Thermal Noise in Cubic Optical Cavities

Abstract

1. Introduction

2. Theoretical Framework

3. Estimation Calculation and Simulation

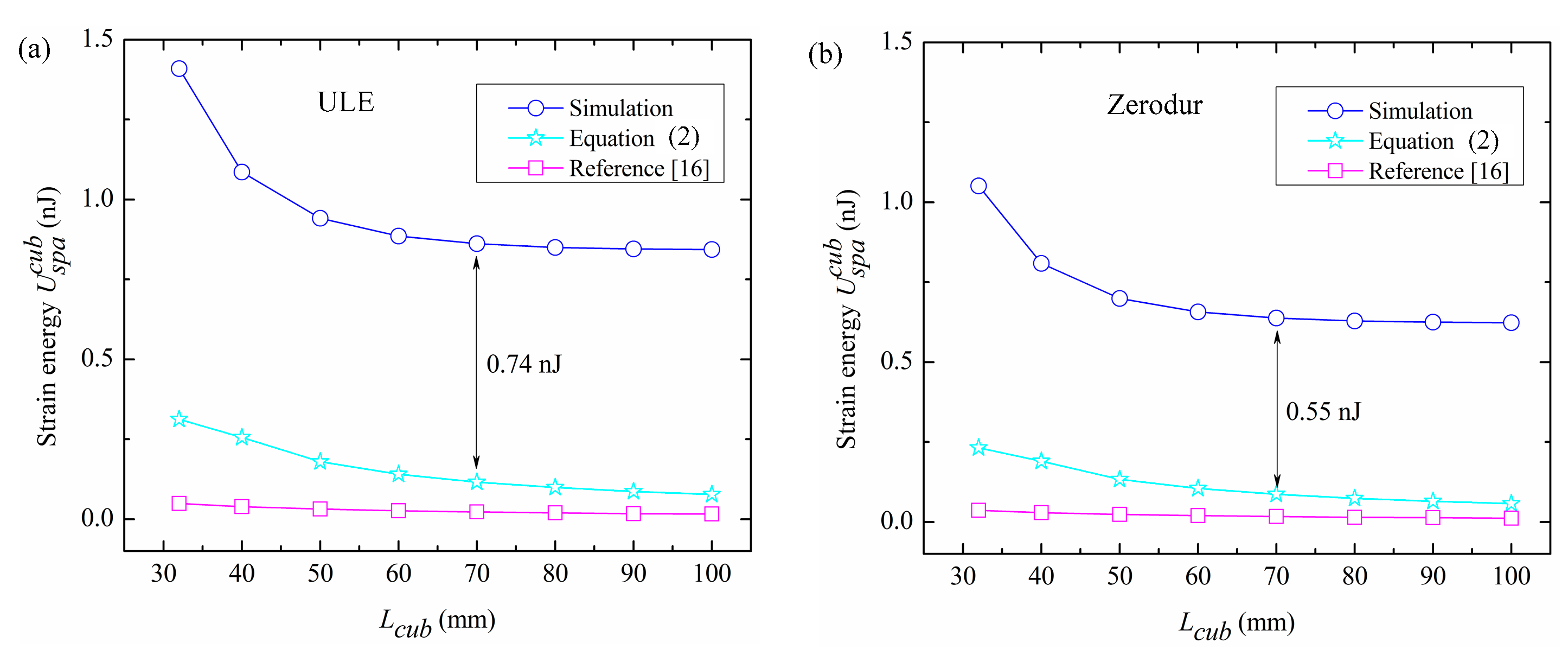

3.1. Comparison of Estimation and Simulation

3.2. The Effect of Cavity Dimensions on Elastic Energy

3.2.1. Room Temperature Materials

3.2.2. Low-Temperature Materials

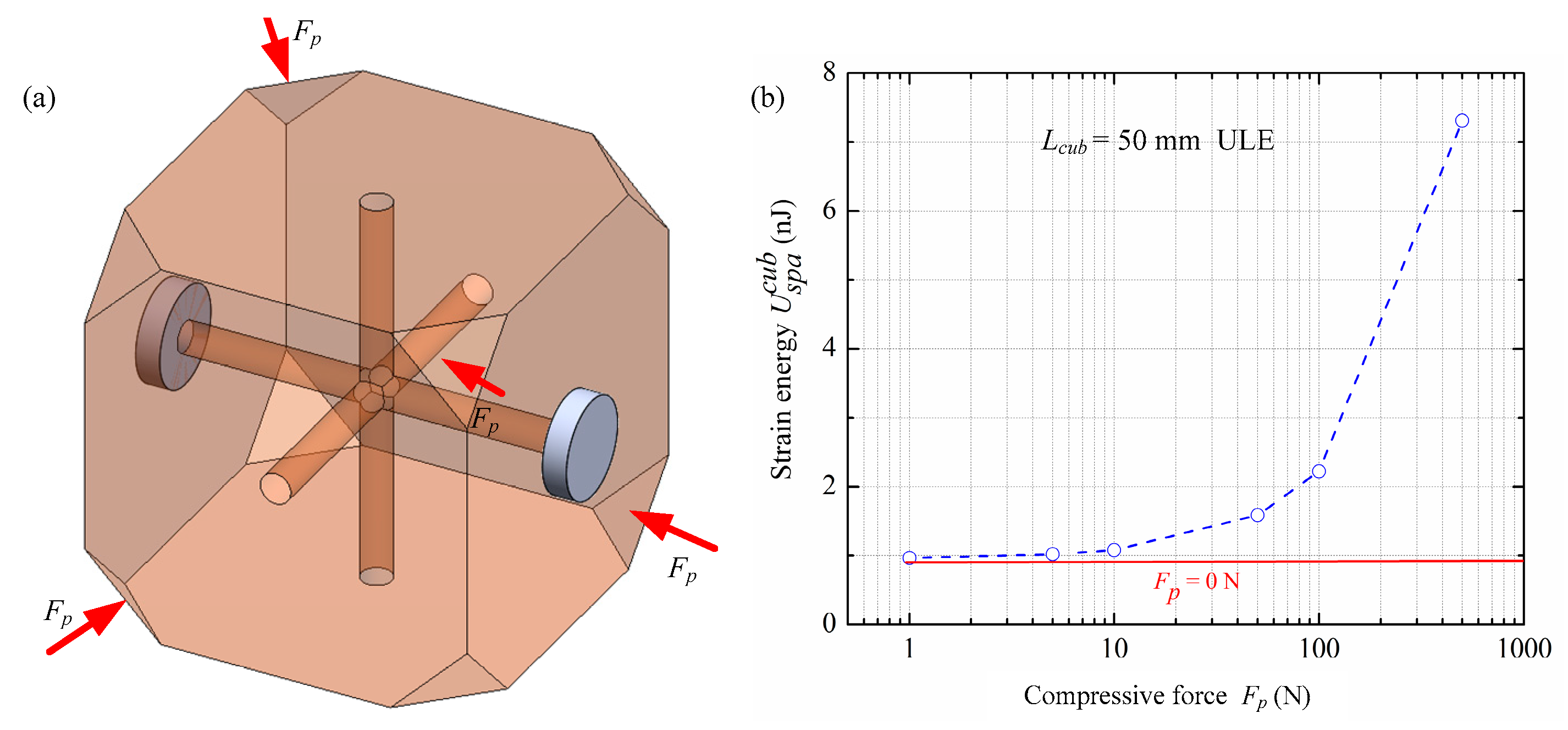

3.3. The Effect of Compressive Force on Elastic Energy

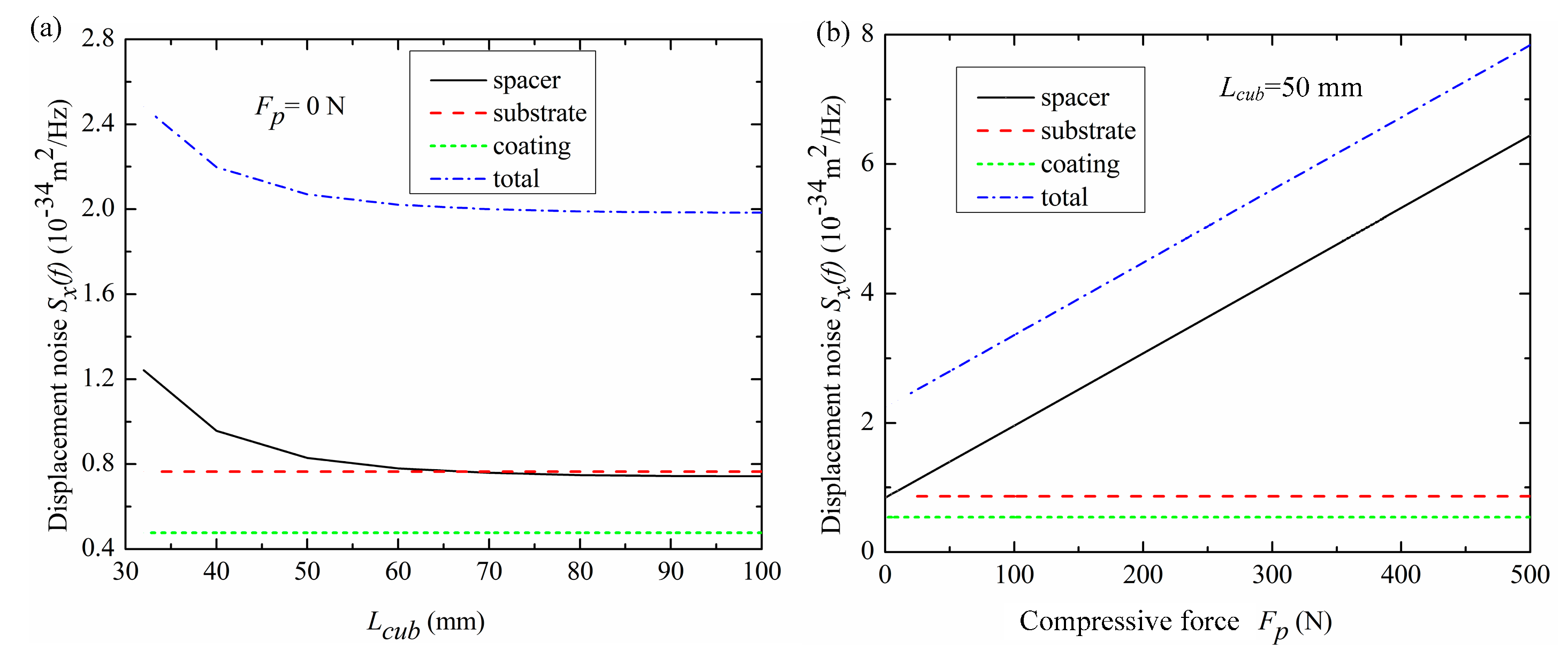

4. Mixed Material Cavities

5. Discussions and Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Katori, H. Optical lattice clocks and quantum metrology. Nat. Photonics 2011, 5, 203–210. [Google Scholar] [CrossRef]

