Progress and Prospect of Sm-Fe-N Magnets

Abstract

1. Introduction

2. Materials

2.1. Rare-Earth-Free Iron-Based Magnets

2.2. Sm-Based Magnets

3. Sm-Fe-N Magnets

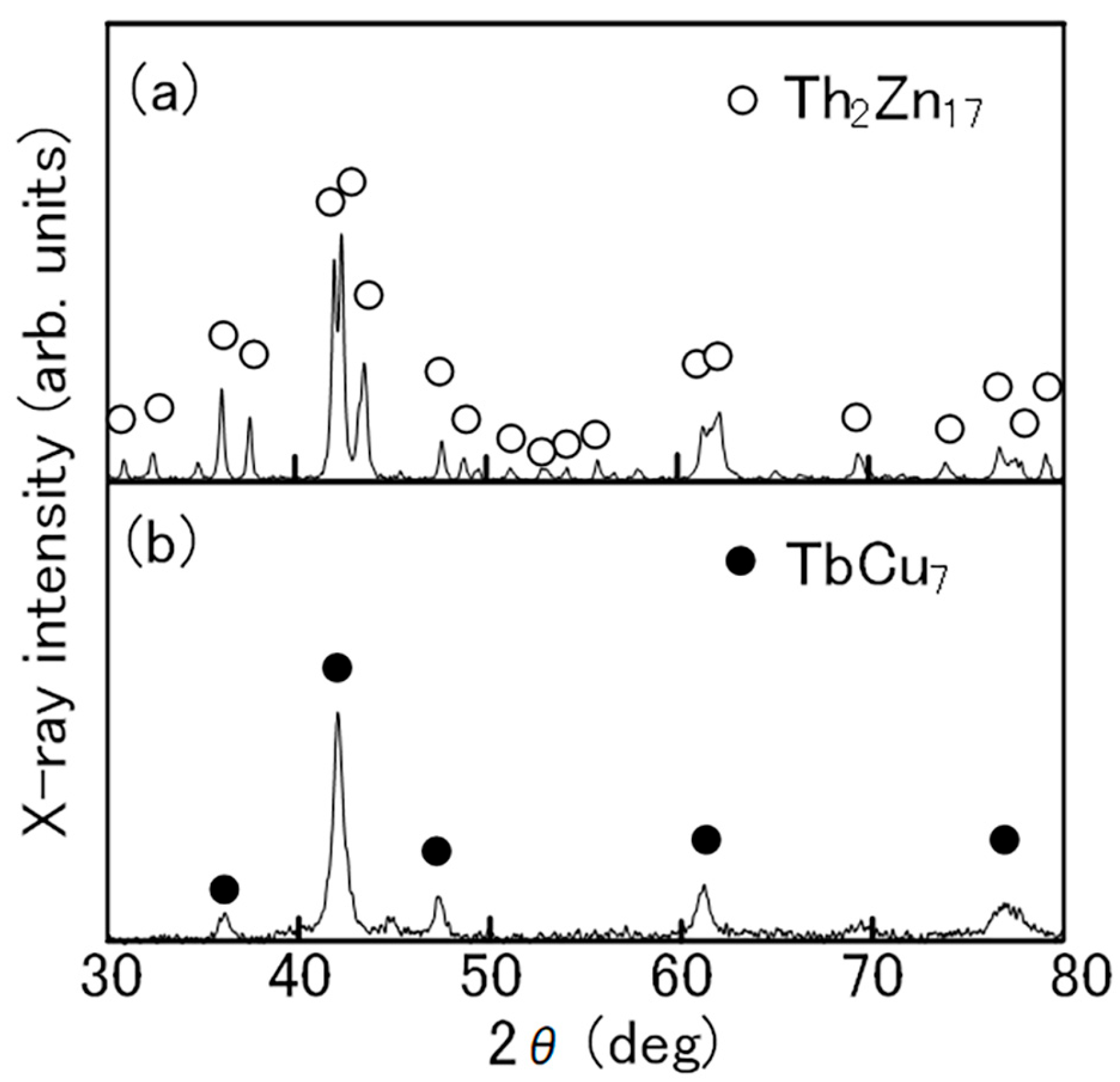

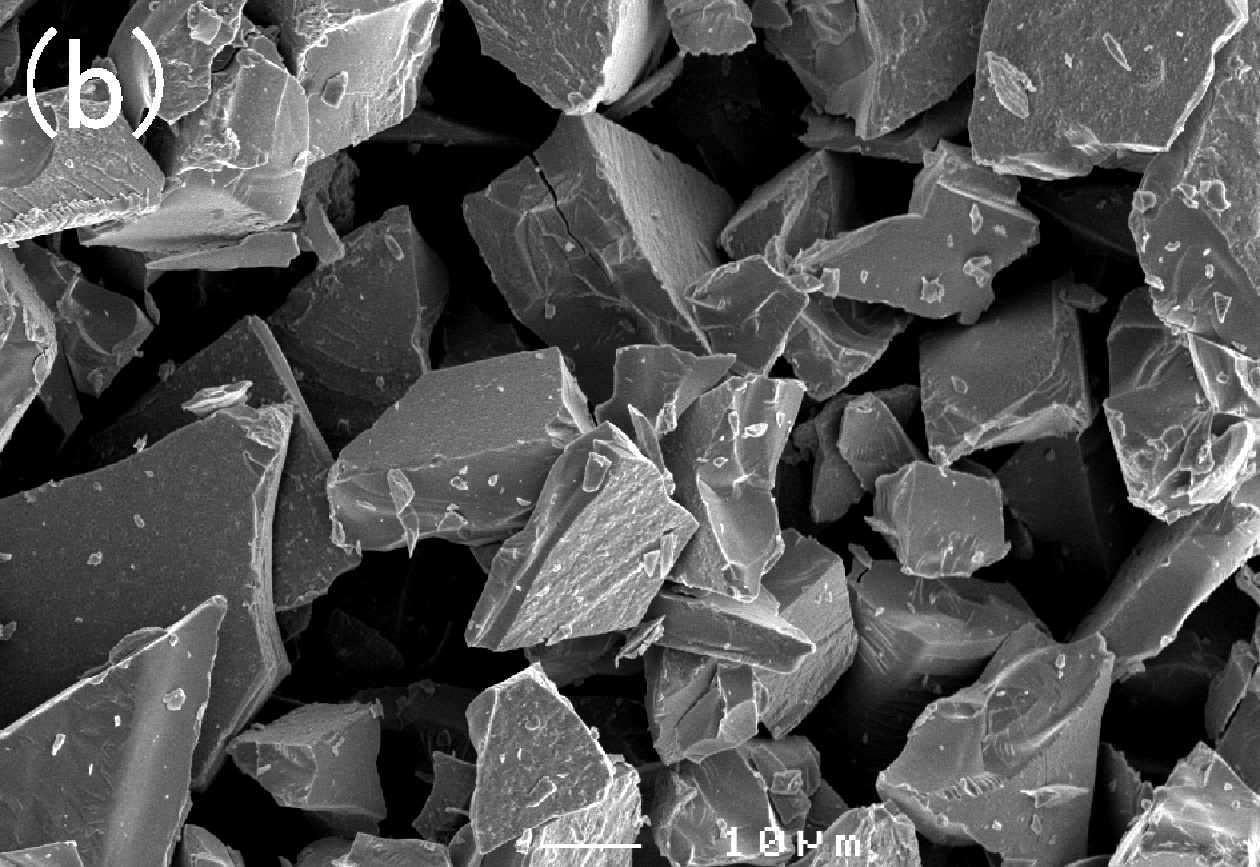

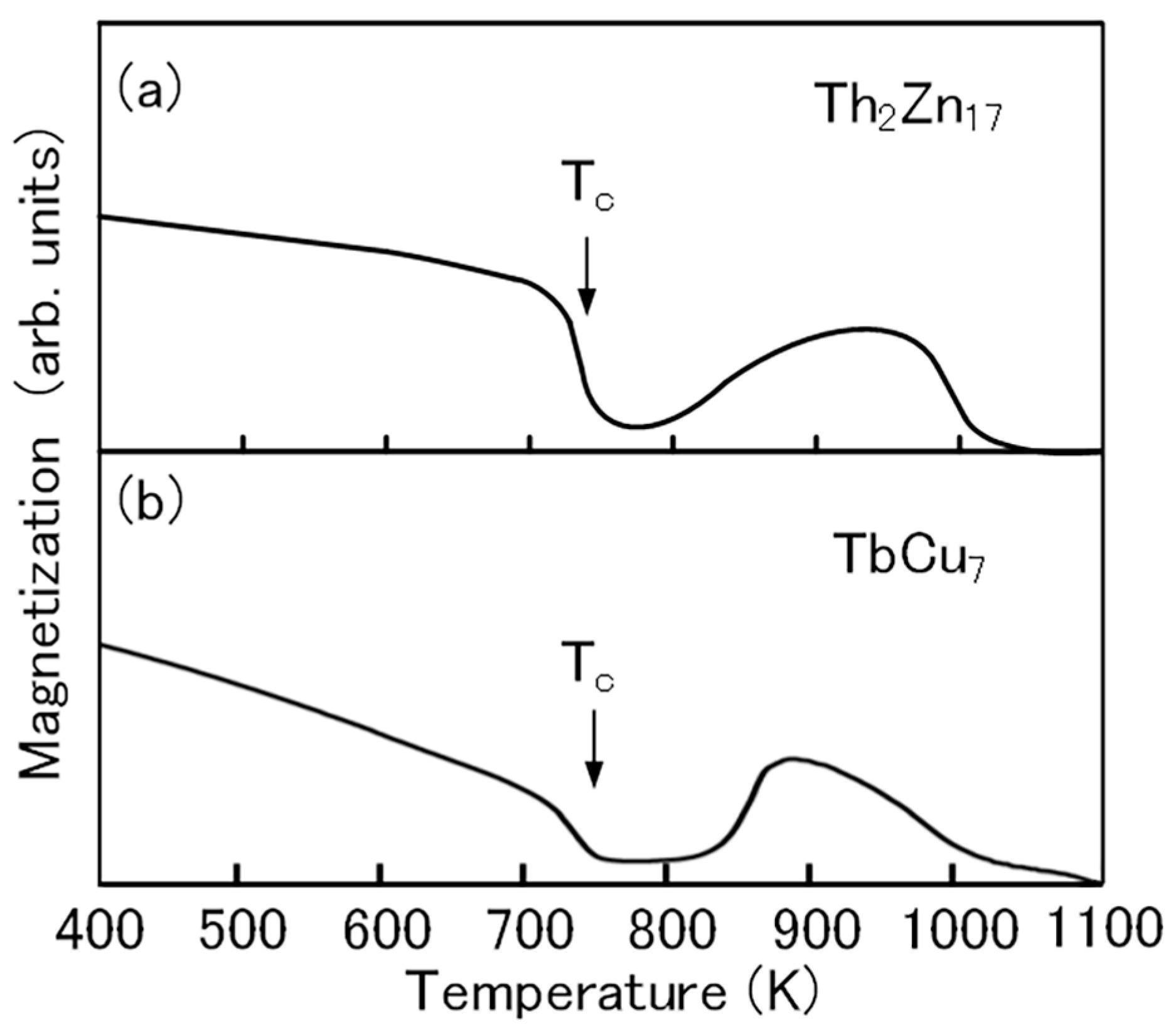

3.1. Sm-Fe-N Powder

3.2. Sm-Fe-N Bonded Magnets

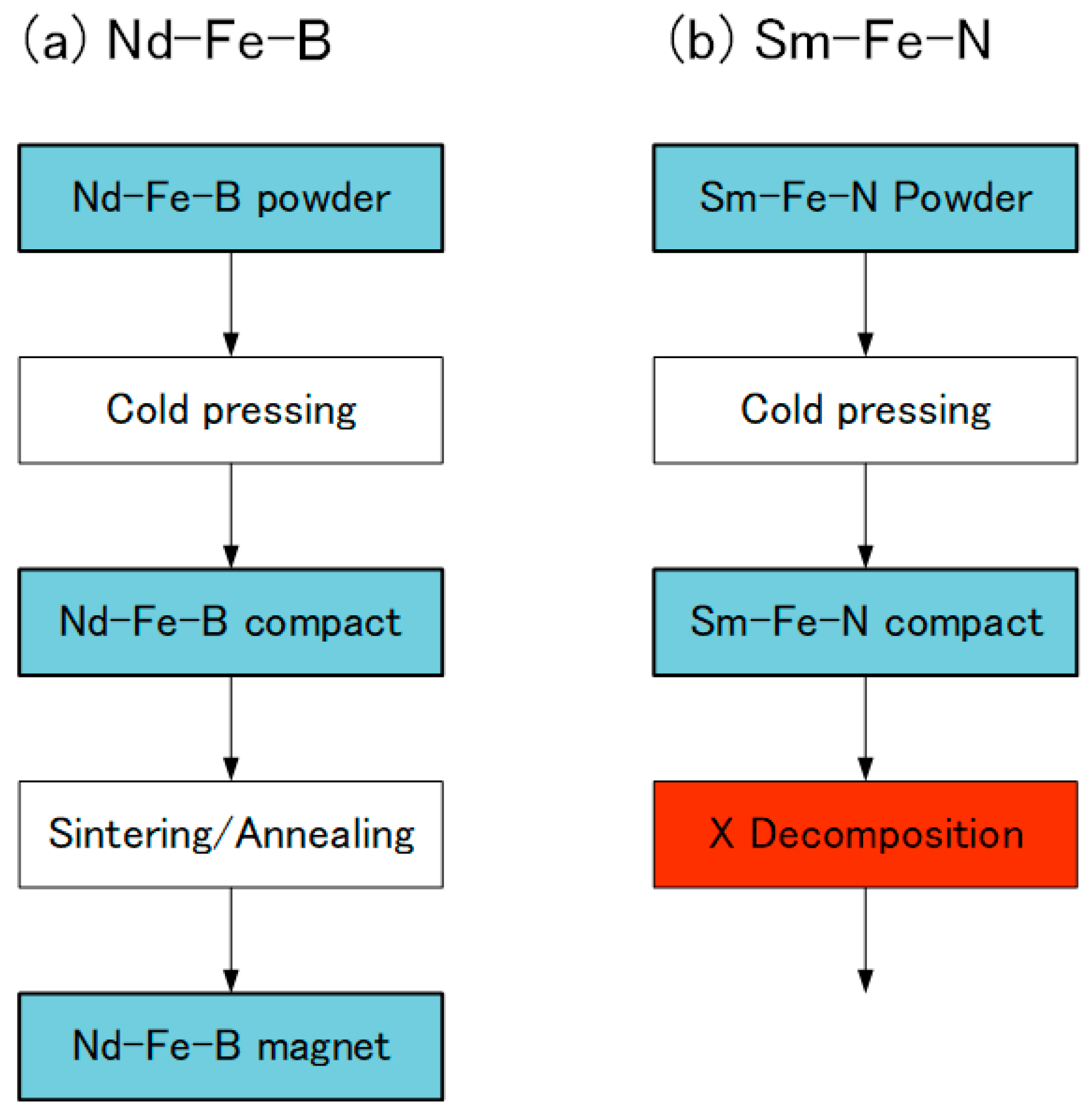

3.3. Sm-Fe-N Sintered Magnets

4. Conclusions

Funding

Data Availability Statement

