Abstract

Epitaxially regrown electrically pumped photonic crystal surface emitting lasers (PCSELs) operating near 2 µm were designed and fabricated within a III-V-Sb material system. A high-index-contrast photonic crystal layer was incorporated into the laser heterostructures by air-pocket-retaining epitaxial regrowth. Transmission electron microscopy studies confirmed uniform and continuous AlGaAsSb initial growth over the nano-patterned GaSb surface, followed by the development of the air-pockets. The PCSEL threshold current density had a minimal value of ~170 A/cm2 in the 160–180 K temperature range when the QW gain spectrum aligned with the Γ2 band edge of the photonic crystal. The devices operated in a continuous wave regime at 160 K. The divergence and polarization of the multimode laser beam emitted from the 200 µm × 200 µm PCSEL aperture were controlled by filamentation.

1. Introduction

GaSb-based type-I quantum well (QW) diode lasers operate in a continuous wave (CW) regime at room temperature (RT) in a spectral range from 1.9 to 3.5 µm [1,2]. The corresponding 100 µm current stripe edge emitting lasers generate CW power of ~2 W near 2 µm [3] and ~1 W near 3 µm [4]. Similar to the majority of high-power edge emitters, these devices produce highly divergent, astigmatic, and non-diffraction limited beams. Photonic crystal surface emitting laser (PCSEL) architecture holds promise to address the brightness limitation of the edge emitters through efficient in-plane multidirectional diffraction yielding coherent lasing over a large area. However, non-linear effects such as spatial hole burning triggering filament formation can complicate the situation. The role of filamentation has not yet been discussed in the context of PCSEL development.

The near field of standard edge emitting wide aperture lasers shows filamentation caused by spatial hole burning and coupling between real and imaginary parts of the semiconductor dielectric permittivity [5]. The latter is often characterized by the linewidth enhancement factor, which has been measured to be ~3 in GaSb-based type I QW diode lasers emitting near 2 µm. The filament spacing is inversely proportional to the linewidth enhancement factor and optical loss [5]. The filaments observed in the near field of GaSb-based edge emitting diode lasers are spaced about ~15 µm [6]. When the filament phases lock, the laser can operate in coherent super-mode over a large aperture [7]. However, the high-power beams generated from wide aperture diode lasers remain in multimode. In addition, the spectral linewidth of wide stripe high power lasers comprises an ensemble of narrow lines, as multiple longitudinal Fabry–Perot and several lateral super-modes reach the threshold. The technological inhomogeneities over a large laser stripe area trigger spatial hole burning and hence promote the formation of filaments. This scenario is indirectly supported by the observation of stable, yet device-specific filamentation patterns in our GaSb-based diode lasers. High uniformity of both epitaxial growth and post-growth fabrication are necessary to avoid defect-related dielectric permittivity perturbations. Multidirectional diffraction of light propagating in photonic crystals can assist phase-locking between filaments or even suppress filament formation in diode lasers. The coherent operation over a large emission aperture has been achieved in λ ≈ 1 µm GaAs-based PCSELs [8,9,10], generating a remarkable multi-watt output power in ultra-low divergent beams. It should be noted that these devices were based on mature GaAs-based epitaxial technology and used optimized air-hole retained regrowth [11]. In this paper, we report on λ ≈ 2 µm diode PCSELs relying on III-V-Sb epitaxial regrowth technology being currently developed [12,13,14]. The devices demonstrate band edge lasing with a stable and narrow linewidth at injection currents of up to 20 thresholds. The GaSb-based PCSEL far field pattern had low divergence corresponding to the ~200 µm emission aperture only in one direction. In the perpendicular direction, the beam emitted from the surface produced a multilobe broadened far field pattern. The near field measurements showed filamentation, which contributed to the asymmetry of the laser beam in the far field. We speculate that the technological imperfections and limited area fill factor of the buried photonic crystal used in the current generation of the GaSb-based PCSELs is responsible for this.

