increase the size of the capturing system, and so the power of the oven; (b) to follow the sun, it is possible to move the parabola which keeps the focus always below the stovetop. Movement of the parabola can be automated, as has been suggested by Wolfgang Scheffler [29].

- maximum temperature is around 60 °C [33];

- there is good ventilation to remove humidity from the air in the cabinet during the drying process.

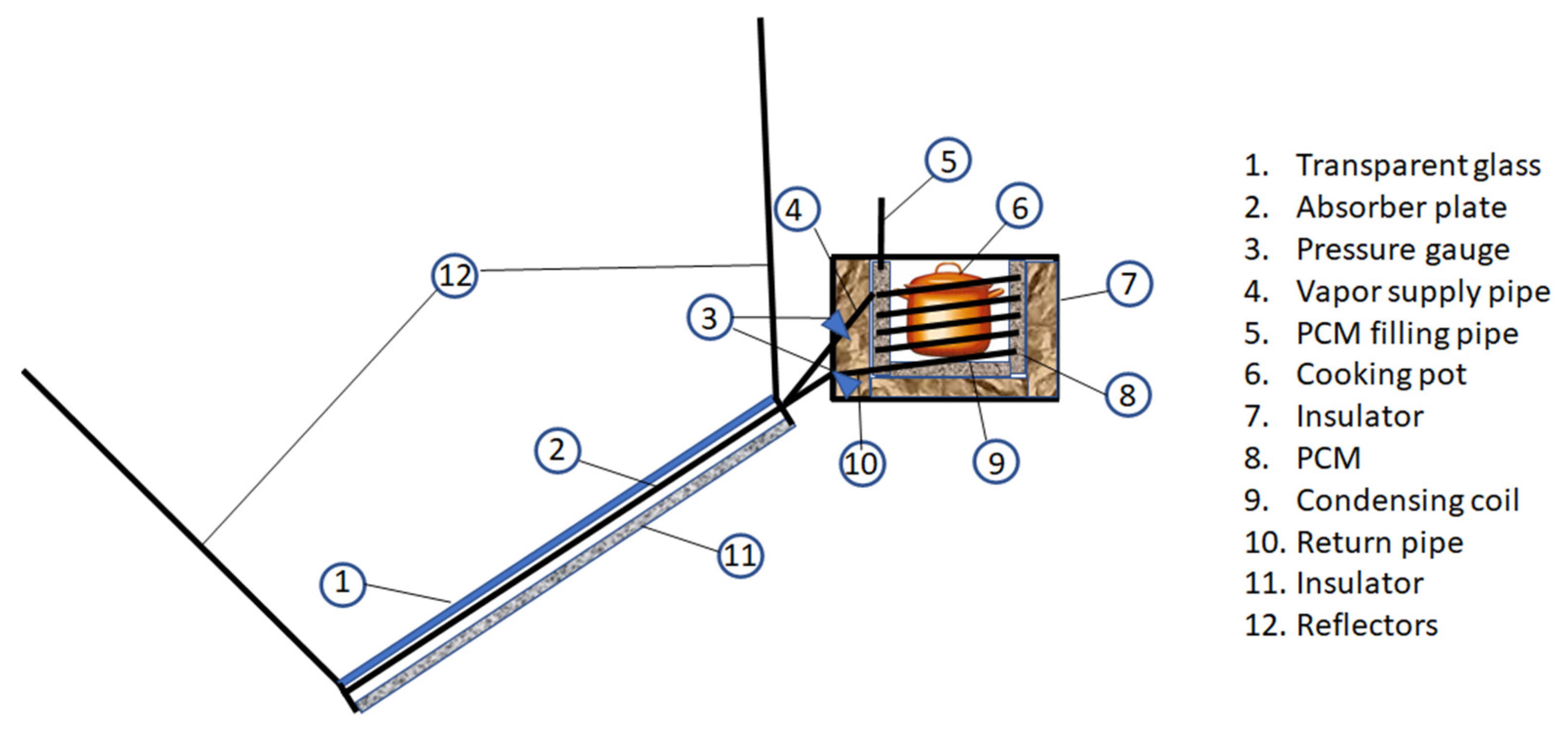

4. Developments in Technology: Heat Storage

4.1. Sensible Heat Storage

4.2. Latent Heat Storage

- phase change temperatures should be in the operating temperature range of the specific application;

- the enthalpy of phase change should be as high as possible;

- the phase change conditions should be reproducible;

- specific heat and thermal conductivity should be as high as possible;

- the volume during phase transitions should show minimal variations.

