1. Introduction

Parameters of nonequilibrium charge carriers in a semiconductor are important for the operation of devices based on it. For some devices—for example, photoconductive dipole antennas [

1]—a short lifetime is required, and it can reach 200–500 fs in some gallium arsenide structures [

2,

3]. Contrary to this, for gallium arsenide X-ray detectors, structures with a long charge carrier lifetime, which can reach hundreds of nanoseconds, are necessary [

4,

5,

6]. Thus, semiconductor material modification methods are required in order to change the charge carrier lifetime. For this purpose, appropriate technologies for modifying the properties of semiconductors (doping from melt, diffusion doping, ion implantation and irradiation, temperature treatments, etc.) were developed [

2,

3,

4,

5,

6,

7]. In particular, it is common knowledge that the diffusion doping of GaAs by Cr allows the fabrication of efficient ionizing radiation detectors on the basis of such materials with electron lifetimes of 20–80 ns [

4,

5,

6].

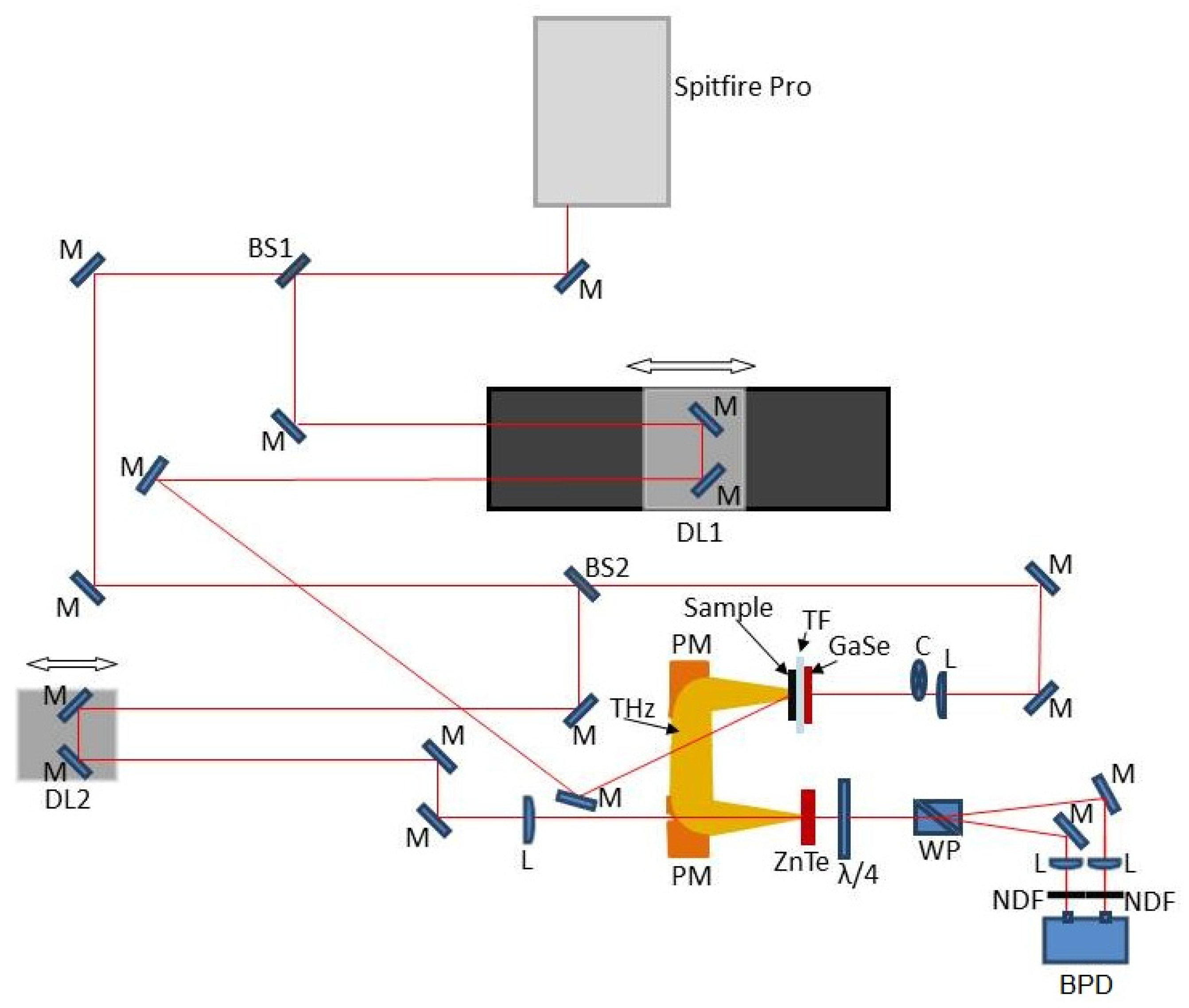

The problem of creating reliable contactless methods for controlling the semiconductor material properties is topical. One of the most promising methods for determining the nonequilibrium charge carrier lifetime is the pump–probe technique, in which, after the excitation of a nonequilibrium charge carrier concentration in a sample by a short, high-intensity laser pulse, a transmission or reflection is sensed by optical or terahertz radiation with certain time delays [

8,

9,

10]. The time resolution of the method may be less than 100 fs. In view of the complexity of the processes occurring in semiconductors when they are photoexcited by short laser pulses, the interpretation and analysis of optical pump–terahertz probe (OPTP) spectroscopy data are still challenging. On the one hand, this method allows the direct sensing of the free charge carrier concentration in semiconductors. On the other hand, due to the photoexcitation character, the OPTP technique can be considered a reliable tool only for studying the temporal dynamics of fast recombination processes at high injection levels, mainly taking place at a semiconductor surface. In view of the above-mentioned problem, it is of interest to determine the extent to which the OPTP method can be used to determine the bulk charge carrier lifetime in semiconductors such as HR GaAs:Cr. In addition, it is meaningful to reveal the dominant recombination mechanisms at the injection levels occurring at OPTP measurements and to determine whether the corresponding experimental data can be used to determine the lifetimes at moderate injection levels. Studies providing new insights into these issues seem to be of interest.

