Design of a Fiber Alkali Vapor Cell for Atomic Magnetometer for Magnetoencephalography Applications

Abstract

1. Introduction

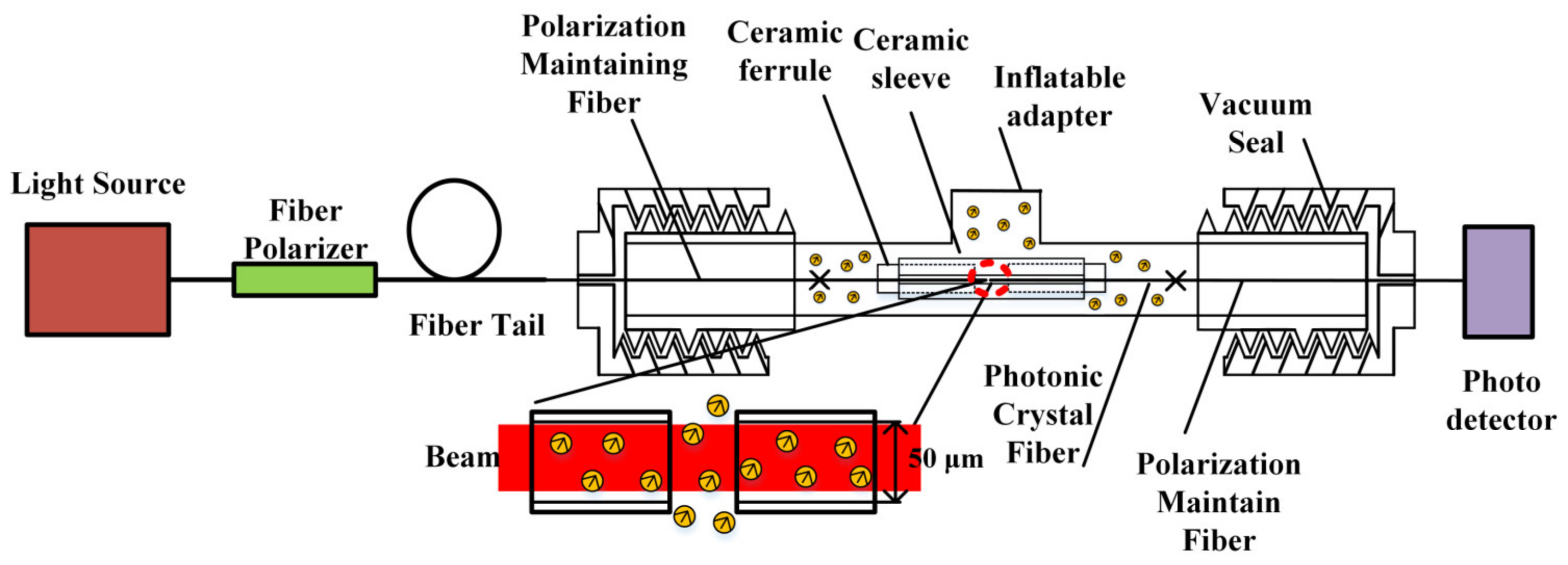

2. Theory Model and Fabrication of Fiber Atomic Vapor

