Dark Noise Suppression of NIR Response Enhanced Si-CMOS Sensor

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Knight, M.W.; Sobhani, H.; Nordlander, P.; Halas, N.J. Photodetection with active optical antennas. Science 2011, 332, 702–704. [Google Scholar] [CrossRef] [PubMed]

- Nazirzadeh, M.A.; Atar, F.B.; Turgut, B.B.; Okyay, A.K. Random sized plasmonic nanoantennas on silicon for low-cost broad-band near-infrared photodetection. Sci. Rep. 2014, 4, 7103. [Google Scholar] [CrossRef] [PubMed]

- Lin, K.T.; Chen, H.L.; Lai, Y.S.; Yu, C.C. Silicon-based broadband antenna for high responsivity and polarization-insensitive photodetection at telecommunication wavelengths. Nat. Commun. 2014, 5, 3288. [Google Scholar] [CrossRef] [PubMed]

- Mark, W.K.; Yumin, W.; Alexander, S.U.; Ali, S.; Bob, Y.Z.; Peter, N. Embedding Plasmonic Nanostructure Diodes Enhances Hot Electron Emission. J. Nano Lett. 2013, 13, 1687–1692. [Google Scholar]

- Kang, Y.; Liu, H.D.; Morse, M.; Paniccia, M.; Zadka, M.; Litski, S.; Sarid, G.; Pauchard, A.; Kuo, Y.H.; Chen, H.W.; et al. Monolithic germaniumsilicon avalanche photodiodes with 340 GHz gain-bandwidth product. J. Nat. Photonics 2009, 3, 59–63. [Google Scholar] [CrossRef]

- Sobhani, A.; Knight, M.W.; Wang, Y.; Zheng, B.; King, N.S.; Brown, L.V. Narrowband photodetection in the near-infrared with a plasmon-induced hot electron device. J. Nat. Commun. 2013, 4, 1643. [Google Scholar] [CrossRef] [PubMed]

- Chandra, A.; Giri, S.; Das, B.; Ghosh, S.; Chattopadhyay, K.K. NIR photodetector based on p-silicon nanowires/n-cadmium sulfide nanoscale junctions. J. Appl. Surf. Sci. 2021, 548, 149256. [Google Scholar] [CrossRef]

- Ajiki, Y.; Kan, T.; Yahiro, M.; Hamada, A.; Adachi, J.; Adachi, C.; Matsumoto, K.; Shimoyama, I. Silicon based near infrared photodetector using self-assembled organic crystalline nano-pillars. J. Appl. Phys. Lett. 2016, 108, 151102. [Google Scholar] [CrossRef]

- Casalino, M.; Coppola, G.; Sirleto, L.; Iodice, M.; Gioffre, M.; Rendina, I.; Sassi, U.; Lombardo, A.; Milana, S.; Sundaram, R.S. NIR silicon Schottky photodetector: From metal to graphene. In Proceedings of the 2014 Fotonica AEIT Italian Conference on Photonics Technologies, Naples, Italy, 12–14 May 2014; IEEE: Piscataway, NJ, USA, 2014; pp. 1–4. [Google Scholar]

- Miskovsky, N.M.; Cutler, P.H.; Mayer, A.; Weiss, B.L.; Brian, W.; Sullivan, T.E.; Lerner, P.B. Nanoscale devices for rectification of high frequency radiation from the infrared through the visible: A new approach. J. Nanotechnol. 2012, 2012, 512379. [Google Scholar] [CrossRef]

- Bonse, J.; Krüger, J.; Höhm, S.; Rosenfeld, A. Femtosecond laser-induced periodic surface structures. J. Laser Appl. 2012, 24, 042006. [Google Scholar] [CrossRef]

- Her, T.H.; Finlay, R.J.; Wu, C.; Deliwala, S.; Mazur, E. Microstructuring of silicon with femtosecond laser pulses. Appl. Phys. Lett. 1998, 73, 1673–1675. [Google Scholar] [CrossRef]

- Her, T.H.; Finlay, R.J.; Wu, C.; Mazur, E. Femtosecond laser-induced formation of spikes on silicon. Appl. Phys. A 2000, 70, 383–385. [Google Scholar] [CrossRef]

- Wu, C.; Crouch, C.H.; Zhao, L.; Carey, J.E.; Younkin, R.; Levinson, J.A.; Mazur, E. Near-unity below-band-gap absorption by microstructured silicon. Appl. Phys. Lett. 2001, 78, 1850. [Google Scholar] [CrossRef]

