Study on Periodic Pulsation Characteristics of Corn Grain in a Grain Cylinder during the Unloading Stage

Abstract

:1. Introduction

2. Materials and Methods

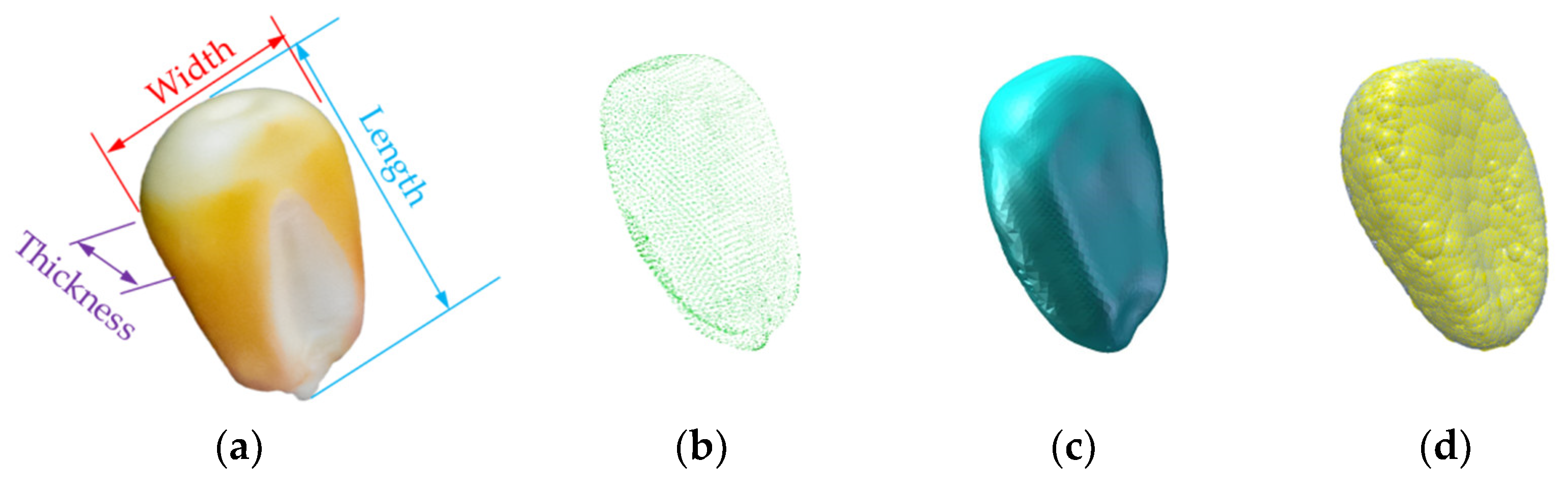

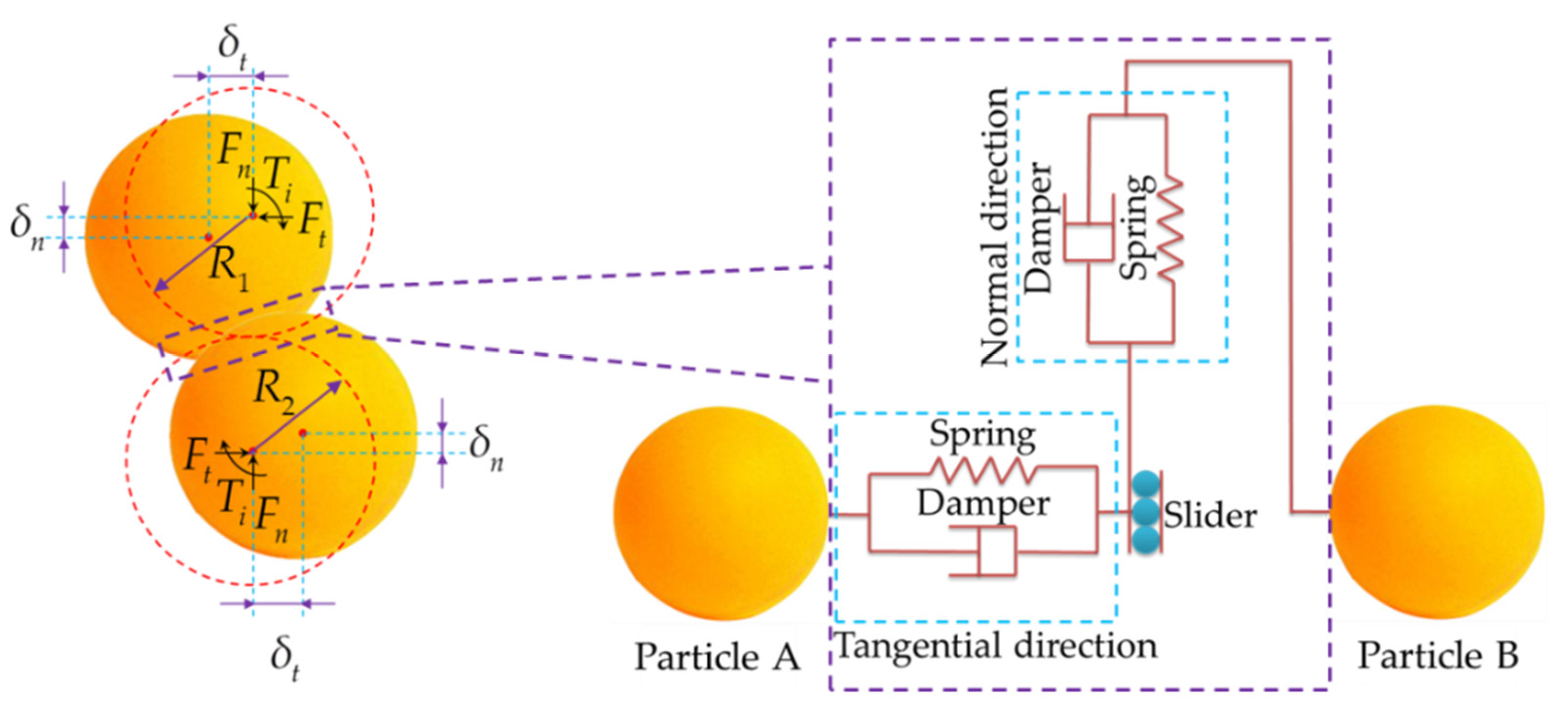

2.1. Establishment of a Discrete Element Model for Corn Grain and Grain Cylinders

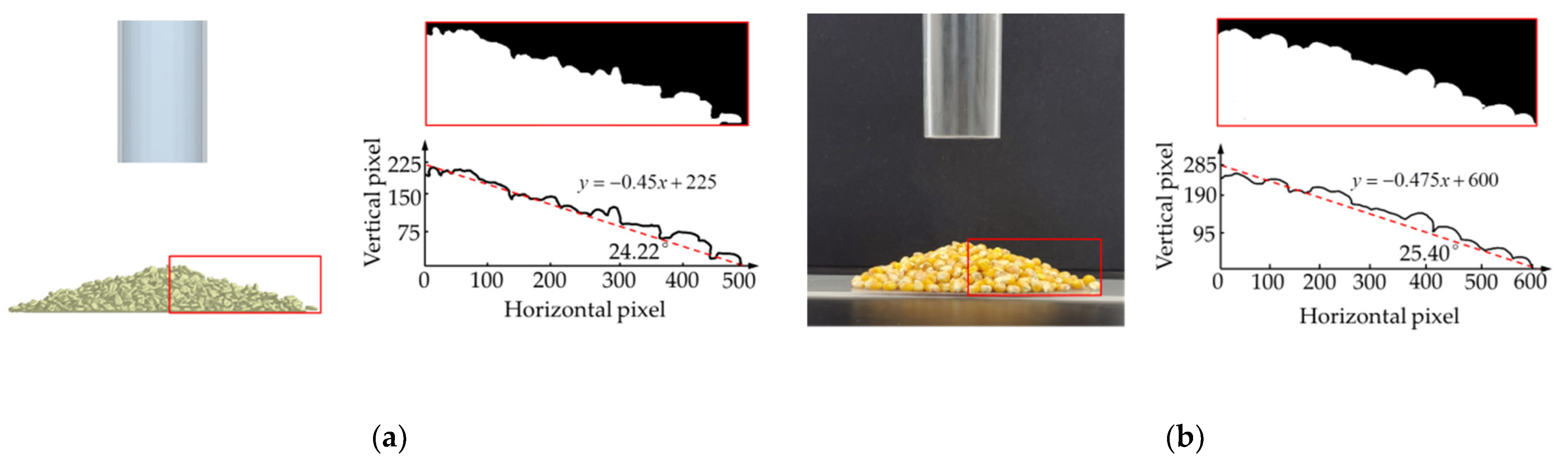

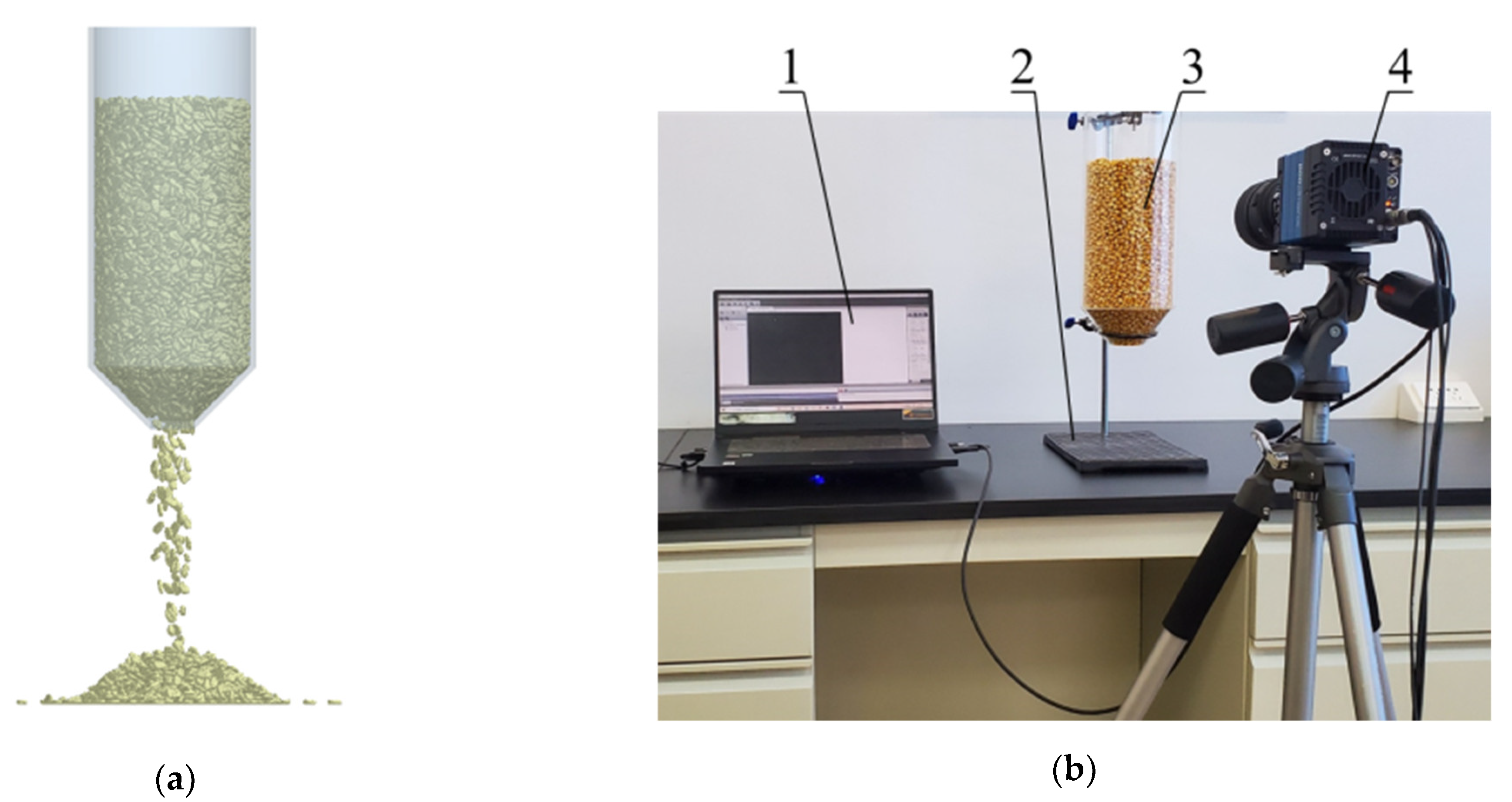

2.2. Comparative Analysis of Simulation and High-Speed Camera Test

3. Results and Discussion

