1. Introduction

There has been a demand of methods and technologies for non-contact and high-resolution shape measurement of three-dimensional (3D) objects, which is expected to have applications in in-situ industrial inspection of manufactured parts, target recognition, corrosion analysis, measurement of surface roughness, and biomedical applications such as 3D intra-oral dental measurements and non-invasive 3D imaging and monitoring of vascular wall deformations [

1,

2]. 3D surface measurement using the structured light techniques [

3,

4,

5] has been attracting increasing attention in the field of optical profilometry and related applications. As indicated in recent review articles [

2,

6], one of the challenging issues in this field is still the development of new fringe-projection technology and hardware, for improving the accuracy, resolution, and speed of a 3D-shape imaging system.

In the diagram of a typical system with structured light, there are two basic parts: one part is the projector for generating structured illuminating patterns onto the observed object, and the other part is a camera for measuring distorted structured patterns on the target, while the projection of structured light patterns has been considered as the critically important part. For generating the structured signal of projecting light, there have been some useful and successful approaches [

7], such as the interferometry with monochromatic light [

8,

9,

10,

11], projection using grating with white light [

12], the acousto-optic fringe projection [

13,

14,

15], the encoded projection techniques [

16], the approach with a sinusoidal phase grating [

17], and the DMD-chip-based digital-light-processing (DLP) projector [

1,

2,

18]. However, the structured optical signal generated using interferometry is very sensitive to vibrations from environmental influences including the structural vibration of the system and the air disturbance, which can weaken the temporal coherence, and yield low-contrast sinusoidal signal since it is difficult to adjust the spatial frequency and obtain a high-spatial-frequency signal. For the method using white-light grating, it usually uses Ronchi grating for which it is difficult to obtain the sinusoidal structured signal. Note that the white-light grating method is basically unable to complete a dynamic and real-time measurement with adjustable spatial frequencies. The higher spatial frequency can be obtained using the acousto-optic approach, but the generating system is complicated compared to others. Noises are possibly introduced when the encoded projection is used in profilometry. The spatial frequency of the sinusoidal structured signal generated by a DLP projector is usually lower, while the illuminating area is also relatively limited.

Even sinusoidal patterns generated with a DLP projector are widely used, it does have its limitations such as the requirement of precise synchronization, speed limit of measurement, and the nonlinear gamma effect of the DLP projector [

19]. Note that the laser-based DLP projector still uses a DLP chipset, but its light source is laser-based instead of light-based, while the laser-based DLP projector also has the drawbacks of a typical DLP projector. Thus, there has still been a very challenging need for developing methods that can generate sinusoidal fringe patterns for improving the 3D surface profilometry accuracy.

Moreover, 3D surface measurement under outdoor environmental conditions has been extremely challenging, since the available methods are unable to go through the restrictions of vibrations from environmental influences and effects of background illumination from sunlight. Meanwhile, for another challenging issue of carrying out 3D surface measurement of objects with a wide range of reflectance [

20], there have been some recently developed techniques such as the dynamic projection theory [

21], the approach utilizing the transitioning state of digital micromirror device [

22], and the method with a dual optical sensing configuration via combining the diffuse reflective light and the specular surface light [

23]. However, these techniques might only be allowed for applications of indoor measurements or under dark environmental conditions.

Generally speaking, the most existing techniques basically suffer the main drawbacks as follows: First of all, phase-shifting-based methods and techniques have a rigorous requirement that the observed target has to remain still during the measuring time, thus vibrations caused by the surrounding environment such as the wind or the observed target itself such as the human breathing during a medical scan will prohibit the practical measurements. Next, if the projected pattern is based on the sinusoidal fringe generated by DLP projector, the intensity deviation of the sinusoidal-fringe curve affected by the Gamma effect and defocusing issue will result in errors of target measurement. Finally, for structured-pattern projections with white light, background illumination is mostly not allowed during the measurement, which indicates that outdoor in-situ measurements of usual objects will be impossible.

Therefore, the purpose of this work will focus on the introduction and analysis of the designed optical system for generating laser-beam-based sinusoidal optical fringe patterns and the experimental measurements and reconstruction of objects for both indoor and outdoor conditions. Note that, in addition to the object surface with the same material and isotropic reflectance, we will apply our approach for measuring the surface shape of object with a wide range of reflectance under different background illuminance, which is based on the combination of the laser-beam-based sinusoidal optical fringe patterns generated using our designed optical system, Fourier transform profilometry (FTP), and the optical filtering processing technique.

