Influence of the Magnetization of Thermally Expandable Particles on the Thermal and Debonding Properties of Bonding Joints

Abstract

1. Introduction

2. Results

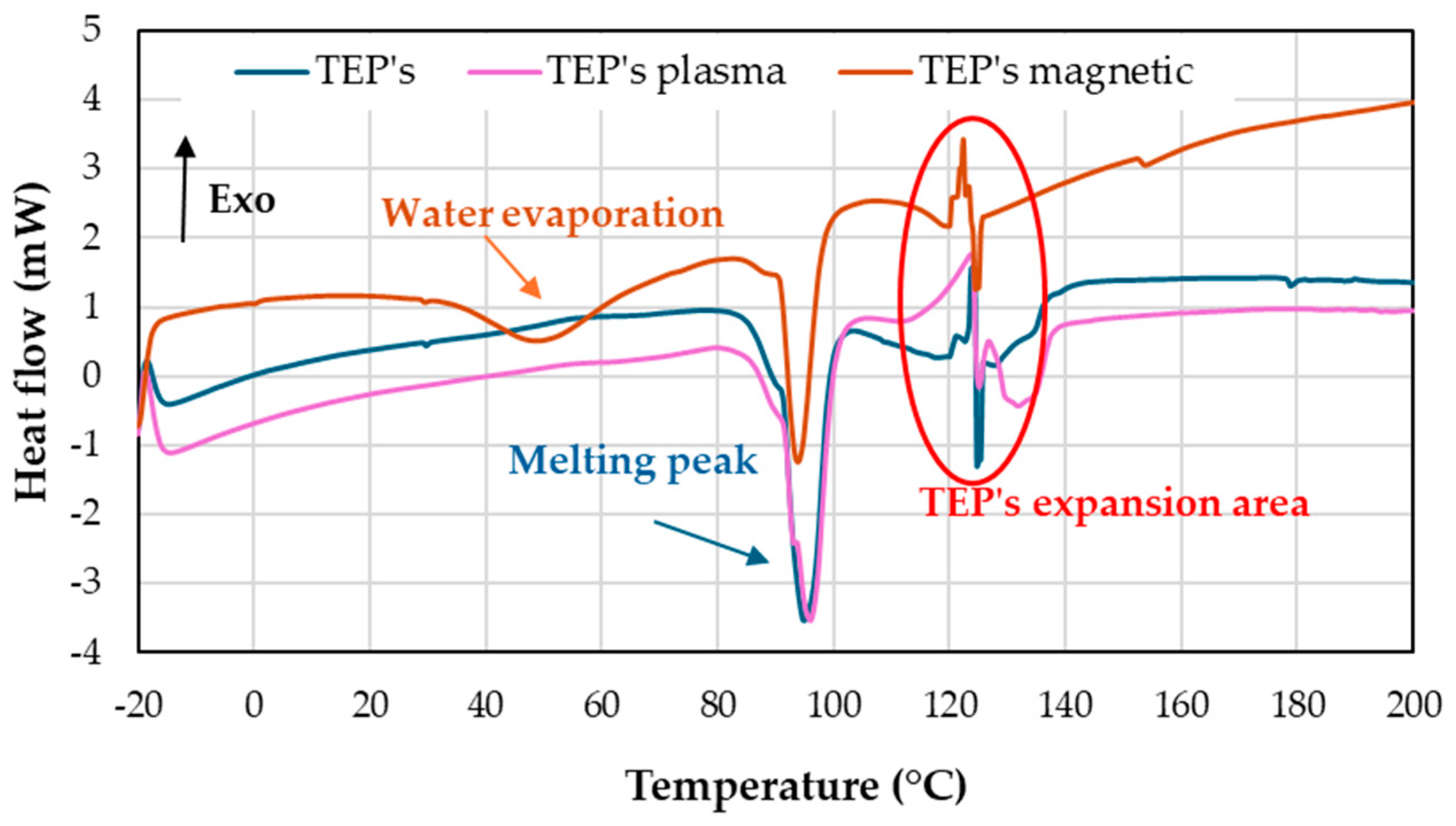

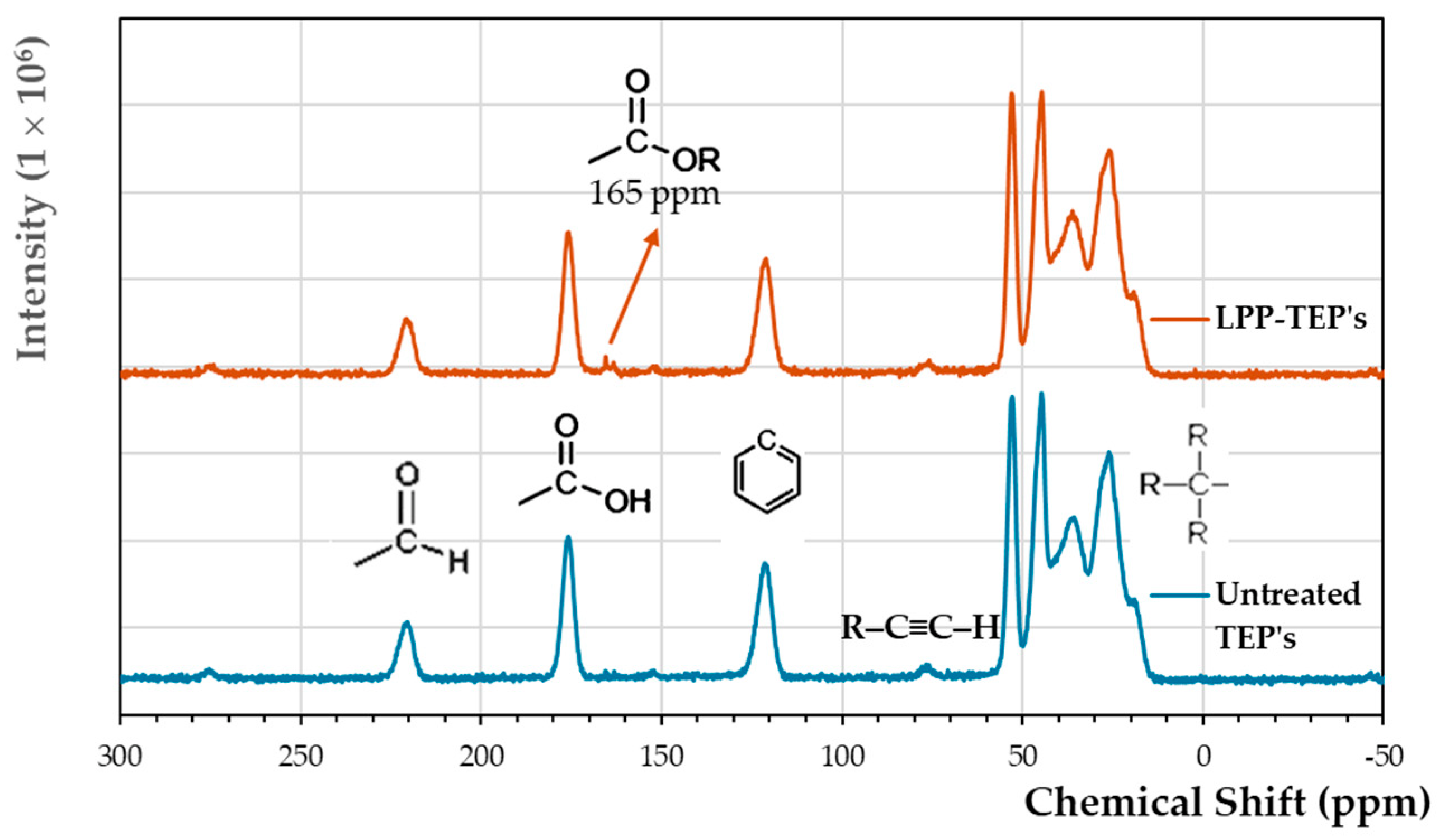

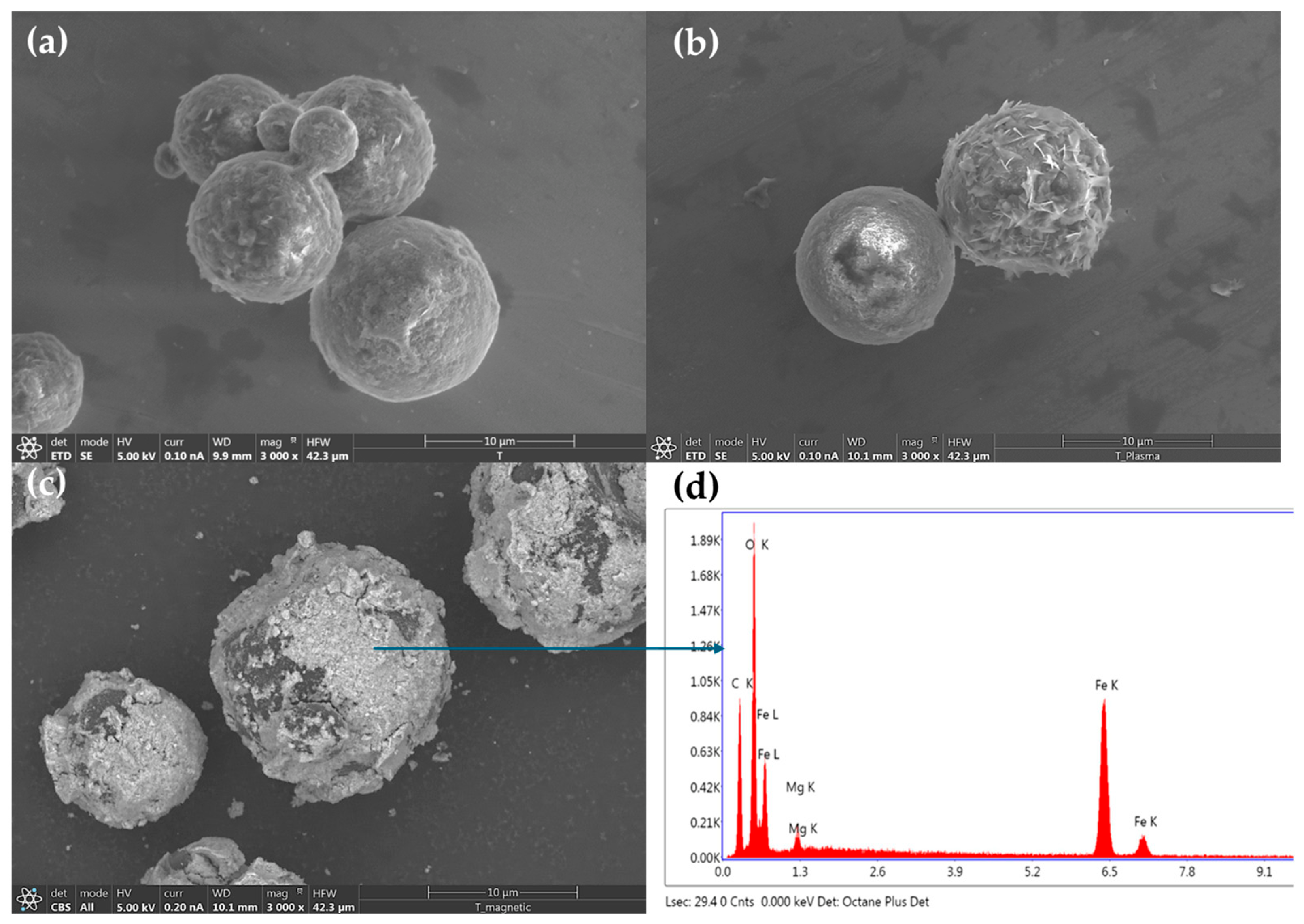

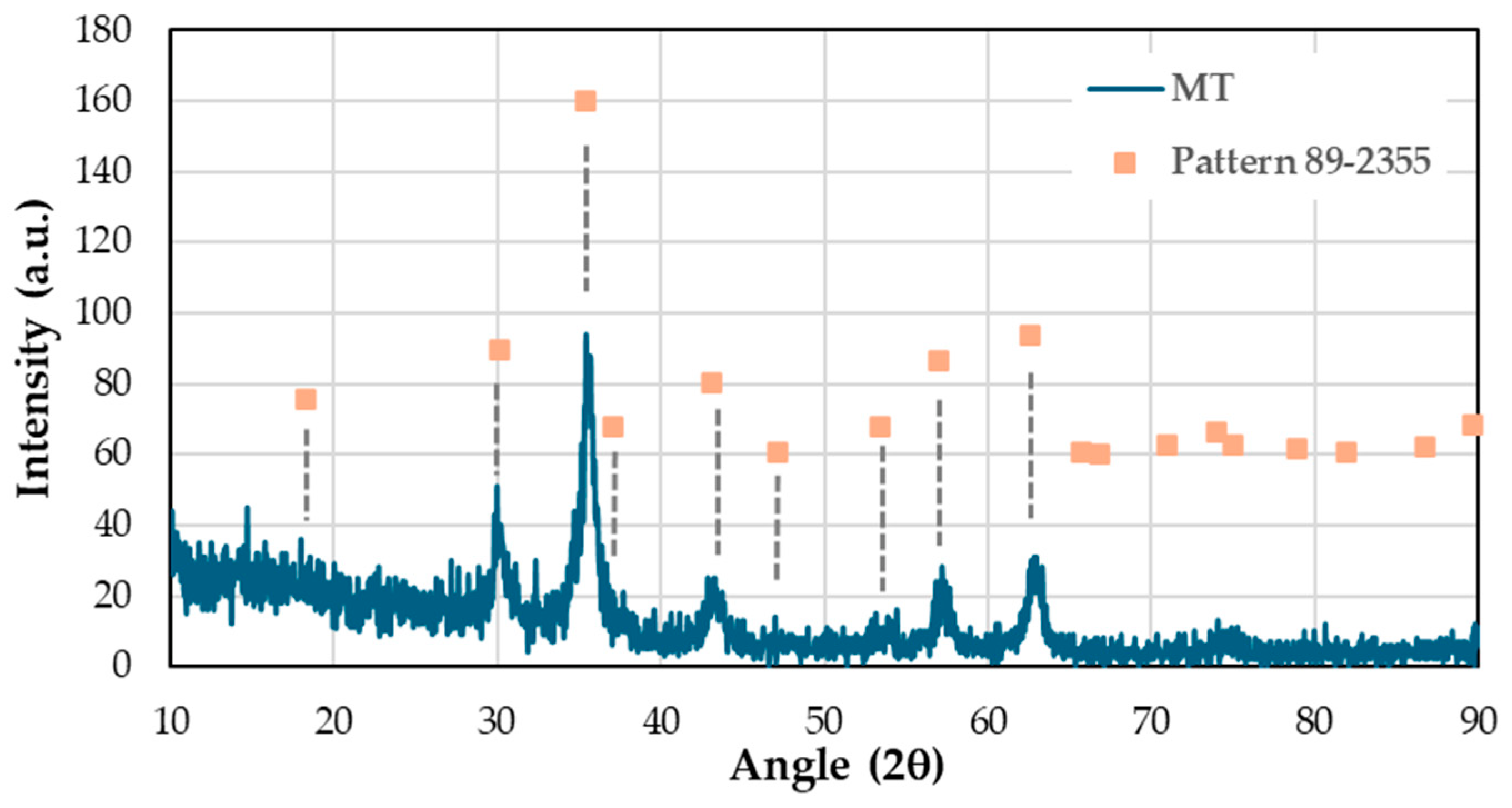

2.1. Characterization of Thermally Expandable Particles

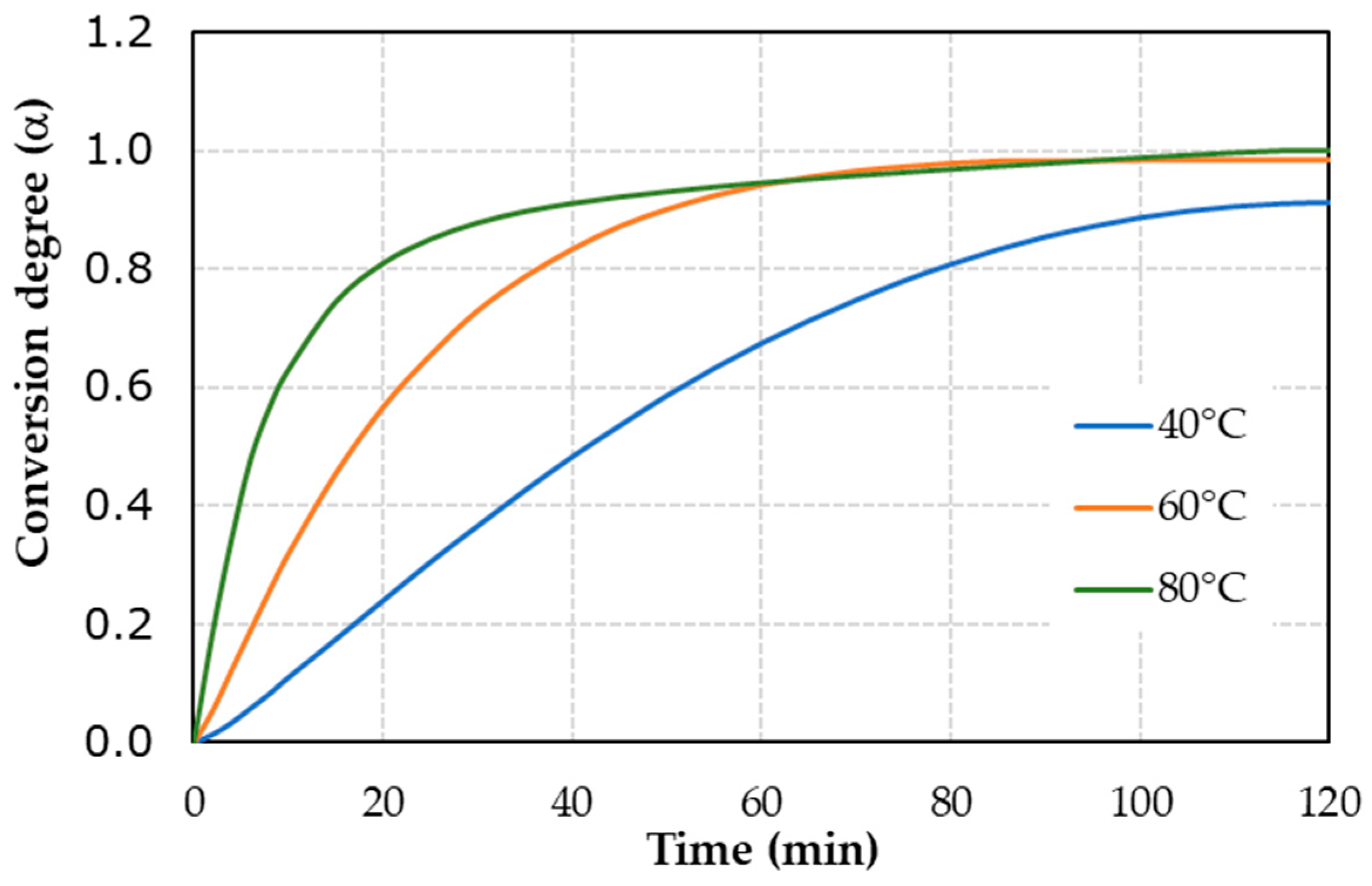

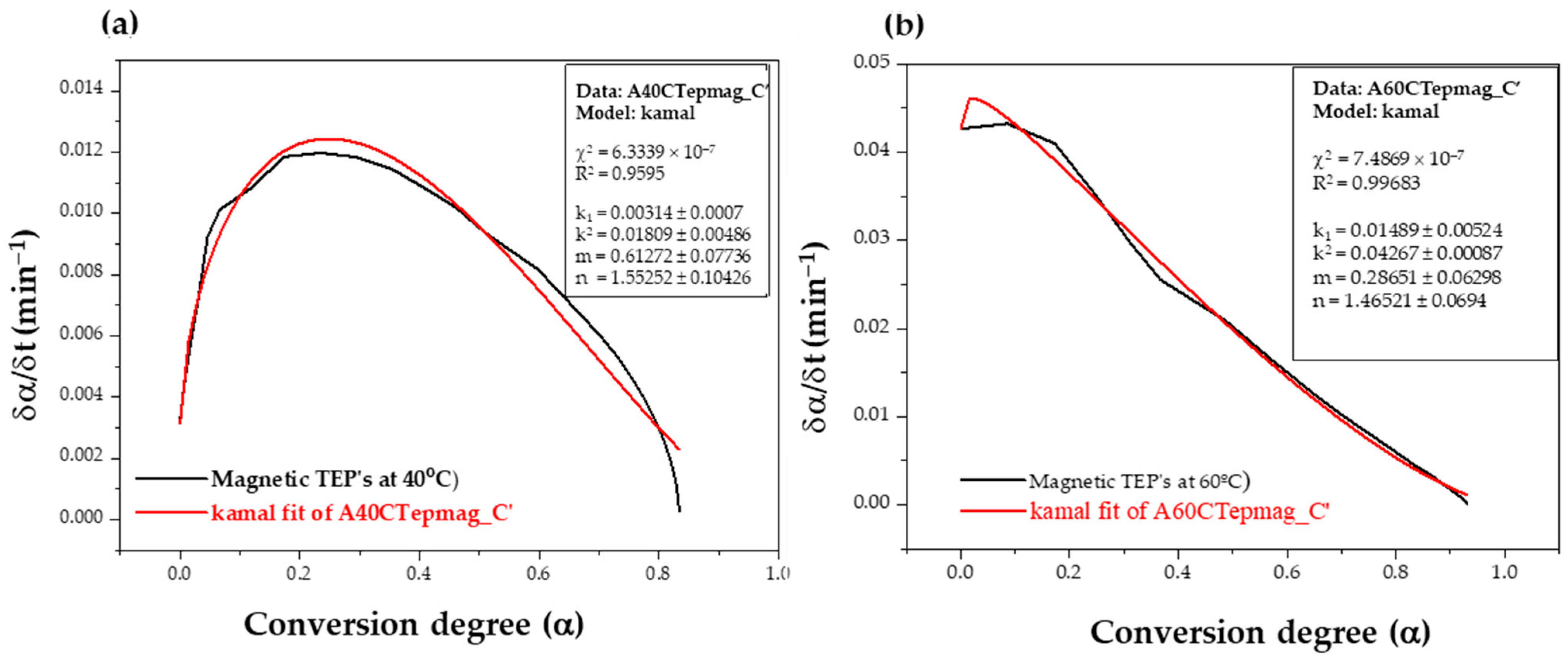

2.2. Influence of the Addition of TEPs on Adhesive Curing Kinetics

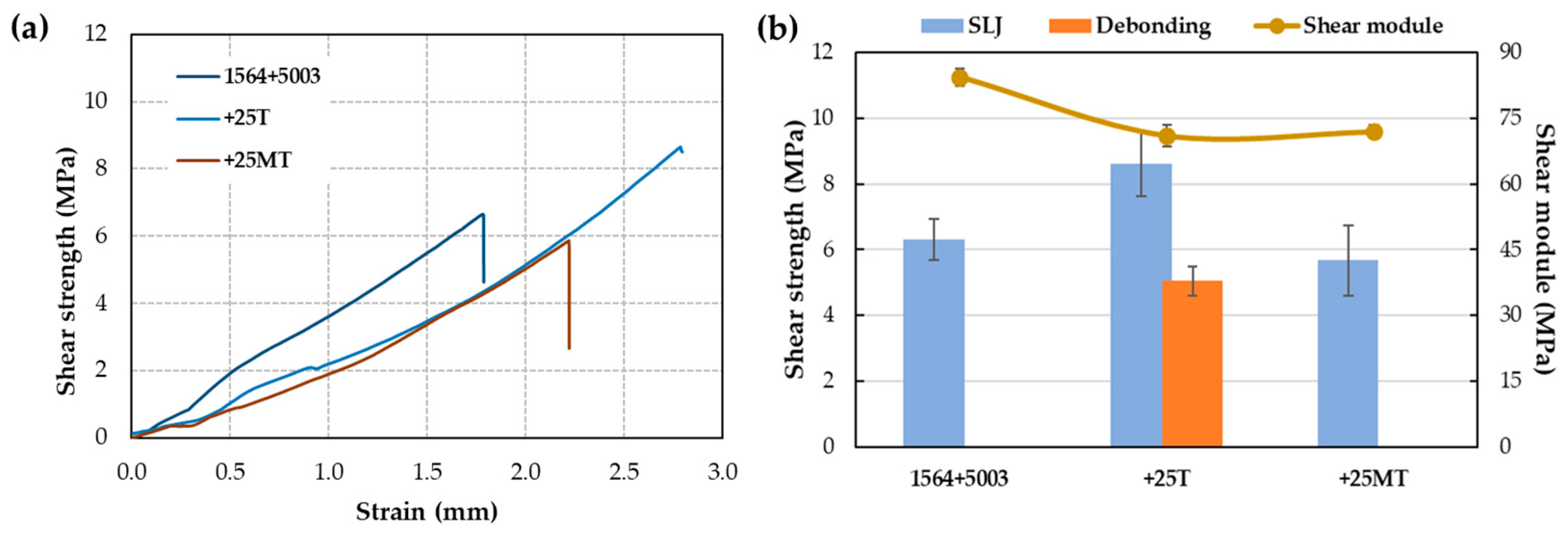

2.3. Examine the Debonding Process Occurring Due to Temperature

2.4. Durability

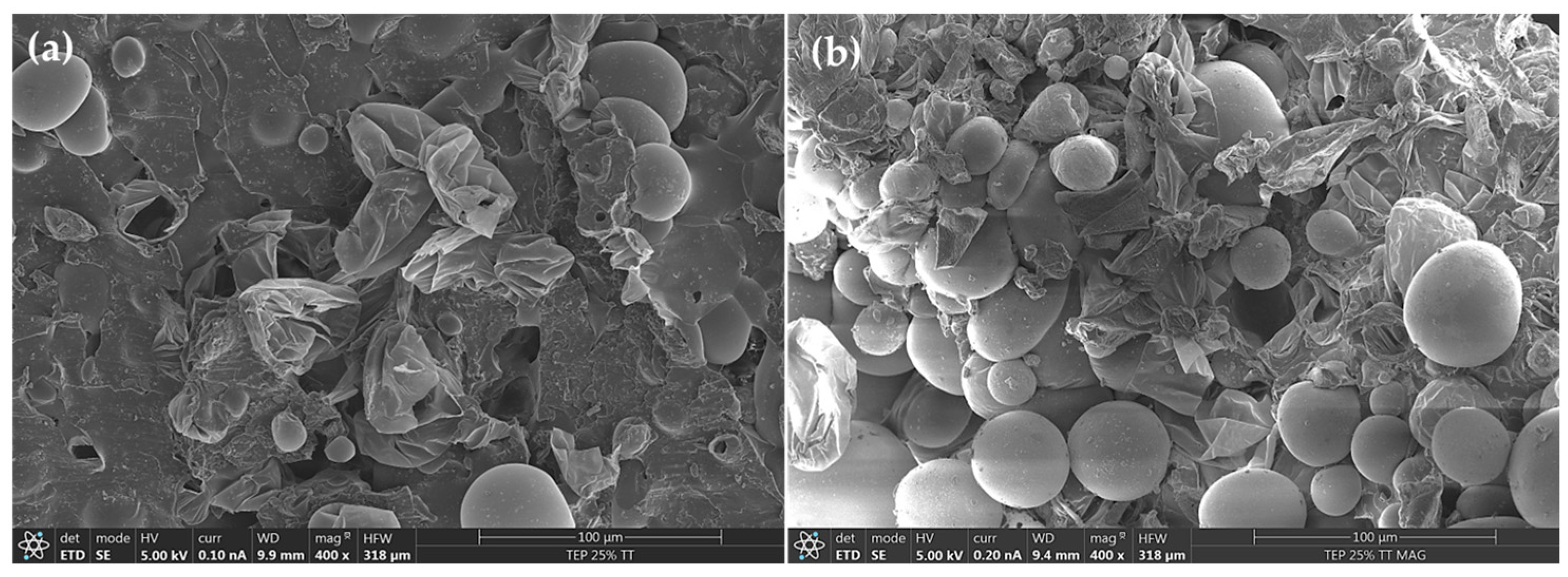

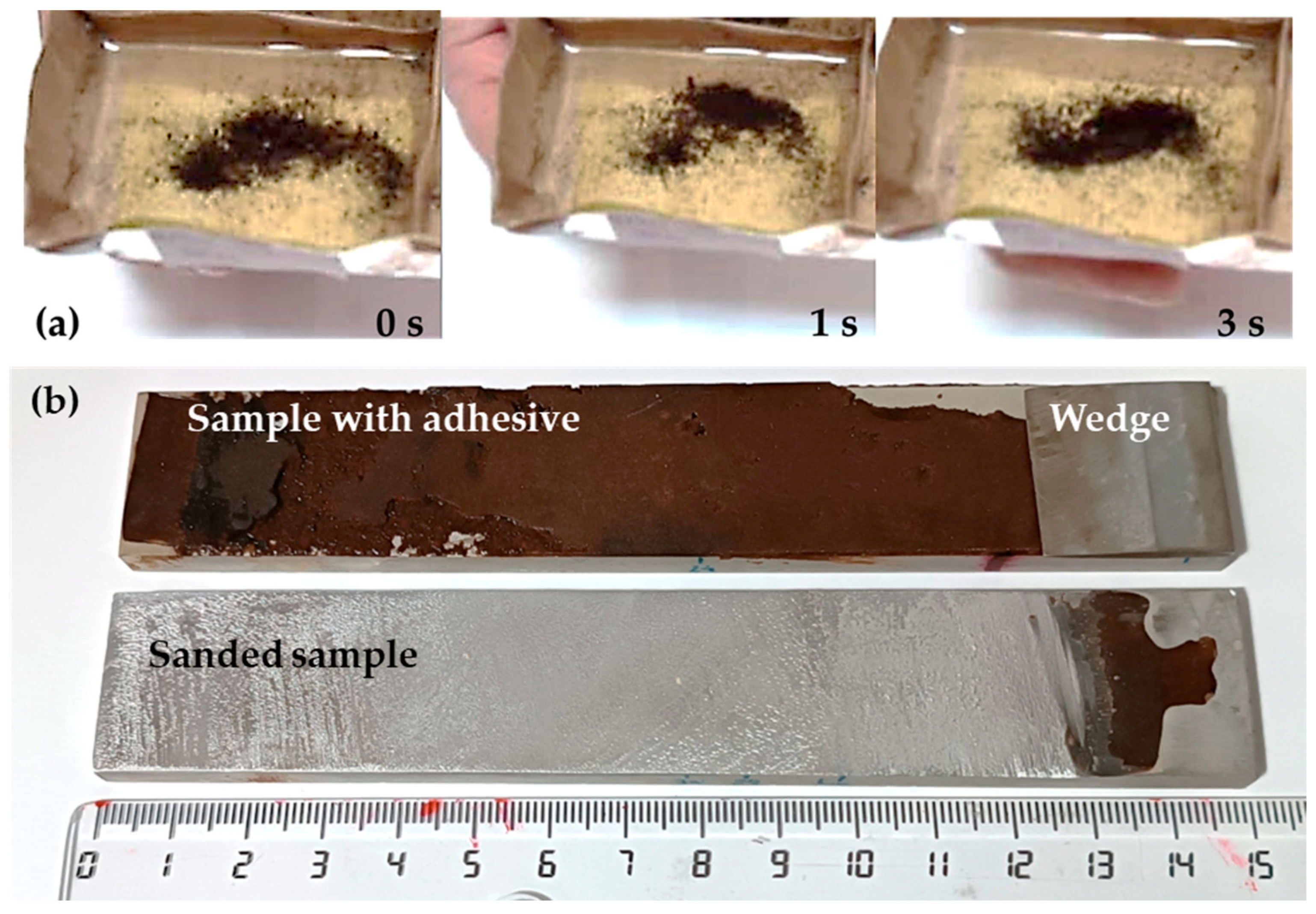

2.5. Mobility of Particles within the Matrix and Recycling of Adherents

3. Discussion

