1. Introduction

Counterfeiting is a growing global concern, threatening brand integrity, consumer trust, and regulatory compliance across multiple industries [

1,

2]. As counterfeiters employ increasingly sophisticated replication methods, conventional anti-counterfeiting measures, such as holographic stickers, watermarks, and serial numbers, are becoming easier to replicate [

3,

4]. Thus, there is a pressing need for innovative, scalable, and cost-efficient solutions that provide robust protection against counterfeiting [

5].

One effective hardware-based solution to this challenge is to embed a unique, observable characteristic within the device or object of interest. This characteristic serves as a distinctive identifier, functioning as a form of fingerprinting that ensures authenticity and enables easy detection of counterfeit products.

Conventional optical identifiers, such as barcodes or QR codes, provide traceability but can be easily copied or visually reproduced, offering limited protection against high-quality counterfeits. Moreover, they rely on visible digital patterns that may interfere with the product’s design or branding. In contrast, holographic identifiers combine aesthetic integration, high design complexity, and resistance to replication, offering an additional layer of security without altering the product’s appearance.

One promising avenue is the use of computer-generated holograms (CGHs), as they are complex optical patterns that are difficult to replicate, due to design complexity, phase control requirements and the need for the original digital blueprint, which makes accurate reproduction challenging [

5,

6,

7,

8]. CGH fabrication techniques, such as laser engraving, suffer from high costs and long processing times. An additional limitation is the restricted versatility in material processing. Different material categories need the use of different laser sources or systems; for instance, metal engraving requires a laser with different specifications (e.g., wavelength) compared to those used for engraving plastic. In the context of engraving anti-counterfeiting tags on products, the process typically involves marking the product’s surface [

9,

10,

11].

Additive Manufacturing (AM) is the layer-by-layer fabrication of parts directly from a digital model, commonly known as 3D printing [

12]. Direct manufacturing through 3D printing is recognized as a transformative process, enabling companies to bypass traditional production methods and move directly to manufacturing of products [

13]. This innovation allows for the full integration of customization and co-creation, where consumers can actively participate in the design and creation of the product, thereby increasing its value [

14]. Unlike traditional manufacturing, which is often tied to specific factories, direct manufacturing through 3D printing offers the advantage of flexibility, allowing products to be made on-demand with lower upfront costs. Furthermore, it reduces the need for extensive storage and transportation. Since products are made on-demand, companies can avoid the costs associated with warehousing and shipping finished goods, resulting in lower overall operational expenses and a more sustainable production process [

15].

In this paper, we present a novel approach to anti-counterfeiting that integrates CGHs directly into the computer-aided design (CAD) design of the object’s surface before 3D printing. By defining the anti-counterfeit tag in the initial design, the holographic features are fabricated on the surface of the printed object in a single step, eliminating the need for post-processing.

This integration provides greater flexibility, allowing the tag to be placed anywhere within the object, whether on its surface or, in the case of non-flat geometries, within its internal areas. By embedding the security tag into the product’s geometry during 3D printing, it also becomes possible to conceal and protect the tag from wear and scratches. Such security tags can be integrated into internal or hidden surfaces, enhancing its durability and security.

SLA 3D printing has emerged as a promising approach for rapid prototyping within injection molding applications [

16], enabling the fabrication of high-precision molds with reduced costs. Unlike traditional metallic inserts, SLA allows the prototyping of multiple geometries without the significant expenses associated with metal tooling, making it an efficient solution for iterative design and small-scale production [

17]. This further strengthens the potential of 3D printed security tags, as they could serve as molds for large-scale production, similar to the injection molding process, thus expanding their applicability and scalability.

We further explored the combination of SLA 3D printed security tags with nanoimprint lithography (NIL). Specifically, we replicated the 3D-printed security tags using NIL to assess the potential for mass replication via a high-throughput process. Therefore, we investigated the feasibility of transferring the 3D printed optical structures onto flexible substrates which are widely used in the packaging industry. Preliminary results indicate that this combined approach successfully enhances the scalability and competence for direct manufacturing of security elements on polymer surfaces.

Furthermore, we introduce a digital reconstruction-based evaluation method, which provides a robust and industrially applicable verification technique for ensuring the authenticity of the fabricated holographic elements. Our results highlight the commercial feasibility of this approach, positioning it as a practical solution for industries requiring secure and scalable anti-counterfeiting measures.

The novelty of this work lies in the integration of established optical and fabrication methods into a unified workflow. By combining 3D printing of holographic masters with UV-NIL replication on flexible substrates and validating the outcome through digital reconstruction, this study demonstrates a scalable and quantitative route for the fabrication and assessment of optical anti-counterfeiting tags.

