2.1. Overall Description of an Integrated Structure as an Example

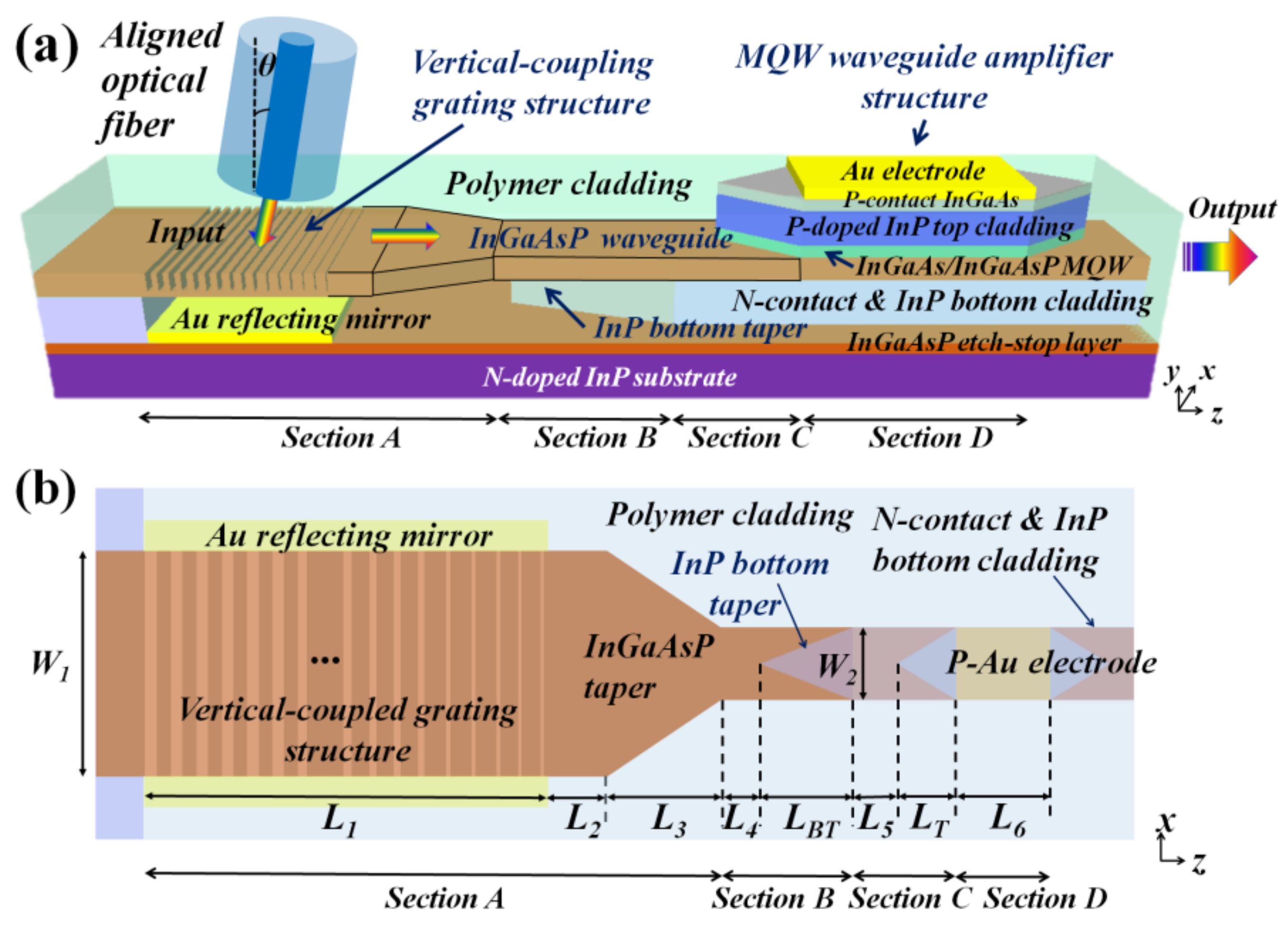

We illustrate the platform using the case of an optical amplifier integrated with a passive waveguide and the incorporation of a surface grating to couple light between the waveguide and an optical fiber. The schematic of the entire integrated device structure is shown in

Figure 1a,b.

As shown by

Figure 1, the entire structure is divided into four sections. In Section A (fiber-coupling structure), an optical beam with a wavelength centered at 1550 nm launched by an aligned optical fiber is first coupled vertically through a surface grating structure into a transparent waveguide made of 500-nm thick undoped InGaAsP materials (with a bandgap wavelength at 1.25 μm so that it is transparent at the 1550-nm wavelength range). The width of this waveguide with the surface grating is ~15 μm so that the beam from the optical fiber with the typical 8.2-μm core diameter, giving a mode diameter of 7.2 μm (measured at 1/e point of the intensity profile), can be captured efficiently into the lowest order mode of the 15-μm side strong-guiding waveguide (i.e., the 7.2-μm 1/e mode width gives the maximum field overlap with the lowest-order mode in the 15-μm wide strong-guiding waveguide). The 15-μm wide waveguide is then tapered down horizontally to a width of 4 μm. The 4-μm wide waveguide then acts as a channel waveguide to bring the beam into the next device section. As explained below, the InP material under this 500-nm thick InGaAsP layer is removed (e.g., via a selective chemical etchant such as HCL that will etch away the InP material without etching the InGaAsP material) and filled with

n~1.5 polymer as the “lower cladding”. The space between the surface grating and the fiber is also filled with

n~1.5 polymer. Note that the choice of the 4-μm waveguide width and other similar choices made below are somewhat flexible.

In Section B (passive waveguide device), the light beam from Section A is propagated into a 4-μm wide, 500-nm thick InGaAsP passive waveguide core. In this region, the material under this 500-nm thick InGaAsP layer has InP material as the lower cladding (i.e., not polymer). To minimize the optical loss when the beam enters from Section A, which has polymer lower cladding, into this region, which has InP as the lower cladding, a tapering structure at the lower InP cladding is used. As described later, this tapering structure underneath the InGaAsP waveguide core is made via photolithography patterning and selective chemical wet etching. The transparent waveguide structure in Section B can be used to make various passive photonic devices, such as optical beam couplers and beam splitters. In this paper, we show it as a transparent waveguide for illustration purposes (see

Section 2.6 for further elaborations on this).

The beam from the passive photonic device in Section B is then brought into Section C via a 4-μm wide connecting waveguide. In Section C (active-passive waveguide connection), the beam is made to slowly connect into an active gain material region through the use of an adiabatic taper structure on top of the 500-nm thick InGaAsP layer (with the bandgap wavelength at 1.25 μm), which is the 4-μm wide connecting channel waveguide from Section B. At the taper, the 500-nm thick InGaAsP waveguide then becomes part of the waveguide core, complete with quantum wells immediately at the top of the 500-nm thick InGaAsP layer, forming a gain waveguide core with a total thickness of 560 nm (the multiple quantum well (MQW) region with three quantum wells immediately on top of the 500-nm thick InGaAsP layer is 60 nm thick). Above this gain waveguide core is 1500-nm thick, lightly P-doped InP material, forming a P-doped top waveguide cladding followed by a 100-nm thick, highly P-doped InGaAs layer that forms the P-ohmic contact layer at the top surface. Below the 560-nm gain waveguide core is a 1350-nm thick, moderately N-doped InP layer forming the lower waveguide cladding. This 1350-nm thick N-doped InP layer also serves as the N-ohmic contact layer. Right below this N-doped InP layer is a 25-nm thick N-doped InGaAsP layer (with the bandgap wavelength at 1.25 μm) that serves as an “etch-stop layer”, whose function will be explained in more detail below. Basically, it is used for optimizing the fiber-coupling grating performances. This tapering structure of Section C acts as an adiabatic mode connection structure to connect the lowest-order mode from the passive waveguide structure of Section B to the lowest-order mode in the active gain waveguide structure of Section D.