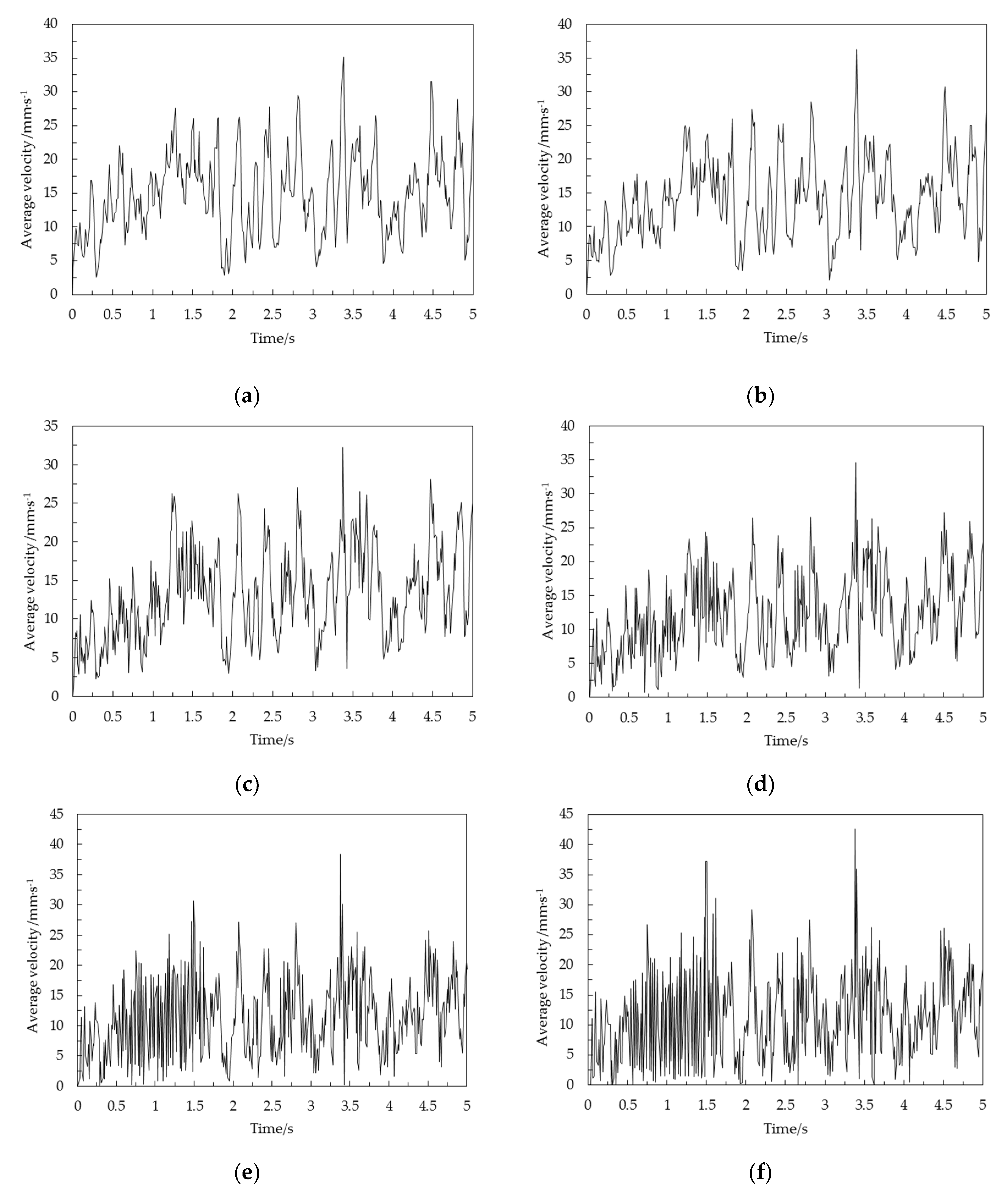

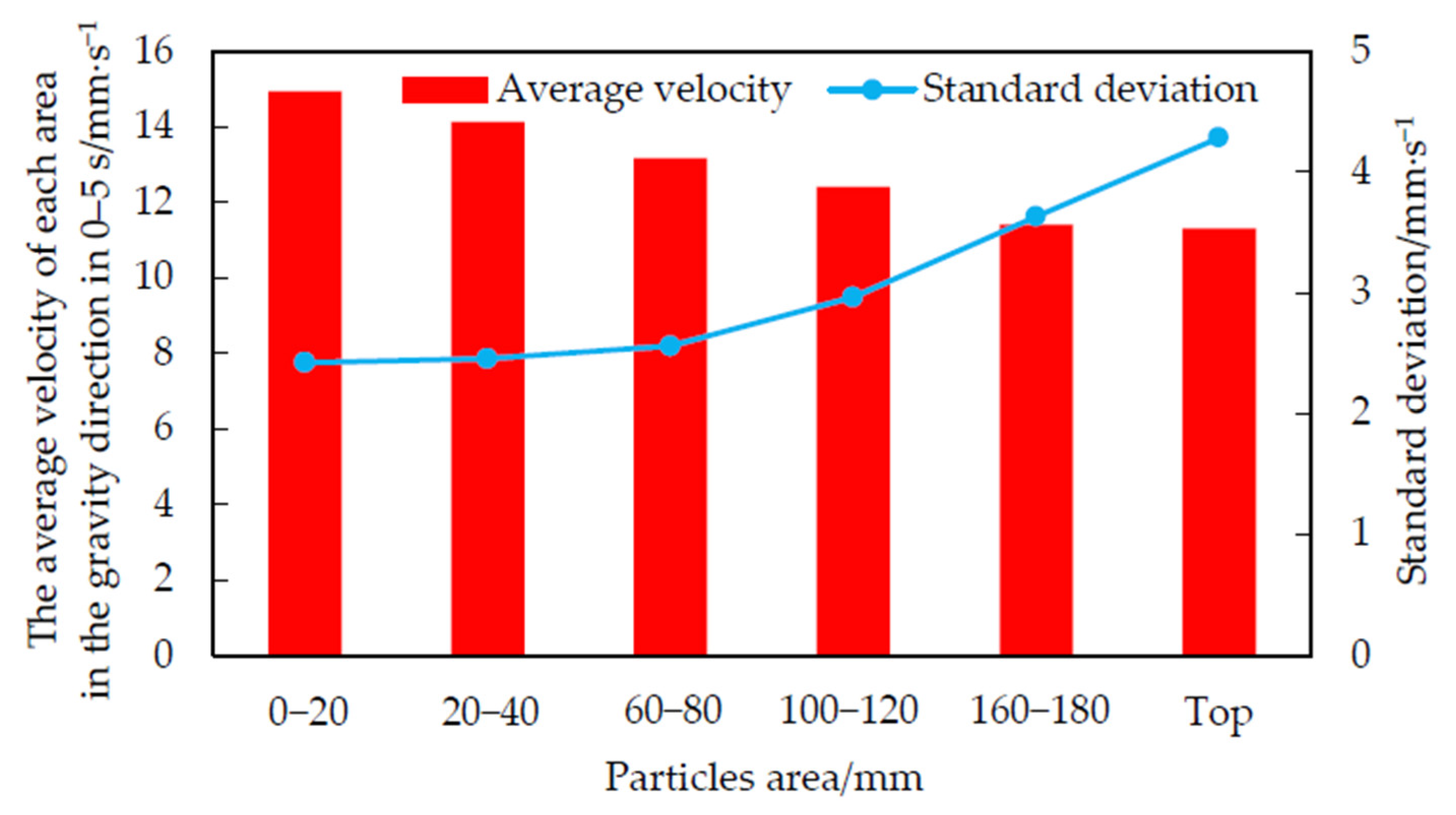

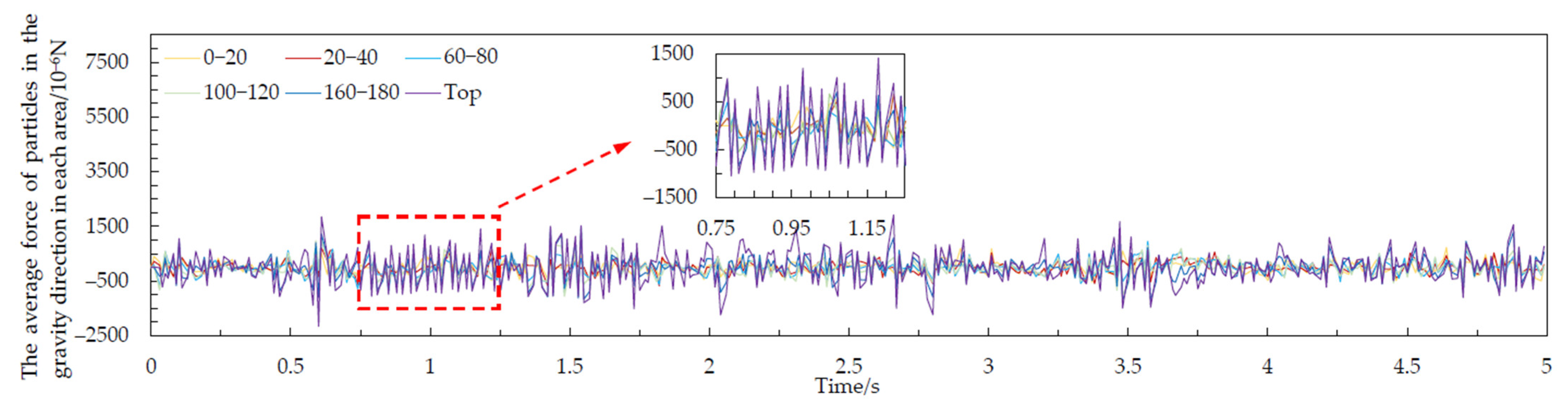

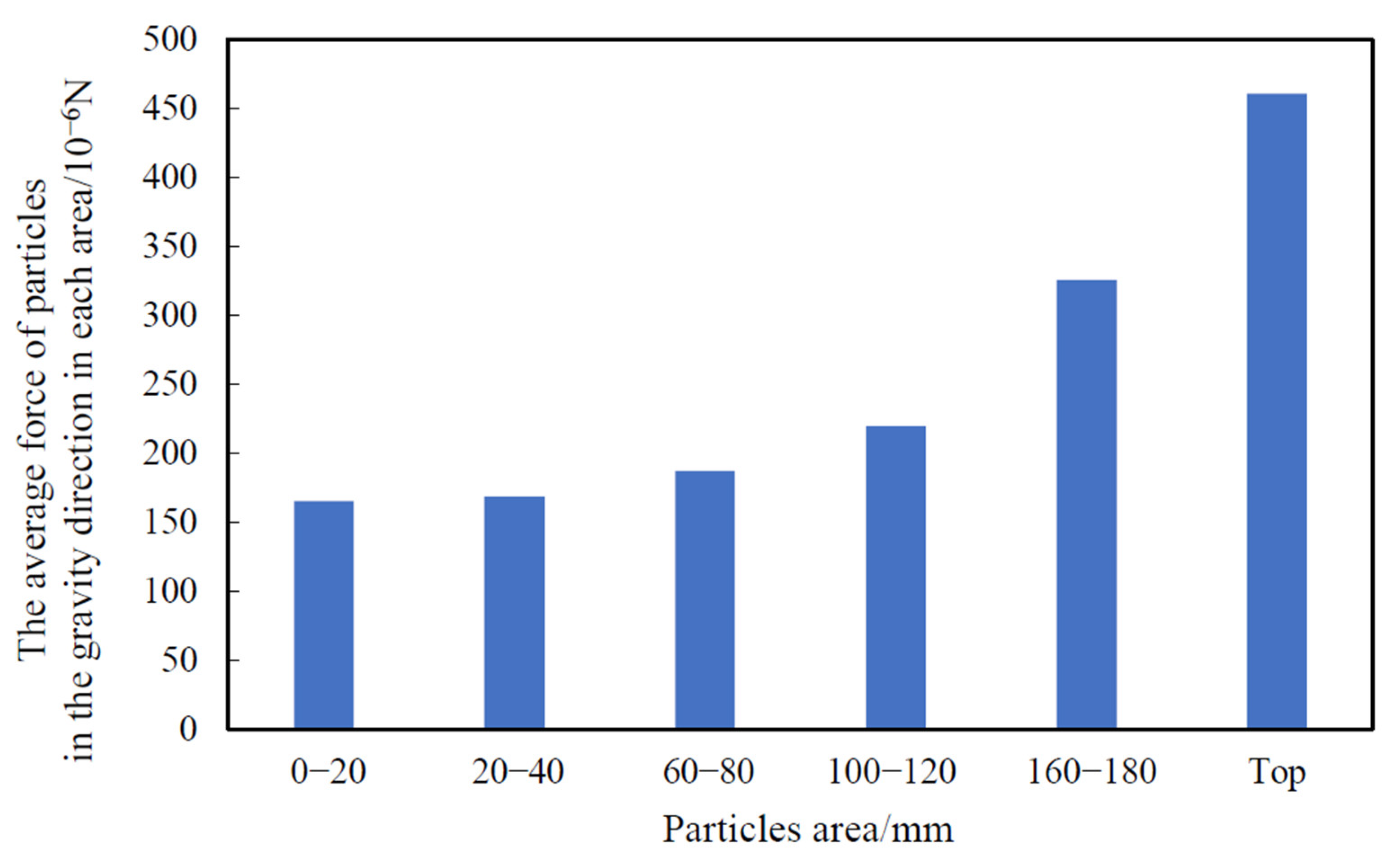

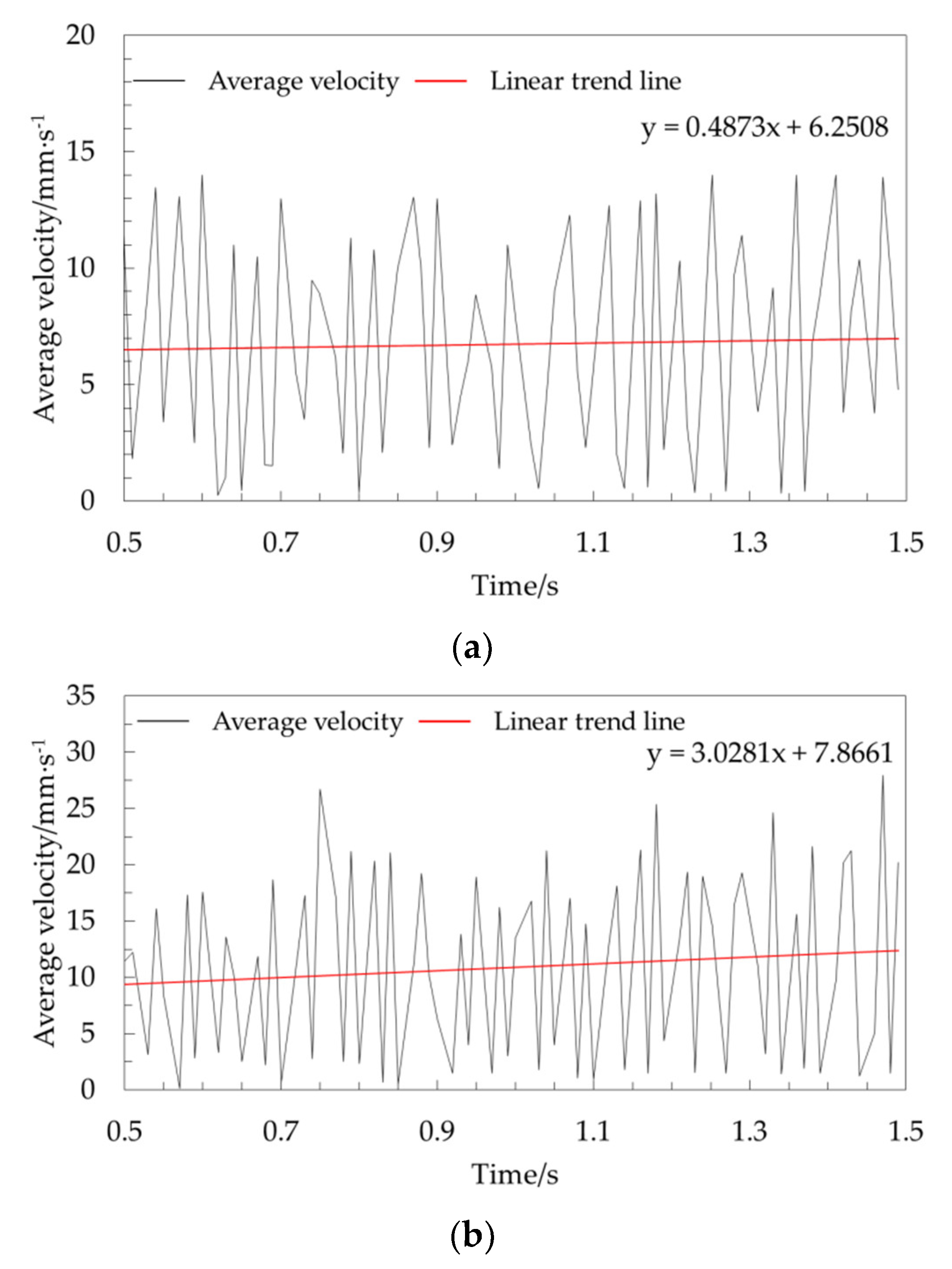

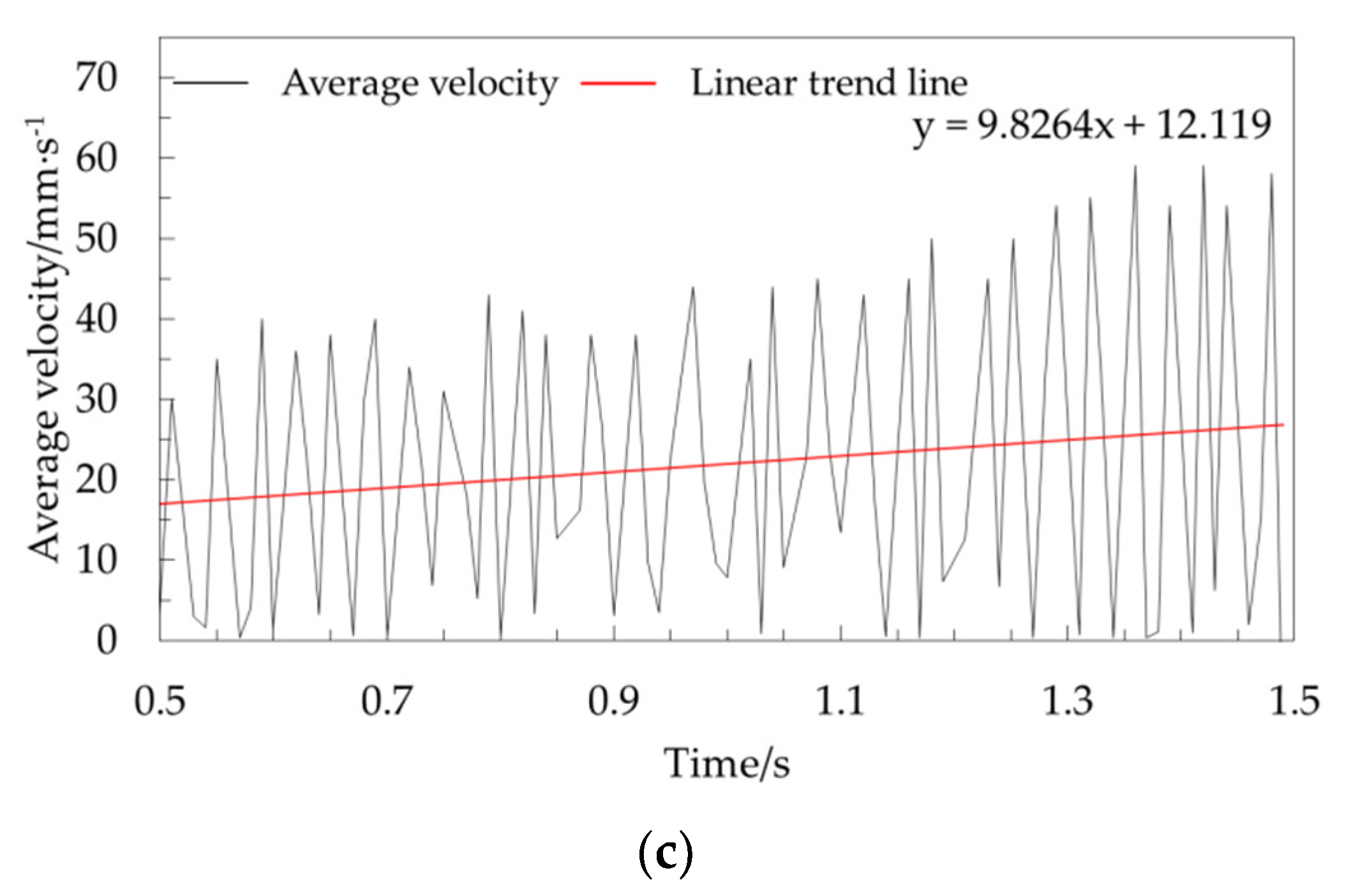

3.1. Pulsation Characteristics of Average Velocity for Corn Grain at Different Storage Heights

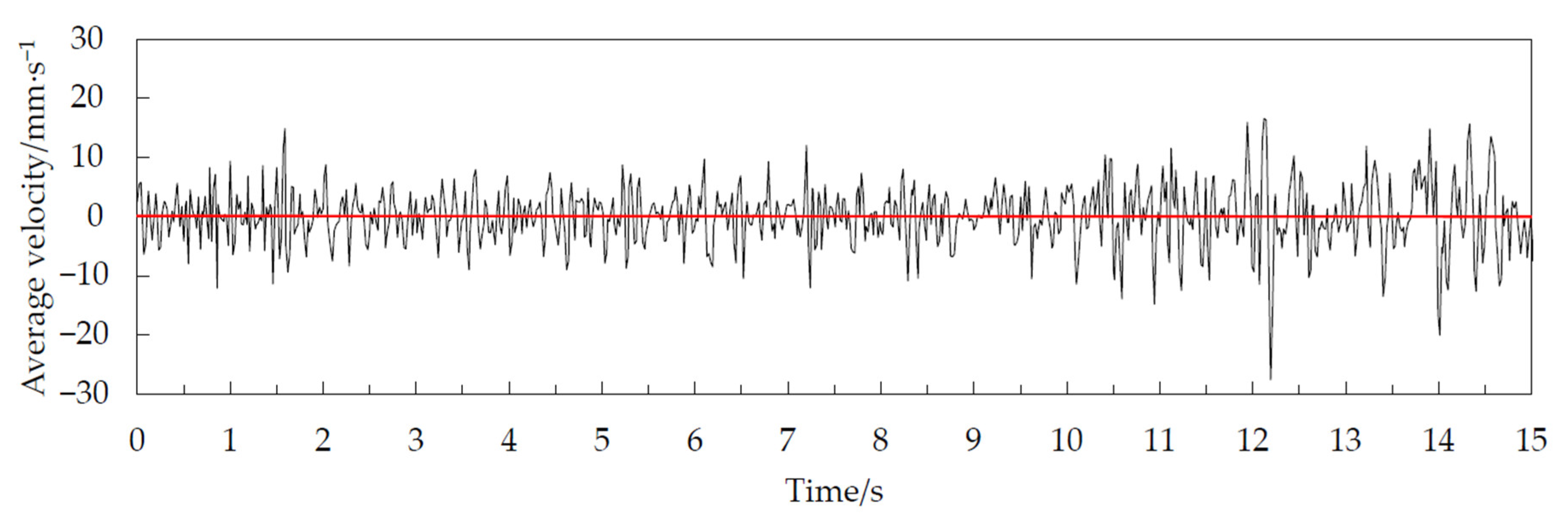

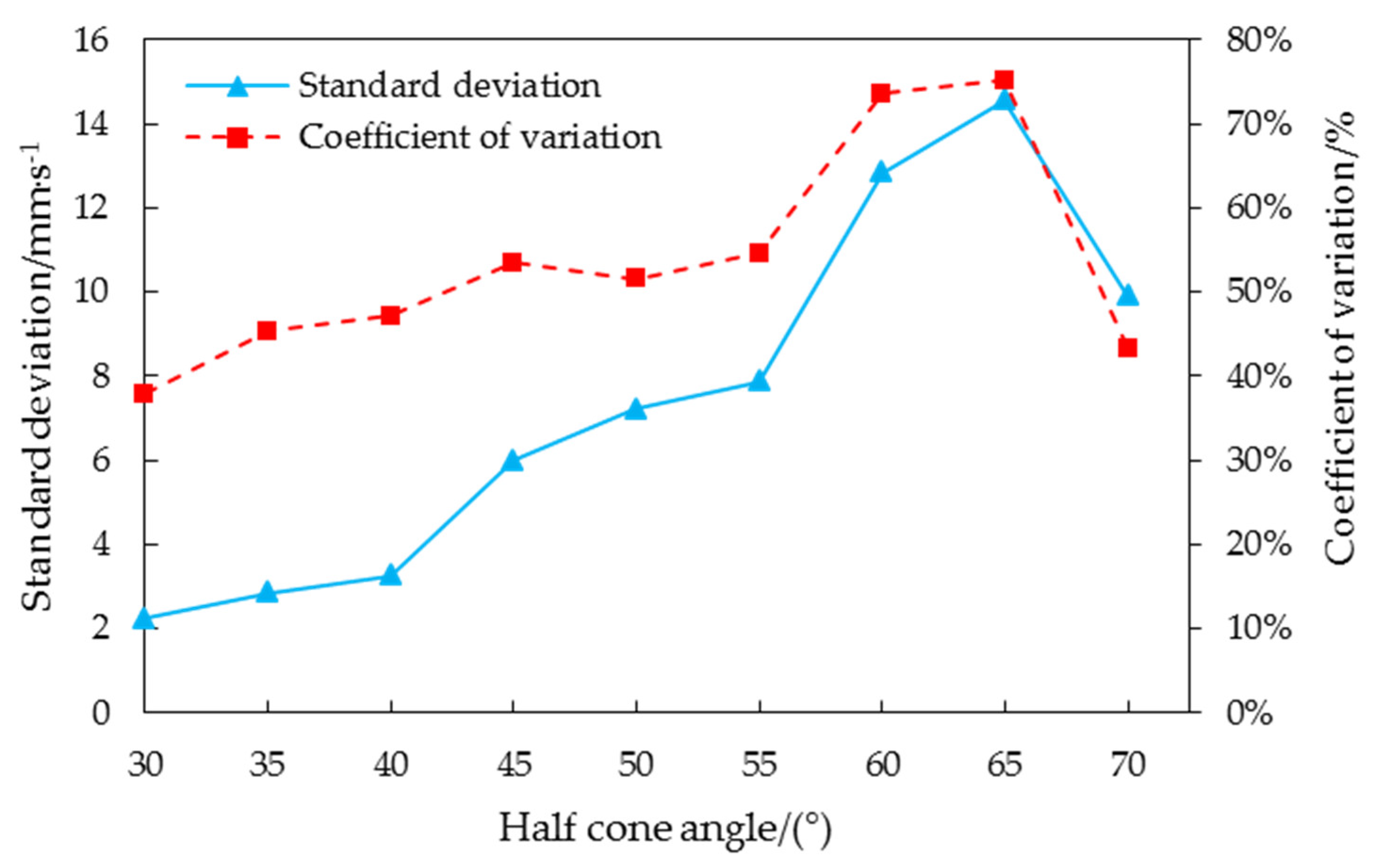

3.2. Effect of the Half Cone Angle on the Pulsation Characteristics of the Grain Layer