2. The Designed Optical System and Theoretical Analysis

An important part of this work is to design and develop an optical system for the sinusoidal optical signal generator. The basic goal of our design is twofold: the first objective is to obtain monochromatic, high contrast, high quality, and truly sinusoidal fringes, and the second one is to overcome the shortcomings of the traditional interferometric system. We know that a interferometric system is usually complex and sensitive to vibrations from environmental influences including the structural vibrations of the operating system and air disturbances from the surrounding environment, which have imposed restrictions on the applications of outdoor and production line in-situ measurement.

2.1. Experimental Methodologies Using the Designed Optical System

Figure 1 is the photo of experimental setup of in-situ measurement under the sunlight, while the parts

S,

G,

L, and

F in

Figure 1 are the main components of the sinusoidal optical signal generator. The optical system starts with a CW-laser source

S with the wavelength

nm, maximum output power of 200 mW, and a small divergence angle (

). A rectangular grating

G illuminated by the laser beam is placed at a front focal point of a positive lens

L. On the conjugate plane of

S, an adjustable spatial-frequency filter

F is set, which is considered that the part

F plays a critical role in this system. For this spatial-frequency filter, a V-shape aperture with a width of 0.5 mm is carved with high precision, we can then choose and allow the selected order of the spatial frequency to pass through. The output of a sinusoidal fringe pattern can then be observed on the plane

P, as indicated in

Figure 1. Note that the design of this adjustable spatial-frequency filter

F containing three accurately-cut slits is actually based on our previous work of measuring modulation transfer function [

24] and a recent study on human face imaging [

25].

Since the focus of this investigation is the indoor and outdoor surface measurement of 3D Objects under different background illuminations and wind conditions, there will be two environmental parameters, the background illuminance E, and the wind speed , to be measured. For both indoor and outdoor measurements, the real-time background illuminance E was measured using a digital luxmeter placed beside the observation plane P. Note that the digital luxmeter should not be illuminated by the signal of the projected fringe pattern when the background illuminance is being measured. The wind speed of indoor measurement is set to zero. For outdoor measurement, the real-time wind speed of the measuring period was monitored and measured using a digital anemometer.

