A Multi-Layered Borophene-Silica-Silver Based Refractive Index Sensor for Biosensing Applications Operated at the Infrared Frequency Spectrum

Abstract

:1. Introduction

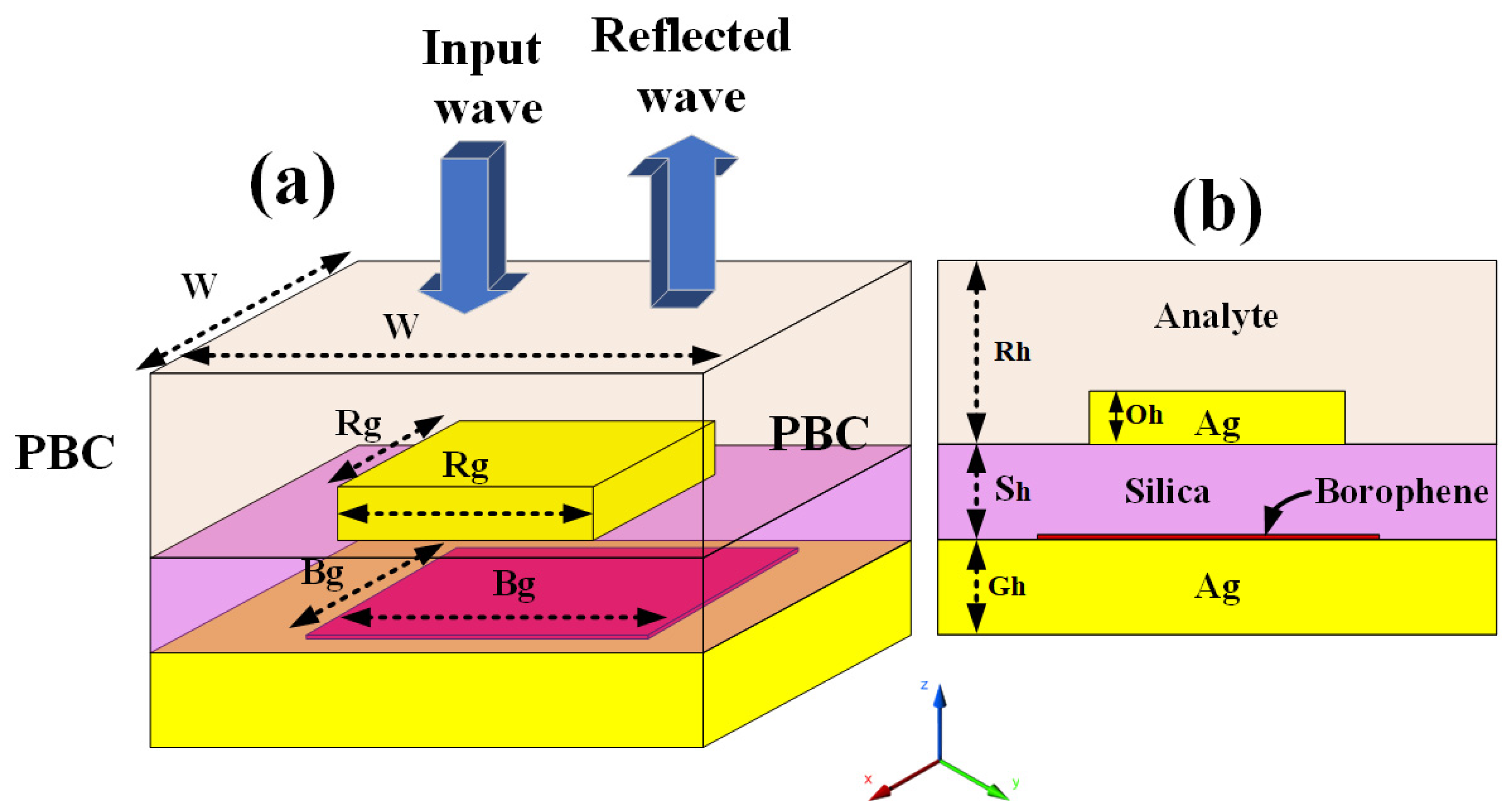

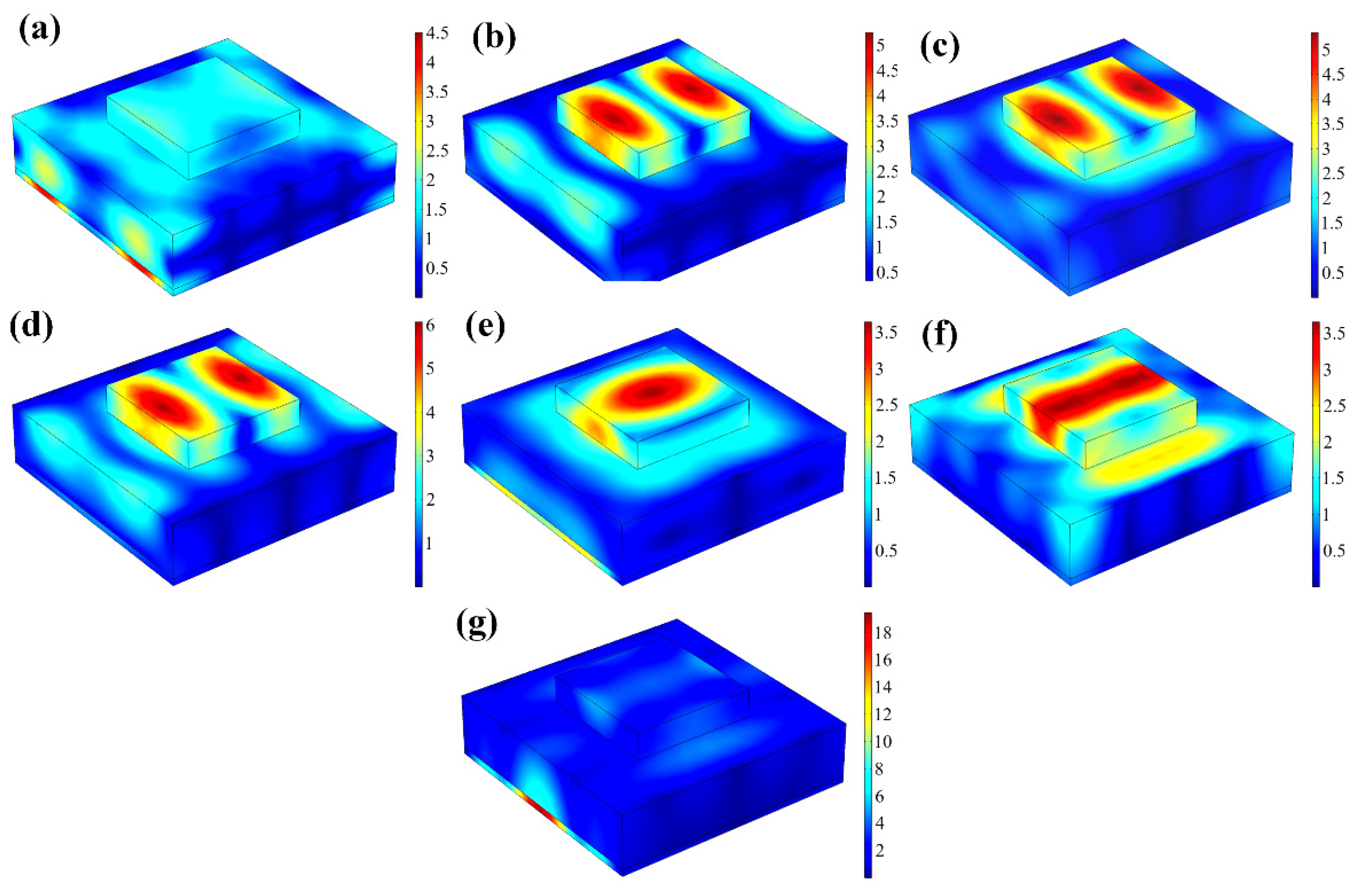

2. Borophene Based Biosensor Structure