After Section C’s taper, in Section D (active waveguide device), the beam enters into the active gain material region. The waveguiding structure with optical gain material in Section D can be used to make an optical amplifier, light-emitting device, laser, optical switches, or a modulator, depending on the application. If needed, the beam in Section D can be transmitted to the next device by connecting Section D’s output to another passive waveguide device section (called Section F) similar to that of Section B via an active-passive waveguide connection section (called Section E), similar to the tapering structure of Section C but oriented in the opposite direction so that the upper part is tapered down to a point from Section D toward Section F. The beam from the active waveguide device section of Section D can then be smoothly propagated into the passive waveguide device section of Section F without much optical loss.

The above layered structure is summarized by

Table 1. The “top view” given by an X-Z horizontal cross-section of the entire structure encompassing Sections A–D is shown in

Figure 1b. As shown in

Figure 1b, W

1 is the width of the vertically coupled apodized grating and W

2 is the width of the InGaAsP channel waveguide. L

1 + L

2 is the length of the grating structure plus the length of a 15-μm wide connecting waveguide (with polymer as the lower cladding), L

3 is the length of the horizontal taper after the grating (tapering from 15 μm to 4 μm horizontally), L

4 + L

BT is the length of a 4-μm wide connecting waveguide (with polymer below) plus the length of a “bottom taper” involving the lower InP cladding, L

5 + L

T is the lengths of the 4-μm wide connecting waveguide (with InP cladding below) plus a “top taper” involving the top MQW+InP structure, and L

6 is the length of the MQW active waveguide device section. Section A is formed by L

1 + L

2 + L

3; Section B is formed by L

4 + L

BT; Section C is formed by L

5 + L

T; and Section D is formed by L

6. As shown in

Figure 1a,b, the InGaAs/InGaAsP MQW structure is constructed on top of the passive 500-nm thick InGaAsP waveguide. The ohmic contact electrodes are formed on the N- and P-ohmic contact regions. The detailed parameters such as the doping type, thickness, refractive index at a 1550-nm wavelength, and the carrier concentration for each semiconductor layer of the MQW gain waveguide structure are given in

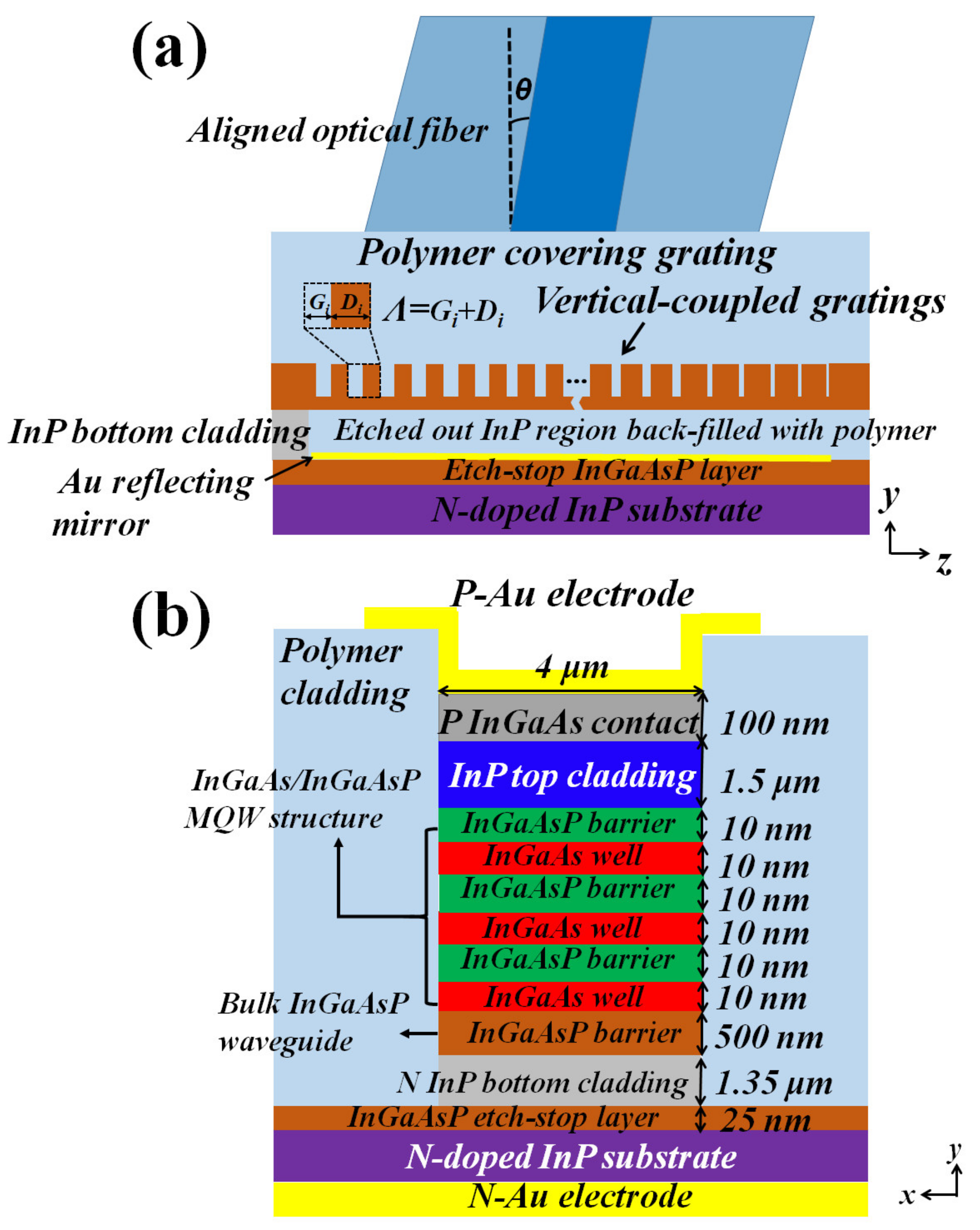

Table 1. The Y-Z (vertical-lateral) cross-sectional drawing for the vertically coupled apodized optical grating region and the Y-X (vertical-fontal) cross-sectional drawing for the active waveguide device section are shown in

Figure 2a,b, respectively. Below, we describe each of the sections (A–D) in more detail.

2.2. Design for the Fiber-Coupling Structure of Section A

Below, we describe the design for the vertically coupled grating together with a suggested fabrication procedure for the design.

To realize coupling of the beam between the optical fiber and the photonic chip, a surface grating can be fabricated by first writing the grating pattern using electron beam lithography (e.g., using the 300-nm thick PMMA as the E-beam resist) on a ~150-nm thick silicon dioxide layer pre-deposited on the 500-nm thick InGaAsP waveguide surface. The grating pattern is then transferred down to the oxide layer using dry etching (e.g., using Reactive Ion Etching (RIE) with, for example, CHF3, Ar, and O2 as the reactive gasses) with the E-beam resist as the dry etching mask. The oxide layer with the transferred pattern is then used as a dry etching mask for etching vertically into the 500-nm thick InGaAsP layer (e.g., using RIE with methane-hydrogen as the reactive gasses) to form the surface grating. As an example, the etch depth into the 500-nm InGaAsP layer can be 400 nm for the gap region of the grating teeth while the ridge region of the grating teeth is unetched. Note that the grating teeth are filled with polymer (with n = 1.5), as described in more detail below.

