1. Introduction

Solid-state microchip technology, which integrates the entire laser resonator into a monolithic gain medium, provides an effective approach to achieving high-performance near-infrared laser output within compact dimensions. Through frequency doubling, such systems can further generate visible laser emissions. In recent years, this technology has been extensively investigated for applications in lidar systems and laser spectroscopy. Similarly to conventional lasers, microchip lasers can employ active or passive Q-switching techniques to generate Q-switched pulse outputs. Passively Q-switched lasers based on bonded microchip configurations exhibit distinctive advantages, including compact size, the generation of short pulses with durations ranging from hundreds of picoseconds to nanoseconds, compatibility with both continuous and pulsed pumping modes, and superior beam quality. These characteristics have enabled their widespread utilization in material composition analysis [

1], automotive engine ignition [

2], and lidar applications [

3].

Conventional solid-state microchip lasers predominantly utilize Cr

4+:YAG-bonded Nd:YAG crystals as gain media, which exhibit poor thermal performance and low optical-to-optical conversion efficiency under high-power pumping conditions. Enhancing the volumetric utilization efficiency of the gain medium serves as an effective strategy to improve output power. Multi-beam pumping at the oscillator stage and beam-splitting techniques at the amplifier stage both significantly increase volumetric utilization. Compared to single-beam lasers, miniaturized multi-beam systems not only achieve superior volumetric efficiency but also demonstrate unique advantages in automotive ignition and long-range laser detection. Specifically, multi-point excitation enhances automotive engine ignition efficiency compared to single-point methods [

4], while multi-beam single-photon-counting lidar systems reduce global terrain-mapping time relative to single-beam configurations [

5]. In the field of online laser-induced breakdown spectroscopy (LIBS) monitoring, translating the sample [

6] and changing sampling points are commonly required to collect multiple spectra for enhanced measurement consistency. Employing a multi-beam laser for plasma excitation enables simultaneous acquisition of spectra from multiple sampling points, significantly improving real-time detection capability.

However, existing multi-beam generation approaches face critical limitations. Direct multi-beam pumping typically employs multiple independent pump sources [

7,

8]. For instance, Nicolaie Pavel et al. [

7] implemented three-beam output using three fiber-coupled diode lasers (core diameter: 600 μm, NA = 0.22). While achieving high output power, this configuration suffers from large system dimensions, high cost, and challenges in miniaturization. Diffractive beam-splitting methods [

9,

10] partially address these issues. Zheng Wang et al. [

10] realized a four-beam output by integrating a diode-pumped solid-state laser with Dammann grating. However, the low first-order diffraction efficiency (65.8%) results in poor energy utilization, and the grating’s limited damage threshold restricts high-power operation.

Alternative approaches include the 2 × 2 microlens array implemented by Yufei Ma et al. [

11], which achieved four-beam output with reduced system size. Nevertheless, this method requires stringent alignment precision, incurs high fabrication costs, and risks thermal deformation in adhesive-bonded lenses under high-power conditions. Yiping Zhou et al. [

12] exploited thermally induced birefringence in side-pumped Nd:YAG amplifier modules to generate jitter-free four-beam output. However, energy utilization remains suboptimal as only extraordinary lights are split into multiple beams, and the output intensity distribution significantly deviates from a Gaussian profile.

A bonded Nd:YAG/Cr4+:YAG laser based on fiber splitter pumping is proposed and demonstrated. Experimental results demonstrate that at a 4.02 mJ pump pulse energy and 100 Hz repetition rate, the system achieves four linearly polarized output beams with an average pulse energy of 0.964 mJ, a repetition rate of 100 Hz, and an optical-to-optical conversion efficiency of 23.98%. The energy distribution ratios for the upper-left, lower-left, upper-right, and lower-right beams are 22.61%, 24.46%, 25.50%, and 27.43%, with pulse widths of 2.184 ns, 2.193 ns, 2.205 ns, and 2.211 ns, respectively. Increasing the optical axis distance transitions the far-field spot pattern from a single circular profile to four fully separated spots, where the lower-right beam exhibits quality factors of Mx2 = 1.181 and My2 = 1.289. Simulations at 4.02 mJ pump energy (with coolant temperature maintained at 293.15 K) show that split pumping reduces the volume-averaged temperature rise in Nd:YAG by 28.81% compared to single-beam pumping, decreases the peak temperature rise by 66.15%, and lowers peak-to-peak temperature variation by 78.6% (1.34 K vs. 6.26 K). Crucially, fiber splitter pumping demonstrates distinct advantages: compared to split pumping with discrete pump sources, it reduces size and cost; compared to diffractive element splitting, it enhances energy utilization and damage threshold; compared to microlens array splitting, it lowers optical complexity and cost; compared to thermally induced birefringence splitting, it achieves superior beam quality.

