1. Introduction

Glass exposed to focused ultrafast laser pulses exhibits local morphological changes to the bulk substrate [

1]. At low pulse energies and repetition rates, quasi-periodic self-organized structures (“nanogratings”) form, oriented perpendicular to the polarization direction [

2,

3]. The nanogratings are associated with permanent strain, imparting a spatially varying stress field within the substrate, which responds by bending to equilibrize the ultrafast laser-induced stresses. The laser-induced stress is nominally permanent, but its stability has not been studied in detail.

Ultrafast laser stress figuring (ULSF) leverages the laser-induced stress to deterministically alter the optical figure and correct low order spatial frequency height errors up to several micrometers as a post-coating figuring process [

4]. The stress pattern produces deformation akin to a thin film with a spatially varying state of plane stress

and thickness

. By imparting a pre-determined stress distribution, ULSF has been shown to correct up to 6th order Zernike polynomial modes with 10–20 nm RMS accuracy in 100 mm-diameter, 1 mm-thick fused silica substrates, for example [

5].

Research on the stability of ultrafast laser-induced modifications and resultant birefringence have previously shown only small changes after low temperature annealing, with lifetimes predicted over 10 years at 800 °C, and fiber Bragg gratings in silica continue to perform well after being exposed to temperatures up to 1000 °C [

