Nanocrystalline–Amorphous Transition in ZrN Nanofilms Induced by Helium Accumulation at Grain Boundaries

Abstract

1. Introduction

2. Results

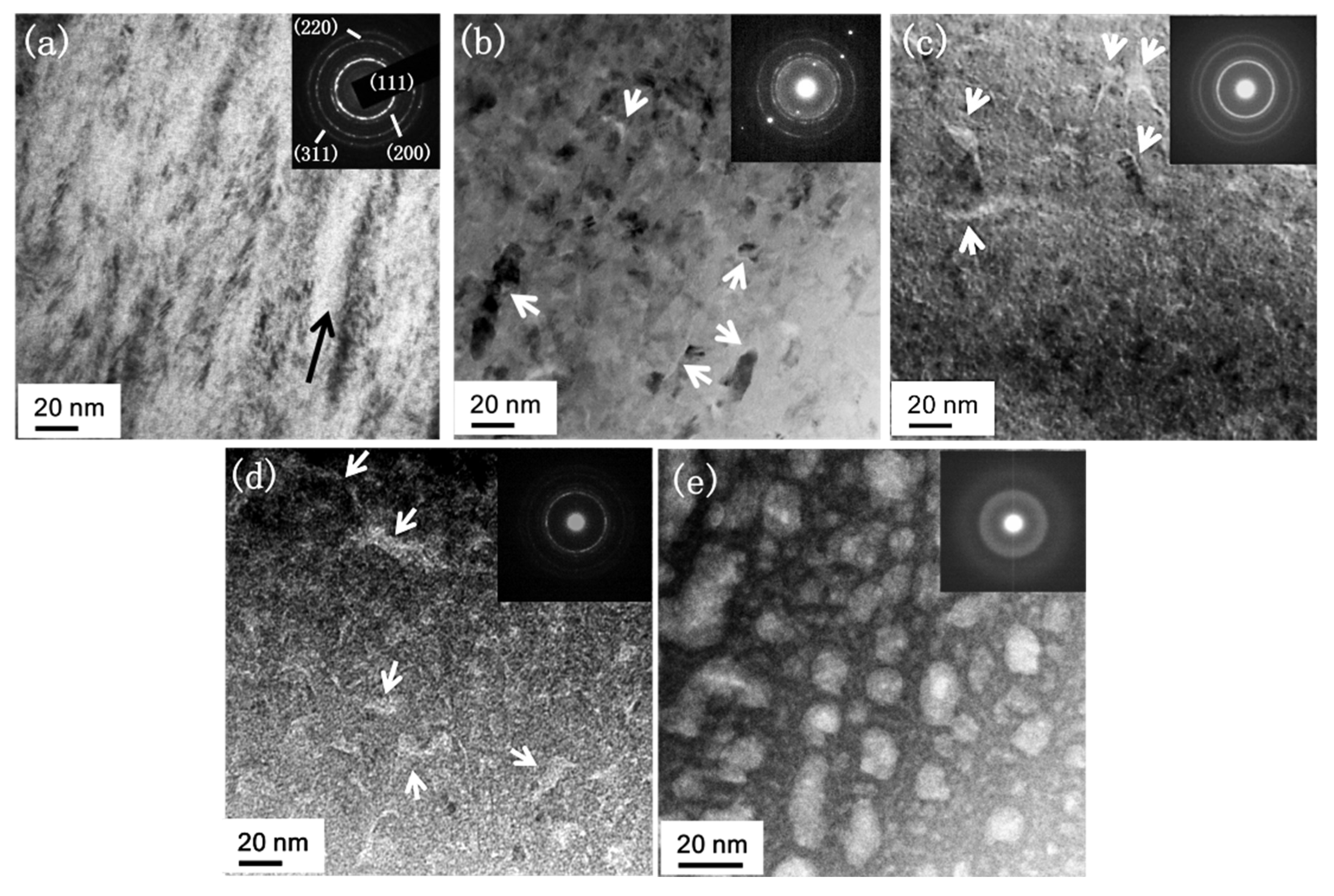

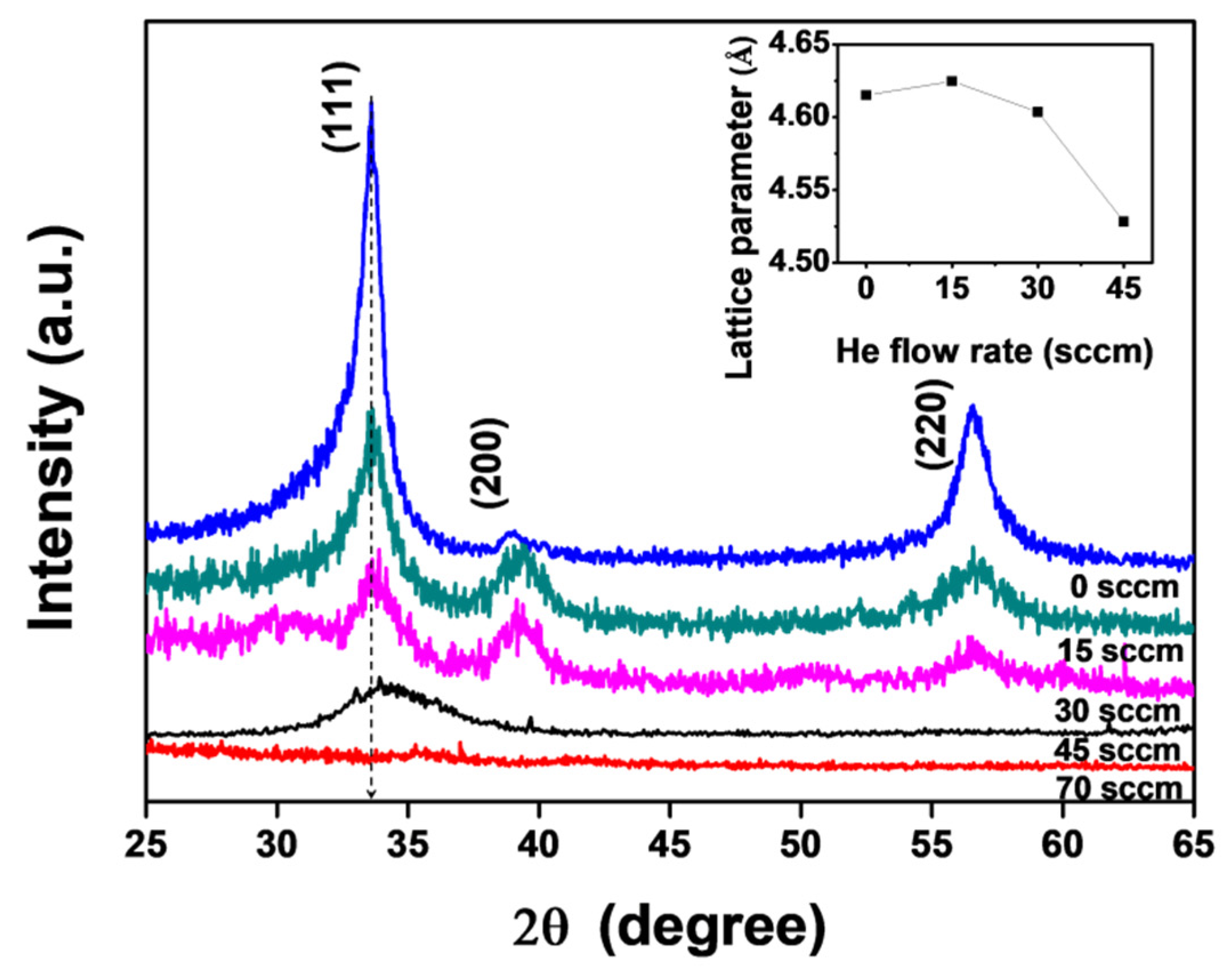

2.1. Microstructure Evolution with He Accumulation

2.2. Blistering on the Surface of ZrN Nanofilms