3.1. Characterization of TEPs

3.2. Influence of the Addition of TEPs on Adhesive Curing Kinetics

3.3. Examine the Debonding Process Occurring Due to Temperature

3.4. Durability

4. Materials and Methods

4.1. Materials

4.1.1. Thermally Expandable Particles

4.1.2. Epoxy Resin

4.2. Characterization of Thermally Expandable Particles

4.2.1. Differential Scanning Calorimetry

4.2.2. Nuclear Magnetic Resonance

4.2.3. Scanning Electron Microscopy

4.2.4. X-ray Diffraction

4.3. Characterization of Filled Adhesive

4.3.1. Influence of TEPs on the Curing Kinetics of Epoxy Resin

4.3.2. Influence of TEPs on the Debonding Process

4.3.3. Influence of TEPs on Durability of Epoxy Resin

5. Conclusions

- Main Novelty and Advantages:

- ○

- Debonding an adhesive bond manufactured with magnetic TEPs by heating offers significant advantages, reducing the energy required for the disassembly of adhesive bonds and facilitating the reuse of substrates, aligning with the principles of a circular economy.

- Detailed Results:

- ○

- The TEPs’ microcapsules open within a temperature range from 90 to 130 °C, rendering thermal curing unfeasible at high temperatures.

- ○

- The curing process can be studied using Kamal’s equation. The TEPs were found to influence the curing degree.

- ○

- The addition of TEPs or magnetic TEPs does not affect the melting temperature.

- ○

- The curing rate varies with temperature and the presence of TEPs.

- General Results:

- ○

- TEPs significantly influence the curing process and mechanical properties of the adhesive.

- ○

- Magnetic TEPs can be manipulated with a magnet when they are embedded in the resin, allowing for a precise placement within the joint.