Conflicts of Interest

References

- Bailey, G.; Mancheri, N.; Van Acker, K. Sustainability of permanent rare earth magnet motors in (H)EV industry. J. Sustain. Metall. 2017, 3, 611–626. [Google Scholar] [CrossRef]

- Sreenivasulu, K.V.; Srikanth, V.V.S.S. Fascinating magnetic energy storage nanomaterials: A brief review. Recent Pat. Nanotechnol. 2017, 11, 116–122. [Google Scholar] [CrossRef]

- Yue, M.; Zhang, X.Y.; Liu, J.P. Fabrication of bulk nanostructured permanent magnets with high energy density: Challenges and approaches. Nanoscale 2017, 9, 3674–3697. [Google Scholar] [CrossRef]

- Ohtani, T.; Kato, N.; Kojima, S.; Kojima, K.; Sakamoto, Y.; Konno, I.; Tsukahara, M.; Kubo, T. Magnetic properties of Mn-Al-C permanent magnet alloys. IEEE Trans. Magn. 1977, 13, 1328–1330. [Google Scholar] [CrossRef]

- Saito, T. Magnetic properties of Mn-Al-C alloy powders produced by mechanical alloying. J. Appl. Phys. 2005, 97, 10F304. [Google Scholar] [CrossRef]

