The Flexural Strength and the Effect of the Autoclave Sterilization of Polypropylene/Natural Rubber Blended Materials

Abstract

1. Introduction

2. Materials and Methods

2.1. Specimen Preparation

2.2. Flexural Strength Testing

2.3. Autoclave Sterilization

2.4. The Data’s Statistical Assessment

3. Results

4. Discussion

5. Conclusions

- 1.

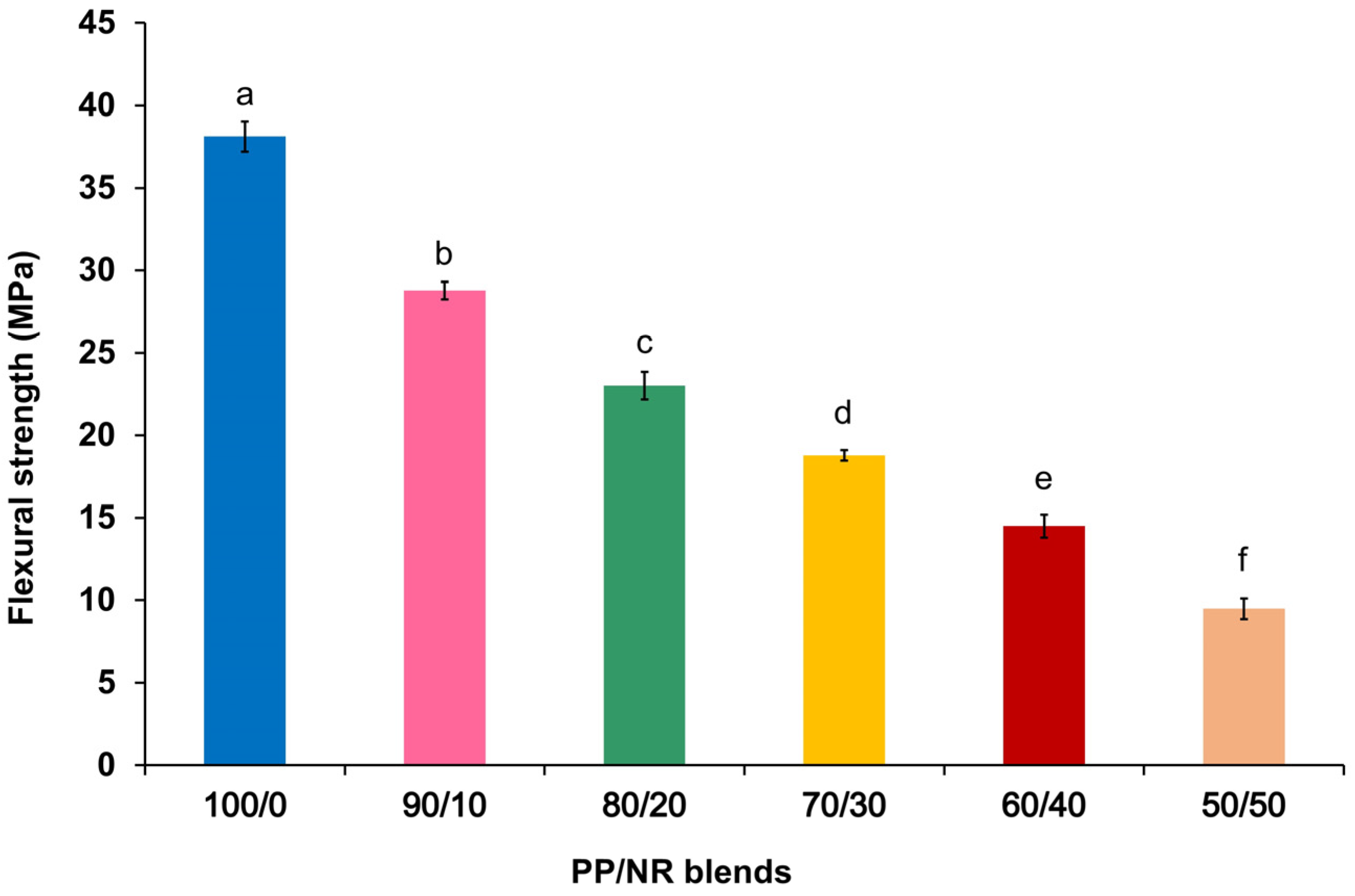

- The lower NR content in PP/NR blends resulted in significantly higher flexural strength.