2.2. Mathematical Description of the Sinusoidal Optical Signal Generator

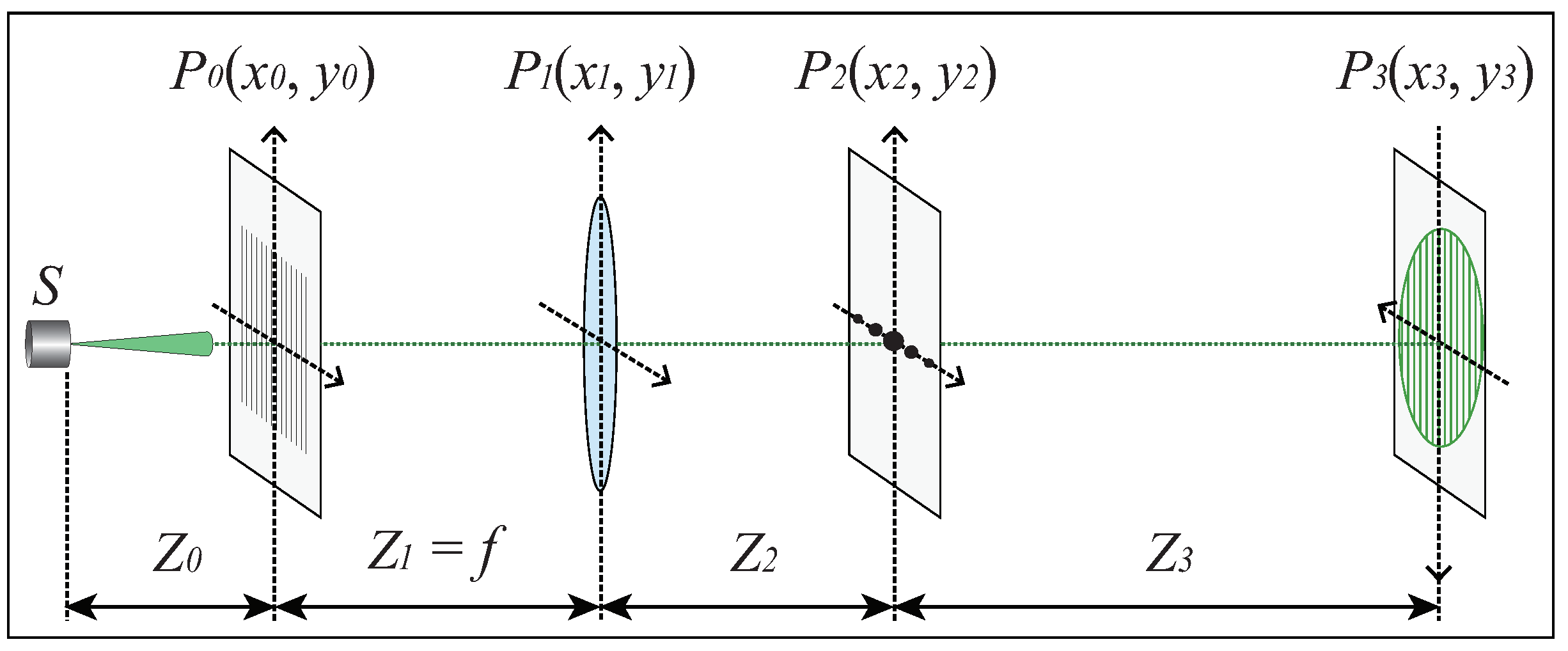

The theoretical description of the sinusoidal fringe pattern generated by the optical system described in

Figure 1 is given as follows. A schematic diagram of

Figure 1 can be sketched using

Figure 2, which will be used to derive a mathematical expression for the sinusoidal fringe pattern obtained at the observation plane

P in

Figure 1, i.e., the plane

in

Figure 2. For other planes in

Figure 2, the grating

G is located at plane

, the positive lens

L is at plane

, and the plane

is the position of the spatial-frequency filter

F.

The filed

from a continuous-wave point source laser

S can be described as

where

A is a complex constant related to the laser power, and

. Taking

for simplicity and using the paraxial approximation, the field

behind the grating

G at the plane

is given by

where

is the distance between the laser source

S and grating

G, and

the transmission function of

G. Considering that

G is one-dimensional,

can be described using

where

and

are the coordinate variables of

, and

a and

d are the optical parameters of grating

G.

H is the grating width, which is assumed, for the sake of simplicity, to be the diameter of the illumination spot of the laser.

Note that the propagation of field

from plane

to plane

is within the Fresnel region. The field

in front of the lens

L at plane

is given by

where

is a complex constant, and

is the distance between the planes

and

. The field

after the lens

L at plane

can be written as

where

denotes the transmission function of the lens

L.

The propagating field

at plane

to

at plane

can be accurately computed using Fresnel diffraction.

denotes the field in front of the spatial-frequency filter

F, and is given by

where

is a complex constant, and

is the distance between the planes

and

. Combining Equations (

2)–(

6) as well as the expression of

, we have

where

is the Bessel function of the first kind,

with the spatial frequency

at plane

defined by

, and

is a complex constant given by

.

The role of the adjustable spatial-frequency filter

F at plane

is to select a

-th order spectrum described in Equation (

7), and let them pass through it, and here we take

. We then get the field

right behind the filter

F in the following form:

The propagation of field

from plane

to

can also be analyzed using Fresnel diffraction, which let the field

at plane

to be given by

where

is also a complex constant, and

is the distance between the planes

and

. Considering that the size of

(

mm in diameter) is much less than that of

, i.e., the spot size of the sinusoidal fringe pattern (

mm in diameter), we take an approximation that

for further derivation of Equation (

9). Equation (

9) then becomes

where the complex parameter

is given by

.

Equation (

10) indicates that the field at the observation plane

is an inverse Fourier transform of the field output from the spatial-frequency filter

F. Combining Equations (

8) and (

10), we have

Obviously,

is a complex constant for determined spatial distances

and

, and the modulus of

represents the amplitude of the generated sinusoidal signal. We see that the fringe intensity will decrease as

increases since

f and

are generally parameters with fixed values. The part of

in Equation (

11) results in a definition of the range of the fringe pattern with a circle of radius

. The term of

is the key part of output of the designed optical system, i.e., the expression of a sinusoidal curve.

2.3. Physical Characteristics of the Generated Sinusoidal Fringe Pattern

From Equation (

11), it can be seen that the

term in Equation (

11) has only one variable

at the plane

along the

-axis, which indicates that the output of this system is monochromatic, high contrast, and truly sinusoidal fringes. The

term also includes the information that the fringe width (related to the spatial frequency of the output fringe pattern) will increase as

increases, which might be useful and important for 3D surface measurement.