Next, we describe the design of the grating structure. To realize high coupling efficiency between the optical fiber and coupling grating structure, the duty cycle and period

Λi of the teeth in the fiber coupling grating are varied, forming an apodized grating. The design is based on Equations (1)–(4) in [

16]. As shown in

Figure 2a,

Gi and

Di (

Λi = Gi +

Di) are the lengths of the gap and ridge region, respectively, for each of the grating periods. The variation of the duty cycle and period enable the coupling strength for the beam energy exiting the grating to be varied along the propagation direction so that the beam intensity profile for the beam coming out of the grating and propagating toward the optical fiber will approximately match the beam shape and size of the optical beam in the single-mode optical fiber. This enables the beam from the waveguide to be efficiently coupled into the optical fiber. As light propagation is reciprocal, that means the beam from the fiber coupling into the waveguide via the surface grating will also be efficient. The specific values for

Gi and

Di are calculated and given in

Table 2. The total length

L1 and the width

W1 (

Figure 1b) of the grating are 20 μm and 15 μm, respectively. We call this grating which uses varying cycles to achieve mode profile shaping and mode matching the “apodized surface grating”.

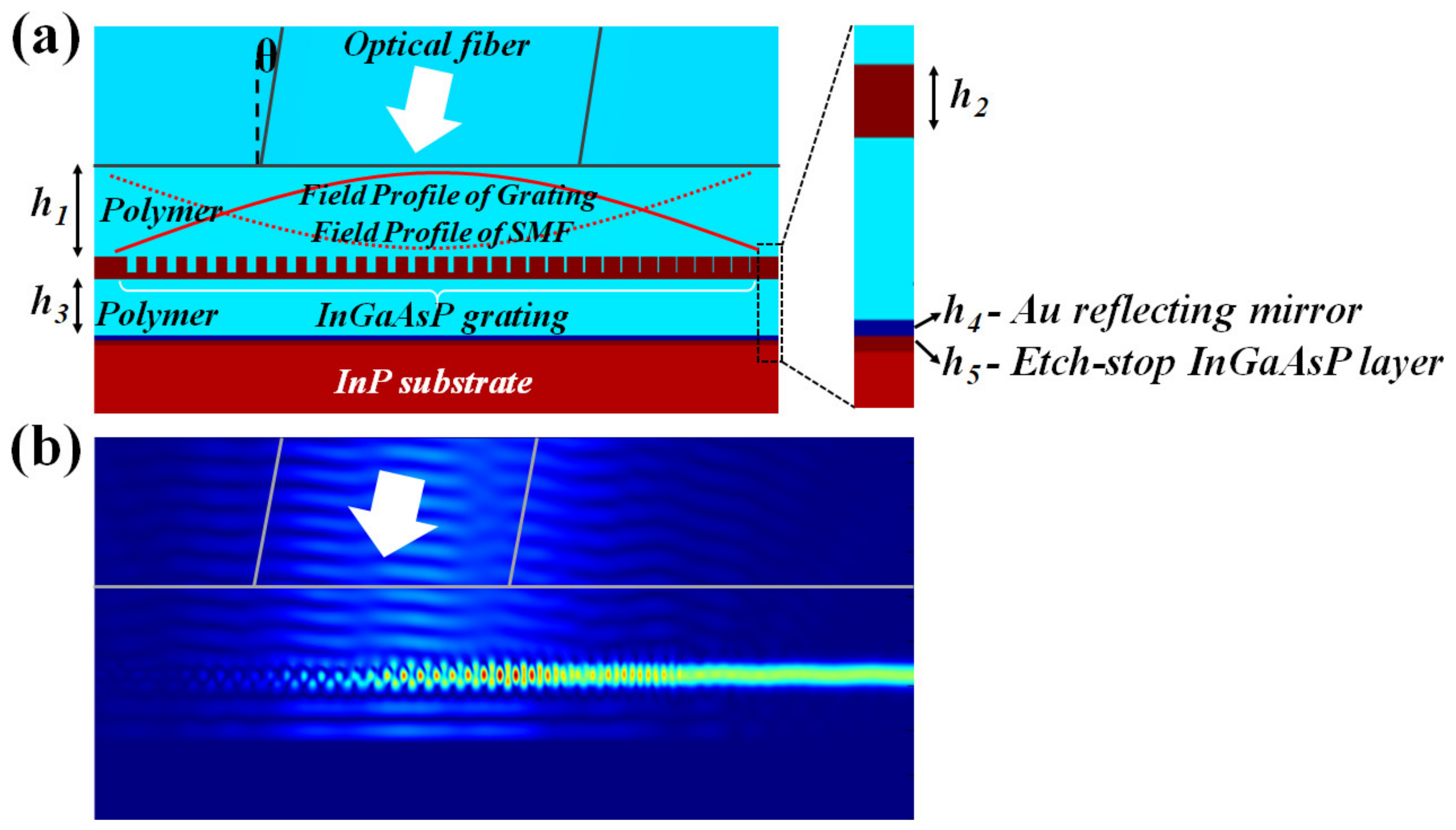

The schematic diagram for the structure used for computational electromagnetic simulation of this vertically coupled InGaAsP apodized surface grating structure is shown in

Figure 3a. To further enhance the coupling efficiency between the optical fiber and the chip, a gold (Au) reflecting surface is formed at a location below the grating region. This is formed by first protecting the surface of the grating region with a 1-µm thick silicon dioxide layer to give a higher mechanical strength. An opening is created on the silicon dioxide layer using photolithography. Dry etching, such as Reactive Ion Etching (e.g., using methane-hydrogen as the reactive etching gasses), is then used to vertically etch into the 500-nm thick InGaAsP waveguide core and then down into the InP material region below the waveguide core. Through the same opening, wet etching involving the use of HCL is then used to selectively wet etch away the InP material below the 500-nm thick InGaAsP waveguide core. HCL etches the InP material much faster than the InGaAsP material, so the InGaAsP waveguide core is basically unetched during the process. The 25-nm thick InGaAsP layer 1350 nm below the bottom of the 500-nm thick InGaAsP waveguide core serves as an etched stop layer, so the HCL wet etching will not penetrate below this etch stop layer and instead will form a smooth surface that is exactly 1350 nm below the bottom of the 500-nm InGaAsP waveguide core. A 100-nm thick piece of gold metal is then deposited onto the surface of this etched stop layer, forming an optical reflector. This deposition can be achieved by titling the chip during deposition so the gold will go underneath the 500-nm thick InGaAsP waveguide with surface grating (a large space is etched on both sides of the grating bridge to enable the gold deposition to go underneath). The hollowed-out bottom region of the grating is then filled with polymer by spin coating (e.g., with Benzocyclobutene (BCB) polymer or, alternatively, with the fluorinated polymer discussed below). The polymer is etched back to clear the grating surface. Any gold deposited on the silicon dioxide material on the grating can then be removed by a gold-etching chemical. After optical fiber alignment, the fiber position is fixed by epoxy so that the epoxy polymer will cover the region between the optical fiber tip and the grating surface.

We note that the removal of the InP material below the 500-nm thick InGaAsP waveguide is not just for placing the reflector. It turns out that when the reflective index of the InP is high, it makes the grating structure highly asymmetric (i.e., the refractive index above the grating waveguide is low (n~1.5), while the refractive index (n~3.1) of the InP material below the grating is too close to the refractive index of the InGaAsP waveguide core material (n~3.4) on which the grating is made). Our simulation showed that as a result of the high refractive index asymmetry, there was an unwanted diffraction order of the grating that emitted a significant amount of optical beam energy at a glancing angle close to the surface, making it impossible to obtain more than the 10% emission efficiency in the vertical direction that we wanted. Hence, in order to achieve a high vertical emission efficiency from the grating of ~50% or higher, we had to replace the material below the 500-nm InGaAsP waveguide with low-refractive index polymer.

