Designing an SOI Interleaver Using Genetic Algorithm

Abstract

1. Introduction

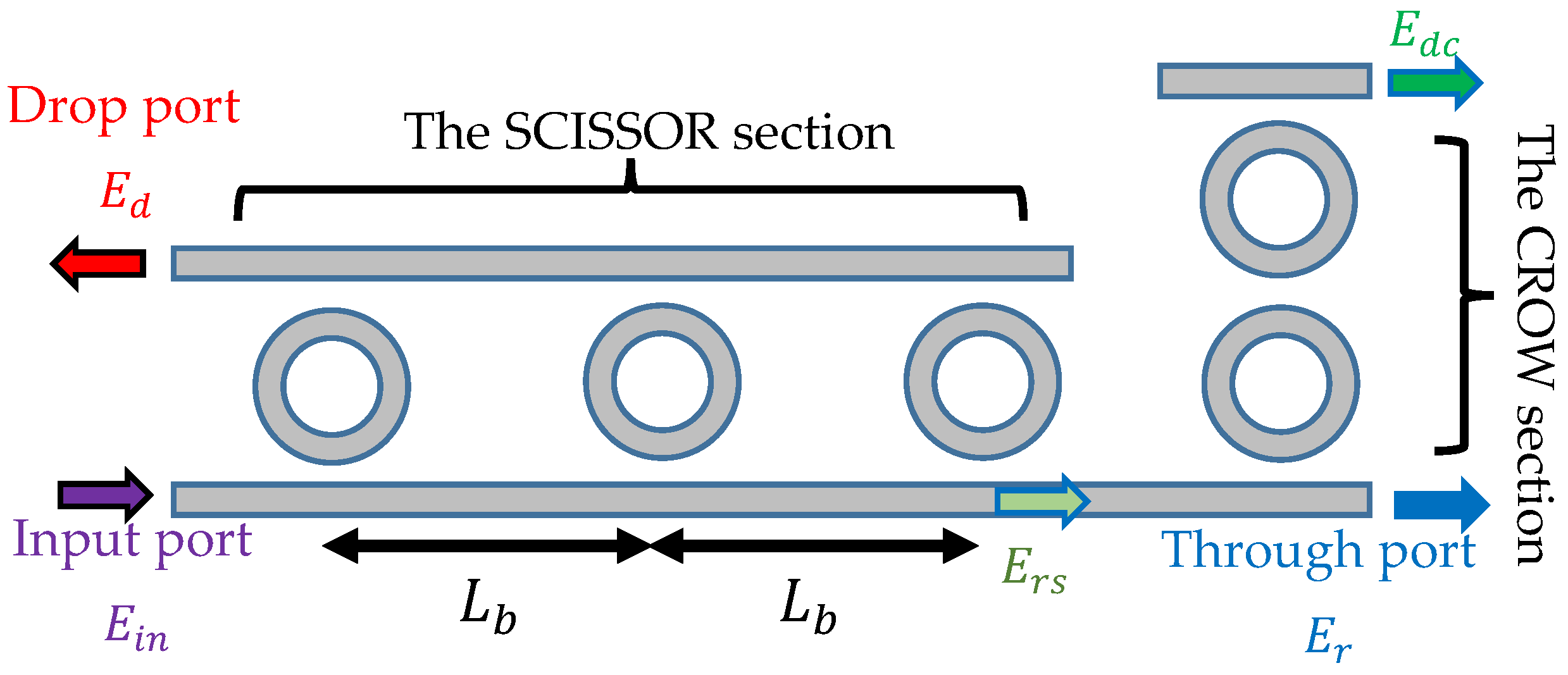

2. An Overview of the Interleaver Circuit

3. The Compromised Optimization Approach

- “a” represents the average of the values in Group A, which contains metrics corresponding to performance parameters that have either met or exceeded the wavelength division multiplexing (WDM) basic targets. A higher “a” value for a chromosome indicates that its performance parameters are further beyond the WDM requirements.

- “b” represents the average of the values in Group B, consisting of negative metrics corresponding to performance parameters falling short of the requirements. Since “b” is negative, larger values imply values closer to zero. Therefore, a higher “b” value suggests that some performance parameters performed poorly.