5. Processed Food by Sun: Ovens and Dryers

6. Perspectives

7. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- McCormick, K.; Neij, L.; Mont, O.; Ryan, C.; Rodhe, H.; Orsato, R. Advancing Sustainable Solutions: An Interdisciplinary and Collaborative Research Agenda. J. Clean. Prod. 2016, 123, 1–4. [Google Scholar] [CrossRef]

- Fiorati, A.; Bellingeri, A.; Punta, C.; Corsi, I.; Venditti, I. Silver Nanoparticles for Water Pollution Monitoring and Treatments: Ecosafety Challenge and Cellulose-Based Hybrids Solution. Polymers 2020, 12, 1635. [Google Scholar] [CrossRef] [PubMed]

- Sampat, A.M.; Ruiz-Mercado, G.J.; Zavala, V.M. Economic and Environmental Analysis for Advancing Sustainable Management of Livestock Waste: A Wisconsin Case Study. ACS Sustain. Chem. Eng. 2018, 6, 6018–6031. [Google Scholar] [CrossRef] [PubMed]

- Venditti, I. Engineered Gold-Based Nanomaterials: Morphologies and Functionalities in Biomedical Applications. A Mini Review. Bioengineering 2019, 6, 53. [Google Scholar] [CrossRef]

- Siddika, A.; Hajimohammadi, A.; Mamun, M.A.; Alyousef, R.; Ferdous, W. Waste Glass in Cement and Geopolymer Concretes: A Review on Durability and Challenges. Polymers 2021, 13, 2071. [Google Scholar] [CrossRef]

- Prosposito, P.; Burratti, L.; Bellingeri, A.; Protano, G.; Faleri, C.; Corsi, I.; Battocchio, C.; Iucci, G.; Tortora, L.; Secchi, V.; et al. Bifunctionalized Silver Nanoparticles as Hg2+ Plasmonic Sensor in Water: Synthesis, Characterizations, and Ecosafety. Nanomaterials 2019, 9, 1353. [Google Scholar] [CrossRef]

- Sadeghi, M.; Kalantar, M. Economic, Environmental and Technical Effects of Photovoltaic Modules in Distribution Networks in Comparison with the Conventional Units. J. Clean. Prod. 2016, 118, 4–18. [Google Scholar] [CrossRef]

- Bonomo, M.; Naponiello, G.; Venditti, I.; Zardetto, V.; Carlo, A.D.; Dini, D. Electrochemical and Photoelectrochemical Properties of Screen-Printed Nickel Oxide Thin Films Obtained from Precursor Pastes with Different Compositions. J. Electrochem. Soc. 2017, 164, H137–H147. [Google Scholar] [CrossRef]

- Blanco, M.; Monteserín, C.; Uranga, N.; Gómez, E.; Aranzabe, E.; García, J.I. Thermal and Photocatalytic Performance of Unsaturated Polyester Resins Modified with TiO2 Nanoparticles as Panel Bodies for Vehicles. Polymers 2021, 13, 2036. [Google Scholar] [CrossRef]

- Pintér, G.; Zsiborács, H.; Hegedűsné Baranyai, N.; Vincze, A.; Birkner, Z. The Economic and Geographical Aspects of the Status of Small-Scale Photovoltaic Systems in Hungary—A Case Study. Energies 2020, 13, 3489. [Google Scholar] [CrossRef]

- Kamarulzaman, A.; Hasanuzzaman, M.; Rahim, N.A. Global Advancement of Solar Drying Technologies and Its Future Prospects: A Review. Sol. Energy 2021, 221, 559–582. [Google Scholar] [CrossRef]

- Eswara, A.R.; Ramakrishnarao, M. Solar Energy in Food Processing—A Critical Appraisal. J. Food Sci. Technol. 2013, 50, 209–227. [Google Scholar] [CrossRef]

- Müller, H.; Brandmayr, S.; Zörner, W. Development of an Evaluation Methodology for the Potential of Solar-Thermal Energy Use in the Food Industry. Energy Proc. 2014, 48, 1194–1201. [Google Scholar] [CrossRef][Green Version]