In the present contribution, SI GaAs:EL2 and HR GaAs:Cr structures are studied by the OPTP method. Both HR GaAs:Cr and SI GaAs:EL2 are appropriate materials for ionizing radiation detectors with long charge carrier lifetimes, at the level of tens and hundreds of nanoseconds [

5,

6,

11]. The EL2 defect states in GaAs are usually associated with As

Ga antisites or their complexes with other intrinsic defects [

12,

13]. These are the midgap donor states [

12,

13]. When the EL2 defect concentration is higher than the concentration of shallow acceptors, while the concentration of shallow acceptors is higher than the concentration of shallow donors in GaAs, the complete compensation of shallow defect states can be reached. This results in a semi-insulating material with a 1.5–3 ns electron lifetime. An alternative approach is doping of n-GaAs with Cr, which is used to achieve the shallow defect state compensation. The Cr-related states are midgap acceptors [

4,

14]. The chromium compensation technology allows the fabrication of HR GaAs:Cr with a 25–80 ns electron lifetime [

6]. Despite the fact that HR GaAs:Cr was successfully used to create ionizing radiation detectors demanded at nuclear physics research centers [

15], the mechanisms responsible for the increase in charge carrier lifetime with the introduction of chromium need further investigation. To the best of our knowledge, OPTP spectroscopy has not previously been used to study GaAs:Cr. Nevertheless, the relaxation dynamics of charge carriers in GaAs:Cr were studied by measuring the photoluminescence decay, stationary photoconductivity and photoelectromagnetic effect [

16,

17]. In these studies, 60–600 ns [

16] and 0.5–5 ns [

17] lifetimes for electrons were obtained at relatively low injection levels. The values obtained in [

16] are in good agreement with the data obtained from the measurements of charge collection efficiency (approximately 80 ns [

4]). The results of Ref. [

17] are better correlated with the OPTP data obtained for SI-GaAs [

9]. As can be seen, there are considerable differences in the charge carrier lifetime values in GaAs obtained by OPTP and by the measurements of photoconductivity decay or charge collection efficiency. This can be attributed to the strong influence of surface states and high injection levels at pump–probe measurements, compared to the two latter methods. To reveal the influence of surface states, in the present study, HR GaAs:Cr and SI GaAs:EL2 wafers with chemically and mechanically treated surfaces were additionally studied by OPTP. The charge carrier lifetimes and contributions from different recombination mechanisms at different injection levels were determined and analyzed for HR GaAs:Cr and SI GaAs:EL2 samples.