The resulting structure showing the optical fiber, the grating, the gold reflector, and the polymer coverage is illustrated in

Figure 3a. In the figure,

h1,

h2,

h3,

h4, and

h5 are the thicknesses of the top polymer cladding layer (

h1), InGaAsP waveguide layer with the grating structure (

h2), bottom polymer cladding layer (

h3), gold reflector layer (

h4), and etched stop InGaAsP layer (

h5). The coupling optical field distribution between the optical fiber and grating was simulated with Lumerical 2D FDTD software, assuming

h1 = 2 μm,

h2 = 500 nm,

h4 = 100 nm, and

h5 = 25 nm. The 2D FDTD simulation approximation was sufficient for the purpose of showing the basic idea of the proposed design. The result is shown in

Figure 3b. It can be seen from the figure that the optical beam from the optical fiber above was coupled into the InGaAsP waveguide efficiently. The vertical beam fiber coupling efficiency (

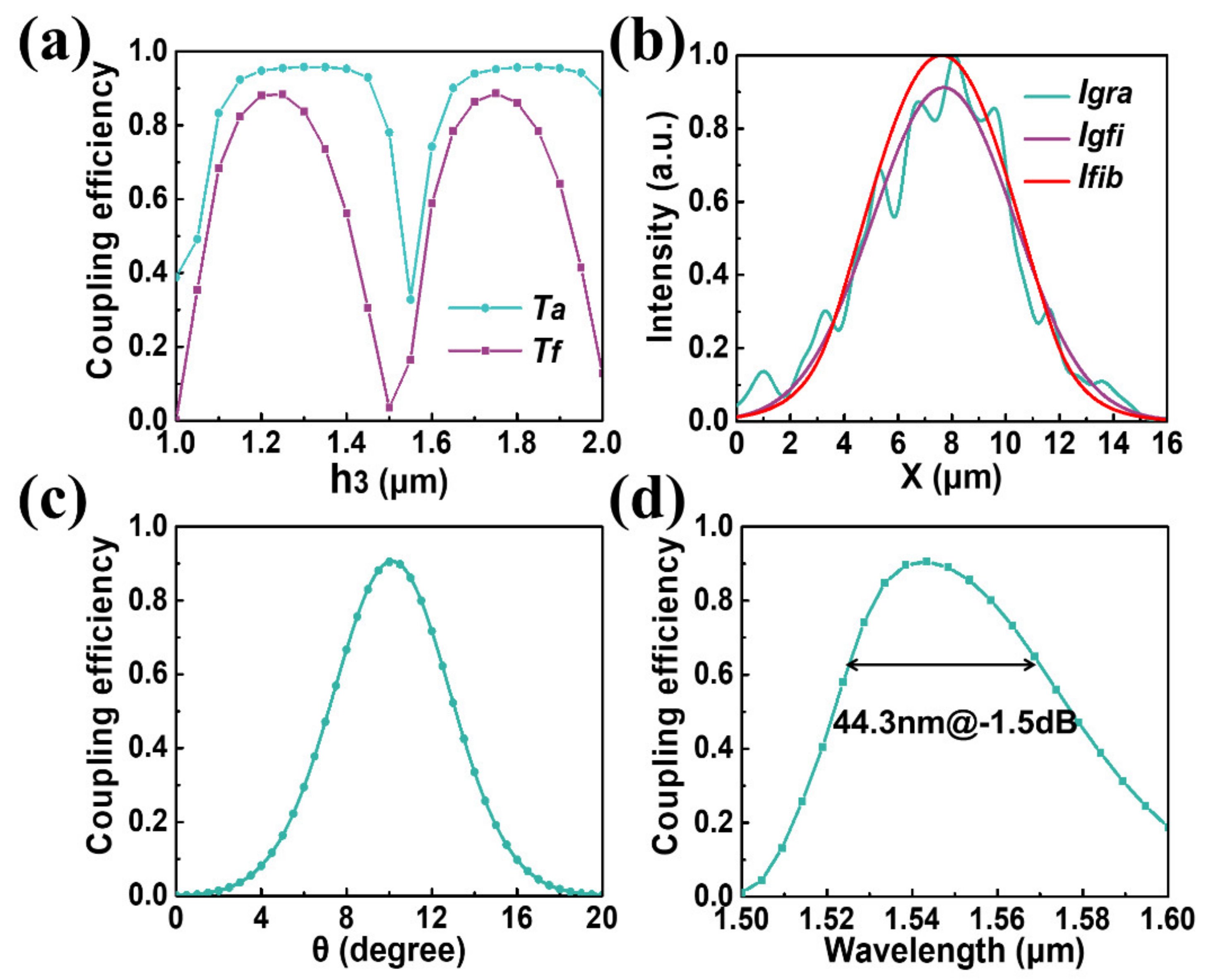

Tf) (between the waveguide and the optical fiber) as a function of the thickness

h3 of the bottom polymer cladding is given in

Figure 4a. More specifically, the beam-coupling efficiency curve (

Tf) for the optical beam from the waveguide emitted into the fiber’s fundamental mode and the efficiency curve (

Ta) for the optical beam from the waveguide emitted vertically in all directions above the grating surface are shown. Note that

Ta includes the optical power emitted into the fiber’s fundamental mode and all the other spatial regions above the grating surface. It was found that when

h3 was 1250 nm, the beam coupling efficiency

Tf reached the maximum value (

Tf = 88.3% and

Ta = 95.5%). Compared with the

Tf of 63% when no gold reflector was used (but still with polymer material filling the space below the grating and with the surface of the InGaAsP etched stop layer as a reflecting surface with only 15% reflectivity intensity), the fiber’s fundamental mode coupling efficiency (

Tf) with the gold reflector was increased by 25%. The gold reflecting surface reflected the beam energy traveling downward from the grating, back to the grating, and then exiting the grating’s top surface.

Figure 4b shows the normalized beam intensity profile (

Igra) for the beam from the grating based on the FDTD simulation. It also shows a Gaussian function fitting curve (

Igfi) for the beam profile

Igra and the normalized beam intensity profile (

Ifib) of the fiber’s fundamental mode. The 1/e width of the Gaussian fitted curve

agfi (=7.4 μm) matched the beam width of the fiber mode intensity profile

afib (=7.2 μm) well. The relationship between the coupling angle

θ and coupling efficiency is given in

Figure 4c. It was found that when

θ = 10°, the coupling efficiency could reach the maximum value (with the wavelength at 1550 nm). With

θ = 10°, the curve for the coupling efficiency as a function of the beam wavelength (

λ) is shown in

Figure 4d. It was found that the coupling efficiency reached the maximum value at the central 1550 nm wavelength, as expected from the design equations we used for designing the grating. The spectral width of the coupling efficiency curve, defined by the two points where the coupling efficiencies dropped by 30% (−1.5 dB) from the peak value, was 44 nm (in wavelength units). We found from the simulation that when the beam was launched from the optical fiber toward the surface grating, the reflection back to the optical fiber was 1.5%. When the beam was launched from the on-chip waveguide toward the grating, the reflection back to the fundamental mode of the waveguide was 2%. These levels of back reflection are low for integrated photonic chip applications.