- Mo, J.P.T. Design of Solar Energy System in Food Manufacturing Environment. Cogent Eng. 2016, 3, 1233613. [Google Scholar] [CrossRef]

- Gorjian, S.; Hosseingholilou, B.; Jathar, L.D.; Samadi, H.; Samanta, S.; Sagade, A.A.; Kant, K.; Sathyamurthy, R. Recent Advancements in Technical Design and Thermal Performance Enhancement of Solar Greenhouse Dryers. Sustainability 2021, 13, 7025. [Google Scholar] [CrossRef]

- Barba, F.J.; Gavahian, M.; Es, I.; Zhu, Z.; Chemat, F.; Lorenzo, J.M.; Mousavi Khaneghah, A. Solar Radiation as a Prospective Energy Source for Green and Economic Processes in the Food Industry: From Waste Biomass Valorization to Dehydration, Cooking, and Baking. J. Clean. Prod. 2019, 220, 1121–1130. [Google Scholar] [CrossRef]

- Bhaskara Rao, T.S.S.; Murugan, S. Solar Drying of Medicinal Herbs: A Review. Sol. Energy 2021, 223, 415–436. [Google Scholar] [CrossRef]

- Kryza, F. The Power of Light: The Epic Story of Man’s Quest to Harness the Sun; McGraw-Hill: New York, NY, USA; London, UK, 2003. [Google Scholar]

- Butti, K.; Perlin, J. A Golden Thread: 2500 Years of Solar Architecture and Technology; Cheshire Books: Backley, UK, 1980; ISBN 0-442-24005-8. [Google Scholar]

- Smith, Z.A.; Taylor, K.D. Renewable and Alternative Energy Resources: A Reference Handbook; ABC-CLIO: Santa Barbara, CA, USA, 2008; ISBN 978-1-59884-089-6. [Google Scholar]

- Battaglia, A. Solar Multiple Collector (Patent) Italian Central State Archive. 1886. [Google Scholar]

- Russel, J.T. Inventors and Inventions; Marshall Cavendish Corporation: Singapore, 2008; Volume 5, ISBN 978-0-7614-7761-7. [Google Scholar]

- Löf, G. Active Solar Systems (Solar Heat Technologies); The MIT Press: Cambridge, MA, USA, 1993; ISBN 978-0-262-12167-5. [Google Scholar]

- Kumar, M.; Sansaniwal, S.K.; Khatak, P. Progress in Solar Dryers for Drying Various Commodities. Renew. Sustain. Energy Rev. 2016, 55, 346–360. [Google Scholar] [CrossRef]

- Ekechukwu, O.V.; Norton, B. Review of Solar-Energy Drying Systems II: An Overview of Solar Drying Technology. Energy Conv. 1999, 41, 615–655. [Google Scholar] [CrossRef]

- Jangde, P.K.; Singh, A.; Arjunan, T.V. Efficient Solar Drying Techniques: A Review. Environ. Sci. Pollut. Res. 2021. [Google Scholar] [CrossRef]

- Udomkun, P.; Romuli, S.; Schock, S.; Mahayothee, B.; Sartas, M.; Wossen, T.; Njukwe, E.; Vanlauwe, B.; Müller, J. Review of Solar Dryers for Agricultural Products in Asia and Africa: An Innovation Landscape Approach. J. Environ. Manag. 2020, 268, 110730. [Google Scholar] [CrossRef]

- Aramesh, M.; Ghalebani, M.; Kasaeian, A.; Zamani, H.; Lorenzini, G.; Mahian, O.; Wongwises, S. A Review of Recent Advances in Solar Cooking Technology. Renew. Energy 2019, 140, 419–435. [Google Scholar] [CrossRef]

- Scheffler, W. Available online: http://www.solare-bruecke.org/index.php/en/ (accessed on 28 July 2021).