6,

7,

8,

9,

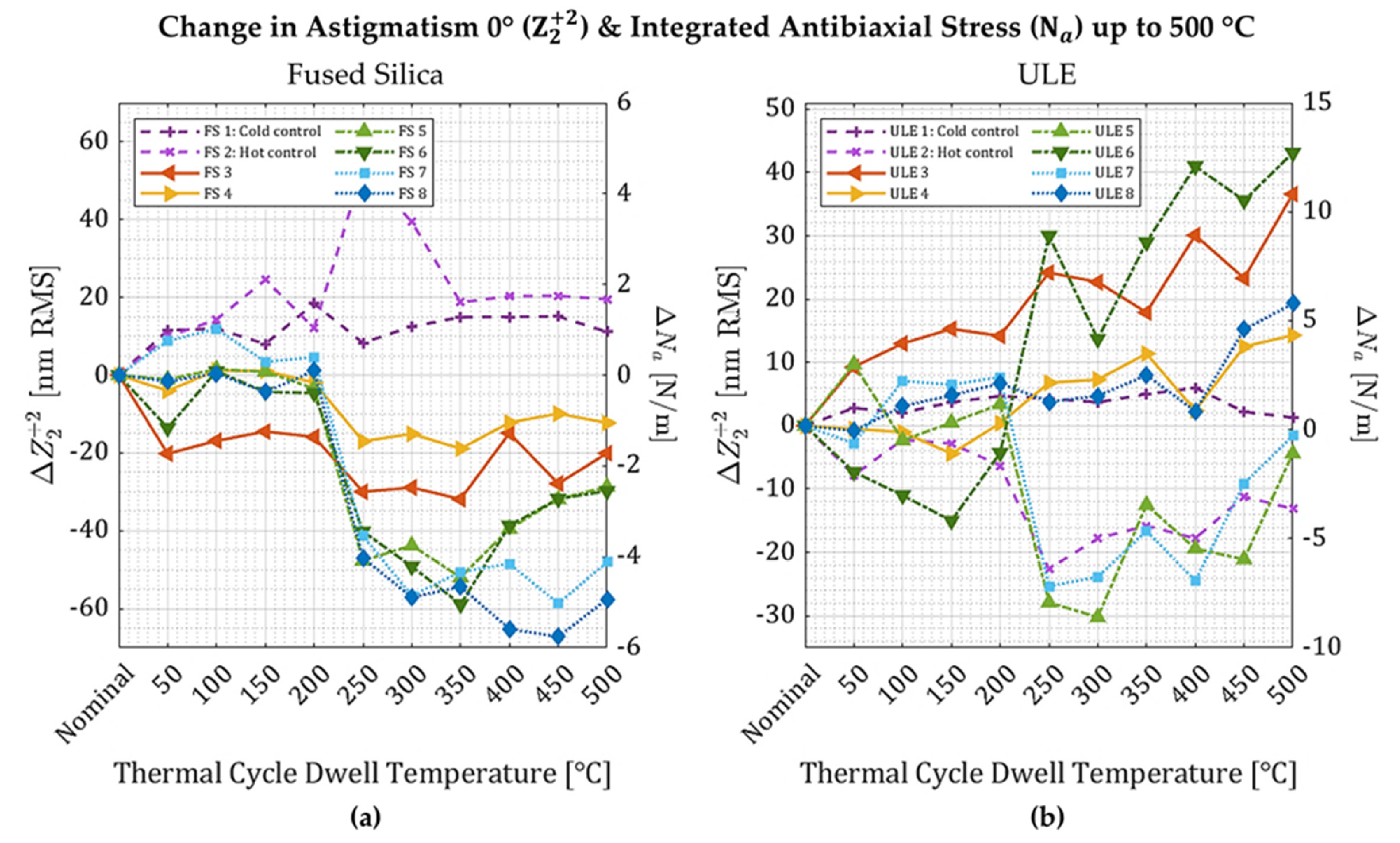

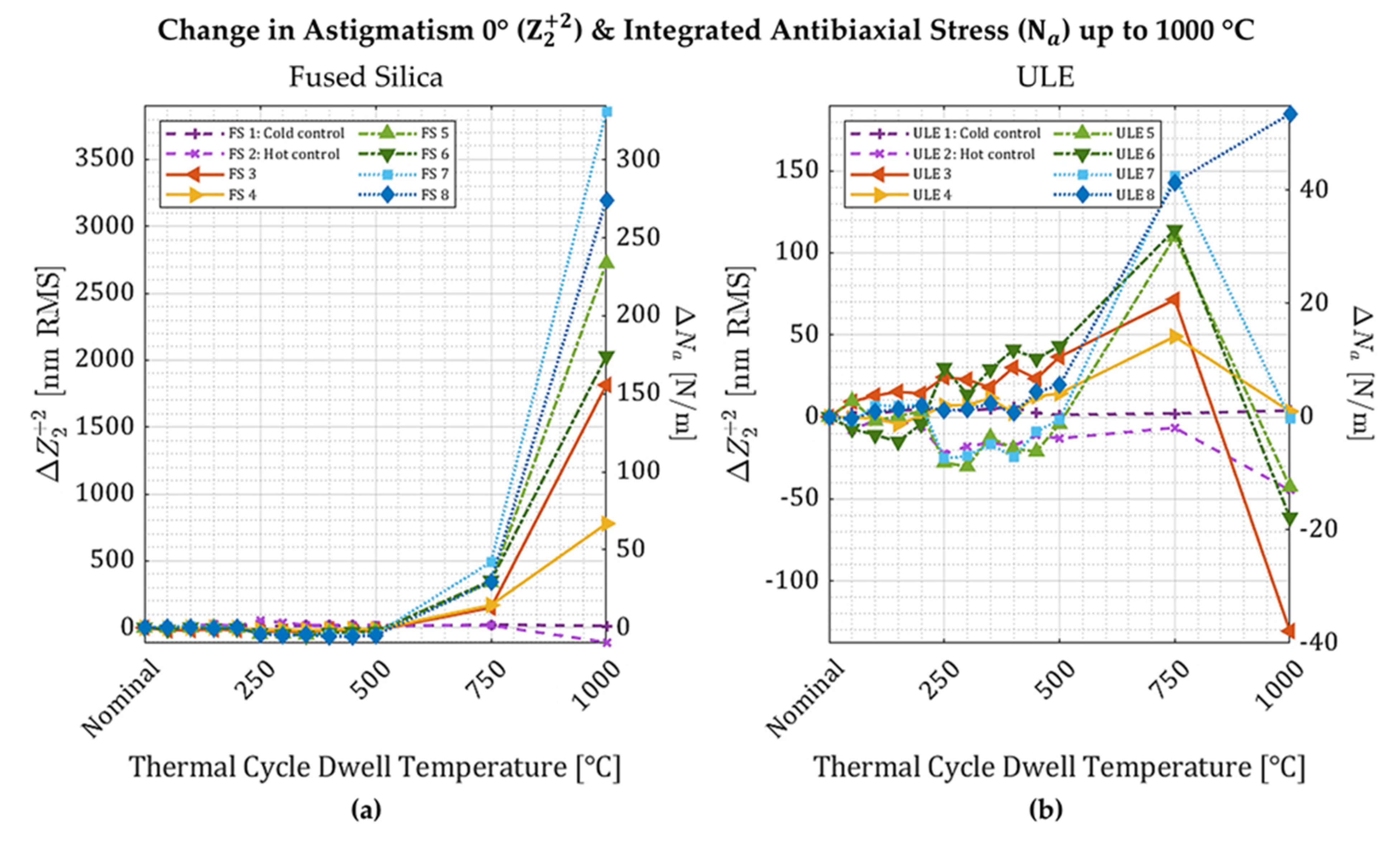

10]. This suggests that ULSF-generated stress fields may also be stable, but the lifetime stability of the induced stress field itself has not yet been rigorously tested. To address this lack of data, we investigate the stability of ULSF modifications in uncoated fused silica (FS) and Corning ultra-low expansion (ULE) glass through a series of isochronal annealing experiments on 25.4 mm- and 100 mm-diameter wafers figured with single-Zernike term deformation. By exposing laser-figured samples to increasingly elevated temperatures, each at constant duration (i.e., isochronal), we examine the thermal stability of ultrafast laser-generated stress states in both materials. We track 15 Zernike terms throughout the thermal cycling regimen and find the stress state to be stable up to about 200–250 °C, with greater (though still small) changes in magnitude at higher temperatures for both fused silica and ULE. In

Section 2 we detail materials and methods used to prepare study samples with ULSF and carry out the isochronal annealing regimen. Results of both experiments are reported in in detail in

Section 3. Finally, we discuss potential sources of the observed response to thermal cycling in

Section 4.

2. Materials and Methods

Two experiments were conducted to examine the stability of ultrafast laser-generated stress in fused silica and ULE glass. Experiment 1 included 16 25.4 mm-diameter samples, and Experiment 2 included five 100 mm-diameter samples to obtain higher measurement sensitivity. ULSF was used to induce deformation composed of a single Zernike polynomial: astigmatism 0° () for Experiment 1 and trefoil 30° () for Experiment 2. After ULSF, the wafers were thermally cycled between 50 and 1000 °C (Experiment 1) or 100 and 500 °C (Experiment 2). We tracked 15 Zernike terms over the course of the isochronal annealing regimen, most of which did not change significantly.