3. The Characteristics of Fiber Cell

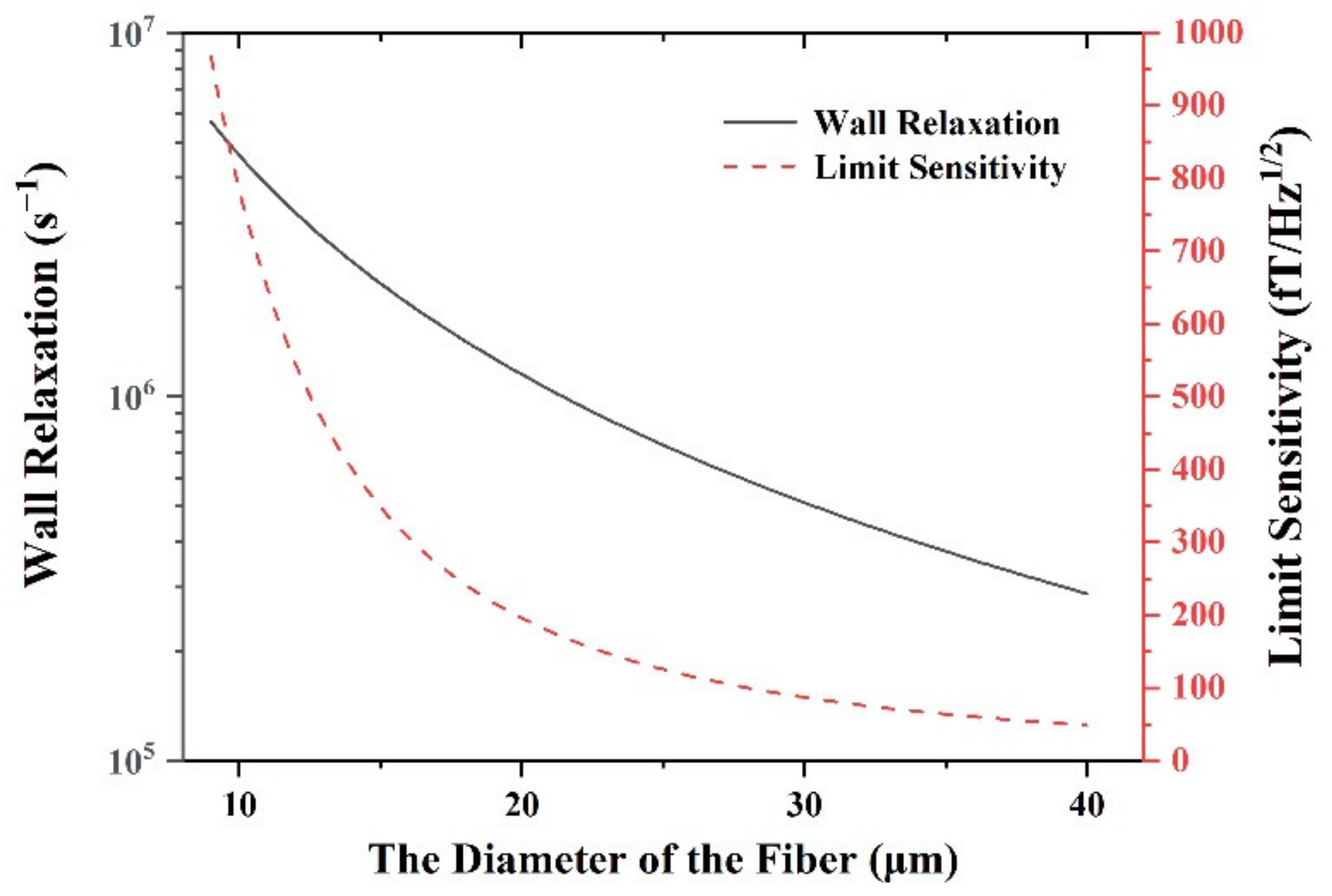

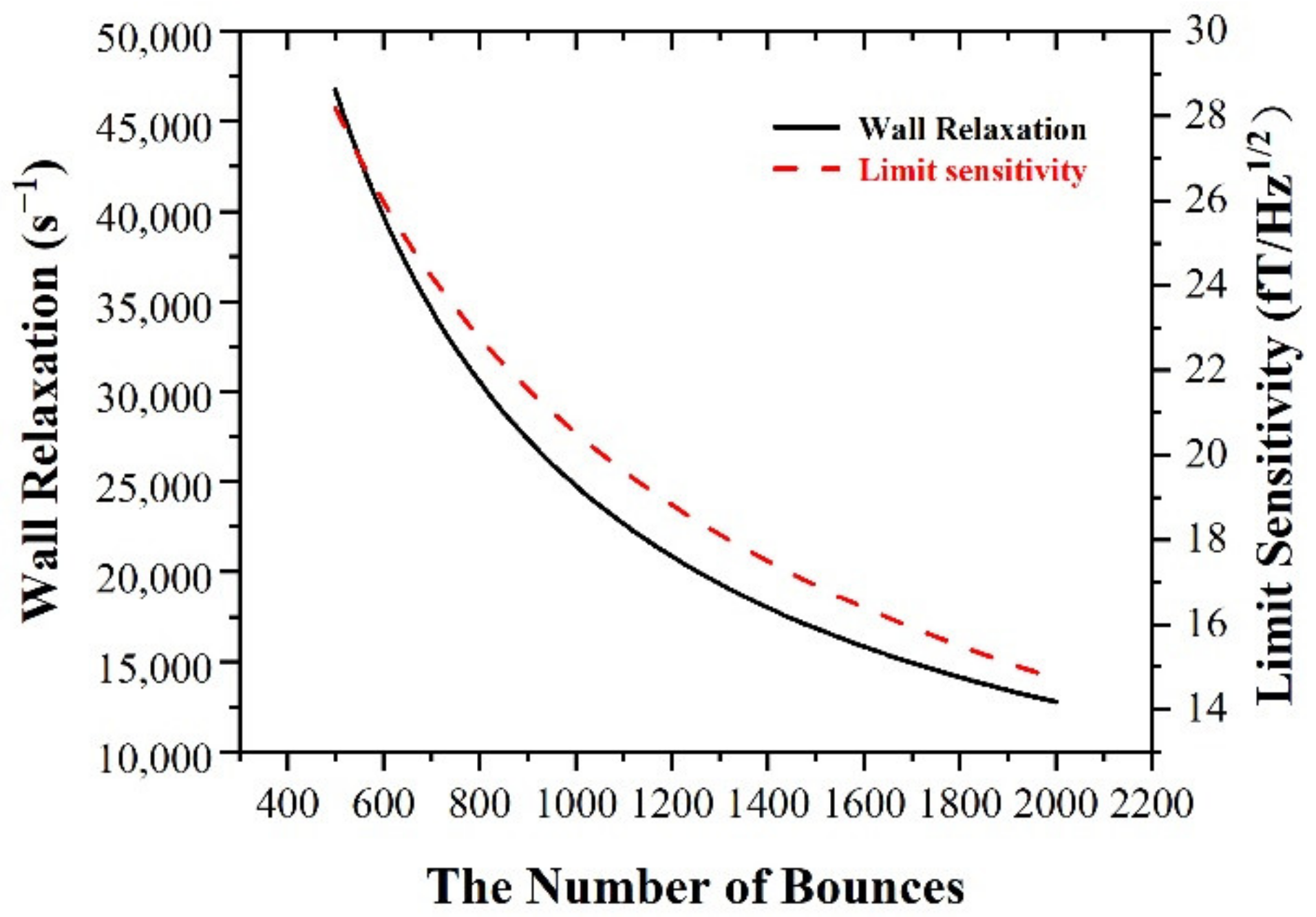

3.1. Relaxation of the Fiber Cell

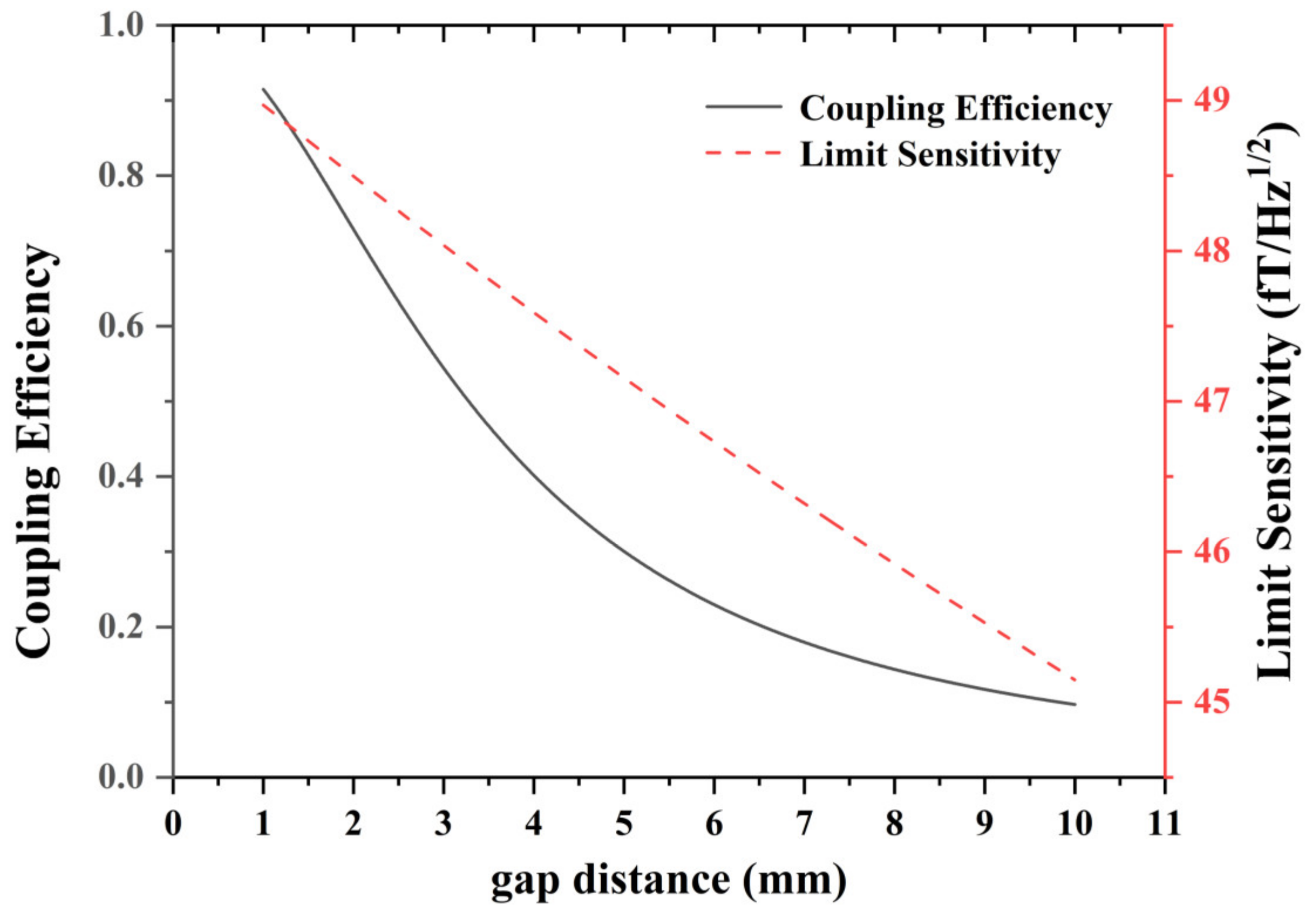