- Apaolaza-Pagoaga, X.; Sagade, A.A.; Rodrigues Ruivo, C.; Carrillo-Andrés, A. Performance of Solar Funnel Cookers Using Intermediate Temperature Test Load under Low Sun Elevation. Sol. Energy 2021, 225, 978–1000. [Google Scholar] [CrossRef]

- El-Sebaii, A.A.; Ibrahim, A. Experimental Testing of a Box-Type Solar Cooker Using the Standard Procedure of Cooking Power. Renew. Energy 2005, 30, 1861–1871. [Google Scholar] [CrossRef]

- Coccia, G.; Aquilanti, A.; Tomassetti, S.; Ishibashi, A.; Di Nicola, G. Design, Manufacture and Test of a Low-Cost Solar Cooker with High-Performance Light-Concentrating Lens. Sol. Energy 2021, 224, 1028–1039. [Google Scholar] [CrossRef]

- Deus, V.L.; de Cerqueira e Silva, M.B.; Maciel, L.F.; Miranda, L.C.R.; Hirooka, E.Y.; Soares, S.E.; Ferreira, E.; Bispo, E.D.S. Influence of Drying Methods on Cocoa (Theobroma cacao L.): Antioxidant Activity and Presence of Ochratoxin A. Food Sci. Technol. 2018, 38, 278–285. [Google Scholar] [CrossRef]

- Saxena, A.; Goel, V.; Karakilcik, M. Solar Food Processing and Cooking Methodologies. In Applications of Solar Energy; Tyagi, H., Agarwal, A.K., Chakraborty, P.R., Powar, S., Eds.; Energy, Environment, and Sustainability; Springer: Singapore, 2018; pp. 251–294. ISBN 978-981-10-7205-5. [Google Scholar]

- Cuce, E.; Cuce, P.M. A Comprehensive Review on Solar Cookers. Appl. Energy 2013, 102, 1399–1421. [Google Scholar] [CrossRef]

- Sidik, N.A.C.; Kean, T.H.; Chow, H.K.; Rajaandra, A.; Rahman, S.; Kaur, J. Performance Enhancement of Cold Thermal Energy Storage System Using Nanofluid Phase Change Materials: A Review. Int. Commun. Heat Mass 2018, 94, 85–95. [Google Scholar] [CrossRef]

- Abuelnuor, A.A.A.; Omara, A.A.M.; Saqr, K.M.; Elhag, I.H.I. Improving Indoor Thermal Comfort by Using Phase Change Materials: A Review. Int. J. Energy Res. 2018, 42, 2084–2103. [Google Scholar] [CrossRef]

- Haraksingh, I.; Mc Doom, I.A.; Headley, O.S.C. A Natural Convection Flat-Plate Collector Solar Cooker with Short Term Storage. Renew. Energy 1996, 9, 729–732. [Google Scholar] [CrossRef]

- Esen, M. Thermal Performance of a Solar Cooker Integrated Vacuum-Tube Collector with Heat Pipes Containing Different Refrigerants. Sol. Energy 2004, 76, 751–757. [Google Scholar] [CrossRef]

- Mawire, A.; Phori, A.; Taole, S. Performance Comparison of Thermal Energy Storage Oils for Solar Cookers during Charging. Appl. Therm. Eng. 2014, 73, 1323–1331. [Google Scholar] [CrossRef]

- Nyahoro, P.K.; Johnson, R.R.; Edwards, J. Simulated Performance of Thermal Storage in a Solar Cooker. Available online: http://ir-library.ku.ac.ke/handle/123456789/11127 (accessed on 15 July 2021).

- Mawire, A.; Mcpherson, M.; Vandenheetkamp, R. Simulated Energy and Exergy Analyses of the Charging of an Oil–Pebble Bed Thermal Energy Storage System for a Solar Cooker. Sol. Energ. Mat. Sol. Cells 2008, 92, 1668–1676. [Google Scholar] [CrossRef]

- Prasanna, U.R.; Umanand, L. Modeling and Design of a Solar Thermal System for Hybrid Cooking Application. Appl. Energy 2011, 88, 1740–1755. [Google Scholar] [CrossRef]

- Yang, L.; Zhang, N.; Yuan, Y.; Cao, X.; Xiang, B. Thermal Performance of Stearic Acid/Carbon Nanotube Composite Phase Change Materials for Energy Storage Prepared by Ball Milling. Int. J. Energy Res. 2019, 43, 6327–6336. [Google Scholar] [CrossRef]

- Chen, C.; Wang, L.; Huang, Y. Morphology and Thermal Properties of Electrospun Fatty Acids/Polyethylene Terephthalate Composite Fibers as Novel Form-Stable Phase Change Materials. Sol. Energ. Mat. Sol. Cells 2008, 92, 1382–1387. [Google Scholar] [CrossRef]