- Carey, J.E.; Crouch, C.H.; Shen, M.; Mazur, E. Visible and near-infrared responsivity of femtosecond-laser microstructured silicon photodiodes. Opt. Lett. 2005, 30, 1773. [Google Scholar] [CrossRef]

- Myers, R.A.; Farrell, R.; Karger, A.M.; Carey, J.E.; Mazur, E. Enhancing near-infrared avalanche photodiode performance by femtosecond laser microstructuring. Appl. Opt. 2006, 45, 8825. [Google Scholar] [CrossRef]

- Huang, Z.; Carey, J.E.; Liu, M.; Guo, X.; Mazur, E.; Campbell, J.C. Microstructured silicon photodetector. Appl. Phys. Lett. 2006, 89, 516. [Google Scholar] [CrossRef]

- Wang, X.; Huang, Y.; Liu, D.; Zhu, X.; Wang, B.; Zhu, H. Fabrication of tellurium doped silicon detector by femtosecond laser and excimer laser. Chin. J. Lasers 2013, 40, 0302001. [Google Scholar] [CrossRef]

- Du, L.; Wu, Z.; Rui, L.; Fei, T.; Jiang, Y. Near-infrared photoresponse of femtosecond laser processed Se-doped silicon n+ − n photodiodes. Opt. Lett. 2016, 41, 5031. [Google Scholar] [CrossRef]

- Li, C.H.; Zhao, J.H.; Yu, X.Y.; Chen, Q.D.; Feng, J.; Han, P.D.; Sun, H.B. Sulfur-Doped Silicon Photodiode by Ion Implantation and Femtosecond Laser Annealing. IEEE Sens. J. 2017, 17, 2367. [Google Scholar] [CrossRef]

- Mo, Y.; Bazant, M.Z.; Kaxiras, E. Sulfur point defects in crystalline and amorphous silicon. Phys. Rev. B 2004, 70, 3352. [Google Scholar] [CrossRef]

- Dong, X.; Li, N.; Liang, C.; Sun, H.; Feng, G.; Zhu, Z.; Shao, H.; Rong, X.; Zhao, L.; Zhuang, J. Strong Mid-Infrared Absorption and High Crystallinity of Microstructured Silicon Formed by Femtosecond Laser Irradiation in NF3 Atmosphere. Appl. Phys. Express 2013, 6, 1301. [Google Scholar] [CrossRef]

- Smith, M.J.; Sher, M.J.; Franta, B.; Lin, Y.T.; Mazur, E.; Gradecak, S. The origins of pressure-induced phase transformations during the surface texturing of silicon using femtosecond laser irradiation. J. Appl. Phys. 2012, 112, 083518. [Google Scholar] [CrossRef]

- Smith, M.J.; Lin, Y.T.; Sher, M.J.; Winkler, M.T.; Mazur, E.; Gradecak, S. Pressure-induced phase transformations during femtosecond-laser doping of silicon. J. Appl. Phys. 2011, 110, 053524. [Google Scholar] [CrossRef]

- Schade, M.; Varlamova, O.; Reif, J.; Blumtritt, H.; Erfurth, W.; Leipner, H.S. High-resolution investigations of ripple structures formed by femtosecond laser irradiation of silicon. Anal. Bioanal. Chem. 2010, 396, 1905. [Google Scholar] [CrossRef] [PubMed][Green Version]

- Lee, Y.H.; Oehrlein, G.S.; Ransom, C. RIE-induced damage and contamination in silicon. Radiat. Eff. Defects Solids 1989, 111–112, 221–232. [Google Scholar] [CrossRef]

- Crouch, C.H.; Carey, J.E.; Shen, M.; Mazur, E.; Genin, F.Y. Infrared absorption by sulfur-doped silicon formed by femtosecond laser irradiation. Appl. Phys. A 2004, 79, 1635–1641. [Google Scholar] [CrossRef]