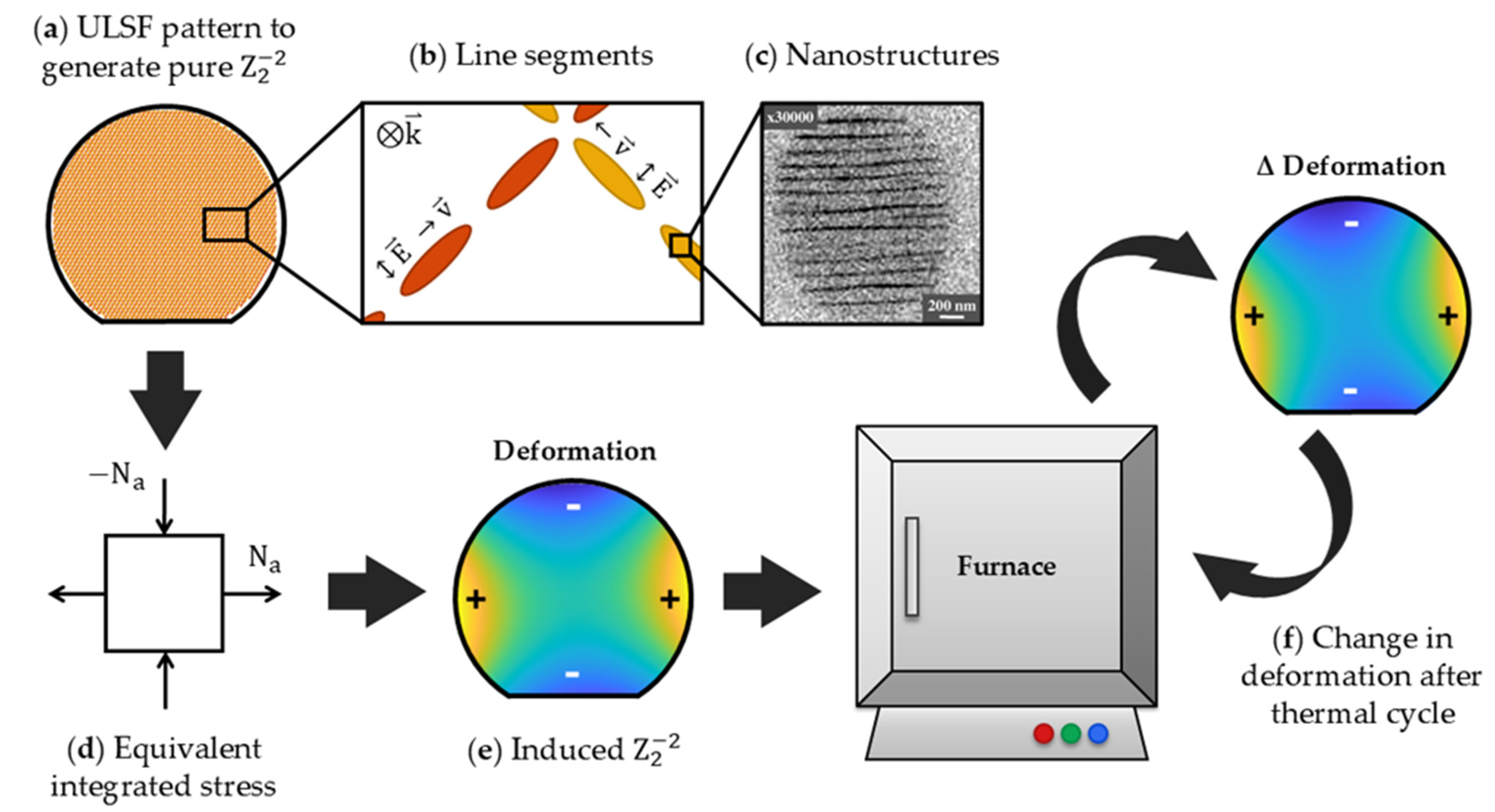

ULSF was used to induce either astigmatism 0° or trefoil 30° using pulse patterns generated for each wafer and the target deformation (

Figure 1a). A convenient representation of the plane stress state are the equibiaxial (

), antibiaxial (

), and shear (

) integrated stress states, which for uniform stress distributions produce deformation corresponding to the Zernike polynomials power (

), astigmatism 0° (

), and astigmatism 45° (

), respectively [

5]. Nanogratings resulting from ultrafast laser pulses were written in 5–45 μm “line segments” within the substrate at several orientations and depths (

Figure 1a–c). The equivalent stress state for patterns inducing astigmatism 0° (

Figure 1d) consists of orthogonal, opposite plane stress components producing antibiaxial stress; the stress state for patterns inducing trefoil 30° consists of a combination of non-uniform antibiaxial stress and shear stress (shear stress is equivalent to a 45–rotated antibiaxial stress). The wafer bends to maintain static equilibrium in response to ULSF-induced stress (

Figure 1e). The wafer shape changes in response to annealing (

Figure 1f).