3. Experimental Results and Discussions

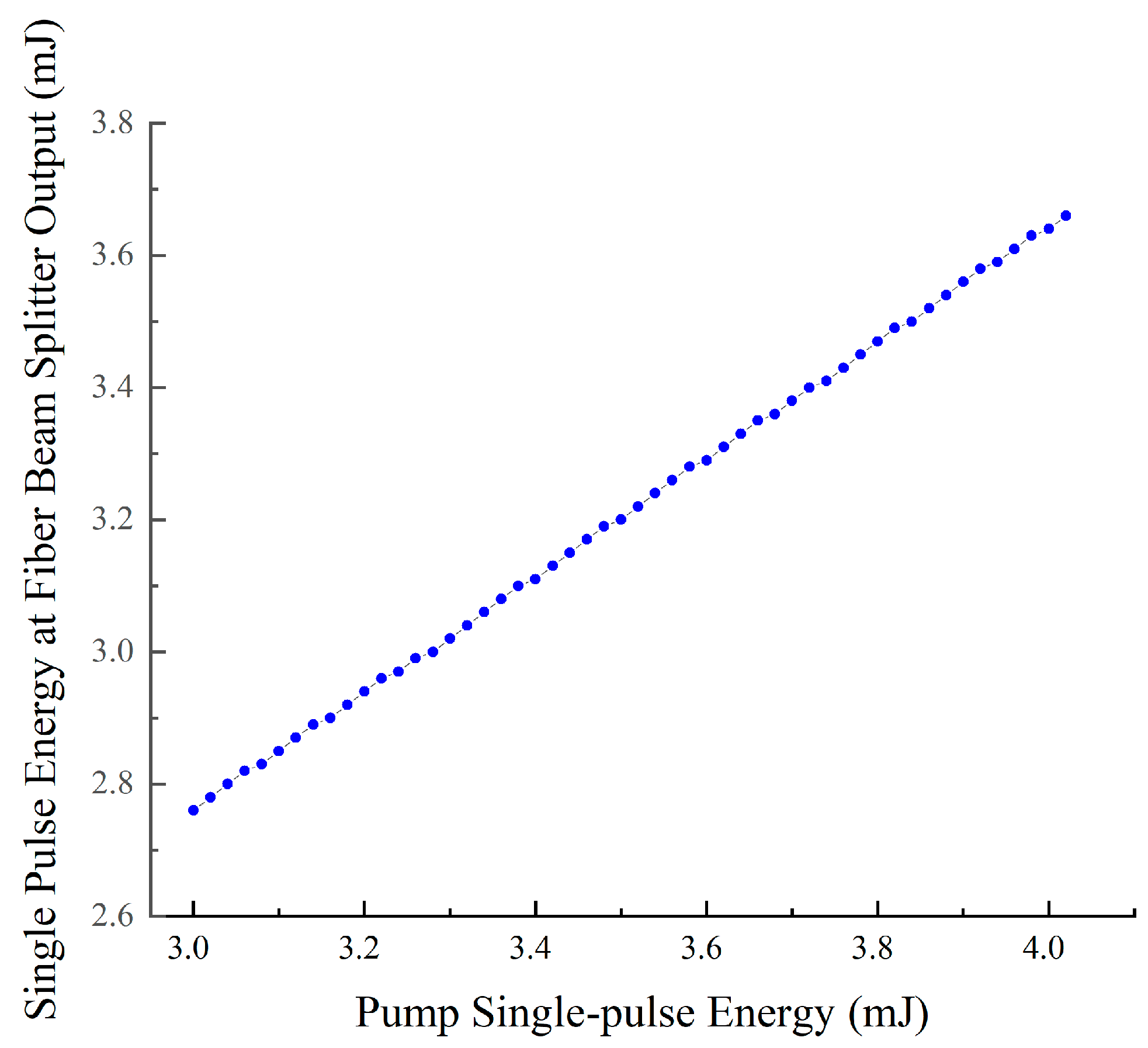

During experiments, the beam-splitting laser operated with fixed pump parameters: 230 μs pulse width and 100 Hz repetition rate. First, the splitting efficiency of the fiber beam splitter was investigated. Prior to fusion splicing the semiconductor laser’s output fiber to the beam splitter, we performed measurements and generated the pump pulse energy versus driving voltage curve of the laser. After fusion splicing the semiconductor laser to the 1 × 4 fiber beam splitter, the collective energy of the four output beams was measured at different driving voltages. The resulting pump pulse energy and splitter output single-pulse energy are depicted in

Figure 2.

The relationship between pump pulse energy and the output single-pulse energy for the 1 × 4 fiber beam splitter exhibits near-linear characteristics: at 3 mJ pump energy, the splitter delivers 2.76 mJ output energy with 92% splitting efficiency; at 4.02 mJ pump energy, the output reaches 3.66 mJ while the efficiency slightly decreases to 91.04%.

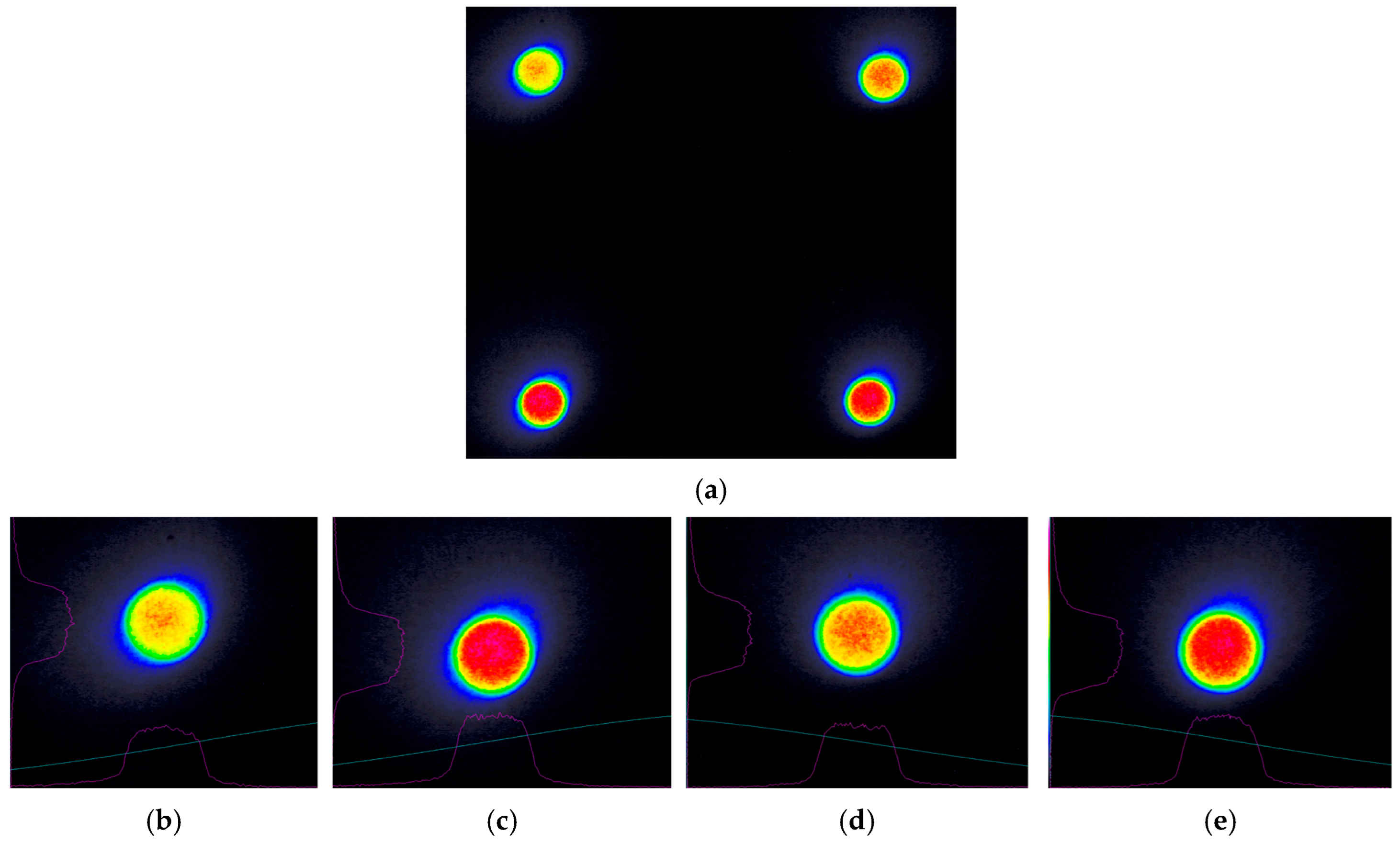

At 4.02 mJ pump pulse energy, the output beams from the fiber beam splitter were collimated and focused by lenses with focal lengths of 150 mm and 200 mm, respectively. The resulting spot patterns were captured via CCD near the back focal plane of the 200 mm lens, as illustrated in

Figure 3.

