Recent Applications of Antireflection Coatings in Solar Cells

Abstract

1. Introduction

2. The Design Principle of Antireflection Coatings

2.1. Single Layer Antireflection Coating (SLARC)

2.2. Double Layer Antireflection Coating (DLARC)

2.3. Triple Layer Antireflection Coating (TLARC)

2.4. Gradient Refractive Index (GRIN) Coating

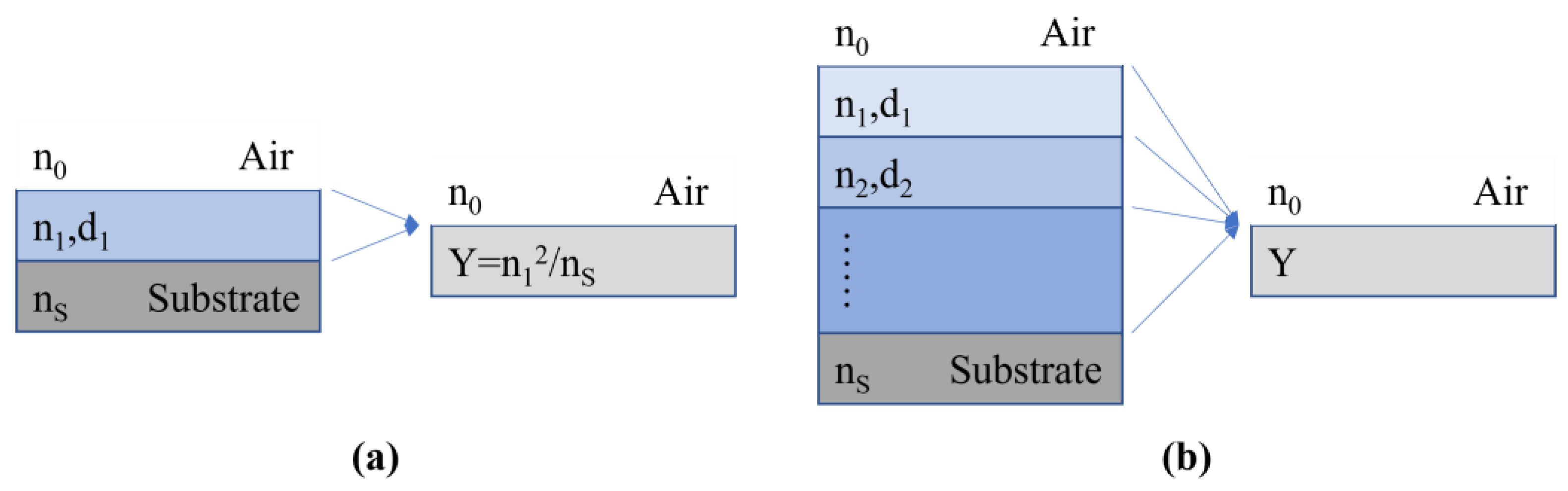

2.5. Equivalent Layer of the Symmetrical Film System

3. The Latest Applications of ARCs in the First, Second, and Third Generation of Solar Cells

3.1. The First Generation of Solar Cells

3.2. The Second Generation of Solar Cells

3.3. The Third Generation of Solar Cells

4. Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Green, M.A.; Dunlop, E.D.; Hohl-Ebinger, J.; Yoshita, M.; Kopidakis, N.; Hao, X. Solar Cell Efficiency Tables (Version 59). Prog Photovolt. Res. Appl. 2022, 30, 3–12. [Google Scholar] [CrossRef]

- Kumar, K.R.T.; Ramakrishna, M.; Sukumar, G.D. A Review on PV Cells and Nanocomposite-Coated PV Systems. Int. J. Energy Res. 2018, 42, 2305–2319. [Google Scholar] [CrossRef]

- Kumar, S.G.; Shetty, A.P.; Prashanth, C.R. Solar Cell Material Based on the Optimum Values of Key Parameters Using PC1D. In Proceedings of the 2021 2nd International Conference for Emerging Technology (INCET), Belagavi, India, 21 May 2021; pp. 1–6. [Google Scholar]

- Meng, L.; Shi, L.; Ge, Y.; Tang, J.; Chen, Y.; Zhong, H. Photon Management of Combining Nanostructural Antireflection and Perovskite Down-Shifting Composite Films for Improving the Efficiency of Silicon Solar Cells. Sol. Energy Mater. Sol. Cells 2021, 220, 110856. [Google Scholar] [CrossRef]

- Shanmugam, N.; Pugazhendhi, R.; Elavarasan, R.; Kasiviswanathan, P.; Das, N. Anti-Reflective Coating Materials: A Holistic Review from PV Perspective. Energies 2020, 13, 2631. [Google Scholar] [CrossRef]

- Sarkin, A.; Ekren, N.; Saglam, S. A Review of Anti-Reflection and Self-Cleaning Coatings on Photovoltaic Panels. Sol. Energy 2020, 199, 63–73. [Google Scholar] [CrossRef]

- Tang, J.F.; Gu, P.F.; Liu, X. Modern Optical Thin Film Technology; Zhejiang University Press: Hangzhou, China, 2006; ISBN 978-7-308-04977-1. [Google Scholar]

- Chattopadhyay, S.; Huang, Y.F.; Jen, Y.J.; Ganguly, A.; Chen, K.H.; Chen, L.C. Anti-Reflecting and Photonic Nanostructures. Mater. Sci. Eng. R Rep. 2010, 69, 1–35. [Google Scholar] [CrossRef]

- Moys, B. Theory of Double-Layer Antireflection Coatings. Thin Solid Film. 1974, 21, 145–157. [Google Scholar] [CrossRef]

- Cox, J.; Hass, G.; Thelen, A. Triple-Layer Antireflection Coatings on Glass for Visible and Near Infrared. J. Opt. Soc. Am. 1962, 52, 965–969. [Google Scholar] [CrossRef]

- Li, Z.Y. Study on Gradient Refractive Index Reduced Reflection Photovoltaic Glass. Ph.D. Thesis, Ocean University of China, Qingdao, China, 2014. [Google Scholar]

- Epstein, L.I. The Design of Optical Filters. J. Opt. Soc. Am. JOSA 1952, 42, 806–810. [Google Scholar] [CrossRef]

- Aiken, D. High Performance Anti-Reflection Coatings for Broadband Multi-Junction Solar Cells. Sol. Energy Mater. Sol. Cells 2000, 64, 393–404. [Google Scholar] [CrossRef]

- Zhao, J.; Green, M.A. Optimized Antireflection Coatings for High-Efficiency Silicon Solar Cells. IEEE Trans. Electron Devices 1991, 38, 1925–1934. [Google Scholar] [CrossRef]

- Zhu, M.F.; Xiong, S.Z. Solar Cell Basics and Applications, 2nd ed.; Science Press: Beijing, China, 2014; ISBN 978-7-03-039789-8. [Google Scholar]

- Zhao, J.; Wang, A.; Green, M. Double-Layer Antireflection Coating for High-Efficiency Passivated Emitter Silicon Solar-Cells. IEEE Trans. Electron Devices 1994, 41, 1592–1594. [Google Scholar] [CrossRef]

- Vila, M.; Román, E.; Prieto, C. Electrical Conduction Mechanism in Silicon Nitride and Oxy-Nitride-Sputtered Thin Films. J. Appl. Phys. 2005, 97, 113710. [Google Scholar] [CrossRef]

