Effect of Temperature on the Adhesion and Bactericidal Activities of Ag+-Doped BiVO4 Ceramic Tiles

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Ag+-Doped BiVO4 Functionalized Ceramic Tiles Preparation

2.3. Disinfection Experiment

2.4. Characterization

3. Results and Discussion

3.1. Phase, Chemical and Optical Characterization

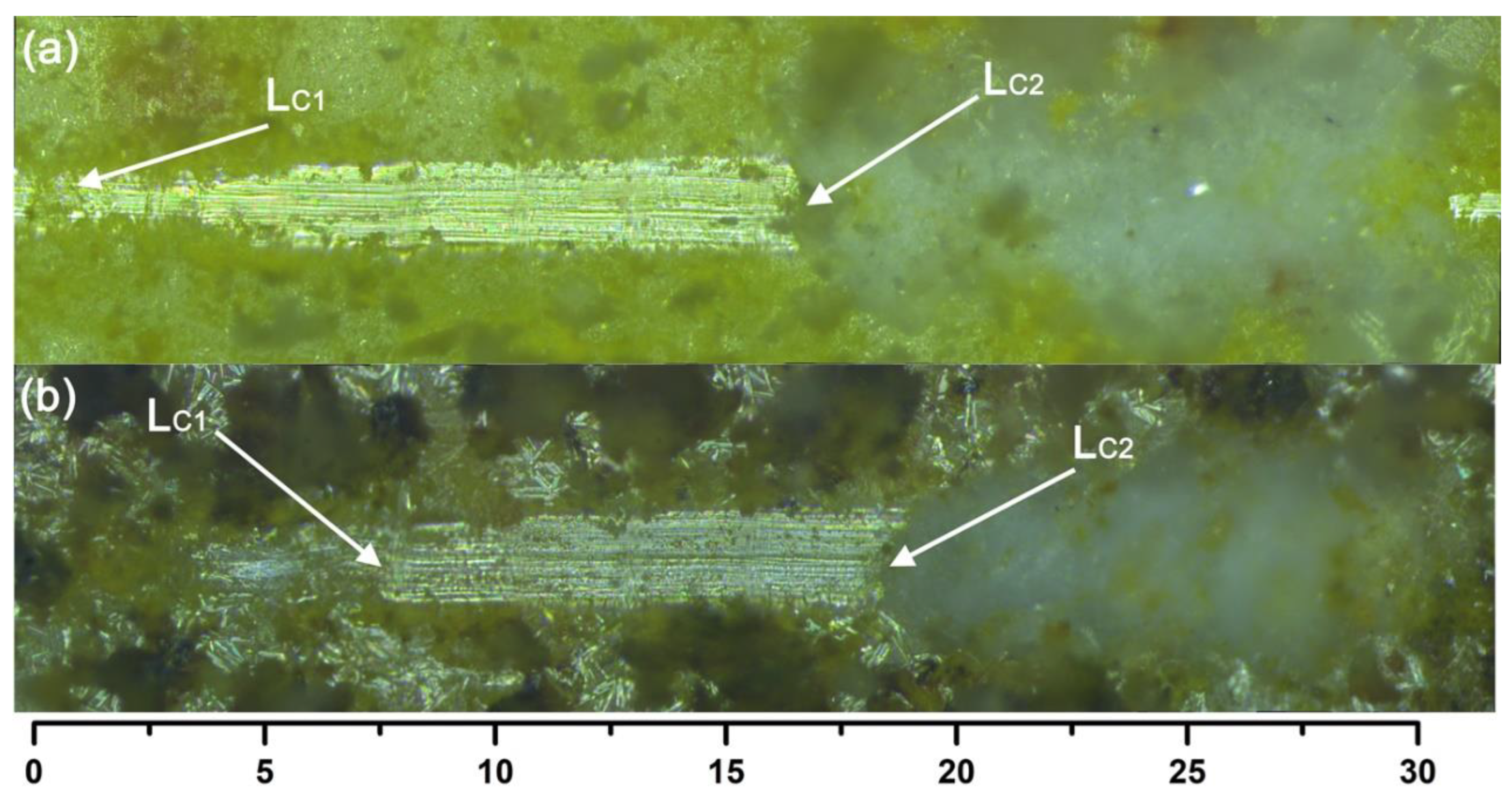

