Enhancement in Structural and Electroluminescence Properties of Green Light Emission for Semipolar (11–22) InGaN/GaN Based Grown on m-Plane Sapphire via Low Temperature Ammonia Treatment (LTAT)

Abstract

:1. Introduction

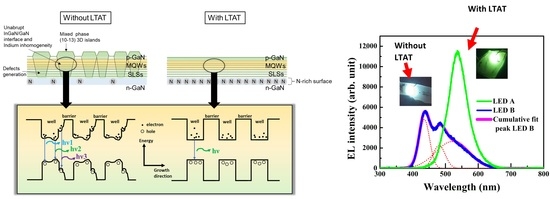

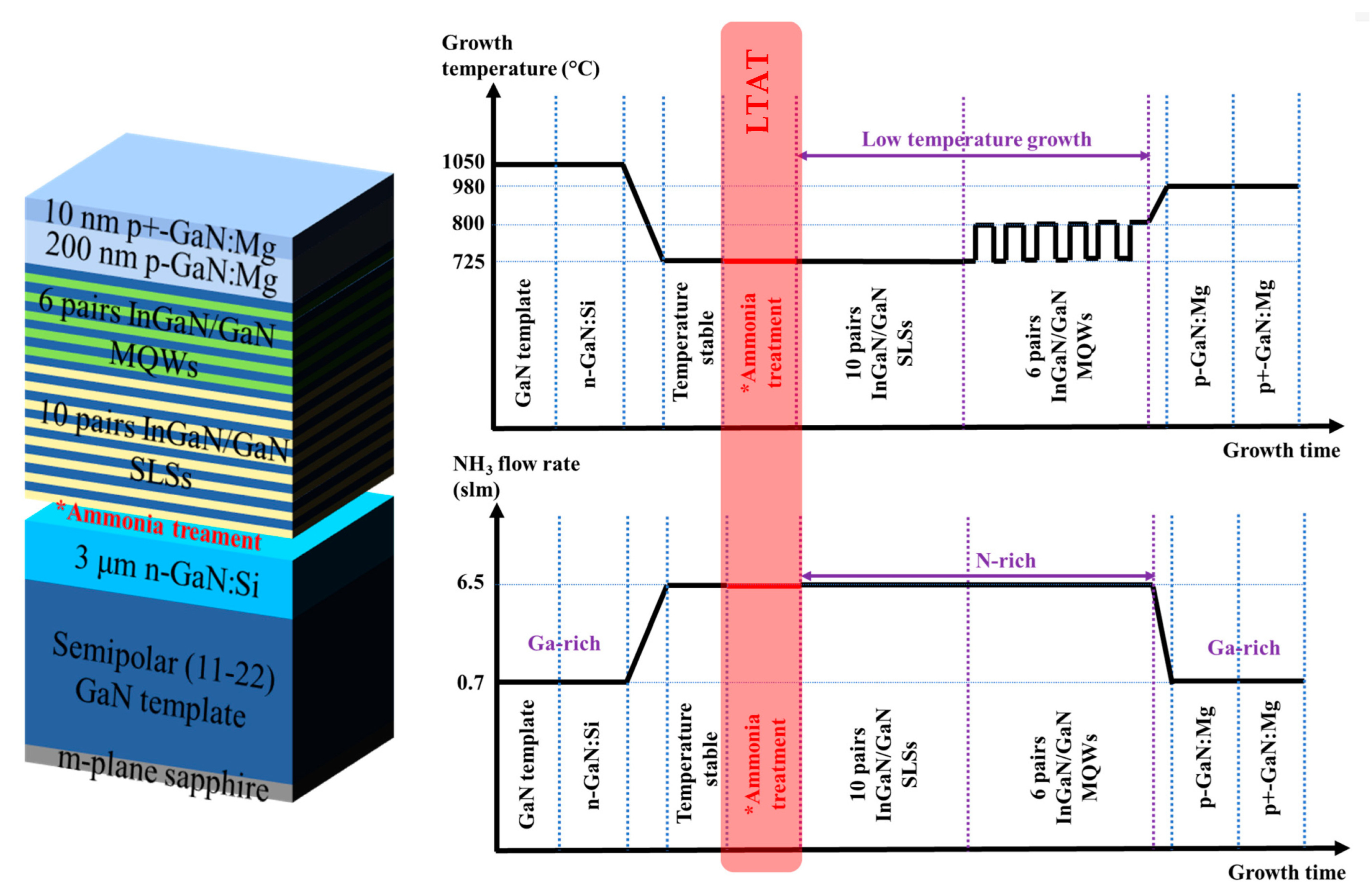

2. Materials and Methods

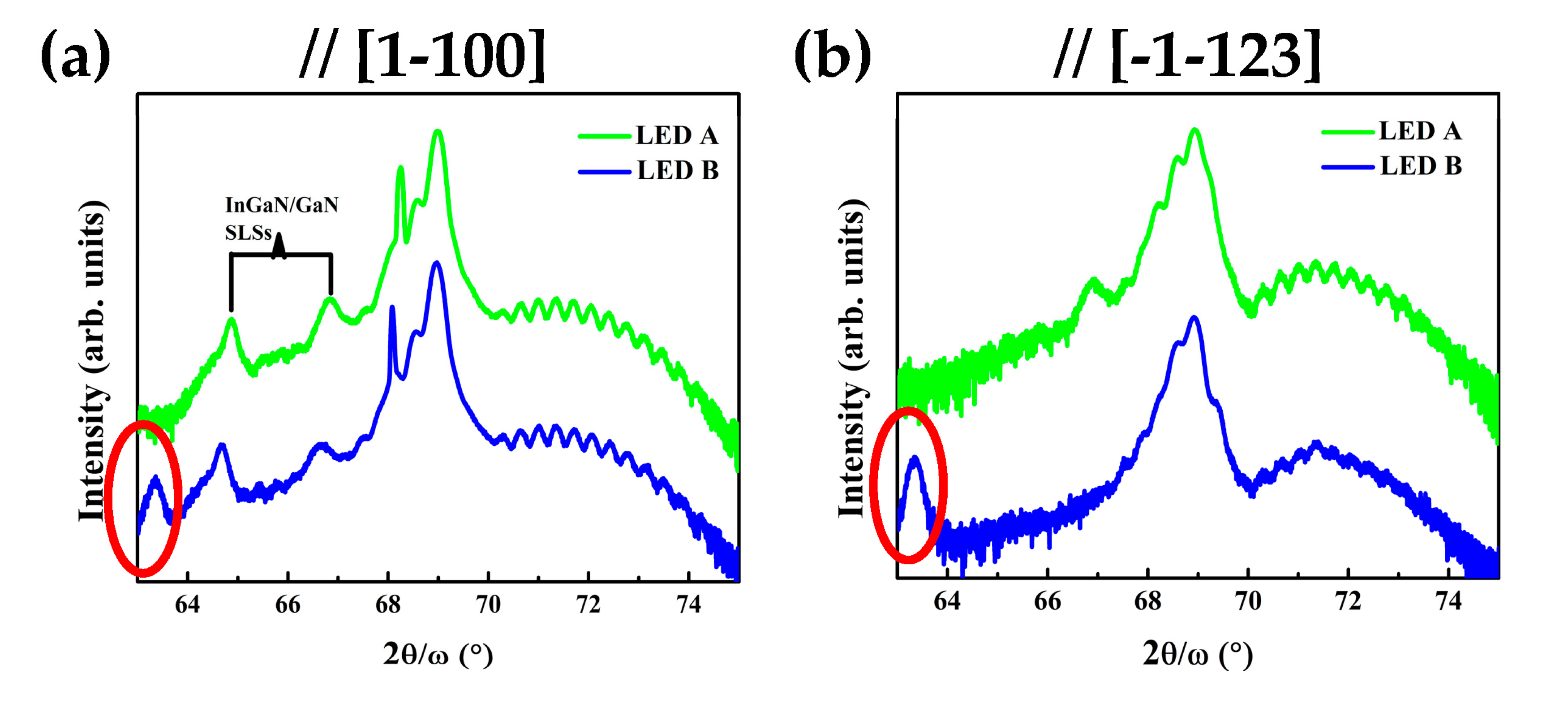