- Marcos, M.A.; Cabaleiro, D.; Hamze, S.; Fedele, L.; Bobbo, S.; Estellé, P.; Lugo, L. NePCM Based on Silver Dispersions in Poly(Ethylene Glycol) as a Stable Solution for Thermal Storage. Nanomaterials 2019, 10, 19. [Google Scholar] [CrossRef] [PubMed]

- Mofijur, M.; Mahlia, T.; Silitonga, A.; Ong, H.; Silakhori, M.; Hasan, M.; Putra, N.; Rahman, S.M. Phase Change Materials (PCM) for Solar Energy Usages and Storage: An Overview. Energies 2019, 12, 3167. [Google Scholar] [CrossRef]

- Alva, G.; Lin, Y.; Fang, G. An Overview of Thermal Energy Storage Systems. Energy 2018, 144, 341–378. [Google Scholar] [CrossRef]

- Kibria, M.A.; Anisur, M.R.; Mahfuz, M.H.; Saidur, R.; Metselaar, I.H.S.C. A Review on Thermophysical Properties of Nanoparticle Dispersed Phase Change Materials. Energy Convers. Manag. 2015, 95, 69–89. [Google Scholar] [CrossRef]

- Sharma, A.; Chen, C.R.; Murty, V.V.S.; Shukla, A. Solar Cooker with Latent Heat Storage Systems: A Review. Renew. Sustain. Energy Rev. 2009, 13, 1599–1605. [Google Scholar] [CrossRef]

- Saini, G.; Singh, H.; Saini, K.; Yadav, A. Experimental Investigation of the Solar Cooker during Sunshine and Off-Sunshine Hours Using the Thermal Energy Storage Unit Based on a Parabolic Trough Collector. Int. J. Ambient Energy 2016, 37, 597–608. [Google Scholar] [CrossRef]

- Lamidi, R.O. Recent Advances in Sustainable Drying of Agricultural Produce—A Review. Appl. Energy 2019, 233, 367–385. [Google Scholar] [CrossRef]

- Jain, D. Performance of Indirect through Pass Natural Convective Solar Crop Dryer with Phase Change Thermal Energy Storage. Renew. Energy 2015, 80, 244–250. [Google Scholar] [CrossRef]

- Sharma, S.D.; Iwata, T.; Kitano, H.; Sagara, K. Thermal Performance of a Solar Cooker Based on an Evacuated Tube Solar Collector with a PCM Storage Unit. Sol. Energy 2005, 78, 416–426. [Google Scholar] [CrossRef]

- Coccia, G.; Aquilanti, A.; Tomassetti, S.; Comodi, G.; Di Nicola, G. Design, Realization, and Tests of a Portable Solar Box Cooker Coupled with an Erythritol-Based PCM Thermal Energy Storage. Sol. Energy 2020, 201, 530–540. [Google Scholar] [CrossRef]

- Buddhi, D.; Sharma, S.D.; Sharma, A. Thermal Performance Evaluation of a Latent Heat Storage Unit for Late Evening Cooking in a Solar Cooker Having Three Reflectors. Energy Convers. Manag. 2003, 9, 809–817. [Google Scholar] [CrossRef]

- Sharma, S.D.; Buddhi, D.; Sawhney, R.L.; Sharma, A. Design, Development and Performance Evaluation of a Latent Heat Storage Unit for Evening Cooking in a Solar Cooker. Energy Convers. Manag. 2000, 41, 1497–1508. [Google Scholar] [CrossRef]

- Buddhi, D.; Sahoo, L.K. Solar Cooker with Latent Heat Storage: Design and Experimental Testing. Energy Convers. Manag. 1997, 38, 493–498. [Google Scholar] [CrossRef]

- Domanski, R.; El-Sebaii, A.A.; Jaworski, M. Cooking during Off-Sunshine Hours Using PCMs as Storage Media. Energy 1995, 20, 607–616. [Google Scholar] [CrossRef]

- Hussein, H.M.S.; El-Ghetany, H.H.; Nada, S.A. Experimental Investigation of Novel Indirect Solar Cooker with Indoor PCM Thermal Storage and Cooking Unit. Energy Convers. Manag. 2008, 49, 2237–2246. [Google Scholar] [CrossRef]

- Mussard, M.; Nydal, O.J. Charging of a Heat Storage Coupled with a Low-Cost Small-Scale Solar Parabolic Trough for Cooking Purposes. Sol. Energy 2013, 95, 144–154. [Google Scholar] [CrossRef]