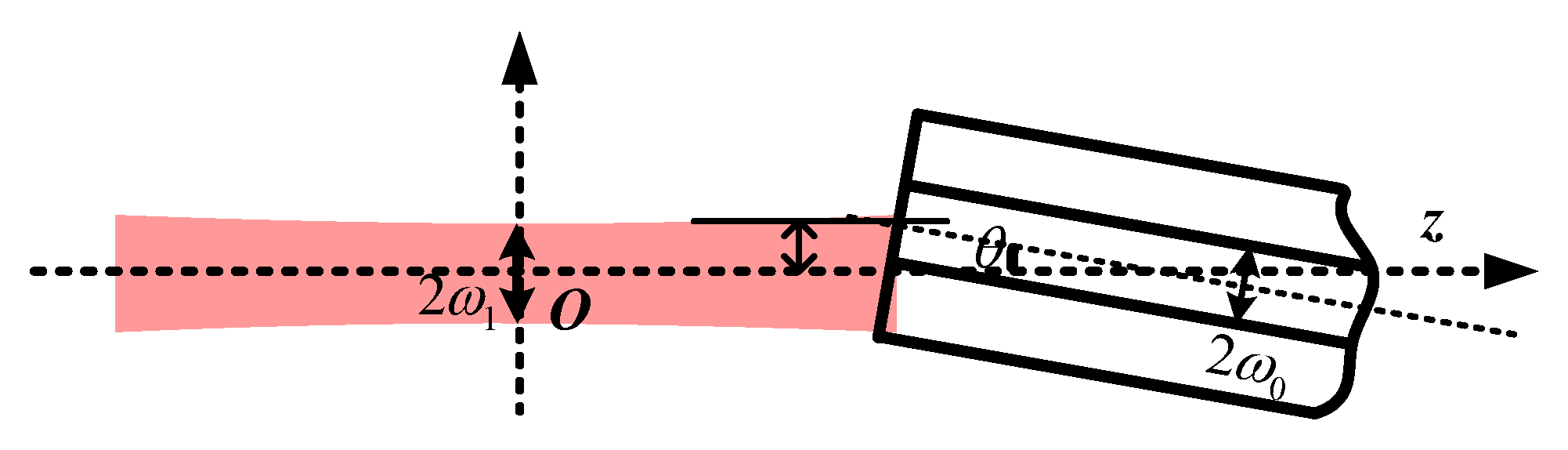

3.2. Light Loss of the Fiber Cell

3.3. The Coating of the Fiber Cell

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Syrjl, J.; Basti, A.; Guidotti, R.; Marzetti, L.; Pizzella, V. Decoding working memory task condition using magnetoencephalography source level long-range phase coupling patterns. J. Neural. Eng. 2021, 18, 016027. [Google Scholar] [CrossRef] [PubMed]