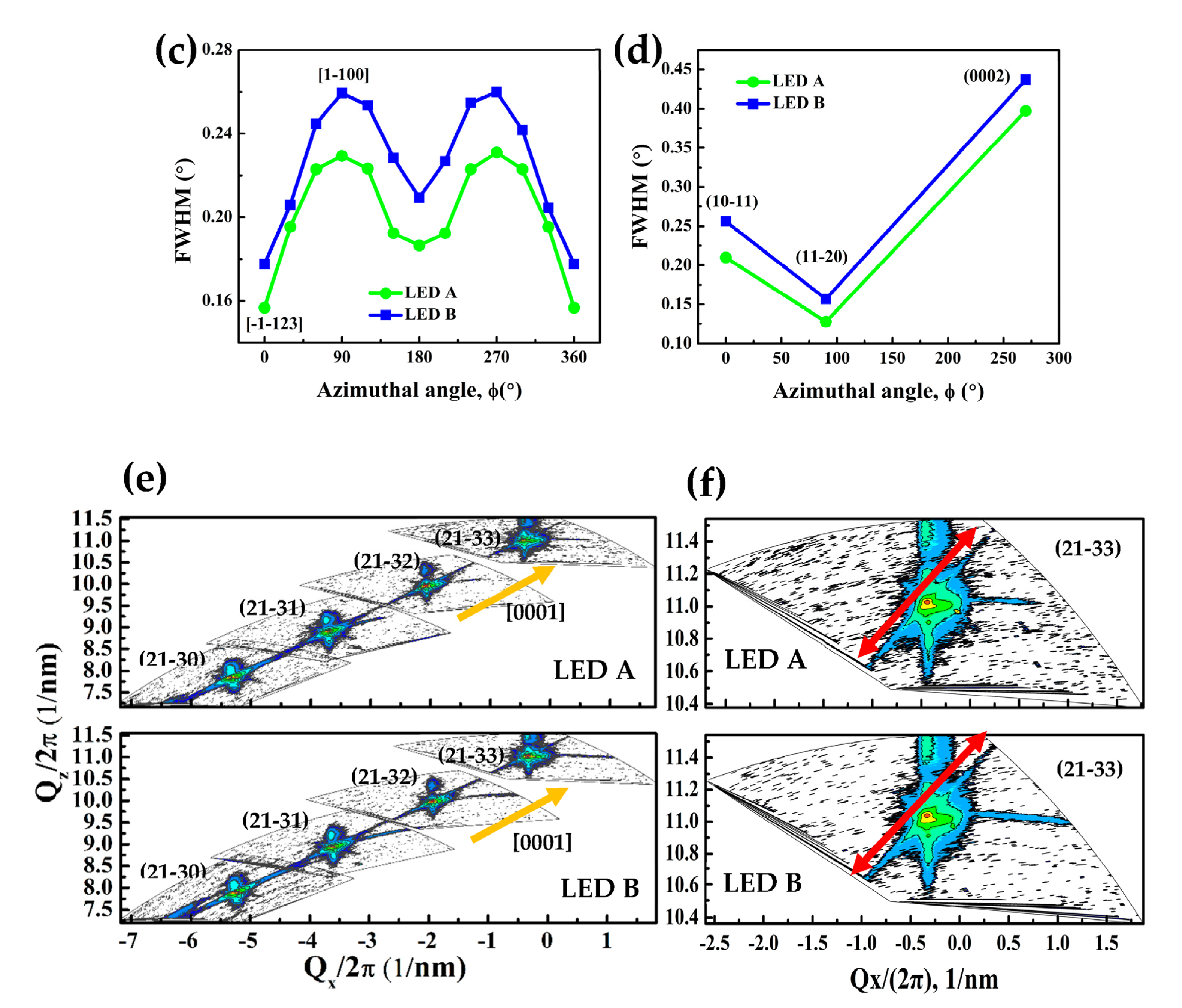

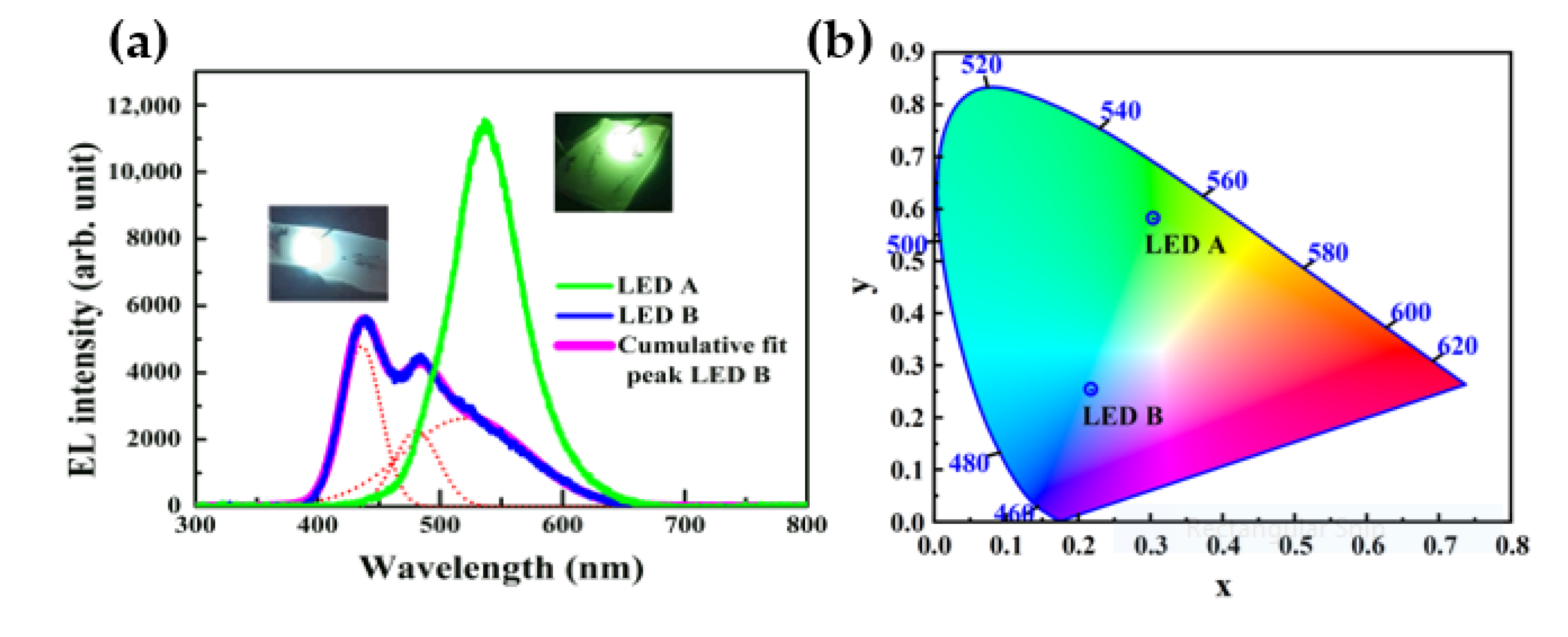

3. Results

4. Discussions

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Talnishnikh, N.A.; Ivanov, A.E.; Smirnova, A.G.; Shabunina, E.I.; Shmidt, N.M. The contribution of the in distribution in InGaN/GaN MQW to the “green gap” phenomenon. J. Phys. Conf. Ser. 2019, 1199, 012015. [Google Scholar] [CrossRef]