2. Device Fabrication

Laser heterostructures were grown by solid-source molecular beam epitaxy (MBE) using cracked arsenic and antimony sources on tellurium-doped GaSb substrates. The growth was performed in two steps. The first step included the growth of an incomplete laser heterostructure (the first epi), and the second step involved its regrowth following the etching of the nanopattern. The first epi comprised Al0.6Ga0.4As0.05Sb0.95 n-cladding, the Al0.2Ga0.8As0.02Sb0.98 n-side waveguide core layer, and an active region containing three Ga0.75In.0.25Sb QWs separated by 20 nm Al0.2Ga0.8As0.02Sb0.98 barriers. The barrier after the last QW was compositionally graded to GaSb over a thickness of about 50 nm, and the first epi was terminated with a 400 nm thick GaSb layer. The incomplete laser heterostructure was removed from the MBE reactor and covered with a ~300 nm thick silicon nitride film. The electron beam lithography was used to form a hard mask for dry etching of the photonic crystal pattern. The pattern comprised a 2D square lattice of right isosceles triangles with ~300 nm legs loosely aligned to (110) crystal planes and an X direction in the square photonic crystal. The period of the square lattice of 540 nm was selected to align the stop band with the QW gain spectra at reduced temperatures. This was done to eliminate the effect of the thermionic carrier delocalization on the laser injection efficiency and QW differential gain. The reference edge emitters fabricated from the same wafer demonstrated pour performance parameters at room temperature due to the suboptimal laser heterostructure design. Specifically, the introduction of the 400 nm GaSb layer into the laser waveguide core is expected to promote carrier delocalization from active QWs, leading to gaining degradation and excessive carrier accumulation in GaSb at elevated temperatures. This is by no means a fundamental limitation as carrier leakage stoppers similar to those we used in the cascade diode laser design [1] can be utilized after appropriate adjustments. However, at this stage of the GaSb-based PCSEL technology development, we chose to minimize the supplementary design optimization steps and relied on a reduction of the operation temperature to reach lasing.

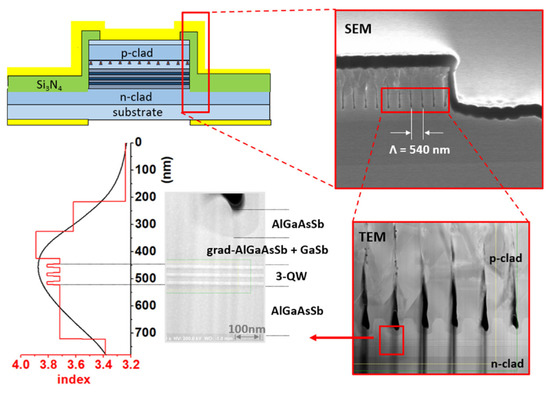

The epitaxial regrowth step (the second epi) required the preparation of the surface of the nano-patterned GaSb layer, which included chemical cleaning and surface oxide desorption. The remnants of the silicon nitride mask were removed by CF4/O2 plasma and then the structures were immersed into concentrated ultra-pure HCl right before loading into the load-lock chamber. The thermal oxide desorption was performed in the main reactor at ~540 °C. The readiness of the GaSb surface for the regrowth was controlled by reflection high energy electron diffraction measurements, where 1 × 3 surface reconstruction was observed. Then, the growth temperature was ramped down to around 420 °C and the nanopatterned structures were regrown with the following sequence: 1.5 µm thick Al0.6Ga0.4As0.05Sb0.95 Be-doped p-cladding layer, 200 nm Be-doped graded composition layers, and 100 nm GaSb p-cap layer. The substrate-side outcoupled PCSELs were fabricated from the regrown structures (Figure 1, top left). The square mesas with 200 µm sides roughly aligned to the X directions of the photonic crystal were etched down to n-cladding (Figure 1, top right). The wafer with a finished p-side was lapped and polished down to a ~200 µm thickness. The n-side metallization had square windows (200 µm side) aligned to the etched mesas on the p-side.

Figure 1.

Tope left: Schematic cross-section of the substrate outcoupled etched mesa PCSEL. Top right: Cross-section SEM image of the PCSEL cleaved through the mesa. Bottom right: Cross-section TEM image of the regrowth interface containing air-pockets. Bottom right: Magnified TEM image of the active region overlapped with the corresponding calculated index profile and laser fundamental mode.