- Aberle, A.G. Overview on SiN Surface Passivation of Crystalline Silicon Solar Cells. Sol. Energy Mater. Sol. Cells 2001, 65, 239–248. [Google Scholar] [CrossRef]

- Li, M.; Zeng, L.; Chen, Y.; Zhuang, L.; Wang, X.; Shen, H. Realization of Colored Multicrystalline Silicon Solar Cells with SiO2/SiNx:H Double Layer Antireflection Coatings. Int. J. Photoenergy 2013, 2013, 352473. [Google Scholar] [CrossRef]

- Li, M.; Shen, H.; Zhuang, L.; Chen, D.; Liang, X. SiO2 Antireflection Coatings Fabricated by Electron-Beam Evaporation for Black Monocrystalline Silicon Solar Cells. Int. J. Photoenergy 2014, 2014, 670438. [Google Scholar] [CrossRef]

- Aroutiounian, V.M.; Martirosyan, K.; Soukiassian, P. Low Reflectance of Diamond-like Carbon/Porous Silicon Double Layer Antireflection Coating for Silicon Solar Cells. J. Phys. D Appl. Phys. 2004, 37, L25–L28. [Google Scholar] [CrossRef]

- Bilyalov, R.R.; Lüdemann, R.; Wettling, W.; Stalmans, L.; Poortmans, J.; Nijs, J.; Schirone, L.; Sotgiu, G.; Strehlke, S.; Lévy-Clément, C. Multicrystalline Silicon Solar Cells with Porous Silicon Emitter. Sol. Energy Mater. Sol. Cells 2000, 60, 391–420. [Google Scholar] [CrossRef]

- Strehlke, S.; Bastide, S.; Guillet, J.; Levy-Clement, C. Design of Porous Silicon Antireflection Coatings for Silicon Solar Cells. Mater. Sci. Eng. 2000, B69-70, 81–86. [Google Scholar] [CrossRef]

- Pislaru-Danescu, L.; Chitanu, E.; El-Leathey, L.; Marinescu, V.; Marin, D.; Sbarcea, B. Synthesis and Characterization of Antireflective ZnO Nanoparticles Coatings Used for Energy Improving Efficiency of Silicone Solar Cells. Electron. Mater. Lett. 2018, 14, 376–386. [Google Scholar] [CrossRef]

- Chung, R.J.; Lin, Z.C.; Lin, C.A.; Lai, K.Y. Study of an Antireflection Surface Constructed of Controlled ZnO Nanostructures. Thin Solid Film. 2014, 570, 504–509. [Google Scholar] [CrossRef]

- Richards, B. Single-Material TiO2 Double-Layer Antireflection Coatings. Sol. Energy Mater. Sol. Cells 2003, 79, 369–390. [Google Scholar] [CrossRef]

- Zhao, J.; WANG, A.; Altermatt, P.; Green, M. 24 Percent Efficient Silicon Solar-Cells with Double-Layer Antireflection Coating and Reduced Resistance Loss. Appl. Phys. Lett. 1995, 66, 3636–3638. [Google Scholar] [CrossRef]

- Parm, I.; Kim, K.; Lim, D.; Lee, J.; Heo, J.; Kim, J.; Kim, D.; Lee, S.; Yi, J. High-Density Inductively Coupled Plasma Chemical Vapor Deposition of Silicon Nitride for Solar Cell Application. Sol. Energy Mater. Sol. Cells 2002, 74, 97–105. [Google Scholar] [CrossRef]

- Zahid, M.; Khokhar, M.; Kim, Y.; Yi, J. Utilization of CaF2/ITO Double-Layer Anti-Reflective Coating for Increasing the Efficiency in Rear Emitter SHJ Solar Cells. Cryst. Res. Technol. 2022, 57, 2100233. [Google Scholar] [CrossRef]

- Haider, J.; Rahman, M.; Corcoran, B.; Hashmi, M.S.J. Simulation of Thermal Stress in Magnetron Sputtered Thin Coating by Finite Element Analysis. J. Mater. Process. Technol. 2005, 168, 36–41. [Google Scholar] [CrossRef]

- Su, H.; Huang, J.; Yu, Z. Effects of High-Low Temperature Test on Laser Films in Normal Atmosphere. Chin. J. Lasers 2011, 38, 157–162. [Google Scholar]

- Tian, X. Study on the Thermodynamic Matching Problem between Substrate and Thin Film in Optical Thin Film Technology. Ph.D. Thesis, University of Chinese Academy of Sciences (Institute of Optoelectronic Technology, Chinese Academy of Sciences), Beijing, China, 2020. [Google Scholar]

- Hou, G.; Garcia, I.; Rey-Stolle, I. High-Low Refractive Index Stacks for Broadband Antireflection Coatings for Multijunction Solar Cells. Sol. Energy 2021, 217, 29–39. [Google Scholar] [CrossRef]

- Hou, B.; Kim, B.; Lee, H.K.H.; Cho, Y.; Giraud, P.; Liu, M.; Zhang, J.; Davies, M.L.; Durrant, J.R.; Tsoi, W.C.; et al. Multiphoton Absorption Stimulated Metal Chalcogenide Quantum Dot Solar Cells under Ambient and Concentrated Irradiance. Adv. Funct. Mater. 2020, 30, 2004563. [Google Scholar] [CrossRef]

- Santhosh, S.; Rajasekar, R.; Gobinath, V.; Moganapriya, C.; Kumar, S.; Sri, A. Influence of Electrosprayed MoSe2 Antireflective Surface Coatings on Performance of Multicrystalline Silicon Solar Cell. Silicon 2021, 14, 6039–6051. [Google Scholar] [CrossRef]

- Chinnasamy, M.; Rathanasamy, R.; Sivaraj, S.; Kaliyannan, G.; Anbupalani, M.; Jaganathan, S. Influence of ZnSe Surface Coatings for Enhancing the Performance of Multicrystalline Silicon Solar Cells. J. Electron. Mater. 2022, 51, 2833–2842. [Google Scholar] [CrossRef]

- Shah, D.K.; Devendra, K.C.; Umar, A.; Algadi, H.; Akhtar, M.S.; Yang, O.-B. Influence of Efficient Thickness of Antireflection Coating Layer of HfO2 for Crystalline Silicon Solar Cell. Inorganics 2022, 10, 171. [Google Scholar] [CrossRef]

- Sagar, R.; Rao, A. Nanoscale TiO2 and Ta2O5 as Efficient Antireflection Coatings on Commercial Monocrystalline Silicon Solar Cell. J. Alloy. Compd. 2021, 862, 158464. [Google Scholar] [CrossRef]

- Swathi, R.; Shanthi, J.; Aishwarya, S.; Anoop, K. Photon Management by Scratch-Resistant Antireflection Coating for the Efficiency Enhancement of Silicon Solar Cell. Int. J. Energy Res. 2022, 46, 15485–15498. [Google Scholar] [CrossRef]

- Malik, P.; Gupta, H.; Ghosh, S.; Srivastava, P. Study of Optical Properties of Single and Double Layered Amorphous Silicon Nitride Films for Photovoltaics Applications. Silicon 2022, 2022, 1–9. [Google Scholar] [CrossRef]