- Auf Der Maur, M.; Pecchia, A.; Penazzi, G.; Rodrigues, W.; Di Carlo, A. Unraveling the “Green Gap” problem: The role of random alloy fluctuations in InGaN/GaN light emitting diodes. Phys. Rev. Lett. 2016, 116, 027401. [Google Scholar] [CrossRef] [PubMed]

- Massabuau, F.C.-P.; Davies, M.J.; Oehler, F.; Pamenter, S.K.; Thrush, E.J.; Kappers, M.J.; Kovács, A.; Williams, T.; Hopkins, M.A.; Humphreys, C.J.; et al. The impact of trench defects in InGaN/GaN light emitting diodes and implications for the “green gap” problem. Appl. Phys. Lett. 2014, 105, 112110. [Google Scholar] [CrossRef]

- Langer, T.; Kruse, A.; Ketzer, F.A.; Schwiegel, A.; Hoffmann, L.; Jönen, H.; Bremers, H.; Rossow, U.; Hangleiter, A. Origin of the “green gap”: Increasing nonradiative recombination in indium-rich GaInN/GaN quantum well structures. Phys. Status Solidi C 2011, 8, 2170–2172. [Google Scholar] [CrossRef]

- Usman, M.; Munsif, M.; Mushtaq, U.; Anwar, A.-R.; Muhammad, N. Green gap in GaN-based light-emitting diodes: In perspective. Crit. Rev. Solid State Mater. Sci. 2020, 46, 450–467. [Google Scholar] [CrossRef]

- Ding, B. Improving radiative recombination efficiency of green light-emitting diodes. Mater. Sci. Technol. 2018, 34, 1615–1630. [Google Scholar] [CrossRef]

- Zhao, X.; Tang, B.; Gong, L.; Bai, J.; Ping, J.; Zhou, S. Rational construction of staggered InGaN quantum wells for efficient yellow light-emitting diodes. Appl. Phys. Lett. 2021, 118, 182102. [Google Scholar] [CrossRef]

- Zhao, X.; Tang, B.; Gong, L.; Bai, J.; Ping, J.; Zhou, S. Effect of strain relaxation on performance of InGaN/GaN green LEDs grown on 4-inch sapphire substrate with sputtered AlN nucleation layer. Sci. Rep. 2019, 9, 1–9. [Google Scholar] [CrossRef]

- Zhou, S.; Wan, Z.; Lei, Y.; Tang, B.; Tao, G.; Du, P.; Zhao, X. InGaN quantum well with gradually varying indium content for high-efficiency GaN-based green light-emitting diodes. Opt. Lett. 2022, 47, 1291–1294. [Google Scholar] [CrossRef]

- Northrup, J.E. GaN and InGaN(112̱2) surfaces: Group-III adlayers and indium incorporation. Appl. Phys. Lett. 2009, 95, 133107. [Google Scholar] [CrossRef] [Green Version]

- Monavarian, M.; Metzner, S.; Izyumskaya, N.; Okur, S.; Zhang, F.; Can, N.; Das, S.; Avrutin, V.; Özgür, F.; Bertram, F.; et al. GaN and InGaN (11-22) oriented InGaN-based light emitting diodes. Gallium Nitride Mater. Devices X 2015, 95, 133107. [Google Scholar] [CrossRef]

- Zhao, Y.; Yan, Q.; Huang, C.-Y.; Huang, S.-C.; Hsu, P.S.; Tanaka, S.; Pan, C.-C.; Kawaguchi, Y.; Fujito, K.; Van De Walle, C.G.; et al. Indium incorporation and emission properties of nonpolar and semipolar InGaN quantum wells. Appl. Phys. Lett. 2012, 100, 201108. [Google Scholar] [CrossRef]

- Wernicke, T.; Schade, L.; Netzel, C.; Rass, J.; Hoffmann, V.; Ploch, S.; Knauer, A.; Weyers, M.; Schwarz, U.; Kneissl, M. Indium incorporation and emission wavelength of polar, nonpolar and semipolar InGaN quantum wells. Semicond. Sci. Technol. 2012, 27. [Google Scholar] [CrossRef]