- ○

- The shear strength of adhesive bonds can be enhanced by the presence of TEPs, but magnetic TEPs reduce shear strength while increasing durability under the studied conditions of temperature and humidity.

- Future Study Outlook:

- ○

- Further investigation is required to validate the performance of debonding technologies in practical applications.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Sarfraz, M.S.; Hong, H.; Kim, S.S. Recent Developments in the Manufacturing Technologies of Composite Components and Their Cost-Effectiveness in the Automotive Industry: A Review Study. Compos. Struct. 2021, 266, 113864. [Google Scholar] [CrossRef]

- Czerwinski, F. Current Trends in Automotive Lightweighting Strategies and Materials. Materials 2021, 14, 6631. [Google Scholar] [CrossRef] [PubMed]

- Sakai, S.i.; Yoshida, H.; Hiratsuka, J.; Vandecasteele, C.; Kohlmeyer, R.; Rotter, V.S.; Passarini, F.; Santini, A.; Peeler, M.; Li, J.; et al. An International Comparative Study of End-of-Life Vehicle (ELV) Recycling Systems. J. Mater. Cycles Waste Manag. 2014, 16, 1–20. [Google Scholar] [CrossRef]

- D’Adamo, I.; Gastaldi, M.; Rosa, P. Recycling of End-of-Life Vehicles: Assessing Trends and Performances in Europe. Technol. Forecast. Soc. Chang. 2020, 152, 119887. [Google Scholar] [CrossRef]

- Jang, Y.C.; Choi, K.; Jeong, J.; Kim, H.; Kim, J.-G. Recycling and Material-Flow Analysis of End-of-Life Vehicles towards Resource Circulation in South Korea. Sustainability 2022, 14, 1270. [Google Scholar] [CrossRef]

- Mura, M.; Longo, M.; Zanni, S. Circular Economy in Italian SMEs: A Multi-Method Study. J. Clean. Prod. 2020, 245, 118821. [Google Scholar] [CrossRef]

