Abstract

Halide perovskite solar cells (PSCs) exhibit remarkable potential for addressing global energy challenges due to their exceptional photovoltaic properties and cost-effectiveness. However, their widespread adoption is hindered by the presence of toxic lead in the perovskite materials, posing risks to both human health and the environment. This review comprehensively examines the environmental safety concerns associated with PSCs, focusing on the toxicity of lead and its potential for leakage during device operation and end-of-life disposal. Strategies to mitigate lead leakage are explored, including advanced external encapsulation methods, internal lead immobilization techniques, and innovative recycling approaches. These strategies are evaluated based on their effectiveness, feasibility, and potential challenges, highlighting the need for a multi-pronged approach to ensure the responsible and sustainable development of PSC technology. By addressing the toxicity issue and implementing robust prevention and recycling strategies, PSCs can become a driving force for the global transition towards clean and renewable energy while minimizing environmental and health risks.

1. Introduction

In recent years, metal halide perovskites (MHPs) have experienced remarkable advancements as a novel functional material, quickly becoming a focal point in the field of optoelectronics. MHPs exhibit several advantages, including ease of processing, low cost, high light absorption coefficients, high charge carrier mobility, and tunable optoelectronic characteristics [1], which have led to their widespread application in perovskite solar cells (PSCs) [2,3,4,5], light-emitting diodes (LEDs) [6,7,8], photodetectors [9], X-ray detectors [10], gas sensors [11], field-effect transistors [12,13], lasers [14], etc. Despite the rapid development in MHP-based optoelectronic technologies, some stability issues persist, such as ion migration, phase transitions, phase segregation, and component volatilization, which can lead to material degradation and performance deterioration of the devices, particularly under environmental stresses like high temperatures, high humidity, and ultraviolet (UV) exposure [4,15,16]. Furthermore, the deployment of PSC components in commercial applications often occurs in open fields or on rooftops, where they can be subjected to various weather and environmental factors, including debris, hail, snow, strong winds, and fires. In such scenarios, the performance of the devices can decrease dramatically, and since halide perovskites are ionic compounds, they are prone to decomposition into highly toxic soluble lead salts, halide anions, organic cations, and other components under the influence of moisture, heat, light, or mechanical stress. These constituents can subsequently leach into groundwater or soil along with rainwater, resulting in soil and water contamination [17,18,19]. Although the lead content in perovskite solar cell modules is only a few hundred milligrams per square meter, the high toxicity of lead to both humans and ecosystems necessitates a careful assessment and management of this issue before the widespread use of lead-based perovskite photovoltaic devices.

Regarding the toxicity issues of perovskites, the industry has raised the question of whether it is possible to achieve excellent optoelectronic performance using lead-free perovskites. Researchers have attempted to replace lead with other metals that have similar orbital configurations, such as group IV elements with identical valence electron configuration [20,21]. Among these, tin (Sn)-based perovskites have been the most extensively studied since Sn2+ has an ionic radius (118 pm) similar to that of Pb2+ (119 pm) [20,22]. Although Sn-based perovskites also exhibit excellent charge-transport properties, Sn2+ is readily oxidized to Sn4+ (standard reduction potential E0 for Sn2+/Sn4+ is 0.15 V, while E0 for Pb2+/Pb4+ is 1.67 V) [23], creating defects and degrading optoelectronic performance. Moreover, the acute toxicity of Sn2+ ions is considered higher than that of Pb2+ [24]. Germanium (Ge), another group IV element, has a smaller ionic radius (73 pm) and is more easily oxidized, leading to inferior stability of Ge-based perovskites [25]. Researchers have also explored other lead-free perovskites based on metals with ns2 orbital configurations, such as Bi3+, Sb3+, and Ag+ [26,27,28,29]. However, the metal halides derived from these metals typically form low-dimensional crystal structures, which exhibit wide bandgaps and poor charge transport [30]. Despite some progress in this field, both the power conversion efficiency (PCE) and stability of lead-free PSCs remain substantially inferior to their lead-based halide PSCs [31,32]. By now, lead-based perovskites remain the mainstream choice in terms of the outstanding optoelectronic properties [33]. Therefore, addressing the toxicity issue and mitigating the risk of lead leakage from PSC devices is crucial for the responsible and sustainable development of this promising technology.

To achieve this goal, a comprehensive understanding of the sources and pathways of lead exposure is essential. This involves evaluating the potential for lead release during various stages of the PSC life cycle, including device fabrication, operation, and end-of-life disposal. This review offers an in-depth analysis of the environmental risks linked to PSCs and highlights recent progress in reducing lead leakage. It will explore various strategies, including advanced encapsulation methods, chemical absorption techniques, and innovative recycling approaches, with a focus on their effectiveness, feasibility, and potential challenges. By shedding light on these critical issues, this review seeks to facilitate the development of PSCs into a truly sustainable and responsible technology that can drive the global transition towards clean and renewable energy.

2. Environmental Risks of Halide Perovskite Materials

2.1. Lead Toxicity of Halide Perovskites

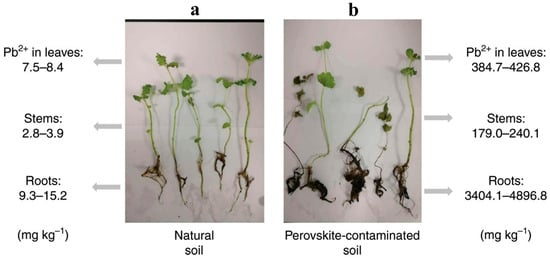

As a toxic heavy metal, lead disrupts critical biological functions and adversely impacts multiple organ systems. While its general health and environmental risks are well documented, the unique risks posed by lead leakage from MHP-based optoelectronic devices warrant focused attention. The toxicity of lead arises from its similarity to biologically essential ions (such as Ca2+, Fe2+, and Zn2+), enabling it to mimic these essential cations, compete for binding sites, and disrupt normal physiological functions, such as inhibiting calcium signaling and reacting with proteins [34]. Oxidative stress [35], carcinogenicity [36], and bioaccumulation further exacerbate its hazards [37]. Critically, MHP-derived lead introduces novel exposure pathways and ecological amplification effects. For example, experimental studies reveal that Pb leaked from perovskite degradation in soil disproportionately enhances plant uptake: mint plants grown in perovskite-contaminated soil (250 mg kg−1 Pb) absorbed 366-fold more lead than those in natural lead-polluted soil (36.3 mg kg−1 Pb), leading to rapid blackening, rotting, and death (Figure 1) [38]. Although the lead content in perovskite-contaminated soil only increased sevenfold, the absorption of lead by plants increased 366-fold. This highlights the heightened bioavailability of perovskite-associated Pb compared to conventional lead pollutants, threatening the ecological pyramid.

Figure 1.

Lead concentration in different parts of mint plants grown in (a) control soil and (b) perovskite-contaminated soil. Reprinted with permission from Ref. [38]. Copyright 2020 Springer Nature.

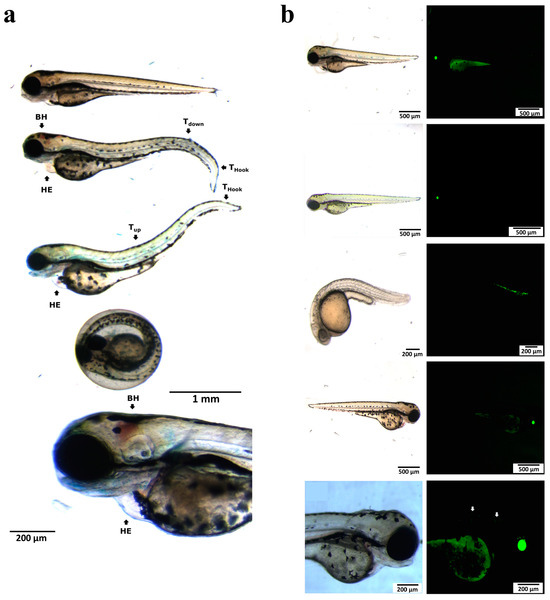

More importantly, lead exposure has long-term irreversible toxic effects on humans and animals, which have been confirmed by numerous studies. Babayigit et al. [24] demonstrated PbI2’s developmental toxicity using Danio rerio embryos (85% genetic similarity to humans), linking it to spinal curvature, cardiac edema, and brain vascular defects (Figure 2a). The analysis of heat shock protein 701 further confirmed concentration-dependent developmental impairment (Figure 2b). Such findings underscore the cascading risks of perovskite-derived Pb entering the food chain and affecting vulnerable populations, including infants and children.

Figure 2.

(a) PbI2-induced morphologically defective phenotypes of Danio rerio and the amplification of a cerebrovascular defect in PbI2-treated group. (b) Stereo (left) and fluorescence (right) images of Tg(hsp70l:GFP) of embryos treated with different PbI2 concentrations. Reprinted with permission from Ref. [24]. Copyright 2016 Springer Nature.

When the structure of MHPs is damaged, their perovskite material begins to collapse until complete degradation, and decomposition products such as PbI2 can easily dissolve in water on rainy days. Then, lead from MHPs may contaminate water and crops, entering the human body. Lead accumulates in bones (half-life: 40–50 years) and organs, causing anemia, neurodevelopmental disorders, and systemic damage [34,39]. Higher exposure levels and younger age (especially fetuses) increase toxicity. Excessive lead affects multiple systems, causing anemia, kidney damage, high blood pressure, and neurological disorders [40,41,42,43,44]. For children, blood lead levels exceeding 100 μg L−1 define poisoning, necessitating strict limits on MHP devices used in child-accessible applications. A large-scale deployment of perovskite photovoltaic devices in the future would magnify these risks. While current lead content in perovskite solar cells (0.1 mg cm−2) is lower than in silicon modules [45,46,47], if all electricity in China and globally were to be supplied by perovskite PV devices, about 493 tons of lead per year in China and 1325 tons globally would be required (assuming 20% efficiency). This scale, driven by rising energy demands from AI and data centers, positions perovskite-derived lead pollution as a critical future challenge. Currently, existing relevant regulations, such as the EU’s RoHS2 (2011/65/EU) (no more than 0.1% Pb by weight in electronic products) [48], may not be sufficient to address the lifecycle risks of MHPs in the future, emphasizing the need for device–human isolation strategies and leakage prevention, especially for indoor applications. In short, the hazards of lead poisoning should be taken seriously and effectively addressed.