- Coccia, G.; Di Nicola, G.; Tomassetti, S.; Pierantozzi, M.; Chieruzzi, M.; Torre, L. Experimental Validation of a High-Temperature Solar Box Cooker with a Solar-Salt-Based Thermal Storage Unit. Sol. Energy 2018, 170, 1016–1025. [Google Scholar] [CrossRef]

- Cabeza, L.F.; Castell, A.; Barreneche, C.; de Gracia, A.; Fernández, A.I. Materials Used as PCM in Thermal Energy Storage in Buildings: A Review. Renew. Sustain. Energy Rev. 2011, 15, 1675–1695. [Google Scholar] [CrossRef]

- Farid, M.M.; Khudhair, A.M.; Razack, S.A.K.; Al-Hallaj, S. A Review on Phase Change Energy Storage: Materials and Applications. Energy Convers. Manag. 2004, 45, 1597–1615. [Google Scholar] [CrossRef]

- Xu, X.; Zhang, X.; Liu, S. Experimental Study on Cold Storage Box with Nanocomposite Phase Change Material and Vacuum Insulation Panel. Int. J. Energy Res. 2018, 42, 4429–4438. [Google Scholar] [CrossRef]

- Zhang, P.; Ma, F.; Xiao, X. Thermal Energy Storage and Retrieval Characteristics of a Molten-Salt Latent Heat Thermal Energy Storage System. Appl. Energy 2016, 173, 255–271. [Google Scholar] [CrossRef]

- Şahan, N.; Paksoy, H. Developing Microencapsulated 12-Hydroxystearic Acid (HSA) for Phase Change Material Use. Int. J. Energy Res. 2018, 42, 3351–3360. [Google Scholar] [CrossRef]

- Viegas, O.; Novo, P.; Pinto, E.; Pinho, O.; Ferreira, I.M.P.L.V.O. Effect of Charcoal Types and Grilling Conditions on Formation of Heterocyclic Aromatic Amines (HAs) and Polycyclic Aromatic Hydrocarbons (PAHs) in Grilled Muscle Foods. Food Chem. Toxicol. 2012, 50, 2128–2134. [Google Scholar] [CrossRef]

- Iessa, L.; De Vries, Y.A.; Swinkels, C.E.; Smits, M.; Butijn, C.A.A. What’s Cooking? Unverified Assumptions, Overlooking of Local Needs and pro-Solution Biases in the Solar Cooking Literature. Energy Res. Soc. Sci. 2017, 28, 98–108. [Google Scholar] [CrossRef]

- Touma, J. Solar Cooking: Any Place on Our Menu? In Empowering Lebanon with Renewable Energy. 2016. Available online: www.cedro-undp.org (accessed on 20 July 2021).

- Mekonnen, B.Y.; Kebede, A.Y. Development and Performance Evaluation of a Solar Baking Oven. In Advances of Science and Technology; Habtu, N.G., Ayele, D.W., Fanta, S.W., Admasu, B.T., Bitew, M.A., Eds.; Lecture Notes of the Institute for Computer Sciences; Social Informatics and Telecommunications Engineering; Springer International Publishing: Cham, Switzerland, 2020; Volume 308, pp. 610–622. ISBN 978-3-030-43689-6. [Google Scholar]

- Singh, O.K. Development of a Solar Cooking System Suitable for Indoor Cooking and Its Exergy and Enviroeconomic Analyses. Sol. Energy 2021, 217, 223–234. [Google Scholar] [CrossRef]

- Bhave, A.G.; Kale, C.K. Development of a Thermal Storage Type Solar Cooker for High Temperature Cooking Using Solar Salt. Sol. Energy Mat. Sol. Cells 2020, 208, 110394. [Google Scholar] [CrossRef]

- Masera, O.; Edwards, R.; Arnez, C.A.; Berrueta, V.; Johnson, M.; Bracho, L.R.; Riojas-Rodríguez, H.; Smith, K.R. Impact of Patsari Improved Cookstoves on Indoor Air Quality in Michoacán, Mexico. Energy Sustain. Dev. 2007, 11, 45–56. [Google Scholar] [CrossRef]