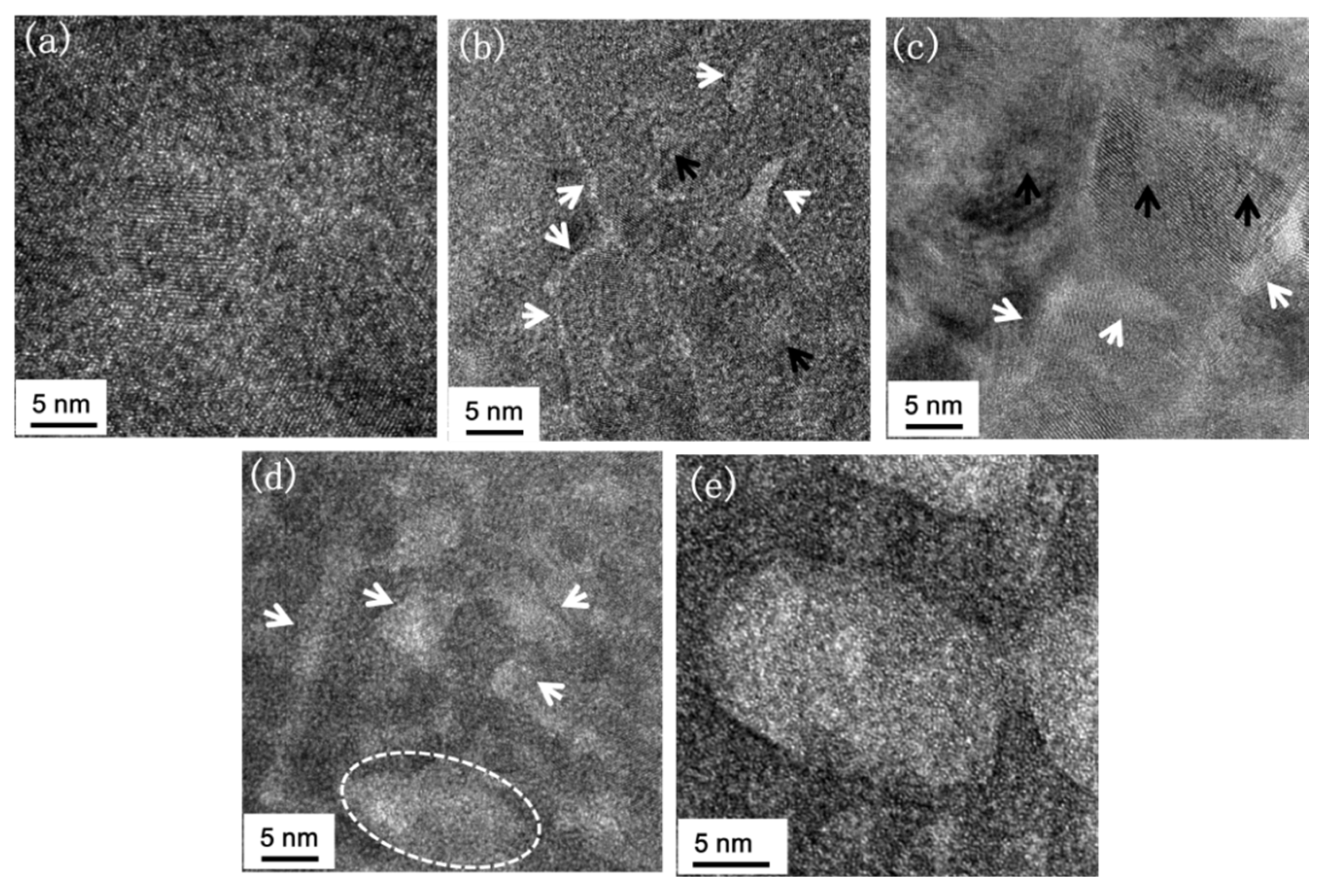

2.3. Interaction of He Bubbles and Grain Boundaries

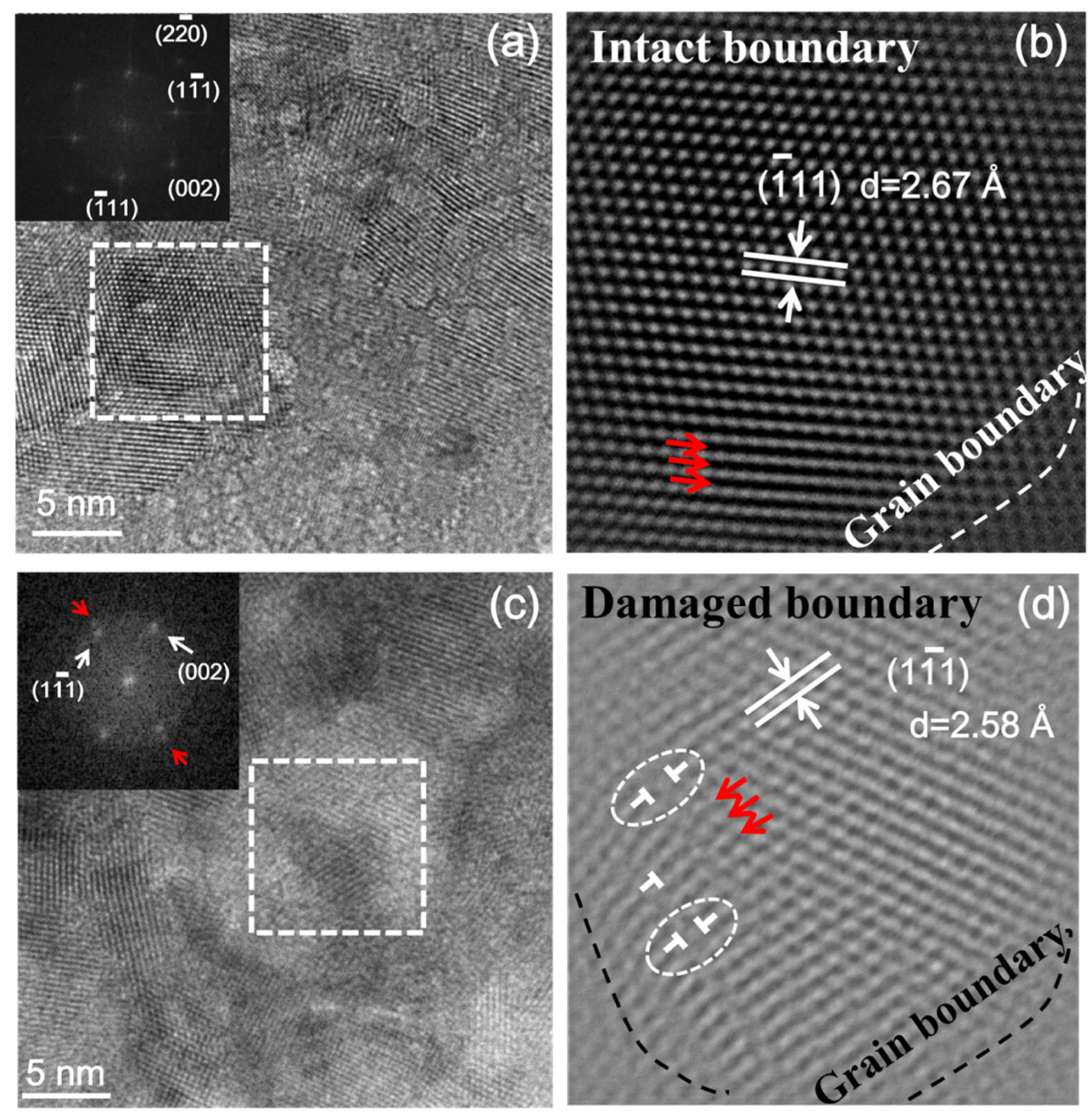

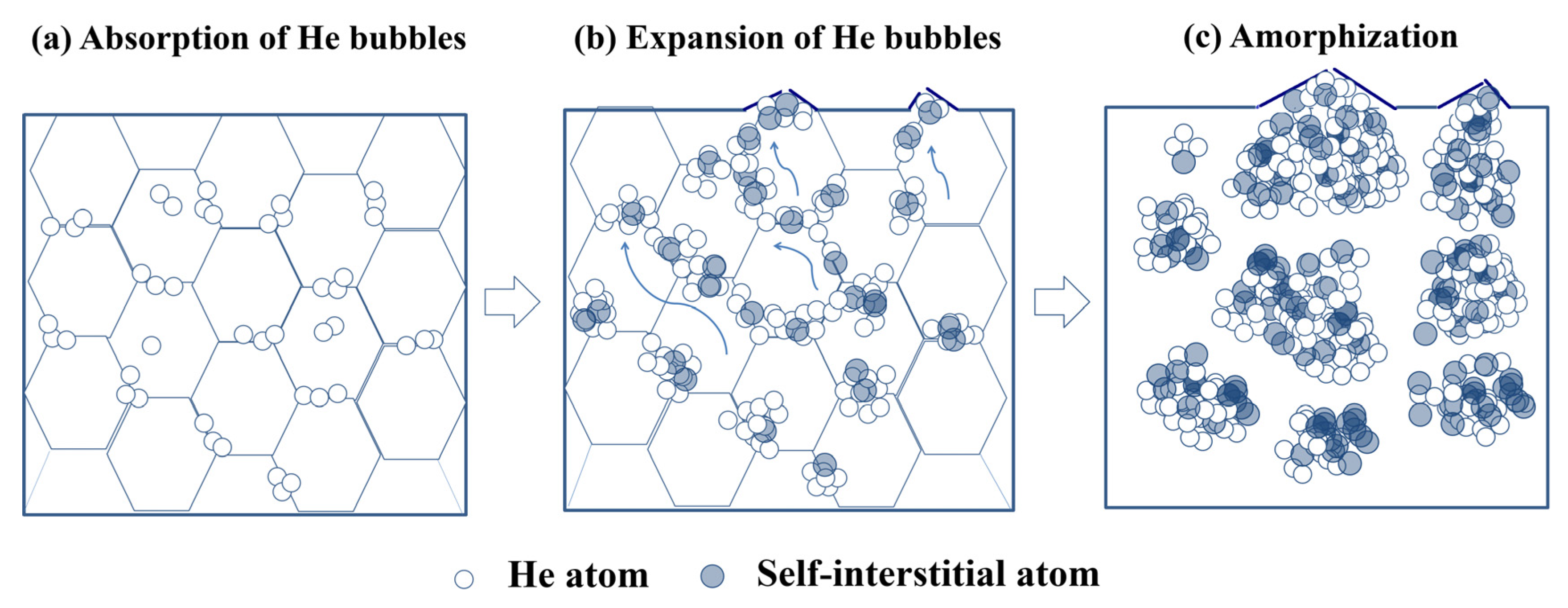

2.4. Degradation of Grain Boundaries Induced by He Accumulation

2.5. Mechanical Properties of ZrN Nanofilms

3. Discussion

4. Experimental Section

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Yang, W.; Pang, J.; Zheng, S.; Wang, J.; Zhang, X.; Ma, X. Interface effects on He ion irradiation in nanostructured materials. Materials 2019, 12, 2639. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.; Araujo, R.; Swadener, J.G.; Wang, Y.Q.; Zhang, X.; Fu, E.G.; Cagin, T. Ion irradiation effects in nanocrystalline TiN coatings. Nucl. Instrum. Methods Phys. Res. B 2007, 261, 1162–1166. [Google Scholar] [CrossRef]

- Jiao, L.; Chen, A.; Myers, M.T.; General, M.J.; Shao, L.; Zhang, X.; Wang, H. Enhanced ion irradiation tolerance properties in TiN/MgO nanolayer films. J. Nucl. Mater. 2013, 434, 217–222. [Google Scholar] [CrossRef]

- Kim, I.; Jiao, L.; Khatkhatay, F.; Martin, M.; Lee, J.; Shao, L.; Zhang, X.; Swadener, J.; Wang, Y.; Gan, J.; et al. Size-dependent radiation tolerance in ion irradiated TiN/AlN nanolayer films. J. Nucl. Mater. 2013, 441, 47–53. [Google Scholar] [CrossRef]