- Falet, J.P.R.; Cté, J.; Tarka, V.; Martinez-Moreno, Z.E.; Voss, P.; Villers-Sidani, E.D. Mapping the human auditory cortex using spectrotemporal receptive fields generated with magnetoencephalography. NeuroImage 2021, 238, 118222. [Google Scholar] [CrossRef] [PubMed]

- Kim, K.; Begus, S.; Xia, H.; Lee, S.K.; Jazbinsek, V.; Trontelj, Z.; Romalis, M.V. Multi-Channel Atomic Magnetometer for Magnetoencephalography: A Configuration Study. NeuroImage 2014, 89, 143. [Google Scholar] [CrossRef] [PubMed]

- Vennemann, T.; Jeong, M.; Yoon, D.; Magrez, A.; Berger, H.; Yang, L.; Živković, I.; Babkevich, P.; Rønnow, H.M. Note: Commercial SQUID Magnetometer-Compatible NMR Probe and its Application for Studying a Quantum Magnet. Rev. Sci. Instrum. 2018, 89, 46101. [Google Scholar] [CrossRef]

- Dang, H.B.; Maloof, A.C.; Romalis, M.V. Ultra-high sensitivity magnetic field and magnetization measurements with an atomic magnetometer. Appl. Phys. Lett. 2010, 97, 227. [Google Scholar] [CrossRef]

- Shah, V.; Romalis, M.V. Spin-Exchange-Relaxation-Free Magnetometry Using Elliptically-Polarized Light. Phys. Rev. A 2009, 80, 13416. [Google Scholar] [CrossRef]

- Kitching, J. Chip-scale atomic devices. Appl. Phys. Rev. 2018, 5, 031302. [Google Scholar] [CrossRef]

- Wang, X.; Ye, M.; Lu, F.; Mao, Y.; Tian, H.; Li, J. Recent Progress on Micro-Fabricated Alkali Metal Vapor Cells. Biosensors 2022, 12, 165. [Google Scholar] [CrossRef]

- Hu, J.; Lu, J.; Liang, Z.; Liu, L.; Wang, W.; Zhou, P.; Ye, M. Integrated Polarization-Splitting Grating Coupler for Chip-Scale Atomic Magnetometer. Biosensors 2022, 12, 529. [Google Scholar] [CrossRef]

- Mhaskar, R.; Svenja, K.; John, K. A low-power, high-sensitivity micromachined optical magnetometer. Appl. Phys. Lett. 2012, 101, 241105. [Google Scholar] [CrossRef]

- Osborne, J.; Orton, J.; Alem, O.; Shah, V. Fully integrated standalone zero field optically pumped magnetometer for biomagnetism. In Proceedings of the Steep Dispersion Engineering and Opto-Atomic Precision Metrology XI, San Francisco, CA, USA, 29 January–1 February 2018; p. 210548. [Google Scholar] [CrossRef]

- Liu, X.; Yang, Y.; Ding, M.; Quan, W.; Hu, Y.; Li, Y.; Jin, W.; Fang, J. Single-fiber Sagnac Interferometer for Atomic Spin Precession Detection. J. Lightwave Technol. 2019, 37, 1317. [Google Scholar] [CrossRef]

- Tian, Y.; Wang, Z.; Wang, L. Hollow fibers: From fabrication to applications. Chem. Commun. 2021, 57, 9166–9177. [Google Scholar] [CrossRef]

- Ritter, R.; Gruhler, N.; Pernice, W.; Kübler, H.; Pfau, T.; Löw, R. Atomic vapor spectroscopy in integrated photonic structures. Appl. Phys. Lett. 2015, 107, 041101. [Google Scholar] [CrossRef]

- Epple, G.; Joly, N.Y.; Euser, T.G.; Russell, P.S.J.; Loew, R. Effect of stray fields on Rydberg states in hollow-core PCF probed by higher-order modes. Opt. Lett. 2017, 42, 3271. [Google Scholar] [CrossRef]

- Veit, C.; Epple, G.; Kübler, H.; Euser, T.G.; Russell, P.S.J.; Löw, R. RF-dressed Rydberg atoms in hollow-core fibres. J. Phys. B 2016, 49, 134005. [Google Scholar] [CrossRef]

- Donvalkar, P.S.; Ramelow, S.; Clemmen, S.; Gaeta, A.L. Continuous generation of rubidium vapor in hollow-core photonic bandgap fibers. Opt. Lett. 2015, 40, 5379. [Google Scholar] [CrossRef]