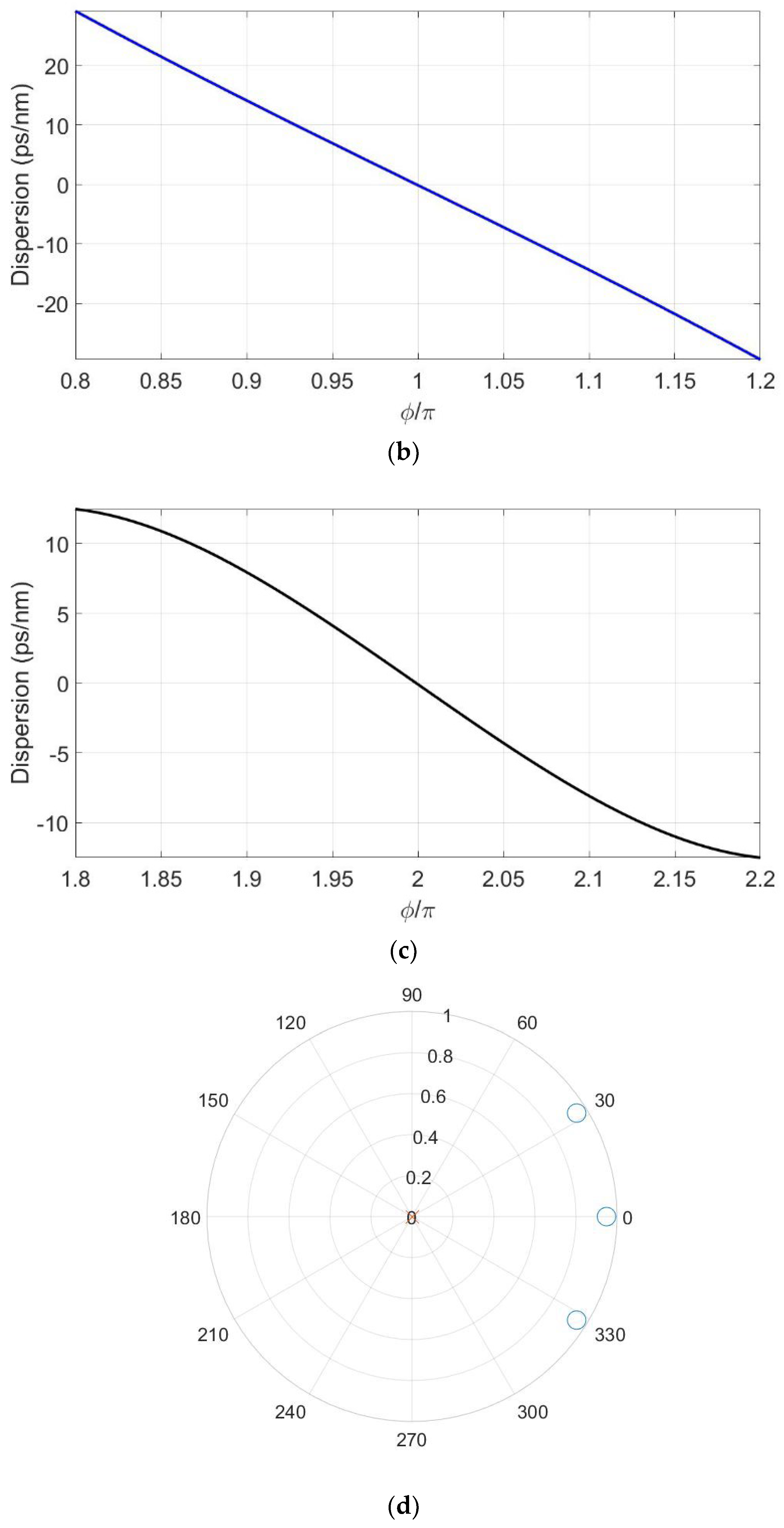

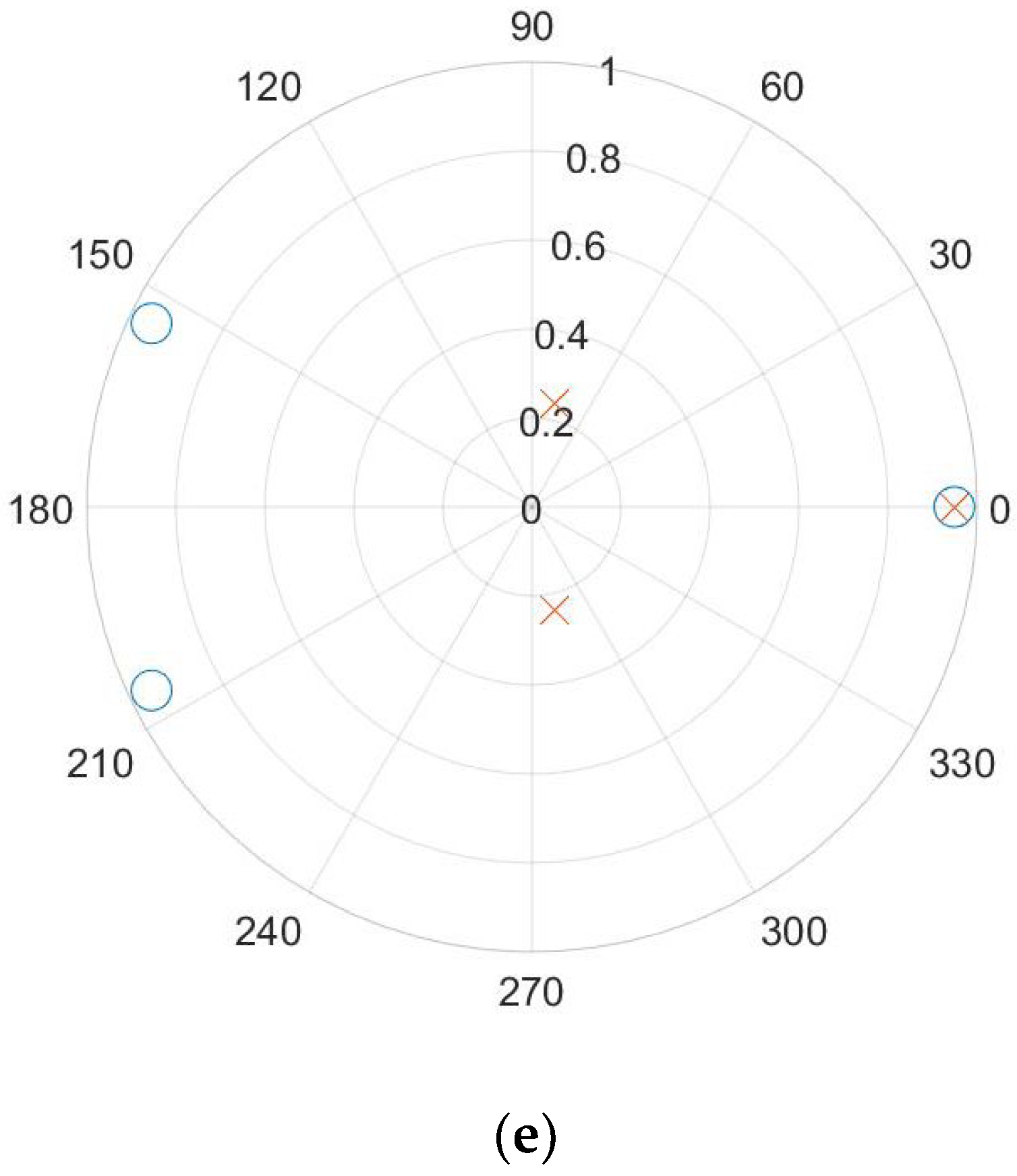

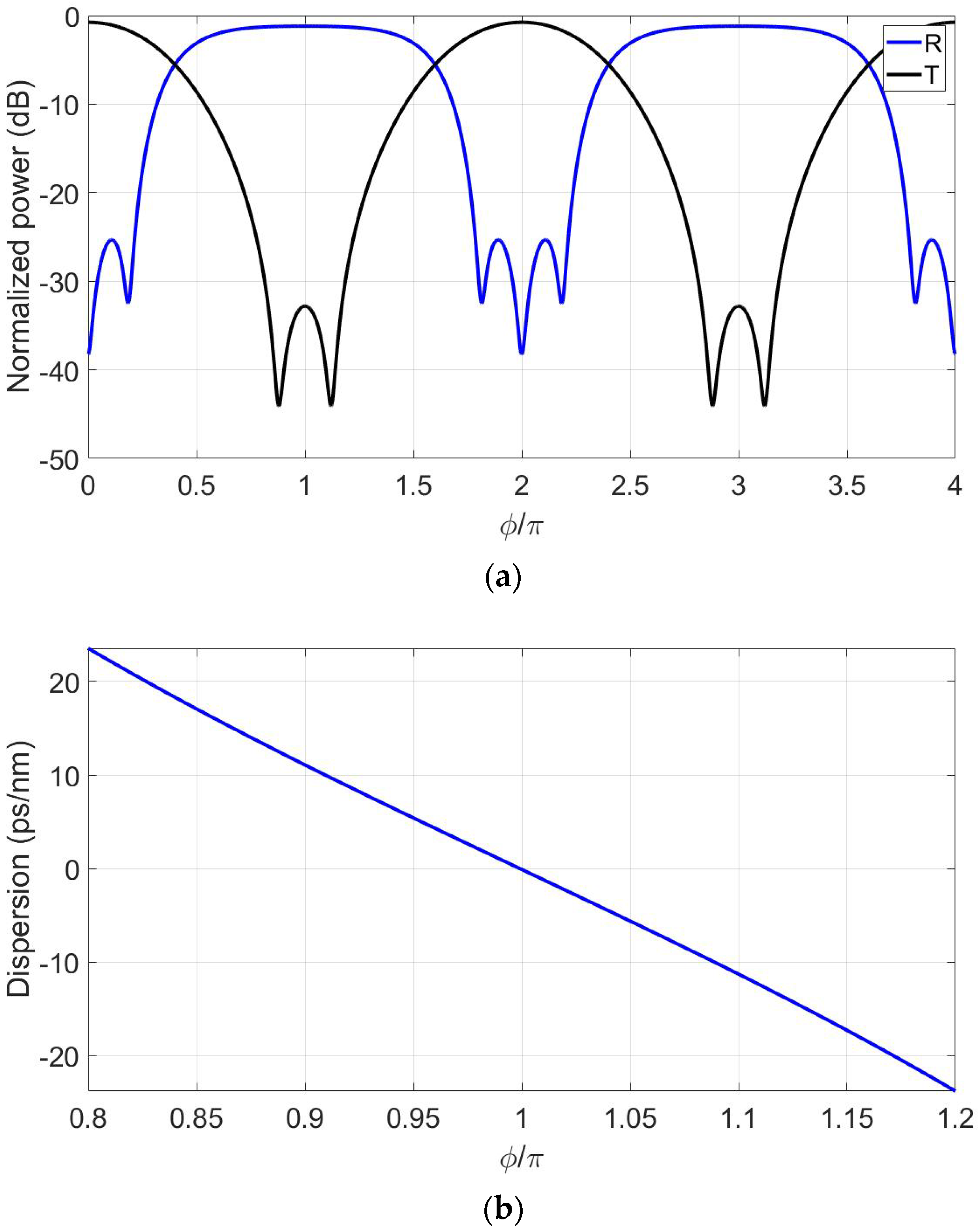