Transmission electron microscopy (TEM) was used to investigate the formation of the buried air-pockets during regrowth with the AlGaAsSb p-cladding material. Figure 1 (bottom row) shows the cross-section TEM images of the regrown diode PCSEL structures. Uniform coverage of the nano-patterned GaSb surface with ~100 nm AlGaAsSb was observed inside the ~300 nm deep etched holes. The selected regrowth regimes yielded elongated non-uniform air-pockets, which are expected to contribute to the excess scattering losses of the photonic crystal modes. The calculated fundamental laser mode intensity distribution is shown together with the estimated refractive index profile aligned to TEM image of the regrown sample in the left bottom part of Figure 1. The estimated overlap with the photonic crystal layer is ~18%, while the areal fill-factor of the high-index contrast “atom” in the photonic crystal unit cell is about 4%.

The individual 500 by 500 µm2 chips were cleaved from the processed wafer. The devices were attached epi-side down onto copper blocks and bolted to the cold finger of the liquid nitrogen optical cryostat with CaF2 windows for characterization.

3. Characterization Results and Discussion

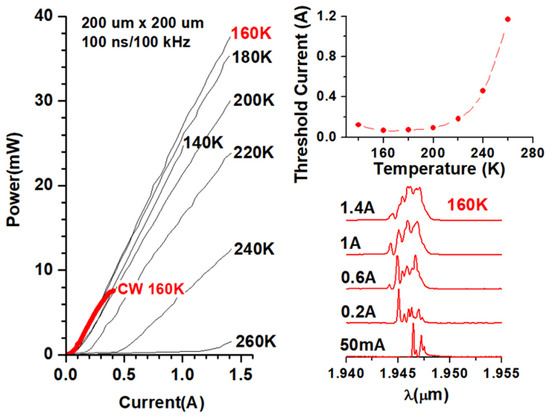

The light-current characteristics of the PCSELs were measured in a 1% duty cycle regime in the temperature range from 140 to 260 K and in the CW regime at 160 K (Figure 2, left). In the temperature range from 160 to 180 K, the laser threshold took a nearly minimum value of ~70 mA. The corresponding threshold current density was ~170 A/cm2 or ~60 A/cm2 per QW. This was two to three times higher compared with the values measured at the same temperatures for typical 100 µm wide, 1 mm long, uncoated edge emitting lasers emitting near 2 µm with total optical losses of ~15 cm−1 [15].

Figure 2.

Left: Power–current characteristics measured in a 1% duty cycle and in the CW regime at several temperatures. Right top: temperature dependence of the PCSEL threshold current. Right bottom: PCSEL emission spectra measured at 160 K for different injection currents.

The PCSEL output power in a 1% duty cycle regime was measured using a liquid nitrogen cooled 4 mm diameter InSb photodetector equipped with a gold-coated integrating sphere. The lock-in amplifier was used to minimize the thermal background noise. The system was calibrated for a 2 µm range using a home-made high-power edge emitting laser. The PCSEL surface emission slope efficiency took a maximum value of about 30 mW/A at 160 K. This value was about an order of magnitude lower compared with the single facet slope efficiency of the uncoated 1 mm long, 2 µm range wide stripe edge emitters with mirror losses of ~12 cm−1. The PCSEL threshold current and slope efficiency at different temperatures are shown in Table 1.

Table 1.

Temperature dependence of the PCSEL threshold current and slope efficiency.

The PCSEL power in the CW regime was measured directly using a calibrated thermopile detector. The CW output power at 160 K was limited by a thermal roll-over at ~8 mW. The intercept of the CW power–current characteristics with those measured in the 1% duty cycle regime allowed for a rough estimation of the device thermal resistance to be about 65 K/W. This value is about twice higher than the expected number for standard edge emitting lasers of a similar thermal footprint, i.e., 200 × 200 µm2. Arguably, degradation of the thermal transport through the p-cladding material containing excessively elongated air-pockets (Figure 1) accounts for increased thermal resistance. When the device operating temperature either decreased or increased with respect to ~160 K, both the slope efficiency and threshold current degraded (Figure 2). This can be explained by the minimal detuning of the QW gain peak from the photonic crystal band edge near 160 K. The effect of detuning on the laser threshold was amplified by the reduction of the injection efficiency and the decrease in the carrier lifetime when the device temperature increased above 200 K. The laser surface emission spectra were multimode (Figure 2, right bottom) with the number of lasing lines increasing rapidly near the threshold and resulting in an overall linewidth of ~2 nm at the injection currents, corresponding to 10 to 20 thresholds.