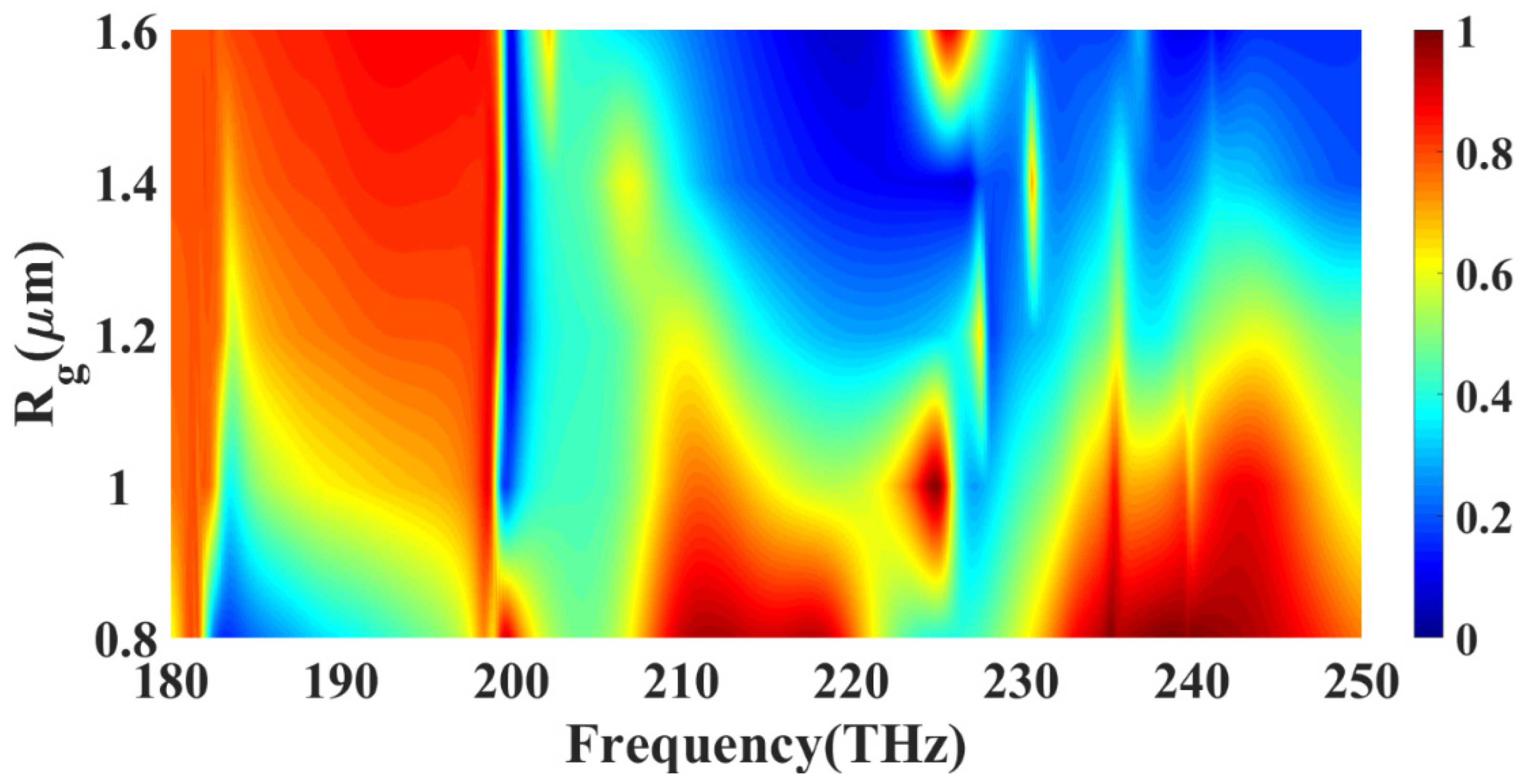

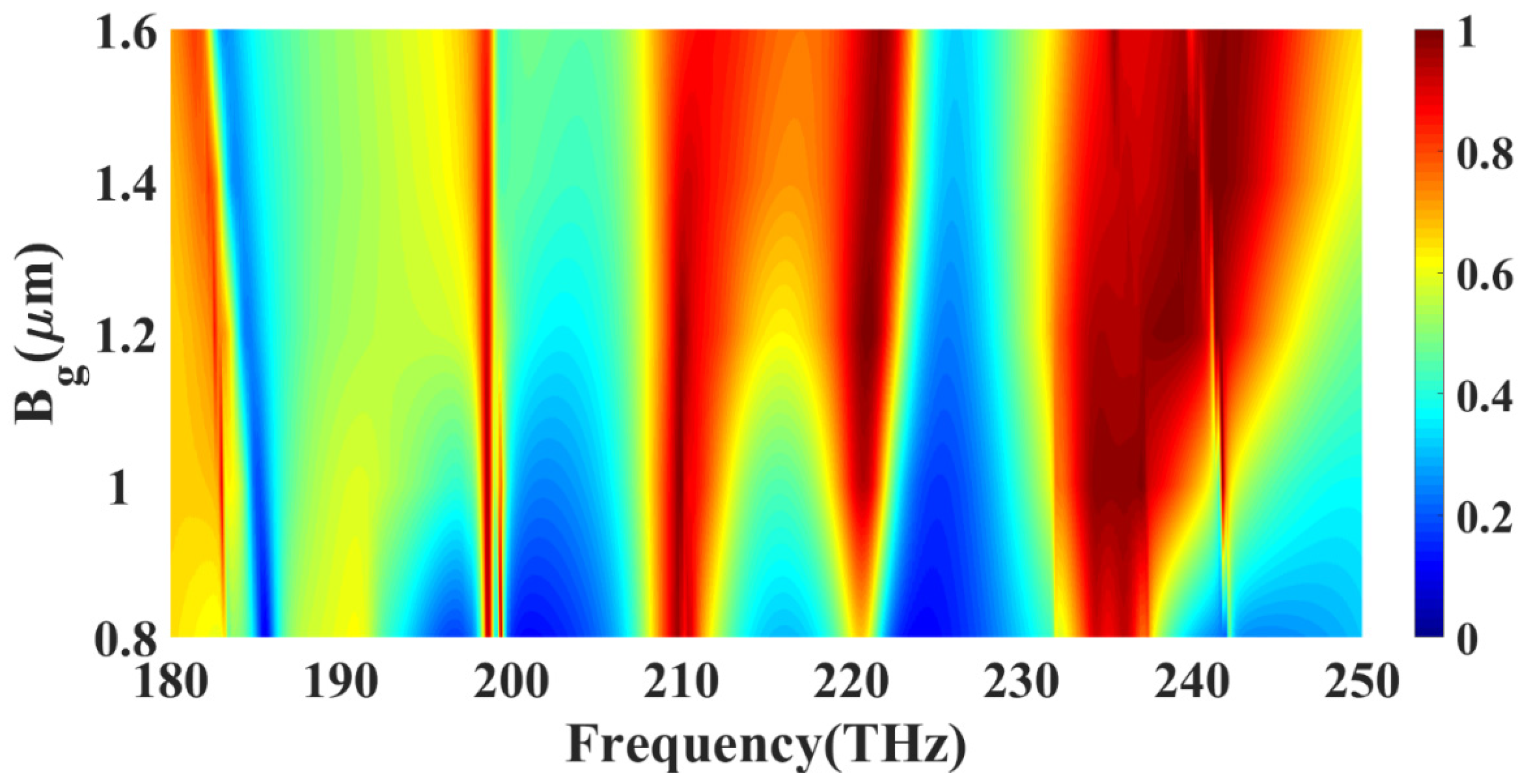

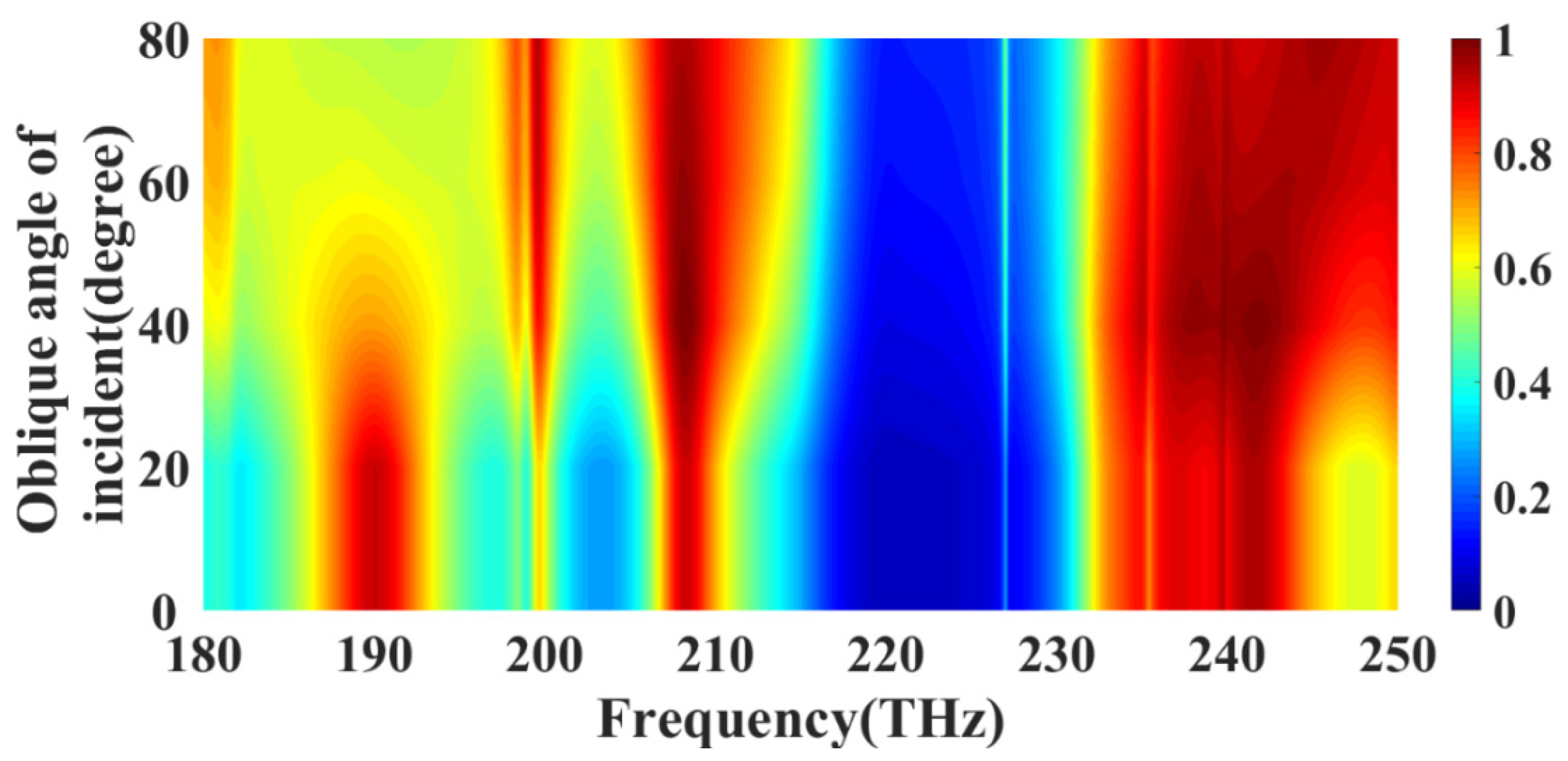

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ferrari, A.C.; Bonaccorso, F.; Fal’ko, V.; Novoselov, K.S.; Roche, S.; Bøggild, P.; Borini, S.; Koppens, F.H.L.; Palermo, V.; Pugno, N.; et al. Science and Technology Roadmap for Graphene, Related Two-Dimensional Crystals, and Hybrid Systems. Nanoscale 2015, 7, 4598–4810. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Novoselov, K.S.; Fal’Ko, V.I.; Colombo, L.; Gellert, P.R.; Schwab, M.G.; Kim, K. A Roadmap for Graphene. Nature 2012, 490, 192–200. [Google Scholar] [CrossRef] [PubMed]

- Klinovaja, J.; Loss, D. Spintronics in MoS2 Monolayer Quantum Wires. Phys. Rev. B-Condens. Matter Mater. Phys. 2013, 88, 075404. [Google Scholar] [CrossRef] [Green Version]