3.3. Discussion

4. Conclusions

- (1)

- An accurate discrete element model of corn grain was established by laser scanning and natural rest angle comparison. A model of the vertical grain cylinder was established according to similarity theory. The maximum error of the comparison between high-speed imaging and the discrete element simulation grain unloading test was 2.71%. The real grain unloading environment of a vertical grain cylinder could be simulated by the discrete element method.

- (2)

- With the increase in grain unloading height, the average speed of corn grain increased in unit time. The higher the unloading height, the more significant the periodic pulsation characteristics. The grain pulsation in the grain cylinder was gradually transmitted upward, and the pulsation characteristics were gradually magnified in the process of transmission. However, the average speed decreased with increasing height.

- (3)

- When the half cone angle was in the range of 30–65°, the speed of the top corn grain increased gradually with increasing half cone angle. The phenomenon of periodic pulsation became more significant with increasing half cone angle. The half cone angle in the range of 65–70° was the critical state of corn grain changing from funnel flow to overall flow in the grain cylinder.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Soleymani, A. Corn (Zea mays L.) yield and yield components as affected by light properties in response to plant parameters and N fertilization. Biocatal. Agric. Biotechnol. 2018, 15, 173–180. [Google Scholar] [CrossRef]

- Baum, M.E.; Licht, M.A.; Huber, I.; Archontoulis, S.V. Impacts of climate change on the optimum planting date of different maize cultivars in the central US Corn Belt. Eur. J. Agron. 2020, 119, 126101. [Google Scholar] [CrossRef]

- Hu, R.; Dunmire, K.M.; Truelock, C.N.; Paulk, C.B.; Aldrich, G.; Li, Y. Antioxidant performances of corn gluten meal and DDGS protein hydrolysates in food, pet food, and feed systems. J. Agric. Food Res. 2020, 2, 100030. [Google Scholar] [CrossRef]