The measurements shown in

Figure 3a indicate an inter-beam center distance of approximately 3.6 mm. The analysis of

Figure 3b–e reveals that all four output beams from the fiber beam splitter exhibit nearly flat-top intensity distributions. To investigate the energy distribution uniformity of the fiber beam splitter output pulses, the beam spot images were first converted to grayscale. After noise reduction using a Gaussian filter, the area, centroid position, and pixel values of each spot were extracted. Selected spots were then iterated through to calculate pixel count, total brightness (sum of grayscale values within the region, representing the spot’s total energy), and diameter. The resulting energy distribution ratios for the upper-left, lower-left, upper-right, and lower-right output beams are 22.16%, 27.66%, 23.76%, and 26.42%, respectively, as detailed in

Table 1.

Subsequent beam-splitting pumping experiments were conducted. Since the semiconductor laser’s output fiber had been fusion-spliced to the 1 × 4 fiber beam splitter, direct measurement of pump pulse energy was unfeasible. Therefore, the corresponding pump pulse energy was determined based on the pump pulse energy versus driving voltage curve established prior to splicing. The threshold pump single-pulse energy was determined to be 3.18 mJ. At this energy level, the laser generated four output beams (

Figure 4a)—three with higher intensity and one with lower intensity—and thus yielded an average single-pulse energy of 0.298 mJ at 100 Hz. The spot profiles measured 4.602 mm (x-direction) and 4.914 mm (y-direction) across all four beams. When pump energy increased to 4.02 mJ, the system produced four intensity-balanced spots (

Figure 4b) with 0.964 mJ average pulse energy at 100 Hz, exhibiting spot profiles of 5.342 mm (x-direction) and 5.309 mm (y-direction). All spot patterns in

Figure 4 were recorded with a CCD positioned 200 mm from the laser output mirror.

At threshold pump energy, intensity variations among the four output beams were observed. The first reason is the non-uniform energy distribution ratios of the four output beams (

Table 1). The second reason is that these discrepancies originate from fabrication tolerances: while the four output end-faces of the fiber splitter should ideally be coplanar along the pump propagation axis, practical manufacturing introduces sub-millimeter deviations in axial alignment. After collimation and focusing through the lens assembly, these deviations cause the axial displacement of focal points, resulting in non-uniform laser power density distribution on the crystal surface and consequent output intensity variations.

The grayscale summation method, previously employed for studying the energy distribution ratio of the fiber beam splitter output, was applied to calculate the energy distribution ratio of the beam-splitting pumped laser output at 4.02 mJ pump pulse energy. The resulting ratios for the upper-left, lower-left, upper-right, and lower-right beams were 22.61%, 24.46%, 25.50%, and 27.43%, respectively, as detailed in

Table 2.

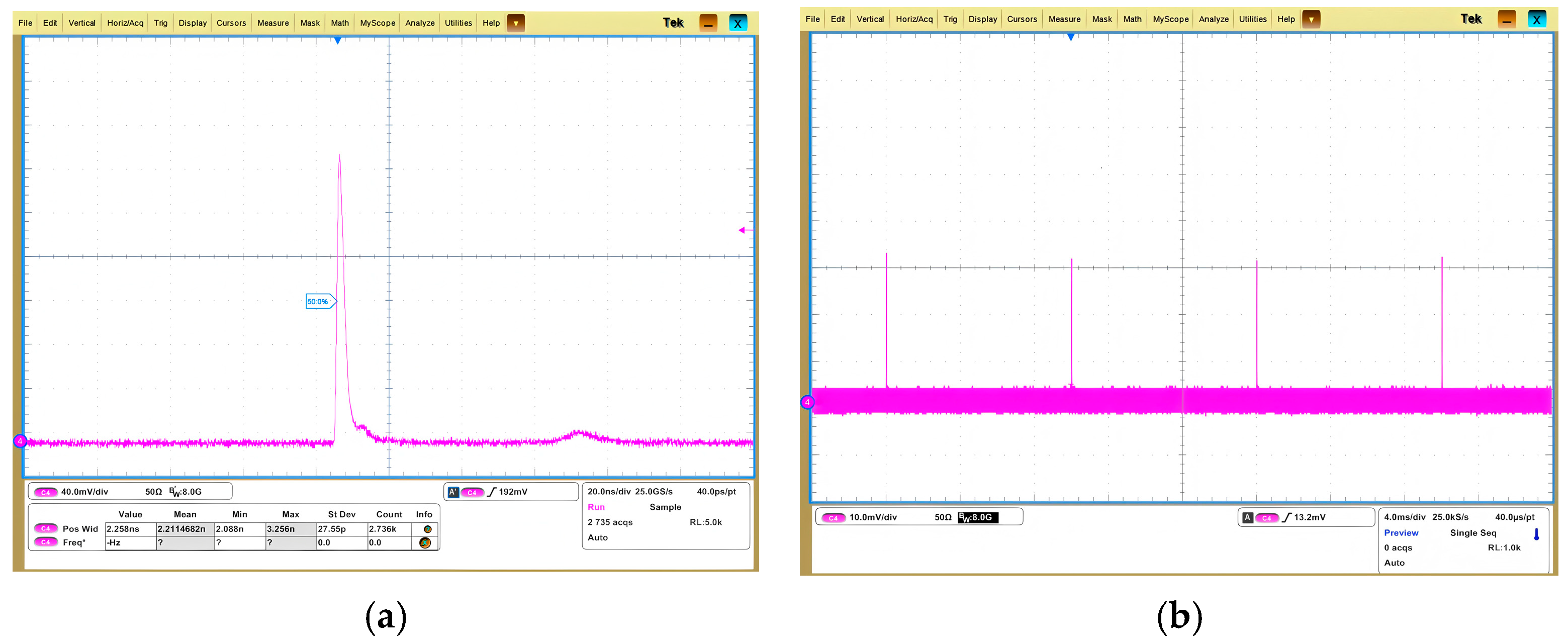

Figure 5a displays the oscilloscope-measured pulse waveform of the lower-right beam from the beam-splitting pumped laser, exhibiting a pulse width of 2.211 ns. The upper-left, lower-left, and upper-right beams show pulse widths of 2.184 ns, 2.193 ns, and 2.205 ns, respectively.

Figure 5b presents the repetition frequency measurement results for the beam-splitting pumped laser.