- Xu, Y.; Gan, Z.; Zhang, S.C. Enhanced Thermoelectric Performance and Anomalous Seebeck Effects in Topological Insulators. Phys. Rev. Lett. 2014, 112, 226801. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Mannix, A.J.; Zhou, X.F.; Kiraly, B.; Wood, J.D.; Alducin, D.; Myers, B.D.; Liu, X.; Fisher, B.L.; Santiago, U.; Guest, J.R.; et al. Synthesis of Borophenes: Anisotropic, Two-Dimensional Boron Polymorphs. Science 2015, 350, 1513–1516. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Geim, A.K.; Novoselov, K.S. The Rise of Graphene. In Nanoscience and Technology: A Collection of Reviews from Nature Journals; World Scientific Publishing Co.: Singapore, 2009; pp. 11–19. ISBN 9789814287005. [Google Scholar]

- Arora, R.B.; Madan, B.R.; Pathak, R.K. Antiarrhythmics. VIII. Chloroquine, Amodiaquine, Procaine Amide and Quinidine in Experimental Auricular Arrhythmias Simulating Clinical Disorders. Indian J. Med. Res. 1956, 44, 453–462. [Google Scholar] [CrossRef] [Green Version]

- Eigler, S. A New Parameter Based on Graphene for Characterizing Transparent, Conductive Materials. Carbon N. Y. 2009, 47, 2936–2939. [Google Scholar] [CrossRef]

- Ponraj, J.S.; Xu, Z.Q.; Dhanabalan, S.C.; Mu, H.; Wang, Y.; Yuan, J.; Li, P.; Thakur, S.; Ashrafi, M.; McCoubrey, K.; et al. Photonics and Optoelectronics of Two-Dimensional Materials beyond Graphene. Nanotechnology 2016, 27, 462001. [Google Scholar] [CrossRef]

- Rakhshani, M.R. Wide-Angle Perfect Absorber Using a 3D Nanorod Metasurface as a Plasmonic Sensor for Detecting Cancerous Cells and Its Tuning with a Graphene Layer. Photonics Nanostruct. Fundam. Appl. 2021, 43, 100883. [Google Scholar] [CrossRef]

- Wang, J. Two-Dimensional Semiconductors for Ultrafast Photonic Applications. In Optical Components and Materials XII; Jiang, S., Digonnet, M.J.F., Eds.; SPIE: Bellingham, WA, USA, 2015; Volume 9359, p. 935902. [Google Scholar]

- Luo, A.-P.; Liu, M.; Wang, X.-D.; Ning, Q.-Y.; Xu, W.-C.; Luo, Z.-C. Few-Layer MoS2-Deposited Microfiber as Highly Nonlinear Photonic Device for Pulse Shaping in a Fiber Laser [Invited]. Photonics Res. 2015, 3, A69. [Google Scholar] [CrossRef]

- Li, L.; Yu, Y.; Ye, G.J.; Ge, Q.; Ou, X.; Wu, H.; Feng, D.; Chen, X.H.; Zhang, Y. Black Phosphorus Field-Effect Transistors. Nat. Nanotechnol. 2014, 9, 372–377. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Mak, K.F.; Lee, C.; Hone, J.; Shan, J.; Heinz, T.F. Atomically Thin MoS2: A New Direct-Gap Semiconductor. Phys. Rev. Lett. 2010, 105, 136805. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lei, Z.; Guo, B. 2D Material-Based Optical Biosensor: Status and Prospect. Adv. Sci. 2022, 9, 2102924. [Google Scholar] [CrossRef] [PubMed]

- Xie, Z.; Meng, X.; Li, X.; Liang, W.; Huang, W.; Chen, K.; Chen, J.; Xing, C.; Qiu, M.; Zhang, B.; et al. Two-Dimensional Borophene: Properties, Fabrication, and Promising Applications. Research 2020, 2020, 2624617. [Google Scholar] [CrossRef]

- Meng, F.; Chen, X.; Sun, S.; He, J. Electronic and Magnetic Properties of Pristine and Hydrogenated Borophene Nanoribbons. Phys. E Low-Dimens. Syst. Nanostructures 2017, 91, 106–112. [Google Scholar] [CrossRef] [Green Version]

- Moradiani, F.; Farmani, A.; Mozaffari, M.H.; Seifouri, M.; Abedi, K. Systematic Engineering of a Nanostructure Plasmonic Sensing Platform for Ultrasensitive Biomaterial Detection. Opt. Commun. 2020, 474, 126178. [Google Scholar] [CrossRef]

- Baetens, R.; Jelle, B.P.; Gustavsen, A. Properties, Requirements and Possibilities of Smart Windows for Dynamic Daylight and Solar Energy Control in Buildings: A State-of-the-Art Review. Sol. Energy Mater. Sol. Cells 2010, 94, 87–105. [Google Scholar] [CrossRef] [Green Version]

- Zhang, L.; Zhou, Y.; Guo, L.; Zhao, W.; Barnes, A.; Zhang, H.T.; Eaton, C.; Zheng, Y.; Brahlek, M.; Haneef, H.F.; et al. Correlated Metals as Transparent Conductors. Nat. Mater. 2016, 15, 204–210. [Google Scholar] [CrossRef]

- Rakhshani, M.R.; Rashki, M. Metamaterial Perfect Absorber Using Elliptical Nanoparticles in Multilayer Metasurface Structure with Polarization Independence. Opt. Express 2022, 30, 10387. [Google Scholar] [CrossRef]