- 2.

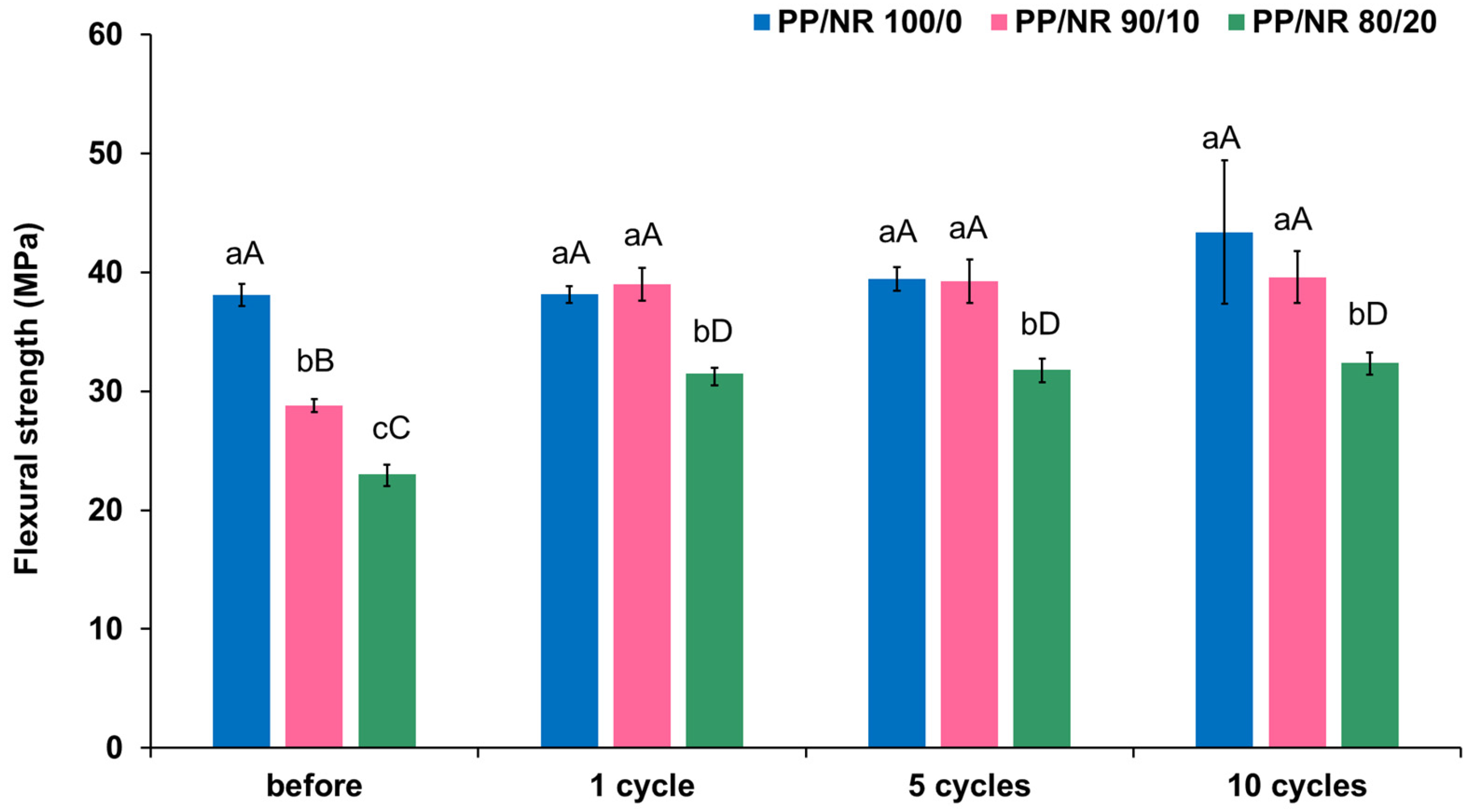

- Autoclave sterilization had an effect on the flexural strength of PP/NR blends. After autoclave sterilization, the 90/10 ratio showed flexural strength comparable to pure PP. However, the 90/10 and 80/20 ratios exhibited flexural strength with an acceptable range for customized rubber dam clamps. This implied that the 90/10 PP/NR blend is suitable as a candidate for developing rubber dam clamps.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- e Cunha, A.F.F.; Madalena, I.R.; Küchler, E.C.; Pereira, T.L.; Honorato, R.; Lepri, C.P. Polyethylene terephthalate clamps: Optimization in endodontic and restorative practices. J. Clin. Exp. Dent. 2022, 14, e621–e624. [Google Scholar] [CrossRef] [PubMed]

- Zahran, S.; Patel, S.; Koller, G.; Mannocci, F. The impact of an enhanced infection control protocol on molar root canal treatment outcome-a randomized clinical trial. Int. Endod. J. 2021, 54, 1993–2005. [Google Scholar] [CrossRef] [PubMed]

- Stevenson, R.G., III. Best practices: Restorative complications. In Avoiding and Treating Dental Complications: Best Practices in Dentistry; Wiley: Hoboken, NJ, USA, 2016; pp. 1–28. [Google Scholar]

- Mendes, A.C.B.; Restrepo, M.; Azevedo, E.R.; Cordeiro, R.D.C.L.; Santos-Pinto, L.; Zuanon, A.C.C. Effect of rubber dam clamps on demineralized cervical enamel of permanent teeth. J. Dent. Child. 2018, 85, 3–7. [Google Scholar]

- Chhabra, M.; Greenwell, A.L. Effect of Repeated Sterilization on the Tensile Strength of Rubber Dam Clamps. Pediatr. Dent. 2018, 40, 220–223. [Google Scholar] [PubMed]

- Mackenzie, L.; Waplington, M.; Bonsor, S. Splendid isolation: A practical guide to the use of rubber dam Part 1. Dent. Update 2020, 47, 548–558. [Google Scholar] [CrossRef]

- Eskibağlar, M.; Erdem, S.; Kaman, M.O. Evaluation of the effect of different rubber dam clamps on the mandibular first molar with Finite element analysis. Comput. Methods Biomech. Biomed. Eng. 2023, 27, 1704–1713. [Google Scholar] [CrossRef] [PubMed]