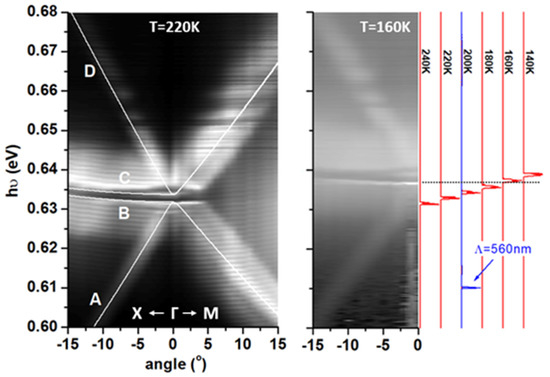

Figure 3 shows the results of the angle resolved electro-luminescence measurements, presented in the form of the |photon energy| vs. |surface emission angle| intensity map. The measured map corresponds to the in-plane photonic crystal band structure plotted in two high symmetry directions X and M near the Γ2 point (details of the measurements can be found in [14]). In the left part of Figure 3, one can see the map plotted in a linear intensity scale and measured at 220 K in the 80% duty cycle regime. This regime revealed all four sub bands thanks to the broad spectrum of abundant electroluminescence produced by the QWs. The 2D simulation of the band structure overlapped with the experimental data. In the right part of Figure 3, the experimental band structure measured in the X direction at 160 K for a 30 mA current is plotted, i.e., in the regime for which Joule heat leads to only a couple of degrees of overheating. The intensity map is plotted in log-scale as low energy sub bands have a significantly reduced intensity due to the blue shifted electroluminescence. The low energy band edge of the photonic crystal aligns well with the corresponding laser line measured at 160 K in a 1% duty cycle regime. This alignment and the observed PCSEL’s line shift with temperature (Figure 3, right) at a rate of ~0.05 meV/K confirm the photonic-crystal controlled lasing (the III–V semiconductor bandgap shifts at an order of magnitude faster at a rate of ~0.35 meV/K). The approximate value for the effective index of the in-plane guided laser mode can be estimated from the Bragg condition as neff ≈ λ0/Λ (λ0 is free space wavelength and Λ is the photonic crystal grating period) as ~3.6. When the period of the buried photonic crystal was changed from 540 to 560 nm, the PCSEL wavelength shifted proportionally (Figure 3, right ~200 K laser lines).

Figure 3.

The |photon energy| vs. |surface emission angle| intensity maps measured in the pulsed regime (100 ns, 8 MHz) at 220 K and 170 mA in X and M directions (left), and in X direction at 160 K at 30 mA (right). The corresponding PCSEL (period 540 nm) emission spectra (100 ns, 100 kHz) measured at 800 mA and at different temperatures are shown on the right. The 200 K emission spectrum of the PCSEL with a 560 nm period is also shown.