- Rakhshani, M.R. Tunable and Sensitive Refractive Index Sensors by Plasmonic Absorbers with Circular Arrays of Nanorods and Nanotubes for Detecting Cancerous Cells. Plasmonics 2020, 15, 2071–2080. [Google Scholar] [CrossRef]

- Amoosoltani, N.; Mehrabi, K.; Zarifkar, A.; Farmani, A.; Yasrebi, N. Double-Ring Resonator Plasmonic Refractive Index Sensor Utilizing Dual-Band Unidirectional Reflectionless Propagation Effect. Plasmonics 2021, 16, 1277–1285. [Google Scholar] [CrossRef]

- Hamouleh-Alipour, A.; Mir, A.; Farmani, A. Design and Analytical Evaluation of a High Resistance Sensitivity Bolometer Sensor Based on Plasmonic Metasurface Structure. IEEE J. Sel. Top. Quantum Electron. 2022, 28, 1–7. [Google Scholar] [CrossRef]

- Rakhshani, M.R. Three-Dimensional Polarization-Insensitive Perfect Absorber Using Nanorods Array for Sensing and Imaging. IEEE Sens. J. 2020, 20, 14166–14172. [Google Scholar] [CrossRef]

- Rakhshani, M.R. Refractive Index Sensor Based on Dual Side-Coupled Rectangular Resonators and Nanorods Array for Medical Applications. Opt. Quantum Electron. 2021, 53, 232. [Google Scholar] [CrossRef]

- Rakhshani, M.R. Narrowband Plasmonic Absorber Using Gold Nanoparticle Arrays for Refractive Index Sensing. IEEE Sens. J. 2022, 22, 4043–4050. [Google Scholar] [CrossRef]

- Rashid, K.S.; Tathfif, I.; Yaseer, A.A.; Hassan, M.F.; Sagor, R.H. Cog-Shaped Refractive Index Sensor Embedded with Gold Nanorods for Temperature Sensing of Multiple Analytes. Opt. Express 2021, 29, 37541. [Google Scholar] [CrossRef]

- Rakhshani, M.R.; Mansouri-Birjandi, M.A. High Sensitivity Plasmonic Refractive Index Sensing and Its Application for Human Blood Group Identification. Sens. Actuators B Chem. 2017, 249, 168–176. [Google Scholar] [CrossRef]

- Rakhshani, M.R.; Mansouri-Birjandi, M.A. A High-Sensitivity Sensor Based on Three-Dimensional Metal–Insulator–Metal Racetrack Resonator and Application for Hemoglobin Detection. Photonics Nanostruct.-Fundam. Appl. 2018, 32, 28–34. [Google Scholar] [CrossRef]

- Hassan, M.F.; Tathfif, I.; Radoan, M.; Sagor, R.H. A Concentric Double-Ring Resonator Based Plasmonic Refractive Index Sensor with Glucose Sensing Capability. In Proceedings of the IEEE Region 10 Annual International Conference, Osaka, Japan, 16–19 November 2020; Volume 2020, pp. 91–96. [Google Scholar]

- Rashid, K.S.; Hassan, M.F.; Yaseer, A.A.; Tathfif, I.; Sagor, R.H. Gas-Sensing and Label-Free Detection of Biomaterials Employing Multiple Rings Structured Plasmonic Nanosensor. Sens. Bio-Sens. Res. 2021, 33, 100440. [Google Scholar] [CrossRef]

- Giovannetti, G.; Khomyakov, P.A.; Brocks, G.; Karpan, V.M.; Van Den Brink, J.; Kelly, P.J. Doping Graphene with Metal Contacts. Phys. Rev. Lett. 2008, 101, 026803. [Google Scholar] [CrossRef]

- Feng, B.; Sugino, O.; Liu, R.Y.; Zhang, J.; Yukawa, R.; Kawamura, M.; Iimori, T.; Kim, H.; Hasegawa, Y.; Li, H.; et al. Dirac Fermions in Borophene. Phys. Rev. Lett. 2017, 118, 096401. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Massote, D.V.P.; Liang, L.; Kharche, N.; Meunier, V. Electronic, Vibrational, Raman, and Scanning Tunneling Microscopy Signatures of Two-Dimensional Boron Nanomaterials. Phys. Rev. B 2016, 94, 195416. [Google Scholar] [CrossRef] [Green Version]

- Tsafack, T.; Yakobson, B.I. Thermomechanical Analysis of Two-Dimensional Boron Monolayers. Phys. Rev. B 2016, 93, 165434. [Google Scholar] [CrossRef] [Green Version]

- Sun, H.; Li, Q.; Wan, X.G. First-Principles Study of Thermal Properties of Borophene. Phys. Chem. Chem. Phys. 2016, 18, 14927–14932. [Google Scholar] [CrossRef]

- Peng, B.; Zhang, H.; Shao, H.; Xu, Y.; Zhang, R.; Zhu, H. The Electronic, Optical, and Thermodynamic Properties of Borophene from First-Principles Calculations. J. Mater. Chem. C 2016, 4, 3592–3598. [Google Scholar] [CrossRef] [Green Version]

- Kondo, T. Recent Progress in Boron Nanomaterials. Sci. Technol. Adv. Mater. 2017, 18, 780–804. [Google Scholar] [CrossRef] [Green Version]