2.2. Mechanism and Effect of Lead Leakage

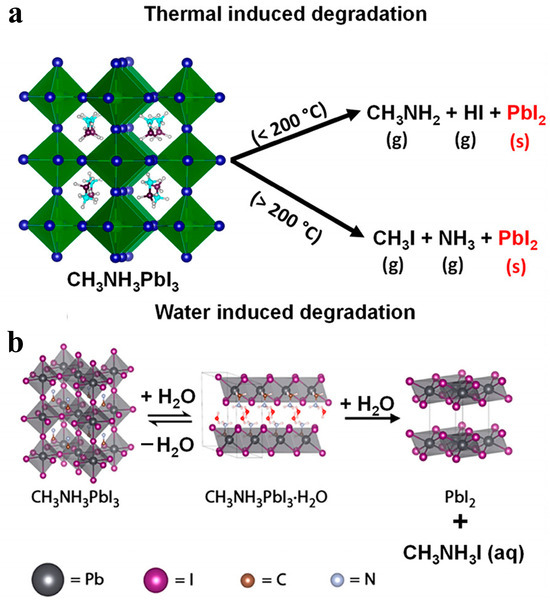

Lead mainly exists as divalent ions (Pb2+) in PSCs. The decomposition pathways of MHPs under thermal, aqueous, and environmental stresses have been extensively studied. The degradation mechanism of MAPbI3 exhibits temperature-dependent behavior (Figure 3a): below 200 °C, it primarily decomposes into volatile HI and CH3NH2 while retaining solid PbI2; above this thermal threshold (>200 °C), the decomposition shifts toward producing thermodynamically favored gaseous species including NH3 and CH3I, with a persistent formation of crystalline PbI2 as the inorganic residue [33]. Recent studies have provided deeper insights into the aging atomistic pathway of perovskite MAPbI3 through combined theoretical and experimental approaches [49,50]. At the atomic scale, MAPbI3 degradation follows a two-step pathway: (1) the initial loss of MA+ cations, forming a metastable intermediate phase MA0.5PbI3 with ordered MA+ vacancies that preserves the perovskite framework and (2) subsequent collapse into 6H-PbI2 via Pb2+ and I− diffusion, as revealed by atomic-resolution TEM imaging and DFT calculations [49,50]. This process aligns with the aforementioned thermal decomposition trends.

Figure 3.

(a) Thermally induced degradation reaction of MAPbI3. Reprinted with permission from ref. [33]. Copyright 2020 American Chemical Society. (b) Water-induced degradation reaction of MAPbI3. Reprinted with permission from Ref. [51]. Copyright 2020 John Wiley and Sons.

In aqueous environments (Figure 3b), MAPbI3 perovskite undergoes a spontaneous irreversible dissolution process, forming hydrated intermediates (APbX3·H2O) with one-dimensional [PbI3]− double chains (Equation (1)) [51]. Subsequently, the perovskite surface dissolves rapidly first, exposing I− and forming stronger Pb-I bonds on the surface. The low-dimensional hydrated perovskite decomposes into I2 under ultraviolet or light exposure, further promoting the degradation process (Equations (2) and (3)) [51]. Since there is a strong hydrogen bond between PbX2 and water molecules, PbX2 has a high solubility constant in water (Ksp ≈ 9.8 × 10−9) [52], making it easy to dissolve in water and enter the environment. In acidic environments (such as under acid rain conditions), the irreversible flow of Pb2+ from broken devices into water accelerates significantly (Equation (4)), causing more severe Pb leakage and environmental pollution [51]. While mixed cationic systems (such as FA0.85Cs0.15PbI3) have been shown to exhibit relatively good stability, phase segregation is known to occur under humid and light conditions, and PbI2 degradation products are also inevitably formed [53]. Crucially, PbI2 serves as the primary lead reservoir across degradation scenarios, with its hydrolysis and dissolution being the dominant pathways for environmental lead release. The understanding of this mechanism is helpful for the subsequent analysis and discussion of lead storage strategy.

(A = MA, FA, Cs, or mixture; X = Br, I, or mixture)

(4 − n)APbX3 + nAPbX3∙H2O + (2 − n)H2O ↔ A4PbX6∙2H2O + 3PbX2

A4PbX6∙2H2O → PbX2 + 4A+ + 4X− + 2H2O

PbX2 + 2H3O+ → Pb2+ + 2HX + 2H2O

3. Strategies of Lead Leakage Suppression for Perovskite Solar Cells

3.1. External Encapsulation

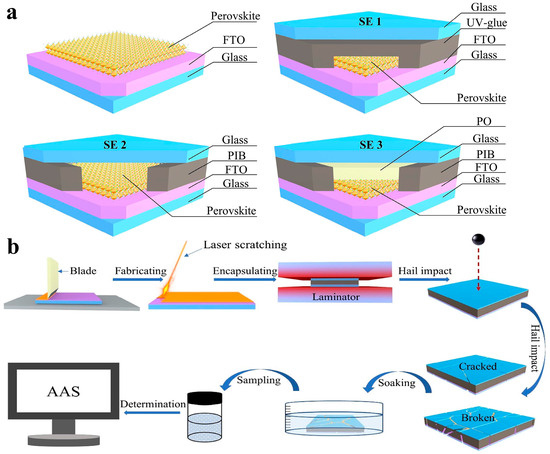

Lamination encapsulation constitutes a mature protective method in photovoltaic module manufacturing, effectively isolating the device from ambient environmental degradation factors [54]. Photovoltaic modules are typically encapsulated with ethylene-vinyl acetate (EVA, a copolymer synthesized from ethylene and vinyl acetate), sandwiched between a tempered front glass pane and a reinforced back sheet to provide mechanical protection and environmental isolation for the solar cells [55]. A five-layer stack structure of glass/EVA/PSC/EVA/glass has been adopted for encapsulating PSCs, significantly enhancing the operational stability of the devices [56,57]. EVA has the advantages of good light transmittance, elasticity, adhesion strength to glass, and melt flowability. Therefore, EVA can protect the devices without affecting their efficiency and has been used as an encapsulation material in nearly 80% of photovoltaic modules. The usual UV-curing adhesive was also reported to encapsulate PSCs for better stability [58,59,60]. In addition, new encapsulation materials and encapsulation methods with better sealing effects and suppression of lead leakage have been developed. For example, Wan et al. combined two encapsulants, polyolefin (PO) and polyisobutylene (PIB), to develop a “sandwich” encapsulation method in which PO was coated on top of the electrode, and the sides of the PSCs were encapsulated with PIB, as shown in Figure 4a [61]. After these devices were damaged under the same conditions, they were immersed in solutions with different pH values (simulating seawater, lake water, and rainwater) to assess the lead leakage (Figure 4b). This “sandwich” encapsulant greatly reduced the damage to the devices caused by hail and acid rain. Under the protection of the “sandwich” encapsulation, the lead leakage in the soil was reduced to 3.4 ppm [61], which is much lower than the 70 ppm predicted by Hailegnaw et al. in 2016 [62].

Figure 4.

(a) Unencapsulated perovskite devices and devices with different “sandwich” encapsulation methods. (b) Schematic diagram of the lead leakage testing process of PSCs. Reprinted with permission from Ref. [61]. Copyright 2021 Elsevier.

However, traditional EVA and PO/PIB sandwich encapsulation methods suffer from limitations such as thermomechanical stress-induced delamination and insufficient edge sealing under extreme weather conditions. To address this issue, Wang et al. [63] reported a room-temperature self-cross-linked fluorosilicone polymer (CFDP) that achieved nondestructive encapsulation without requiring high-temperature processing. This material demonstrated exceptional moisture barrier properties, maintaining 98% of normalized PCE after 1000 h in damp heat (85 °C/85% RH) and reducing lead leakage to <0.08 ppm in rainwater immersion tests [63]. The CFDP’s strong coordination with Pb2+ ions and high thermal conductivity (0.51 W m−1 K−1) effectively mitigated heat-induced perovskite decomposition, addressing a critical limitation of traditional encapsulants like EVA and PIB. Recently, Mariani et al. [64] also reported a low-temperature strain-free encapsulation technology using a PIB/hexagonal boron nitride (h-BN) composite. The addition of two-dimensional h-BN flakes enhances the thermal management and barrier properties of the encapsulant. This encapsulation strategy eliminates edge sealants while passing IEC 61215-standard [65] tests (85 °C/85% RH and −40 to 85 °C thermal cycling) with lead leakage below 100 ppb [64]. This strategy minimizes dead zones and is applicable to various cell configurations, including semi-transparent PSCs for building-integrated photovoltaics (BIPVs), with significant potential for large-scale production and commercialization.