- Luo, C.; Liu, Y.; Peng, B.; Chen, M.; Liu, Z.; Li, Z.; Kuang, H.; Gong, B.; Li, Z.; Sun, H. PEEK for oral applications: Recent advances in mechanical and adhesive properties. Polymers 2023, 15, 386. [Google Scholar] [CrossRef] [PubMed]

- Bendjaouahdou, C.; Bensaad, S. Aging studies of a polypropylene and natural rubber blend. Int. J. Ind. Chem. 2018, 9, 345–352. [Google Scholar] [CrossRef]

- Mohamad, N.; Zainol, N.S.; Rahim, F.F.; Ab Maulod, H.E.; Abd Rahim, T.; Shamsuri, S.R.; Azam, M.; Yaakub, M.; Abdollah, M.F.B.; Abd Manaf, M.E. Mechanical and morphological properties of polypropylene/epoxidized natural rubber blends at various mixing ratio. Procedia Eng. 2013, 68, 439–445. [Google Scholar] [CrossRef]

- Saowapark, T.; Amphaiphan, U.; Chaichana, E.; Wongwitthayakool, P. Enhancing properties of deproteinized natural rubber with rice husk ash silica for use as a dental material. Key Eng. Mater. 2016, 675–676, 564–568. [Google Scholar] [CrossRef]

- Hashim, A.S.; Ong, S.K. Natural Rubber and Its Derivatives; IntechOpen: Rijeka, Croatia, 2017. [Google Scholar]

- Phinyocheep, P.; Tessanan, W. Natural rubber-based mechanical modifiers for poly (lactic acid). Int. J. Sci. Innov. Technol. 2020, 3, 86–94. [Google Scholar]

- Wissamitanan, T.; Dechwayukul, C.; Kalkornsurapranee, E.; Thongruang, W. Proper blends of biodegradable polycaprolactone and natural rubber for 3D printing. Polymers 2020, 12, 2416. [Google Scholar] [CrossRef] [PubMed]

- Lendvai, L. A novel preparation method of polypropylene/natural rubber blends with improved toughness. Polym. Int. 2021, 70, 298–307. [Google Scholar] [CrossRef]

- ASTM D790; Standard Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials. American Society for Testing and Materials (ASTM): West Conshohocken, PA, USA, 2003.