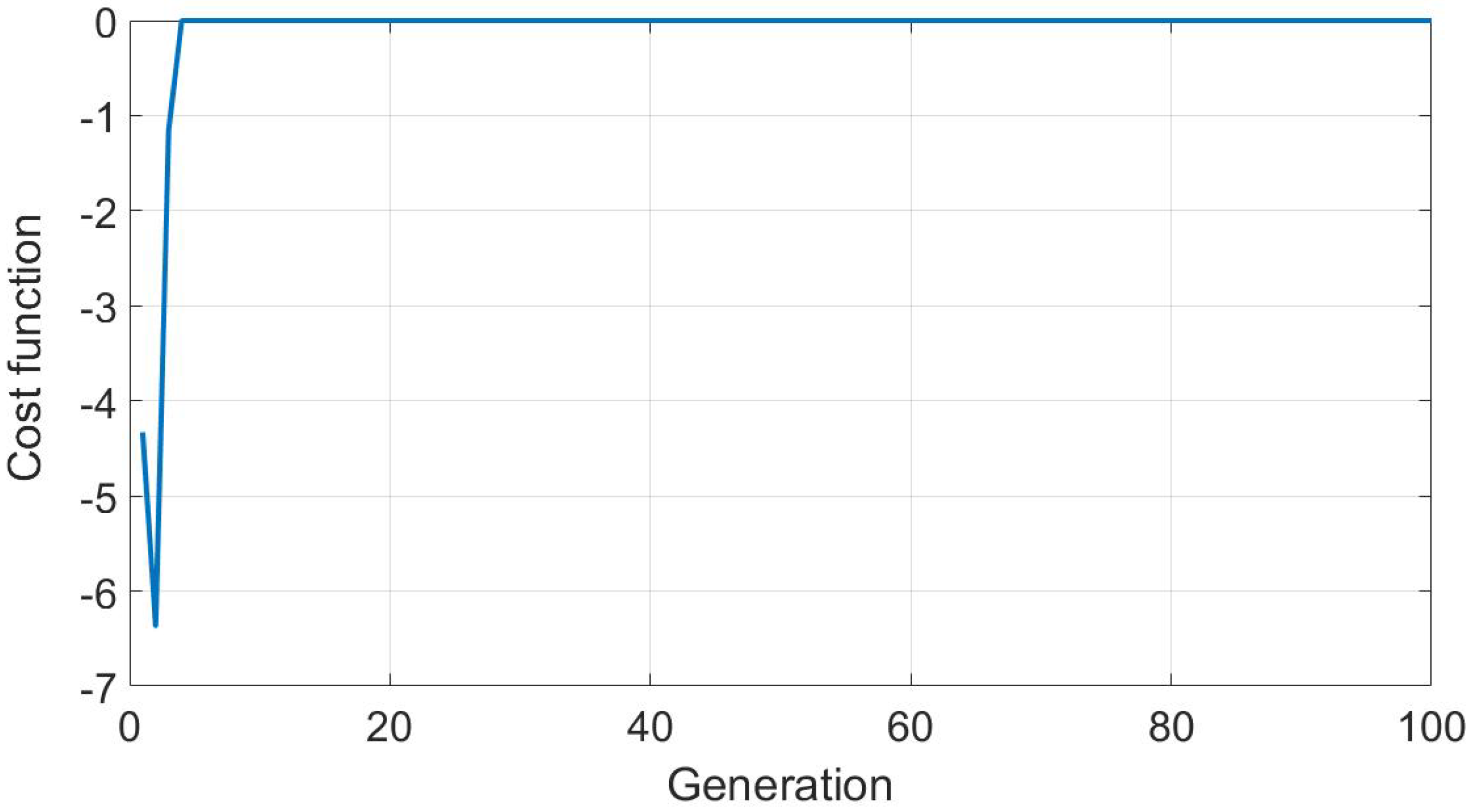

4. Optimization Results

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Monir, M.; El-Refaei, H.; Khalil, D.; Omar, O. Assessment of the NM-lines sensitivity for measurement errors. Fiber Integr. Opt. 2007, 26, 1–15. [Google Scholar] [CrossRef]