- Nussupov, K.K.; Beisenkhanov, N.B.; Keiinbay, S.; Sultanov, A.T. Silicon Carbide Synthesized by RF Magnetron Sputtering in the Composition of a Double Layer Antireflection Coating SiC/MgF2. Opt. Mater. 2022, 128, 112370. [Google Scholar] [CrossRef]

- Rathanasamy, R.; Kaliyannan, G.V.; Sivaraj, S.; Saminathan, A.; Krishnan, B.; Palanichamy, D.; Uddin, M.E. Influence of Silicon Dioxide-Titanium Dioxide Antireflective Electrosprayed Coatings on Multicrystalline Silicon Cells. Adv. Mater. Sci. Eng. 2022, 2022, 9444524. [Google Scholar] [CrossRef]

- Alam, K.; Khan, K.I.; Ullah, A.; Ullah, A.; Ali, S.; Ullah, S.; Ali, A.; Hussain, S. Fabrication of Superhydrophillic and Graded Index Antireflective Double Layer Coating for Solar Photovoltaics Module Using Aerosol Impact Deposition Assembly. Thin Solid Film. 2021, 721, 138518. [Google Scholar] [CrossRef]

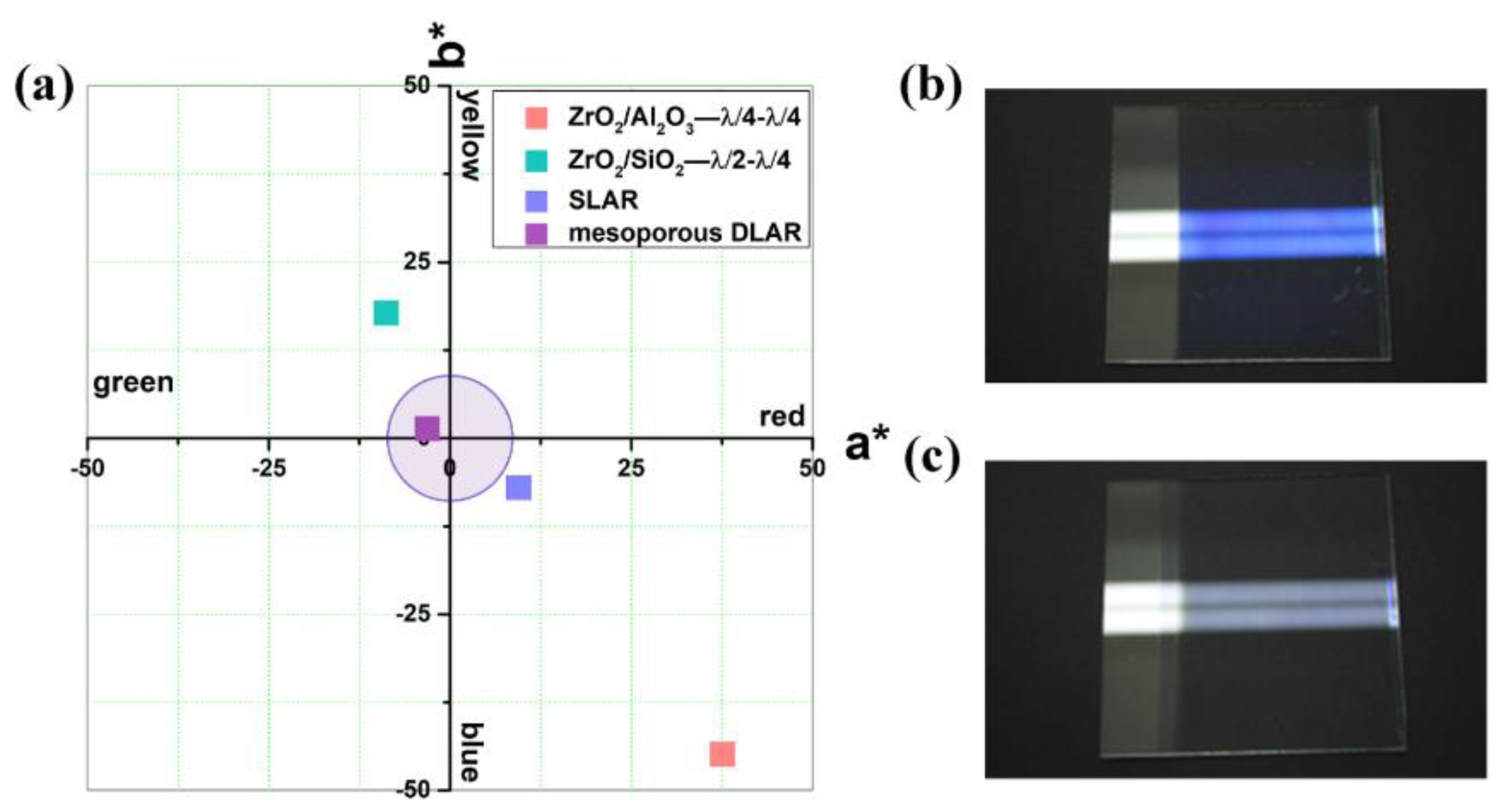

- Pfeiffer, K.; Dewald, W.; Szeghalmi, A. Antireflection Coating with Consistent Near-Neutral Color on Complex-Shaped Substrates Prepared by ALD. Opt. Lett. 2019, 44, 3270. [Google Scholar] [CrossRef]