3.2. Adhesion of Coating on Ceramic Tiles

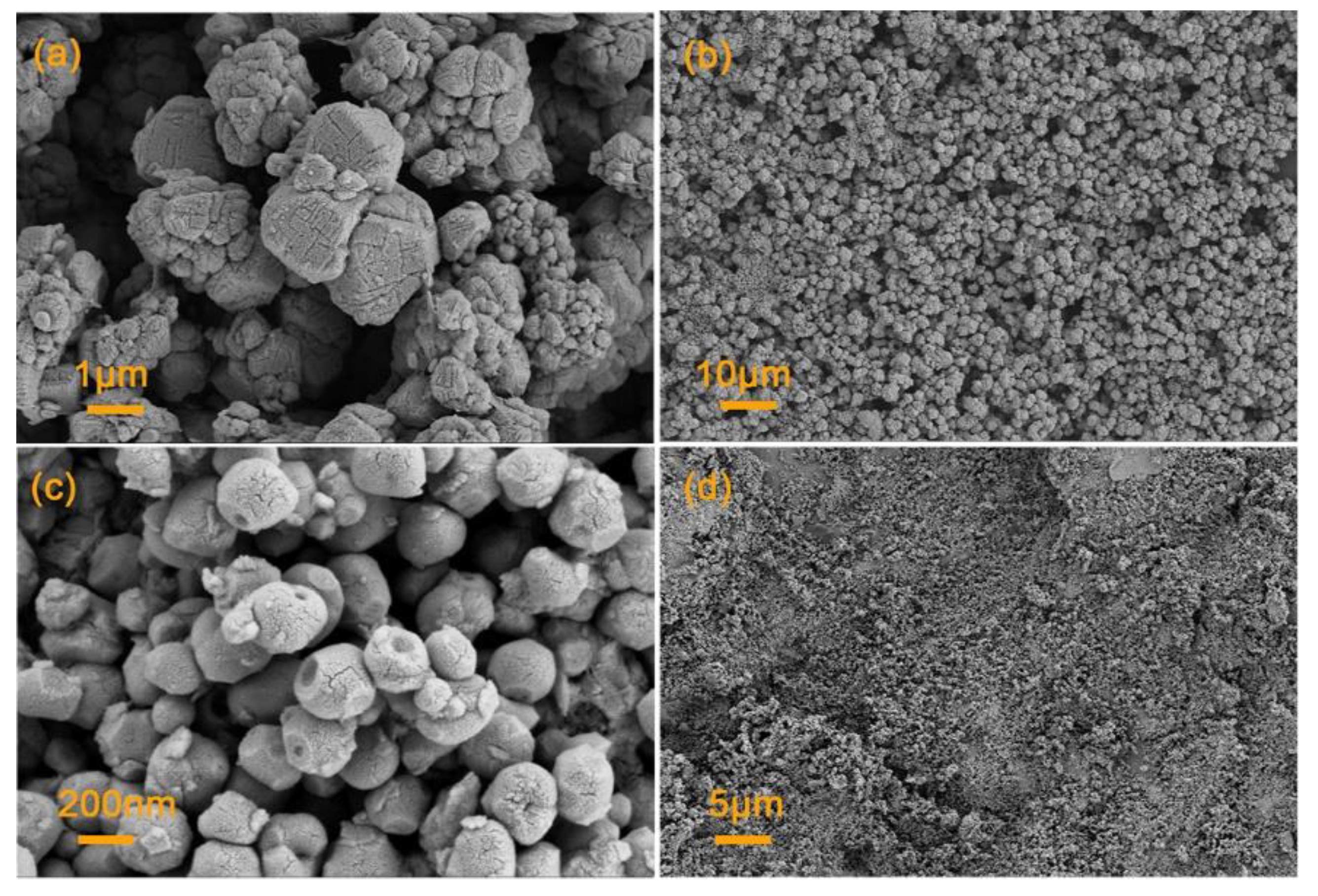

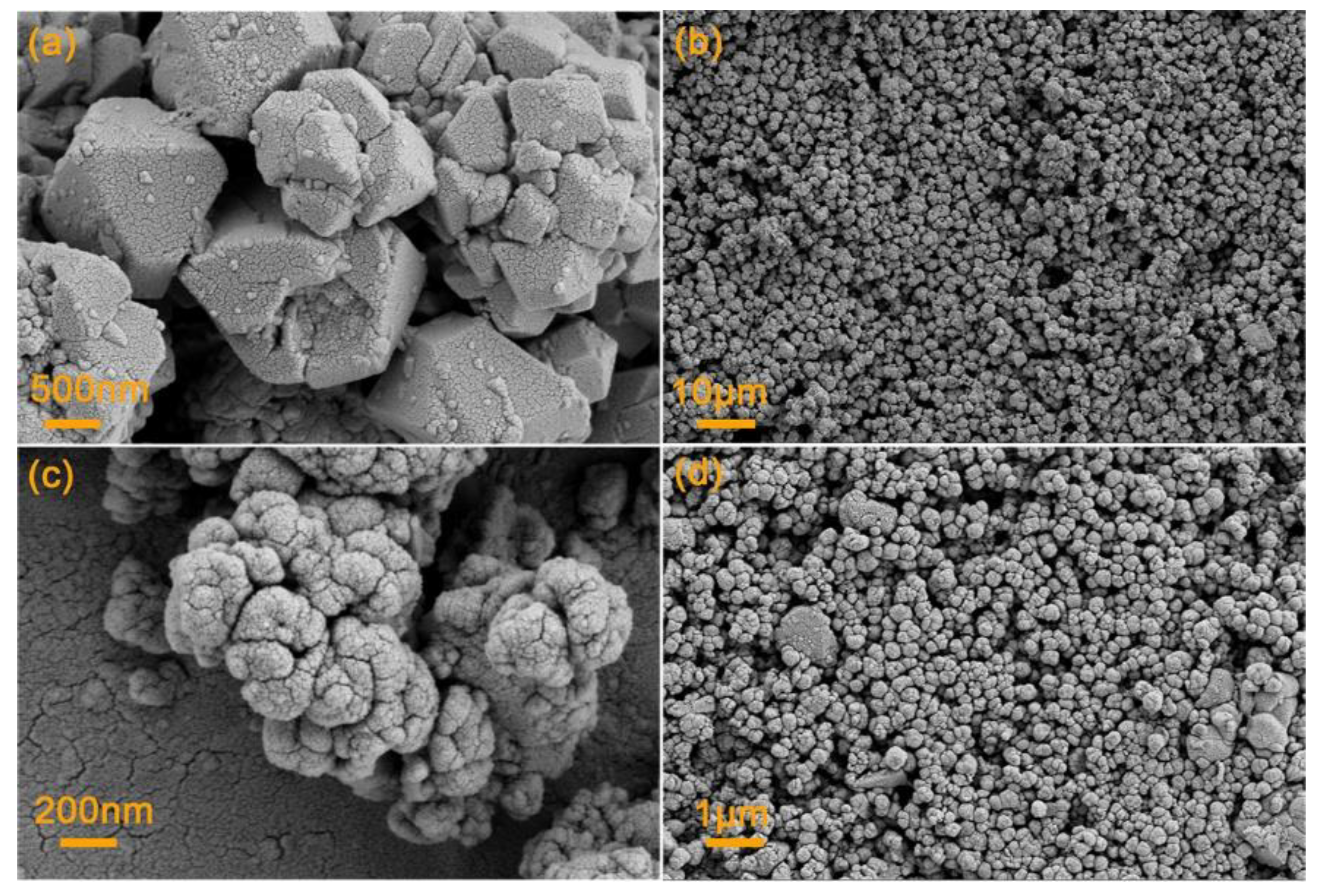

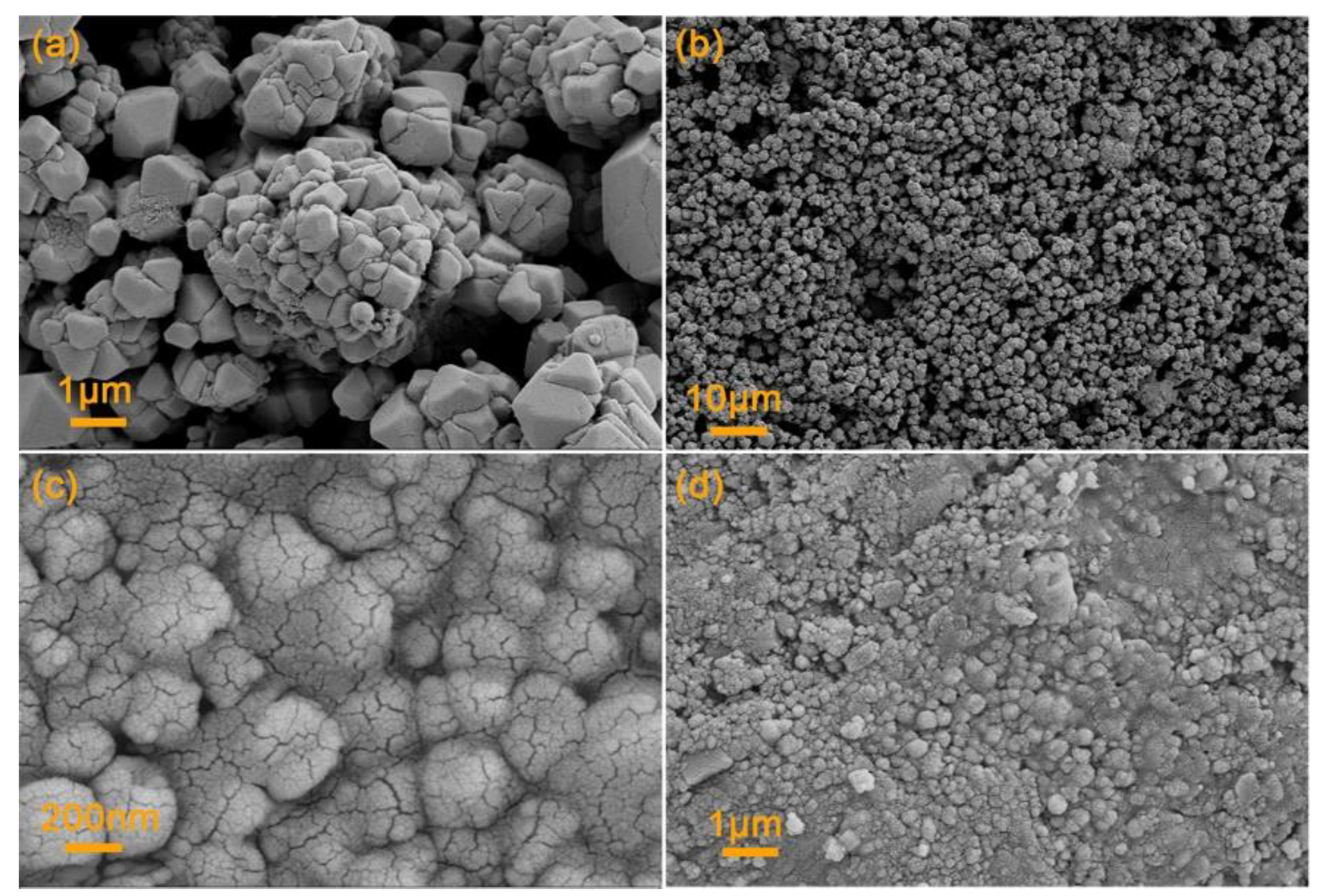