- Choi, J.-H.; Baek, S.-H.; Kim, H.-W.; Na, H.; Lee, S.-N. Indium Localization-Induced Red, Green, and Blue Emissions of Semipolar (11-22) GaN-Based Light-Emitting Diodes. Phys. Status Solidi A 2020, 217, 2000219. [Google Scholar] [CrossRef]

- Tsai, C.-L. Effects of underlying InGaN/GaN superlattice structures on the structural and optical properties of InGaN LEDs. J. Lumin- 2016, 174, 36–41. [Google Scholar] [CrossRef]

- Ryu, H.-Y.; Choi, W.J. Optimization of InGaN/GaN superlattice structures for high-efficiency vertical blue light-emitting diodes. J. Appl. Phys. 2013, 114, 173101. [Google Scholar] [CrossRef]

- Liu, M.; Zhao, J.; Zhou, S.; Gao, Y.; Hu, J.; Liu, X.; Ding, X. An InGaN/GaN Superlattice to Enhance the Performance of Green LEDs: Exploring the Role of V-Pits. Nanomaterials 2018, 8, 450. [Google Scholar] [CrossRef]

- Zhao, X.; Huang, K.; Bruckbauer, J.; Shen, S.; Zhu, C.; Fletcher, P.; Feng, P.; Cai, Y.; Bai, J.; Trager-Cowan, C.; et al. Influence of an InGaN superlattice pre-layer on the performance of semi-polar (11–22) green LEDs grown on silicon. Sci. Rep. 2020, 10, 1–8. [Google Scholar] [CrossRef]

- Zhou, S.; Liu, X.; Yan, H.; Gao, Y.; Xu, H.; Zhao, J.; Quan, Z.; Gui, C.; Liu, S. The effect of nanometre-scale V-pits on electronic and optical properties and efficiency droop of GaN-based green light-emitting diodes. Sci. Rep. 2018, 8, 1–12. [Google Scholar] [CrossRef]

- Zhao, X.; Wan, Z.; Gong, L.; Tao, G.; Zhou, S. Enhanced Optoelectronic Performance of Yellow Light-Emitting Diodes Grown on InGaN/GaN Pre-Well Structure. Nanomaterials 2021, 11, 3231. [Google Scholar] [CrossRef]

- Davies, M.J.; Dawson, P.; Massabuau, F.C.-P.; Le Fol, A.; Oliver, R.A.; Kappers, M.J.; Humphreys, C.J. A study of the inclusion of prelayers in InGaN/GaN single- and multiple-quantum-well structures. Phys. Status Solidi B Basic Res. 2014, 252, 866–872. [Google Scholar] [CrossRef]

- Haller, C.; Carlin, J.-F.; Jacopin, G.; Liu, W.; Martin, D.; Butté, R.; Grandjean, N. GaN surface as the source of non-radiative defects in InGaN/GaN quantum wells. Appl. Phys. Lett. 2018, 113, 111106. [Google Scholar] [CrossRef]

- Lee, K.; Lee, C.-R.; Lee, J.H.; Chung, T.-H.; Ryu, M.-Y.; Jeong, K.-U.; Leem, J.-Y.; Kim, J.S. Influences of Si-doped graded short-period superlattice on green InGaN/GaN light-emitting diodes. Opt. Express 2016, 24, 7743–7751. [Google Scholar] [CrossRef] [PubMed]

- Yang, J.; Zhao, D.G.; Jiang, D.S.; Chen, P.; Zhu, J.J.; Liu, Z.S.; Liu, W.; Li, X.; Liang, F.; Liu, S.T.; et al. Investigation on the corrosive effect of NH3 during InGaN/GaN multi-quantum well growth in light emitting diodes. Sci. Rep. 2017, 7, 44850. [Google Scholar] [CrossRef]