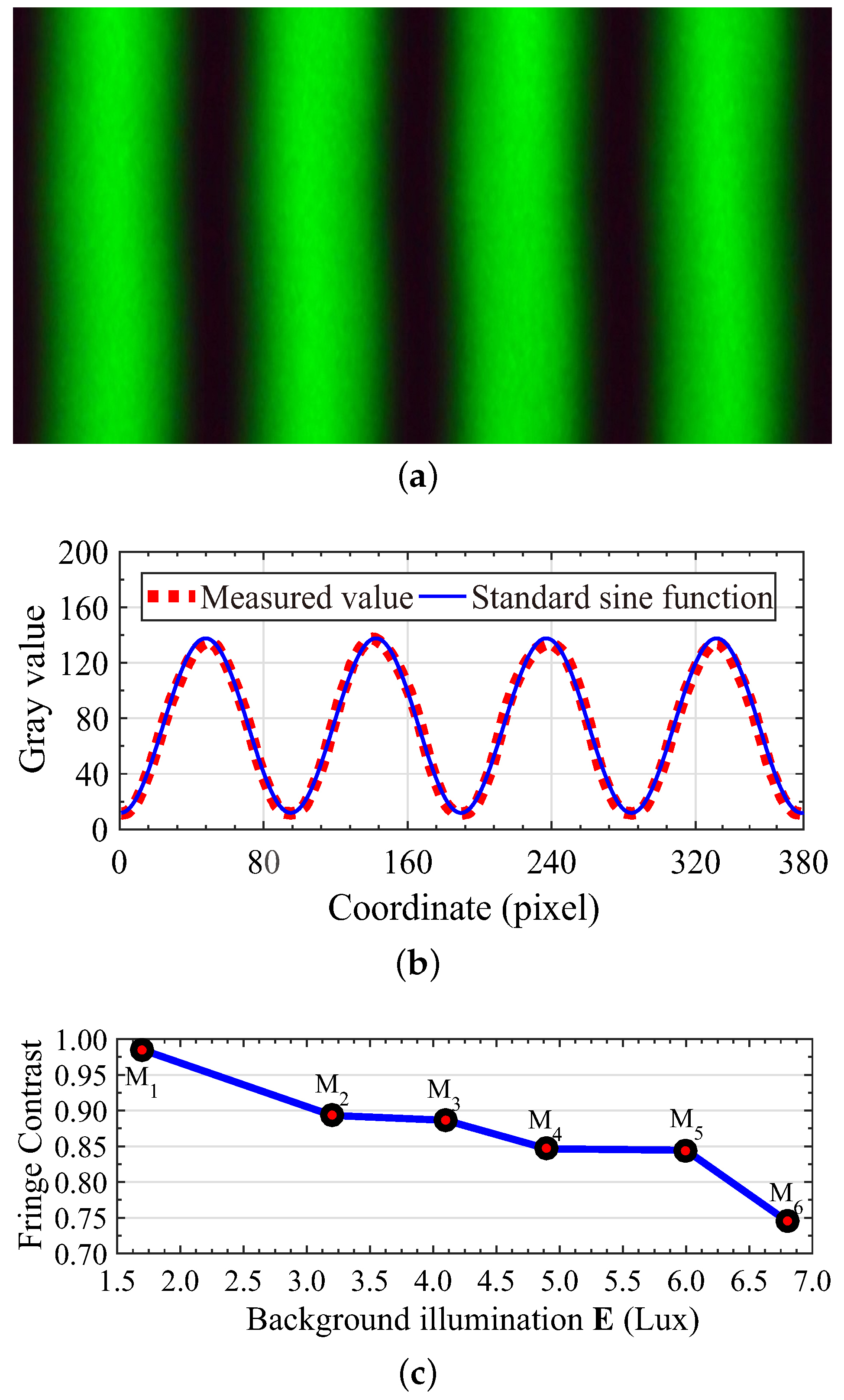

The light-intensity distribution of the sinusoidal fringe pattern generated using the developed optical system is measured using a CMOS camera, and the camera uses an Aptina CMOS sensor with the sensor size of 5.70 × 4.28 mm and each pixel size of 2.2 × 2.2 μm. Due to the fact that the laser power is high, the exposure time and the

value of the camera must be carefully adjusted for obtaining a color picture of the fringe pattern with good quality, as shown in