- Slepkov, A.D.; Bhagwat, A.R.; Venkataraman, V.; Londero, P.; Gaeta, A.L. Generation of large alkali vapor densities inside bare hollow-core photonic band-gap fibers. Opt. Express 2008, 16, 18976. [Google Scholar] [CrossRef]

- Vogl, U.; Peuntinger, C.; Joly, N.Y.; Russell, P.S.J.; Marquardt, C.; Leuchs, G. Atomic mercury vapor inside a hollow-core photonic crystal fiber. Opt. Express 2014, 22, 29375. [Google Scholar] [CrossRef]

- Kaczmarek, K.T.; Saunders, D.J.; Sprague, M.R.; Kolthammer, W.S.; Feizpour, A.; Ledingham, P.M.; Brecht, B.; Poem, E.; Walmsley, I.A.; Nunn, J. Ultrahigh and persistent optical depths of cesium in Kagomé-type hollow-core photonic crystal fibers. Opt. Lett. 2015, 40, 5582. [Google Scholar] [CrossRef]

- Gutekunst, J.; Weller, D.; Kübler, H.; Negel, J.; Ahmed, M.A.; Graf, T.; Löw, R. Fiber-integrated spectroscopy device for hot alkali vapor. Appl. Opt. 2017, 56, 5898. [Google Scholar] [CrossRef]

- Kamra, A.; Ghosh, B.; Ghosh, T.K. Spin Relaxation due to Electron–Electron Magnetic Interaction in High Lande g-Factor Semiconductors. J. Appl. Phys. 2010, 108, 54505. [Google Scholar] [CrossRef]

- Budker, D.; Romalis, M. Optical magnetometry. Nat. Phys. 2007, 3, 227–234. [Google Scholar] [CrossRef]

- Sander, T.H.; Preusser, J.; Mhaskar, R.; Kitching, J.; Trahms, L.; Knappe, S. Magnetoencephalography with a chip-scale atomic magnetometer. Biomed. Opt. Express 2012, 3, 981–990. [Google Scholar] [CrossRef]

- Seltzer, S.J. Developments in Alkali-Metal Atomic Magnetometry. Ph.D. Thesis, Princeton University, Princeton, NJ, USA, 2008. [Google Scholar]

- Seltzer, S.J.; Romalis, M.V. High-temperature alkali vapor cells with antirelaxation surface coatings. J. Appl. Phys. 2009, 106, 114905. [Google Scholar] [CrossRef]

- Rampulla, D.M.; Oncel, N.; Abelev, E.; Yi, Y.W.; Knappe, S.; Bernasek, S.L. Effects of organic film morphology on the formation of Rb clusters on surface coatings in alkali metal vapor cells. Appl. Phys. Lett. 2009, 94, 103116. [Google Scholar] [CrossRef]

- Rosen, M.S.; Chupp, T.E.; Coulter, K.P.; Welsh, R.C.; Swanson, S.D. Polarized 129Xe optical pumping/spin exchange and delivery system for magnetic resonance spectroscopy and imaging studies. Rev. Sci. Instrum. 1999, 70, 1546–1552. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, X.; Hu, Y.; Li, Y.; Wu, X.; Chang, M.; Zhang, X. Design of a Fiber Alkali Vapor Cell for Atomic Magnetometer for Magnetoencephalography Applications. Photonics 2022, 9, 749. https://doi.org/10.3390/photonics9100749

Liu X, Hu Y, Li Y, Wu X, Chang M, Zhang X. Design of a Fiber Alkali Vapor Cell for Atomic Magnetometer for Magnetoencephalography Applications. Photonics. 2022; 9(10):749. https://doi.org/10.3390/photonics9100749

Chicago/Turabian StyleLiu, Xuejing, Yanhui Hu, Yang Li, Xudong Wu, Min Chang, and Xuedian Zhang. 2022. "Design of a Fiber Alkali Vapor Cell for Atomic Magnetometer for Magnetoencephalography Applications" Photonics 9, no. 10: 749. https://doi.org/10.3390/photonics9100749

APA StyleLiu, X., Hu, Y., Li, Y., Wu, X., Chang, M., & Zhang, X. (2022). Design of a Fiber Alkali Vapor Cell for Atomic Magnetometer for Magnetoencephalography Applications. Photonics, 9(10), 749. https://doi.org/10.3390/photonics9100749