- Monir, M.; El-Refaei, H.; Khalil, D. Single-mode refractive index reconstruction using an NM-line technique. Fiber Integr. Opt. 2006, 25, 69–74. [Google Scholar] [CrossRef]

- Mahrous, H.; Fedawy, M.; El Sabbagh, M.; Fikry, W.; Gad, M. 130 Gbps low-loss electro-optic modulator based on metal-oxide-semiconductor technology. Optik 2020, 217, 164928. [Google Scholar] [CrossRef]

- Mahrous, H.; Fedawy, M.; El Sabbagh, M.; Fikry, W.; Gad, M. A compact 120 GHz monolithic silicon-on-silica electro-optic modulator. Opt. Quantum Electron. 2020, 52, 111. [Google Scholar] [CrossRef]

- Mahrous, H.; Azmy, M.; Afifi, A.; Abouelainain, A.; Kotb, A.; Fedawy, M.; Fikry, W.; Gad, M.; Selim, D. Design of compact, high-speed and low-loss silicon-on-silica electro-optic modulators. Semicond. Sci. Technol. 2020, 35, 095017. [Google Scholar] [CrossRef]

- Mahrous, H.; Gad, M.; El Sabbagh, M.; Fedawy, M.; Fikry, W. A High-Speed Electro-Optic Modulator with Optimized Electrode Positions. In Proceedings of the 2018 13th International Conference on Computer Engineering and Systems, ICCES 2018, Cairo, Egypt, 18–19 December 2018; pp. 530–535. [Google Scholar] [CrossRef]

- Rahim, A.; Hermans, A.; Wohlfeil, B.; Petousi, D.; Kuyken, B.; Van Thourhout, D.; Baets, R. Taking silicon photonics modulators to a higher performance level: State-of-the-art and a review of new technologies. Adv. Photonics 2021, 3, 024003. [Google Scholar] [CrossRef]

- Shalaby, R.A.; Adib, G.; Sabry, Y.M.; Gad, M.; Khalil, D.; Sabry, Y.M.; Khalil, D. Silicon photonic coupled-ring resonator in nested configuration comprising different length scales. In Proceedings of the 2019 14th International Conference on Computer Engineering and Systems (ICCES), Cairo, Egypt, 17 December 2019; Institute of Electrical and Electronics Engineers (IEEE): Piscataway, NJ, USA, 2020; pp. 432–437. [Google Scholar] [CrossRef]

- Labib, M.; Gad, M.; Sabry, Y.M.; Khalil, D. Strip Waveguide Enabling Low Loss for Silicon on Silica Technology in the MIR. In Proceedings of the 2018 13th International Conference on Computer Engineering and Systems, ICCES 2018, Cairo, Egypt, 18–19 December 2018; Institute of Electrical and Electronics Engineers Inc.: Piscataway, NJ, USA, 2019; pp. 536–540. [Google Scholar] [CrossRef]

- Labib, M.; Gad, M.; Sabry, Y.M.; Khalil, D. Optimization of silicon on silica waveguides for mid-infrared applications at 4.28 um. Silicon Photonics XIV 2019, 10923, 155–165. [Google Scholar] [CrossRef]

- Labib, M.; Gad, M.; Sabry, Y.M.; Khalil, D. Extended Wavelength Silicon-on-Silica Photonics Platform: Design Case Study for Gas Sensing in the Mid-infrared Range. Silicon 2025, 17, 2089–2103. [Google Scholar] [CrossRef]

- Shukri, Z.; Rezaei, H.; Fasihanifard, M.; Ghofrani, S.; Bissonnette, J.; Gravey, T.; Romanuik, S.; Tewari, R.; Zandi, K. Photonic integrated circuit microchip-based optical gyroscopes for high-precision inertial measurement units. Integr. Opt. Devices Mater. Technol. XXIX 2025, 13369, 74–87. [Google Scholar] [CrossRef]

- Wang, L.; Sun, D.; Liu, W.; Lu, Z.; Fan, S.; Liu, H.; Jin, L.; Feng, J.; Xu, W.; Jiao, H.; et al. Analysis and suppression of passive chip stray light for integrated optical gyroscopes. Opt. Commun. 2025, 577, 131454. [Google Scholar] [CrossRef]

- Griol, A.; Håkansson, A.; Brimont, A.; Cuesta, F.; Martí, J.; Galán, J.V.; Sanchis, P.; Villalba, P. Highly efficient crossing structure for silicon-on-insulator waveguides. Opt. Lett. 2009, 34, 2760–2762. [Google Scholar] [CrossRef]

- Shoji, T.; Tsuchizawa, T.; Watanabe, T.; Yamada, K.; Morita, H. Spot-size converter for low-loss coupling between 0.3-μm-square Si wire waveguides and single-mode fibers. In Proceedings of the 15th Annual Meeting of the IEEE Lasers and Electro-Optics Society, Glasgow, UK, 10–14 November 2002; IEEE: Piscataway, NJ, USA, 2003; pp. 289–290. [Google Scholar] [CrossRef]