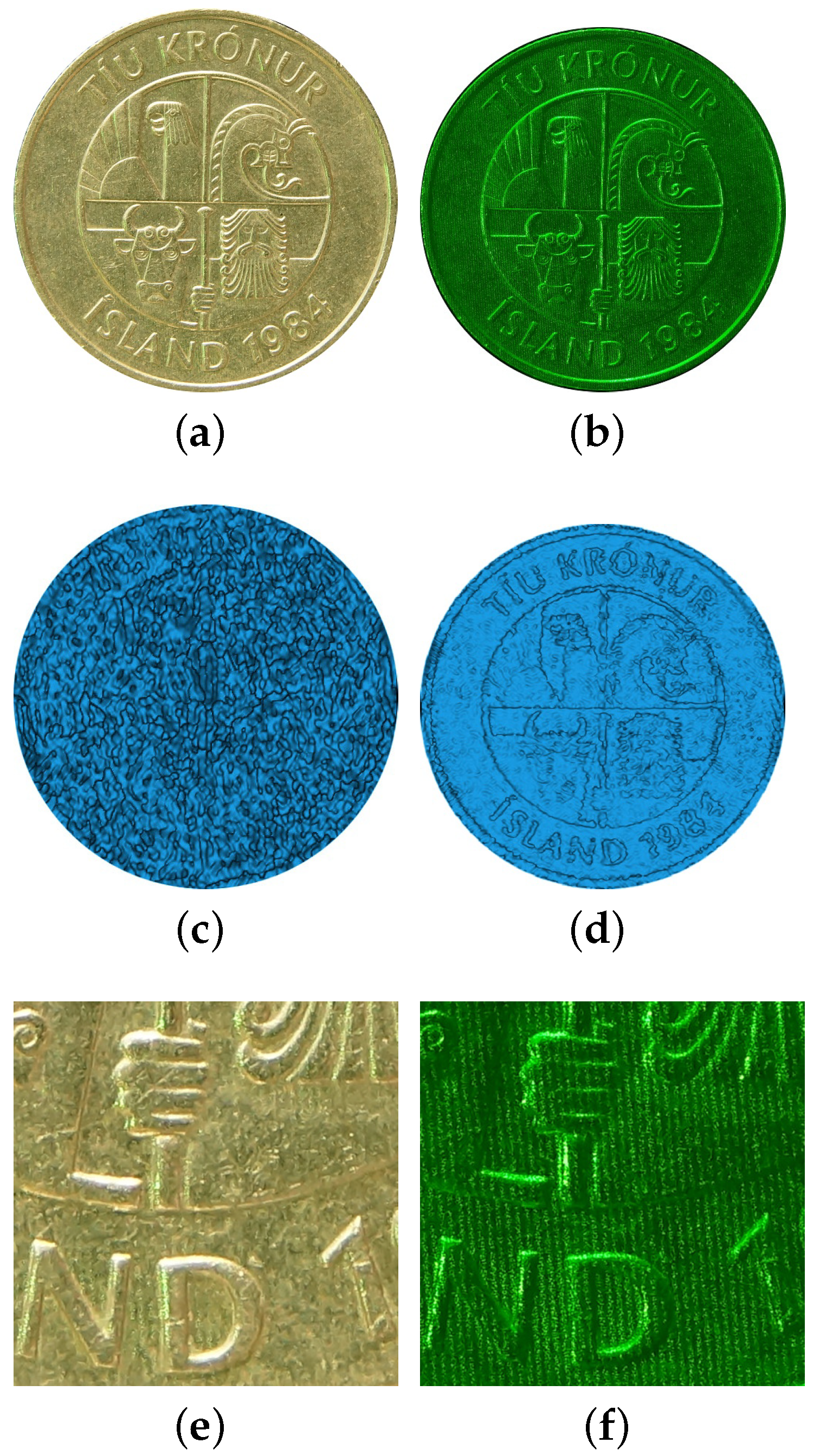

Figure 3a.