- Swallows, M.D.; Bishof, M.; Lin, Y.; Blatt, S.; Martin, M.J.; Rey, A.M.; Ye, J. Suppression of collisional shifts in a strongly interacting lattice clock. Science 2011, 331, 1043–1046. [Google Scholar] [CrossRef] [PubMed]

- Huntemann, N.; Okhapkin, M.; Lipphardt, B.; Weyers, S.; Tamm, C.; Peik, E. High-accuracy optical clock based on the octupole transition in 171Yb+. Phys. Rev. Lett. 2012, 108, 090801. [Google Scholar] [CrossRef]

- Sherman, J.; Lemke, N.; Hinkley, N.; Pizzocaro, M.; Fox, R.; Ludlow, A.; Oates, C. High-accuracy measurement of atomic polarizability in an optical lattice clock. Phys. Rev. Lett. 2012, 108, 153002. [Google Scholar] [CrossRef]

- McFerran, J.J.; Yi, L.; Mejri, S.; Di Manno, S.; Zhang, W.; Guéna, J.; Le Coq, Y.; Bize, S. Neutral atom frequency reference in the deep ultraviolet with fractional uncertainty = 5.7 × 10−15. Phys. Rev. Lett. 2012, 108, 183004. [Google Scholar] [CrossRef]

- Herrmann, S.; Senger, A.; Mohle, K.; Nagel, M.; Kovalchuk, E.; Peters, A. Rotating optical cavity experiment testing Lorentz invariance at the 10−17 level. Phys. Rev. D 2009, 80, 105011. [Google Scholar] [CrossRef]

- Kennedy, C.; Oelker, E.; Robinson, J.M.; Bothwell, T.; Kedar, D.; Milner, W.; Marti, E.; Derevianko, A.; Ye, J. Precision metrology meets cosmology: Improved constraints on ultralight dark matter from atom-cavity frequency comparisons. Phys. Rev. Lett. 2020, 125, 201302. [Google Scholar] [CrossRef] [PubMed]