- Beyerlein, I.J.; Demkowicz, M.J.; Misra, A.; Uberuaga, B.P. Defect-interface interactions. Prog. Mater. Sci. 2015, 74, 125–210. [Google Scholar] [CrossRef]

- Sagaradze, V.V.; Kozlov, K.A.; Kataeva, N.V. Oxide-Dispersion Strengthened Radiation-Resistant Steels. Phys. Met. Metallogr. 2018, 119, 1350–1353. [Google Scholar] [CrossRef]

- Misra, A.; Demkowicz, M.J.; Zhang, X.; Hoagland, R.G. The radiation damage tolerance of ultra-high strength nanolayered composites. JOM 2007, 59, 62–65. [Google Scholar] [CrossRef]

- Kombaiah, B.; Zhou, Y.; Jin, K.; Manzoor, A.; Poplawsky, J.D.; Aguiar, J.A.; Bei, H.; Aidhy, D.S.; Edmondson, P.D.; Zhang, Y. Nanoprecipitates to Enhance Radiation Tolerance in High-Entropy Alloys. ACS Nano 2023, 15, 3912–3924. [Google Scholar] [CrossRef]

- Odette, G.R.; Alinger, M.J.; Wirth, B.D. Recent developments in irradiation-resistant Steels. Annu. Rev. Mater. Res. 2008, 38, 471–503. [Google Scholar] [CrossRef]

- Zinkle, S.J.; Busby, J.T. Structural materials for fission & fusion energy. Mater. Today 2009, 12, 12–19. [Google Scholar]

- Uglov, V.; Abadias, G.; Zlotski, S.; Kvasov, N.; Saladukhin, I.; Malashevih, A. Blister formation in ZrN/SiN multilayers after He irradiation. Surf. Coat. Technol. 2018, 355, 311–317. [Google Scholar] [CrossRef]

- Lasa, A.; Tähtinen, S.K.; Nordlund, K. Loop punching and bubble rupture causing surface roughening—A model for W fuzz growth. Europhys. Lett. 2014, 105, 25002. [Google Scholar] [CrossRef]

- Chen, C.; Zhang, Y.; Wang, Y.; Crespillo, M.; Fontana, C.; Graham, J.; Duscher, G.; Shannon, S.; Weber, W. Dose dependence of helium bubble formation in nano-engineered SiC at 700 °C. J. Nucl. Mater. 2016, 472, 153–160. [Google Scholar] [CrossRef]

- Muntifering, B.; Blair, S.J.; Gong, C.; Dunn, A.; Dingreville, R.; Qu, J.; Hattar, K. Cavity evolution at grain boundaries as a function of radiation damage and thermal conditions in nanocrystalline nickel. Mater. Res. Lett. 2015, 4, 96–103. [Google Scholar] [CrossRef]

- Van Vuuren, A.J.; Neethling, J.H.; Skuratov, V.A.; Uglov, V.V.; Petrovich, S. The effect of He and swift heavy ions on nanocrystalline zirconium nitride. Nucl. Instrum. Methods Phys. Res. B 2014, 326, 19–22. [Google Scholar] [CrossRef]

- Chen, C.; Zhang, Y.; Fu, E.; Wang, Y.; Crespillo, M.; Liu, C.; Shannon, S.; Weber, W. Irradiation-induced microstructural change in helium-implanted single crystal and nano-engineered SiC. J. Nucl. Mater. 2014, 453, 280–286. [Google Scholar] [CrossRef]

- Lao, Y.; Niu, W.; Shi, Y.; Du, H.; Zhang, H.; Hu, S.; Wang, Y. Effects of intragranular defects on helium accumulation damage in nanocrystalline nitrides. J. Alloys Compd. 2018, 739, 401–406. [Google Scholar] [CrossRef]

- Kleykamp, H. Selection of materials as diluents for burning of plutonium fuels in nuclear reactors. J. Nucl. Mater. 1999, 275, 1–11. [Google Scholar] [CrossRef]

