Waste-to-Reuse Foam Glasses Produced from Soda-Lime-Silicate Glass, Cathode Ray Tube Glass, and Aluminium Dross

Abstract

:1. Introduction

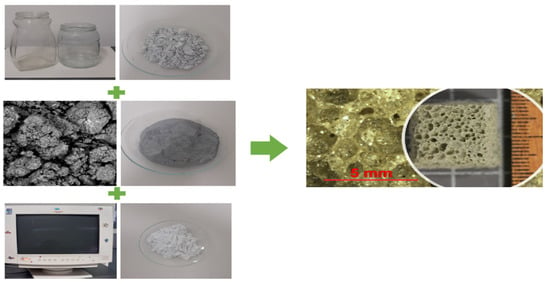

2. Experimental Procedures and Methods

2.1. Materials and Experimental Procedures

2.2. Characterization Methods

3. Results and Discussion

3.1. Characterization of the Raw Materials

3.2. Sintering Behavior

3.3. Microstructure

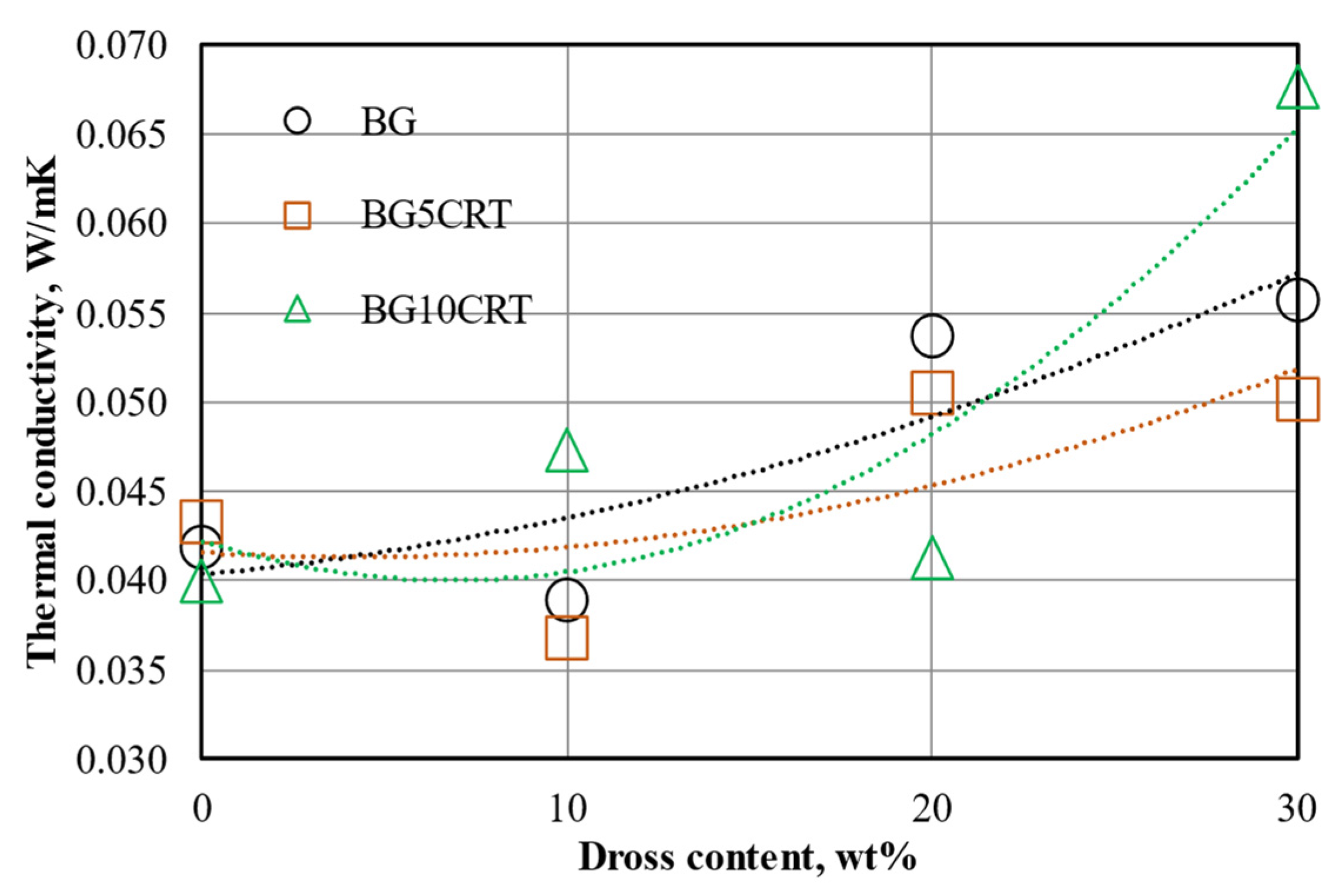

3.4. Properties

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Shen, H.; Liu, B.; Ekberg, C.; Zhang, S. Harmless disposal and resource utilization for secondary aluminum dross: A review. Sci. Total Environ. 2021, 760, 143968. [Google Scholar] [CrossRef]

- Zhang, J.; Liu, B.; Zhao, S.; Shen, H.; Liu, J.; Zhang, S. Preparation and characterization of glass ceramic foams based on municipal solid waste incineration ashes using secondary aluminium ash as foaming agent. Constr. Build. Mater. 2020, 262, 120781. [Google Scholar] [CrossRef]

- Hwang, J.; Huang, X.; Xu, Z. Recovery of Metals from Aluminum Dross and Saltcake. J. Miner. Mater. Charact. Eng. 2006, 5, 47–62. [Google Scholar] [CrossRef]

- Kekesi, T. Characterization and complete utilization of aluminium melting dross. In Proceedings of the International V4 Waste Recycling 21 Conference, Miskolc, Miskolci Egyetem, Miskolc-Egyetemváros, Hungary, 22–23 November 2018; pp. 162–177, ISBN 9789633581735. [Google Scholar]

- Illés, I.; Sassi, M.; Zakiyya, H.; Kékesi, T. The Fundamental Kinetic Characteristics of Aqueous Dissolution of Chloride and Fluoride Salts from Secondary Aluminium Dross. Kékesi, Tamás (szerk.) MultiScience—XXXIII. In Proceedings of the microCAD International Multidisciplinary Scientific Conference 2019, Miskolc, Hungary, 23 May 2017. [Google Scholar]