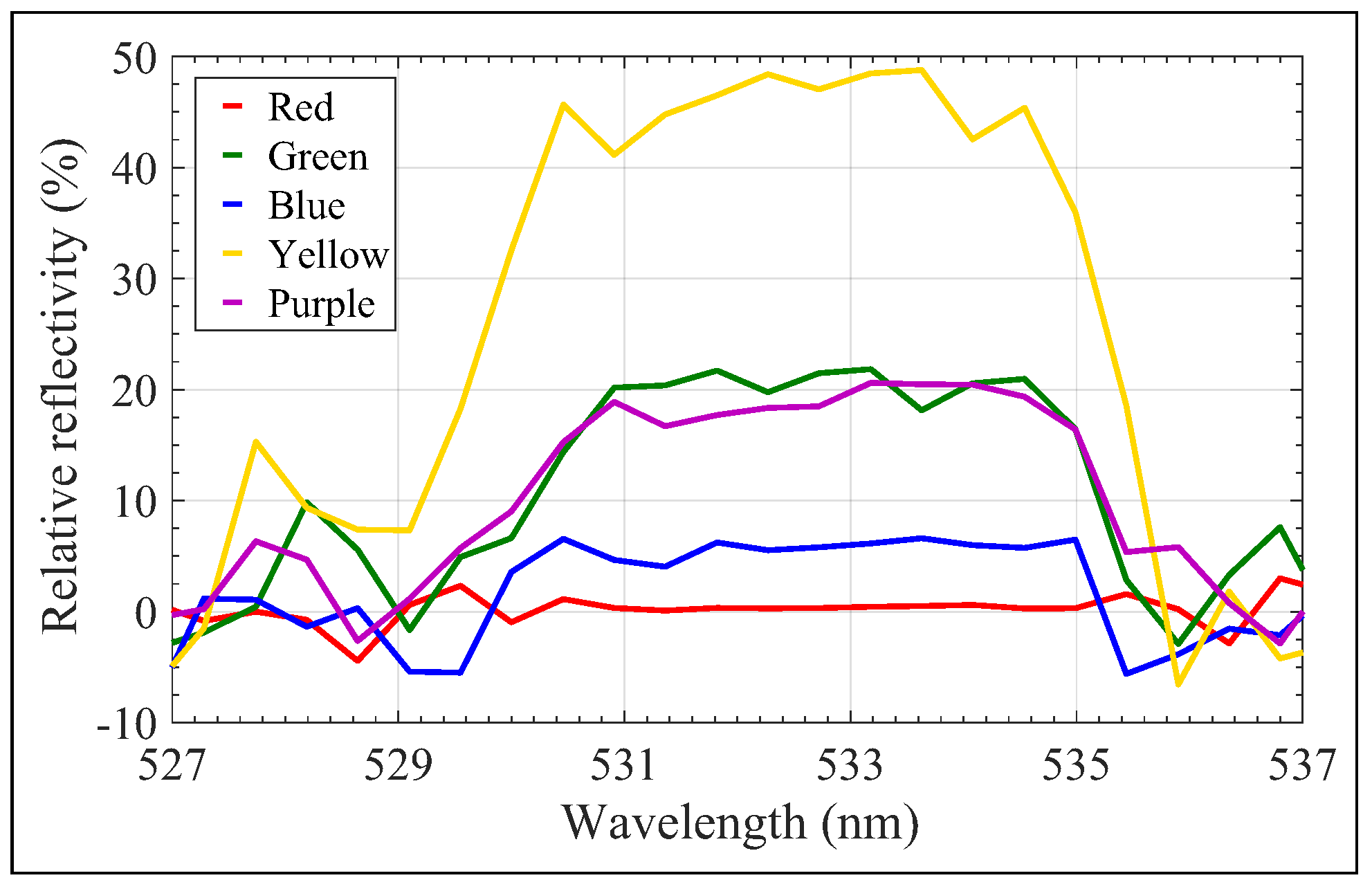

The measured light-intensity distribution of the sinusoidal fringe pattern is compared with the standard sine function in

Figure 3b. Fringe contrast denoted by

is one important measure of the output pattern quality, while the fringe contrast of the sinusoidal signal curve shown in

Figure 3b is 0.847 with

and

being 137.6 and 11.4, respectively, which responds to the measurement of

in

Figure 3c. The background illumination of the measurement

in

Figure 3c is 1.7, 3.2, 4.1, 4.9, 6.0, and 6.8

, respectively, which results in the contrast of the same sinusoidal curve having different values, i.e., 0.985 (

), 0.893 (

), 0.886 (

), 0.847 (

), 0.844 (

), and 0.745 (

). The difference or the error between the measured intensity curve and that of the standard sine function, as indicated in

Figure 3b, may have over-estimated the real error value, since the measured intensity distribution is affected by the nonlinear gamma effect of the CMOS camera, dark current, lab background light noises, and other possible items from the measuring instruments and related hardware devices.

Figure 3c indicates that the fringe contrast will decrease as the background illumination goes up. However, the optical filter can be employed for removing the effect of background illumination to remain the fringe contrast and improve the accuracy of reconstruction.

Based on Equation (

11) and the related derivation process, it should be noted that the output fringe pattern is not affected by the focusing issue at all, which is different from the focusing feature of the fringe pattern generated by a DLP projector, an image with programmed intensity distribution.