For most samples, a commercial ultrafast laser (TruMicro 2030, Trumpf GmbH + Co. KG., Stuttgart, Germany) was used for ULSF, with a λ = 1030 nm source beam, 350 fs pulse duration, 1 μJ pulse energy, and 200 kHz repetition rate. The pulses were focused into the substrate with a NA 0.4 objective lens (LMH-20X-1064, Thorlabs Inc., Newton, NJ, USA) and translated with an XYZ stage (PRO165LM-200, Planar DL-200 XY, Aerotech, Inc., Pitttsburgh, PA, USA) across the substrate, with a segment length and pitch of 45 and 50 μm, respectively. The samples were either 25.4 mm-diameter or 100 mm-diameter double-side polished, uncoated wafers, made of Corning 7980 fused silica or Corning ULE 7972. The 25.4 mm-diameter fused silica wafers were 0.5 mm-thick, and all others were 1 mm-thick. All wafers had an orientation flat to facilitate metrology.

Most wafers were figured with ULSF then thermally cycled. Some wafers (“hot controls”) were not figured but were thermally cycled, and some wafers (“cold controls”) were neither figured nor thermally cycled. All figured and hot control wafers were thermally cycled in a high temperature furnace (KSL-1200X, MTI Corp., Richmond, CA, USA) at multiple dwell temperatures. The ramp rate was 6 °C per minute, and the dwell time for all cycles was 4 h, after which the furnace was shut off and the samples allowed to cool back down to 50 °C. An additional 30 min dwell was added for cycles over 500 °C at 65–75% of the target dwell temperature to mitigate ramp deceleration. The temperature was monitored using a thermocouple (XC-20-K-60, DwyerOmega, Michigan City, IN, USA). The ULE samples were thoroughly cleaned and contained within fused silica trays for the 1000 °C thermal cycle to prevent crystallization due to the risk of nucleation in the presence of atmospheric contaminants within the furnace at elevated temperatures [

12].

To monitor changes in surface figure, all wafers including controls were measured on a phase-shifting Fizeau interferometer (S100|HR, Äpre Instruments, Tucson, AZ, USA) with variable coherence source illumination (SpectrÄ Gen4, Äpre Instruments, Tucson, AZ, USA) after each thermal cycle, mounted on a hexapod (Puna STD11, Symétrie, Nimes, France) for positioning with respect to a transmission flat. Zernike coefficient data was extracted and analyzed with custom software that was also used to prepare machine code to produce ULSF patterns. Equibiaxial, antibiaxial, and shear integrated stress was calculated using a modified Stoney’s equation [

5].

2.1. Experiment 1

Six fused silica wafers (25.4 mm-diameter, 0.5 mm-thick) and six ULE wafers (25.4 mm-diameter, 1 mm-thick) were figured with ULSF to produce astigmatism 0° (

) with three different magnitudes of stress. Astigmatism 0° was chosen as the deformation term because it has a large ratio of deformation to stress. The magnitude of figured astigmatism 0° ranged from 1.1 to 3.7 μm RMS for the fused silica wafers and 0.3 to 1.2 μm RMS for the ULE wafers, corresponding to 90–350 N/m integrated antibiaxial stress (

Table 1). Two additional unfigured wafers of each material were used as controls for each material; one was never annealed (cold control, FS 1 and ULE 1), and the other completed the thermal cycling regimen with the figured wafers (hot control, FS 2 and ULE 2). The 12 figured wafers and 2 hot controls were thermally cycled at dwell temperatures from 50 to 500 °C in 50 °C increments and at 750 °C and 1000 °C.

2.2. Experiment 2

One fused silica and two ULE wafers (100 mm-diameter, 1.0 mm-thick) were figured with approximately 2 μm RMS trefoil 30° (

) in order to detect smaller changes in integrated stress (

Table 1). The deformation caused by a change in stress is proportional to the square of the diameter-to-thickness ratio of the substrate, so these wafers are 4–16× more sensitive than those in Experiment 1. Trefoil 30° is preferred for wafers with larger aspect ratios due to mount-induced astigmatic deformation during measurement.