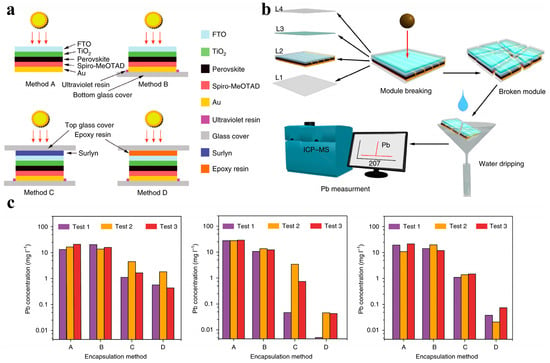

In the practical application of perovskite photovoltaic devices, lead leakage is not only caused by intrinsic material degradation but more critically from mechanical damage under extreme environmental stressors. For instance, abrupt temperature fluctuations or hail impacts can fracture conventional encapsulation layers, exposing the perovskite active layer and accelerating lead ion diffusion into the environment. To systematically evaluate the efficacy of encapsulation strategies in mitigating lead leakage from damaged PSC modules, Jiang et al. conducted a realistic simulation of mechanical damage (e.g., hail impact) and performed quantitative analysis of lead leakage rates under simulated environmental conditions (Figure 5) [66]. Their comparative study of four encapsulation architectures revealed that lead leakage exhibits a strong dependence on encapsulation design and environmental factors. Notably, combining self-healing polymers with front-side glass encapsulation proves effective in reducing lead leakage. In particular, epoxy resin (ER)-based polymers with a relatively low transition temperature (about 42 °C) are easy to heal at high temperatures, and it is more effective in reducing the lead leakage rate from 30 mg h−1 m−2 to 0.08 mg h−1 m−2 in comparison with the method of encapsulating with UV-cured resin-covered glass [66]. These results show that using the appropriate encapsulation materials and methods is the most direct strategy to inhibit lead leakage. The high mechanical strength and self-healing mechanism of ER film can effectively reduce the lead leakage in PSCs, providing new insights into the encapsulation methods of PSCs.

Figure 5.

(a) Schematic diagram of four encapsulation methods. (b) Schematic diagram of Pb leakage test for perovskite solar module damaged by external impact. (c) Lead concentration test under different experimental conditions. Reprinted with permission from Ref. [66]. Copyright 2019 Springer Nature.

Although appropriate encapsulation architectures can initially inhibit the leakage of lead from PSCs, their long-term operational reliability remains constrained by environmental stressors. Mechanical degradation or chemical corrosion of encapsulation layers, triggered by thermal cycling, exposure to moisture, or physical shock, creates microcracks and interfacial delamination that enable water-soluble Pb2+ species to rapidly escape into the surrounding environment via hydrolysis pathway, posing significant ecological risks [67]. Therefore, simple encapsulation may not be sufficient to completely inhibit lead leakage. In contrast, chemical encapsulation utilizes special lead-capturing materials within the encapsulation matrix to immobilize lead ions through the formation of stable insoluble compounds, as well as their chemical conversion to low-toxicity chelates through coordination bonds. This dual-action approach effectively reduces lead bioavailability and mobility in ecosystems. Coating the front and back of a complete solar cell with an encapsulation layer containing lead capture materials is the most reported effective strategy for PSCs. Compounds containing phosphine [45,68], sulfonic acid [69,70], and carboxyl [71] with strong binding ability to lead ions are usually chosen as lead capture materials. Recently, a series of PSC chemical encapsulation materials and strategies with multiple functions such as enhanced stability, improved resistance to mechanical impact, and reduced lead leakage have been reported.

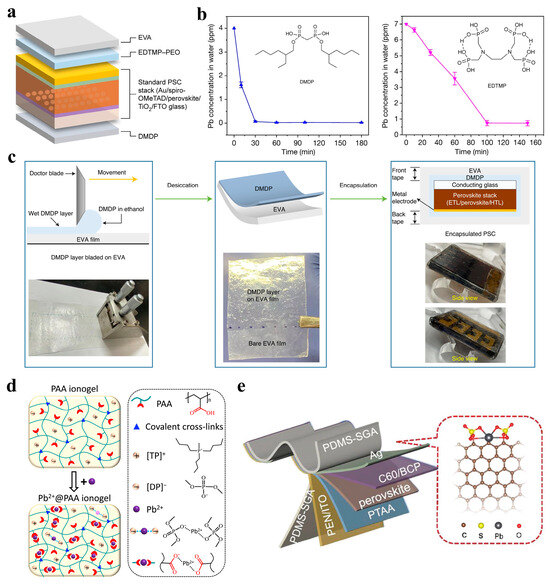

Li et al. developed a dual-side chemical encapsulation strategy for PSCs, employing distinct functional layers on opposing surfaces [45]. For frontal protection, they implemented a transparent P,P′-di(2-ethylhexyl) methylenediphosphonic acid (DMDP) coating on glass substrates, leveraging its dual phosphonic acid moieties per molecule to strongly chelate Pb2+ ions (Figure 6a). The rear encapsulation comprised a composite film blending N,N,N′,N′-ethylendiaminetetramethylphosphonic acid (EDTMP), a potent lead-chelating agent, with polyethylene oxide (PEO), subsequently laminated with EVA. As demonstrated in Figure 6b, both the DMDP and EDTMP-PEO layers exhibited exceptional Pb2+ adsorption capacities. Crucially, these films exhibited swelling rather than dissolution upon water exposure, enabling >96% Pb2+ retention within damaged devices through physical entrapment and chemical immobilization. Extending this approach, the team engineered an innovative Pb-capturing adhesive by depositing DMDP onto EVA sheets, creating a multifunctional “transparent tape” for device encapsulation (Figure 6c) [72]. This design demonstrated remarkable environmental resilience, maintaining >99.9% Pb absorption efficiency during week-long outdoor exposure while preserving photovoltaic performance. The delayed Pb release mechanism provides critical time windows for post-damage remediation without compromising initial device functionality.

Figure 6.

(a) The device structure consists of two lead absorbing films (DMDP and EDTMP-PEO). (b) Chemical structure and lead trapping capacity of DMDP and EDTMP. Reprinted with permission from Ref. [45]. Copyright 2020 Springer Nature. (c) The fabrication and encapsulation process of DMDP and EVA. Reprinted with permission from Ref. [72]. Copyright 2021 Springer Nature. (d) Scheme of ionogel microstructure and lead adsorption mechanism. Reprinted with permission from Ref. [73]. Copyright 2021 AAAS. (e) Schematic of flexible PSCs encapsulated with S-GA/PDMS mixture on both the front side and back side. Reprinted with permission from Ref. [74]. Copyright 2021 Wiley-VCH.

From a physical mechanics perspective, enhancing the impact resistance of devices can reduce the likelihood of device damage, thereby minimizing lead leakage. Xiao et al. [73] reported a robust and self-healing ionic gel containing lead-adsorbing acrylic acid (AA) and tributyl(methyl)phosphonium dimethylphosphinate (TPDP) ionic liquid, which can be used as a component of encapsulation material for PSCs, simultaneously reducing lead leakage and enhancing device stability (Figure 6d). Wrapping the front and back of PSCs with an ionic gel layer, and subjecting them to a simulated hail test followed by a 24 h water immersion, resulted in lead leakage from the damaged PSC modules of less than 1 ppb, which was undetectable by the instrument. This encapsulation method is more effective in suppressing lead leakage than PO sealant and standard glass cover encapsulation. The high impact resistance of stretchable encapsulation materials and the strong lead-binding ability of AA monomers are the main reasons for their high lead fixation performance. As shown in Figure 6d, the carboxyl radicals on polyacrylic acid (PAA) are the functional groups for capturing Pb2+. Thanks to the clamp-like cross-linked polymer network of PAA, this encapsulant is very effective in preventing lead leakage. Li et al. [74] developed an encapsulation method for flexible PSCs in which they mixed sulfonated graphene aerogel (S-GA) with PDMS as a lead-absorbing encapsulant and placed it on both sides of the device, as shown in Figure 6e. The large specific surface area and excellent flexibility of S-GA provide sufficient adsorption sites to capture dissociated lead ions, forming strong ionic bonds with Pb2+ through SO32−, giving it superior lead capture ability in aqueous solutions. Under various simulated conditions, such as scraping, bending, wrinkling, and thermal cycling, the encapsulant can capture more than 99% of the leaked lead from damaged flexible PSCs. This method can reduce the lead leakage after the degradation of flexible PSCs to 10 ppb, far below the hazardous waste limit specified by the US Resource Conservation and Recovery Act [74]. This is a pioneering experimental study on the lead leakage dynamics of flexible PSCs and assesses the efficacy of sulfonated aerogel encapsulation under realistic environmental conditions, offering critical insights for developing safe and reliable flexible PSCs and advancing the commercialization of perovskite-based electronic devices.

Recently, nanostructured adsorption layers have emerged as a promising strategy for mitigating lead leakage in perovskite photovoltaics. Valastro et al. demonstrated this concept through the development of a titanium dioxide (TiO2) sponge layer synthesized via a scalable, solvent-free sputtering process [75]. The porous structure of TiO2 layer allows high surface reactivity and accessibility, capturing Pb ions within branched nanopores. Experimental results indicate this approach significantly reduces Pb release into water. For instance, after soaking in water for ten days, the Pb concentration in water with TiO2-covered PSCs was 0.26 ppm, compared to 2.65 ppm in uncovered PSCs, demonstrating a Pb sequestration efficiency (SQE) of 90.2% [75]. Even under simulated heavy rainfall conditions, the TiO2 layer achieved an average SQE of 89%. This method offers a sustainable solution for preventing environmental contamination from perovskite devices.