3. Experimental Results

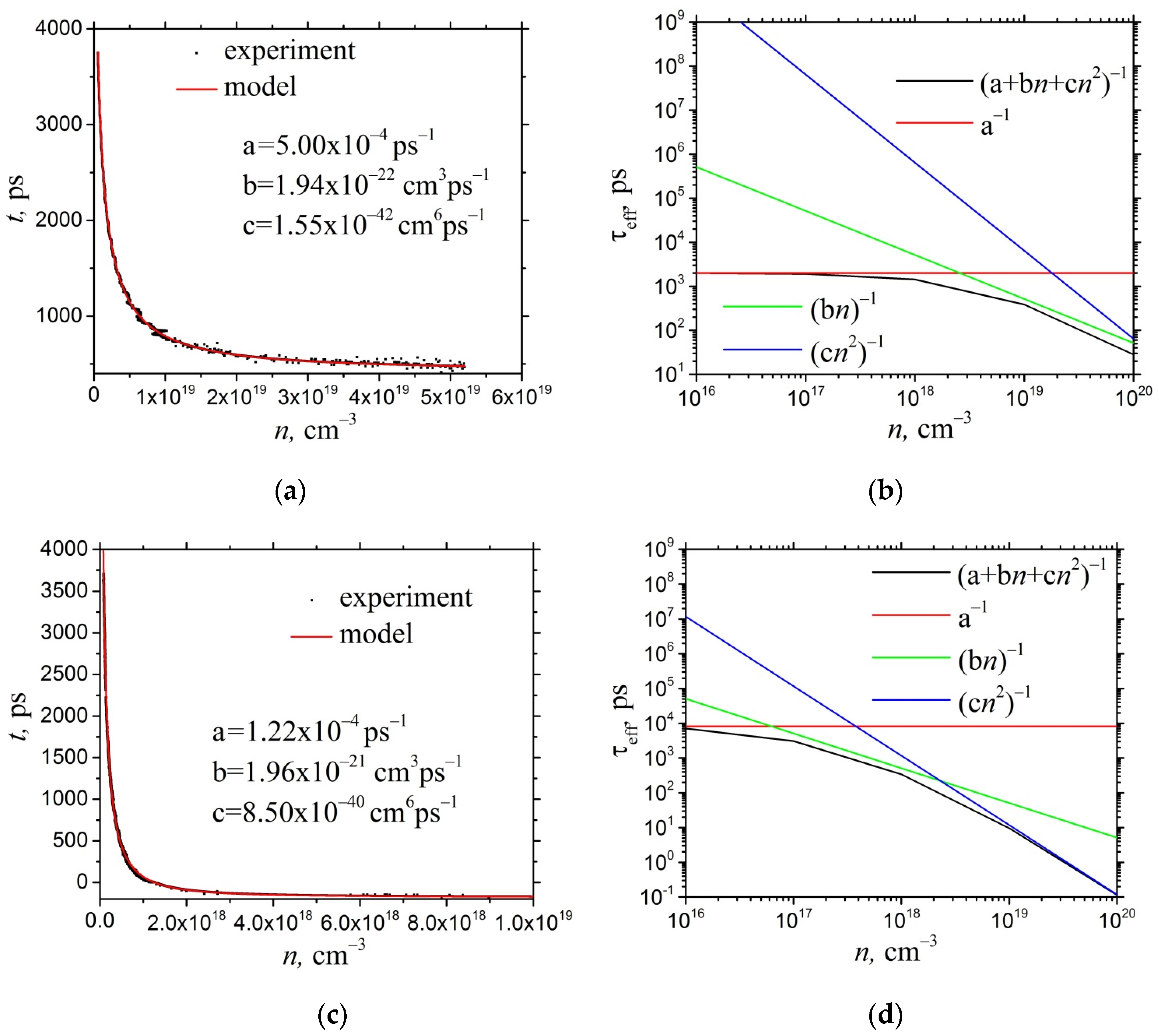

The OPTP experimental data for HR GaAs:Cr shown in

Figure 2 indicate that expression (4) allows a rather smooth experimental data approximation. This could not be reached using the approximation by expression (2). The experimental and model dependences of the nonequilibrium charge carrier concentration are shown in