- Mostafa, M.; Ali, A. Enhanced alumina recovery from secondary aluminum dross for high purity nanostructured alumina powder production: Kinetic study. J. Environ. Manag. 2018, 212, 278–291. [Google Scholar]

- Theam, Y.; Ee, L.; Mohd, F.; Shahabaldin, R. Optimization of aluminium recovery from water treatment sludge using response surface methodology. J. Environ. Manag. 2018, 228, 13–19. [Google Scholar]

- Tsakiridis, P. Aluminium salt slag characterization and utilization. J. Hazard. Mater. 2012, 217–218, 1–10. [Google Scholar] [CrossRef]

- Elsarrag, E.; Elhoweris, A.; Alhorr, Y. The production of hydrogen as an alternative energy carrier from aluminium waste. Energy Sustain. Soc. 2017, 7, 9. [Google Scholar] [CrossRef] [Green Version]

- El-Amir, A.A.; Attia, M.A.; Newishy, M.; Fend, T.; Emad, M. Aluminium dross/soda lime glass waste-derived high-quality glass foam. J. Mater. Res. Technol. 2021, 15, 4940–4948. [Google Scholar] [CrossRef]

- Sassi, M.; Ibrahim, J.-E.F.M.; Simon, A. Characterization of foam glass produced from waste CRT glass and aluminium dross. J. Phys. Conf. Ser. 2020, 1527, 012037. [Google Scholar] [CrossRef]

- Tsakiridis, P.; Oustadakis, P.; Agatzini-Leonardou, S. Aluminium recovery during black dross hydrothermal treatment. J. Environ. Chem. Eng. 2013, 1, 23–32. [Google Scholar] [CrossRef]

- Bajare, D.; Korjakins, A.; Kazjonovs, J. Application of aluminium dross and glass waste for production of expanded clay aggregate. In Proceedings of the 3rd International Scientific Conference, Riga, Latvia, 13 October 2011. [Google Scholar]

- Arunabh, M.; Kamalesh, K. Recovery of valuable products from hazardous aluminum dross: A review. Resour. Conserv. Recycl. 2018, 130, 95–108. [Google Scholar]