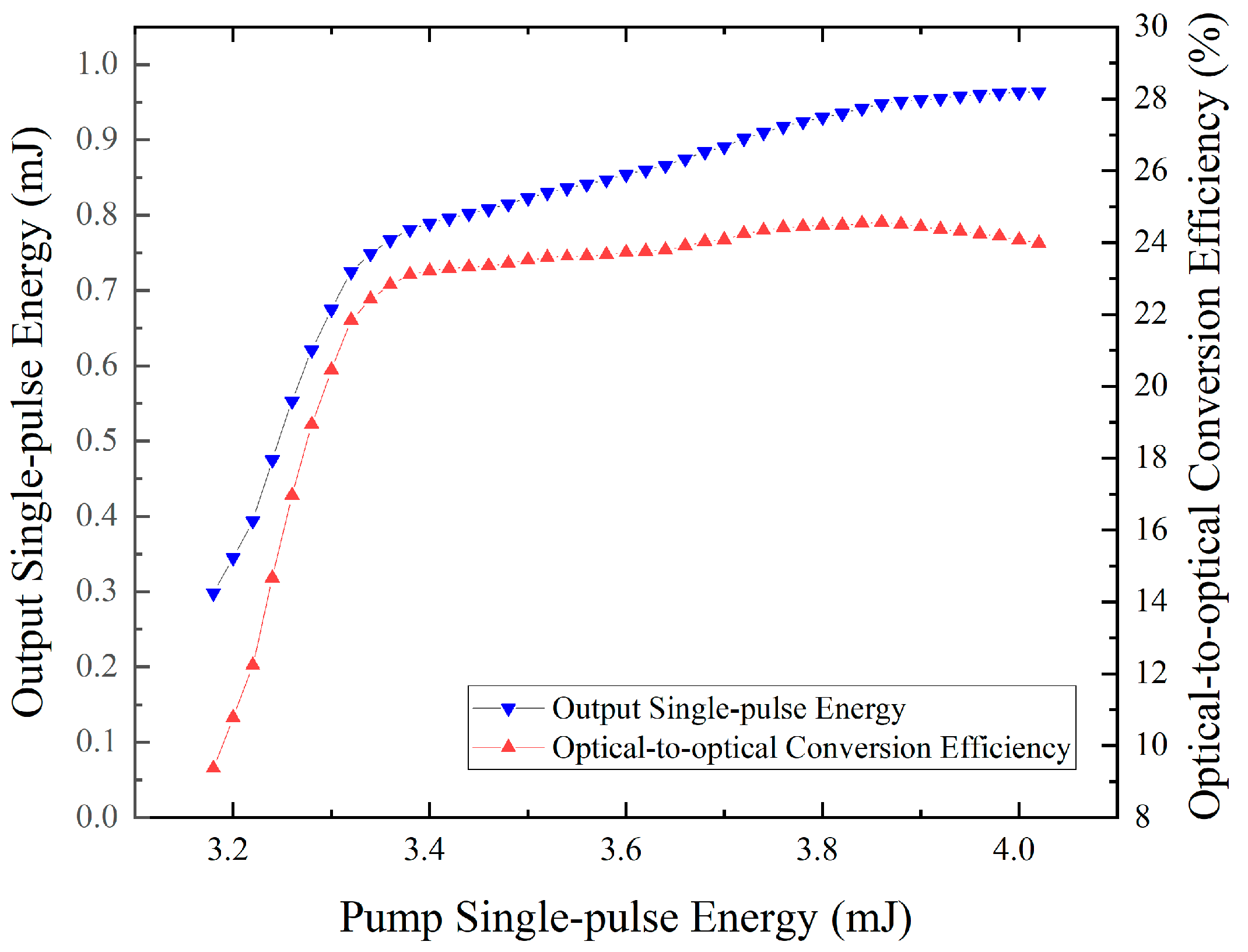

Figure 6 shows the output single-pulse energy and optical-to-optical conversion efficiency of the beam-splitting pumped laser versus the pump single-pulse energy from the semiconductor laser.

Within the pump pulse energy range of 3.18–3.32 mJ, the average output pulse energy surged from 0.298 mJ to 0.725 mJ, accompanied by an increase in optical-to-optical conversion efficiency from 9.37% to 21.84%. A steady growth in output pulse energy was observed within the 3.32–3.86 mJ pump energy range. At 3.86 mJ pump energy, the output reached 0.948 mJ, achieving the peak conversion efficiency of 24.56%. Further pump energy increases induced gain saturation due to limited energy storage in the bonded crystal, resulting in markedly reduced output growth rate and declining conversion efficiency. At 4.02 mJ pump energy, the output was 0.964 mJ with 23.98% conversion efficiency.