- Wang, X.; Miao, Y.; Dong, R.; Zha, H.; Xia, T.; Chen, Z.; Kusnierek, K.; Mi, G.; Sun, H.; Li, M. Machine learning-based in-season nitrogen status diagnosis and side-dress nitrogen recommendation for corn. Eur. J. Agron. 2021, 123, 126193. [Google Scholar] [CrossRef]

- Zhao, Z.; Chen, J.; Bai, Y.; Wang, P. Assessing the sustainability of grass-based livestock husbandry in Hulun Buir, China. Phys. Chem. Earth Parts A/B/C 2020, 120, 102907. [Google Scholar] [CrossRef]

- Du, J.; Liu, C.; Wang, C.; Wu, P.; Ding, Y.; Wang, L. Discharge of granular materials in a hemispherical bottom silo under vertical vibration. Powder Technol. 2020, 372, 128–135. [Google Scholar] [CrossRef]

- Lyu, L.; Zhang, Y.; Zhang, D.; Zhang, Q.; Zhang, M. Method to detect granary storage weight based on the Janssen model. Grain Oil Sci. Technol. 2018, 1, 20–27. [Google Scholar] [CrossRef]

- Uñac, R.O.; Vidales, A.M.; Benegas, O.A.; Ippolito, I. Experimental study of discharge rate fluctuations in a silo with different hopper geometries. Powder Technol. 2012, 225, 214–220. [Google Scholar] [CrossRef]

- Hillewaere, J.; Degroote, J.; Lombaert, G.; Vierendeels, J.; Degrande, G. Wind-structure interaction simulations of ovalling vibrations in silo groups. J. Fluids Struct. 2015, 59, 328–350. [Google Scholar] [CrossRef] [Green Version]

- Pieraccini, L.; Palermo, M.; Stefano, S.; Trombetti, T. On the fundamental periods of vibration of flat-bottom ground-supported circular silos containing gran-like material. Procedia Eng. 2017, 199, 248–253. [Google Scholar] [CrossRef]

- Ayuga, F.; Guaita, M.; Aguado, P.J.; Couto, A. Discharge and the eccentricity of the hopper influence on the silo wall pressures. J. Eng. Mech. 2001, 127, 1067–1074. [Google Scholar] [CrossRef]

- Yuan, F.; Du, Q.; Xu, Z.; Liu, H.; Wang, S. Mechanism of dynamic pressure increase of grain silo wall based on simulation of discharge flow states. Nongye Gongcheng Xuebao/Trans. Chin. Soc. Agric. Eng. 2019, 35, 286–293. [Google Scholar] [CrossRef]

- Ding, S.; Li, H.; Ooi, J.Y.; Rotter, J.M. Prediction of flow patterns during silo discharges using a finite element approach and its preliminary experimental verification. Particuology 2015, 18, 42–49. [Google Scholar] [CrossRef]

- Wang, Y.; Lu, Y.; Ooi, J.Y. Finite element modelling of wall pressures in a cylindrical silo with conical hopper using an Arbitrary Lagrangian-Eulerian formulation. Powder Technol. 2014, 257, 181–190. [Google Scholar] [CrossRef] [Green Version]

- Wang, Z.; Li, Y.; Liu, H.; Meng, W.; Xu, X.; Liu, X. Experimental study on side pressure of grain silo under storage and discharging state. Nongye Gongcheng Xuebao/Trans. Chin. Soc. Agric. Eng. 2020, 36, 292–299. [Google Scholar] [CrossRef]

- Chen, J.; Chen, G.; Liu, W.; Ge, M.; Tan, H. Determination of characteristic height with Janssen formula of storage material and its variation law in silo with flat bottom. Nongye Gongcheng Xuebao/Trans. Chin. Soc. Agric. Eng. 2020, 36, 307–316. [Google Scholar] [CrossRef]

- Xu, Y.; Kafui, K.D.; Thornton, G. Silo discharge simulations with different particulate properties using the distinct element method. Nongye Gongcheng Xuebao/Trans. Chin. Soc. Agric. Eng. 1999, 15, 65–69. [Google Scholar]

- Feng, Y.; Li, M. Simulation of meso-mechanism of silo unloading grain aching based on improved particle composition mechanical model. Nongye Gongcheng Xuebao/Trans. Chin. Soc. Agric. Eng. 2018, 34, 286–293. [Google Scholar] [CrossRef]

- Wang, Y.; Lu, Y.; Ooi, J.Y. A numerical study of wall pressure and granular flow in a flat-bottomed silo. Powder Technol. 2015, 282, 43–54. [Google Scholar] [CrossRef] [Green Version]

- Gokul Kumar, B.; Velmurugan, V.; Paramasivam, V.; Thanikaikarasan, S. Prediction of material discontinuity and modal analysis of aluminium beam using finite element method. Mater. Today Proc. 2020, 21, 782–786. [Google Scholar] [CrossRef]

- Bartilson, D.T.; Jang, J.; Smyth, A.W. Symmetry properties of natural frequency and mode shape sensitivities in symmetric structures. Mech. Syst. Signal Process. 2020, 143, 106797. [Google Scholar] [CrossRef]

- Muite, B.K.; Quinn, S.F.; Sundaresan, S.; Rao, K.K. Silo music and silo quake: Granular flow-induced vibration. Powder Technol. 2004, 145, 190–202. [Google Scholar] [CrossRef] [Green Version]

- Tejchman, J. Technical concept to prevent the silo honking. Powder Technol. 1999, 106, 7–22. [Google Scholar] [CrossRef]

- Pan, D.; Li, S.; Xu, Z.; Zhang, Y.; Lin, P.; Li, H. A deterministic-stochastic identification and modelling method of discrete fracture networks using laser scanning: Development and case study. Eng. Geol. 2019, 262, 105310. [Google Scholar] [CrossRef]

- Guan, X.; Liu, K.; Qiu, B.; Dong, X.; Xue, X. Extraction of geometric parameters of soybean canopy by airborne 3D laser scanning. Nongye Gongcheng Xuebao/Trans. Chin. Soc. Agric. Eng. 2019, 35, 96–103. [Google Scholar] [CrossRef]

- Żmuda-Trzebiatowski, Ł.; Iwicki, P. Impact of geometrical imperfections on estimation of buckling and limit loads in a silo segment using the vibration correlation technique. Materials 2021, 14, 567. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.; Jia, F.G.; Han, Y.L.; Zhang, Y.X.; Cao, B. Cyclical pulsation properties of particles in cone silo. Wuli Xuebao/Acta Phys. Sin. 2017, 66, 14501. [Google Scholar] [CrossRef]

- Geiger, M.; Messner, A.; Engel, U. Production of microparts—Size effects in bulk metal forming, similarity theory. Prod. Eng. Wiss. Ges. für Prod. 1997, 4, 55–58. [Google Scholar]

- Romuli, S.; Karaj, S.; Müller, J. Discrete element method simulation of the hulling process of Jatropha curcas L. fruits. Biosyst. Eng. 2017, 155, 55–67. [Google Scholar] [CrossRef]

- Azmir, J.; Hou, Q.; Yu, A. Discrete particle simulation of food grain drying in a fluidised bed. Powder Technol. 2018, 323, 238–249. [Google Scholar] [CrossRef]