- Wheeler, K.; Peralta, P.; Parra, M.; McClellan, K.; Dunwoody, J.; Egeland, G. Effect of sintering conditions on the microstructure and mechanical properties of ZrN as a surrogate for actinide nitride fuels. J. Nucl. Mater. 2007, 366, 306–316. [Google Scholar] [CrossRef]

- Janse van Vuuren, A.; Skuratov, V.; Uglov, V.; Neethling, J.; Zlotski, S. Radiation tolerance of nanostructured ZrN coatings against swift heavy ion irradiation. J. Nucl. Mater. 2013, 442, 507–511. [Google Scholar] [CrossRef]

- Taylor, C.A.; Patel, M.K.; Aguiar, J.A.; Zhang, Y.; Crespillo, M.L.; Wen, J.; Xue, H.; Wang, Y.; Weber, W.J. Bubble formation and lattice parameter changes resulting from He irradiation of defect-fluorite Gd2Zr2O7. Acta Mater. 2016, 115, 115–122. [Google Scholar] [CrossRef]

- Trinkaus, H.; Wolfer, W. Conditions for dislocation loop punching by helium bubbles. J. Nucl. Mater. 1984, 122, 552–557. [Google Scholar] [CrossRef]

- Bai, X.M.; Voter, A.F.; Hoagland, R.G.; Nastasi, M.; Uberuaga, B.P. Efficient annealing of radiation damage near grain boundaries via interstitial emission. Science 2010, 327, 1631–1634. [Google Scholar] [CrossRef]

- Wei, Y.; Liu, P.; Zhu, Y.; Wang, Z.; Wan, F.; Zhan, Q. Evaluation of irradiation hardening and microstructure evolution under the synergistic interaction of He and subsequent Fe ions irradiation in CLAM steel. J. Alloys Compd. 2016, 676, 481–488. [Google Scholar] [CrossRef]

- Zhu, Y.T.; Langdon, T.G. Influence of grain size on deformation mechanisms: An extension to nanocrystalline materials. Mater. Sci. Eng. A 2005, 409, 234–242. [Google Scholar] [CrossRef]

- Wang, L.; Zhang, Y.; Zeng, Z.; Zhou, H.; He, J.; Liu, P.; Chen, M.; Han, J.; Srolovitz, D.J.; Teng, J.; et al. Tracking the sliding of grain boundaries at the atomic scale. Science 2022, 375, 1261–1265. [Google Scholar] [CrossRef]

- Hu, J.; Shi, Y.N.; Sauvage, X.; Sha, G.; Lu, K. Grain boundary stability governs hardening and softening in extremely fine nanograined metals. Science 2017, 355, 1292–1296. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xiao, X.; Sun, S.; Jiang, W.; Qin, X.; Liu, Q.; Lao, Y. Nanocrystalline–Amorphous Transition in ZrN Nanofilms Induced by Helium Accumulation at Grain Boundaries. Inorganics 2025, 13, 158. https://doi.org/10.3390/inorganics13050158

Xiao X, Sun S, Jiang W, Qin X, Liu Q, Lao Y. Nanocrystalline–Amorphous Transition in ZrN Nanofilms Induced by Helium Accumulation at Grain Boundaries. Inorganics. 2025; 13(5):158. https://doi.org/10.3390/inorganics13050158

Chicago/Turabian StyleXiao, Xin, Sen Sun, Wei Jiang, Xiaoling Qin, Qinxin Liu, and Yuanxia Lao. 2025. "Nanocrystalline–Amorphous Transition in ZrN Nanofilms Induced by Helium Accumulation at Grain Boundaries" Inorganics 13, no. 5: 158. https://doi.org/10.3390/inorganics13050158

APA StyleXiao, X., Sun, S., Jiang, W., Qin, X., Liu, Q., & Lao, Y. (2025). Nanocrystalline–Amorphous Transition in ZrN Nanofilms Induced by Helium Accumulation at Grain Boundaries. Inorganics, 13(5), 158. https://doi.org/10.3390/inorganics13050158