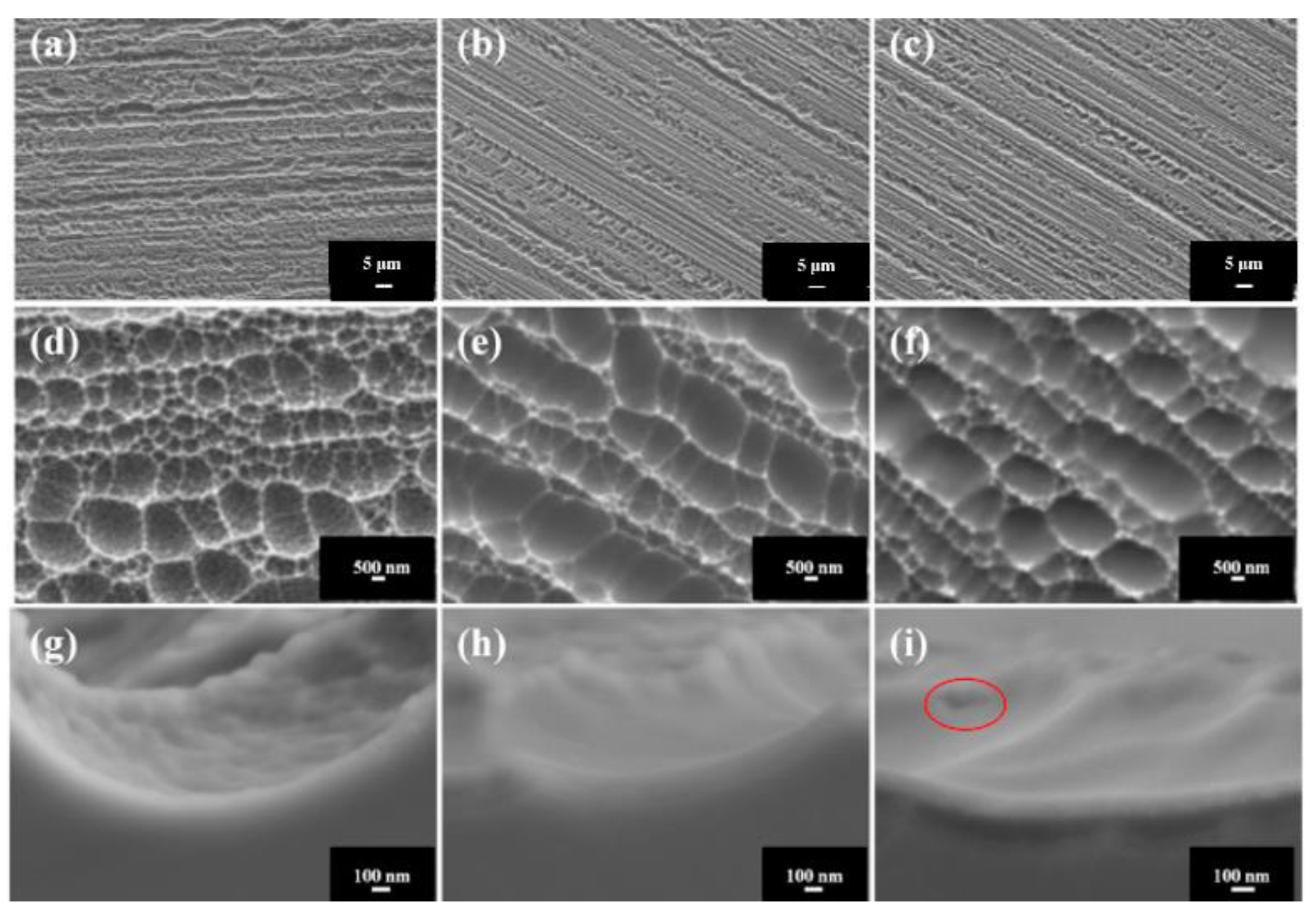

- Xu, Y.; Zhang, J.; Ai, L.; Lou, X.; Lin, S.; Lu, Y.; Fan, B.; Jin, J.; Song, W. Fabrication of Mesoporous Double-Layer Antireflection Coatings with near-Neutral Color and Application in Crystalline Silicon Solar Modules. Sol. Energy 2020, 201, 149–156. [Google Scholar] [CrossRef]

- Xiao, X.; Zhu, H.; Liu, Z.; Tu, J. Multilayer Antireflection Coatings Design for SiO2-Passivated Silicon Solar Cells. Materialwiss. Werkstofftech. 2022, 53, 80–88. [Google Scholar] [CrossRef]

- Sarker, M.S.; Khatun, M.F.; Al Ahmed, S.R.; Hossain, J. Optimization of Multilayer Antireflection Coatings for Improving Performance of Silicon Solar Cells. In Proceedings of the 2019 International Conference on Computer, Communication, Chemical, Materials and Electronic Engineering (IC4ME2), Rajshahi, Bangladesh, 11–12 July 2019; pp. 1–4. [Google Scholar]

- Liao, K.; Chen, J.; Xia, L.; Zhong, S.; Luo, X. Study about the Effect of Antireflection Coating Stacks (TiO2-SiO2/SiO2/SiNx) on the Performances of Multicrystalline Silicon Solar Cells under the Encapsulation Condition. Opt. Mater. 2020, 109, 110318. [Google Scholar] [CrossRef]

- Bouhafs, D.; Moussi, A.; Chikouche, A.; Ruiz, J.M. Design and Simulation of Antireflection Coating Systems for Optoelectronic Devices: Application to Silicon Solar Cells. Sol. Energy Mater. Sol. Cells 1998, 52, 79–93. [Google Scholar] [CrossRef]

- Zhang, S.; Yao, Y.; Hu, D.; Lian, W.; Qian, H.; Jie, J.; Wei, Q.; Ni, Z.; Zhang, X.; Xie, L. Application of Silicon Oxide on High Efficiency Monocrystalline Silicon PERC Solar Cells. Energies 2019, 12, 1168. [Google Scholar] [CrossRef]

- Xiong, C.; Xu, W.; Zhao, Y.; Xiao, J.; Zhu, X. New Design Graded Refractive Index Antireflection Coatings for Silicon Solar Cells. Mod. Phys. Lett. B 2017, 31, 1740028. [Google Scholar] [CrossRef]

- Ma, Q.; Zhang, W.; Ma, D.; Fan, Z.; Ma, X.; Jiang, Z. Optimal Design of Quadruple-Layer Antireflection Coating Structure for Conversion Efficiency Enhancement in Crystalline Silicon Solar Cells. Optik 2019, 177, 123–130. [Google Scholar] [CrossRef]

- Ho, W.-J.; Hsu, H.-W.; Yang, H.-Y.; Liu, J.-J.; Tsai, Y.-T.; Chiu, W.-C. Plasmonic Scattering and Coupling Effects of Indium Nanoparticles Sheets Embedded in SiO2 AR-Coating on Performance Enhancement of Silicon Solar Cells. In Proceedings of the 2020 47th IEEE Photovoltaic Specialists Conference (PVSC), Virtual, 15 June–21 August 2020; pp. 0231–0233. [Google Scholar]

- Alone-Alaluf, M.; Appelbaum, J.; Croitoru, N. Properties of GaAs Solar Cells Coated with Diamondlike Carbon Films. Thin Solid Films 1998, 320, 159–162. [Google Scholar] [CrossRef]

- Dabaghyan, G.A.; Matevosyan, L.M.; Avjyan, K.E. Determination of Refractive Index and Thickness of Nanosized Amorphous Carbon Films Via Visible Range Reflectance Spectra. J. Contemp. Phys. 2019, 54, 185–187. [Google Scholar] [CrossRef]

- Hovhannisyan, A. Single-Layer Antireflection Coatings for GaAs Solar Cells. J. Contemp. Phys. 2008, 43, 136–138. [Google Scholar] [CrossRef]

- Makableh, Y.F.; Vasan, R.; Sarker, J.C.; Nusir, A.I.; Seal, S.; Manasreh, M.O. Enhancement of GaAs Solar Cell Performance by Using a ZnO Sol–Gel Anti-Reflection Coating. Sol. Energy Mater. Sol. Cells 2014, 123, 178–182. [Google Scholar] [CrossRef]

- Mercy, P.A.M.; Wilson, K.S.J.; Fathima, M.I. Analysis of Reflectance of Various DLARC Systems in Solar Cells. AIP Conf. Proc. 2020, 2265, 030307. [Google Scholar] [CrossRef]

- Saint-Andre, S.; Rodriguez, D.; Perillo, P.; Barrera, M. TiO2 Nanotubes Antireflection Coating Design for GaAs Solar Cells. Sol. Energy Mater. Sol. Cells 2021, 230, 111201. [Google Scholar] [CrossRef]

- Ma, C.; Zhao, C.; Fan, X.; Liu, Z.; Liu, J. Preparation of Non-Stoichiometric Al2O3 Film with Broadband Antireflective by Magnetron Sputtering. Chem. Phys. Lett. 2021, 764, 138299. [Google Scholar] [CrossRef]