- Wang, Y.; Liang, Z.; Zhang, D.; Cui, T.; Shi, S.; Li, K.; Yang, L. Calibration method of contact characteristic parameters for corn seeds based on EDEM. Nongye Gongcheng Xuebao/Trans. Chin. Soc. Agric. Eng. 2016, 32, 36–42. [Google Scholar] [CrossRef]

- Mindlin, R.D.; Deresiewicz, H. Elastic spheres in contact under varying oblique forces. J. Appl. Mech. 1953, 20, 327–344. [Google Scholar] [CrossRef]

- Sakaguchi, H.; Ozaki, E.; Igarashi, T. Plugging of the flow of granular materials during the discharge from a silo. Int. J. Mod. Phys. B 1993, 7, 1949–1963. [Google Scholar] [CrossRef]

- Mousaviraad, M.; Tekeste, M.Z. Effect of moisture content of corn on discrete element modeling input parameters estimation. In Proceedings of the ASABE 2018 Annual International Meeting, Detroit, MI, USA, 29 July–1 August 2018. [Google Scholar]

- Wang, J.; Xu, C.; Xu, Y.; Wang, Z.; Qi, X.; Wang, J.; Zhou, W.; Tang, H.; Wang, Q. Influencing factors analysis and simulation calibration of restitution coefficient of rice grain. Appl. Sci. 2021, 11, 5884. [Google Scholar] [CrossRef]

- Mousaviraad, M.; Tekeste, M.; Rosentrater, K.A. Calibration and validation of a discrete element model of corn using grain flow simulation in a commercial screw grain auger. Trans. ASABE 2017, 60, 1403–1415. [Google Scholar] [CrossRef] [Green Version]

- Mousaviraad, M.; Tekeste, M.; Rosentrater, K. Discrete element method (DEM) simulation of corn grain flow in commercial screw auger. In Proceedings of the 2016 American Society of Agricultural and Biological Engineers Annual International Meeting, ASABE 2016, Orlando, FL, USA, 17–20 July 2016. [Google Scholar]

- Liu, J.S.; Gao, C.Q.; Nie, Y.J.; Yang, B.; Ge, R.Y.; Xu, Z.H. Numerical simulation of Fertilizer Shunt-Plate with uniformity based on EDEM software. Comput. Electron. Agric. 2020, 178, 105737. [Google Scholar] [CrossRef]

- Meng, Z.; Wang, H.; Yang, W. Experiment on angle of repose and angle of surface friction of cohesionless sediment. Tianjin Daxue Xuebao (Ziran Kexue yu Gongcheng Jishu Ban)/J. Tianjin Univ. Sci. Technol. 2015, 48, 1014–1022. [Google Scholar] [CrossRef]

- Ileleji, K.E.; Zhou, B. The angle of repose of bulk corn stover particles. Powder Technol. 2008, 187, 110–118. [Google Scholar] [CrossRef]

- Yang, D.; Tong, P.; Deng, X. A central difference method with low numerical dispersion for solving the scalar wave equation. Geophys. Prospect. 2012, 60, 885–905. [Google Scholar] [CrossRef]

- Yu, L.; Zhang, Q.; Meng, X.; Yan, Z. Design of the granary temperature and humidity measure and control systembased on Zigbee wireless sensor network. In Proceedings of the 2011 International Conference on Electrical and Control Engineering, ICECE 2011—Proceedings, Guimarães, Portugal, 25–28 September 2011; pp. 1055–1058. [Google Scholar]

- Fürll, C.; Hoffmann, T. The influence of the granulometric condition on the flow characteristics of shredded grain products in their dependence on the duration of storage. Powder Technol. 2013, 235, 307–311. [Google Scholar] [CrossRef]

- Saleh, K.; Golshan, S.; Zarghami, R. A review on gravity flow of free-flowing granular solids in silos—Basics and practical aspects. Chem. Eng. Sci. 2018, 192, 1011–1035. [Google Scholar] [CrossRef]

- Kobyłka, R.; Molenda, M.; Horabik, J. DEM simulation of the pressure distribution and flow pattern in a model grain silo with an annular segment attached to the wall. Biosyst. Eng. 2020, 193, 75–89. [Google Scholar] [CrossRef]

- Golshan, S.; Esgandari, B.; Zarghami, R.; Blais, B.; Saleh, K. Experimental and DEM studies of velocity profiles and residence time distribution of non-spherical particles in silos. Powder Technol. 2020, 373, 510–521. [Google Scholar] [CrossRef]

- Fullard, L.A.; Davies, C.E.; Neather, A.C.; Breard, E.C.P.; Godfrey, A.J.R.; Lube, G. Testing steady and transient velocity scalings in a silo. Adv. Powder Technol. 2018, 29, 310–318. [Google Scholar] [CrossRef]

- Wilde, K.; Tejchman, J.; Rucka, M.; Niedostatkiewicz, M. Experimental and theoretical investigations of silo music. Powder Technol. 2010, 198, 38–48. [Google Scholar] [CrossRef]

| Parameters | Numerical Value | References |

|---|---|---|

| Density of corn grain/(kg/m3) | 1150 | [34] |

| Poisson’s ratio of corn grain | 0.357 | |

| Elastic modulus of corn grain/(MPa) | 1500 | |

| Plexiglass density/(kg/m3) | 1180 | [35] |

| Poisson’s ratio of plexiglass | 0.5 | |

| Elastic modulus of plexiglass/(MPa) | 1770 | |

| Static friction coefficient between corn grain and corn grain | 0.275 | [34,36] |

| Rolling friction coefficient between corn grain and corn grain | 0.05 | |

| Collision recovery coefficient between corn grain and corn grain | 0.382 | |

| Static friction coefficient between corn grain and plexiglass | 0.351 | [37] |

| Rolling friction coefficient between corn grain and plexiglass | 0.093 | |

| Collision recovery coefficient between corn grain and plexiglass | 0.709 | [36] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tang, H.; Xu, C.; Qi, X.; Wang, Z.; Wang, J.; Zhou, W.; Wang, Q.; Wang, J. Study on Periodic Pulsation Characteristics of Corn Grain in a Grain Cylinder during the Unloading Stage. Foods 2021, 10, 2314. https://doi.org/10.3390/foods10102314

Tang H, Xu C, Qi X, Wang Z, Wang J, Zhou W, Wang Q, Wang J. Study on Periodic Pulsation Characteristics of Corn Grain in a Grain Cylinder during the Unloading Stage. Foods. 2021; 10(10):2314. https://doi.org/10.3390/foods10102314

Chicago/Turabian StyleTang, Han, Changsu Xu, Xin Qi, Ziming Wang, Jinfeng Wang, Wenqi Zhou, Qi Wang, and Jinwu Wang. 2021. "Study on Periodic Pulsation Characteristics of Corn Grain in a Grain Cylinder during the Unloading Stage" Foods 10, no. 10: 2314. https://doi.org/10.3390/foods10102314

APA StyleTang, H., Xu, C., Qi, X., Wang, Z., Wang, J., Zhou, W., Wang, Q., & Wang, J. (2021). Study on Periodic Pulsation Characteristics of Corn Grain in a Grain Cylinder during the Unloading Stage. Foods, 10(10), 2314. https://doi.org/10.3390/foods10102314