4. Conclusions

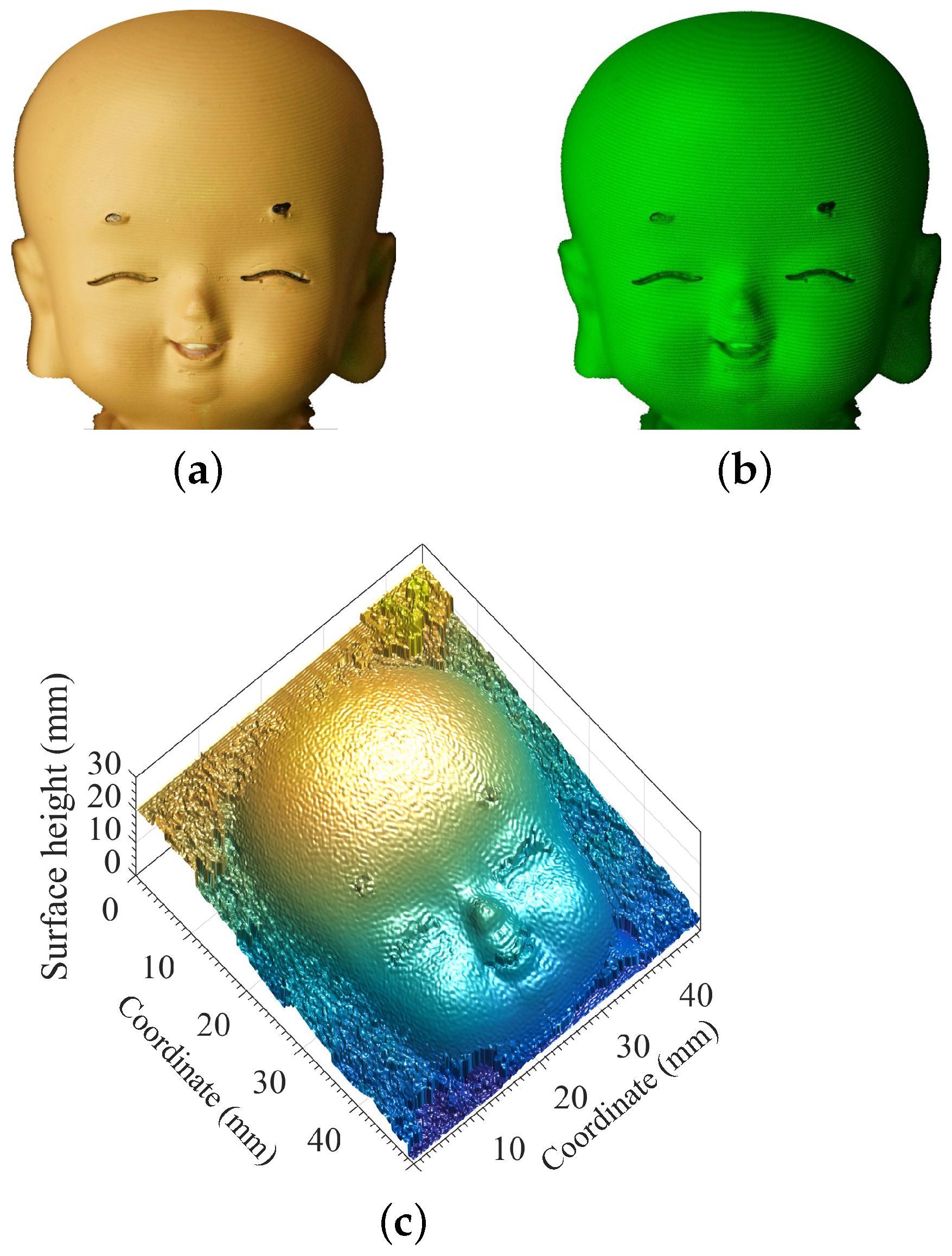

Both theoretical and experimental results of this work have indicated that the proposed approach of 3D surface measurement is capable of being successfully completed under complicated outdoor conditions. The critical important basis for carrying outdoor 3D surface measurement is the proposed and designed novel sinusoidal optical signal generator as well as the combination of the projected laser-beam-based sinusoidal optical signal, the optical filtering technique, and the single-shot approach based on Fourier transform profilometry. The designed optical system can generate monochromatic, high contrast, and truly sinusoidal fringe patterns with high-accuracy applications to 3D-surface measurement, as we presented in our experimental results of this work. The time-invariant feature of the sinusoidal fringe pattern generated using the designed optical system is important and useful for 3D-surface measurement of both static and dynamic objects. In addition to the higher fringe contrast as discussed above, the fringe pattern is a monochromatic signal, which can be combined with an optical filter to effectively reduce or remove the influence of the environmental noisy light signals as we indicated and discussed in