- Li, D.; Gao, J.; Cheng, P.; He, J.; Yin, Y.; Hu, Y.; Chen, L.; Cheng, Y.; Zhao, J. 2D Boron Sheets: Structure, Growth, and Electronic and Thermal Transport Properties. Adv. Funct. Mater. 2020, 30, 1904349. [Google Scholar] [CrossRef]

- Bezugly, V.; Kunstmann, J.; Grundkötter-Stock, B.; Frauenheim, T.; Niehaus, T.; Cuniberti, G. Highly Conductive Boron Nanotubes: Transport Properties, Work Functions, and Structural Stabilities. ACS Nano 2011, 5, 4997–5005. [Google Scholar] [CrossRef]

- Zhang, Z.; Penev, E.S.; Yakobson, B.I. Two-Dimensional Boron: Structures, Properties and Applications. Chem. Soc. Rev. 2017, 46, 6746–6763. [Google Scholar] [CrossRef]

- Johnson, P.B.; Christy, R.W. Optical Constants of the Noble Metals. Phys. Rev. B 1972, 6, 4370–4379. [Google Scholar] [CrossRef]

- Tathfif, I.; Yaseer, A.A.; Rashid, K.S.; Sagor, R.H. Metal-Insulator-Metal Waveguide-Based Optical Pressure Sensor Embedded with Arrays of Silver Nanorods. Opt. Express 2021, 29, 32365. [Google Scholar] [CrossRef] [PubMed]

- Tathfif, I.; Rashid, K.S.; Yaseer, A.A.; Sagor, R.H. Alternative Material Titanium Nitride Based Refractive Index Sensor Embedded with Defects: An Emerging Solution in Sensing Arena. Results Phys. 2021, 29, 104795. [Google Scholar] [CrossRef]

- Xu, Y.; Wu, L.; Ang, L.K. Surface Exciton Polaritons: A Promising Mechanism for Refractive-Index Sensing. Phys. Rev. Appl. 2019, 12, 024029. [Google Scholar] [CrossRef] [Green Version]

- Shih, W.-C.; Santos, G.M.; Zhao, F.; Zenasni, O.; Arnob, M.M.P. Simultaneous Chemical and Refractive Index Sensing in the 1–2.5 Μm Near-Infrared Wavelength Range on Nanoporous Gold Disks. Nano Lett. 2016, 16, 4641–4647. [Google Scholar] [CrossRef]

- Pinapati, P.; Cherukulappurath, S. Hybrid Dielectric-Plasmonic Nanocomposite Arrays for Bulk and Local Refractive Index Sensing. Plasmonics 2020, 15, 441–447. [Google Scholar] [CrossRef]

- Stakenborg, T.; Lagae, L. Gold Nanoring as a Sensitive Plasmonic Biosensor for On-Chip DNA Detection. Appl. Phys. Lett. 2012, 100, 173114. [Google Scholar] [CrossRef] [Green Version]

- Lodewijks, K.; Van Roy, W.; Borghs, G.; Lagae, L.; Van Dorpe, P. Boosting the Figure-Of-Merit of LSPR-Based Refractive Index Sensing by Phase-Sensitive Measurements. Nano Lett. 2012, 12, 1655–1659. [Google Scholar] [CrossRef] [Green Version]

- Chen, H.; Kou, X.; Yang, Z.; Ni, W.; Wang, J. Shape- and Size-Dependent Refractive Index Sensitivity of Gold Nanoparticles. Langmuir 2008, 24, 5233–5237. [Google Scholar] [CrossRef]

- Pryce, I.M.; Kelaita, Y.A.; Aydin, K.; Atwater, H.A. Compliant Metamaterials for Resonantly Enhanced Infrared Absorption Spectroscopy and Refractive Index Sensing. ACS Nano 2011, 5, 8167–8174. [Google Scholar] [CrossRef]