- Sánchez-Sánchez, A.; Pérez-Armenta, C.; Luque-González, J.M.; Ortega-Moñux, A.; Wangüemert-Pérez, J.G.; Molina-Fernández, Í.; Halir, R. Ultra-compact broadband spot size converter using metamaterial cell-based inverse design. arXiv 2025, arXiv:2501.06390. [Google Scholar]

- Huang, S.Y.; Barz, S. Compact inverse designed vertical coupler with bottom reflector for sub-decibel fiber-to-chip coupling on silicon on insulator platform. Sci. Rep. 2025, 15, 2925. [Google Scholar] [CrossRef] [PubMed]

- Yuan, Q.; Peczek, A.; Frankel, J.; Rishavy, D.; Mai, C.; Christenson, E.; Pratap, D.; Zimmermann, L. Fully Automated Wafer-Level Edge Coupling Measurement System for Silicon Photonics Integrated Circuits; IEEE Transactions on Semiconductor Manufacturing: Piscataway, NJ, USA, 2025. [Google Scholar] [CrossRef]

- Yi, X.; Zhao, W.; Zhang, L.; Dai, D. Polarization-insensitive and low-loss O-band edge coupler for silicon photonics. Opt. Lett. 2025, 50, 1699–1702. [Google Scholar] [CrossRef]

- Cutolo, A.; Iodice, M.; Irace, A.; Spirito, P.; Zeni, L. An electrically controlled Bragg reflector integrated in a rib silicon on insulator waveguide. Appl. Phys. Lett. 1997, 71, 199–201. [Google Scholar] [CrossRef]

- Fu, P.H.; Huang, T.Y.; Fan, K.W.; Huang, D.W. Optimization for ultrabroadband polarization beam splitters using a genetic algorithm. IEEE Photonics J. 2019, 11, 1–11. [Google Scholar] [CrossRef]

- Zafar, H.; Pereira, M.F. An efficient and compact mid-infrared polarization splitter and rotator based on a bifurcated tapered-bent waveguide. Sci. Rep. 2025, 15, 5160. [Google Scholar] [CrossRef]

- Dai, D.; Tang, Y.; Bowers, J.E. Mode conversion in tapered submicron silicon ridge optical waveguides. Opt. Express 2012, 20, 13425. [Google Scholar] [CrossRef]

- Zafar, H.; Pereira, M.F. Recent Progress in Light Polarization Control Schemes for Silicon Integrated Photonics. Laser Photonics Rev. 2024, 18, 2301025. [Google Scholar] [CrossRef]

- Shahwar, D.; Yoon, H.H.; Akkanen, S.-T.; Li, D.; tul Muntaha, S.; Cherchi, M.; Aalto, T.; Sun, Z. Polarization management in silicon photonics. Npj Nanophotonics 2024, 1, 35. [Google Scholar] [CrossRef]

- Sanchis, P.; Cuesta-Soto, F.; Blasco, J.; García, J.; Martínez, A.; Marti, J.; Riboli, F.; Pavesi, L. All-optical MZI XOR logic gate based on Si slot waveguides filled by Si-nc embedded in SiO2. In Proceedings of the IEEE International Conference on Group IV Photonics GFP, Ottawa, ON, Canada, 13–15 September 2006; pp. 81–83. [Google Scholar] [CrossRef]

- Ranacher, C.; Carinthian, C.C.; Hedenig, U.; Grille, T.; Lavchiev, V.; Jakoby, B. A photonic silicon waveguide gas sensor using evanescent-wave absorption. In Proceedings of the IEEE Sensors, Orlando, FL, USA, 30 October–3 November 2016; pp. 1–3. [Google Scholar] [CrossRef]

- Passaro, V.M.N.; Dell’Olio, F.; Casamassima, B.; De Leonardis, F. Guided-wave optical biosensors. Sensors 2007, 7, 508–536. [Google Scholar] [CrossRef]

- Lai, W.-C.; Chakravarty, S.; Wang, X.; Lin, C.; Chen, R.T. On-chip methane sensing by near-IR absorption signatures in a photonic crystal slot waveguide. Opt. Lett. 2011, 36, 984. [Google Scholar] [CrossRef] [PubMed]

- Robinson, J.T.; Chen, L.; Lipson, M. On-chip gas detection in silicon optical microcavities. Opt. InfoBase Conf. Pap. 2008, 16, 4296–4301. [Google Scholar] [CrossRef]

- Claes, T.; Molera, J.G.; De Vos, K.; Schacht, E.; Baets, R.; Bienstman, P. Label-free biosensing with a slot-waveguide-based ring resonator in silicon on insulator. IEEE Photonics J. 2009, 1, 197–204. [Google Scholar] [CrossRef]

- Baird, C.L.; Myszka, D.G. Current and emerging commercial optical biosensors. J. Mol. Recognit. 2001, 14, 261–268. [Google Scholar] [CrossRef]

- Ryckeboer, E.; Bockstaele, R.; Vanslembrouck, M.; Baets, R. Glucose sensing by waveguide-based absorption spectroscopy on a silicon chip. Biomed. Opt. Express 2014, 5, 1636. [Google Scholar] [CrossRef]