- Khadir, A.; Kouzou, A.; Abdelhafidi, M.K. Effect of Anti-Reflective Coating on CIGS Solar Cells Performance. In Proceedings of the 2020 17th International Multi-Conference on Systems, Signals & Devices (SSD), Monastir, Tunisia, 3 July 2020; pp. 621–625. [Google Scholar]

- Bhattacharya, R.N.; Contreras, M.A.; Teeter, G. 18.5% Copper Indium Gallium Diselenide (CIGS) Device Using Single-Layer, Chemical-Bath-Deposited ZnS(O,OH). Jpn. J. Appl. Phys. Part 2 Lett. Express Lett. 2004, 43, L1475–L1476. [Google Scholar] [CrossRef]

- El Islam Boukortt, N.; Patané, S. High-Efficiency Cu (In1-XGax) Se2 Solar Cell Investigation with Single Layer Antireflection Coating of MgF2. In Proceedings of the 2019 2nd International Conference on Smart Grid and Renewable Energy (SGRE), Doha, Qatar, 19–21 November 2019; pp. 1–5. [Google Scholar]

- Cho, D.; Lee, W.; Kim, M.; Shin, B.; Chung, Y. Color Tuning in Cu(In,Ga)Se2 Thin-Film Solar Cells by Controlling Optical Interference in Transparent Front Layers. Prog. Photovolt. 2020, 28, 798–807. [Google Scholar] [CrossRef]

- Scholtz, L.; Sutta, P.; Calta, P.; Novak, P.; Solanska, M.; Mullerova, J. Investigation of Barium Titanate Thin Films as Simple Antireflection Coatings for Solar Cells. Appl. Surf. Sci. 2018, 461, 249–254. [Google Scholar] [CrossRef]

- Würfel, U.; Herterich, J.; List, M.; Faisst, J.; Bhuyian, M.F.M.; Schleiermacher, H.-F.; Knupfer, K.T.; Zimmermann, B. A 1 cm2 Organic Solar Cell with 15.2% Certified Efficiency: Detailed Characterization and Identification of Optimization Potential. Solar RRL 2021, 5, 2000802. [Google Scholar] [CrossRef]

- Suleimanov, S.; Berger, P.; Dyskin, V.; Dzhanklich, M.; Kulagina, N.; Kim, M. Increasing the Efficiency of Organic Solar Cells by Antireflection Coatings Based on Fluoride Composites. Tech. Phys. Lett. 2018, 44, 295–296. [Google Scholar] [CrossRef]

- Jang, W.; Park, K.H.; Wang, D.H. Increased Omnidirectional Light Absorbance by Using Hollow Silica Nanoparticles in an Anti-Reflective Pattern for Efficient Organic Photovoltaic Devices. Org. Electron. 2018, 53, 315–319. [Google Scholar] [CrossRef]

- Huang, X.; Sun, B.; Li, Y.; Jiang, C.; Fan, D.; Fan, J.; Forrest, S.P. 15.9% Organic Tandem Solar Cell with Extended near-Infrared Absorption. Appl. Phys. Lett. 2020, 116, 153501. [Google Scholar] [CrossRef]

- Kim, J.-H.; Choi, Y.J.; Lee, J.; Lee, S.G. Highly Transparent Antireflection Coatings on Fullerene-Free Organic Solar Cells Using Polymeric Nanoparticles. Thin Solid Films 2022, 742, 139043. [Google Scholar] [CrossRef]

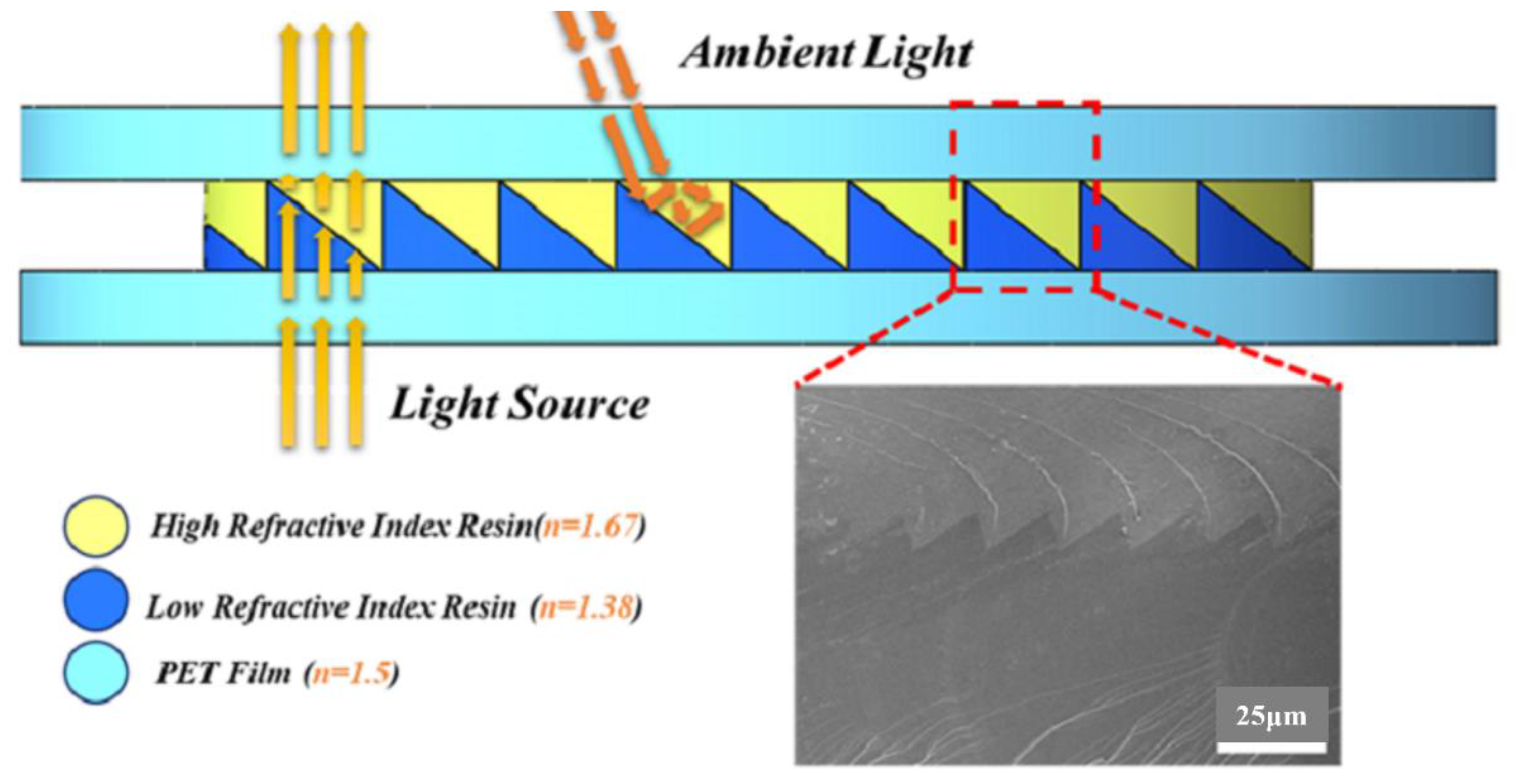

- Zhang, J.; Li, B.; Song, H.; Zhao, C.; Liang, S.; Dong, Z.; Yu, J. High Refractive Index Diphenyl Sulfide Photopolymers for Solar Cell Antireflection Coatings. Energies 2022, 15, 3972. [Google Scholar] [CrossRef]