- Bozsaky, D. The historical development of thermal insulation materials. Period. Polytech. Archit. 2010, 41, 49–56. [Google Scholar] [CrossRef]

- Attila, Y.; Guden, M.; Tasdemirci, A. Foam glass processing using a polishing glass powder residue. Ceram. Int. 2013, 39, 5869–5877. [Google Scholar] [CrossRef] [Green Version]

- Marinov, M.; Lakov, L.T. Granulated foam glass. Production, physical and mechanical properties. Sci. Proceeding XIII Int. Congr. Mach. Technol. Mater. 2016, 10, 42–44. [Google Scholar]

- Taoyong, L.; Piao, L.; Xiaogang, G.; Jiashuo, Z.; Qianxing, H.; Zhiwei, L.; Zhou, X.; Qifeng, Y.; Yougen, T.; Anxian, L. Preparation, characterization and discussion of glass ceramic foam material: Analysis of glass phase, fractal dimension and self-foaming mechanism. Mater. Chem. Phys. 2020, 243, 122614. [Google Scholar]

- Li, J.; Zhuang, X.; Monfort, E.; Querol, X.; Llaudis, A.S.; Font, O.; Moreno, N.; Ten, F.J.G.; Maria, I. Utilization of coal fly ash from a Chinese power plant for manufacturing highly insulating foam glass: Implications of physical, mechanical properties and environmental features. Constr. Build. Mater. 2018, 175, 64–76. [Google Scholar] [CrossRef]

- Foamit, Foamit, Applications for Civil Engineering. 2019. Available online: http://www.foamit.fi/wp-content/uploads/2016/10/Foamedglass.pdf (accessed on 1 November 2021).

- Baidzhanov, D.; Nuguzhinov, Z.S.; Fedorchenko, V.; Kropachev, P.A. Thermal insulation material based on local technogenic raw material. Glass Ceram. 2016, 73, 427–430. [Google Scholar] [CrossRef]

- Hu, L.; Bu, F.; Guo, F.; Zhang, Z. Construction method of foam glass thermal insulation material in sloping roof. IOP Conf. Ser. Earth Environ. Sci. 2017, 61, 012122. [Google Scholar] [CrossRef] [Green Version]

- Ewais, E.M.M.; Attia, M.A.; El-Amir, A.A.; Elshenway, A.M.; Fend, T. Optimal conditions and significant factors for fabrication of soda lime glass foam from industrial waste using nano AlN. J. Alloys Compd. 2018, 747, 408–415. [Google Scholar] [CrossRef]

- Barbosa, A.R.J.; Lopes, A.A.S.; Sequeira, S.I.H.; Oliveira, J.P.; Davarpanah, A.; Mohseni, F.; Amaral, V.S.; Monteiro, R.C.C. Effect of processing conditions on the properties of recycled cathode ray tube glass foams. J. Porous Mater. 2016, 23, 1663–1669. [Google Scholar] [CrossRef]

- König, J.; Lopez-Gil, A.; Cimavilla-Roman, P.; Rodriguez-Perez, M.A.; Petersen, R.R.; Østergaard, M.B.; Iversen, N.; Yue, Y.; Matjaž, S. Synthesis and properties of open- and closed-porous foamed glass with a low density. Constr. Build. Mater. 2020, 247, 118574. [Google Scholar] [CrossRef]

- König, J.; Nemanic, V.; Zumer, M.; Rasmus, R.P.; Martin, B.Ø.; Yue, Y.; Suvorov, D. Evaluation of the contributions to the effective thermal conductivity of an open-porous-type foamed glass. Constr. Build. Mater. 2019, 214, 337–343. [Google Scholar] [CrossRef]

- da Silvaa, R.C.; Kubaski, E.T.; Tenório-Neto, E.T.; Lima-Tenório, M.K.; Tebcherani, S.M. Foam glass using sodium hydroxide as foaming agent: Study on the reaction mechanism in soda-lime glass matrix. J. Non-Cryst. Solids 2019, 511, 177–182. [Google Scholar] [CrossRef]

- Bai, C.; Li, H.; Bernardo, E.; Colombo, P. Waste-to-resource preparation of glass-containing foams from geopolymers. Ceram. Int. 2018, 45, 7196–7202. [Google Scholar] [CrossRef]