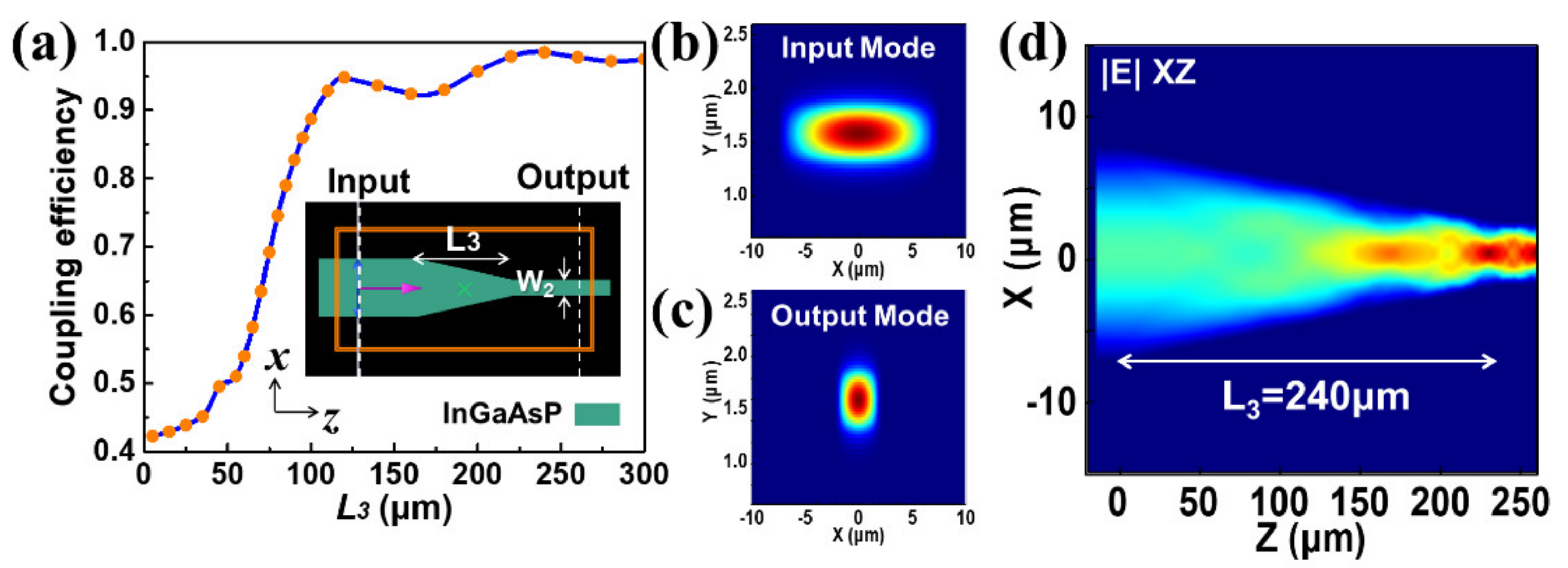

In Section A, a light beam coupled into the 500-nm InGaAsP waveguide via the surface grating has a 1/e beam intensity width of about 7.2 μm. This 7.2-μm beam width is guided by the 500-nm thick InGaAsP waveguide with a width of 15 μm. As illustrated in

Figure 5, this 15-μm waveguide width is then tapered down horizontally to about 4 μm with a tapering length

L3.

Figure 5a shows the transmission efficiency for the lowest-order transverse-electric (TE) mode at the initial 15-μm wide waveguide, propagating to the lowest-order transverse-electric (TE) mode at the final 4-μm wide waveguide of this tapering region as a function of the tapering length

L3. Note that TE mode has an electric field pointing in the planar or horizontal direction. This efficiency is referred to as the “lowest-order TE-mode connection efficiency”, or simply as the “mode connection efficiency”, which will also be the case for all the other tapering sections described below. The figure shows that an efficiency of 98.5% can be achieved at

L3 = 240 μm.

Figure 5b,c shows the optical mode at the input and output regions of this taper.

Figure 5d shows a horizontal cross-section illustrating the behavior of the propagating beam in the taper with

L3 = 240 μm.

To reduce the optical absorption loss and improve the thermal stability of the fiber-mode coupling gratings, instead of using BCB polymer, highly fluorinated polymer can be used as the cladding material above and below the grating, which is composed of fluorinated bis-phenol-A novolac resin (FSU-8) and fluorinated, epoxy-terminated, low-molecular-weight bisphenol A polycarbonate (FBPA-PC EP). The fluorinated polymer has low optical absorption loss at the 1550-nm wavelength range due to reduced vibration overtone by replacing the C-H bonds with C-F bonds [

17,

18]. More importantly, the polymer material, when used for covering the InGaAsP grating teeth, can help to lower the temperature dependence of the grating coupling wavelength, making it athermal. As the coefficient of thermal expansion (CTE) of the InGaAsP guiding layer is positive while the thermo-optic coefficient of the fluorinated polymer covering layer is negative, the fluorinated polymer can be used to reduce the wavelength shift of the grating (

Δλ) with temperature

T (see [

16,

19]). In fact, the thermal dependence of the refractive index of the fluorinated polymer can be tuned by incorporating different percentages of the FSU-8 content into the polymers. The tuning will allow one to design it to substantially cancel the wavelength shift of the grating with the temperature.

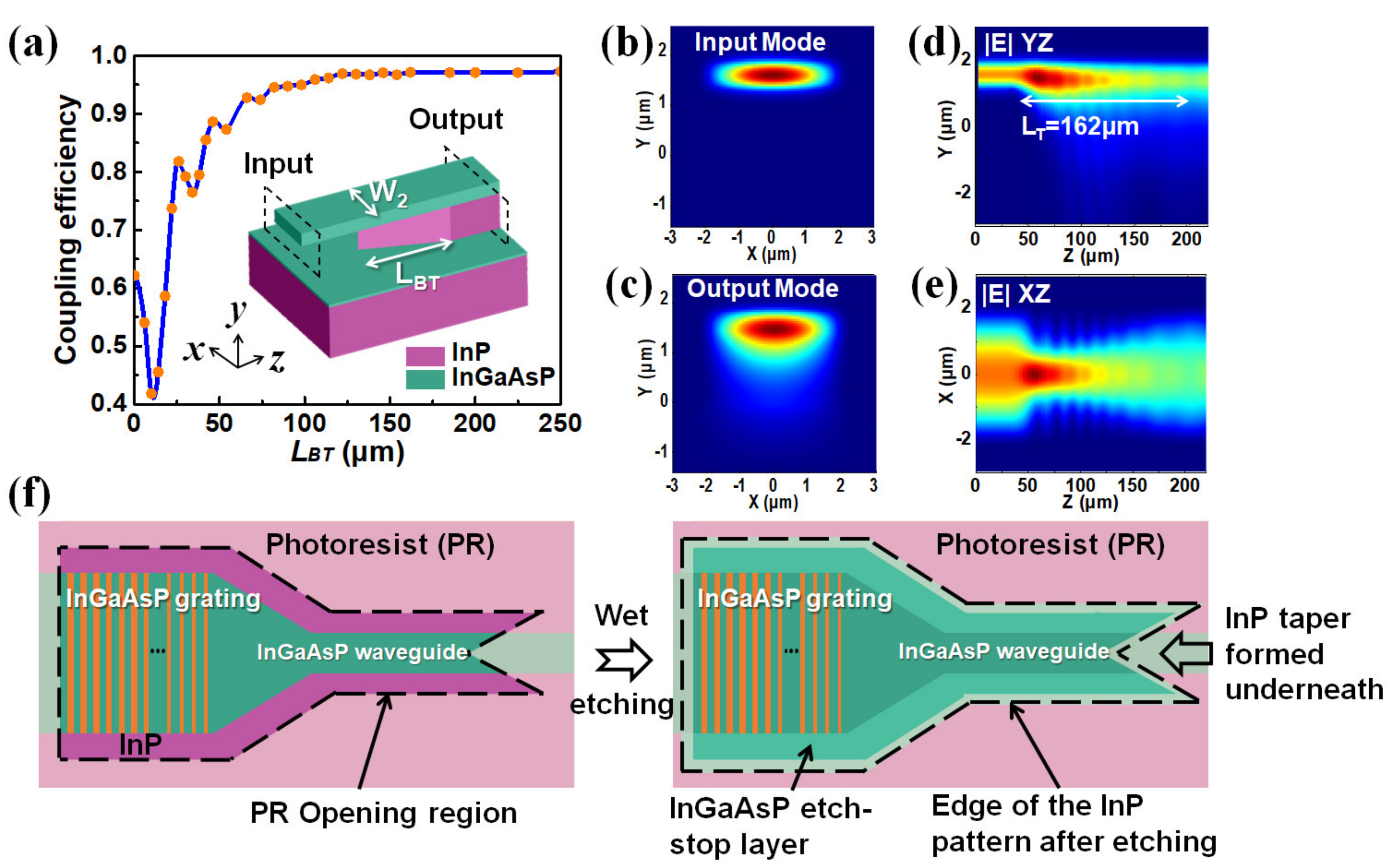

2.3. Design for the Passive Waveguide Device of Section B

Afterward, the light beam is propagated into Section B, for which the material under this 500-nm thick InGaAsP layer has InP material as the lower cladding (i.e., not polymer). The width of the waveguide at the input was assumed to be 4 μm wide. In our simulation, there could be an optical loss of about 37.8% when the beam entered from the region with polymer lower cladding to the region with InP lower cladding if the polymer-to-InP transition region had a straight edge crossing the width of the waveguide. However, this loss could be minimized with a tapering structure at the InP lower cladding as shown in