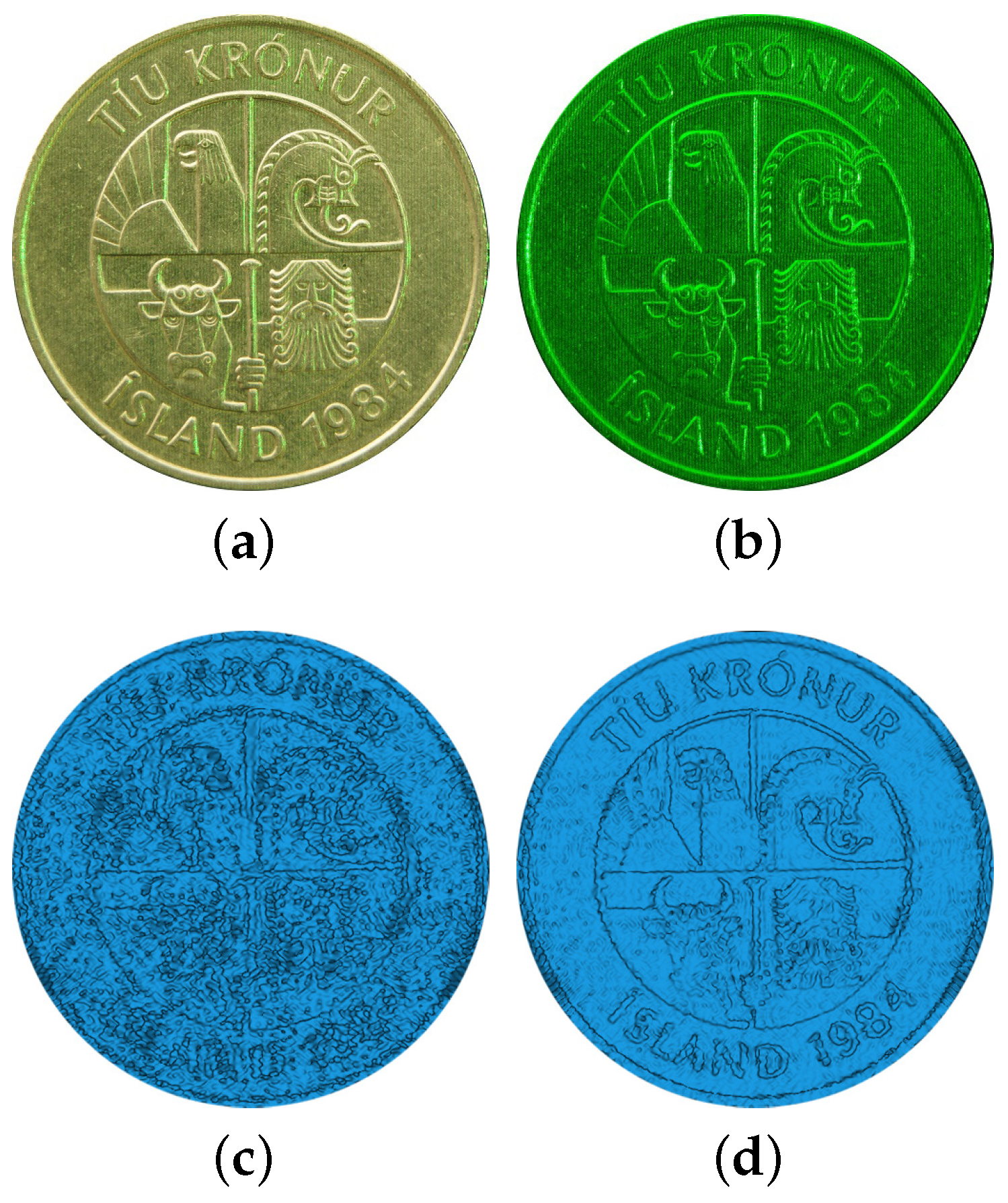

Section 3. Moreover, the fringe-pattern signal is not sensitive to vibrations from environmental influences including the structural vibration of the system and the air disturbance, which has overcome the outdoor and in-situ measurement restrictions of the traditional interferometric system, especially for the applications of 3D surface profilometry. Experimental results indicate that outdoor in-situ measurements and accurate reconstructions can be obtained for much stronger outdoor environmental illumination such as the background illuminance

for measuring the 3D-printed color object with varying surface reflectivity,

E = 12,000

for measuring the human-head model, and

E = 35,000

for measuring the selected coin. The portable and stable optical setup of 3D surface measurement developed in this study can be used to measure objects with even or varying surface reflectivity under windy conditions and strong environmental illuminations and obtain accurate reconstructions.