- Omar, A.-Z.; Shuhaimi, A.; Makinudin, A.H.A.; Khudus, M.I.A.; Supangat, A. Embedded AlN/GaN multi-layer for enhanced crystal quality and surface morphology of semi-polar (11-22) GaN on m-plane sapphire. Mater. Sci. Semicond. Process. 2018, 86, 1–7. [Google Scholar] [CrossRef]

- Ploch, S.; Frentrup, M.; Wernicke, T.; Pristovsek, M.; Weyers, M.; Kneissl, M. Orientation control of GaN {112¯2} and {101¯3¯} grown on (101¯0) sapphire by metal-organic vapor phase epitaxy. J. Cryst. Growth 2010, 312, 2171–2174. [Google Scholar] [CrossRef]

- Zhao, G.; Wang, L.; Li, H.; Meng, Y.; Li, F.; Yang, S.; Wang, Z. Structural and optical properties of semi-polar (11-22) InGaN/GaN green light-emitting diode structure. Appl. Phys. Lett. 2018, 112, 52105. [Google Scholar] [CrossRef]

- Ooi, C.S.; Shuhaimi, A.; Tan, G.; Al-Zuhairi, O.; Majid, W.H.A. Effect of Flux Rate Variation at Fixed V/III Ratio on Semi-Polar (112¯2) GaN: Crystal Quality and Surface Morphology Study. Crystals 2022, 12, 247. [Google Scholar] [CrossRef]

- Sun, Q.; Leung, B.; Yerino, C.D.; Zhang, Y.; Han, J. Improving microstructural quality of semipolar (112̱2) GaN on m-plane sapphire by a two-step growth process. Appl. Phys. Lett. 2009, 95, 231904. [Google Scholar] [CrossRef]

- Song, K.-R.; Cho, C.-Y.; Lee, S.-N. Effect of a patterned sapphire substrate on indium localization in semipolar (11-22) GaN-based light-emitting diodes. Thin Solid Films 2020, 707, 138077. [Google Scholar] [CrossRef]

- Sun, Q.; Han, J. Heteroepitaxy of Nonpolar and Semipolar GaN. Springer Ser. Mater. Sci. 2012, 156, 1–27. [Google Scholar] [CrossRef]

- DaSilva, Y.A.R.; Chauvat, M.P.; Ruterana, P.; Lahourcade, L.; Monroy, E.; Nataf, G. Defect structure in heteroepitaxial semipolar (11\bar {2} 2) (Ga, Al)N. J. Phys. Condens. Matter 2010, 22, 355802. [Google Scholar] [CrossRef] [PubMed]

- Zhao, G.; Wang, L.; Yang, S.; Li, H.; Wei, H.; Han, D.; Wang, Z. Anisotropic structural and optical properties of semi-polar (11–22) GaN grown on m-plane sapphire using double AlN buffer layers. Sci. Rep. 2016, 6, 1–10. [Google Scholar] [CrossRef]

- Pristovsek, M.; Frentrup, M.; Zhu, T.; Kusch, G.; Humphreys, C.J. X-ray characterisation of the basal stacking fault densities of (1122) GaN. CrystEngComm 2021, 23, 6059–6069. [Google Scholar] [CrossRef]

- Meng, Y.; Wang, L.; Zhao, G.; Li, F.; Li, H.; Yang, S.; Wang, Z. Red Emission of InGaN/GaN Multiple-Quantum-Well Light-Emitting Diode Structures with Indium-Rich Clusters. Phys. Status Solidi A 2018, 215, 1800455. [Google Scholar] [CrossRef]

- Ware, C. (Ed.) Color. In Information Visualization, 4th ed.; Morgan Kaufmann: Burlington, MA, USA, 2021; pp. 95–141. [Google Scholar] [CrossRef]

- Chuo, C.-C.; Chang, M.N.; Pan, F.-M.; Lee, C.-M.; Chyi, J.-I. Effect of composition inhomogeneity on the photoluminescence of InGaN/GaN multiple quantum wells upon thermal annealing. Appl. Phys. Lett. 2002, 80, 1138–1140. [Google Scholar] [CrossRef]