Figure 1, which is illustrated with more detail in

Figure 6. The structure at Section B could be formed by first etching the 4-μm wide InGaAsP beam using dry etching by RIE (after photolithography patterning) to etch through the 500-nm thick InGaAsP layer down partially into the InP layer of the lower cladding. The tapering structure underneath has a tapering length

LBT and can then be made via patterning a slanted opening in the photolithography pattern (see

Figure 6f) so that during the under-etching of the InP material for the grating region via wet selective etchant (e.g., with a selective chemical etchant such as HCL that will etch away the InP material without etching the InGaAsP material), a taper shape can be formed accordingly. The taper tip shown in

Figure 6a was assumed to have a width of 100 nm, and it was tapered up to the width of W

2, which was assumed to be 4 μm wide for the case in

Figure 6a, which shows the mode connection efficiency of this tapering region as a function of the tapering length

LBT.

Figure 6a shows that the mode connection efficiency was 95.3% at

LBT = 100 μm, and the mode connection efficiency was 97.1% at

LBT = 162 μm. The amount of reflection back to the fundamental waveguide mode of the input beam was less than 0.5% for the taper. It was found that when there was no taper (i.e., when the taper length was zero), the amount of loss was 37.8%.

Figure 6b,c shows the optical mode at the input and output regions of this taper, respectively.

Figure 6d,e shows a horizontal cross-section and vertical cross-section, respectively, illustrating the behavior of the propagating beam in the taper with

LBT = 162 μm. Hence, the length

LBT could be chosen to be around 160 μm for typical applications.

After the beam entered the transparent waveguide structure of Section B (with InP material as the lower cladding), the beam could be led to various passive photonic devices made by the transparent waveguide structure as needed. (These are not illustrated in

Figure 1b, for which only a straight waveguide is shown) After the beam was processed by the passive photonic devices, it would be moved to a channel waveguide with a waveguide width of 4 μm as the “output waveguide for the passive waveguide device section”.

2.4. Design for the Active-Passive Waveguide Connection (Section C)

The optical beam from the passive waveguide device (Section B) then enters Section C using the 4-μm wide output waveguide. In Section C, the beam is slowly connected into an active gain material region with the use of an adiabatic taper structure made on top of the 500-nm thick and 4-μm wide InGaAsP waveguiding layer from Section B (with InP below the InGaAsP layer). The taper structure is shown in

Figure 7. At the taper, the 500-nm thick and 4-μm wide InGaAsP waveguide becomes part of the waveguide core, completed with a 60-nm thick InGaAs/InGaAsP multi-quantum well (MQW) structure immediately at the top of the InGaAsP layer, forming a gain waveguide core with a total thickness of 560 nm. Above this gain waveguide core is 1500-nm thick P-doped InP material forming a P-doped top waveguide cladding, followed by a 100-nm highly P-doped InGaAs layer forming the P-ohmic contact layer at the top surface. Below the 560-nm thick gain waveguide core is a 1350-nm thick, moderately N-doped InP layer forming a lower waveguide cladding. This 1350-nm thick n-InP layer also serves as the N-ohmic contact layer in the situation where the N-ohmic contact metal is made from the top surface using a “via hole” that is etched through the top surface so that the metal can be deposited from the top to make contact with this n-InP layer. The N-ohmic contact metal can also be made at the bottom of the N-doped substrate.

For the 60-nm thick InGaAs/InGaAsP MQW structure, there are 3 InGaAs quantum wells, and the thickness of the quantum well is 10 nm, sandwiched by InGaAsP barrier material (see details in

Table 1). The width of the MQW waveguide at the end of the taper is 4 μm, matching the width of the 500-nm thick InGaAsP layer at the beginning of the taper. The total length of the taper is

LT.

Figure 7a shows the lowest-order TE-mode connection efficiency of this tapering region as a function of the tapering length

LT.

Figure 7a shows that the mode connection efficiency was 72.0% at

LT = 22 μm, and the mode connection efficiency was ~99% at

LT = 114 μm. It was found that when there was no taper (i.e., when the taper length was zero), the amount of optical loss was 31%. The taper tip shown in

Figure 7a was assumed to have a width of 100 nm, and it was tapered up to the width of W

2, which was assumed to be 4 μm wide for the case in

Figure 7a.

Figure 7b,c shows the optical mode at the input and output regions of this taper.

Figure 7d,e shows a horizontal cross-section and vertical cross-section, respectively, illustrating the behavior of the propagating beam in the taper with

LT = 114 μm. At

LT > 175 μm, the mode connection efficiency reached a steady value of 99.5%. Hence, the length

LT could be chosen to be around 114 μm for typical applications.

Table 3 gives a summary of the various parameters used for the MQW active waveguide part. The amount of reflection back to the fundamental waveguide mode of the input beam was less than 0.2% for this taper.