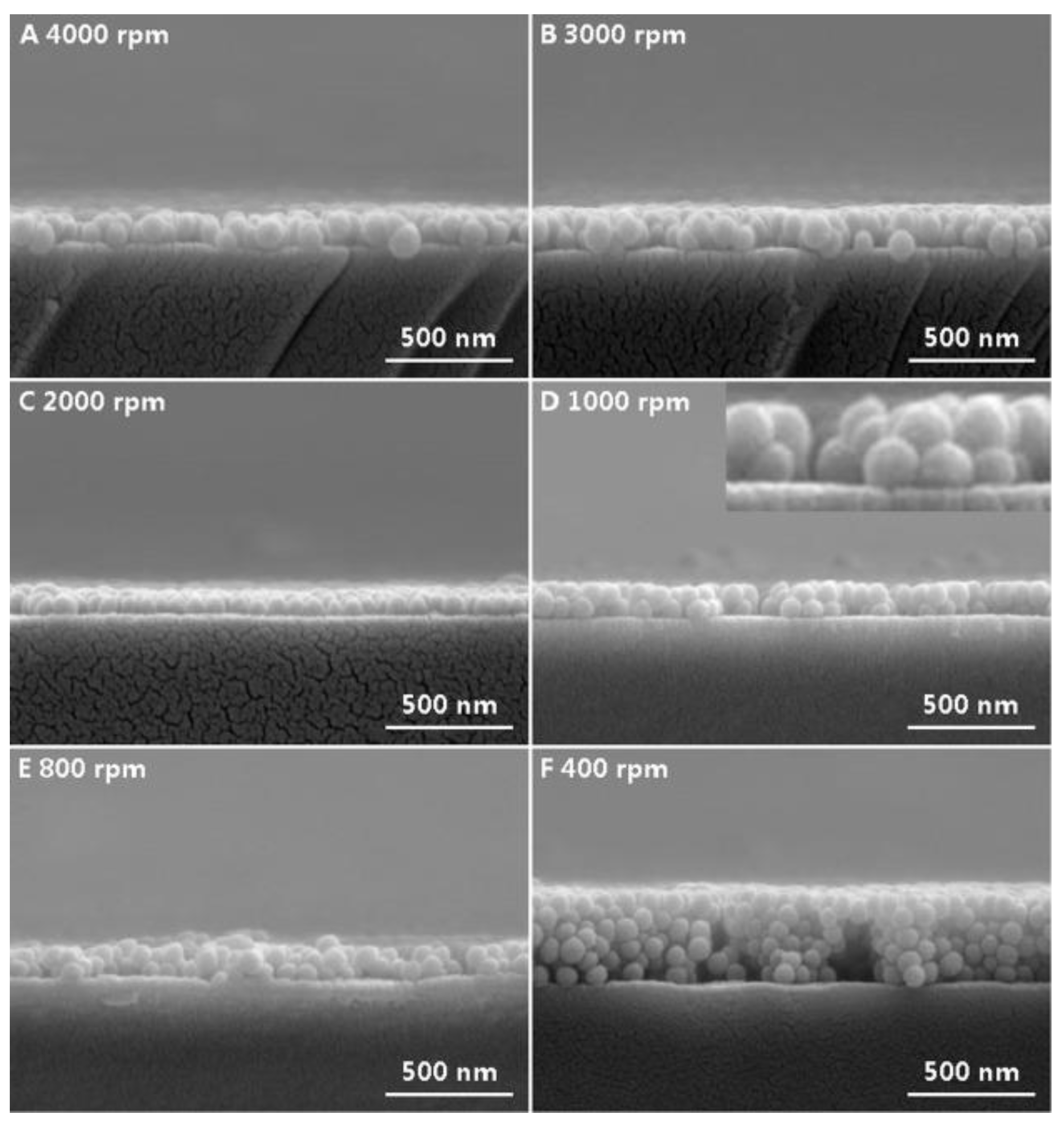

- Luo, Q.; Deng, X.; Zhang, C.; Yu, M.; Zhou, X.; Wang, Z.; Chen, X.; Huang, S. Enhancing Photovoltaic Performance of Perovskite Solar Cells with Silica Check for Nanosphere Antireflection Coatings. Sol. Energy 2018, 169, 128–135. [Google Scholar] [CrossRef]

- Kim, D.I.; Lee, J.W.; Jeong, R.H.; Yang, J.W.; Park, S.; Boo, J.-H. Optical and Water-Repellent Characteristics of an Anti-Reflection Protection Layer for Perovskite Solar Cells Fabricated in Ambient Air. Energy 2020, 210, 118582. [Google Scholar] [CrossRef]

- Zhang, J.; Li, X.; Zhong, M.; Zhang, Z.; Jia, M.; Li, J.; Gao, X.; Chen, L.; Li, Q.; Zhang, W.; et al. Near 90% Transparent ITO-Based Flexible Electrode with Double-Sided Antireflection Layers for Highly Efficient Flexible Optoelectronic Devices. Small 2022, 18, 2201716. [Google Scholar] [CrossRef] [PubMed]

- Kim, M.; Kang, T.-W.; Kim, S.H.; Jung, E.H.; Park, H.H.; Seo, J.; Lee, S.-J. Antireflective, Self-Cleaning and Protective Film by Continuous Sputtering of a Plasma Polymer on Inorganic Multilayer for Perovskite Solar Cells Application. Sol. Energy Mater. Sol. Cells 2019, 191, 55–61. [Google Scholar] [CrossRef]

- Xie, C.; Wang, Y.; Zhang, Z.-X.; Wang, D.; Luo, L.-B. Graphene/Semiconductor Hybrid Heterostructures for Optoelectronic Device Applications. Nano Today 2018, 19, 41–83. [Google Scholar] [CrossRef]

- Huang, K.; Yu, X.; Cong, J.; Yang, D. Progress of Graphene-Silicon Heterojunction Photovoltaic Devices. Adv. Mater. Interfaces 2018, 5, 1801520. [Google Scholar] [CrossRef]

- Li, X.; Lv, Z.; Zhu, H. Carbon/Silicon Heterojunction Solar Cells: State of the Art and Prospects. Adv. Mater. 2015, 27, 6549–6574. [Google Scholar] [CrossRef]

- Shi, E.; Zhang, L.; Li, Z.; Li, P.; Shang, Y.; Jia, Y.; Wei, J.; Wang, K.; Zhu, H.; Wu, D.; et al. TiO2-Coated Carbon Nanotube-Silicon Solar Cells with Efficiency of 15%. Sci. Rep. 2012, 2, 884. [Google Scholar] [CrossRef]

- Shi, E.; Li, H.; Yang, L.; Zhang, L.; Li, Z.; Li, P.; Shang, Y.; Wu, S.; Li, X.; Wei, J.; et al. Colloidal Antireflection Coating Improves Graphene-Silicon Solar Cells. Nano Lett. 2013, 13, 1776–1781. [Google Scholar] [CrossRef] [PubMed]

- Li, D.; Kunz, T.; Wolf, N.; Liebig, J.; Wittmann, S.; Ahmad, T.; Hessmann, M.; Auer, R.; Goken, M.; Brabec, C. Silicon Nitride and Intrinsic Amorphous Silicon Double Antireflection Coatings for Thin-Film Solar Cells on Foreign Substrates. Thin Solid Films 2015, 583, 25–33. [Google Scholar] [CrossRef]