- Chou, C.W.; Hume, D.B.; Rosenband, T.; Wineland, D.J. Optical clocks and relativity. Science 2010, 329, 1630–1633. [Google Scholar] [CrossRef] [PubMed]

- Jiang, H.; Kéfélian, F.; Crane, S.; Lopez, O.; Lours, M.; Millo, J.; Holleville, D.; Lemonde, P.; Chardonnet, C.; AmyKlein, A.; et al. Long-distance frequency transfer over an urban fiber link using optical phase stabilization. J. Opt. Soc. Am. B 2008, 25, 2029–2035. [Google Scholar] [CrossRef]

- Predehl, K.; Grosche, G.; Raupach, S.M.F.; Droste, S.; Terra, O.; Alnis, J.; Legero, T.; Hnsch, T.W.; Udem, T.; Holzwarth, R.; et al. A 920-kilometer optical fiber link for frequency metrology at the 19th decimal place. Science 2012, 336, 441–444. [Google Scholar] [CrossRef] [PubMed]

- Matei, D.G.; Legero, T.; Häfner, S.; Grebing, C.; Weyrich, R.; Zhang, W.; Sonderhouse, L.; Robinson, J.M.; Ye, J.; Riehle, F.; et al. 1.5 μm Lasers with Sub-10 mHz Linewidth. Phys. Rev. Lett. 2017, 118, 263202. [Google Scholar] [CrossRef] [PubMed]

- Robinson, J.M.; Oelker, E.; Milner, W.R.; Zhang, W.; Legero, T.; Matei, D.G.; Riehle, F.; Sterr, U.; Ye, J. Crystalline optical cavity at 4 K with thermal-noise limited instability and ultralow drift. Optica 2019, 6, 240–243. [Google Scholar] [CrossRef]

- Barger, R.L.; Sorem, M.S.; Hall, L.J. Frequency stabilization of a cw dye laser. Appl. Phys. Lett. 1973, 22, 573–575. [Google Scholar] [CrossRef]

- Drever, R.W.P.; Hall, J.L.; Kowalski, F.V.; Hough, J.; Ford, G.M.; Munley, A.J.; Ward, H. Laser phase and frequency stabilization using an optical resonator. Appl. Phys. B 1983, 22, 97–105. [Google Scholar] [CrossRef]

- Levin, Y. Internal thermal noise in the LIGO test masses: A direct approach. Phys. Rev. D 1998, 57, 110403. [Google Scholar] [CrossRef]

- Numata, K.; Kemery, A.; Camp, J. Thermal-noise limit in the frequency stabilization of lasers with rigid cavities. Phys. Rev. Lett. 2004, 93, 250602. [Google Scholar] [CrossRef] [PubMed]

- Kessler, T.; Legero, T.; Sterr, U. Thermal noise in optical cavities revisited. J. Opt. Soc. Am. B 2012, 29, 178. [Google Scholar] [CrossRef]

- Legero, T.; Kessler, T.; Sterr, U. Tuning the thermal expansion properties of optical reference cavities with fused silica mirrors. J. Opt. Soc. Am. B 2010, 27, 914. [Google Scholar] [CrossRef]

- Webster, S.A.; Gill, P. Low-thermal-noise optical cavity. In Proceedings of the 2010 IEEE International Frequency Control Symposium, Newport Beach, CA, USA, 1–4 June 2010; Volume 470. [Google Scholar]

- Zhang, J.; Luo, Y.; Ouyang, B.; Deng, K.; Lu, Z.; Luo, J. Design of an optical reference cavity with low thermal noise limit and flexible thermal expansion properties. Eur. Phys. J. D 2013, 67, 46. [Google Scholar] [CrossRef][Green Version]

- Cole, G.D.; Zhang, W.; Martin, M.J.; Ye, J.; Aspelmeyer, M. Tenfold reduction of Brownian noise in high-reflectivity optical coatings. Nat. Photonics 2013, 67, 46. [Google Scholar] [CrossRef]

- Bruckner, F.; Friedrich, D.; Clausnitzer, T.; Britzger, M.; Burmeister, O.; Danzmann, K.; Kley, E.B.; Tunnermann, A.; Schnabel, R. Realization of amonolithic high-reflectivity cavity mirror from a single silicon crystal. Phys. Rev. Lett. 2010, 104, 163903. [Google Scholar] [CrossRef]