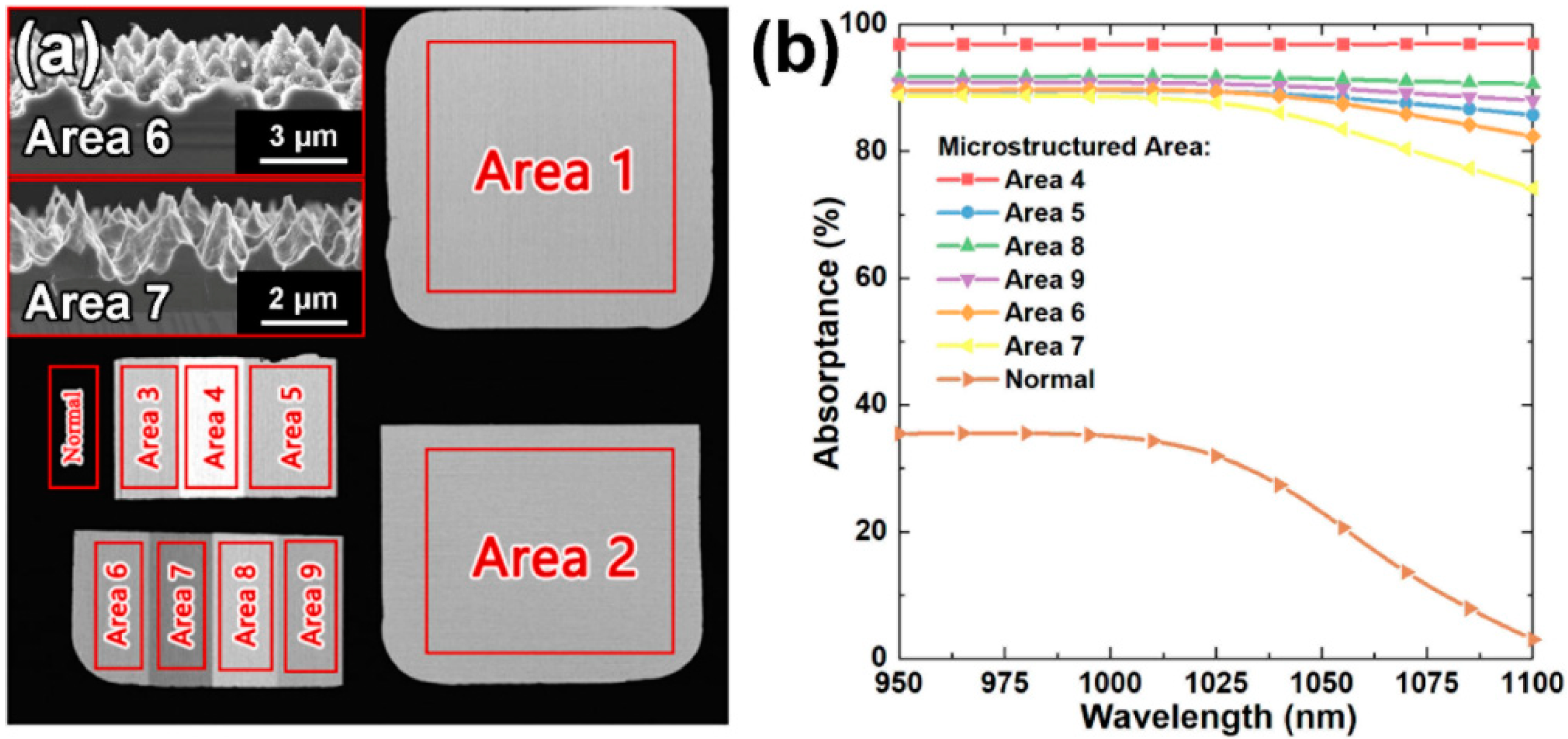

| Influence (kJ/m2) | Etching Time (s) | Gray Value | |

|---|---|---|---|

| Normal | - | - | 260 |

| Area 1 | 0.3 | - | 3100 |

| Area 2 | 0.35 | - | 3200 |

| Area 3 | 0.45 | - | 3600 |

| Area 4 | 0.95 | - | 4100 |

| Area 5 | 0.95 | 200 | 3500 |

| Area 6 | 0.2 | - | 2800 |

| Area 7 | 0.2 | 50 | 2300 |

| Area 8 | 0.38 | - | 3300 |

| Area 9 | 0.38 | 50 | 2900 |

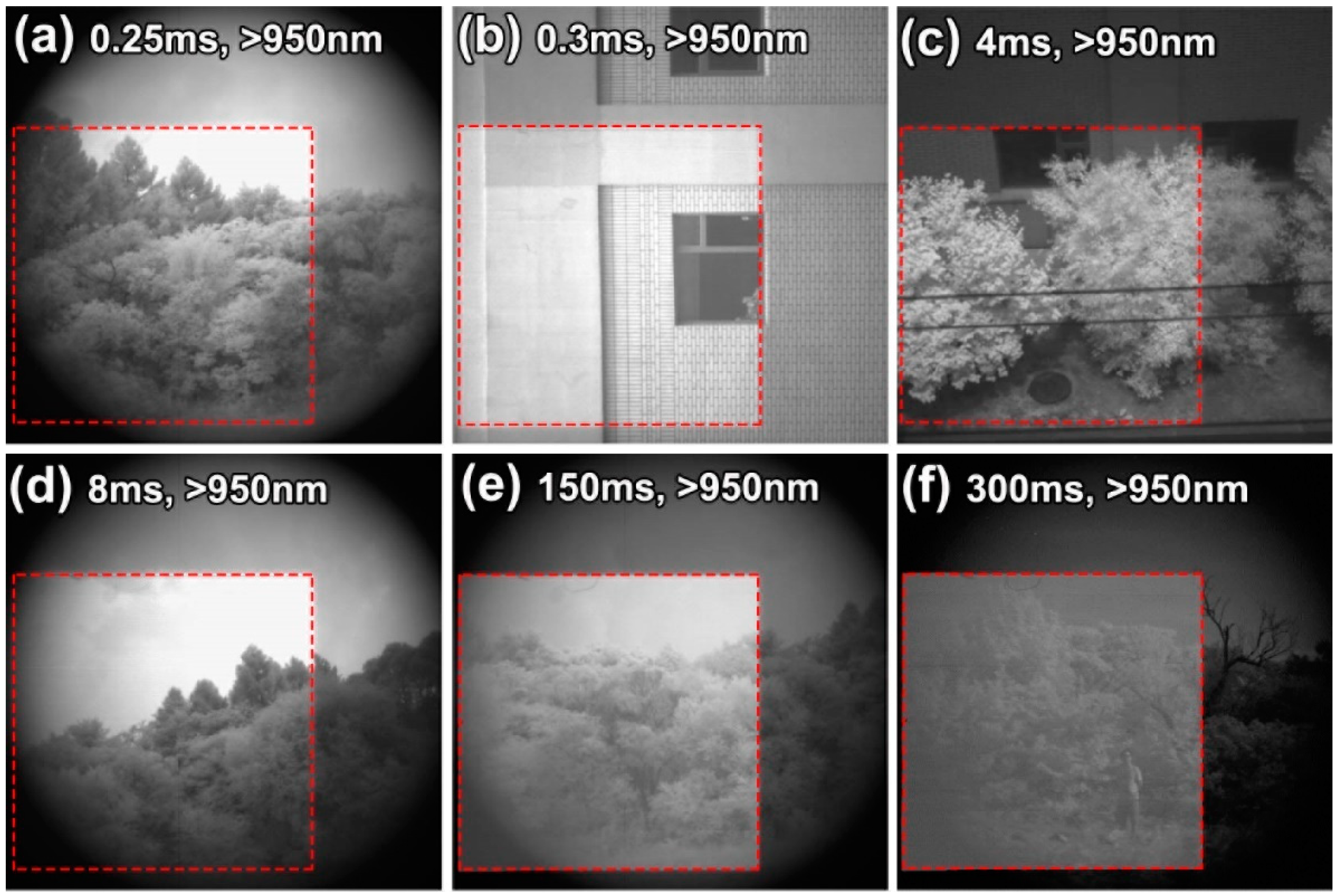

| Influence (kJ/m2) | Etching Time (s) | Gray Value | |

|---|---|---|---|

| Unprocessed Area | - | - | 290 |

| Microstructured Area | 0.13 | - | 1900 |

| Microstructured Area | 0.13 | 50 | 1200 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, K.; Peng, C.; Hou, Z. Dark Noise Suppression of NIR Response Enhanced Si-CMOS Sensor. Photonics 2022, 9, 307. https://doi.org/10.3390/photonics9050307

Wang K, Peng C, Hou Z. Dark Noise Suppression of NIR Response Enhanced Si-CMOS Sensor. Photonics. 2022; 9(5):307. https://doi.org/10.3390/photonics9050307

Chicago/Turabian StyleWang, Ke, Chengxiang Peng, and Zuoxun Hou. 2022. "Dark Noise Suppression of NIR Response Enhanced Si-CMOS Sensor" Photonics 9, no. 5: 307. https://doi.org/10.3390/photonics9050307

APA StyleWang, K., Peng, C., & Hou, Z. (2022). Dark Noise Suppression of NIR Response Enhanced Si-CMOS Sensor. Photonics, 9(5), 307. https://doi.org/10.3390/photonics9050307