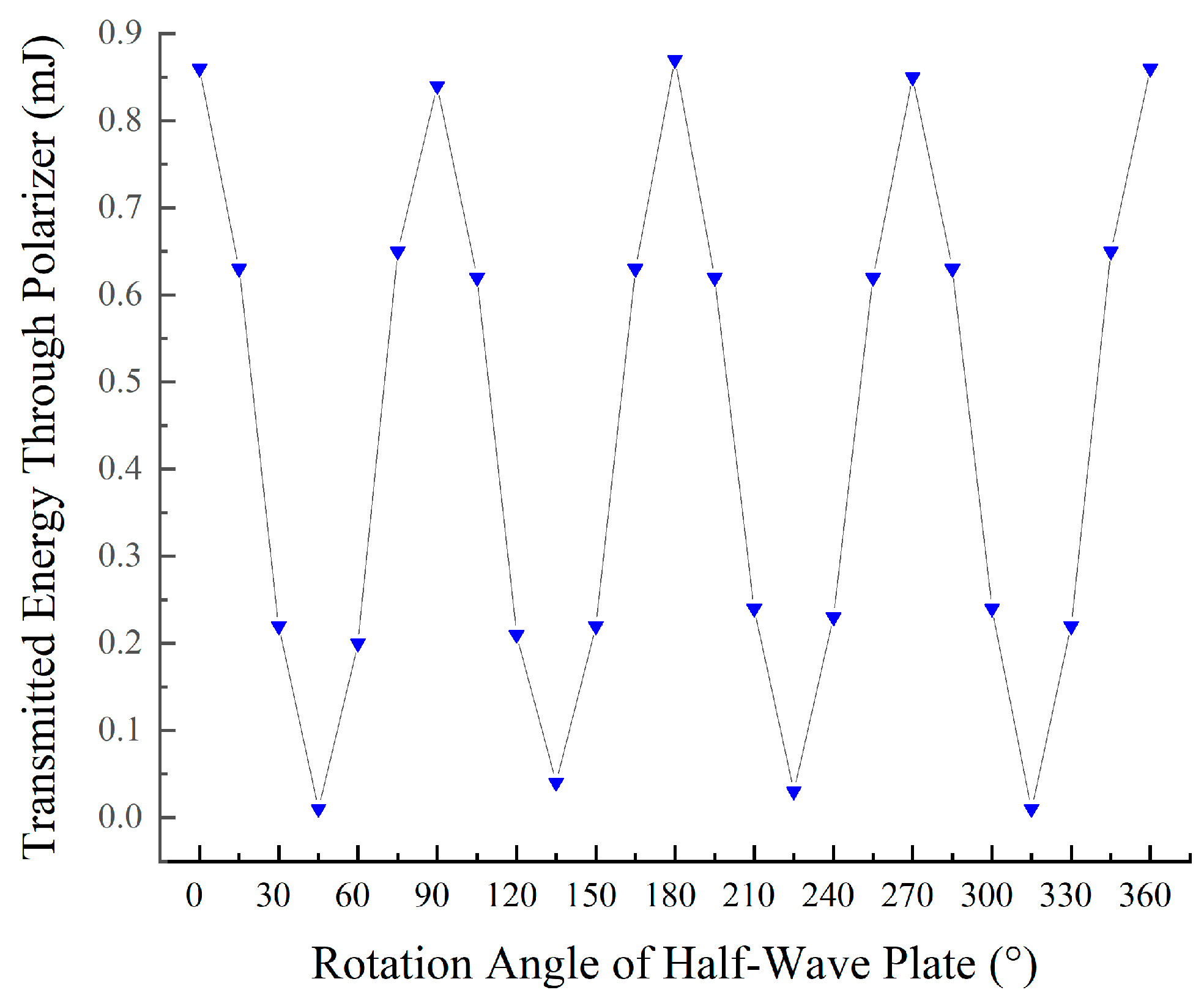

The polarization state of the beam-splitting pumped laser output was subsequently investigated. At 4.02 mJ pump pulse energy, the four output beams were passed through a half-wave plate followed by a polarizer. The transmitted energy through the polarizer was measured with an energy meter as a function of the half-wave plate rotation angle, with the results presented in

Figure 7.

When the half-wave plate was rotated to 45°, 135°, 225°, and 315°, extinction occurred in all four beams, confirming linearly polarized output from the beam-splitting pumped laser.