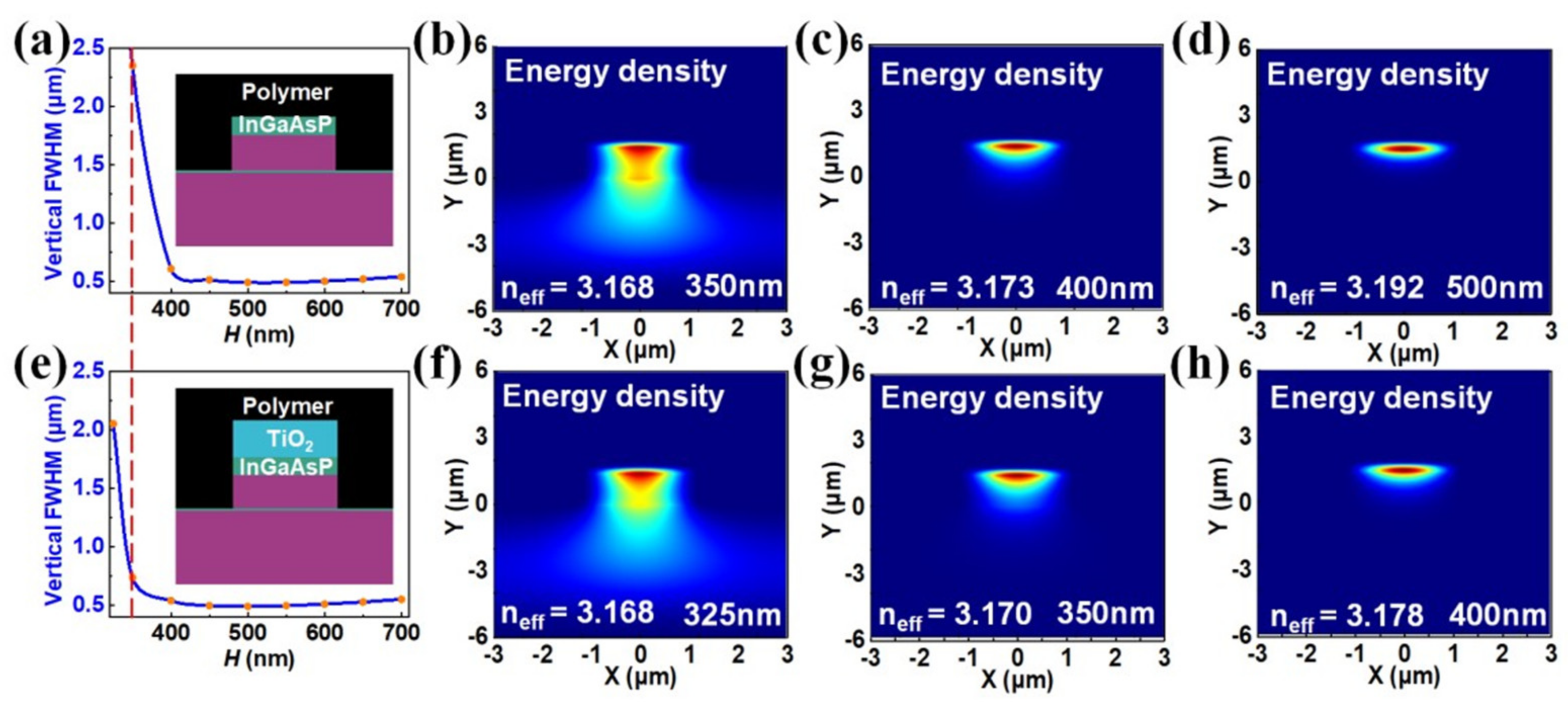

2.6. Design Rationales and Possible Variations

The 500-nm thickness chosen for the InGaAsP layer was to ensure that the mode in the passive waveguide device (at a waveguide width of 4 μm) was reasonably well confined vertically. The mode there was more sensitive than the mode at the active waveguide device, as the waveguide’s vertical structure at the passive waveguide device was highly asymmetrical in terms of the refractive indices of the upper cladding and that of the lower cladding. The asymmetrical waveguide could have a mode cutoff thickness for the lowest-order mode, whereas the symmetric waveguide did not have a mode cutoff thickness. Importantly, when the thickness goes below 400 nm, the mode in the passive waveguide device (at a 4-μm waveguide width) will extend downward a lot more due to the much lower refractive index of the top cladding. In

Figure 8a, we show the vertical mode size (measured at the FWHM of the energy density profile) in the 4-μm wide output region of the passive waveguide device as a function of the thickness for this InGaAsP layer, with

n = 1.5 polymer as the top cladding and InP as the bottom cladding.

Figure 8b–d shows the 2D mode intensity profiles at the output region of the passive waveguide device for the InGaAsP waveguide core thicknesses of 350 nm, 400 nm, and 500 nm, respectively. We can see that at the InGaAsP core thickness of 400 nm, the mode still had a reasonably well-confined vertical mode size, but at a thickness of 350 nm, the mode became very large vertically and had a lot of mode energy channeling toward the substrate direction. Thus, the choice of the 500-nm core thickness for the structure described above was a safe choice.

In

Figure 8e, we changed the top cladding material to titanium dioxide (TiO

2) (

n ~2.43) for the mode simulation (with a waveguide width of 4 μm).

Figure 8f–h shows the 2D mode intensity profiles at the output region of the passive waveguide device for the InGaAsP waveguide core thicknesses of 325 nm, 350 nm, and 400 nm, respectively (with TiO

2 as the top cladding material). We can see that at the InGaAsP core thickness of 350 nm, the mode still had a reasonably well-confined vertical mode size, but at a thickness of 325 nm, the mode became very large vertically and had a lot of mode energy channeling toward the substrate’s direction. Thus, with TiO

2 used as the top cladding material, the waveguide core thickness could be reduced to 350 nm (at a waveguide width of 4 μm). At the passive waveguide device, the total waveguide core thickness would be 410 nm (with the 60-nm MQW structure added on top of the 350-nm thick InGaAasP layer). Thus, with the use of TiO

2 as the top cladding, the 410-nm thick waveguide core may be a more ideal thickness for the active gain waveguide structure. In that case, the gain material’s overlapping factor can be increased to 3.74%, giving an optical gain coefficient of 0.0056/μm, which would correspond to an optical power gain of over 24.3 dB (or 270 times) for a 1-mm propagation length.

The figure above explains the choice of 500 nm for the InGaAsP layer when polymer with n = 1.5 was used as the top cladding material. We discussed the possible variation of reducing the InGaAsP layer thickness to 350 nm if the top cladding was changed to a material with a higher refractive index of n = 2.43 (e.g., with the use of TiO2 as the top cladding material). These data assumed a waveguide width of 4 μm at the passive waveguide device. If the waveguide width is narrower, the vertical mode size will be enlarged, and the choice of the core thickness may have to be larger. This factor places a constraint on the connecting waveguide width at least at the passive waveguide device (which has a high width sensitivity, as noted above). In addition, while the 4-μm wide waveguide is not a single-mode waveguide laterally (i.e., in the horizontal direction), in the passive waveguide device, it is possible to connect the 4-μm wide input waveguide after the bottom tapering region to a rib waveguide structure to put it in a single lateral mode if needed for certain passive device applications. Note that the vertical direction is already in the single mode. Similarly, in the active waveguide device, the 4-μm wide input waveguide after the top tapering region can be connected to a rib waveguide structure to put it in a single lateral mode if needed for certain active device applications.

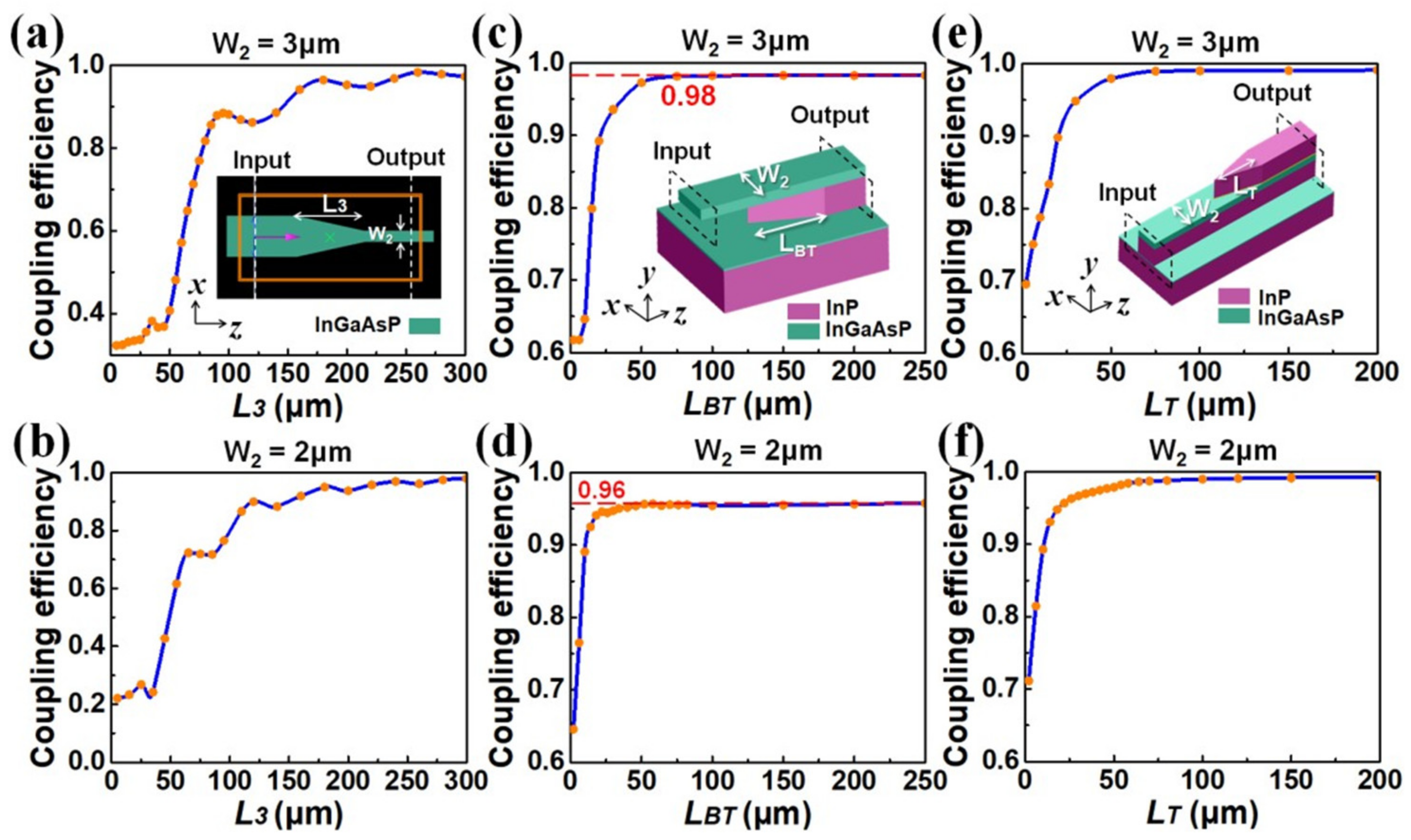

To investigate the effect of changing the connecting waveguide width, we investigated the required grating output region taper length (

L3), bottom taper length (

LBT) at the passive waveguide device, and the upper taper length (

LT) at the active-passive waveguide connection for the situation where a narrower connecting waveguide width (

W2) was used.