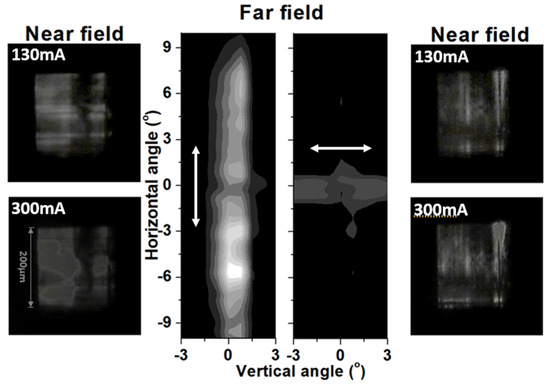

The single spatial mode PCSEL operation over the area of 200 by 200 µm2 would result in the sub-degree beam divergence in the far field. Figure 4 shows the far field patterns measured for two orthogonal polarizations in X directions. The low divergence was observed only in one of the directions. In the other direction, the beam showed a broad far field pattern. The polarization of the beam was correlated with its shape, i.e., for each of the orthogonal polarizations, the far field pattern elongation was parallel to the polarization direction. Qualitatively, in both X directions, the device showed very similar field patterns. However, one of the polarization directions demonstrated a lower threshold and higher efficiency. In an ideal square lattice with square isosceles triangular atoms, the perpendicular X directions are equivalent. The apparent disparity between the X directions indicates asymmetry of the regrowth rates in two perpendicular (110) directions, leading to corresponding asymmetry of the buried air-holes. It is not unusual to observe different growth dynamics on two perpendicular 110 planes of zinc-blende crystals due to their apparently different group V surface compositions [16].

Figure 4.

Near and far field patterns measured at 160 K for two electric field polarizations (direction are shown by arrows in the far field plots). The far field patterns were measured in a 1% duty cycle regime (100 ns/100 kHz) well above the threshold (at 500 mA). Near field patterns were measured at 0.1% duty cycle (100 ns/10 kHz) below (top images) and above (bottom images) the threshold.

We measured the near field patterns for each polarization (Figure 4). The dark regions in the near field patterns corresponding to both polarizations indicated structural nonuniformity, likely associated with lateral inhomogeneity of the buried photonic crystal layer. The near field patterns showed clear filaments aligned perpendicular to the polarization direction of the surface emission. The filament spacing was 15–20 µm (close to what was previously observed for GaSb-based edge emitters [6]).

The polarization and shape of the beam in the far field is consistent with the scenario of the surface outcoupling of the TE polarized light propagating along one of the X directions. The coupling between two perpendicular X directions appears to be rather limited. However, the stable far field pattern with a dip at the zero angle implies a certain degree of phase-locking between filaments. Arguably, insufficient coupling between waves propagating in two perpendicular X directions and lateral nonuniformity in still immature III-V-Sb regrowth technology promote filament formation.

In the framework of the coupled-wave approximation, coupling between partial TE-polarized waves propagating in perpendicular X directions of the square 2D photonic crystal can be achieved only via intermediate states [17]. The coupling coefficients controlling this process (κ2D) are smaller than those responsible for the distributed backward reflection (κ1D) [17]. According to qualitative analysis presented in [17], one can correlate the values of the κ1D and κ2D with photonic bandgaps between the modes at zero in-plane momentum near the Γ2 point. Indeed, Figure 3 shows a bandgap of ~3 meV between mode A and modes C and D—proportional to κ1D. At the same time, separation between modes A and B (proportional to κ2D in simplified picture) is minimal, if any. Generally, all coupling coefficients initially scale with the area fill factor of the photonic crystal unit cell. The estimated fill factor for the PCSELs studied in this work is on lower side (~4%), while values closer to 10% would be preferred [18]. The limited gap between C and D bands can also be explained by the low area fill factor and by smearing of the isosceles triangular shape during regrowth, yielding a suboptimal, i.e., more symmetric shape, of the buried air-pockets. Asymmetric atom shape and area fill factors in excess of 10% are preferred for increased surface outcoupling efficiency [19]. It is challenging to achieve area fill factors >10% in devices operating at longer wavelengths due to the higher ratio between the necessary photonic crystal period and the realistic size of the buried air-pocket. An increase in the lateral dimension of the etched holes will be offset by the thicker material layer grown inside the etched area during regrowth before the shadow effect will start “sealing” the air-pocket. Multiple air-pocket unit cell designs can help to improve the area fill factor. It is also clear that lateral uniformity of the buried photonic crystal should be improved in our PCSELs. Again, unit cells with multiple etched holes of smaller lateral dimensions can be beneficial. Fundamentally, a reduction in the net linewidth enhancement factor in compressively strained QWs by negative detuning [20] can help to reduce the tendency to filament formation. The minimization of the edge reflection effects by using shallow and/or circular mesa designs can also help to promote lasing supported purely by 2D in-plane feedback and not from the reflection from the mesa sidewalls acting as parasitic facets.