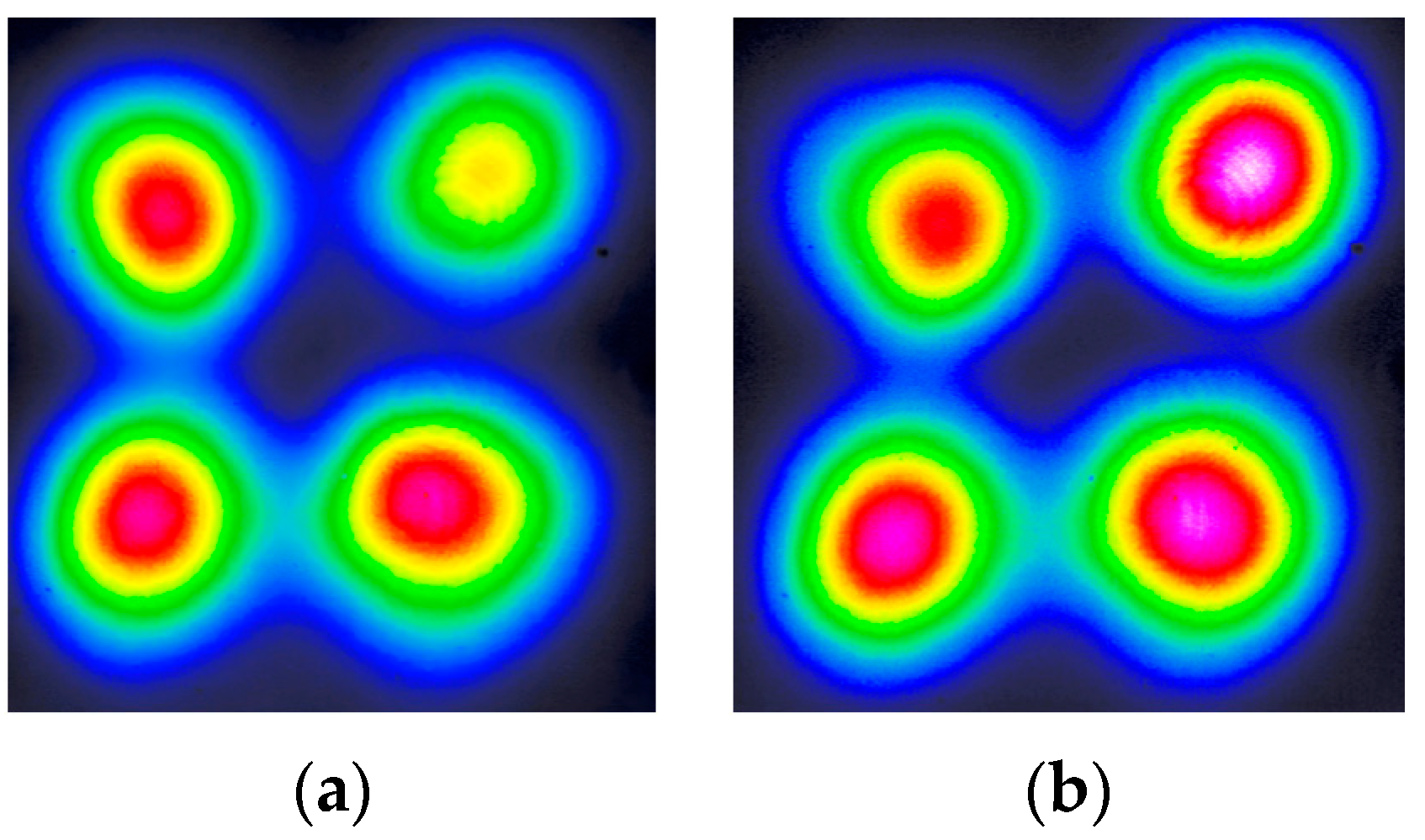

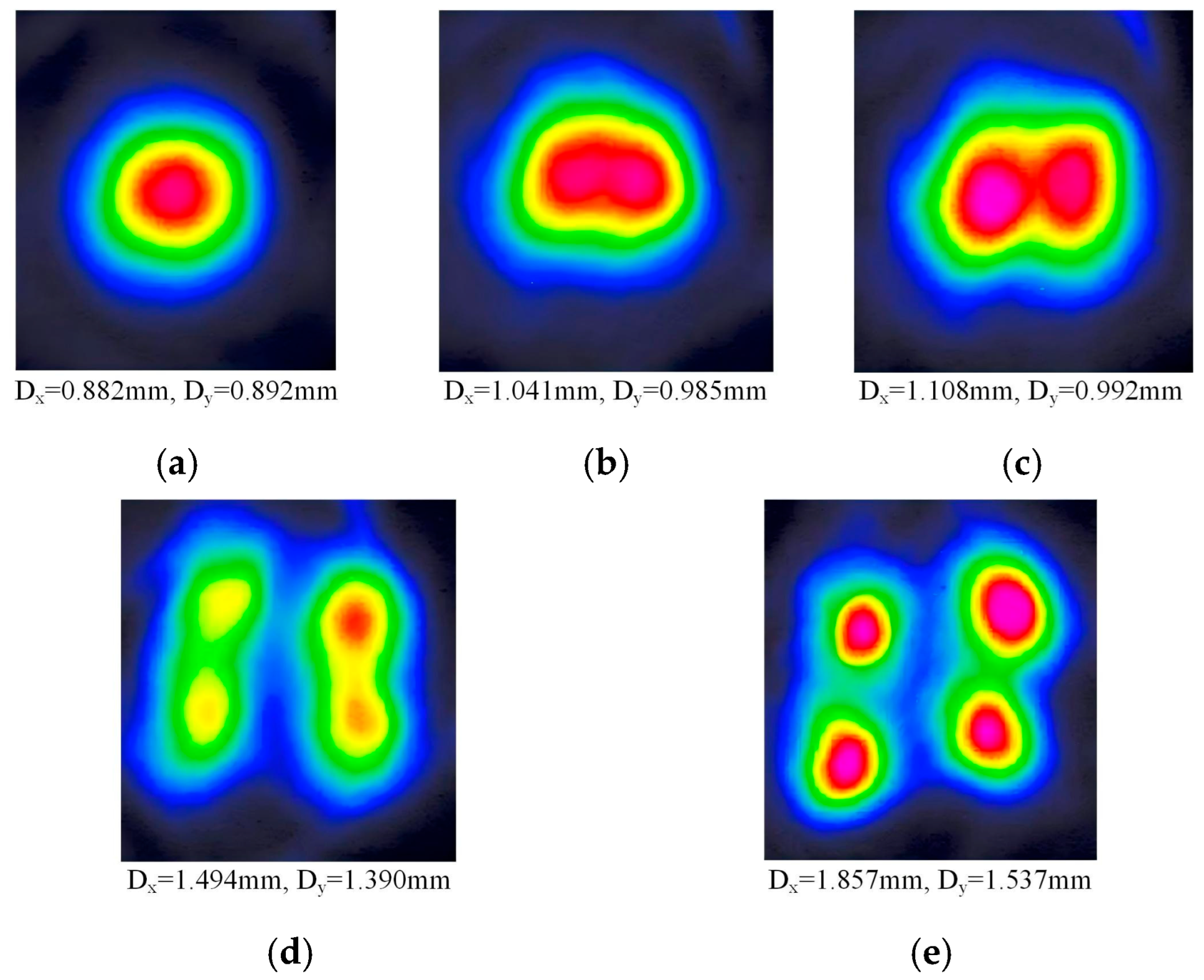

Subsequent investigations focused on the far-field beam characteristics of the split-pumping laser. When the pump single-pulse energy is 4.02 mJ, the output beams were collimated and focused using a 200 mm focal-length lens. The far-field beam distributions were systematically measured at varying optical axis positions during quad-beam operation, as depicted in

Figure 8.

The spatial evolution of far-field beam profiles reveals distinct characteristics at different optical axis positions (Z). At Z = 180 mm, the four beams exhibit significant overlapping regions that undergo coherent combination [

13], producing a single circular spot through constructive interference. When Z increases to 200 mm, incipient beam separation along the x-axis induces elliptical spot deformation. Further progression to Z = 210 mm enhances x-axis divergence, splitting the profile into dual circular lobes. At Z = 220 mm, emerging y-axis separation generates bilateral elongated spots. Complete spatial decoupling occurs at Z = 230 mm, where independent circular spots are formed with full separation in both x- and y-axes.

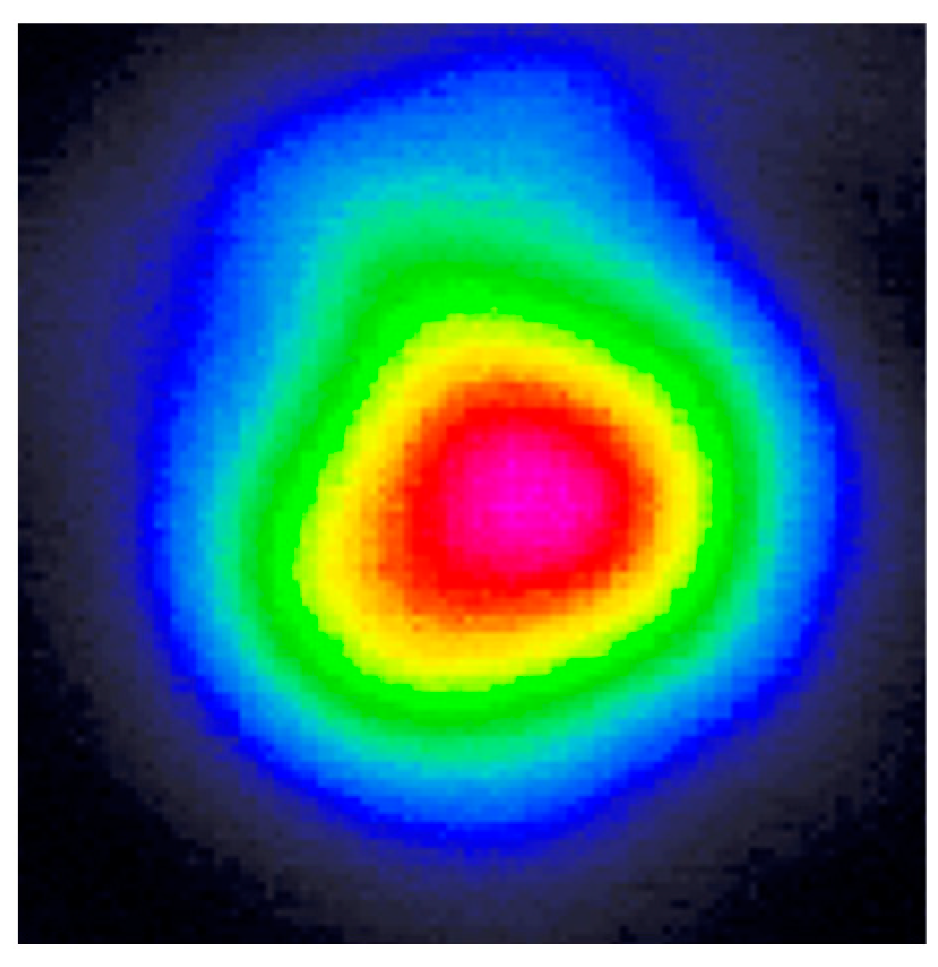

To evaluate beam quality at a pump pulse energy of 4.02 mJ, the output beam was focused using a 250 mm focal length lens. After blocking the lower-left, upper-left, and upper-right segments of the spot, only the lower-right beam was retained. The far-field spot distribution at Z = 615 mm is shown in

Figure 9, with measured spot diameters of 0.901 mm and 0.963 mm in the x-and y-directions, respectively.