FS B, ULE B, and ULE C were figured with the same laser parameters as in Experiment 1, except ULE C was figured with a 225 kHz repetition rate as we used a slightly different calibration to generate the ULSF pattern; similar repetition rates do not significantly alter the ULSF result when all other processing parameters are held. Additionally, the segment length and pitch were 20 and 25 μm for FS B and 5 and 10 μm for ULE B. The wafers were thermally cycled between 100 and 500 °C with steps of 100 °C between cycles. We monitored the average root sum squared (RSS) of both trefoil 30° and trefoil 0° to reduce error from small clocking differences between measurements on the interferometer.

4. Discussion

Thermal stability of ultrafast laser-induced stress is similar in ULE and fused silica but exhibits some notable differences. After thermal cycling between 200 °C and 500 °C, fused silica samples figured with either astigmatism 0° or trefoil 30° relaxed slightly whereas the figured term for ULE sometimes relaxed like fused silica but sometimes

increased. Furthermore, the behavior at very high temperatures is very different. The increase in antibiaxial stress for both materials up to 750 °C continues for fused silica at 1000 °C, but most ULE samples relax at 1000 °C. Cavillon et al. describe a “steep decay” in ultrafast laser-induced retardance, associated with erasure of nanostructures beginning around 1100–1250 °C for silica and driven by the glass viscosity behavior at high temperatures [

13]. Though here the final thermal cycle was only 1000 °C, the change in antibiaxial stress in ULE samples 2–7 appear to show the beginning of such a decline. Since ULE has a lower softening point (1490 °C) than fused silica (1600 °C), it is likely that ULE requires a lower temperature to enter the erasure range which is in agreement with isochronal annealing retardance results reported in Refs. [

10,

13,

14]. ULE is also inhomogeneous, which could contribute to more variation in behavior between samples than in fused silica, similar to Refs. [

10,

14].

The onset of significant low-temperature changes in stress in both materials is likely due to point defect erasure, which occurs around 200–500 °C [

6,

15]. Point defects—dangling silicon or oxygen bonds within the amorphous glass structure that can recombine or convert into other defects as well as affect local density—are known to occur in ultrafast laser-induced modifications [

15,

16,

17]. Their position with respect to the nanostructures is at least partially dependent on the laser writing parameters [

6,

13], and whether stress increases or decreases upon erasure could be related to their location with respect to the nanostructures. Wang et al. [

6] theorized that retardance from laser-generated nanogratings in silica glass decreased after thermal annealing at low temperatures when defects were between the nanostructures and increased when point defects were within the nanostructures. In the fused silica samples, erasure of point defects occurring between the nanostructures could be causing a decrease in induced stress after annealing beyond 200 °C. ULE is composed of alternating layers of titania-doped silica and undoped silica about 50–500 μm thick [

18,

19], and the ultrafast laser-generated modifications in this work (approximately 25–40 μm in length) fit within either a doped or undoped ULE layer [

3]. If the modifications are written mostly in undoped silica layers, then point defects may occur between the nanostructures and lead to stress relaxation after cycling beyond 200 °C, similar to the fused silica samples. In titania-doped layers, the defects may occur within the nanostructures and produce an increase in the figured term instead.

The observed increase in stress at 750 °C is similar to behavior found in Wang et al. where an increase in birefringence was attributed to permanent changes in material densification leading directly to strain after annealing at temperatures between 600 and 900 °C [

6]. Porous and densified material alternate within the nanostructures, and changes to the density within or between the nanogratings produces changes in stress and elastic modulus [

1,

16,

20]. Thermal relaxation of structurally dense regions leads to net volume expansion resulting in higher compressive stress, and it has been suggested that the location of density relaxation affects whether stress (via retardance) increases or decreases in this temperature range [

6]. As densified regions preferentially within the modifications gradually anneal, form birefringence and the measured retardance should decrease [

6]. Relaxation of densification located preferentially surrounding the periodic structure of the nanogratings should result in an increase in material density around the nanolayers, local compression due to volume expansion, and an increase in retardance [

6]. Accumulated compression in the latter situation could contribute to an increase in stress. This seems to fit with the observed behavior of ULE samples 3–7 after annealing at 750 °C as well as the fused silica samples and ULE 8 up to 1000 °C. Decreased retardance in the former situation is unlikely to cause an increase in stress since relaxation of densified regions within the nanogratings only leads to a changing fill factor in the nanostructure as pores begin to disappear [

13].