3.2. Lead Immobilization Within PSCs

In addition to physically or chemically encapsulating the entire external structure of the device, incorporating lead-absorbing materials internally can serve as an “additional line of defense” against Pb leakage. Although the addition of lead trapping materials in the PSC encapsulation layers can prevent the ingress of water and oxygen and effectively suppress lead leakage from the device, the lead capture materials on the front of the PSCs are inevitably exposed to ultraviolet radiation from sunlight and may become damaged after prolonged exposure, thereby generating free Pb ions. In PSCs that are not completely damaged, the lead capture materials on the back of the device cannot capture lead that leaks from the front. Moreover, lead capture materials on the surface of the device, when soaked in rainwater for extended periods, may also adsorb other cations such as Cd2+, Ca2+, Mg2+, etc., which can lead to saturation of the metal ion capture function and loss of the ability to continuously adsorb subsequently leaking Pb ions. In contrast, incorporating lead adsorption materials within the PSCs can effectively avoid these issues. This strategy of incorporating lead-absorbing materials internally provides an ideal method that can rapidly capture Pb2+ as soon as the perovskite is decomposed by rainwater, and the impact of external factors such as rainwater and ultraviolet light on the lead capture materials is minimal.

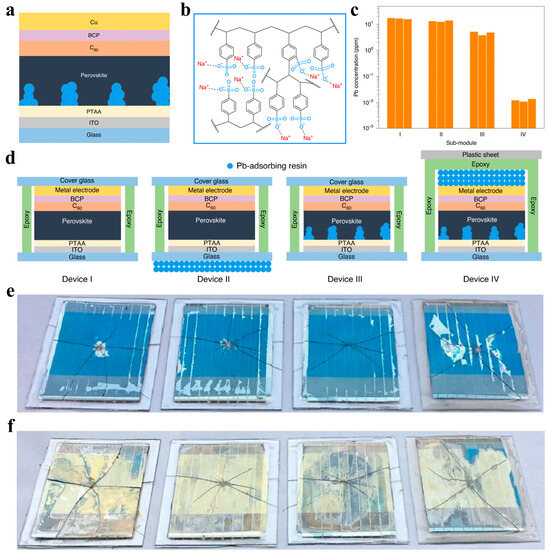

An effective approach involves directly incorporating lead-absorbing materials into the perovskite layer to enhance both its stability and lead capture ability. Chen et al. [70] reported an impressive work, where they developed a novel approach to mitigate lead leakage from damaged perovskite solar modules by incorporating a mesoporous sulfonic acid-based cation exchange resin (CER) directly into the perovskite layer, as shown in Figure 7a. The resin, composed of a cross-linked styrene-divinylbenzene copolymer functionalized with sulfonic acid groups (Figure 7b), operates through a dual mechanism of “ion exchange” and “physical blocking”. The sulfonic acid groups act as active adsorption sites, where the Na+ ions in the resin undergo ion exchange with Pb2+ ions from decomposed perovskites under aqueous conditions (e.g., acidic rainwater). This process is driven by the strong affinity of sulfonic acid groups for divalent cations like Pb2+, effectively trapping them within the resin’s porous matrix. The mesoporous structure further enhances adsorption capacity by providing a high density of accessible binding sites and prolonging the interaction time between Pb2+ and the resin. The authors systematically evaluated Pb leakage in perovskite modules with varying encapsulation strategies through water-dripping tests, simulating highly acidic rainfall conditions (Figure 7c–f). As evidenced by the results of lead leaching concentrations in Figure 7c, the strategy of embedded mesoporous CER within the perovskite layer (Device III) is more effective in preventing lead leakage than just coating lead capture materials on the device’s surface (Device II). This built-in lead adsorption framework serves as the first layer of protection against lead leakage, which can be further combined with appropriate external encapsulation to synergistically produce better lead leakage inhibition results, achieving an impressive lowest Pb concentration of 11.9 ± 1.4 ppb.

Figure 7.

(a) The device structure of PSCs containing CERs. (b) The chemical structure of CERs. (c) Concentrations of lead in polluted water from four types of devices. (d) Schematic diagram of four different encapsulation devices. (e,f) PSCs after (e) damage and after (f) water-dripping tests. Reprinted with permission from Ref. [70]. Copyright 2021 Springer Nature.

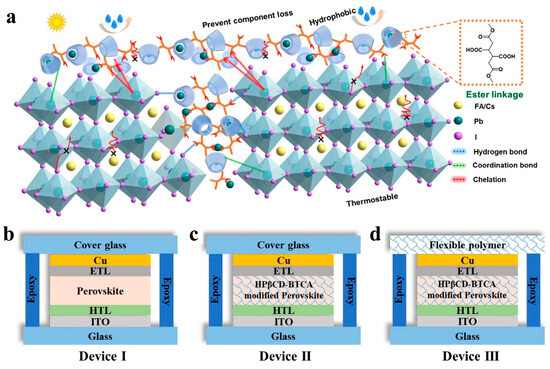

In addition to lead adsorbing resins, a variety of polymers, organic small molecules, and metal–organic framework (MOF) materials containing amide and carboxyl groups have been developed as lead adsorption materials and added to the perovskite layer. Depending on their structural design, these materials can serve multiple functions: in addition to capturing the leaking lead ions, they can also promote the nucleation and crystallization of perovskite, passivate grain boundary defects, and block the ingress of water vapor. Our group also has proposed a comprehensive strategy of supramolecular complex network to solve the lead leakage issue [46]. As shown in Figure 8a, the cross-linking supramolecular complexes of 2-hydroxypropyl β-cyclodextrin (HPβCD) and 1,2,3,4-butane tetracarboxylic acid (BTCA) were introduced into perovskite films, which were shown to improve the stability of the entire process from perovskite precursor to film and final device, effectively inhibiting lead leakage from severely damaged PSCs and reducing lead toxicity. The built-in HPβCD-BTCA cross-linking complex modification increases the PCE of PSCs to 22.14% and extends the working life to 4000 h. In addition, the external package, combined with the chemical chelation of the built-in supramolecular complex and the flexible HPβCD-BTCA fiber membrane (Figure 8b), retains 97% of the initial efficiency after 522 h of dynamic water scouring, with minimized lead leakage from severely damaged PSCs and resulting in only 14 ppb lead contamination in water [46].

Figure 8.

(a) Schematic illustration of chemical interactions between cross-linking HPβCD-BTCA supramolecular complex and perovskite structure. (b–d) Schematic of device configurations with different perovskite films and encapsulation modes. Reprinted with permission from Ref. [46]. Copyright 2023 Springer Nature.

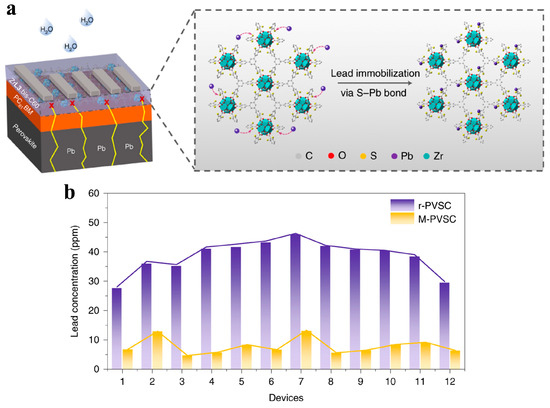

Alternatively, the lead capture materials can be added to the charge transport interface, acting as an interface modifier. In particular, the electron transport layer (ETL) and hole transport layer (HTL), which are adjacent to the perovskite layer, can capture Pb ions immediately upon the occurrence of lead leakage from the perovskite layer. Wu et al. used a two-dimensional conjugated MOF and applied it as an electron extraction layer and lead absorption layer at the perovskite/cathode interface [76]. The Zr (IV)-based MOF ZrL3 was prepared by solvothermal method, and its densely arranged thiol groups provided spatial shielding and had cross-linked disulfide bonds to capture free lead ions. As shown in Figure 9a, Pb2+ from perovskite dissociation did not accumulate on the Ag electrode in the component with the MOF layer, demonstrating that lead ions are trapped by forming Pb-S bonds with the MOF to form insoluble complexes. The concentration of Pb2+ in polluted water for PSCs with ZrL3:bis-C60 as the ETL (7.6 ppm) was much lower than that for control PSCs with bis-C60 as the ETL (38.4 ppm, Figure 9b), indicating that more than 80% of Pb2+ ions leaked from degraded PSCs could be captured by ZrL3. This significantly reduced lead leakage due to the formation of water-insoluble Pb2+-ZrL3 complexes by thiolated ZrL3 capturing free Pb2+ ions. These results show that in PSC devices, the ETL can also serve multiple functions, improving the long-term operational stability of the device while reducing lead leakage into the environment.

Figure 9.

(a) Schematic illustration of the lead immobilization by the S-Pb bond between the perovskite and ZrL3. (b) Test of Pb concentration in the contaminated water. Reprinted with permission from Ref. [76]. Copyright 2020 Springer Nature.

Additionally, the surface of the perovskite layer can be further post-treated, such as with thiol modification, to improve its hydrophobicity and photostability. Other strategies based on surface or interface engineering have also been employed to suppress lead leakage, including superhydrophobic barrier layers, biomimetic shielding interfaces, and polymer resin protective layers [33,66,70,77]. In summary, integrating lead capture materials into the perovskite layer, using post-synthesis treatments, and incorporating these materials at charge transport interfaces are effective strategies for reducing lead leakage of PSCs. In order to alleviate end-user concerns and accelerate the commercialization and practical application of perovskite photovoltaic devices, there is a need to develop more durable, environmentally friendly, and sustainable photovoltaic devices. In this regard, the exploration of optimal strategies for mitigating Pb leakage from MHPs without compromising device performance is a research direction that merits sustained attention.

4. Sustainable Lead Recovery for Perovskite Solar Cells

Controlling lead leakage in PSCs directly mitigates lead-related health risks and environmental damage. Yet, as the perovskite photovoltaic industry expands, lead will inevitably disperse into the environment over time. Consequently, establishing robust recycling protocols throughout the lifecycle of perovskite devices becomes crucial. Developing an integrated, cost-effective, and secure approach to recover lead and other valuable materials from PSCs is essential. This recovery process significantly diminishes lead contamination risks, conserves resources, reduces manufacturing time, and decreases energy payback periods. Creating a circular economy model with closed-loop recycling represents the foundation for sustainable large-scale commercialization of perovskite photovoltaic technology.