- Arriagada, C.; Navarrete, I.; Lopez, M. Understanding the effect of porosity on the mechanical and thermal performance of glass foam lightweight aggregates and the influence of production factors. Constr. Build. Mater. 2019, 228, 116746. [Google Scholar] [CrossRef]

- Wang, H.; Chen, Z.; Ji, R.; Liu, L.; Wang, X. Integrated utilization of high alumina fly ash for synthesis of foam glass ceramic. Ceram. Int. 2018, 44, 13681–13688. [Google Scholar] [CrossRef]

- Ji, R.; Zheng, Y.; Zou, Z.; Chen, Z.; Wei, S.; Jin, X.; Zhang, M. Utilization of mineral wool waste and waste glass for synthesis of foam glass at low temperature. Constr. Build. Mater. 2019, 215, 623–632. [Google Scholar] [CrossRef]

- Chen, Z.; Wang, H.; Ji, R.; Liu, L.; Cheeseman, C.; Wang, X. Reuse of mineral wool waste and recycled glass in ceramic foams. Ceram. Int. 2019, 45, 15057–15064. [Google Scholar] [CrossRef]

- Taoyong, L.; Changwei, L.; Jianlei, L.; Lei, H.; Hua, G.; Cui, L.; Xin, Z.; Hui, T.; Qifeng, Y.; Anxian, L. Phase evolution, pore morphology and microstructure of glass ceramic foams derived from tailings wastes. Ceram. Int. 2018, 44, 14393–14400. [Google Scholar]

- Nagrockiene, D.; Barkauskas, K. Utilization of Waste Glass Powder in Cement Mortar. Environ. Sci. Proc. 2021, 9, 25. [Google Scholar] [CrossRef]

- Kurpinska, M.; Leszek, K.; Miruszewski, T.; Byczuk, M. Application of artificial neural networks to predict insulation properties of lightweight concrete. Appl. Sci. 2021, 11, 10544. [Google Scholar] [CrossRef]

- Yuxi, G.; Yihe, Z.; Hongwei, H.; Ke, M.; Kunran, H.; Pan, H.; Wang, X.; Zhilei, Z.; Xianghai, M. Novel glass ceramic foams materials based on red mud. Ceram. Int. 2014, 40, 6677–6683. [Google Scholar]

- Tulyaganov, D.; Fernandes, H.; Agathopoulos, S.; Ferreira, J. Preparation and characterization of high compressive strength foams from sheet glass. J. Porous Mater. 2006, 13, 33–139. [Google Scholar] [CrossRef]

- Yang, L.; Shili, Z.; Shuhua, M.; Chunli, L.; Xiaohui, W. Preparation of sintered foamed ceramics derived entirely from coal fly ash. Constr. Build. Mater. 2018, 163, 529–538. [Google Scholar]

- Xi, C.; Zheng, F.; Jiahe, X.; Yang, W.; Peng, Y.; Li, Y.; Li, P.; Zhen, Q. Preparation of glass-ceramic foams using extracted titanium tailing and glass waste as raw materials. Constr. Build. Mater. 2018, 190, 896–909. [Google Scholar] [CrossRef]

- Bawab, J.; Khatib, J.; Jahami, A.; Elkordi, A.; Ghorbel, E. Structural performance of reinforced concrete beams incorporating Cathode-Ray Tube (CRT) glass Waste. Buildings 2021, 11, 67. [Google Scholar] [CrossRef]

- Choi, S.Y.; Choi, Y.S.; Kim, I.S.; Yang, E.I. An Experimental Study on Flexural Behaviors of Reinforced Concrete Member Replaced Heavyweight Waste Glass as Fine Aggregate under Cyclic Loading. Appl. Sci. 2018, 8, 2208. [Google Scholar] [CrossRef] [Green Version]

- Meng, W.; Wang, X.; Yuan, W.; Wang, J.; Songa, G. The recycling of leaded glass in cathode ray tube (CRT). Procedia Environ. Sci. 2016, 31, 954–960. [Google Scholar] [CrossRef] [Green Version]

- Grause, G.; Takahashi, K.; Yoshioka, T. Thermogravimetric Investigation of the Lead Volatilization from Waste Cathode-Ray Tube Glass. Recycling 2016, 1, 111–121. [Google Scholar] [CrossRef] [Green Version]