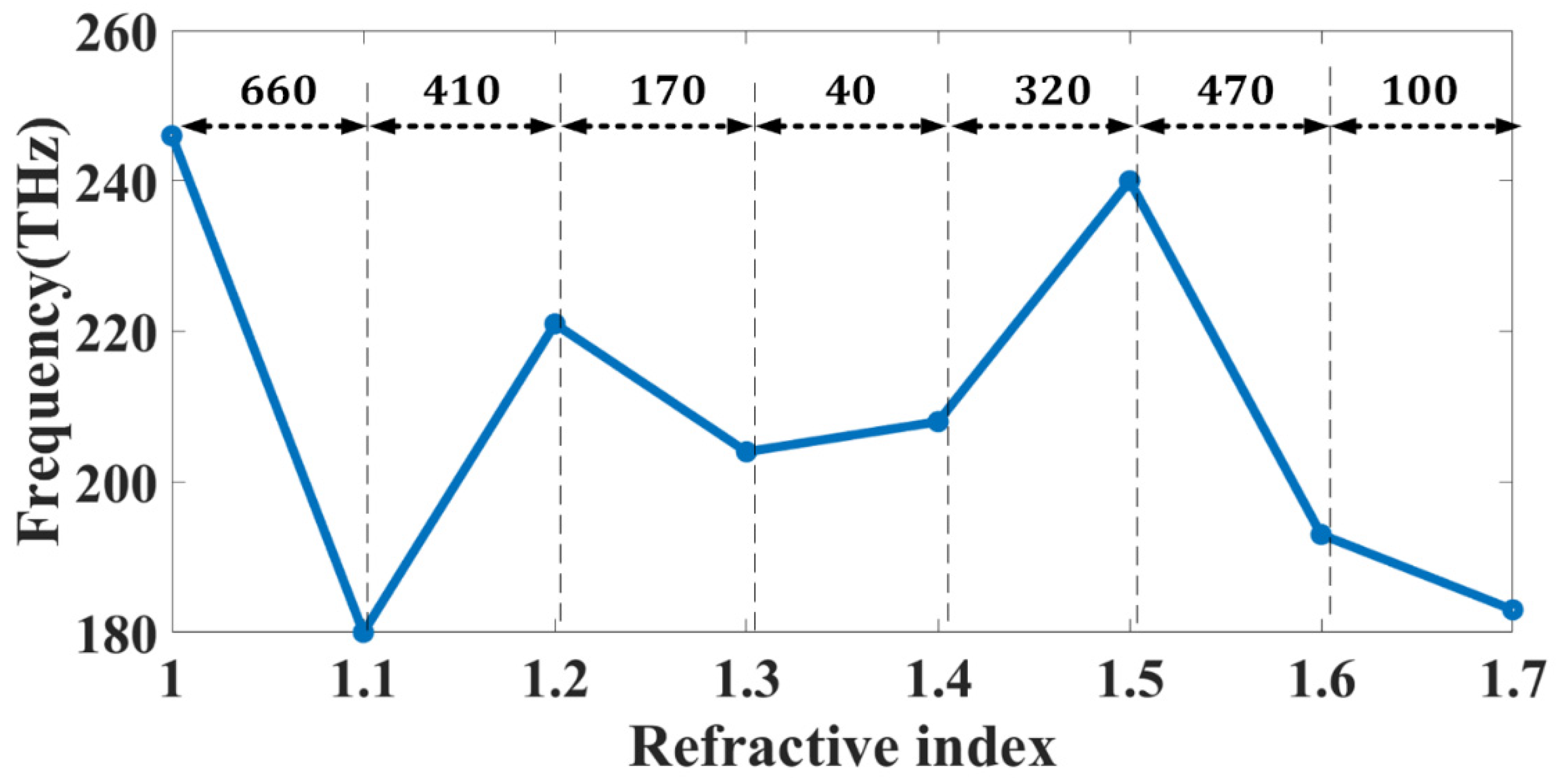

| Refractive Index | Peak Resonating Frequency (in THz) | Equivalent Wavelength (in µm) | Sensitivity (THz/RIU) | Sensitivity (nm/RIU) |

|---|---|---|---|---|

| 1 | 246 | 1.2195 | 660 | 4471 |

| 1.1 | 180 | 1.6666 | 410 | 3092 |

| 1.2 | 221 | 1.3574 | 170 | 1131 |

| 1.3 | 204 | 1.4705 | 40 | 282 |

| 1.4 | 208 | 1.4423 | 320 | 1923 |

| 1.5 | 240 | 1.2500 | 470 | 3044 |

| 1.6 | 193 | 1.5544 | 100 | 849 |

| 1.7 | 183 | 1.6393 | - | - |

| Structure Type | FOM (RIU−1) | Wavelength (nm) | Sensitivity (nm/RIU) | Reference |

|---|---|---|---|---|

| Discs | - | 1000~2500 | 525.7 | [47] |

| Nanocomposite arrays | 10 | 500~900 | 300 | [48] |

| Nanorings | 3.1 | 798 | 350 | [49] |

| Nanorings | 16.5 | 980 | 380 | [50] |

| Nanoparticles | 0.6 | 527 | 44 | [51] |

| Split-ring resonators | 8.5 | 1420 | 1192 | [52] |

| Nanorods and nanotube arrays | 19.5 | 500~2500 | 1055 | [22] |

| Rectangular Array | 444 | 1200~1600 (180–250 THz) | 4471 | Our Work |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alharbi, A.G.; Sorathiya, V.; Lavadiya, S. A Multi-Layered Borophene-Silica-Silver Based Refractive Index Sensor for Biosensing Applications Operated at the Infrared Frequency Spectrum. Photonics 2022, 9, 279. https://doi.org/10.3390/photonics9050279

Alharbi AG, Sorathiya V, Lavadiya S. A Multi-Layered Borophene-Silica-Silver Based Refractive Index Sensor for Biosensing Applications Operated at the Infrared Frequency Spectrum. Photonics. 2022; 9(5):279. https://doi.org/10.3390/photonics9050279

Chicago/Turabian StyleAlharbi, Abdullah G., Vishal Sorathiya, and Sunil Lavadiya. 2022. "A Multi-Layered Borophene-Silica-Silver Based Refractive Index Sensor for Biosensing Applications Operated at the Infrared Frequency Spectrum" Photonics 9, no. 5: 279. https://doi.org/10.3390/photonics9050279

APA StyleAlharbi, A. G., Sorathiya, V., & Lavadiya, S. (2022). A Multi-Layered Borophene-Silica-Silver Based Refractive Index Sensor for Biosensing Applications Operated at the Infrared Frequency Spectrum. Photonics, 9(5), 279. https://doi.org/10.3390/photonics9050279