- Torres, A.; Huang, J.; Bowers, J.; Davenport, M.; Tran, M.; Pintus, P.; Komljenovic, T.; Xie, W. Heterogeneous silicon photonics sensing for autonomous cars [Invited]. Opt. Express 2019, 27, 3642–3663. [Google Scholar] [CrossRef]

- Okamoto, K. Fundamentals of Optical Waveguides, 2nd ed.; Elsevier: Amsterdam, The Netherlands, 2006. [Google Scholar] [CrossRef]

- Yevick, D.; Hermansson, B. Efficient Beam Propagation Techniques. IEEE J. Quantum Electron. 1990, 26, 109–112. [Google Scholar] [CrossRef]

- Aparecido de Paula, R.; Aldaya, I.; Sutili, T.; Figueiredo, R.C.; Pita, J.L.; Bustamante, Y.R.R. Design of a silicon Mach–Zehnder modulator via deep learning and evolutionary algorithms. Sci. Rep. 2023, 13, 14662. [Google Scholar] [CrossRef]

- Mao, S.; Cheng, L.; Zhao, C.; Khan, F.N.; Li, Q.; Fu, H.Y.; Nadeem Khan, F.; Li, Q.; Fu, H.Y. Inverse design for silicon photonics: From iterative optimization algorithms to deep neural networks. Appl. Sci. 2021, 11, 3822. [Google Scholar] [CrossRef]

- Chen, Z.H.; Chen, W.; Cheng, Z.; Lu, G.W.; Wang, J. Ultra-compact spot size converter based on digital metamaterials. Opt. Commun. 2022, 508, 127865. [Google Scholar] [CrossRef]

- Silfies, M.; Kalantarov, D.; Search, C.P. Robust highly stable multi-resonator refractive index sensor. Opt. Commun. 2018, 410, 174–179. [Google Scholar] [CrossRef]

- Ma, H.; Huang, J.; Zhang, K.; Yang, J. Arbitrary-direction, multichannel and ultra-compact power splitters by inverse design method. Opt. Commun. 2020, 462, 125329. [Google Scholar] [CrossRef]

- Kaalund, C.J.; Peng, G.D. Pole-zero diagram approach to the design of ring resonator-based filters for photonic applications. J. Light. Technol. 2004, 22, 1548–1559. [Google Scholar] [CrossRef]

- Gad, M.; Ackert, J.; Yevick, D.; Chrostowski, L.; Jessop, P. Ring resonator wavelength division multiplexing interleaver. J. Light. Technol. 2011, 29, 2102–2108. [Google Scholar] [CrossRef]

- Kumar, M.; Husain, M.; Upreti, N.; Gupta, D. Genetic Algorithm: Review and Application. SSRN Electron. J. 2020, 2, 451–454. [Google Scholar] [CrossRef]

- Sivanandam, S.N.; Deepa, S.N. Introduction to Genetic Algorithms; Springer: Berlin/Heidelberg, Germany, 2008; pp. 1–442. [Google Scholar] [CrossRef]

- Mykel, T.A.W.; Kochenderfer, J. Algorithms for Optimization; The MIT Press: Cambridge, MA, USA, 2019. [Google Scholar]

- Li, Z.; Zhou, Z.; Qiu, C.; Chen, Y.; Liang, B.; Wang, Y.; Liang, L.; Lei, Y.; Song, Y.; Jia, P.; et al. The Intelligent Design of Silicon Photonic Devices. Adv. Opt. Mater. 2024, 12, 2301337. [Google Scholar] [CrossRef]

- Crepinsek, M.; Liu, S.H.; Mernik, M. Exploration and exploitation in evolutionary algorithms. ACM Comput. Surv. (CSUR) 2013, 45, 33. [Google Scholar] [CrossRef]

- Hassanat, A.; Almohammadi, K.; Alkafaween, E.; Abunawas, E.; Hammouri, A.; Prasath, V.B.S. Choosing mutation and crossover ratios for genetic algorithms-a review with a new dynamic approach. Information 2019, 10, 390. [Google Scholar] [CrossRef]

- Abdel-Khalek, H.; Amin, F.M.; Wassel, A.R.; El-Mahalawy, A.M. Enhancement of structure and optical dispersion properties of N,N′-Bis(3-methylphenyl)-N,N′-diphenylbenzidine thin films: Impact of UV irradiation. Opt. Mater. 2021, 113, 110867. [Google Scholar] [CrossRef]

- Gad-Elrab, A.A.A.; El-aal, S.A.; Ghali, N.I.; Zaghrout, A.A.S. An Adaptive Context Modeling Approach Using Genetic Algorithm in IoTs Environments. Adv. Intell. Syst. Comput. AISC 2020, 1129, 184–204. [Google Scholar] [CrossRef]

- Zhou, X.; Yi, D.; Chan, D.W.U.; Tsang, H.K. Silicon photonics for high-speed communications and photonic signal processing. Npj Nanophotonics 2024, 1, 27. [Google Scholar] [CrossRef]