3.3. Coating Microstructure and Morphology

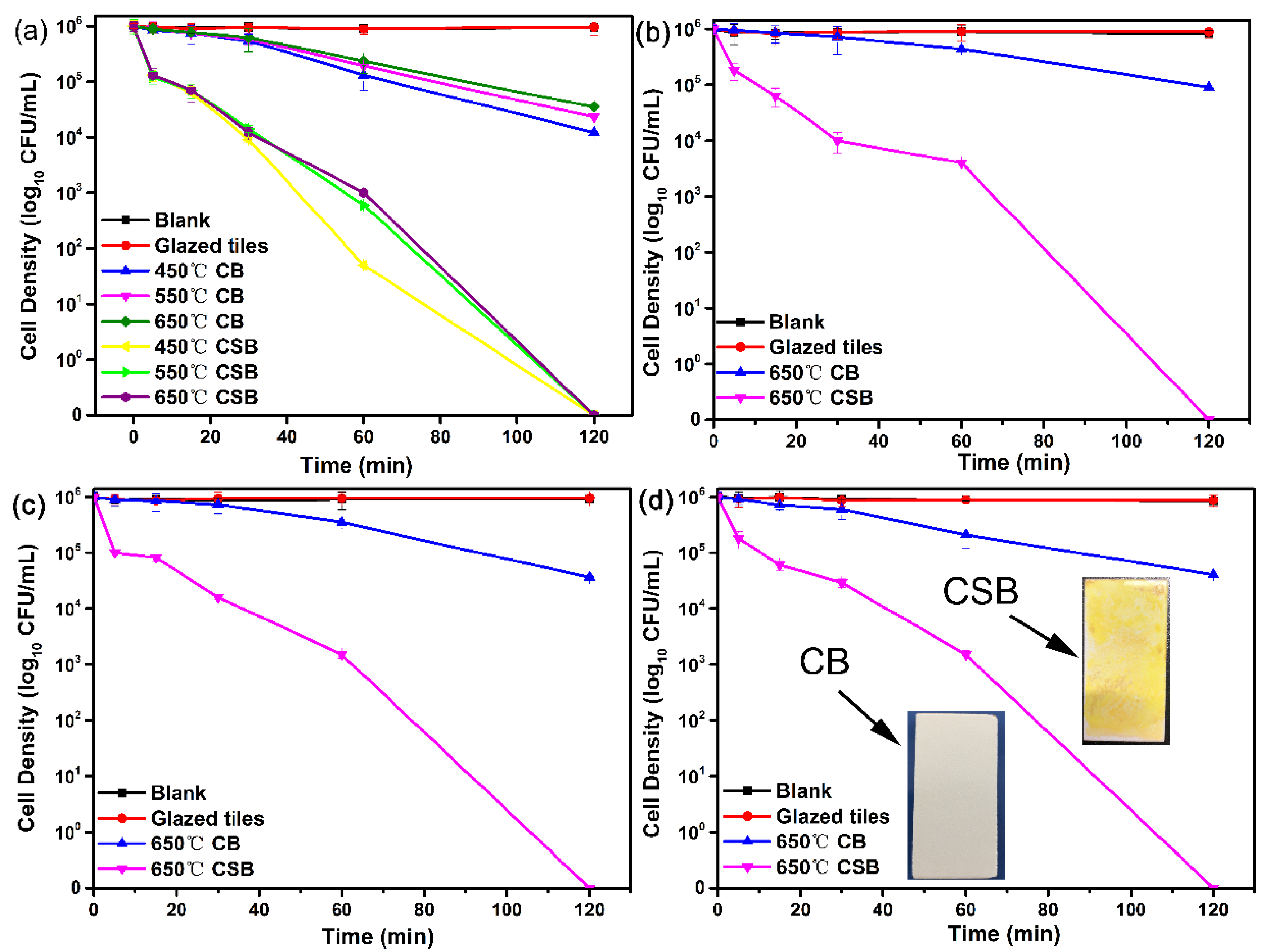

3.4. Disinfection Results

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- da Silva, A.L.; Dondi, M.; Raimondo, M.; Hotza, D. Photocatalytic ceramic tiles: Challenges and technological solutions. J. Eur. Ceram. Soc. 2018, 38, 1002–1017. [Google Scholar] [CrossRef]