4. Summary

The 2 µm III-V-Sb diode PCSELs based on air-pocket retaining epitaxial regrowth technology have been designed and fabricated. TEM studies confirmed the regrowth of the nano-patterned GaSb surface with AlGaAsSb and integration of the buried high-index contrast photonic crystal layer into the laser heterostructure. The angle-resolved electroluminescence analysis demonstrated a well resolved set of four sub bands corresponding to the Γ2 point of the square photonic lattice. The PCSEL emission line was aligned to the low energy side of the photonic crystal bandgap. The device far field pattern was controlled by filamentation. Filament spacing of about 15–20 µm was observed in the near fields. We speculate that limited 2D feedback associated with a low area fill factor for the buried air-pockets and laterally inhomogeneous regrowth promote filament formation and reduce the coherence of the beam emitted from the surface.

Author Contributions

Conceptualization, L.S.; methodology, R.L., L.S., A.S., G.K., D.Z. and K.K.; validation, R.L. and G.K.; formal analysis, R.L.; investigation, R.L., L.S. and G.K.; resources, G.L.B.; data curation, R.L.; writing—original draft, R.L.; writing—review & editing, L.S.; visualization, D.Z.; supervision, L.S.; funding acquisition, L.S. and G.L.B. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the US Army Research Office (US ARO) (W911NF2210068).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Acknowledgments

This work was supported in part by the U.S. Department of Energy, Office of Basic Energy Sciences, through the Center for Functional Nanomaterials, Brookhaven National Laboratory, under Contract DE-SC0012704.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Shterengas, L.; Kipshidze, G.; Hosoda, T.; Liang, R.; Feng, T.; Wang, M.; Stein, A.; Belenky, G. Cascade pumping of 1.9-3.3 μm type-I quantum well GaSb-based diode lasers. IEEE J. Sel. Top. Quantum Electron. 2017, 23, 16921011. [Google Scholar] [CrossRef]

- Belenky, G.; Shterengas, L.; Kipshidze, G.; Hosoda, T. Type-I diode lasers for spectral region above 3 µm. IEEE J. Sel. Top. Quantum Electron. 2011, 17, 1426. [Google Scholar] [CrossRef]

- Hosoda, T.; Feng, T.; Shterengas, L.; Kipshidze, G.; Belenky, G. High power cascade diode lasers emitting near 2 μm. Appl. Phys. Lett. 2016, 108, 131109. [Google Scholar] [CrossRef]

- Shterengas, L.; Liang, R.; Kipshidze, G.; Hosoda, T.; Belenky, G.; Bowman, S.S.; Tober, R.L. Cascade type-I quantum well diode lasers emitting 960 mW near 3 μm. Appl. Phys. Lett. 2014, 105, 161112. [Google Scholar] [CrossRef]

- Mehuys, D.; Lang, R.; Mittelstein, M.; Salzman, J.; Yariv, A. Self-stabilized nonlinear lateral modes of broad area lasers. IEEE J. Quantum Electron. 1987, 23, 1909–1920. [Google Scholar] [CrossRef]

- Shterengas, L.; Belenky, G.L.; Kim, J.G.; Martinelli, R.U. Measurements of α-factor in 2–2.5 µm type-I In (Al)GaAsSb/GaSb high power diode lasers. Appl. Phys. Lett. 2002, 81, 4517. [Google Scholar] [CrossRef]

- Larsson, A.; Salzman, J.; Mittelstein, M.; Yariv, A. Lateral coherence properties of broad-area semiconductor quantum well lasers. J. Appl. Phys. 1986, 60, 66–68. [Google Scholar] [CrossRef]

- Hirose, K.; Liang, Y.; Kurosaka, Y.; Watanabe, A.; Sugiyama, T.; Noda, S. Watt-class high-power high-beam-quality photonic-crystal lasers. Nat. Phot. 2014, 8, 406. [Google Scholar] [CrossRef]