- Xiao, S.; Fan, Q.; Xia, X.; Xiao, Z.; Chen, H.; Xi, W.; Chen, P.; Li, J.; Wang, Y.; Liu, H.; et al. Dependence of the Solar Cell Performance on Nanocarbon/Si Heterojunctions. Chin. Phys. B 2018, 27, 078801. [Google Scholar] [CrossRef]

- Bhopal, M.; Lee, D.; Rehman, M.; Seo, Y.; Lee, S. Vanadium Pentoxide (V2O5) as an Antireflection Coating for Graphene/Silicon Solar Cell. Mater. Sci. Semicond. Process. 2018, 86, 146–150. [Google Scholar] [CrossRef]

- Yoshikawa, K.; Kawasaki, H.; Yoshida, W.; Irie, T.; Konishi, K.; Nakano, K.; Uto, T.; Adachi, D.; Kanematsu, M.; Uzu, H.; et al. Silicon Heterojunction Solar Cell with Interdigitated Back Contacts for a Photoconversion Efficiency over 26%. Nat. Energy 2017, 2, 17032. [Google Scholar] [CrossRef]

- Sahouane, N.; Zerga, A. Optimization of Antireflection Multilayer for Industrial Crystalline Silicon Solar Cells. Energy Procedia 2014, 44, 118–125. [Google Scholar] [CrossRef]

- Herasimenka, S.; Dauksher, W.; Boccard, M.; Bowden, S. ITO/SiOx:H Stacks for Silicon Heterojunction Solar Cells. Sol. Energy Mater. Sol. Cells 2016, 158, 98–101. [Google Scholar] [CrossRef]

- Park, S.; Kim, Y.; Yi, J.; Zahid, M.; Khokhar, M.; Hussain, S. Influence of Al2O3/IZO Double-Layer Antireflective Coating on the Front Side of Rear Emitter Silicon Heterojunction Solar Cell. Vacuum 2022, 200, 110967. [Google Scholar] [CrossRef]

- Xiao, P.; Zhang, M.; Wu, X.; Ding, K.; Pan, J.; Jie, J. Enhancing the Efficiency and Stability of Organic/Silicon Solar Cells Using Graphene Electrode and Double-Layer Anti-Reflection Coating. Sol. Energy 2022, 234, 111–118. [Google Scholar] [CrossRef]

- Shockley, W.; Queisser, H.J. Detailed Balance Limit of Efficiency of P-n Junction Solar Cells. J. Appl. Phys. 1961, 32, 510–519. [Google Scholar] [CrossRef]

- El Amin, A.; Hassan, M. Fabrication Solar Cell of CdTe0.65P0.35/Si with High Efficiency Using Double-Layer Antireflection. Electr. Eng. 2018, 100, 1003–1007. [Google Scholar] [CrossRef]

- Musalinov, S.; Anzulevich, A.; Bychkov, I.; Gudovskikh, A.; Shvarts, M. Influence of Double- and Triple-Layer Antireflection Coatings on the Formation of Photocurrents in Multijunction III-V Solar Cells. Semiconductors 2017, 51, 88–92. [Google Scholar] [CrossRef]

- Kim, T.S.; Kim, H.J.; Han, J.-H.; Choi, W.J.; Yu, K.J. Flexible InGaP/GaAs Tandem Solar Cells Encapsulated with Ultrathin Thermally Grown Silicon Dioxide as a Permanent Water Barrier and an Antireflection Coating. ACS Appl. Energ. Mater. 2022, 5, 227–233. [Google Scholar] [CrossRef]

- Kim, T.S.; Kim, H.J.; Geum, D.-M.; Han, J.-H.; Kim, I.S.; Hong, N.; Ryu, G.H.; Kang, J.; Choi, W.J.; Yu, K.J. Ultra-Lightweight, Flexible InGaP/GaAs Tandem Solar Cells with a Dual-Function Encapsulation Layer. ACS Appl. Mater. Interfaces 2021, 13, 13248–13253. [Google Scholar] [CrossRef] [PubMed]

- Campesato, R.; Greco, E.; Mezzetti, A.; di Fonzo, F.; Bissoli, F.; di Mezza, A. Effective Coating for High Efficiency Triple Junction Solar Cells. In Proceedings of the 2019 European Space Power Conference (ESPC), Côte d’Azur France, 30 September 2019; pp. 1–5. [Google Scholar]

- Zhang, W.; Hu, K.; Tu, J.; Aierken, A.; Xu, D.; Song, G.; Sun, X.; Li, L.; Chen, K.; Zhang, D.; et al. Broadband Graded Refractive Index TiO2/Al2O3/MgF2 Multilayer Antireflection Coating for High Efficiency Multi-Junction Solar Cell. Sol. Energy 2021, 217, 271–279. [Google Scholar] [CrossRef]

- Hongliang, G.; Linfeng, S.; Qiang, S.; Qiming, Z.; Yiyong, W.; Jingdong, X.; Bin, G.; Yanqing, Z. Degradation of Up-Grown Metamorphic InGaP/InGaAs/Ge Solar Cells by Low-Energy Proton Irradiation. Sol. Energy Mater. Sol. Cells 2019, 191, 399–405. [Google Scholar] [CrossRef]

- Singh, G.; Sekhon, J.S.; Verma, S.S. Enhanced Photocurrent in Thin-Film GaAs Solar Cells with Embedded Al Nanoparticles. Energy Sources Part A 2020, 42, 815–823. [Google Scholar] [CrossRef]

- Chaudhry, F.; Escandell, L.; Lopez-Fraguas, E.; Vergaz, R.; Sanchez-Pena, J.; Garcia-Camara, B. Light Absorption Enhancement in Thin Film GaAs Solar Cells Using Dielectric Nanoparticles. Sci. Rep. 2022, 12, 9240. [Google Scholar] [CrossRef]

- Cossio, G.; Yu, E.; Tatavarti, S.; Scandrett, B.; Yu, E. Omnidirectional Current Enhancement From Laminated Moth-Eye Textured Polymer Packaging for Large-Area, Flexible III-V Solar Modules. IEEE J. Photovolt. 2021, 11, 685–691. [Google Scholar] [CrossRef]