- Wei, J.Z.; Song, Z.G.; Yang, Y.B.; Liu, S.Q.; Du, H.L.; Han, J.Z.; Zhou, D.; Wang, C.S.; Yang, Y.C.; Franz, A.; et al. τ-MnAl with high coercivity and saturation magnetization. AIP Adv. 2014, 4, 127113. [Google Scholar] [CrossRef]

- Rial, J.; Villanueva, M.; Céspedes, E.; López, N.; Camarero, J.; Marshall, L.G.; Lewis, L.H.; Bollero, A. Application of a novel flash-milling procedure for coercivity development in nanocrystalline MnAl permanent magnet powders. J. Phys. D: Appl. Phys. 2017, 50, 105004. [Google Scholar] [CrossRef]

- Saito, T.; Nishimura, R.; Nishio-Hamane, D. Magnetic properties of Mn-Bi melt-spun ribbons. J. Magn. Magn. Mater. 2014, 349, 9–14. [Google Scholar] [CrossRef]

- Ly, V.; Wu, X.; Smillie, L.; Shoji, T.; Kato, A.; Manabe, A.; Suzuki, K. Low-temperature phase MnBi compound: A potential candidate for rare-earth free permanent magnets. J. Alloys Compd. 2014, 615, S285–S290. [Google Scholar] [CrossRef]

- Anand, K.; Pulikkotil, J.J.; Auluck, S. Effects of inter-site chemical disorder on the magnetic properties of MnBi. J. Magn. Magn. Mater. 2014, 363, 18–20. [Google Scholar] [CrossRef]

- Poudyal, N.; Liu, X.; Wang, W.; Nguyen, V.V.; Ma, Y.; Gandha, K.; Elkins, K.; Liu, J.P.; Sun, K.; Kramer, M.J.; et al. Processing of MnBi bulk magnets with enhanced energy product. AIP Adv. 2016, 6, 056004. [Google Scholar] [CrossRef]

- Sakuma, A. Electronic structures and magnetism of CuAu-type MnNi and MnGa. J. Magn. Magn. Mater. 1998, 187, 105–112. [Google Scholar] [CrossRef]

- Saito, T.; Nishimura, R. Hard magnetic properties of Mn-Ga melt-spun ribbons. J. Appl. Phys. 2012, 112, 083901. [Google Scholar] [CrossRef]

- Lu, Q.M.; Yue, M.; Zhang, H.G.; Wang, M.L.; Yu, F.; Huang, Q.Z.; Ryan, D.H.; Altounian, Z. Intrinsic magnetic properties of single-phase Mn1+xGa (0 < x < 1) alloys. Sci. Rep. 2015, 5, 17086. [Google Scholar]

- El-Gendy, A.A.; Hadjipanayis, G. High Coercivity in Annealed Melt-Spun Mn-Ga Ribbons. IEEE Trans. Magn. 2014, 50, 1–3. [Google Scholar] [CrossRef]

- Yang, J.; Yang, W.; Shao, Z.; Liang, D.; Zhao, H.; Xia, Y.; Yang, Y. Mn-Based permanent magnets. Chin. Phys. B 2018, 27, 117503. [Google Scholar] [CrossRef]

- Lu, Q.M.; Wang, D.J.; Li, C.H.; Zhang, H.G.; Yue, M. Recrystallization induced coercivity and magnetic properties enhancement in hot-deformed L10-Mn1.8Ga magnet. J. Magn. Magn. Mater. 2019, 474, 167–172. [Google Scholar] [CrossRef]

- Hao, L.; Xiong, W. An evaluation of the Mn–Ga system: Phase diagram, crystal structure, magnetism, and thermodynamic properties. Calphad 2020, 68, 101722. [Google Scholar] [CrossRef]

- El-Gendy, A.A.; Hadjipanayis, G. Nanostructured D022-Mn3Ga with high coercivity. J. Phys. D Appl. Phys. 2015, 48, 125001. [Google Scholar]

- Thanh, P.T.; Ngoc, N.H.; Lam, N.M.; Hai, K.X.; Yen, N.H.; Anh, T.V.; Dan, N.H. Structure and magnetic properties of melt-spun Mn-Ga-Cu-Al ribbons. Mater. Res. Exp. 2023, 10, 086101. [Google Scholar] [CrossRef]

- Kriste, G.; Freudenberger, J.; Wurmehl, S. Phase transformation in Mn3Ga considering different degrees of deformation. Acta Mater. 2023, 258, 119025. [Google Scholar] [CrossRef]

- Keller, T.; Baker, I. Manganese-based permanent magnet materials. Prog. Mater. Sci. 2022, 124, 100872. [Google Scholar] [CrossRef]

- Sagawa, M.; Horosawa, S.; Yamamoto, H.; Fujimura, S.; Matsuura, Y. Nd-Fe-B permanent magnet materials. Jpn. J. Appl. Phys. 1987, 6, 785–800. [Google Scholar]

- Néel, L.; Pauleve, J.; Pauthenet, R.; Laugier, J.; Dautreppe, D. Magnetic properties of an iron—nickel single crystal ordered by neutron bombardment. J. Appl. Phys. 1964, 35, 873–876. [Google Scholar]

- Takahashi, M.; Shoji, H.; Takahashi, H.; Nashi, H.; Wakiyama, T.; Matsui, M. Magnetic moment of α″‐Fe16N2 films (invited). J. Appl. Phys. 1994, 76, 6642–6647. [Google Scholar]

- Kotsugi, M.; Mitsumata, C.; Maruyama, H.; Wakita, T.; Taniuchi, T.; Ono, K.; Suzuki, M.; Kawamura, N.; Ishimatsu, N.; Oshima, M.; et al. Novel magnetic domain structure in iron meteorite induced by the presence of L10-FeNi. Appl. Phys. Exp. 2010, 3, 013001. [Google Scholar] [CrossRef]