- Li, Y.; Fujikawa, K.; Wang, J.; Li, X.; Ju, Y.; Chen, C. The Potential and Trend of End-of-Life Passenger Vehicles Recycling in China. Sustainability 2020, 12, 1455. [Google Scholar] [CrossRef]

- Shah, V.; Bhaliya, J.; Patel, G.M.; Deshmukh, K. Advances in Polymeric Nanocomposites for Automotive Applications: A Review. Polym. Adv. Technol. 2022, 33, 3023–3048. [Google Scholar] [CrossRef]

- Agarwal, J.; Sahoo, S.; Mohanty, S.; Nayak, S.K. Progress of Novel Techniques for Lightweight Automobile Applications through Innovative Eco-Friendly Composite Materials: A Review. J. Thermoplast. Compos. Mater. 2020, 33, 978–1013. [Google Scholar] [CrossRef]

- Kawajiri, K.; Kobayashi, M.; Sakamoto, K. Lightweight Materials Equal Lightweight Greenhouse Gas Emissions?: A Historical Analysis of Greenhouse Gases of Vehicle Material Substitution. J. Clean. Prod. 2020, 253, 119805. [Google Scholar] [CrossRef]

- Cavezza, F.; Boehm, M.; Terryn, H.; Hauffman, T. A Review on Adhesively Bonded Aluminium Joints in the Automotive Industry. Metals 2020, 10, 730. [Google Scholar] [CrossRef]

- Perez, M.; Akhavan-Safar, A.; Carbas, R.J.C.; Marques, E.A.S.; Wenig, S.; da Silva, L.F.M. Loading Rate and Temperature Interaction Effects on the Mode I Fracture Response of a Ductile Polyurethane Adhesive Used in the Automotive Industry. Materials 2022, 15, 8948. [Google Scholar] [CrossRef] [PubMed]

- Bruckner, T.M.; Singewald, T.D.; Gruber, R.; Hader-Kregl, L.; Müller, M.; Kern, C.; Hafner, M.; Paulik, C. Influence of Hollow Glass Microspheres on 1K Epoxy Structural Adhesive for the Automotive Industry. Int. J. Adhes. Adhes. 2023, 124, 103396. [Google Scholar] [CrossRef]

- Rosendo, D.; Viana, G.; Carbas, R.; Marques, E.; da Silva, L.F. Effect of Temperature and Moisture on the Impact Behaviour of Adhesive Joints for the Automotive Industry. J. Appl. Comput. Mech. 2021, 7, 1488–1500. [Google Scholar] [CrossRef]

- Marques, A.C.; Mocanu, A.; Tomić, N.Z.; Balos, S.; Stammen, E.; Lundevall, A.; Abrahami, S.T.; Günther, R.; de Kok, J.M.M.; de Freitas, S.T. Review on Adhesives and Surface Treatments for Structural Applications: Recent Developments on Sustainability and Implementation for Metal and Composite Substrates. Materials 2020, 13, 5590. [Google Scholar] [CrossRef] [PubMed]

- Galvez, P.; Abenojar, J.; Martinez, M.A. Effect of Moisture and Temperature on the Thermal and Mechanical Properties of a Ductile Epoxy Adhesive for Use in Steel Structures Reinforced with CFRP. Compos. Part B Eng. 2019, 176, 107194. [Google Scholar] [CrossRef]

- Encinas, N.; Lavat-Gil, M.; Dillingham, R.G.; Abenojar, J.; Martínez, M.A. Cold Plasma Effect on Short Glass Fibre Reinforced Composites Adhesion Properties. Int. J. Adhes. Adhes. 2014, 48, 85–91. [Google Scholar] [CrossRef]

- Abenojar, J.; Tutor, J.; Ballesteros, Y.; del Real, J.C.; Martínez, M.A. Erosion-Wear, Mechanical and Thermal Properties of Silica Filled Epoxy Nanocomposites. Compos. Part B Eng. 2017, 120, 42–53. [Google Scholar] [CrossRef]

- Abenojar, J.; Lopez de Armentia, S.; Barbosa, A.Q.; Martinez, M.A.; del Real, J.C.; da Silva, L.F.M.; Velasco, F. Magnetic Cork Particles as Reinforcement in an Epoxy Resin: Effect of Size and Amount on Thermal Properties. J. Therm. Anal. Calorim. 2023, 148, 1981–1995. [Google Scholar] [CrossRef]

- Shishesaz, M.; Hosseini, M. Effects of Joint Geometry and Material on Stress Distribution, Strength and Failure of Bonded Composite Joints: An Overview. J. Adhes. 2020, 96, 1053–1121. [Google Scholar] [CrossRef]

- Adams, R.D.; Cooper, D.G.A.; Pearson, S. Vibration Damping of Adhesiovely Bonded Joints. In Handbook of Adhesion Technology; da Silva, L.F., Öchsner, A., Adams, R.D., Eds.; Springer International Publishing: Cham, Switzerland, 2021; pp. 854–875. ISBN 978-3-319-55410-5. [Google Scholar]

- Koh, E.; Park, S. Self-Anticorrosion Performance Efficiency of Renewable Dimer-Acid-Based Polyol Microcapsules Containing Corrosion Inhibitors with Two Triazole Groups. Prog. Org. Coat. 2017, 109, 61–69. [Google Scholar] [CrossRef]

- Madhi, A. Smart Epoxy/Polyurethane/Carbon Quantum Dots Hybrid Coatings: Synthesis and Study of UV-Shielding, Viscoelastic, and Anti-Corrosive Properties. Polym. Plast. Technol. Mater. 2023, 62, 403–418. [Google Scholar] [CrossRef]

- Baena, M.D. Debonding of Structural Adhesive Joints. In Structural Adhesive Joints: Design, Analysis and Testing; Mittal, K.L., Panigrahi, S.K., Eds.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2020; pp. 135–138. ISBN 978111973643. [Google Scholar]

- Kemal, A. Functionally Graded Adhesively Bonded Joints. In Progressin Adhesion and Adhesives; Mittal, K.L., Ed.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2015; pp. 57–78. ISBN 9781119162193. [Google Scholar]

- Das, R.-R. Failure Analysis of Strucutral Adhesive Joints with Functionally Grades Tubular Adherends. In Structural Adhesive Joints: Design, Analysis and Testing; Mittal, K.L., Panigrahi, S.K., Eds.; John Wiley & Sons, Inc.: New York, NY, USA, 2020; pp. 205–219. ISBN 9781119736431. [Google Scholar]

- dos Reis, M.Q.; Marques, E.A.S.; Carbas, R.J.C.; da Silva, L.F.M. Functionally Graded Adherends in Adhesive Joints: An Overview. J. Adv. Join. Process. 2020, 2, 100033. [Google Scholar] [CrossRef]

- Li, R.; Noda, N.A.; Takaki, R.; Sano, Y.; Takase, Y.; Miyazaki, T. Most Suitable Evaluation Method for Adhesive Strength to Minimize Bend Effect in Lap Joints in Terms of the Intensity of Singular Stress Field. Int. J. Adhes. Adhes. 2018, 86, 45–58. [Google Scholar] [CrossRef]