- da Silva, A.L.; Muche, D.N.F.; Dey, S.; Hotza, D.; Castro, R.H.R. Photocatalytic Nb2O5-doped TiO2 nanoparticles for glazed ceramic tiles. Ceram. Int. 2016, 42, 5113–5122. [Google Scholar] [CrossRef] [Green Version]

- Fujishima, A.; Zhang, X.; Tryk, D.A. TiO2 photocatalysis and related surface phenomena. Surf. Sci. Rep. 2008, 63, 515–582. [Google Scholar] [CrossRef]

- Zhang, H.; Banfield, J.F. Structural Characteristics and Mechanical and Thermodynamic Properties of Nanocrystalline TiO2. Chem. Rev. 2014, 114, 9613–9644. [Google Scholar] [CrossRef] [PubMed]

- Seabra, M.P.; Pires, R.R.; Labrincha, J.A. Ceramic tiles for photodegradation of Orange II solutions. Chem. Eng. J. 2011, 171, 692–702. [Google Scholar] [CrossRef]

- Ye, L.; Su, Y.; Jin, X.; Xie, H.; Zhang, C. Recent advances in BiOX (X = Cl, Br and I) photocatalysts: Synthesis, modification, facet effects and mechanisms. Environ. Sci. Nano 2014, 1, 90–112. [Google Scholar] [CrossRef]

- Qu, Z.; Liu, P.; Yang, X.; Wang, F.; Zhang, W.; Fei, C. Microstructure and Characteristic of BiVO4; Prepared under Different pH Values: Photocatalytic Efficiency and Antibacterial Activity. Materials 2016, 9, 129. [Google Scholar] [CrossRef] [Green Version]

- Zhao, D.; Wang, W.; Sun, Y.; Fan, Z.; Du, M.; Zhang, Q.; Ji, F.; Xu, X. One-step synthesis of composite material MWCNT@BiVO4 and its photocatalytic activity. RSC Adv. 2017, 7, 33671–33679. [Google Scholar] [CrossRef] [Green Version]

- Regmi, C.; Dhakal, D.; Lee, S.W. Visible-light-induced Ag/BiVO4 semiconductor with enhanced photocatalytic and antibacterial performance. Nanotechnology 2018, 29, 064001. [Google Scholar] [CrossRef]

- Guo, R.; Yan, A.; Xu, J.; Xu, B.; Li, T.; Liu, X.; Yi, T.; Luo, S. Effects of morphology on the visible-light-driven photocatalytic and bactericidal properties of BiVO4/CdS heterojunctions: A discussion on photocatalysis mechanism. J. Alloy. Compd. 2020, 817, 153246. [Google Scholar] [CrossRef]

- He, Z.; Shi, Y.; Gao, C.; Wen, L.; Chen, J.; Song, S. BiOCl/BiVO4 p–n Heterojunction with Enhanced Photocatalytic Activity under Visible-Light Irradiation. J. Phys. Chem. C 2013, 118, 389–398. [Google Scholar] [CrossRef]

- Xu, X.; Yan, Q.; Gu, X.; Luo, Y. The preparation and photocatalytic performance of BiOCl@Ag, a visible-light responsive catalyst. J. Mater. Sci. Mater. Electron. 2019, 30, 8892–8902. [Google Scholar] [CrossRef]

- Di, J.; Xia, J.; Ji, M.; Wang, B.; Yin, S.; Huang, Y.; Chen, Z.; Li, H. New insight of Ag quantum dots with the improved molecular oxygen activation ability for photocatalytic applications. Appl. Catal. B Environ. 2016, 188, 376–387. [Google Scholar] [CrossRef]

- Simončič, B.; Klemenčič, D. Preparation and performance of silver as an antimicrobial agent for textiles: A review. Text. Res. J. 2015, 86, 210–223. [Google Scholar] [CrossRef]