- Woodgate, C.D.; Patrick, C.E.; Lewis, L.H.; Staunton, J.B. Revisiting Néel 60 years on: The magnetic anisotropy of L10 FeNi (tetrataenite). J. Appl. Phys. 2023, 134, 163905. [Google Scholar] [CrossRef]

- Li, D.; Li, Y.; Pan, D.; Zhang, Z.; Cho, C.J. Prospect and status of iron-based rare-earth-free permanent magnetic materials. J. Magn. Magn. Mater. 2019, 469, 535–544. [Google Scholar] [CrossRef]

- Goto, S.; Kura, H.; Watanabe, E.; Hayashi, Y.; Yanagihara, H.; Shimada, Y.; Mizuguchi, M.; Takanashi, K.; Kita, E. Synthesis of single-phase L10- FeNi magnet powder by nitrogen insertion and topotactic extraction. Sci. Rep. 2017, 7, 13216. [Google Scholar] [CrossRef]

- Hlova, I.Z.; Dolotko, O.; Abramchuk, M.; Biswas, A.; Mudryk, Y.; Pecharsky, V.K. Enhancement of hard magnetism and chemical order of synthetic L10-FeNi. J. Alloys Compd. 2024, 981, 173619. [Google Scholar] [CrossRef]

- Bhattacharyya, S. Iron nitride family at reduced dimensions: A review of their synthesis protocols and structural and magnetic properties. J. Phys. Chem. C 2015, 119, 1601–1622. [Google Scholar] [CrossRef]

- Coey, J.M.D. Hard magnetic materials: A perspective. IEEE Trans. Magn. 2011, 47, 4671–4681. [Google Scholar] [CrossRef]

- Kim, T.K.; Takahashi, M. New magnetic material having ultrahigh magnetic moment. Appl. Phys. Lett. 1972, 20, 492–494. [Google Scholar] [CrossRef]

- Sugita, Y.; Mitsuoka, K.; Komuro, M.; Hoshiya, H.; Kozono, Y.; Hanazono, M. Giant magnetic moment and other magnetic properties of epitaxially grown Fe16N2 single-crystal films. J. Appl. Phys. 1991, 70, 5977–5982. [Google Scholar] [CrossRef]

- Jack, K.H. The synthesis and characterization of bulk α″-Fe16N2. J. Alloys Compd. 1995, 222, 160–166. [Google Scholar] [CrossRef]

- Nakajima, K.; Okamoto, S. Nitrogen-implantation-induced transformation of iron to crystalline Fe16N2 in epitaxial iron films. Appl. Phys. Lett. 1989, 54, 2536–2538. [Google Scholar] [CrossRef]

- Sun, D.C.; Jiang, E.Y.; Tian, M.B.; Lin, C.; Zhang, X.X. Epitaxial single crystal Fe16N2 films grown by facing targets sputtering. J. Appl. Phys. 1996, 79, 5440–5442. [Google Scholar] [CrossRef]

- Sugita, Y.; Takahashi, H.; Komuro, M.; Mitsuoka, K.; Sakuma, A. Magnetic and mössbauer studies of single-crystal Fe16N2, and Fe-N martensite films epitaxially grown by molecular beam epitaxy. J. Appl. Phys. 1994, 76, 6637–6641. [Google Scholar] [CrossRef]

- Shinno, H.; Saito, K. Effects of film thickness on formation processes of Fe16N2 in nitrogen ion-implanted Fe films. Surf. Coating. Technol. 1998, 103, 129–134. [Google Scholar] [CrossRef]

- Ogawa, T.; Ogata, Y.; Gallage, R.; Kobayashi, N.; Hayashi, N.; Kusano, Y.; Yamamoto, S.; Kohara, K.; Doi, M.; Takano, M.; et al. Challenge to the synthesis of α″-Fe16N2 phase compound nanoparticle with high saturation magnetization for rare earth-free new permanent magnetic material. Appl. Phys. Exp. 2013, 6, 073007. [Google Scholar] [CrossRef]

- Dirba, I.; Schwöbel, C.A.; Diop, L.V.B.; Duerrschnabel, M.; Molina-Luna, L.; Hofmann, K.; Komissinskiy, P.; Kleebe, H.-J.; Gutfleisch, O. Synthesis, morphology, thermal stability and magnetic properties of α″-Fe16N2 nanoparticles obtained by hydrogen reduction of γ-Fe2O3 and subsequent nitrogenation. Acta Mater. 2017, 123, 214. [Google Scholar] [CrossRef]

- Saito, T.; Yamamoto, H. Hard magnetic properties of Fe16N2 magnets. AIP Adv. 2024, 14, 015149. [Google Scholar] [CrossRef]

- Coey, J.M.D. Permanent magnets: Plugging the gap. Scr. Mater. 2012, 67, 524–529. [Google Scholar] [CrossRef]

- Hirosawa, S. Current status of research and development toward permanent magnets free from critical elements. J. Magn. Soc. Jpn. 2015, 39, 85–95. [Google Scholar] [CrossRef]

- Ohashi, M. The present and the future of rare earth resources predicted from its supply and demand. IEEJ Trans. Fund. Mater. 2016, 136, 491–494. (In Japanese) [Google Scholar] [CrossRef]

- Coey, J.M.D.; Sun, H. Improved magnetic properties by treatment of iron-based rare earth intermetallic compounds in ammonia. J. Magn. Magn. Mater. 1990, 87, L251–L254. [Google Scholar] [CrossRef]

- De Boer, F.R.; Huang, Y.K.; De Mooij, D.B.; Buschow, K.H.J. Magnetic properties of a series of novel ternary intermetallics (RFe10V2). J. Less-Common Met. 1987, 135, 199–204. [Google Scholar] [CrossRef]