Figure 2a, while the calculated effective charge carrier lifetime dependence with the resolution into contributions from different recombination mechanisms for the HR GaAs:Cr sample at the photoexcitation power of 260 mW are given in

Figure 2b. The values of coefficients

a,

b and

c obtained as a result of the approximation (

Figure 2a) were used to obtain the curves shown in

Figure 2b. In

Figure 2b, the black curve represents the dependence τ

eff (

n) according to Equation (3). The red curve represents the lifetime if it was determined only by the surface and bulk Shockley–Read–Hall recombination (values

b =

c = 0 were substituted into Equation (3)). Similarly, the green and blue curves describe the contributions of radiative recombination together with the Auger recombination via traps (at

a =

c = 0 substituted to (3)) and interband Auger recombination (at

a =

b = 0 substituted to (3)). As seen in

Figure 2b, at nonequilibrium charge carrier concentration levels above 3 × 10

18 cm

−3, the Auger recombination mechanisms predominate in GaAs:Cr. At the injection levels of 5 × 10

17 cm

−3 and lower, the lifetime is determined almost exclusively by the bulk and surface Shockley–Read–Hall recombination and it amounts to approximately 2 ns.

The measurements of the same sample were performed at a different photoexcitation pulse power. This was done to check how the range of nonequilbrum charge carrier concentration, at which the experimental data were measured, influences the approximation results and the fitting parameter values. As expected, the obtained dependences show that the nonequilibrium charge carrier lifetime in the limit of low photoexcitation injection levels is determined by the SRH recombination and is 1.4–2 ns for the measurements taken at different photoexcitation power levels (different by one order of magnitude;

Figures S1a,b and S2a,b in Supplementary Materials). Thus, the obtained deviation of the extracted

a parameter values is not too large. Comparatively, the

b parameter values decrease with the photoexcitation power increase from 20 to 260 mW. As it appears, more accurate values for the coefficient

b are obtained in the case of measurements with a large photoexcitation level, when the contribution to the total recombination rate from the trap-assisted Auger recombination is larger. The Auger band-to-band recombination coefficient

c can be determined only with a large error, since the reachable injection levels are insufficient for this mechanism to dominate in the recombination process. As can be seen in

Figure 2, the predominant contribution from the band-to-band Auger recombination occurs at injection levels that were not reached in the experiment.

Further measurements were performed on the samples after chemical and mechanical surface treatments. The results of the measurements and the data analysis for HR GaAs:Cr samples after SiO

2 film deposition on the surface, oxidization in oxygen plasma and etching in sulfuric acid solution are presented in

Figures S2–S4 in the Supplementary Materials. As was established for the HR GaAs:Cr sample, the deposition of a 20 nm thick SiO

2 film, etching in a sulfuric acid solution and plasma oxidation did not lead to a lifetime increase. The values of coefficients

a and

b also did not change considerably. The observed deviation in

c coefficient was probably induced by the insufficiently wide range of experimental data to determine them more precisely.

The mechanical grinding of the HR GaAs:Cr sample surface led to an increase in the charge carrier lifetime in HR GaAs:Cr samples (

Figure 2c,d) in the limit of low injection levels. This can be attributed to the filling of SRH recombination centers as a result of the electron redistribution from the created surface defect states. However, at the injection level of 10

18 cm

−3, the charge carrier lifetime was somewhat reduced to 700–800 ps, which is slightly lower than that of the initial sample. This could also be associated with the generated defect states and Auger recombination with their participation. The role of Auger recombination is predominant at an injection level of ~10

17 cm

−3 and higher.