- Shen, Y.; Wang, X.; Zuo, G.; Li, F.; Meng, Y. Influence of Heat Treatment on Photocatalytic Performance of BiVO4 Synthesized by Hydrothermal Method. High Temp. Mater. Processes 2016, 35, 853–856. [Google Scholar] [CrossRef]

- Murugan, K.; Subasri, R.; Rao, T.N.; Gandhi, A.S.; Murty, B.S. Synthesis, characterization and demonstration of self-cleaning TiO2 coatings on glass and glazed ceramic tiles. Prog. Org. Coat. 2013, 76, 1756–1760. [Google Scholar] [CrossRef]

- ASTM D3359-08; Standard Test Methods for Measuring Adhesion by Tape Test. ASTM International: West Conshohocken, PA, USA, 2008.

- Wang, K.; Liang, L.; Liu, H.; Xie, X.; Hao, Q.; Liu, C. Facile synthesis of hollow and porous Ag+/Ag/BiVO4 composite fibers with enhanced visible-light photocatalytic performance. Mater. Lett. 2015, 161, 336–339. [Google Scholar] [CrossRef]

- Zhou, B.; Zhao, X.; Liu, H.; Qu, J.; Huang, C.P. Synthesis of visible-light sensitive M–BiVO4 (M=Ag, Co, and Ni) for the photocatalytic degradation of organic pollutants. Sep. Purif. Technol. 2011, 77, 275–282. [Google Scholar] [CrossRef]

- Shan, L.; Liu, Y.; Ma, C.; Dong, L.; Liu, L.; Wu, Z. Enhanced Photocatalytic Performance in Ag+-Induced BiVO4/β-Bi2O3 Heterojunctions. Eur. J. Inorg. Chem. 2016, 2016, 232–239. [Google Scholar] [CrossRef]

- Thalluri, S.M.; Hussain, M.; Saracco, G.; Barber, J.; Russo, N. Green-Synthesized BiVO4 Oriented along {040} Facets for Visible-Light-Driven Ethylene Degradation. Ind. Eng. Chem. Res. 2014, 53, 2640–2646. [Google Scholar] [CrossRef]

- Sayama, K.; Nomura, A.; Arai, T.; Sugita, T.; Abe, R.; Yanagida, M.; Oi, T.; Iwasaki, Y.; Abe, Y.; Sugihara, H. Photoelectrochemical Decomposition of Water into H2 and O2 on Porous BiVO4 Thin-Film Electrodes under Visible Light and Significant Effect of Ag Ion Treatment. J. Phys. Chem. B 2006, 110, 11352–11360. [Google Scholar] [CrossRef] [PubMed]

- Yan, M.; Wu, Y.; Yan, Y.; Yan, X.; Zhu, F.; Hua, Y.; Shi, W. Synthesis and Characterization of Novel BiVO4/Ag3VO4 Heterojunction with Enhanced Visible-Light-Driven Photocatalytic Degradation of Dyes. ACS Sustain. Chem. Eng. 2016, 4, 757–766. [Google Scholar] [CrossRef]

- Zeng, X.; Lan, S.; Lo, I.M.C. Rapid disinfection of E. coli by a ternary BiVO4/Ag/g-C3N4 composite under visible light: Photocatalytic mechanism and performance investigation in authentic sewage. Environ. Sci. Nano 2019, 6, 610–623. [Google Scholar] [CrossRef]

- Raimondo, M.; Guarini, G.; Zanelli, C.; Marani, F.; Fossa, L.; Dondi, M. Printing nano TiO2 on large-sized building materials: Technologies, surface modifications and functional behaviour. Ceram. Int. 2012, 38, 4685–4693. [Google Scholar] [CrossRef]

- Bondioli, F.; Taurino, R.; Ferrari, A.M. Functionalization of ceramic tile surface by sol-gel technique. J. Colloid Interface Sci. 2009, 334, 195–201. [Google Scholar] [CrossRef]

- de Niederhãusern, S.; Bondi, M.; Bondioli, F. Self-Cleaning and Antibacteric Ceramic Tile Surface. Int. J. Appl. Ceram. Technol. 2013, 10, 949–956. [Google Scholar] [CrossRef]