- Schulze, P.; Bett, A.; Bivour, M.; Caprioglio, P.; Gerspacher, F.; Kabakl, O.; Richter, A.; Stolterfoht, M.; Zhang, Q.; Neher, D.; et al. 25.1% High-Efficiency Monolithic Perovskite Silicon Tandem Solar Cell with a High Bandgap Perovskite Absorber. Sol. RRL 2020, 4, 2000152. [Google Scholar] [CrossRef]

| Classification | Material | Optical Property (%) | Range (nm) | H (%) | ηgain (%) | Reference Cell | Reference |

|---|---|---|---|---|---|---|---|

| polysilicon | MoSe2 | Rgain = 70.00 | 400–800 | 18.67 | 37.18 | bare | [35] |

| polysilicon | ZnSe | Rgain = 70.09 | 400–800 | 19.95 | 29.80 | bare | [36] |

| crystalline silicon | HfO2 | Rgain = 39.77 | 300–1200 | 21.15 * | 72.37 * | bare | [37] |

| monocrystalline silicon | TiO2 | / | / | 17.87 | 4.02 | bare | [38] |

| Ta2O5 | / | / | 18.80 | 9.43 | bare | ||

| polysilicon | VTES/PF-127 | Tmax = 92.83 | 400–800 | 10.56 | 8.75 | bare | [39] |

| crystalline silicon | a-SiNx:H DLARC | / | / | 17.5 | 20.69 | bare | [40] |

| crystalline silicon | SiC/MgF2 | R < 3 | 475–1020 | / | / | / | [41] |

| polysilicon | TiO2/SiO2 | Rgain = 70.59 | 400–800 | 18.9 | 29.99 | bare | [42] |

| polysilicon | dense SiO2/porous SiO2 | Rgain = 77.78 | 300–1200 | / | / | / | [43] |

| monocrystalline silicon | dense SiO2/porous SiO2 | Tave = 99.28 | 380–780 | 20.94 | 2.40 | bare | [45] |

| polysilicon | TiO2-SiO2/SiO2/SiNx | Rgain = 24.23 | 300–1200 | 16.27 | 1.12 | coated with SiNx | [48] |

| monocrystalline silicon (PERC) | SiOx/SiNx/SiNx | Rgain = 10.90 * | 300–1100 | 21.5 | 0.70 | coated with SiNx/SiNx/ SiNx | [50] |

| nanostructured black silicon | nanoporous SiO2/SiO2/SiOxNy/PS | R < 2 * | 430–1200 | / | / | / | [51] |

| crystalline silicon | SiO2/SiNx:H/ SiNx:H/SiO2 | Rgain = 45.45 | 350–1100 | 14.25 | 30.38 | coated with SiNx:H DLARC | [52] |

| SiO2/SiNx:H/ SiNx:H/Al2O3 | Rgain = 54.55 | 350–1100 | 14.43 | 32.02 | |||

| crystalline silicon | 1-In-NP sheet/SiO2 | / | / | / | 34.27 | bare | [53] |

| 2-In-NP sheets/SiO2 | / | / | / | 38.59 | |||

| 3-In-NP sheets/SiO2 | / | / | / | 39.57 | |||

| SiO2 | / | / | / | 27.13 |

| Classification | Material | Optical Property (%) | Range (nm) | η (%) | ηgain (%) | Reference Cell | Reference |

|---|---|---|---|---|---|---|---|

| GaAs | TiO2 DLARC | R = 1.81 | 400–1000 | 20.6 * | 46.10 * | bare | [59] |

| GaAs | MgF2 | / | / | 27.71 | 1.69 | bare | [60] |

| Al2O3/MgF2 | / | / | 28.36 | 4.07 | |||

| CIGS | MgF2 | / | / | 20.52 * | 8.06 * | bare | [61] |

| CIGS | MgF2 | / | / | 22.62 * | 3.29 * | bare | [63] |

| a-Si | 110 nm BTO/a-Si:H/SiO2 | Tgain = 34.4 | 400–1100 | / | / | bare | [65] |

| 60 nm BTO/a-Si:H/SiO2 | Tgain = 18.9 | 400–1100 | / | / | bare | ||

| 112 nm BTO/SiO2 | Tgain = 17.5 | 400–1100 | / | / | bare | ||

| 61 nm BTO/SiO2 | Tgain = 15.8 | 400–1100 | / | / | bare | ||

| a-Si | nanoporous PDMS/PQDF DLARC | Tmax increased by 6% (compared with nanoporous PDMS) | 380–780 | 10 | 11.73 | bare | [4] |

| Classification | Material | Optical Property (%) | Range (nm) | η (%) | ηgain (%) | Reference Cell | Reference |

|---|---|---|---|---|---|---|---|

| OSC | MgF2-CaF2 mixture (55:45) | Δη = 3.2 | bare | [67] | |||

| MgF2-CaF2 mixture (95:5) | Δη = 3.3 | ||||||

| OSC | Hollow SiO2 NPs | R > 90 | 420–1000 | 6.53 | 8.83 | bare | [68] |

| OSC | SiO2/MgF2 | R decreased by 4% | 400–1000 | 15.9 | 4.61 | bare | [69] |

| OSC | Poly(styrene-co-acrylic acid) nanoparticle | Tmax = 98.9 | 400–800 | 12.8 | 6.67 | bare | [70] |

| OSC | high-low RI resin | Tmax = 99.86 | 300–800 | / | / | / | [71] |

| PSC | SiO2 NPs(1000 rpm) | Tmax = 96.1 | 400–800 | 15.82 | 6.82 | bare | [72] |

| PSC | dense TiO2/mesoporous TiO2 | Tmax ≈ 80 | 300–1200 | 13.95 | 24.78 | bare | [73] |

| PSC | SiO2 NPs +SnO2-PEG | Tgain = 16.93 | 400–800 | 20.85 | 10.90 | bare | [74] |

| PSC | PPFC(70nm)/NSN/HC-PET | Rmin = 1.71 | 400–1200 | 17 | 5.59 | coated with HC-PET | [75] |

| G-CNT/Si | PMMA | / | / | 9.1 | 19.74 | bare | [82] |

| Gr/Si | V2O5 | Rmin = 2–3 | 300–1000 | 3.03 | 191.35 | bare | [83] |

| SHJ | CaF2/ITO | Rgain = 31.70 | 300–1100 | 21.05 | 2.93 | coated with ITO | [29] |

| SHJ | Al2O3/IZO | 4.9 | 300–1100 | 21.57 | 3.85 | coated with IZO | [87] |

| Organic/Si | 60 nm PMMA/1-Gr/60 nm PEDOT:PSS | / | / | 13.01 | 25.46 | coated with 60 nm PEDOT:PSS | [88] |

| Dual-junction InGaP/GaAs | SiO2 | / | / | 28.77 | 2.24 | bare | [92] |

| dual-junction InGaP/GaAs | Al2O3/SiO2 | / | / | 27.4 | 6.30 | bare | [93] |

| GaInP/InGaAs/Ge TJ | TiO2/Al2O3/MgF2 | Rgain = 86.82 | 380–1800 | 32.71 * | 29.44 * | bare | [95] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ji, C.; Liu, W.; Bao, Y.; Chen, X.; Yang, G.; Wei, B.; Yang, F.; Wang, X. Recent Applications of Antireflection Coatings in Solar Cells. Photonics 2022, 9, 906. https://doi.org/10.3390/photonics9120906

Ji C, Liu W, Bao Y, Chen X, Yang G, Wei B, Yang F, Wang X. Recent Applications of Antireflection Coatings in Solar Cells. Photonics. 2022; 9(12):906. https://doi.org/10.3390/photonics9120906

Chicago/Turabian StyleJi, Chunxue, Wen Liu, Yidi Bao, Xiaoling Chen, Guiqiang Yang, Bo Wei, Fuhua Yang, and Xiaodong Wang. 2022. "Recent Applications of Antireflection Coatings in Solar Cells" Photonics 9, no. 12: 906. https://doi.org/10.3390/photonics9120906

APA StyleJi, C., Liu, W., Bao, Y., Chen, X., Yang, G., Wei, B., Yang, F., & Wang, X. (2022). Recent Applications of Antireflection Coatings in Solar Cells. Photonics, 9(12), 906. https://doi.org/10.3390/photonics9120906