- Hirayama, Y.; Takahashi, Y.K.; Hirosawa, S.; Hono, K. Intrinsic hard magnetic properties of Sm(Fe1-xCoX) compound with the ThMn12 structure. Scr. Mater. 2017, 138, 62–65. [Google Scholar] [CrossRef]

- Liu, N.C.; Kamprath, N.; Wickramasekara, L.; Cadieu, F.J.; Stadelmaier, H.H. Crystal structure of R(Ti,Fe)12(R=Nd,Sm) compound. J. Appl. Phys. 1988, 63, 3589–3591. [Google Scholar] [CrossRef]

- Cadieu, F.J.; Hegde, H.; Navarathna, A.; Rani, R.; Chen, K. High-energy product ThMn12 Sm-Fe-T and Sm-Fe permanent magnets synthesized as oriented sputtered films. Appl. Phys. Lett. 1991, 59, 875–877. [Google Scholar] [CrossRef]

- Wang, D.; Liou, S.H.; He, P.; Sellmyer, D.J.; Hadjipanayis, G.C.; Zhang, Y. SmFe12 and SmFe12Nx films fabricated by sputtering. J. Magn. Magn. Mater. 1993, 124, 62–68. [Google Scholar] [CrossRef]

- Shultz, L.; Wecker, J. Coercivity in ThMn12-type magnets. J. Appl. Phys. 1988, 64, 5711–5713. [Google Scholar] [CrossRef]

- Otani, Y.; Li, H.S.; Coey, J.M.D. Coercivity mechanism of melt-spun SmFe11Ti. IEEE Trans. Magn. 1990, 26, 2658–2660. [Google Scholar] [CrossRef]

- Ohashi, K.; Tawara, Y.; Osugi, R.; Shimao, M. Magnetic properties of Fe-rich rare-earth intermetallic compounds with a ThMn12 structure. J. Appl. Phys. 1988, 64, 5714–5716. [Google Scholar] [CrossRef]

- Saito, T.; Miyoshi, H.; Nishio-Hamane, D. Structures and magnetic properties of Sm-Fe-Ti nanocomposite magnets with SmFe12 phase. J. Alloys Compd. 2012, 519, 144–148. [Google Scholar] [CrossRef]

- Gabay, A.M.; Hadjipanayis, G.C. Recent developments in RFe12-type compounds for permanent magnets. Scr. Mater. 2018, 154, 284–288. [Google Scholar] [CrossRef]

- Tozman, P.; Sepehri-Amin, H.; Hono, K. Prospects for the development of SmFe 12-based permanent magnets with a ThMn 12 -type phase. Scr. Mater. 2021, 194, 113686. [Google Scholar] [CrossRef]

- Iriyama, T.; Kobayashi, K.; Imaoka, N.; Fukuda, T.; Kato, H.; Nakagawa, Y. Effect of Nitrogen Content on Magnetic Properties of Sm2Fel7Nx (O<x<6). IEEE Trans. Magn. 1992, 28, 2326–2331. [Google Scholar]

- Katter, M.; Wecker, J.; Schultz, L. Structural and hard magnetic properties of rapidly solidified Sm–Fe–N. J. Appl. Phys. 1991, 70, 3188–3196. [Google Scholar] [CrossRef]

- Wang, K.Y.; Wang, Y.Z.; Hu, B.P.; Lai, W.Y. Magnetic properties of Sm-Fe-Ti and its nitrides with TbCu7-type structure. Physica B: Cond. Mat. 1994, 203, 54–58. [Google Scholar] [CrossRef]

- Yoneyama, T.; Yamamoto, T.; Hidaka, T. Magnetic properties of rapidly quenched high remanence Zr added Sm–Fe–N isotropic powders. Appl. Phys. Lett. 1995, 67, 3197–3199. [Google Scholar] [CrossRef]

- Omatsuzawa, R.; Murashige, K.; Iriyama, T. Magnetic properties of TbCu7-type Sm-Fe-N melt-spun ribbons. Trans. Magn. Soc. Jpn. 2004, 4, 113–116. [Google Scholar] [CrossRef]

- Teresiak, A.; Kubis, M.; Mattern, M.; Wolf, M.; Müller, K.-H. Formation of modified TbCu7 and Th2Zn17 type structures during annealing of mechanical-alloyed Sm–Fe powders. J. Alloys Compd. 1998, 274, 284–293. [Google Scholar] [CrossRef]

- Saito, T. Development of Sm-Fe-N Magnets (Japanese). In Development of Higher Output Motors for Next-Generation EV/HEV and Related Materials; Technical Information Institute CO., LTD: Tokyo, Japan, 2022; pp. 178–189. [Google Scholar]

- Kawamoto, A.; Ishikawa, T.; Yasuda, S.; Takeya, K.; Ishizaka, K.; Iseki, T.; Ohmori, K. Sm2Fe17N3 magnet powder made by reduction and diffusion method. IEEE Trans. Magn. 1999, 35, 3322–3324. [Google Scholar] [CrossRef]

- Ishikawa, T.; Yokosawa, K.; Watanabe, K.; Ohmori, K. Modified Process for High-Performance Anisotropic Sm2Fe17N3 Magnet Powder. J. Phys.: Conf. Ser. 2011, 266, 012033. [Google Scholar]

- Deng, G.; Jing, Q.; Wang, X.; He, G.; Yu, X. Synthesis mechanism of Sm2Fe17 alloy produced in reduction-diffusion process. J. Rare Earths 2010, 28, 420–424. [Google Scholar] [CrossRef]

- Tada, S.; Tomimoto, T.; Kume, M. High-coercivity anisotropic SmFeN magnetic materials. In Proceedings of the 22nd International Workshop on Rare-Earth Permanent Magnets and Their Applications, Nagasaki, Japan, , 2–5 September 2012; pp. 48–53. [Google Scholar]