SI GaAs:EL2 samples were studied similarly. For the reference SI GaAs:EL2 sample, the maximum charge carrier lifetime, due to the SRH recombination (25 ns), was determined (

Figure 3). The obtained Auger recombination coefficients

b and

c were significantly lower than the values obtained for other samples. In this case, the mechanical surface grinding led to an increase in surface and SRH recombination (

Figure 3c,d). Therefore, it can be supposed that the mechanical treatment generated the defect states, which, in some way, reduced the active SRH recombination center concentration.

4. Discussion

The obtained results show that the OPTP technique usually yields higher charge carrier lifetime values compared to the values deduced from the charge collection efficiency measurements. This is due to the higher injection levels and the increased role of Auger recombination in OPTP measurements. The lifetime values obtained using the model accounting for the contribution of different recombination mechanisms and extrapolating the results to the low injection limit amounted to 1–3 ns for HR GaAs:Cr. These injection levels and the corresponding lifetimes are more consistent with the carrier lifetimes and injection levels occurring in HR GaAs:Cr-based ionizing radiation semiconductor detectors.

The OPTP measurements at different photoexcitation power values show that the results are still sensitive to the range of injection levels, especially for the Auger and radiative recombination contributions to the charge carrier lifetime. On the other hand, the SRH recombination rate values are less sensitive to the injection level and can be robustly determined from the OPTP experiments. The charge carrier lifetimes determined by the SRH recombination are important for the HR GaAs:Cr-based X-ray sensor operation. For proper bulk charge carrier lifetime extraction and exclusion of the influence of surface recombination, measurements on samples of different thicknesses would be helpful. However, the measurements performed for the HR GaAs:Cr samples with various surface treatments show that the contribution from the SRH surface is not too large.