Beam radii of the lower-right beam segment were sequentially measured at 20 distinct positions along the optical axis.

Figure 10 illustrates the variation in beam half-widths in the x- and y-directions with optical axis position. Gaussian beam fitting yielded beam quality factors of

Mx2 = 1.181 and

My2 = 1.289 in the respective directions.

This study achieved an optical-to-optical conversion efficiency of 23.98% under beam-splitting pumping at 4.02 mJ pump pulse energy. Compared with conventional single-beam pumping, the split-beam approach not only offers advantages in gain volume but also demonstrates superior thermal performance, as revealed by COMSOL Multiphysics 6.2 simulations. Under identical pump energy conditions, numerical simulations using the Laser Heating Module compared temperature field distributions within the bonded Nd:YAG/Cr

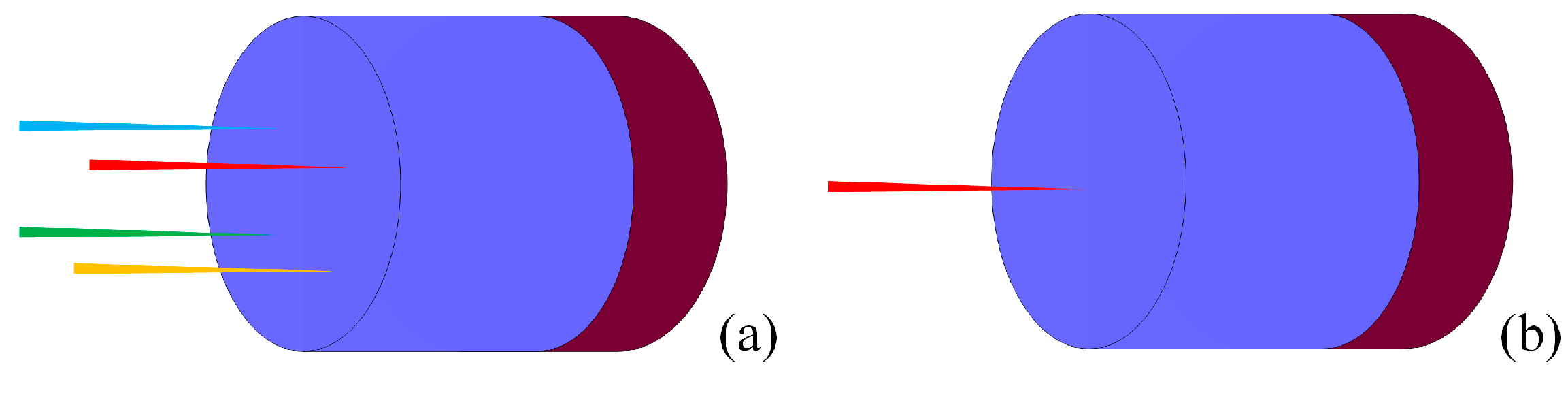

4+:YAG crystal for single-beam versus quad-beam pumping modes. The two pumping configurations are illustrated in

Figure 11a,b, where blue regions denote the Nd:YAG gain medium and brown sections represent the Cr

4+:YAG saturable absorber.

The side surface of the bonded crystal was wrapped in a copper-ring heat sink cooled by circulating water. In simulations, both ambient and coolant temperatures were set to 293.15 K. The pump beam from the fiber beam splitter was modeled with a flat-top intensity profile, featuring a center wavelength of 808.6 nm and spectral bandwidth of 3.5 nm. The absorption coefficient of Nd:YAG at 808.6 nm was set to 5.5 cm

−1 (experimentally determined). The oarameters of the Nd:YAG and Cr

4+:YAG crystals used in simulations are listed in

Table 3.

In addition to the aforementioned parameters, temperature field simulations require the estimation of the convective heat transfer coefficient between the copper heat sink and coolant. In the experimental setup, the water tank operates at a flow rate of 6 L/min through a cooling channel with 0.008 m diameter, yielding an average flow velocity of 1.99 m/s. Based on thermodynamic and heat transfer principles, the convective heat transfer coefficient ℎ is calculated via the Nusselt number

Nu, which for internal pipe flow satisfies Equation (1):

In the equation,

k denotes the fluid’s thermal conductivity (hereafter the same) and

D represents the pipe diameter (hereafter the same). The Nusselt number

Nu is typically calculated via the Reynolds number

Re (Equation (2)) and Prandtl number

Pr (Equation (3)):

In Equations (2) and (3), ρ denotes the fluid density, v denotes the flow velocity, μ denotes the dynamic viscosity, and Cp denotes the specific heat capacity. For the experimental water-cooling system operating at 20 °C, the water properties are defined as ρ = 998.2 kg/m3, μ = 1.01 × 10−3 Pa·s, Cp = 4.183 kJ/(kg·K), k = 0.599 W/(m·K). Substituting these parameters into Equations (2) and (3) yields a Reynolds number Re = 15,734.0 kg/(Pa·s·m) and a Prandtl number Pr = 7.05 (J·m·Pa·s)/(kg·W) for the coolant flow.

The study by Dawid Taler et al. [

14] demonstrates that for internal pipe flow within the ranges 3 <

Pr ≤ 1000 and 3000 ≤

Re ≤ 10

6, the Nusselt number

Nu conforms to Equation (4):

Substituting the Reynolds number (Re) and Prandtl number (Pr) of the coolant into Equation (4) yields a Nusselt number (Nu) of 207.3. This value, when applied to Equation (1), determines the convective heat transfer coefficient between the copper heat sink and coolant as 15,507.69 W/(m2·K).

Prior experimental studies revealed that the beam-splitting pumped laser achieved a maximum single-pulse energy output at 4.02 mJ pump pulse energy. In this work, the output pulse energy from the fiber beam splitter was fixed at 3.66 mJ (corresponding to 4.02 mJ pump energy as shown in

Figure 2) for dynamic temperature field simulations in the bonded crystal under both multi-beam and single-beam pumping. Due to pulsed pumping, the crystal temperature did not remain constant but exhibited periodic oscillations upon reaching system stability—a condition defined in this study as the dynamic thermal equilibrium.