- Okada, S.; Takagi, K.; Ozaki, K. Direction preparation of submicron-sized Sm2Fe17 ultrafine powders by reduction-diffusion technique. J. Alloys Compd. 2016, 663, 872–879. [Google Scholar] [CrossRef]

- Okada, S.; Suzuki, K.; Node, E.; Takagi, K.; Ozaki, K.; Enokido, Y. Preparation of submicron-sized Sm2Fe17N3 fine powder with high coercivity by reduction-diffusion process. J. Alloys Compd. 2017, 695, 1617–1623. [Google Scholar] [CrossRef]

- Coey, J.M.D.; Stamenov, P.; Porter, S.B.; Venkatesan, M.; Zhang, R.; Iriyama, T. Sm-Fe-N revisited; remanence enhancement in melt-spun Nitroquench material. J. Magn. Magn. Mater. 2019, 480, 186–192. [Google Scholar] [CrossRef]

- Cabral, F.A.O.; Gama, S.; De Morais, E.; Sanjurjo, N.L.; Ribeiro, C.A.; Colucci, C.C. Study of thermal decomposition mechanism of Fe17Sm2N3 phase. IEEE Trans. Magn. 1996, 32, 4365–4367. [Google Scholar] [CrossRef]

- Hirayama, Y.; Panda, A.K.; Ohkubo, T.; Hono, K. High coercivity Sm2Fe17N3 submicron size powder prepared by polymerized-complex and reduction–diffusion process. Scr. Mater. 2016, 120, 27–30. [Google Scholar] [CrossRef]

- Liang, D.; Yang, D.; Wang, X.; Xu, Q.; Han, J.; Liu, S.; Wang, C.; Du, H.; Zhu, X.; Yuan, T.; et al. Study of the anisotropic Sm2Fe17N3 powders with high performance. AIP Adv. 2023, 13, 025104. [Google Scholar] [CrossRef]

- Takagi, K.; Hirayama, Y.; Okada, S.; Yamauchi, W.; Ozaki, K. Novel powder processing technologies for production of rare-earth permanent magnets. Sci. Tech. Adv. Mater. 2021, 22, 150–159. [Google Scholar] [CrossRef]

- Matsuura, M.; Shiraiwa, T.; Tezuka, N.; Sugimoto, S.; Shoji, T.; Sakuma, N.; Haga, K. High coercive Zn-bonded Sm-Fe-N magnets prepared using fine Zn particles with low oxygen content. J. Magn. Magn. Mater. 2018, 452, 243–248. [Google Scholar] [CrossRef]

- Otani, Y.; Moukarika, A.; Sun, H.; Coey, J.M.D.; Devlin, E.; Harris, I.R. Metal bonded Sm2Fe17N3-δ magnets. J. Appl. Phys. 1991, 69, 6735–6737. [Google Scholar] [CrossRef]

- Machida, K.; Noguchi, K.; Nishimura, M.; Adachi, G. High-performance alloyed in metal-bonded magnets produced from Zn/Sm2Fe17Nx powders. J. Appl. Phys. 2000, 87, 5317–5319. [Google Scholar] [CrossRef]

- Matsuura, M.; Yamamoto, K.; Tezuka, N.; Sugimoto, S. Microstructural changes in high-coercivity Zn-bonded Sm-Fe-N magnets. J. Magn. Magn. Mater. 2020, 510, 166943. [Google Scholar] [CrossRef]

- Shi, D.; Zheng, J.; Cai, W.; Huang, H.; Chen, H.; Qiao, L.; Ying, Y.; Li, W.; Yu, J.; Li, J.; et al. Properties of bulk magnets prepared by hot pressing using Zn-coated Sm-Fe-N magnetic powder by electrodeposition. Surf. Interfaces 2024, 45, 103916. [Google Scholar] [CrossRef]

- Lu, C.; Zhu, J.; Gong, J.; Gao, X. A method to improving the coercivity of sintered anisotropic Sm-Fe-N magnets. J. Magn. Magn. Mater. 2016, 461, 48–52. [Google Scholar] [CrossRef]

- Otogawa, K.; Takagi, K.; Asahi, T. Consolidation of Sm2Fe17N3 magnets with Sm-based eutectic alloy binder. J. Alloys Compd. 2018, 746, 16–26. [Google Scholar] [CrossRef]

- Saito, T.; Deguchi, T.; Yamamoto, H. Magnetic properties of Sm-Fe-N bulk magnets produced from Cu-plated Sm-Fe-N powder. AIP Adv. 2017, 7, 056204. [Google Scholar] [CrossRef]

- Leonowicz, M.; Kaszuwara, W.; Jezierska, E.; Januszewski, D.; Mendoza, G.; Davies, H.A.; Paszula, J. Application of the shock compaction technique for consolidation of hard magnetic powders. J. Appl. Phys. 1998, 83, 6634–6636. [Google Scholar] [CrossRef]

- Mashimo, T.; Huang, X.; Hirosawa, S.; Makita, K.; Kato, Y.; Mitsudo, S.; Motokawa, M. Magnetic properties of fully dense Sm2Fe17Nx magnets prepared by shock compression. J. Magn. Magn. Mater. 2000, 210, 109–120. [Google Scholar] [CrossRef]

- Saito, T.; Fukui, M.; Takeishi, H. Sm-Fe-N bulk magnets produced by the compression shearing method. Scr. Mater. 2005, 53, 1117–1121. [Google Scholar] [CrossRef]