- Xu, G.; Zhang, L.; Liu, J.; Gao, J.; Chen, L.; Dong, R.; Liu, T.; Zhang, S. Estimation of thermal noise for spindle optical reference cavities. Opt. Commun. 2016, 360, 61–67. [Google Scholar] [CrossRef]

- Robinson, J.M.; Oelker, E.; Milner, W.R.; Kedar, D.; Zhang, W.; Legero, T.; Matei, D.G.; Hafner, S.; Riehle, F.; Sterr, U.; et al. Thermal noise and mechanical loss of SiO2/Ta2O5 optical coatings at cryogenic temperatures. Opt. Lett. 2021, 46, 592–595. [Google Scholar] [CrossRef] [PubMed]

- Webster, S.; Gill, P. Force-insensitive optical cavity. Opt. Lett. 2011, 36, 3572. [Google Scholar] [CrossRef]

- Leibrandt, D.R.; Thorpe, M.J.; Notcutt, M.; Drullinger, R.E.; Rosenband, T.; Bergquist, J.C. Spherical reference cavities for frequency stabilization of lasers in non-laboratory environments. Opt. Express 2011, 19, 3471–3482. [Google Scholar] [CrossRef] [PubMed]

- Leibrandt, D.R.; Thorpe, M.J.; Bergquist, J.C.; Rosenband, T. Field-test of a robust, portable, frequency-stable laser. Opt. Express 2011, 19, 10278–10286. [Google Scholar] [CrossRef]

- Vogt, S.; Lisdat, C.; Legero, T.; Sterr, U.; Ernsting, I.; Nevsky, A.; Schiller, S. Demonstration of a transportable 1 Hz-linewidth laser. Appl. Phys. B 2011, 104, 741. [Google Scholar] [CrossRef]

- Argence, B.; Argence, B.; Prevost, E.; Lévèque, T.; Le Goff, R.; Bize, S.; Lemonde, P.; Santarelli, G. Prototype of an ultra-stable optical cavity for space applications. Opt. Express 2012, 20, 25409–25420. [Google Scholar] [CrossRef]

- Leibrandt, D.R.; Bergquist, J.C.; Rosenband, T. Cavity-stabilized laser with acceleration sensitivity below 10−12 g−1. Phys. Rev. A 2013, 87, 023829. [Google Scholar] [CrossRef]

- Chen, Q.; Nevsky, A.; Cardace, M.; Schiller, S.; Legero, T.; Häfner, S.; Uhde, A.; Sterr, U. A compact, robust, and transportable ultra-stable laser with a fractional frequency instability of 1 × 10−15. Rev. Sci. Instrum. 2014, 85, 113107. [Google Scholar] [CrossRef] [PubMed]

- Świerad, D.; Häfner, S.; Vogt, S.; Venon, B.; Holleville, D.; Bize, S.; Kulosa, A.; Bode, S.; Singh, Y.; Bongs, K.; et al. Ultra-stable clock laser system development towards space applications. Sci. Rep. 2016, 6, 33973. [Google Scholar] [CrossRef] [PubMed]

- Koller, S.B.; Grotti, J.; Vogt, S.; Al-Masoudi, A.; Dörscher, S.; Häfner, S.; Sterr, U.; Lisdat, C. Transportable Optical Lattice Clock with 7 × 10−17 Uncertainty. Phys. Rev. Lett. 2017, 187, 073601. [Google Scholar] [CrossRef]

- Cao, J.; Zhang, P.; Shang, J.; Cui, K.; Yuan, J.; Chao, S.; Wang, S.; Shu, H.; Huang, X. A compact, transportable single-ion optical clock with 7.8 × 10−17 systematic uncertainty. Appl. Phys. B 2017, 123, 112. [Google Scholar] [CrossRef]

- SOC2-Towards Neutral-Atom Space Optical Clocks. Available online: http://www.exphy.uni-duesseldorf.de/optical_clock/soc2/index.php (accessed on 5 July 2021).

- LISA-Laser Interferometer Space Antenna-NASA Home Page. Available online: https://lisa.nasa.gov/index.html (accessed on 5 July 2021).