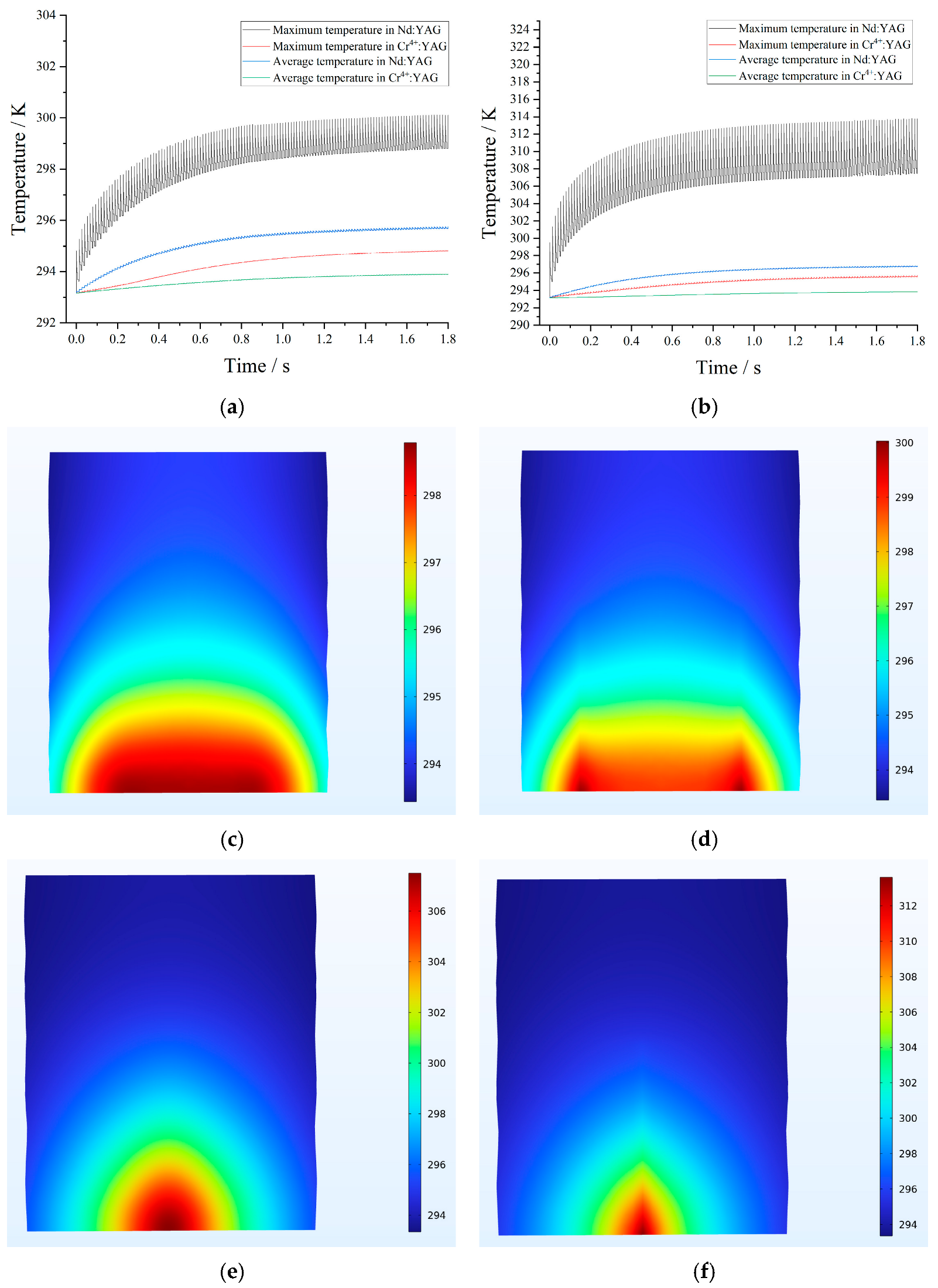

Figure 12a,b reveal that at a pump single-pulse energy of 4.02 mJ under splitter-pumped dynamic thermal equilibrium, the Nd:YAG segment exhibits a volume-averaged temperature rise of 2.57 K and a peak temperature rise of 6.97 K relative to the coolant temperature (293.15 K); the Cr

4+:YAG segment shows corresponding rises of 0.74 K (volume-averaged) and 1.66 K (peak). In contrast, single-beam pumping under dynamic equilibrium yields higher thermal rises: the Nd:YAG segment reaches 3.61 K (volume-averaged) and 20.59 K (peak), while the Cr

4+:YAG segment attains 0.66 K (volume-averaged) and 2.90 K (peak). Experimental results demonstrate that splitter pumping reduces the volume-averaged temperature rise in Nd:YAG by 28.81% (2.57 K vs. 3.61 K) and its peak temperature rise by 66.15% (6.97 K vs. 20.59 K), whereas the Cr

4+:YAG peak temperature rise decreases by 42.76% (1.66 K vs. 2.90 K).

As shown in

Figure 12c–f, thermal peak locations consistently coincide with pump beam entry points in both configurations, with splitter pumping achieving superior temperature uniformity across the crystal. Furthermore, the peak-to-peak temperature variation at thermal peaks under splitter-pumped dynamic equilibrium (1.34 K) shows a 78.6% reduction compared to single-beam pumping (6.26 K).

4. Conclusions

This study pioneers the implementation of beam-splitting pumping in a bonded Nd:YAG/Cr4+:YAG laser via a fiber beam splitter. At 4.02 mJ pump pulse energy, the system achieves four linearly polarized output beams with an average pulse energy of 0.964 mJ, a repetition rate of 100 Hz, and an optical-to-optical conversion efficiency of 23.98%. The energy distribution ratios for the upper-left, lower-left, upper-right, and lower-right beams are 22.61%, 24.46%, 25.50%, and 27.43%, with pulse widths of 2.184 ns, 2.193 ns, 2.205 ns, and 2.211 ns, respectively. As the optical axis distance increased, the far-field spot pattern transitioned from a single circular profile to four fully separated spots, with the lower-right beam exhibiting beam quality factors of Mx2 = 1.181 and My2 = 1.289.

Compared to multi-pump-source approaches for beam-splitting pumping [

7,

8], the fiber splitter method offers significantly reduced system volume and cost. The achieved conversion efficiency surpasses those reported for diffractive beam splitting (4.84% [

10]), microlens array splitting (14.75% [

11]), and thermally induced birefringence splitting (<2% [

12]).

Simulations at 293.15 K coolant temperature and 4.02 mJ pump energy demonstrate that split pumping reduces the volume-averaged temperature rise in Nd:YAG by 28.81% versus single-beam pumping (2.57 K vs. 3.61 K), decreases the peak temperature rise by 66.15% (6.97 K vs. 20.59 K), and suppresses peak-to-peak temperature variation by 78.6% (1.34 K vs. 6.26 K).

This compact, cost-effective laser demonstrates favorable beam quality and high beam-splitting efficiency, showing potential for automotive engine multi-point ignition, multi-beam single-photon LiDAR detection, and laser-induced breakdown spectroscopy online analysis. To further optimize performance, the axial alignment precision of the fiber splitter will be refined to balance gain disparities among beams.