- Takagi, K.; Nakayama, H.; Ozaki, K.; Kobayashi, K. Fabrication of High-performance Sm–Fe–N isotropic bulk magnets by a combination of High-pressure compaction and current sintering. J. Magn. Magn. Mater. 2012, 324, 1337–1341. [Google Scholar] [CrossRef]

- Ito, S.; Kikuchi, M.; Fujii, T.; Ishikawa, T. HIP sintering and magnetic properties of Sm2Fe17N3 with Zn additive. J. Magn. Magn. Mater. 2004, 270, 15–21. [Google Scholar] [CrossRef]

- Dongtao, Z.; Ming, Y.; Jiuxing, Z. Structures and magnetic properties of Sm-Fe-N sintering magnets prepared by spark plasma sintering method. J. Rare Earths 2006, 24, 325–328. [Google Scholar] [CrossRef]

- Saito, T. Structures and magnetic properties of Sm-Fe-N bulk magnets produced by spark plasma sintering method. J. Mater. Res. 2007, 22, 3130–3136. [Google Scholar] [CrossRef]

- Saito, T.; Kikuchi, K. Structures and magnetic properties of Sm2Fe17N3 bulk magnets prepared by spark plasma sintering with dynamic compression. J. Magn. Magn. Mater. 2024, 605, 172320. [Google Scholar] [CrossRef]

- Hosokawa, A.; Yoneyama, N.; Nakanowatari, I.; Eguchi, H.; Takagi, K. Production of anisotropic Sm-Fe-N magnet sheet by modified powder rolling. Mater. Lett. 2021, 294, 129815. [Google Scholar] [CrossRef]

- Coey, J.M.D.; Iriyama, T. Bonded Sm-Fe-N Permanent Magnets. In Modern Permanent Magnets; Woodhead Publishing: Cambridge, MA, USA, 2022; pp. 305–342. [Google Scholar]

- Xu, J.; Yi, Y.; Jia, B.; Xue, H.; Tian, G.; Ma, Z.; Hou, Y. Composition and microstructural control of Sm2Fe17N3 powders: A promising candidate for next-generation permanent magnets. J. Mater. Chem. C. 2024, 12, 14714. [Google Scholar] [CrossRef]

- Shi, D.-S.; Zheng, J.-W.; Liu, J.-M.; Cai, W.; Huang, H.; Chen, H.-B.; Qiao, L.; Lin, M.; Ying, Y.; Li, W.-C.; et al. Grain boundary regulation and microstructural evolution of Sm–Fe–N magnets via Zn electrodeposition. Rare Met. 2025. [Google Scholar] [CrossRef]

| Phase | Saturation Magnetization 4πMs (T) | Anisotropy Constant K1 (MJm−3) | Curie Temperature Tc (K) |

|---|---|---|---|

| Nd2Fe14B | 1.61 | 4.3 | 588 |

| L10-FeNi | 1.6 | 1.0 | 773 |

| α″-Fe16N2 | 2.4 | 1.0 | 810 |

| Phase | Saturation Magnetization 4πMs (T) | Anisotropy Constant K1 (MJm−3) | Curie Temperature Tc (K) |

|---|---|---|---|

| Nd2Fe14B | 1.61 | 4.3 | 588 |

| SmFe12 | 1.64 | 3.8 | 555 |

| Sm2Fe17N3 | 1.54 | 8.6 | 749 |

| Phase | Saturation Magnetization 4πMs (T) | Anisotropy Constant K1 (MJm−3) | Curie Temperature Tc (K) |

|---|---|---|---|

| SmFe12 | 1.64 | 3.8 | 555 |

| SmFe11Ti | 1.21 | 4.0 | 590 |

| Sm-Fe-N Powder (Production) | Remanence Magnetization Ir (T) | Intrinsic Coercivity Hcj (kA/m) | Curie Temperature T c (K) |

|---|---|---|---|

| Th2Zn17-type (RD process) | 1.08 | 840 | 740 |

| TbCu7-type (melt-spinning) | 1.02 | 756 | 740 |

| Manufacturer | Powder | Resin | Magnetic Properties |

|---|---|---|---|

| Sumitomo Metal Mining Co., Ltd. (Tokyo, Japan) | Th2Zn17-type Sm-Fe-N powder | PA12 (anisotropic) | Br = 0.80 (T) Hcj = 800 (kA/m) (BH)max = 115 (kJ/m3) |

| Nichia Corporation (Tokushima, Japan) | Th2Zn17-type Sm-Fe-N powder | PA12 (anisotropic) | Br = 0.78 (T) Hcj = 870 (kA/m) (BH)max = 112 (kJ/m3) |

| Daido Electronics Co., Ltd. ( Gifu, Japan) | TbCu7-type Sm-Fe-N powder | Epoxy (isotropic) | Br = 0.785 (T) Hcj = 735 (kA/m) (BH)max =105 (kJ/m3) |

| Hangzhou Chase Technology (Hangzhou, China) | Th2Zn17-type Sm-Fe-N powder | PA11/PA12 (anisotropic) | Br = 0.836 (T) Hcj = 569 (kA/m) (BH)max = 86.8 (kJ/m3) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Saito, T. Progress and Prospect of Sm-Fe-N Magnets. Inorganics 2025, 13, 322. https://doi.org/10.3390/inorganics13100322

Saito T. Progress and Prospect of Sm-Fe-N Magnets. Inorganics. 2025; 13(10):322. https://doi.org/10.3390/inorganics13100322

Chicago/Turabian StyleSaito, Tetsuji. 2025. "Progress and Prospect of Sm-Fe-N Magnets" Inorganics 13, no. 10: 322. https://doi.org/10.3390/inorganics13100322

APA StyleSaito, T. (2025). Progress and Prospect of Sm-Fe-N Magnets. Inorganics, 13(10), 322. https://doi.org/10.3390/inorganics13100322