- Lan, Y.; Li, D.; Kai, H.; Zou, B.; Zhang, G.; Feng, S. Inverse design of ultra-compact optical logic gates by genetic algorithm. Opt. Commun. 2024, 569, 130800. [Google Scholar] [CrossRef]

- Fan, Z.Y.; Lin, J.M.; Zhang, T.; Dai, J.; Xu, X.Y.; Xu, K. Efficient off-chip configuration method for scalable programmable photonic integrated circuits. Commun. Phys. 2025, 8, 218. [Google Scholar] [CrossRef]

- Grover, R.; Van, V.; Ibrahim, T.A.; Absil, P.P.; Calhoun, L.C.; Johnson, F.G.; Hryniewicz, J.V.; Ho, P.T. Parallel-cascaded semiconductor microring resonators for high-order and wide-FSR filters. J. Light. Technol. 2002, 20, 900–905. [Google Scholar] [CrossRef]

- Cho, S.-Y.; Soref, R. Apodized SCISSORs for filtering and switching. Opt. Express 2008, 16, 19078. [Google Scholar] [CrossRef]

- Poon, J.; Scheuer, J.; Mookherjea, S.; Paloczi, G.T.; Huang, Y.; Yariv, A. Matrix analysis of microring coupled-resonator optical waveguides. Opt. Express 2004, 12, 90. [Google Scholar] [CrossRef]

- Celo, D.; Goodwill, D.J.; Bernier, E. Interferometric microring-resonant 2 × 2 optical switches. Opt. Express 2008, 16, 13304–13314. [Google Scholar] [CrossRef]

- Jeong, S.-H.; Shimura, D.; Simoyama, T.; Seki, M.; Yokoyama, N.; Ohtsuka, M.; Koshino, K.; Horikawa, T.; Tanaka, Y.; Morito, K. Low-loss, flat-topped and spectrally uniform silicon-nanowire-based 5th-order CROW fabricated by ArF-immersion lithography process on a 300-mm SOI wafer. Opt. Express 2013, 21, 30163. [Google Scholar] [CrossRef]

- Bruce, A.J.; Brenner, I.; Nielsen, T.N.; Gomez, L.T.; Madsen, C.K.; Lenz, G.; Cappuzzo, M.A.; Adams, L.E. An All-Pass Filter Dispersion Compensator Using Planar Waveguide Ring Resonators. In Proceedings of the Optical Fiber Communication Conference and the International Conference on Integrated Optics and Optical Fiber Communication, San Diego, CA, USA, 21–26 February 1999; p. FE6. [Google Scholar]

- Kaalund, C.J.; Jin, Z.; Li, W.; Peng, G.-D. Novel optical wavelength interleaver based on symmetrically parallel-coupled and apodized ring resonator arrays. Photorefractive Fiber Cryst. Devices Mater. Opt. Prop. Appl. IX 2003, 5206, 157. [Google Scholar] [CrossRef][Green Version]

- Gómez, J.D.D. Apodized Coupled Resonator Optical Waveguides: Theory, Design and Characterization. Doctoral Dissertation, Universitat Politècnica de València, Valencia, Spain, 2013. [Google Scholar]

- Gad, M.; Yevick, D.; Jessop, P. Compound ring resonator circuit for integrated optics applications. J. Opt. Soc. Am. A 2009, 26, 2023. [Google Scholar] [CrossRef]

- Mahrous, H.; Fedawy, M.; Abboud, M.; Shaker, A.; Fikry, W.; Gad, M. A Multi-Objective Genetic Algorithm Approach for Silicon Photonics Design. Photonics 2024, 11, 80. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gad, M.; Fedawy, M.; Abboud, M.; Mahrous, H.; Ebrahim, G.A.; Salah, M.M.; Shaker, A.; Fikry, W.; Ibrahim, M. Designing an SOI Interleaver Using Genetic Algorithm. Photonics 2025, 12, 775. https://doi.org/10.3390/photonics12080775

Gad M, Fedawy M, Abboud M, Mahrous H, Ebrahim GA, Salah MM, Shaker A, Fikry W, Ibrahim M. Designing an SOI Interleaver Using Genetic Algorithm. Photonics. 2025; 12(8):775. https://doi.org/10.3390/photonics12080775

Chicago/Turabian StyleGad, Michael, Mostafa Fedawy, Mira Abboud, Hany Mahrous, Gamal A. Ebrahim, Mostafa M. Salah, Ahmed Shaker, W. Fikry, and Michael Ibrahim. 2025. "Designing an SOI Interleaver Using Genetic Algorithm" Photonics 12, no. 8: 775. https://doi.org/10.3390/photonics12080775

APA StyleGad, M., Fedawy, M., Abboud, M., Mahrous, H., Ebrahim, G. A., Salah, M. M., Shaker, A., Fikry, W., & Ibrahim, M. (2025). Designing an SOI Interleaver Using Genetic Algorithm. Photonics, 12(8), 775. https://doi.org/10.3390/photonics12080775