Although changes in densification appear to contribute to birefringence relaxation, the experiments reviewed often report a decrease in retardance indicating a possible reduction in stress at high temperatures [

6,

9,

10,

13,

14,

21,

22], whereas we observe an increase in stress in fused silica. Occasionally, previously published results included a sample appearing to show an increase in measured retardance during the annealing regimen, indicating a potential increase in stress [

6,

9,

14,

21]. This has been explained as a combination of relaxation of dense regions within the nanogratings and point defect erasure related to the morphology of the nanostructures and laser writing parameters occurring at different temperatures [

6,

13,

22]. However, while we do observe changes in stress at similar annealing temperatures, the direction of change is not uniformly relaxation and not always in a uniform direction for all tracked Zernike terms. The shift we observe into increasing magnitudes of astigmatism 0°, astigmatism 45°, or power at high temperatures and in different directions suggests that there may be another mechanism at play, such as preferential relaxation of the stress fields in certain directions, and the full picture of stress behavior between 500 and 1000 °C may be obscured by measuring retardance alone. For example, in Ref. [

22] the authors report that birefringence of ultrafast laser-generated nanogratings decreased during thermal annealing, but changes to the extraordinary index increased after 500 °C. They speculate that the local nanostructure material composition anneals at different rates; perhaps such behavior contributes to directional stress stability, though this is not the only possible explanation for our observations.