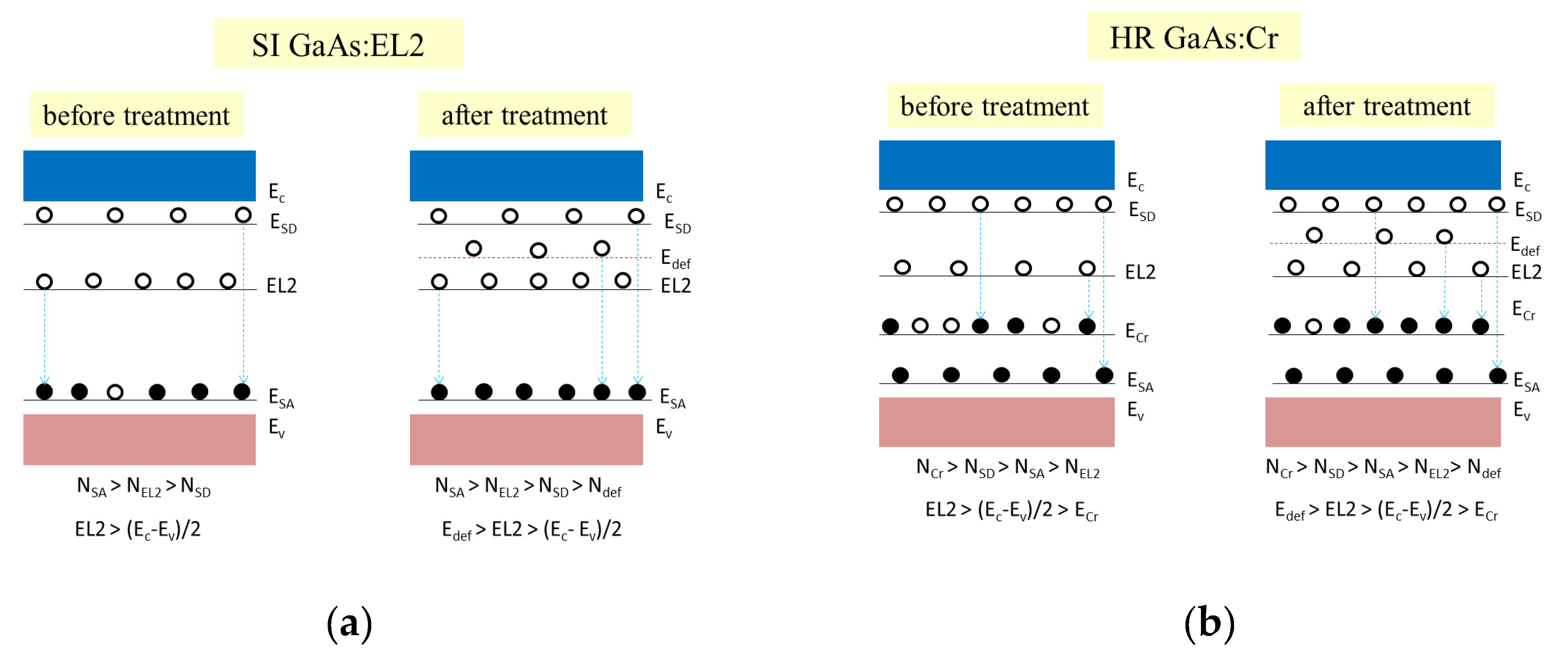

The different influences of surface grinding on the charge carrier lifetimes in SI GaAs:EL2 and HR GaAs:Cr samples could be explained with the use of simple energy diagrams assuming that grinding and subsequent surface reconstruction led to the appearance of additional surface donor-like defect levels in the upper half of the band gap (

Figure 4). The formation of such levels was found in Ref. [

22] by DFT calculations. In the SI GaAs:EL2 sample, these defect states increased the compensation level, slightly increasing the concentration of active hole traps, but the concentration of SRH recombination centers increased, leading to a charge carrier lifetime reduction (

Figure 4a). In the HR GaAs:Cr sample, the defect states increased the filling of the Cr-related acceptor states, reducing the SRH recombination rate, and could also act as deep traps for charge carriers, both increasing the charge carrier lifetime.

As a result of the performed experiments, the time dynamics of the nonequilibrium charge carrier relaxation processes in SI GaAs:EL2 and HR GaAs:Cr semiconductor crystals were studied using the OPTP method. The obtained experimental data were analyzed within the model, taking into account the Shockley–Read–Hall surface and bulk recombination, radiative recombination, band-to-band and trap-assisted Auger recombination. It was found that, at the nonequilibrium charge carrier concentration levels arising in the measurements, with the sample excitation by radiation with a pulse duration of 35 fs, and the pulse energy of 0.26 mJ at the central wavelength of 791 nm, the Auger recombination mechanisms have a significant effect, which leads to the relaxation of the nonequilibrium carrier concentration in HR GaAs:Cr semiconductor crystals during the characteristic times of the order of 500 ps or less. The Auger recombination mechanisms provide a dominant contribution to the nonequilibrium charge carrier recombination rate at injection levels above ~(0.5–3)·10

18 cm

−3. At lower concentrations, the main recombination mechanism is the SRH recombination. For most HR GaAs:Cr samples, the characteristic lifetimes, due to the SRH recombination, are equal to 1.4–2 ns. The obtained Auger recombination coefficients

b and

c at the level of 2 × 10

−10 cm

3/s and 1.5 × 10

−30 cm

6/s are in agreement with those obtained earlier for GaAs by measuring the photoluminescence relaxation kinetics [

23]. The results indicate that it is possible to use the terahertz pump–probe spectroscopy method for determining the lifetime in GaAs semiconductor crystals intended for the manufacture of devices requiring long nonequilibrium charge carrier lifetimes.

There is experimental evidence that, at high-intensity fluxes and in high-energy beams, the GaAs detector charge collection efficiency is decreased and the rise time is increased. Usually, during the operation of ionizing radiation detectors on SI-GaAs, the injection level is not high, as a single beta-particle having energy of 2 MeV can produce 1 electron–hole pair per energy of 4.2 eV and have an energy loss of 6 MeV/cm [

24]. Thus, a single beta-particle having the energy of 2 MeV can produce 166 electron–hole pairs per 1 μm of path. Taking into account the track diameter of the order of few microns, one can calculate the electron concentration ~ 10

12–10

14 cm

−3. For tracking applications—for example, at the Large Hadron Collider or Forward Calorimeter of International Linear Collider (FCAL ILC)—much larger, higher-energy particle fluxes are available, leading to high injection levels and making high-injection-level measurements of charge carrier lifetime very much relevant.