Figure 9a,b shows the mode connection efficiency for the grating output region as a function of

L3 for the cases of

W2 = 3 μm and

W2 = 2 μm, respectively. We saw that the mode connection efficiencies for these two cases were not much different from that of the

W2 = 4 μm case (meaning

L3 = 240 μm chosen for the 4-μm case could still be used).

Figure 9c,d shows the mode connection efficiency for the passive waveguide device as a function of

LBT for the cases of

W2 = 3 μm and

W2 = 2 μm, respectively. We saw that the

W2 = 3 μm case could achieve a mode connection efficiency of ~95% when

LBT was longer than ~30 μm, and after that, it seemed to saturate at a maximum efficiency of ~98% (i.e., it could not get higher) at

LBT > 50 μm. The

W2 = 2 μm case could achieve an efficiency of ~95% at

LBT ~30 μm but saturated at 96% at

LBT > 50 μm. These were to be compared with the

W2 = 4 μm case, for which the efficiency could also reach ~98% but at a long length of

LBT ~250 μm (see

Figure 6).

Figure 9e,f shows the mode connection efficiency for the active-passive waveguide connection as a function of

LT for the cases of

W2 = 3 μm and

W2 = 2 μm, respectively. We saw that the

W2 = 3 μm case could achieve a mode connection efficiency of ~80% at

LT = 10 μm, it reached ~98% when

LT ~50 μm, and after that, it seemed to saturate at the maximum efficiency of ~99% at

LT > 100 μm. The

W2 = 2 μm case could achieve a mode connection efficiency of ~90% at

LT = 10 μm. It reached ~98% when

LT ~50 μm, and after that, it seemed to saturate at a maximum efficiency of ~99% at

LT >100 μm. These were to be compared with the

W2 = 4 μm case, for which the efficiency could also reach ~99% but at a long length of

LBT ~200 μm (see

Figure 7).

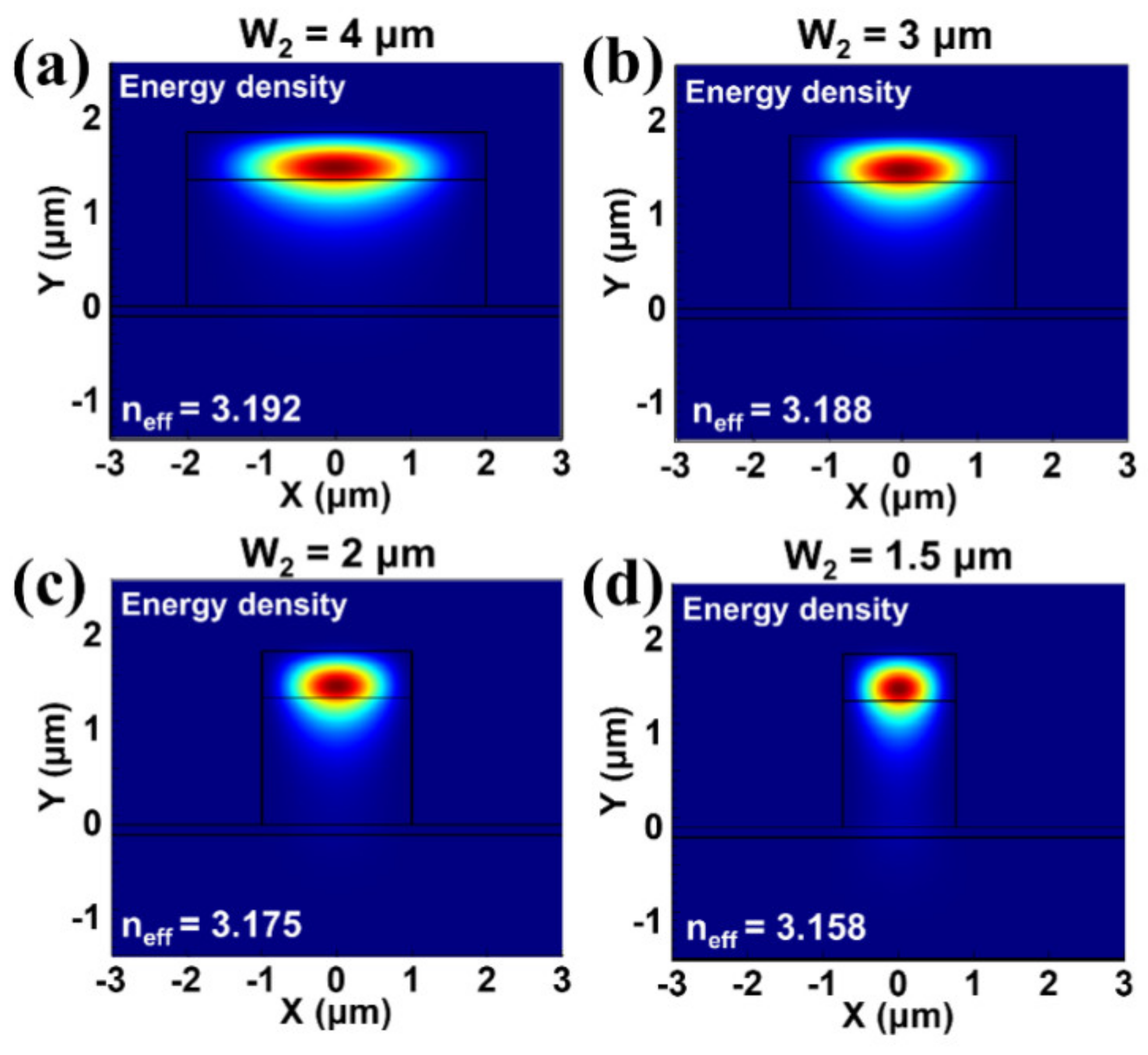

The 2D mode profiles with

W2 = 4 μm,

W2 = 3 μm,

W2 = 2 μm, and

W2 = 1.5 μm and their respective propagating indices are shown in

Figure 10a–d, respectively. These were simulated with polymer as the upper cladding and material at both sides of the waveguide. Our simulation showed that at

W2 = 1.5 μm, the mode began to be coupled to the substrate at the passive waveguide device as the real part of its propagating refractive index (

n = 3.158) became lower than the refractive index of the InP lower cladding (

n = 3.17), and in fact, the imaginary part of its propagating refractive index had a high nonzero value when the absorbing boundary was used for boundary lines surrounding the substrate, indicating energy loss through the substrate.

Thus, from the above data, we can conclude that it is possible to use a W2 narrower than 4 μm but wider than (or equal to) 2 μm to achieve roughly the same mode connection efficiency but with a taper length a few times shorter for both LBT and LT than that of the 4-μm wide case. These analyses also show that the device structures were reasonably tolerant to structural and fabrication variations in terms of impacting the device performances.