- Goodenough, J.; Fitzgerald, A.; Bean, K.; Hatcliffe, J.; Slark, A.; Hamerton, I.; Bond, I. Reversible Adhesives and Debondable Joints for Fibre-Reinforced Plastics: Characteristics, Capabilities, and Opportunities. Mater. Chem. Phys. 2023, 299, 127464. [Google Scholar] [CrossRef]

- Budhe, S.; Banea, M.D.; de Barros, S.; da Silva, L.F.M. An Updated Review of Adhesively Bonded Joints in Composite Materials. Int. J. Adhes. Adhes. 2017, 72, 30–42. [Google Scholar] [CrossRef]

- Tenorio-Alfonso, A.; Sánchez, M.C.; Franco, J.M. A Review of the Sustainable Approaches in the Production of Bio-Based Polyurethanes and Their Applications in the Adhesive Field. J. Polym. Environ. 2020, 28, 749–774. [Google Scholar] [CrossRef]

- Gonçalves, F.A.M.M.; Santos, M.; Cernadas, T.; Ferreira, P.; Alves, P. Advances in the Development of Biobased Epoxy Resins: Insight into More Sustainable Materials and Future Applications. Int. Mater. Rev. 2022, 67, 119–149. [Google Scholar] [CrossRef]

- Roig, A.; Ramis, X.; De la Flor, S.; Serra, À. Eugenol-Based Dual-Cured Materials with Multiple Dynamic Exchangeable Bonds. Eur. Polym. J. 2024, 206, 112782. [Google Scholar] [CrossRef]

- Carbonell-Blasco, M.P.; Moyano, M.A.; Hernández-Fernández, C.; Sierra-Molero, F.J.; Pastor, I.M.; Alonso, D.A.; Arán-Aís, F.; Orgilés-Calpena, E. Polyurethane Adhesives with Chemically Debondable Properties via Diels–Alder Bonds. Polymers 2024, 16, 21. [Google Scholar] [CrossRef]

- Roig, A.; Molina, L.; Serra, À.; Santiago, D.; De la Flor, S. Structural Reversible Adhesives Based on Thiol-Epoxy Vitrimers. Polym. Test. 2023, 128, 108205. [Google Scholar] [CrossRef]

- Avshalomov, R.; Jarach, N.; Dodiuk, H. Breaking the Unbreakable Bond: Towards Sustainable Adhesives’ Future. Eur. Polym. J. 2024, 209, 112920. [Google Scholar] [CrossRef]

- Banea, M.D.; Da Silva, L.F.M.; Campilho, R.D.S.G.; Sato, C. Smart Adhesive Joints: An Overview of Recent Developments. J. Adhes. 2014, 90, 16–40. [Google Scholar] [CrossRef]

- Banea, M.D.; Da Silva, L.F.M.; Carbas, R.J.C.; Campilho, R.D.S.G. Structural Adhesives Modified with Thermally Expandable Particles. J. Adhes. 2015, 91, 823–840. [Google Scholar] [CrossRef]

- Banea, M.D.; Da Silva, L.F.M.; Carbas, R.J.C.; Campilho, R.D.S.G. Mechanical and Thermal Characterization of a Structural Polyurethane Adhesive Modified with Thermally Expandable Particles. Int. J. Adhes. Adhes. 2014, 54, 191–199. [Google Scholar] [CrossRef]

- Banea, M.D.; Da Silva, L.F.M.; Carbas, R.J.C. Debonding on Command of Adhesive Joints for the Automotive Industry. Int. J. Adhes. Adhes. 2015, 59, 14–20. [Google Scholar] [CrossRef]

- Banea, M.D.; da Silva, L.F.M.; Carbas, R.J.C.; de Barros, S. Debonding on Command of Multi-Material Adhesive Joints. J. Adhes. 2017, 93, 756–770. [Google Scholar] [CrossRef]

- Banea, M.D.; Da Silva, L.F.M.; Carbas, R.; Barros, S.D.E. Effect of Temperature and Moisture on the Tensile Properties of a TEPS-Modified Adhesive. Mater. Plast. 2018, 55, 478–481. [Google Scholar] [CrossRef]

- Banea, M.D.; Da Silva, L.F.M.; Carbas, R.J.C.; Cavalcanti, D.K.K.; De Souza, L.F.G. The Effect of Environment and Fatigue Loading on the Behaviour of TEPs-Modified Adhesives. J. Adhes. 2020, 96, 423–436. [Google Scholar] [CrossRef]

- Piazza, G.; Burczyk, M.; Gerini-Romagnoli, M.; Belingardi, G.; Nassar, S.A. Effect of Thermally Expandable Particle Additives on the Mechanical and Reversibility Performance of Adhesive Joints. J. Adv. Join. Process. 2022, 5, 100088. [Google Scholar] [CrossRef]

- Banea, M.D.; da Silva, L.F.M.; Carbas, R.J.C.; Barbosa, A.Q.; de Barros, S.; Viana, G. Effect of Water on the Behaviour of Adhesives Modified with Thermally Expandable Particles. Int. J. Adhes. Adhes. 2018, 84, 250–256. [Google Scholar] [CrossRef]

- Ciardiello, R.; Martorana, B.; Lambertini, V.G.; Brunella, V. Iron-Based Reversible Adhesives: Effect of Particles Size on Mechanical Properties. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2018, 232, 1446–1455. [Google Scholar] [CrossRef]

- da Silva, C.I.; Barbosa, A.Q.; Marques, J.B.; Carbas, R.C.; Marques, E.A.S.; Abenojar, J.; da Silva, L.F. Mechanical Characterisation of Graded Single Lap Joints Using Magnetised Cork Microparticles. In Advanced Joining Processes in Advanced Structured Materials; Öchsner, A., da Silva, L.F., Altenbach, H., Eds.; Springer: Singapore, 2019; Volume 125, pp. 153–174. ISBN 978-981-15-2956-6. [Google Scholar]

- da Silva, C.I.; Cunha, M.R.O.; Barbosa, A.Q.; Carbas, R.J.C.; Marques, E.A.S.; da Silva, L.F.M. Functionally Graded Adhesive Joints Using Magnetic Microparticles with a Polyurethane Adhesive. J. Adv. Join. Process. 2021, 3, 100048. [Google Scholar] [CrossRef]

- Carbas, R.J.C.; Da Silva, L.F.M.; Critchlow, G.W. Adhesively Bonded Functionally Graded Joints by Induction Heating. Int. J. Adhes. Adhes. 2014, 48, 110–118. [Google Scholar] [CrossRef]

- Saeedifar, M.; Saleh, M.N.; De Freitas, S.T.; Zarouchas, D. Damage Characterization of Adhesively-Bonded Bi-Material Joints Using Acoustic Emission. Compos. Part B Eng. 2019, 176, 107356. [Google Scholar] [CrossRef]

- Özer, H.; Öz, Ö. The Use of the Exponential Drucker-Prager Material Model for Defining the Failure Loads of the Mono and Bi-Adhesive Joints. Int. J. Adhes. Adhes. 2017, 76, 17–29. [Google Scholar] [CrossRef]

- Chiminelli, A.; Breto, R.; Izquierdo, S.; Bergamasco, L.; Duvivier, E.; Lizaranzu, M. Analysis of Mixed Adhesive Joints Considering the Compaction Process. Int. J. Adhes. Adhes. 2017, 76, 3–10. [Google Scholar] [CrossRef]