- Luo, J.; Sheng, L.; Duan, H.; Gong, Y.; Hu, S.; Ji, J.; Liu, Q.; Mei, J.; Milyukov, V.; Sazhin, M.; et al. TianQin: A space-borne gravitational wave detector. Class. Quantum Grav. 2016, 33, 035010. [Google Scholar] [CrossRef]

- Tao, B.; Chen, Q. A vibration-sensitive-cavity design holds impact of higher than 100g. Appl. Phys. B 2018, 124, 228. [Google Scholar] [CrossRef]

- Hafiz, M.A.; Ablewski, P.; Masoudi, A.A.; Martínez, H.Á.; Balling, P.; Barwood, G.; Benkler, E.; Bober, M.; Borkowski, M.; Bowden, W.; et al. Guidelines for developing optical clocks with 10–18 fractional frequency uncertainty. arXiv 2019, arXiv:1906.11495. [Google Scholar]

- Chen, X.; Jiang, Y.; Li, B.; Yu, H.; Jiang, H.; Wang, T.; Yao, Y.; Ma, L. Laser frequency instability of 6 × 10−16 using 10-cm-long cavities on a cubic spacer. Chin. Opt. Lett. 2020, 18, 030201. [Google Scholar] [CrossRef]

- Wang, S.; Cao, J.; Yuan, J.; Liu, D.; Shu, H.; Huang, X. Integrated multiple wavelength stabilization on a multi-channel cavity for a transportable optical clock. Opt. Express 2020, 28, 11852–11860. [Google Scholar] [CrossRef] [PubMed]

- Cerdonio, M.; Conti, L.; Heidmann, A.; Pinard, M. Thermoelastic effects at low temperatures and quantum limits in displacement measurements. Phys. Rev. D 2001, 63, 082003. [Google Scholar] [CrossRef]

- Jiang, H. Development of Ultra-Stable Laser Sources and Long-Distance Optical Link via Telecommunication Networks. Ph.D. Thesis, University Pairs, Pairs, France, 2010. [Google Scholar]

| Parameters | dsub (mm) | rmirror (mm) | rvent (mm) | rspa (mm) | lcub (mm) | kB |

|---|---|---|---|---|---|---|

| Value | 6.3 | 12.7 | 3 | 7 | 16.4 | 1.381 × 10−23 J/K |

| Material Properties | ULE [18] | FS [1,2,3,4,5,6,7,8] | Silica <111> [14] | Zerodur [21] | Sapphire [42] | SiO2/Ta2O5 [21] | GaAs/Al GaAs [21] |

|---|---|---|---|---|---|---|---|

| Elastic modulus (GPa) | 67.6 | 73 | 187.5 | 91 | 400 | 91 | 100 |

| Poisson ratio | 0.17 | 0.16 | 0.23 | 0.24 | 0.29 | 0.19 | 0.32 |

| Loss angle | 1.67 × 10−5 | 10−6 | 10−7 | 3 × 10−4 | 3 × 10−9 | 4 × 10−4 | 2.5 × 10−5 |

| Material | Elastic Strain Energy of Spacer (nJ) | |||

|---|---|---|---|---|

| Spacer | Substrate | Estimation | FEA | |

| Equation (2) | Reference [16] | |||

| ULE | ULE | 0.18 | 0.06 | 0.94 |

| ULE | ULE | 0.18 | 0.06 | 0.93 |

| Zerodur | Zerodur | 0.14 | 0.04 | 0.69 |

| Zerodur | Zerodur | 0.14 | 0.04 | 0.74 |

| Silica | Silica | 0.07 | 0.02 | 0.34 |

| Sapphire | Sapphire | 0.03 | 0.01 | 0.16 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, G.; Jiao, D.; Chen, L.; Zhang, L.; Dong, R.; Liu, T.; Wang, J. Thermal Noise in Cubic Optical Cavities. Photonics 2021, 8, 261. https://doi.org/10.3390/photonics8070261

Xu G, Jiao D, Chen L, Zhang L, Dong R, Liu T, Wang J. Thermal Noise in Cubic Optical Cavities. Photonics. 2021; 8(7):261. https://doi.org/10.3390/photonics8070261

Chicago/Turabian StyleXu, Guanjun, Dongdong Jiao, Long Chen, Linbo Zhang, Ruifang Dong, Tao Liu, and Junbiao Wang. 2021. "Thermal Noise in Cubic Optical Cavities" Photonics 8, no. 7: 261. https://doi.org/10.3390/photonics8070261

APA StyleXu, G., Jiao, D., Chen, L., Zhang, L., Dong, R., Liu, T., & Wang, J. (2021). Thermal Noise in Cubic Optical Cavities. Photonics, 8(7), 261. https://doi.org/10.3390/photonics8070261