- Yoshida, M.; De Zoysa, M.; Ishizaki, K.; Tanaka, Y.; Kawasaki, M.; Hatsuda, R.; Song, B.; Gelleta, J.; Noda, S. Double-lattice photonic-crystal resonators enabling high-brightness semiconductor lasers with symmetric narrow-divergence beams. Nat. Mater. 2019, 18, 121–128. [Google Scholar] [CrossRef] [PubMed]

- Yoshida, M.; De Zoysa, M.; Ishizaki, K.; Kunishi, W.; Inoue, T.; Izumi, K.; Hatsuda, R.; Noda, S. Photonic-crystal lasers with high-quality narrow-divergence symmetric beams and their application to LiDAR. J. Phys. Photon 2021, 3, 022006. [Google Scholar] [CrossRef]

- Nishimoto, M.; Ishizaki, K.; Maekawa, K.; Kitamura, K.; Noda, S. Air-hole retained growth by molecular beam epitaxy for fabricating GaAs-based photonic-crystal lasers. Appl. Phys. Exp. 2013, 6, 042002. [Google Scholar] [CrossRef]

- Shterengas, L.; Liu, R.; Kipshidze, G.; Stein, A.; Lee, W.; Hosoda, T.; Zakharov, D.N.; Kisslinger, K.; Belenky, G. Electrically pumped epitaxially regrown GaSb-Based type-I quantum-well surface-emitting lasers with buried high-index-contrast photonic crystal layer. Phys. Status Solidi (RRL) Rapid Res. Lett. 2022, 16, 2100425. [Google Scholar] [CrossRef]

- Lee, W.; Shterengas, L.; Hosoda, T.; Jiang, J.; Kipshidze, G.; Belenky, G. Comparison of the thermal and atomic hydrogen assisted oxide desorption methods for regrowth of the GaSb-based cascade diode lasers. J. Electron. Meter. 2021, 50, 5522. [Google Scholar] [CrossRef]

- Liu, R.; Shterengas, L.; Stein, A.; Kipshidze, G.; Jiang, J.; Hosoda, T.; Belenky, G. GaSb-based heterostructure with buried vacuum pocket photonic crystal layer. IET Electron. Lett. 2020, 56, 388. [Google Scholar] [CrossRef]

- Chen, J.; Donetsky, D.; Shterengas, L.; Kisin, M.; Kipshidze, G.; Belenky, G. Effect of Quantum Well Compressive Strain Above 1% On Differential Gain and Threshold Current Density in Type-I GaSb-Based Diode Lasers. IEEE J. Quantum Electron. 2008, 44, 1204. [Google Scholar] [CrossRef][Green Version]

- Rehm, R.; Walther, M.; Fuchs, F.; Schmitz, J.; Fleissner, J. Passivation of InAs/GaInSb short-period superlattice photodiodes with 10 µm cutoff wavelength by epitaxial overgrowth with AlxGa1−xAsySb1−y. Appl. Phys. Lett. 2005, 86, 173501. [Google Scholar] [CrossRef]

- Sakai, K.; Miyai, E.; Noda, S. Coupled-wave model for square-lattice two-dimensional photonic crystal with transverse-electric-like mode. Appl. Phys. Lett. 2006, 89, 021101. [Google Scholar] [CrossRef]

- Hong, K.; Chen, L.; Huang, K.; Yen, H.; Weng, W.; Chuang, B.; Lu, T. Impact of Air-Hole on the Optical Performances of Epitaxially Regrown P-Side Up Photonic Crystal Surface-Emitting Lasers. IEEE J. Select. Top. Quantum Electron. 2022, 28, 1. [Google Scholar] [CrossRef]

- Liang, Y.; Peng, C.; Sakai, K.; Iwahashi, S.; Noda, S. Three-dimensional coupled-wave model for square-lattice photonic crystal lasers with transverse electric polarization: A general approach. Phys. Rev. B 2011, 84, 195119. [Google Scholar] [CrossRef]

- Yamanaka, T.; Yoshikuni, Y.; Yokoyama, K.; Lui, W.; Seki, S. Theoretical study on enhanced differential gain and extremely reduced linewidth enhancement factor in quantum-well lasers. IEEE J. Quantum Electron. 1993, 29, 1609–1616. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).