- Bauer, G.; Vukelich, S. Solar Ovens Beaten by Rain and Tortillas. Nature 2015, 524, 161. [Google Scholar] [CrossRef]

- Mottram, D.S. Flavour Formation in Meat and Meat Products: A Review. Food Chem. 1998, 62, 415–424. [Google Scholar] [CrossRef]

- Chuah, A.M.; Lee, Y.-C.; Yamaguchi, T.; Takamura, H.; Yin, L.-J.; Matoba, T. Effect of Cooking on the Antioxidant Properties of Coloured Peppers. Food Chem. 2008, 111, 20–28. [Google Scholar] [CrossRef]

- Tabart, J.; Pincemail, J.; Kevers, C.; Defraigne, J.-O.; Dommes, J. Processing Effects on Antioxidant, Glucosinolate, and Sulforaphane Contents in Broccoli and Red Cabbage. Eur. Food Res. Technol. 2018, 244, 2085–2094. [Google Scholar] [CrossRef]

- Lee, S.; Choi, Y.; Jeong, H.S.; Lee, J.; Sung, J. Effect of Different Cooking Methods on the Content of Vitamins and True Retention in Selected Vegetables. Food Sci. Biotechnol. 2017. [Google Scholar] [CrossRef]

- Falconí, C.E.; Yánez-Mendizábal, V. Solar UV-B Radiation Limits Seedborne Anthracnose Infection and Induces Physiological and Biochemical Responses in Lupinus Mutabilis. Plant Pathol. 2019, 68, 1635–1644. [Google Scholar] [CrossRef]

- Mohammed, S.; Edna, M.; Siraj, K. The Effect of Traditional and Improved Solar Drying Methods on the Sensory Quality and Nutritional Composition of Fruits: A Case of Mangoes and Pineapples. Heliyon 2020, 6, e04163. [Google Scholar] [CrossRef]

- Thakur, N.S.; Thakur, A.; Kumar, P. Effect of Different Drying Modes on Phenolics and Antioxidant Potential of Different Parts of Wild Pomegranate Fruits. Sci. Hortic. 2020, 274, 109656. [Google Scholar] [CrossRef]

- Vangdal, E.; Picchi, V.; Fibiani, M.; Lo Scalzo, R. Effects of the Drying Technique on the Retention of Phytochemicals in Conventional and Organic Plums (Prunus domestica L.). LWT-Food Sci. Technol. 2017, 85, 506–509. [Google Scholar] [CrossRef]

- Kiharason, J.W.; Isutsa, D.K.; Ngoda, P.N. Effect of drying method on nutrient integrity of selected components of pumpkin (Cucurbita Moschata Duch.) fruit flour. ARPN J. Agric. Biolog. Sci. 2017, 12, 110–116. [Google Scholar]

- Castillo Téllez, M.; Pilatowsky Figueroa, I.; Castillo Téllez, B.; López Vidaña, E.C.; López Ortiz, A. Solar Drying of Stevia (Rebaudiana Bertoni) Leaves Using Direct and Indirect Technologies. Sol. Energy 2018, 159, 898–907. [Google Scholar] [CrossRef]

- Mabai, P.; Omolola, A.; Jideani, A.I.O. Effect of Drying on Quality and Sensory Attributes of Lemongrass (Cymbopogon Citratus) Tea. J. Food Res. 2018, 7, 68. [Google Scholar] [CrossRef]

- Takahashi, M.; Ohshiro, M.; Ohno, S.; Yonamine, K.; Arakaki, M.; Wada, K. Effects of Solar- and Oven-drying on Physicochemical and Antioxidant Characteristics of Hihatsumodoki (Piper Retrofractum Vahl) Fruit. J. Food Process. Preserv. 2018, 42, e13469. [Google Scholar] [CrossRef]

- Sangwan, A.; Kawatra, A.; Sehgal, S. Nutritional Composition of Ginger Powder Prepared Using Various Drying Methods. J. Food Sci. Technol. 2014, 51, 2260–2262. [Google Scholar] [CrossRef]

- Dzelagha, B.F.; Ngwa, N.M.; Nde Bup, D. A Review of Cocoa Drying Technologies and the Effect on Bean Quality Parameters. Int. J. Food Sci. 2020, 2020, 8830127. [Google Scholar] [CrossRef]