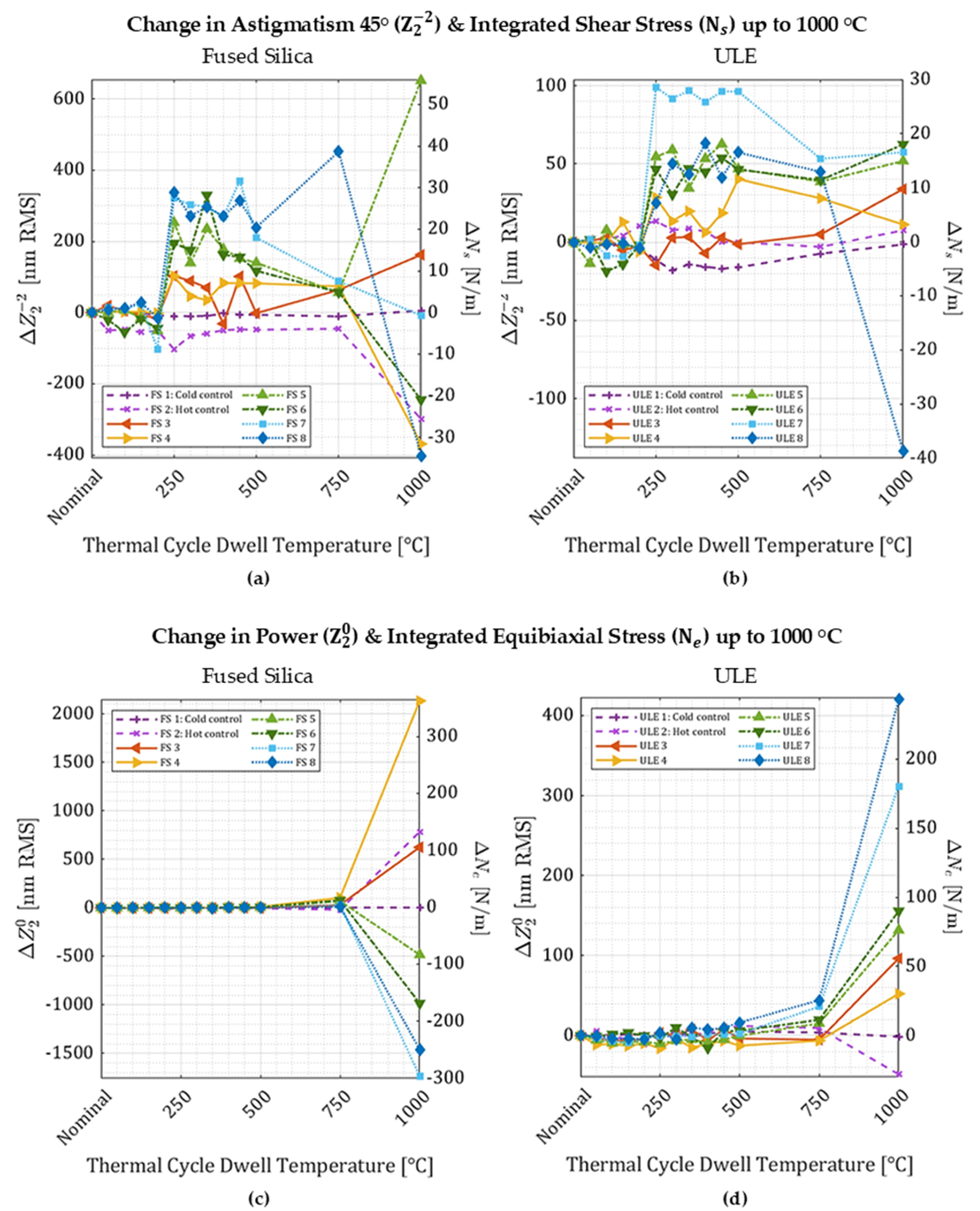

The large change in shear stress after 200 °C and the large change in equibiaxial stress at high temperatures is surprising and suggests that stress stability may be direction dependent. The ULSF pattern includes line segments written in three directions, with the polarization perpendicular to the writing direction (see

Figure 1b). If all properties of the beam were axisymmetric (i.e., Gaussian beam profile, no wavefront error, no pulse front tilt), we would expect no difference in stress from the three writing directions (other than a coordinate transformation) or their stability. However, the stress from each writing direction is not simply related to the other directions through a coordinate rotation [

5]. Therefore, some properties of our laser beam are not axisymmetric. We suspect that the shear stress and power changes occur because some writing directions have different stability than other directions. If some writing directions relaxed at a lower temperature than others (due to more point defects initially, for example), both power and astigmatism 45° deformations could result. An alternative explanation may be that the stress in some regions of the laser-written line segments, such as the start or end of each line segment where shear stress is more prevalent, relax at a lower temperature than other regions. Additional experiments are needed to test these hypotheses.

5. Conclusions

Induced deformation via ultrafast laser stress figuring (ULSF) in both fused silica and Corning ULE is stable to within our measurement noise, up to about 200 °C. Between 200 and 500 °C, induced deformation in the fused silica samples relaxed but increased in ULE, resulting in a -1.8% to +11.5% percent change from the ULSF deformation. Changes in the figured term up to 500 °C are correlated with the temperature at which point defect erasure occurs, and the effect on stress may depend on where the point defects exist. Between 250 and 500 °C there are changes in astigmatism 45° in both materials, even when this term was not induced by ULSF, for the 25.4 mm-diameter samples. All changes in stress are relatively small up to 500 °C compared to changes beyond 500 °C. Stress in ULE drops dramatically at 1000 °C, which is attributed to the onset of nanograting erasure, whereas stress in fused silica increases dramatically.

Confidence in the lifetime stability of ULSF-induced stress supports its viability as a processing tool to supplement thin optics manufacturing. We demonstrated that changes to the induced surface figure after ULSF are limited to the low tens of nanometers up to 200 °C, indicating that ULSF can survive and continue to perform well in common thermal environments. While there is some directional dependence in the stress stability in small mirrors, this is entirely absent in larger diameter mirrors. Using ULSF for post-coating figure correction has been demonstrated previously [

5], and its stability likely depends on the stability of the film, not ULSF. ULSF also represents a critical step toward concurrent figuring and alignment, and it offers a contact-free method of optical surface pre-forming to reduce the need for post-alignment wavefront correction. Further areas of interest regarding thermal stability of ULSF include contributions to directional stress stability from the beam profile, substrate material, and local nanostructure morphology.