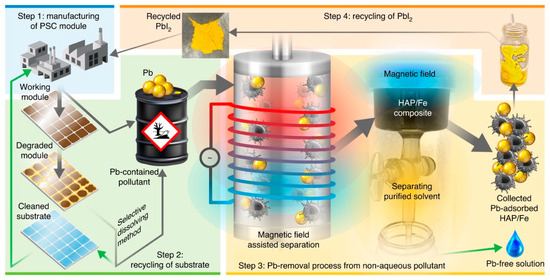

Recent advancements have yielded multiple methodologies for the extraction and recovery of lead [33,78,79,80,81]. Park et al. first used dimethylformamide (DMF) to remove the metal electrode, charge transport layer, and dissolved perovskite (Figure 10) [82]. They employed surface negatively charged iron-modified hydroxyapatite (HAP/Fe) hollow composites, effectively reducing lead concentration to below 15 ppb. Due to the difference in water solubility between HAP/Fe and PbI2, adding 1 M KI solution can recover PbI2 with a recovery rate as high as 99.97%. Finally, they fabricated a device using the recovered materials and achieved a PCE of approximately 18%, comparable to that achieved with commercial PbI2.

Figure 10.

Schematic diagram of PSC preparation and lead-containing pollutant recycling. Reprinted with permission from Ref. [82]. Copyright 2020 Springer Nature.

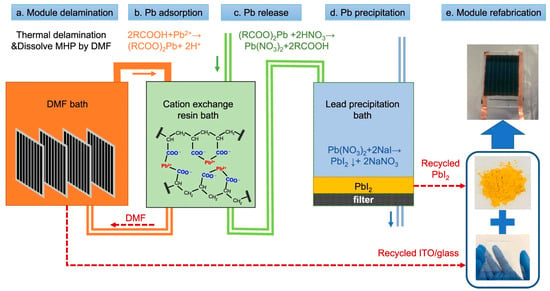

Chen et al. [83] also used DMF to dissolve the perovskite layers after delaminating the encapsulated devices (Figure 11). They then absorbed lead from the dissolved material using CER and subsequently released it into a clean solvent. The PCE results of PSCs prepared with PbI2 of different purities showed that the PCE based on recycled PbI2 was 20.4%, slightly lower than that of commercial PbI2 with 99.99% purity (21.0%) but higher than that of commercial PbI2 with 99% purity (19.4%).

Figure 11.

Roadmap for recycling perovskite solar modules. Reprinted with permission from Ref. [83]. Copyright 2021 Springer Nature.

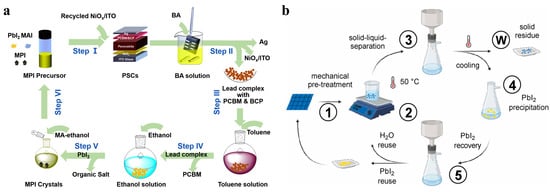

A plethora of alternative chemical reagents that are effective in dissolving lead-containing compounds have also been utilized to address the issue of lead recycling in PSCs. As shown in Figure 12a, butylamine (BA) was used to collect valuable materials (lead iodide, PCBM, organic amine salts, NiOx/ITO, and metal electrodes) in perovskite devices, and a series of recovery procedures were designed to recycle these materials [84]. This strategy achieved a high total Pb recovery rate of more than 98.9%, effectively completing the closed-loop of recycling and remanufacturing of the entire perovskite photovoltaic device. Deng et al. [85] screened several polar Pb solubilizers (DMF, DMSO, and BA) and selected DMF as the optimal solvent (strong solubility and weak C=O-Pb coordination) for dissolving Pb in PSCs. Then, KI was used as a multifunctional precipitant to recover high-purity PbI2 (96.03%). The recovered PbI2, enriched with K+ ions, reduced defects and residual strain, enabling re-fabricated PSCs to achieve a record efficiency of 22.78%, surpassing fresh counterparts (20.76%). The process demonstrated exceptional cyclability (maintaining a high efficiency of 20.79% after four cycles), offering a sustainable pathway to mitigate Pb pollution and reduce production costs, thus advancing scalable PSC commercialization.

Figure 12.

(a) Scheme of the closed-loop recycling process. Reprinted with permission from Ref. [84]. Copyright 2021 Elsevier. (b) Steps for recycling perovskite solar modules. Reprinted with permission from Ref. [86]. Copyright 2023 Elsevier.

Schmidt et al. demonstrated a simple PbI2 recovery process that employing hot water as the exclusive solvent to effectively extract lead from precursor mixtures, plastic-based, and glass-based PSCs (with an efficiency of 92.6–100% after two extractions) [86]. They achieved efficient lead recovery from glass-based PSCs through a stepwise cyclic purification process. Upon cooling of the hot extractant, high-purity (>95.9%) PbI2 crystals precipitated spontaneously from the solution: The first purification cycle recovered 94.4 ± 5.6% of lead, while a subsequent cycle added an additional 10.0 ± 5.2% recovery, making the recovery quantitative (Figure 12b). The remaining solid extraction residue is metal-free and can thus be disposed of as non-hazardous waste. This method exploits the strong temperature dependence of PbI2 solubility in water to provide a simplified and scalable approach for recovering lead from decommissioned PSCs. By exploiting periodic temperature variations, the process effectively separates Pb species from the residue, mitigating the potential risk of lead leaching at the end of the perovskites’ life cycle.

The recovery of perovskite films increases the availability of expensive materials such as transparent conductive substrates and charge transport layers, which can be reused with minimal impact on the device’s photovoltaic performance and reduces the impact of lead leakage on the ecosystem. In conclusion, the recycling of Pb has the dual benefits of protecting the environment and reducing costs.

5. Conclusions and Outlook

The burgeoning field of PSCs has heralded a new era in renewable energy, promising high efficiencies and low-cost production. However, the environmental sustainability of these devices, particularly concerning lead leakage, remains a critical challenge that must be addressed to facilitate their widespread commercialization. This review has delved into the intricacies of lead toxicity within PSCs, elucidating the mechanisms of lead leakage and its profound impacts on both the environment and human health. Furthermore, it has explored a plethora of strategies aimed at mitigating lead leakage, ranging from advanced encapsulation techniques to innovative lead immobilization methods and sustainable recycling practices.

In conclusion, the journey towards environmentally safe PSCs is marked by significant advancements and ongoing research efforts. The development of robust encapsulation materials, such as self-healing polymers and ionic gels, alongside the design of sophisticated multi-layer structures, has shown promise in curbing lead leakage. Internal lead immobilization strategies, including the integration of lead-capturing materials like MOFs and the modification of perovskite layers, offer additional layers of protection. Moreover, the advent of in situ and ex situ adsorption techniques provides innovative avenues for lead management. Recycling and reutilization practices, though in their nascent stages, hold potential for creating a circular economy within the PSC industry.

Fortunately, the large-scale commercialization of cadmium telluride (CdTe) photovoltaics provides valuable experience in mitigating the environmental risks associated with heavy metals. After years of industrial optimization, CdTe photovoltaics technology has successfully developed industrial solutions to address cadmium contamination and achieved compliance with the EU RoHS Directive through exemptions. For example, the use of robust glass-to-glass encapsulation [87] has proven effective in preventing cadmium leakage. In addition, the use of closed-loop hydrometallurgical recovery ensures a high rate of cadmium recovery [88], minimizing cadmium emissions to the environment during the end-of-life phase. This recovery process not only reduces the need for new cadmium and tellurium resources but also reduces the overall environmental impact of CdTe photovoltaics devices. These effective strategies could potentially be applied to perovskite PV devices, but the differences between CdTe and perovskite devices need to be taken into account. The lead content in perovskite solar cells is typically low (0.5~1 g/m2) compared to the high cadmium content in CdTe modules (~7 g/m2) [88]. However, lead ions in perovskites are highly water soluble and carry a public health stigma, posing unique environmental challenges. This requires innovative encapsulation strategies and lead recovery methods. Although perovskite recycling remains at lab-scale, its solution-processable nature enables direct reuse of PbI2 with retained device performance. Additionally, perovskite PVs benefit from inherently lower material usage and a shorter energy payback time, potentially offering a more sustainable solution if advanced encapsulation and scalable recycling methods can be successfully implemented. By combining the successful experience of CdTe PV in recycling with the unique advantages of perovskite (such as solution processability and low-energy manufacturing), it is possible to systematically minimize the environmental risks of lead halide perovskite and pave the way for its sustainable large-scale commercialization.

Looking ahead, several key areas demand focused attention. First, future research should focus on advancing encapsulation materials and techniques. Innovations in flexible and stretchable encapsulation materials are crucial, considering the potential application of perovskite devices in flexible electronics. These materials should not only provide excellent barrier properties against water and oxygen but also be mechanically robust to withstand bending, folding, and stretching without losing their integrity. Second, the development of lead-free or low-lead perovskite alternatives is imperative. Recent strides in exploring tin-based and bismuth-based perovskites offer a glimmer of hope, though their efficiency and stability must be further optimized to match their lead-based counterparts. Third, the scalability of lead mitigation technologies is crucial. The scalability and cost-effectiveness of current recycling technologies need to be improved. Automated recycling processes that can handle large-scale production of perovskite devices should be developed.

In terms of research, interdisciplinary approaches are essential. Collaborations between materials scientists, environmental engineers, and toxicologists can lead to a more comprehensive understanding of lead leakage and its mitigation. Advanced characterization techniques and computational modeling can aid in predicting the long-term behavior of PSCs under various environmental conditions, guiding the development of more resilient materials.