- Imre-Lucaci, Á.; Fogarasi, M.; Imre-Lucaci, F.; Fogarasi, S. Chemical–electrochemical process concept for lead recovery from waste Cathode Ray Tube glass. Materials 2021, 14, 1546. [Google Scholar] [CrossRef]

- Catauro, M.; Lancellotti, I.; Leonelli, C. Addition of WEEE glass to metakaolin-based geopolymeric Binder: A cytotoxicity study. Environments 2017, 4, 89. [Google Scholar] [CrossRef] [Green Version]

- Bernardo, E.; Scarinci, G.; Hreglich, S.; Zangiacomi, G. Effect of time and furnace atmosphere on the sintering of glasses from dismantled cathode ray tubes. J. Eur. Ceram. Soc. 2007, 27, 1637–1643. [Google Scholar] [CrossRef]

- Bertoncello, R.; Milanese, L.; Bouquillon, A.; Dran, J.; Mille, B.; Salomon, J. Leaching of lead silicate glasses in acid environment: Compositional and structural changes. Appl. Phys 2004, 79, 193–198. [Google Scholar] [CrossRef]

- Østergaard, M.B.; Petersen, R.R.; König, J.; Yue, Y. Effect of alkali phosphate content on foaming of CRT panel glass using Mn3O4 and carbon as foaming agents. J. Non-Cryst. Solids 2017, 482, 217–222. [Google Scholar] [CrossRef]

- Méar, F.; Yot, P.; Cambon, M.; Ribes, M. The characterization of waste cathode-ray tube glass. Waste Manag. 2016, 26, 1468–1476. [Google Scholar] [CrossRef]

- Ledwaba, P.; Sosibo, N. Cathode Ray Tube Recycling in South Africa. Recycling 2017, 2, 4. [Google Scholar] [CrossRef] [Green Version]

- Górski, M.; Wielgus, N.; Loska, K.; Kozioł, M.; Landrat, M.; Scierski, W.; Pikon, K. Characteristics of metakaolin-based geopolymer with Cathode Ray Tube glass. Polymers 2021, 13, 1149. [Google Scholar] [CrossRef]

- Bawab, J.; Khatib, J.; El-Hassan, H.; Assi, L.; Kırgız, M.S. Properties of cement-based Materials Containing Cathode-Ray Tube (CRT) glass waste as fine aggregates—A Review. Sustainability 2021, 13, 11529. [Google Scholar] [CrossRef]

- Wielgus, N.; Górski, M.; Kubica, J. Discarded Cathode Ray Tube glass as an alternative for aggregate in a metakaolin-based geopolymer. Sustainability 2021, 13, 479. [Google Scholar] [CrossRef]

- Grdic, D.Z.; Toplicic-Curcic, G.A.; Grdic, Z.J.; Risti, N.S. Durability Properties of Concrete Supplemented with Recycled CRT Glass as Cementitious Material. Materials 2021, 14, 4421. [Google Scholar] [CrossRef]

- Cabrera, M.; Pérez, P.; Rosales, J.; Agrela, F. Feasible use of Cathode Ray Tube glass (CRT) and Recycled Aggregates as Unbound and Cement-Treated granular Materials for Road Sub-Bases. Materials 2020, 13, 748. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Mucsi, G.; CsYke, B.; Kertész, M.; Hoffmann, L. Physical Characteristics and Technology of Glass Foam from Waste Cathode Ray Tube Glass. J. Mater. 2013, 2013, 696428. [Google Scholar] [CrossRef] [Green Version]

- Cosmin, V.; Lazău, I. Glass foam from window panes and bottle glass wastes. Cent. Eur. J. Chem. 2014, 12, 804–811. [Google Scholar]

- Shi, H.; Feng, K.; Wang, H.; Chen, C.; Zhou, H. Influence of aluminium nitride as a foaming agent on the preparation of foam. Int. J. Miner. Metall. Mater. 2016, 23, 595. [Google Scholar] [CrossRef]

- Qin, Z.; Li, G.; Tian, Y.; Ma, Y.; Shen, P. Numerical Simulation of Thermal Conductivity of Foam Glass Based on the Steady-State Method. Materials 2018, 12, 54. [Google Scholar] [CrossRef] [Green Version]

- C-THERM TCi. Available online: https://ctherm.com/products/tci_thermal_conductivity/how_the_tci_works/mtps/ (accessed on 1 November 2021).