- Frentrup, M.; Ploch, S.; Pristovsek, M.; Kneissl, M. Crystal orientation of GaN layers on (101 0) m -plane sapphire. Phys. Status Solidi B Basic Res. 2011, 248, 583–587. [Google Scholar] [CrossRef]

- Mesrine, M.; Grandjean, N.; Massies, J. Efficiency of NH3 as nitrogen source for GaN molecular beam epitaxy. Appl. Phys. Lett. 1998, 72, 350–352. [Google Scholar] [CrossRef]

- Omar, A.-Z.; Bin Abu Bakar, A.S.; Makinudin, A.H.A.; Khudus, M.I.M.A.; Azman, A.; Kamarundzaman, A.; Supangat, A. Effect of low NH3 flux towards high quality semi-polar (11-22) GaN on m-plane sapphire via MOCVD. Superlattices Microstruct. 2018, 117, 207–214. [Google Scholar] [CrossRef]

- Maliakkal, C.B.; Rahman, A.A.; Hatui, N.; Chalke, B.A.; Bapat, R.D.; Bhattacharya, A. Comparison of GaN nanowires grown on c-, r- and m-plane sapphire substrates. J. Cryst. Growth 2016, 439, 47–53. [Google Scholar] [CrossRef]

- Liu, Z.; Nitta, S.; Usami, S.; Robin, Y.; Kushimoto, M.; Deki, M.; Honda, Y.; Pristovsek, M.; Amano, H. Effect of gas phase temperature on InGaN grown by metalorganic vapor phase epitaxy. J. Cryst. Growth 2019, 509, 50–53. [Google Scholar] [CrossRef]

- Foronda, H.M.; Graupeter, S.; Mehnke, F.; Enslin, J.; Wernicke, T.; Kneissl, M. Reducing the grain density in semipolar (11-22) AlGaN surfaces on m-plane sapphire substrates. Jpn. J. Appl. Phys. 2019, 58, SC1026. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tan, G.; Shuhaimi, A.; Norhaniza, R.; Zahir, N.; Low, Y.J.; Wong, Y.H.; Majid, W.H.A. Enhancement in Structural and Electroluminescence Properties of Green Light Emission for Semipolar (11–22) InGaN/GaN Based Grown on m-Plane Sapphire via Low Temperature Ammonia Treatment (LTAT). Photonics 2022, 9, 646. https://doi.org/10.3390/photonics9090646

Tan G, Shuhaimi A, Norhaniza R, Zahir N, Low YJ, Wong YH, Majid WHA. Enhancement in Structural and Electroluminescence Properties of Green Light Emission for Semipolar (11–22) InGaN/GaN Based Grown on m-Plane Sapphire via Low Temperature Ammonia Treatment (LTAT). Photonics. 2022; 9(9):646. https://doi.org/10.3390/photonics9090646

Chicago/Turabian StyleTan, Gary, Ahmad Shuhaimi, Rizuan Norhaniza, Norhilmi Zahir, Yan Jie Low, Yew Hoong Wong, and Wan Haliza Abd Majid. 2022. "Enhancement in Structural and Electroluminescence Properties of Green Light Emission for Semipolar (11–22) InGaN/GaN Based Grown on m-Plane Sapphire via Low Temperature Ammonia Treatment (LTAT)" Photonics 9, no. 9: 646. https://doi.org/10.3390/photonics9090646

APA StyleTan, G., Shuhaimi, A., Norhaniza, R., Zahir, N., Low, Y. J., Wong, Y. H., & Majid, W. H. A. (2022). Enhancement in Structural and Electroluminescence Properties of Green Light Emission for Semipolar (11–22) InGaN/GaN Based Grown on m-Plane Sapphire via Low Temperature Ammonia Treatment (LTAT). Photonics, 9(9), 646. https://doi.org/10.3390/photonics9090646