Moreover, the role of policy and regulation cannot be understated. Policymakers need to play an active role in regulating the production, use, and disposal of halide perovskite-based devices. Clear guidelines and standards for lead content limits, device encapsulation requirements, and end-of-life management should be established. Incentives such as subsidies for the development and use of lead-free perovskite technologies can also promote environmentally friendly growth in the industry.

In essence, the path to environmentally safe PSCs is complex but navigable. With continued innovation, collaborative efforts, and a steadfast commitment to sustainability, the promise of perovskite solar cells as a clean, efficient, and safe renewable energy source can be realized, paving the way for a brighter, greener future.

Author Contributions

Conceptualization, W.L. and T.M.; writing—original draft preparation, W.L., T.M. and M.Y.; writing—review and editing, T.T. and H.P.; supervision, H.P. and M.Y.; funding acquisition, W.L. and T.T. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by National Natural Science Foundation of China (52402203 and 22305215).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

No new data were created or analyzed in this study. Data sharing is not applicable to this article.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Huang, J.; Yuan, Y.; Shao, Y.; Yan, Y. Understanding the physical properties of hybrid perovskites for photovoltaic applications. Nat. Rev. Mater. 2017, 2, 17042. [Google Scholar] [CrossRef]

- Chen, H.; Liu, C.; Xu, J.; Maxwell, A.; Zhou, W.; Yang, Y.; Zhou, Q.; Bati, A.S.R.; Wan, H.; Wang, Z.; et al. Improved charge extraction in inverted perovskite solar cells with dual-site-binding ligands. Science 2024, 384, 189–193. [Google Scholar] [CrossRef]

- Correa-Baena, J.-P.; Saliba, M.; Buonassisi, T.; Grätzel, M.; Abate, A.; Tress, W.; Hagfeldt, A. Promises and challenges of perovskite solar cells. Science 2017, 358, 739–744. [Google Scholar] [CrossRef]

- Jiang, Q.; Tong, J.; Scheidt, R.A.; Wang, X.; Louks, A.E.; Xian, Y.; Tirawat, R.; Palmstrom, A.F.; Hautzinger, M.P.; Harvey, S.P.; et al. Compositional texture engineering for highly stable wide-bandgap perovskite solar cells. Science 2022, 378, 1295–1300. [Google Scholar] [CrossRef]

- Kojima, A.; Teshima, K.; Shirai, Y.; Miyasaka, T. Organometal halide perovskites as visible-light sensitizers for photovoltaic cells. J. Am. Chem. Soc. 2009, 131, 6050–6051. [Google Scholar] [CrossRef]

- Cao, Y.B.; Zhang, D.; Zhang, Q.; Qiu, X.; Zhou, Y.; Poddar, S.; Fu, Y.; Zhu, Y.; Liao, J.-F.; Shu, L.; et al. High-efficiency, flexible and large-area red/green/blue all-inorganic metal halide perovskite quantum wires-based light-emitting diodes. Nat. Commun. 2023, 14, 4611. [Google Scholar] [CrossRef] [PubMed]

- Lin, K.; Xing, J.; Quan, L.N.; de Arquer, F.P.G.; Gong, X.; Lu, J.; Xie, L.; Zhao, W.; Zhang, D.; Yan, C.; et al. Perovskite light-emitting diodes with external quantum efficiency exceeding 20 per cent. Nature 2018, 562, 245–248. [Google Scholar] [CrossRef] [PubMed]

- Liu, X.-K.; Xu, W.; Bai, S.; Jin, Y.; Wang, J.; Friend, R.H.; Gao, F. Metal halide perovskites for light-emitting diodes. Nat. Mater. 2021, 20, 10–21. [Google Scholar] [CrossRef]

- Tang, Y.; Jin, P.; Wang, Y.; Li, D.; Chen, Y.; Ran, P.; Fan, W.; Liang, K.; Ren, H.; Xu, X.; et al. Enabling low-drift flexible perovskite photodetectors by electrical modulation for wearable health monitoring and weak light imaging. Nat. Commun. 2023, 14, 4961. [Google Scholar] [CrossRef]

- Li, W.G.; Wang, X.D.; Huang, Y.H.; Kuang, D.B. Ultrasound-assisted crystallization enables large-area perovskite quasi-monocrystalline film for high-sensitive X-ray etection and imaging. Adv. Mater. 2023, 35, 2210878. [Google Scholar] [CrossRef]

- Zhuang, Y.; Yuan, W.; Qian, L.; Chen, S.; Shi, G. High-performance gas sensors based on a thiocyanate ion-doped organometal halide perovskite. Phys. Chem. Chem. Phys. 2017, 19, 12876–12881. [Google Scholar] [CrossRef] [PubMed]

- Senanayak, S.P.; Yang, B.; Thomas, T.H.; Giesbrecht, N.; Huang, W.; Gann, E.; Nair, B.; Goedel, K.; Guha, S.; Moya, X.; et al. Understanding charge transport in lead iodide perovskite thin-film field-effect transistors. Sci. Adv. 2017, 3, e1601935. [Google Scholar] [CrossRef]

- Liu, A.; Zhu, H.; Bai, S.; Reo, Y.; Caironi, M.; Petrozza, A.; Dou, L.; Noh, Y.-Y. High-performance metal halide perovskite transistors. Nat. Electron. 2023, 6, 559–571. [Google Scholar] [CrossRef]

- Deschler, F.; Price, M.; Pathak, S.; Klintberg, L.E.; Jarausch, D.-D.; Higler, R.; Hüttner, S.; Leijtens, T.; Stranks, S.D.; Snaith, H.J.; et al. High photoluminescence efficiency and optically umped Lalsing in solution-rocessed mixed halide perovskite semiconductors. J. Phys. Chem. Lett. 2014, 5, 1421–1426. [Google Scholar] [CrossRef]

- Wu, W.Q.; Rudd, P.N.; Wang, Q.; Yang, Z.; Huang, J. Blading phase-ure formamidinium-alloyed perovskites for high-efficiency solar cells with low photovoltage deficit and improved stability. Adv. Mater. 2020, 32, 2000995. [Google Scholar] [CrossRef]

- Wang, Z.; Zeng, L.; Zhu, T.; Chen, H.; Chen, B.; Kubicki, D.J.; Balvanz, A.; Li, C.; Maxwell, A.; Ugur, E.; et al. Suppressed phase segregation for triple-junction perovskite solar cells. Nature 2023, 618, 74–79. [Google Scholar] [CrossRef]

- Cheng, R.; Liang, Z.B.; Zhu, L.; Li, H.; Zhang, Y.; Wang, C.F.; Chen, S. Fibrous nanoreactors frommicrofluidic blow spinning for mass production of highly stable ligand-free perovskite quantum dots. Angew. Chem. Int. Ed. 2022, 61, e202204371. [Google Scholar] [CrossRef]

- Jeong, M.; Choi, I.W.; Go, E.M.; Cho, Y.; Kim, M.; Lee, B.; Jeong, S.; Jo, Y.; Choi, H.W.; Lee, J.; et al. Stable perovskite solar cells with efficiency exceeding 24.8% and 0.3 V voltage loss. Science 2020, 369, 1615–1620. [Google Scholar] [CrossRef] [PubMed]

- Yang, W.S.; Park, B.-W.; Jung, E.H.; Jeon, N.J.; Kim, Y.C.; Lee, D.U.; Shin, S.S.; Seo, J.; Kim, E.K.; Noh, J.H.; et al. Iodide management in formamidinium-lead-halide–based perovskite layers for efficient solar cells. Science 2017, 356, 1376–1379. [Google Scholar] [CrossRef]

- Wu, T.; Liu, X.; Luo, X.; Lin, X.; Cui, D.; Wang, Y.; Segawa, H.; Zhang, Y.; Han, L. Lead-free tin perovskite solar cells. Joule 2021, 5, 863–886. [Google Scholar] [CrossRef]

- Wang, M.; Wang, W.; Ma, B.; Shen, W.; Liu, L.; Cao, K.; Chen, S.; Huang, W. Lead-free perovskite materials for solar cells. Nano-Micro Lett. 2021, 13, 62. [Google Scholar] [CrossRef] [PubMed]

- Kim, J.Y.; Lee, J.-W.; Jung, H.S.; Shin, H.; Park, N.-G. High-efficiency perovskite solar cells. Chem. Rev. 2020, 120, 7867–7918. [Google Scholar] [CrossRef]

- Awais, M.; Kirsch, R.L.; Yeddu, V.; Saidaminov, M.I. Tin halide perovskites going forward: Frost diagrams offer hints. ACS Mater. Lett. 2021, 3, 299–307. [Google Scholar] [CrossRef]

- Babayigit, A.; Duy Thanh, D.; Ethirajan, A.; Manca, J.; Muller, M.; Boyen, H.-G.; Conings, B. Assessing the toxicity of Pb- and Sn-based perovskite solar cells in model organism Danio rerio. Sci. Rep. 2016, 6, 18721. [Google Scholar] [CrossRef] [PubMed]

- Krishnamoorthy, T.; Ding, H.; Yan, C.; Leong, W.L.; Baikie, T.; Zhang, Z.; Sherburne, M.; Li, S.; Asta, M.; Mathews, N.; et al. Lead-free germanium iodide perovskite materials for photovoltaic applications. J. Mater. Chem. A 2015, 3, 23829–23832. [Google Scholar] [CrossRef]

- Li, W.G.; Wang, X.D.; Liao, J.F.; Jiang, Y.; Kuang, D.B. Enhanced on-off ratio photodetectors based on lead-free Cs3Bi2I9 single crystal thin films. Adv. Funct. Mater. 2020, 30, 1909701. [Google Scholar] [CrossRef]