- Bonaldo, J.; Banea, M.D.; Carbas, R.J.C.; Da Silva, L.F.M.; De Barros, S. Functionally Graded Adhesive Joints by Using Thermally Expandable Particles. J. Adhes. 2019, 95, 995–1014. [Google Scholar] [CrossRef]

- Carbas, R.J.C.; da Silva, L.F.M.; Andrés, L.F.S. Functionally Graded Adhesive Joints by Graded Mixing of Nanoparticles. Int. J. Adhes. Adhes. 2017, 76, 30–37. [Google Scholar] [CrossRef]

- Abenojar, J.; López de Armentia, S.; Barbosa, A.Q.; Martínez, M.A.; Velasco, F.; da Silva, L.F.M.; del Real Romero, J.C. Coating Cork Particles with Iron Oxide: Effect on Magnetic Properties. Wood Sci. Technol. 2020, 54, 869–889. [Google Scholar] [CrossRef]

- Mohammadkhani, F.; Montazer, M.; Latifi, M. Microwave Absorption Characterization and Wettability of Magnetic Nano Iron Oxide/Recycled PET Nanofibers Web. J. Text. Inst. 2019, 110, 989–999. [Google Scholar] [CrossRef]

- Wang, K.; Deng, Q. The Thermal and Mechanical Properties of Microinhomogeneous Materials. Polymers 2019, 11, 1055. [Google Scholar] [CrossRef]

- Cárdenas, M.A.; García-López, D.; Gobernado-Mitre, I.; Merino, J.C.; Pastor, J.M.; de Martínez, J.D.; Barbeta, J.; Calveras, D. Mechanical and Fire Retardant Properties of EVA/Clay/ATH Nanocomposites—Effect of Particle Size and Surface Treatment of ATH Filler. Polym. Degrad. Stab. 2008, 93, 2032–2037. [Google Scholar] [CrossRef]

- Abenojar, J.; Martínez, M.A.; Velasco, F.; Rodríguez-Pérez, M.A. Atmospheric Plasma Torch Treatment of Polyethylene/Boron Composites: Effect on Thermal Stability. Surf. Coat. Technol. 2014, 239, 70–77. [Google Scholar] [CrossRef]

- Moore, J.W.; Pearson, R.G. Kinetics and Mechanism, 3rd ed.; John Wiley & Sons, Inc.: New York, NY, USA, 1981; ISBN 0-471-03558-0. [Google Scholar]

- Abenojar, J.; Enciso, B.; Pantoja, M.; Velasco, F.; Martínez, M.A. Thermal Characterization and Diffusivity of Two Mono-Component Epoxies for Transformer Insulation. Int. J. Adhes. Adhes. 2020, 103, 102726. [Google Scholar] [CrossRef]

- Abenojar, J.; de Armentia, S.L.; Martinez, M.A.; del Real, J.C. Development of a Green Epoxy Adhesive for Cork by Adding Lignin: Thermal and Bonding Properties. Wood Sci. Technol. 2022, 56, 721–742. [Google Scholar] [CrossRef]

- Kamal, M.R.; Sourour, S. Kinetic and Thermal Characterization of Thermoset Cure. Polym. Eng. Sci. 1973, 13, 59–64. [Google Scholar] [CrossRef]

- Paz-Abuin, S.; Pazos-Pellin, M.; Paz-Paxos, M. Inmfluence of the Reactive of Amine Hydrogens and the Evaporation of Monomers on the Cure Kinetics of Epoxy-Amine: Kinetic Questions. Polymer 1997, 38, 3795–3804. [Google Scholar] [CrossRef]

- Morehouse, D.S.; Tetreault, R.J. Expansible Thermoplastic Polymer Particles Containing Volatile Fluid Foaming Agent and Method of Foaming the Same 1967. U.S. Patent No. 3,615,972, 26 October 1971. [Google Scholar]

- Thermo-Expandable Microcapsule. Matsumoto Microsphere® F and FN Series. Available online: https://www.mtmtys.co.jp/e/product/general/data01.html (accessed on 11 December 2023).

- EN 1465:2009; Adhesives—Determination of Tensile lap-Shear Strength of Bonded Assemblies. JIS: Tai Po Kau, Hong Kong, 2008.

- EN 14444:2005/AC:2008; Structural Adhesives—Qualitative Assessment of Durability of Bonded Assemblies—Wedge Rupture Test. ISO: Geneva, Switzerland, 2008.

| Specimens | ΔHwater (J g−1) | Tm (°C) | ΔHm (J g−1) | TTEPs expansion (°C) |

|---|---|---|---|---|

| TEPs | 95 | −64 | 120–125 | |

| LPP TEPs | 96 | −58 | 120–125 | |

| Magnetic TEPs | −16 | 94 | −31 | 120–125 |

| Samples | Temperature (°C) | αmax 120 min | Kinetic Parameters | ||||

|---|---|---|---|---|---|---|---|

| k1 | k2 | m | n | R2 | |||

| 1564 + 5003 | 40 | 0.74 | 0.007 | 0.004 | 0.086 | 0.894 | 0.98 |

| 60 | 0.96 | 0.029 | 0.018 | 0.130 | 1.110 | 0.97 | |

| 80 | 1 | 0.125 | 0.068 | 0.467 | 1.441 | 1.00 | |

| +25T | 40 | 0.91 | 0.005 | 0.023 | 0.498 | 1.074 | 0.97 |

| 60 | 0.98 | 0.016 | 0.033 | 0.521 | 1.084 | 1.00 | |

| 80 | 1 | 0.110 | 0.209 | 1.007 | 1.094 | 1.00 | |

| +25MT | 40 | 0.83 | 0.003 | 0.018 | 0.613 | 1.553 | 0.96 |

| 60 | 0.93 | 0.015 | 0.043 | 0.287 | 1.465 | 1.00 | |

| 80 | 1 | 0.074 | 0.145 | 0.875 | 1.500 | 0.99 | |

| Resin/Composites | k1 | k2 |

|---|---|---|

| Ea (kJ mol−1) | Ea (kJ mol−1) | |

| 1564 + 5003 | 53 | 51 |

| +25T | 56 | 40 |

| +25MT | 58 | 38 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Abenojar, J.; López de Armentia, S.; del Real, J.-C.; Martínez, M.-A. Influence of the Magnetization of Thermally Expandable Particles on the Thermal and Debonding Properties of Bonding Joints. Inorganics 2024, 12, 129. https://doi.org/10.3390/inorganics12050129

Abenojar J, López de Armentia S, del Real J-C, Martínez M-A. Influence of the Magnetization of Thermally Expandable Particles on the Thermal and Debonding Properties of Bonding Joints. Inorganics. 2024; 12(5):129. https://doi.org/10.3390/inorganics12050129

Chicago/Turabian StyleAbenojar, Juana, Sara López de Armentia, Juan-Carlos del Real, and Miguel-Angel Martínez. 2024. "Influence of the Magnetization of Thermally Expandable Particles on the Thermal and Debonding Properties of Bonding Joints" Inorganics 12, no. 5: 129. https://doi.org/10.3390/inorganics12050129

APA StyleAbenojar, J., López de Armentia, S., del Real, J.-C., & Martínez, M.-A. (2024). Influence of the Magnetization of Thermally Expandable Particles on the Thermal and Debonding Properties of Bonding Joints. Inorganics, 12(5), 129. https://doi.org/10.3390/inorganics12050129