- Mbondo, N.N.; Owino, W.O.; Ambuko, J.; Sila, D.N. Effect of Drying Methods on the Retention of Bioactive Compounds in African Eggplant. Food Sci. Nutr. 2018, 6, 814–823. [Google Scholar] [CrossRef]

- Mendoza, J.M.F.; Gallego-Schmid, A.; Schmidt Rivera, X.C.; Rieradevall, J.; Azapagic, A. Sustainability Assessment of Home-Made Solar Cookers for Use in Developed Countries. Sci. Total Environ. 2019, 648, 184–196. [Google Scholar] [CrossRef]

| Food | Cooking Time (min) | Max Temp (°C) | Solar Cooker Used | Reference |

|---|---|---|---|---|

| rice | 60–120 | 135 | Cookit (solarcookers.com) | [70] |

| potatoes | 180–240 | |||

| beans, lentils | 180–240 | |||

| large roast meat | 300–480 | |||

| bread | 180–240 | |||

| vegetables | 60–120 | |||

| fish | 60–120 | |||

| bread | 50 | 121 | combined solar baking oven | [71] |

| noodles (Maggi) | 45 | 109 | SC with externat rays collector | [72] |

| rice | 65 | |||

| potatoes | 70 | |||

| dal (pulse) | 90 | |||

| rice | 20 | 150–170 | PCM solar cooker device | [73] |

| fried peanuts | 17 |

| Food | Weight | Final Moisture Content | Drying Time (h) | Max Temp (°C) | Reference |

|---|---|---|---|---|---|

| weath flour | 50 kg | 0% | 4 | 60 | [12] |

| curry leaves | 4 kg | 0% | 6 | ||

| mango bar (2 layers) | 7 kg/m3 | <12% | 16 | ||

| fig bar (2 layers) | 7 kg/m3 | <12% | 16 | ||

| mango slices | 7 kg/m3 | <8% | 16 | ||

| apple | 9 kg/m3 | <8% | 10 | 59 | |

| sapota | 4 kg/m3 | <8% | 8 | 50 | |

| papaya | 9 kg/m3 | <8% | 18 | 42 | |

| mango slices | a | <3% | 9 | 40.3 | [81] |

| pinapple slices | a | <5% | 9.5 | ||

| pomegranade (arils) | 2 kg | 12% | 75 | 36 | [82] |

| pomegranade (albedo) | 0.5 kg | 10% | 45 | 37 | |

| plum | 7 kg/m2 | 0% | 192 | 45 | [83] |

| cocoa beans | a | 8.80% | 168 | <60 | [33] |

| pumpkin | a | 12.80% | 13.3 | <60 a | [84] |

| stevia leaves | 1 g | 7.80% | 3.5 | 53 | [85] |

| lemongrass | 50 g | 5.00% | 8 | 50.6 | [86] |

| hihatsumodoki fruit | 1.74 g | 26.10% b | 24 | 41.9 c | [87] |

| ginger powder | a | 3.50 ± 0.08% | a | a | [88] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Battocchio, C.; Bruni, F.; Di Nicola, G.; Gasperi, T.; Iucci, G.; Tofani, D.; Varesano, A.; Venditti, I. Solar Cookers and Dryers: Environmental Sustainability and Nutraceutical Content in Food Processing. Foods 2021, 10, 2326. https://doi.org/10.3390/foods10102326

Battocchio C, Bruni F, Di Nicola G, Gasperi T, Iucci G, Tofani D, Varesano A, Venditti I. Solar Cookers and Dryers: Environmental Sustainability and Nutraceutical Content in Food Processing. Foods. 2021; 10(10):2326. https://doi.org/10.3390/foods10102326

Chicago/Turabian StyleBattocchio, Chiara, Fabio Bruni, Giovanni Di Nicola, Tecla Gasperi, Giovanna Iucci, Daniela Tofani, Alessandro Varesano, and Iole Venditti. 2021. "Solar Cookers and Dryers: Environmental Sustainability and Nutraceutical Content in Food Processing" Foods 10, no. 10: 2326. https://doi.org/10.3390/foods10102326

APA StyleBattocchio, C., Bruni, F., Di Nicola, G., Gasperi, T., Iucci, G., Tofani, D., Varesano, A., & Venditti, I. (2021). Solar Cookers and Dryers: Environmental Sustainability and Nutraceutical Content in Food Processing. Foods, 10(10), 2326. https://doi.org/10.3390/foods10102326