- Wu, X.; Zhang, D.; Wang, X.; Jiang, X.; Liu, B.; Li, B.; Li, Z.; Gao, D.; Zhang, C.; Wang, Y.; et al. Eco-friendly perovskite solar cells: From materials design to device processing and recycling. EcoMat 2023, 5, e12352. [Google Scholar] [CrossRef]

- Zhang, Z.; Sun, Q.; Lu, Y.; Lu, F.; Mu, X.; Wei, S.-H.; Sui, M. Hydrogenated Cs2AgBiBr6 for significantly improved efficiency of lead-free inorganic double perovskite solar cell. Nat. Commun. 2022, 13, 3397. [Google Scholar] [CrossRef]

- Jin, Z.; Zhang, Z.; Xiu, J.; Song, H.; Gatti, T.; He, Z. A critical review on bismuth and antimony halide based perovskites and their derivatives for photovoltaic applications: Recent advances and challenges. J. Mater. Chem. A 2020, 8, 16166–16188. [Google Scholar] [CrossRef]

- Ning, W.; Gao, F. Structural and functional diversity in llead-free halide perovskite materials. Adv. Mater. 2019, 31, 1900326. [Google Scholar] [CrossRef]

- Ke, W.; Kanatzidis, M.G. Prospects for low-toxicity lead-free perovskite solar cells. Nat. Commun. 2019, 10, 965. [Google Scholar] [CrossRef] [PubMed]

- Giustino, F.; Snaith, H.J. Toward lead-ree perovskite solar cells. ACS Energy Lett. 2016, 1, 1233–1240. [Google Scholar] [CrossRef]

- Ravi, V.K.; Mondal, B.; Nawale, V.V.; Nag, A. Don’t let the lead out: New aterial Chemicstry approaches for sustainable lead halide perovskite solar cells. ACS Omega 2020, 5, 29631–29641. [Google Scholar] [CrossRef]

- Babayigit, A.; Ethirajan, A.; Muller, M.; Conings, B. Toxicity of organometal halide perovskite solar cells. Nat. Mater. 2016, 15, 247–251. [Google Scholar] [CrossRef] [PubMed]

- Chen, Z.; Huo, X.; Chen, G.; Luo, X.; Xu, X. Lead (Pb) exposure and heart failure risk. Environ. Sci. Pollut. Res. 2021, 28, 28833–28847. [Google Scholar] [CrossRef]

- Landrigan, P.J.; Boffetta, P.; Apostoli, P. The reproductive toxicity and carcinogenicity of lead: A critical review. Am. J. Ind. Med. 2000, 38, 231–243. [Google Scholar] [CrossRef]

- Wang, Z.-K.; Zhou, X.-L.; Song, X.-B.; Zhuang, D.-M.; Wang, Z.-Y.; Yang, D.-B.; Wang, L. Alleviation of lead-induced apoptosis by puerarin via inhibiting mitochondrial permeability ransitionpore opening in primary cultures of rat proximal tubular cells. Biol. Trace Elem. Res. 2016, 174, 166–176. [Google Scholar] [CrossRef] [PubMed]

- Li, J.; Cao, H.-L.; Jiao, W.-B.; Wang, Q.; Wei, M.; Cantone, I.; Lü, J.; Abate, A. Biological impact of lead from halide perovskites reveals the risk of introducing a safe threshold. Nat. Commun. 2020, 11, 310. [Google Scholar] [CrossRef]

- Luo, T.; Shen, M.; Zhou, J.; Wang, X.; Xia, J.; Fu, Z.; Jin, Y. Chronic exposure to low doses of Pb induces hepatotoxicity at the physiological, biochemical, and transcriptomic levels of mice. Environ. Toxicol. 2019, 34, 521–529. [Google Scholar] [CrossRef]

- Czubowicz, K.; Jęśko, H.; Wencel, P.; Lukiw, W.J.; Strosznajder, R.P. The role of ceramide and sphingosine-1-phosphate in alzheimer’s disease and other neurodegenerative disorders. Mol. Neurobiol. 2019, 56, 5436–5455. [Google Scholar] [CrossRef]

- Mabrouk, A. Thymoquinone attenuates lead-induced nephropathy in rats. J. Biochem. Mol. Toxicol. 2019, 33, e22238. [Google Scholar] [CrossRef] [PubMed]

- Zeng, X.; Zeng, Z.; Wang, Q.; Liang, W.; Guo, Y.; Huo, X. Alterations of the gut microbiota and metabolomics in children with e-waste lead exposure. J. Hazard. Mater. 2022, 434, 128842. [Google Scholar] [CrossRef]

- Togao, M.; Nakayama, S.M.M.; Ikenaka, Y.; Mizukawa, H.; Makino, Y.; Kubota, A.; Matsukawa, T.; Yokoyama, K.; Hirata, T.; Ishizuka, M. Bioimaging of Pb and STIM1 in mice liver, kidney and brain using Laser Ablation Inductively Coupled Plasma Mass Spectrometry (LA-ICP-MS) and immunohistochemistry. Chemosphere 2020, 238, 124581. [Google Scholar] [CrossRef] [PubMed]

- Lukačínová, A.; Rácz, O.; Lovásová, E.; Ništiar, F. Effect of lifetime low dose exposure to heavy metals on selected serum proteins of Wistar rats during three subsequent generations. Ecotoxicol. Environ. Saf. 2011, 74, 1747–1755. [Google Scholar] [CrossRef] [PubMed]

- Li, X.; Zhang, F.; He, H.; Berry, J.J.; Zhu, K.; Xu, T. On-device lead sequestration for perovskite solar cells. Nature 2020, 578, 555–558. [Google Scholar] [CrossRef]

- Yang, M.; Tian, T.; Fang, Y.; Li, W.-G.; Liu, G.; Feng, W.; Xu, M.; Wu, W.-Q. Reducing lead toxicity of perovskite solar cells with a built-in supramolecular complex. Nat. Sustain. 2023, 6, 1455–1464. [Google Scholar] [CrossRef]

- Wu, P.; Wang, S.; Li, X.; Zhang, F. Beyond efficiency fever: Preventing lead leakage for perovskite solar cells. Matter 2022, 5, 1137–1161. [Google Scholar] [CrossRef]

- Abate, A. Perovskite solar cells go lead free. Joule 2017, 1, 659–664. [Google Scholar] [CrossRef]

- Chen, S.; Wu, C.; Han, B.; Liu, Z.; Mi, Z.; Hao, W.; Zhao, J.; Wang, X.; Zhang, Q.; Liu, K.; et al. Atomic-scale imaging of CH3NH3PbI3 structure and its decomposition pathway. Nat. Commun. 2021, 12, 5516. [Google Scholar] [CrossRef]

- Chen, S.; Zhang, X.; Zhao, J.; Zhang, Y.; Kong, G.; Li, Q.; Li, N.; Yu, Y.; Xu, N.; Zhang, J.; et al. Atomic scale insights into structure instability and decomposition pathway of methylammonium lead iodide perovskite. Nat. Commun. 2018, 9, 4807. [Google Scholar] [CrossRef]

- Kundu, S.; Kelly, T.L. In situ studies of the degradation mechanisms of perovskite solar cells. EcoMat 2020, 2, e12025. [Google Scholar] [CrossRef]

- Kadro, J.M.; Hagfeldt, A. The end-of-life of perovskite PV. Joule 2017, 1, 29–46. [Google Scholar] [CrossRef]

- Ho, K.; Wei, M.; Sargent, E.H.; Walker, G.C. Grain transformation and degradation mechanism of formamidinium and cesium lead iodide perovskite under humidity and light. ACS Energy Lett. 2021, 6, 934–940. [Google Scholar] [CrossRef]

- Cheacharoen, R.; Boyd, C.C.; Burkhard, G.F.; Leijtens, T.; Raiford, J.A.; Bush, K.A.; Bent, S.F.; McGehee, M.D. Encapsulating perovskite solar cells to withstand damp heat and thermal cycling. Sustain. Energy Fuels 2018, 2, 2398–2406. [Google Scholar] [CrossRef]

- Huang, Z.; Hu, X.; Liu, C.; Meng, X.; Huang, Z.; Yang, J.; Duan, X.; Long, J.; Zhao, Z.; Tan, L.; et al. Water-resistant and flexible perovskite solar cells via a glued interfacial layer. Adv. Funct. Mater. 2019, 29, 1902629. [Google Scholar] [CrossRef]

- Fu, Z.; Xu, M.; Sheng, Y.; Yan, Z.; Meng, J.; Tong, C.; Li, D.; Wan, Z.; Ming, Y.; Mei, A.; et al. Encapsulation of printable mesoscopic perovskite solar cells enables high emperature and long-term outdoor stability. Adv. Funct. Mater. 2019, 29, 1809129. [Google Scholar] [CrossRef]

- Li, J.; Xia, R.; Qi, W.; Zhou, X.; Cheng, J.; Chen, Y.; Hou, G.; Ding, Y.; Li, Y.; Zhao, Y.; et al. Encapsulation of perovskite solar cells for enhanced stability: Structures, materials and characterization. J. Power Sources 2021, 485, 229313. [Google Scholar] [CrossRef]

- Kim, H.-C.; Jang, T.-W.; Chae, H.-J.; Choi, W.-J.; Ha, M.-N.; Ye, B.-J.; Kim, B.-G.; Jeon, M.-J.; Kim, S.-Y.; Hong, Y.-S. Evaluation and management of lead exposure. Ann. Occup. Environ. Med. 2015, 27, 30. [Google Scholar] [CrossRef] [PubMed]