- Sastri, V.R. Plastics in Medical Devices: Properties, Requirements, and Applications; William Andrew: Norwich, NY, USA, 2021. [Google Scholar]

- Faul, F.; Erdfelder, E.; Lang, A.G.; Buchner, A. G* Power 3: A flexible statistical power analysis program for the social, behavioral, and biomedical sciences. Behav. Res. Methods 2007, 39, 175–191. [Google Scholar] [CrossRef] [PubMed]

- Patel, S.; Hamer, S. A simple guide to using dental dam. Br. Dent. J. 2021, 230, 644–650. [Google Scholar] [CrossRef] [PubMed]

- Jacoby, S.R.; Wehman, T.C.; Lieberman, M.; Lieberman, F. Radiolucent Dental Dam Clamp. U.S. Patent 4,787,849, 29 November 1988. [Google Scholar]

- Jain, A.K.; Gupta, N.K.; Singhal, R.; Nagpal, A. Effect of dynamic crosslinking on crystallization and thermal degradation of polypropylene in polypropylene (PP)/ethylene–propylene DIENE (EPDM) rubber blends. Mater. Manuf. Process. 2002, 17, 415–431. [Google Scholar] [CrossRef]

- Wang, W.; Zhao, G.; Wu, X.; Zhai, Z. The effect of high temperature annealing process on crystallization process of polypropylene, mechanical properties, and surface quality of plastic parts. J. Appl. Polym. Sci. 2015, 132, 42773. [Google Scholar] [CrossRef]

- Yu, W.; Wang, X.; Yin, X.; Ferraris, E.; Zhang, J. The effects of thermal annealing on the performance of material extrusion 3D printed polymer parts. Mater. Des. 2023, 226, 111687. [Google Scholar] [CrossRef]

- Schönhoff, L.M.; Mayinger, F.; Eichberger, M.; Reznikova, E.; Stawarczyk, B. 3D printing of dental restorations: Mechanical properties of thermoplastic polymer materials. J. Mech. Behav. Biomed. Mater. 2021, 119, 104544. [Google Scholar] [CrossRef] [PubMed]

- Fischer, K.M.; Howell, A.P. Reusability of autoclaved 3D printed polypropylene compared to a glass filled polypropylene composite. 3D Print. Med. 2021, 7, 20. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rangsantham, P.; Nonthiphalang, T.; Wongwitthayakool, P.; Sirisinha, C.; Krajangta, N.; Phumpatrakom, P. The Flexural Strength and the Effect of the Autoclave Sterilization of Polypropylene/Natural Rubber Blended Materials. Dent. J. 2024, 12, 361. https://doi.org/10.3390/dj12110361

Rangsantham P, Nonthiphalang T, Wongwitthayakool P, Sirisinha C, Krajangta N, Phumpatrakom P. The Flexural Strength and the Effect of the Autoclave Sterilization of Polypropylene/Natural Rubber Blended Materials. Dentistry Journal. 2024; 12(11):361. https://doi.org/10.3390/dj12110361

Chicago/Turabian StyleRangsantham, Paphavarin, Thitaporn Nonthiphalang, Panjaporn Wongwitthayakool, Chakrit Sirisinha, Nantawan Krajangta, and Panupat Phumpatrakom. 2024. "The Flexural Strength and the Effect of the Autoclave Sterilization of Polypropylene/Natural Rubber Blended Materials" Dentistry Journal 12, no. 11: 361. https://doi.org/10.3390/dj12110361

APA StyleRangsantham, P., Nonthiphalang, T., Wongwitthayakool, P., Sirisinha, C., Krajangta, N., & Phumpatrakom, P. (2024). The Flexural Strength and the Effect of the Autoclave Sterilization of Polypropylene/Natural Rubber Blended Materials. Dentistry Journal, 12(11), 361. https://doi.org/10.3390/dj12110361