- Kete, M.; Pavlica, E.; Fresno, F.; Bratina, G.; Stangar, U.L. Highly active photocatalytic coatings prepared by a low-temperature method. Environ. Sci. Pollut. Res. Int. 2014, 21, 11238–11249. [Google Scholar] [CrossRef]

- Mellott, N.P.; Durucan, C.; Pantano, C.G.; Guglielmi, M. Commercial and laboratory prepared titanium dioxide thin films for self-cleaning glasses: Photocatalytic performance and chemical durability. Thin Solid Film. 2006, 502, 112–120. [Google Scholar] [CrossRef]

- Li, Y.; Sun, H.; Wang, N.; Fang, W.; Li, Z. Effects of pH and temperature on photocatalytic activity of PbTiO3 synthesized by hydrothermal method. Solid State Sci. 2014, 37, 18–22. [Google Scholar] [CrossRef]

- Qi, Y.; Wang, M.; Zhang, Y.; Zhu, T. Effect of calcination temperature on the structure and photocatalytic performance of BiVO4 prepared via an improved solution combustion method. Micro Nano Lett. 2018, 13, 1017–1020. [Google Scholar] [CrossRef]

- Sun, S.Q.; Sun, B.; Zhang, W.; Wang, D. Preparation and antibacterial activity of Ag-TiO2 composite film by liquid phase deposition (LPD) method. Bull. Mater. Sci. 2008, 31, 61–66. [Google Scholar] [CrossRef]

- Jin, Y.; Dai, Z.; Liu, F.; Kim, H.; Tong, M.; Hou, Y. Bactericidal mechanisms of Ag2O/TNBs under both dark and light conditions. Water Res. 2013, 47, 1837–1847. [Google Scholar] [CrossRef] [PubMed]

| Sample | Temperature/°C | Percent of Area Removed | Classification | ||

|---|---|---|---|---|---|

| 1st/% | 2nd/% | 3rd/% | |||

| CB | 450 | 5 | 5 | 10 | 3B |

| CSB | 5 | 10 | 3 | 3B | |

| CB | 550 | 3 | 2 | 6 | 3B |

| CSB | 0 | 1 | 1 | 4B | |

| CB | 650 | 0 | 0 | 0 | 5B |

| CSB | 0 | 0 | 0 | 5B | |

| Sample | Lc1 (N) | Lc2 (N) |

|---|---|---|

| CB | 2.1 ± 0.3 | 17.0 ± 0.5 |

| CSB | 8.0 ± 0.9 | 18.8 ± 1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Y.; Zhao, X.; Wang, H.; Fu, S.; Lv, X.; He, Q.; Liu, R.; Ji, F.; Xu, X. Effect of Temperature on the Adhesion and Bactericidal Activities of Ag+-Doped BiVO4 Ceramic Tiles. Inorganics 2022, 10, 61. https://doi.org/10.3390/inorganics10050061

Zhang Y, Zhao X, Wang H, Fu S, Lv X, He Q, Liu R, Ji F, Xu X. Effect of Temperature on the Adhesion and Bactericidal Activities of Ag+-Doped BiVO4 Ceramic Tiles. Inorganics. 2022; 10(5):61. https://doi.org/10.3390/inorganics10050061

Chicago/Turabian StyleZhang, Ying, Xuhuan Zhao, Hao Wang, Shiqi Fu, Xiulong Lv, Qian He, Rui Liu, Fangying Ji, and Xuan Xu. 2022. "Effect of Temperature on the Adhesion and Bactericidal Activities of Ag+-Doped BiVO4 Ceramic Tiles" Inorganics 10, no. 5: 61. https://doi.org/10.3390/inorganics10050061

APA StyleZhang, Y., Zhao, X., Wang, H., Fu, S., Lv, X., He, Q., Liu, R., Ji, F., & Xu, X. (2022). Effect of Temperature on the Adhesion and Bactericidal Activities of Ag+-Doped BiVO4 Ceramic Tiles. Inorganics, 10(5), 61. https://doi.org/10.3390/inorganics10050061