- Luo, H.; Li, P.; Ma, J.; Han, L.; Zhang, Y.; Song, Y. Sustainable Pb management in perovskite solar cells toward eco-friendly development. Adv. Energy Mater. 2022, 12, 2201242. [Google Scholar] [CrossRef]

- Yin, J.; Cui, J.; Zhou, H.; Cui, S.; Wang, C.; Guo, J.; Wei, J.; Zhang, X. Encapsulation of UV glue, hydrophobicity of binder and carbon electrode enhance the stability of organic-inorganic hybrid perovskite solar cells up to 5 years. Energy Technol. 2020, 8, 2000513. [Google Scholar] [CrossRef]

- Wan, J.; Yu, X.; Zou, J.; Li, K.; Chen, L.; Peng, Y.; Cheng, Y.-b. Lead contamination analysis of perovskite modules under simulated working conditions. Sol. Energy 2021, 226, 85–91. [Google Scholar] [CrossRef]

- Hailegnaw, B.; Kirmayer, S.; Edri, E.; Hodes, G.; Cahen, D. Rain on methylammonium lead iodide based perovskites: Possible environmental effects of perovskite solar cells. J. Phys. Chem. Lett. 2015, 6, 1543–1547. [Google Scholar] [CrossRef] [PubMed]

- Wang, T.; Yang, J.; Cao, Q.; Pu, X.; Li, Y.; Chen, H.; Zhao, J.; Zhang, Y.; Chen, X.; Li, X. Room temperature nondestructive encapsulation via self-crosslinked fluorosilicone polymer enables damp heat-stable sustainable perovskite solar cells. Nat. Commun. 2023, 14, 1342. [Google Scholar] [CrossRef] [PubMed]

- Mariani, P.; Molina-García, M.Á.; Barichello, J.; Zappia, M.I.; Magliano, E.; Castriotta, L.A.; Gabatel, L.; Thorat, S.B.; Del Rio Castillo, A.E.; Drago, F.; et al. Low-temperature strain-free encapsulation for perovskite solar cells and modules passing multifaceted accelerated ageing tests. Nat. Commun. 2024, 15, 4552. [Google Scholar] [CrossRef]

- IEC 61215-1; Terrestrial Photovoltaic (PV) Modules—Design Qualification and Type Approval—Part 1: Test Requirements. IEC: Geneva, Switzerland, 2021.

- Jiang, Y.; Qiu, L.; Juarez-Perez, E.J.; Ono, L.K.; Hu, Z.; Liu, Z.; Wu, Z.; Meng, L.; Wang, Q.; Qi, Y. Reduction of lead leakage from damaged lead halide perovskite solar modules using self-healing polymer-based encapsulation. Nat. Energy 2019, 4, 585–593. [Google Scholar] [CrossRef]

- Ottersböck, B.; Oreski, G.; Pinter, G. Comparison of different microclimate effects on the aging behavior of encapsulation materials used in photovoltaic modules. Polym. Degrad. Stab. 2017, 138, 182–191. [Google Scholar] [CrossRef]

- Meng, X.; Hu, X.; Zhang, Y.; Huang, Z.; Xing, Z.; Gong, C.; Rao, L.; Wang, H.; Wang, F.; Hu, T.; et al. A biomimetic self-shield interface for flexible perovskite solar cells with egligible Lead Lleakage. Adv. Funct. Mater. 2021, 31, 2106460. [Google Scholar] [CrossRef]

- Chen, S.; Deng, Y.; Gu, H.; Xu, S.; Wang, S.; Yu, Z.; Blum, V.; Huang, J. Trapping lead in perovskite solar modules with abundant and low-cost cation-exchange resins. Nat. Energy 2020, 5, 1003–1011. [Google Scholar] [CrossRef]

- Chen, S.; Deng, Y.; Xiao, X.; Xu, S.; Rudd, P.N.; Huang, J. Preventing lead leakage with built-in resin layers for sustainable perovskite solar cells. Nat. Sustain. 2021, 4, 636–643. [Google Scholar] [CrossRef]

- Cho, S.-P.; Lee, H.-J.; Seo, Y.-H.; Na, S.-I. Multifunctional passivation agents for improving efficiency and stability of perovskite solar cells: Synergy of methyl and carbonyl groups. Appl. Surf. Sci. 2022, 575, 151740. [Google Scholar] [CrossRef]

- Li, X.; Zhang, F.; Wang, J.; Tong, J.; Xu, T.; Zhu, K. On-device lead-absorbing tapes for sustainable perovskite solar cells. Nat. Sustain. 2021, 4, 1038–1041. [Google Scholar] [CrossRef]

- Xiao, X.; Wang, M.; Chen, S.; Zhang, Y.; Gu, H.; Deng, Y.; Yang, G.; Fei, C.; Chen, B.; Lin, Y.; et al. Lead-adsorbing ionogel-based encapsulation for impact-resistant, stable, and lead-safe perovskite modules. Sci. Adv. 2021, 7, eabi8249. [Google Scholar] [CrossRef] [PubMed]

- Li, Z.; Wu, X.; Li, B.; Zhang, S.; Gao, D.; Liu, Y.; Li, X.; Zhang, N.; Hu, X.; Zhi, C.; et al. Sulfonated graphene aerogels enable safe-to-use flexible perovskite olar Mmodules. Adv. Energy Mater. 2021, 12, 2103236. [Google Scholar] [CrossRef]

- Valastro, S.; Smecca, E.; Mannino, G.; Bongiorno, C.; Fisicaro, G.; Goedecker, S.; Arena, V.; Spampinato, C.; Deretzis, I.; Dattilo, S.; et al. Preventing lead leakage in perovskite solar cells with a sustainable titanium dioxide sponge. Nat. Sustain. 2023, 6, 974–983. [Google Scholar] [CrossRef]

- Wu, S.; Li, Z.; Li, M.-Q.; Diao, Y.; Lin, F.; Liu, T.; Zhang, J.; Tieu, P.; Gao, W.; Qi, F.; et al. 2D metal-organic framework for stable perovskite solar cells with minimized lead leakage. Nat. Nanotechnol. 2020, 15, 934–940. [Google Scholar] [CrossRef]

- Zhang, H.; Li, K.; Sun, M.; Wang, F.; Wang, H.; Jen, A.K.Y. Design of superhydrophobic surfaces for table perovskite solar cells with reducing lead leakage. Adv. Energy Mater. 2021, 11, 2102281. [Google Scholar] [CrossRef]

- Binek, A.; Petrus, M.L.; Huber, N.; Bristow, H.; Hu, Y.; Bein, T.; Docampo, P. Recycling perovskite solar cells to void lead waste. ACS Appl. Mater. Interfaces 2016, 8, 12881–12886. [Google Scholar] [CrossRef] [PubMed]

- Poll, C.G.; Nelson, G.W.; Pickup, D.M.; Chadwick, A.V.; Riley, D.J.; Payne, D.J. Electrochemical recycling of lead from hybrid organic–inorganic perovskites using deep eutectic solvents. Green Chem. 2016, 18, 2946–2955. [Google Scholar] [CrossRef]

- Xu, J.; Hu, Z.; Huang, L.; Huang, X.; Jia, X.; Zhang, J.; Zhang, J.; Zhu, Y. In situ recycle of PbI2 as a step towards sustainable perovskite solar cells. Prog. Photovolt. Res. Appl. 2017, 25, 1022–1033. [Google Scholar] [CrossRef]

- Zhang, S.; Shen, L.; Huang, M.; Yu, Y.; Lei, L.; Shao, J.; Zhao, Q.; Wu, Z.; Wang, J.; Yang, S. Cyclic tilization of lead in carbon-based perovskite solar cells. ACS Sustain. Chem. Eng. 2018, 6, 7558–7564. [Google Scholar] [CrossRef]

- Park, S.Y.; Park, J.-S.; Kim, B.J.; Lee, H.; Walsh, A.; Zhu, K.; Kim, D.H.; Jung, H.S. Sustainable lead management in halide perovskite solar cells. Nat. Sustain. 2020, 3, 1044–1051. [Google Scholar] [CrossRef]

- Chen, B.; Fei, C.; Chen, S.; Gu, H.; Xiao, X.; Huang, J. Recycling lead and transparent conductors from perovskite solar modules. Nat. Commun. 2021, 12, 5859. [Google Scholar] [CrossRef] [PubMed]

- Feng, X.; Guo, Q.; Xiu, J.; Ying, Z.; Ng, K.W.; Huang, L.; Wang, S.; Pan, H.; Tang, Z.; He, Z. Close-loop recycling of perovskite solar cells through dissolution-recrystallization of perovskite by butylamine. Cell Rep. Phys. Sci. 2021, 2, 100341. [Google Scholar] [CrossRef]

- Deng, F.; Song, X.; Li, Y.; Zhang, W.; Tao, X. Facile eco-friendly process for upcycled sustainable perovskite solar cells. Chem. Eng. J. 2024, 489, 151228. [Google Scholar] [CrossRef]

- Schmidt, F.; Amrein, M.; Hedwig, S.; Kober-Czerny, M.; Paracchino, A.; Holappa, V.; Suhonen, R.; Schäffer, A.; Constable, E.C.; Snaith, H.J.; et al. Organic solvent free PbI2 recycling from perovskite solar cells using hot water. J. Hazard. Mater. 2023, 447, 130829. [Google Scholar] [CrossRef]

- Fthenakis, V.M. Life cycle impact analysis of cadmium in CdTe PV production. Renew. Sustain. Energy Rev. 2004, 8, 303–334. [Google Scholar] [CrossRef]

- Vellini, M.; Gambini, M.; Prattella, V. Environmental impacts of PV technology throughout the life cycle: Importance of the end-of-life management for Si-panels and CdTe-panels. Energy 2017, 138, 1099–1111. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).