- Glass Viscosity Calculation. Available online: https://glassproperties.com/viscosity/ (accessed on 1 November 2021).

- Kacem, I.B.; Gautron, L.; Coillot, D.; Neuville, D.R. Structure and properties of lead silicate glasses and melts. Chem. Geol. 2017, 461, 104–114. [Google Scholar] [CrossRef] [Green Version]

- Veit, U.; Rüssel, C. Viscosity and liquidus temperature of quaternary glasses close to an eutectic composition in the CaO–MgO–Al2O3–SiO2 system. J. Mater. Sci. 2017, 52, 8280–8292. [Google Scholar] [CrossRef]

| Code | Composition, wt% | Foaming Temperature (°C) | |||

|---|---|---|---|---|---|

| Dross | SiC | CRT Glass | SLS Glass | ||

| BG | 2 | 98 | 964 | ||

| BG5CRT | 2 | 5 | 93 | 954 | |

| BG10CRT | 2 | 10 | 88 | 954 | |

| BG10D | 10 | 2 | 88 | 907 | |

| BG20D | 20 | 2 | 78 | 869 | |

| BG30D | 30 | 2 | 68 | 880 | |

| BG5CRT10D | 10 | 2 | 5 | 83 | 899 |

| BG5CRT20D | 20 | 2 | 5 | 73 | 897 |

| BG5CRT30D | 30 | 2 | 5 | 63 | 897 |

| BG10CRT10D | 10 | 2 | 10 | 78 | 922 |

| BG10CRT20D | 20 | 2 | 10 | 68 | 904 |

| BG10CRT30D | 30 | 2 | 10 | 58 | 889 |

| SiO2 | Na2O | K2O | CaO | MgO | Al2O3 | Fe2O3 | Others | |

|---|---|---|---|---|---|---|---|---|

| SLS glass | 71.5 | 12.5 | 0.72 | 8.75 | 2.44 | 1.75 | 1.15 | 1.19 |

| CRT glass | 55.9 | 5.96 | 5.49 | 0.52 | 0.21 | 1.7 | 0.21 | 30.01 |

| Element | Cu | Zn | Pb | Rb | As | Cr | Co | Ni | Sr | Ba | Zr |

|---|---|---|---|---|---|---|---|---|---|---|---|

| ppm | 45 | 1891 | 1071 | <10 | 53 | 93 | <10 | 143 | 3.6 | 7.2 | 5.7 |

| Formula | Phase | Wt% |

|---|---|---|

| MgAl2O4 | Spinel | 68.14 |

| Al2O3 | Corundum | 17.59 |

| AlN | Wurtzit | 8.57 |

| Al(OH)3 | Bayerite | 1.9 |

| CaF2 | Fluorite | 1.72 |

| NaCl | Halite | 1.51 |

| KCl | Sylvine | 0.33 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sassi, M.; Simon, A. Waste-to-Reuse Foam Glasses Produced from Soda-Lime-Silicate Glass, Cathode Ray Tube Glass, and Aluminium Dross. Inorganics 2022, 10, 1. https://doi.org/10.3390/inorganics10010001

Sassi M, Simon A. Waste-to-Reuse Foam Glasses Produced from Soda-Lime-Silicate Glass, Cathode Ray Tube Glass, and Aluminium Dross. Inorganics. 2022; 10(1):1. https://doi.org/10.3390/inorganics10010001

Chicago/Turabian StyleSassi, Meriem, and Andrea Simon. 2022. "Waste-to-Reuse Foam Glasses Produced from Soda-Lime-Silicate Glass, Cathode Ray Tube Glass, and Aluminium Dross" Inorganics 10, no. 1: 1. https://doi.org/10.3390/inorganics10010001

APA StyleSassi, M., & Simon, A. (2022). Waste-to-Reuse Foam Glasses Produced from Soda-Lime-Silicate Glass, Cathode Ray Tube Glass, and Aluminium Dross. Inorganics, 10(1), 1. https://doi.org/10.3390/inorganics10010001