3. Results

3.1. Fabrication

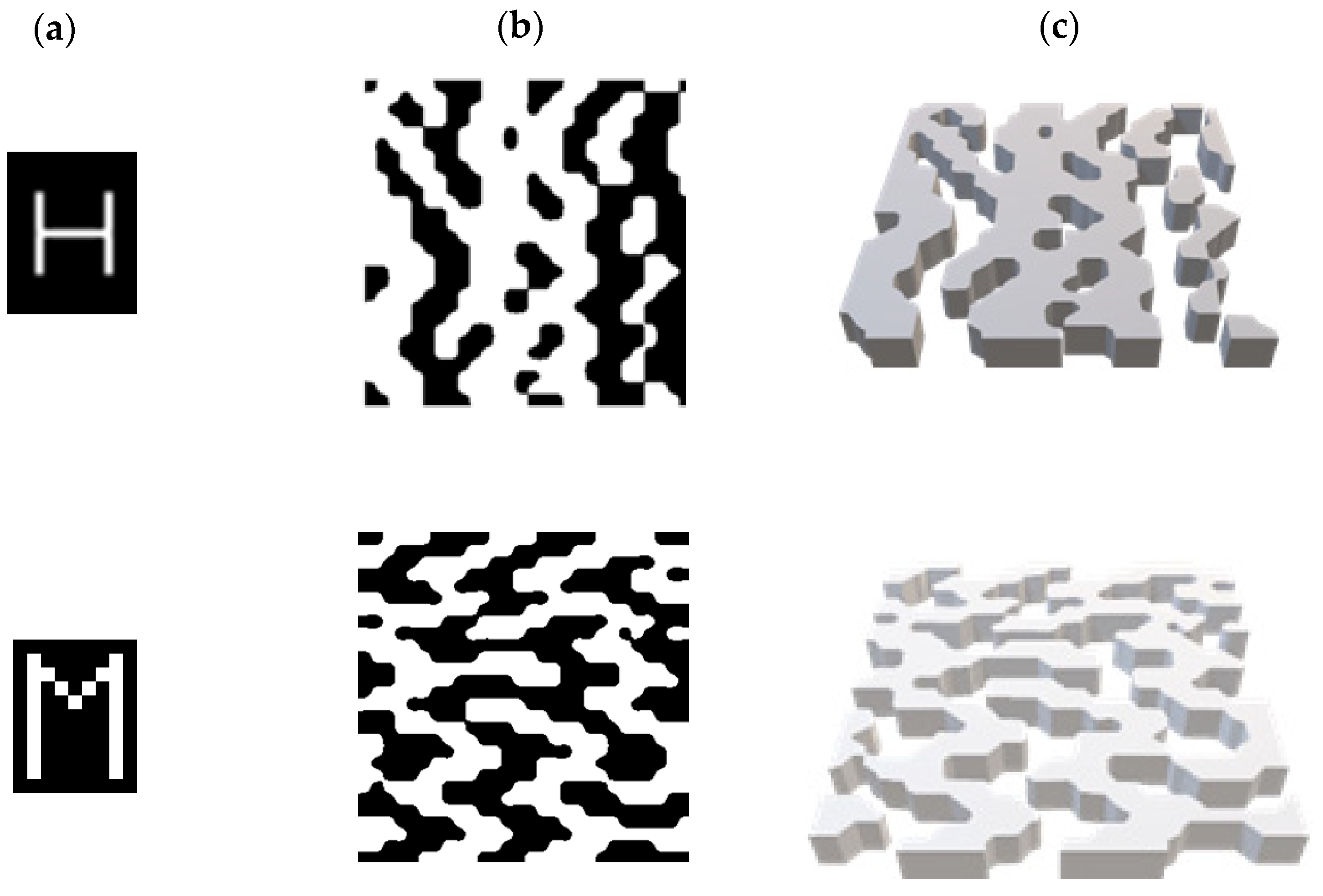

The successful integration of computer-generated holograms into 3D-printed objects for anti-counterfeiting tags was achieved through a direct 3D printing method, without the need for additional steps like laser engraving. This approach enabled the seamless embedding of the CGHs directly into the 3D-printed structures, ensuring efficient and precise manufacturing. By incorporating the CGHs into the 3D printing process, the need for post-production steps was eliminated, simplifying the workflow and offering a high-throughput solution. This method also ensured that the features were integrated within the object, making them more resistant to tampering and enhancing their durability.

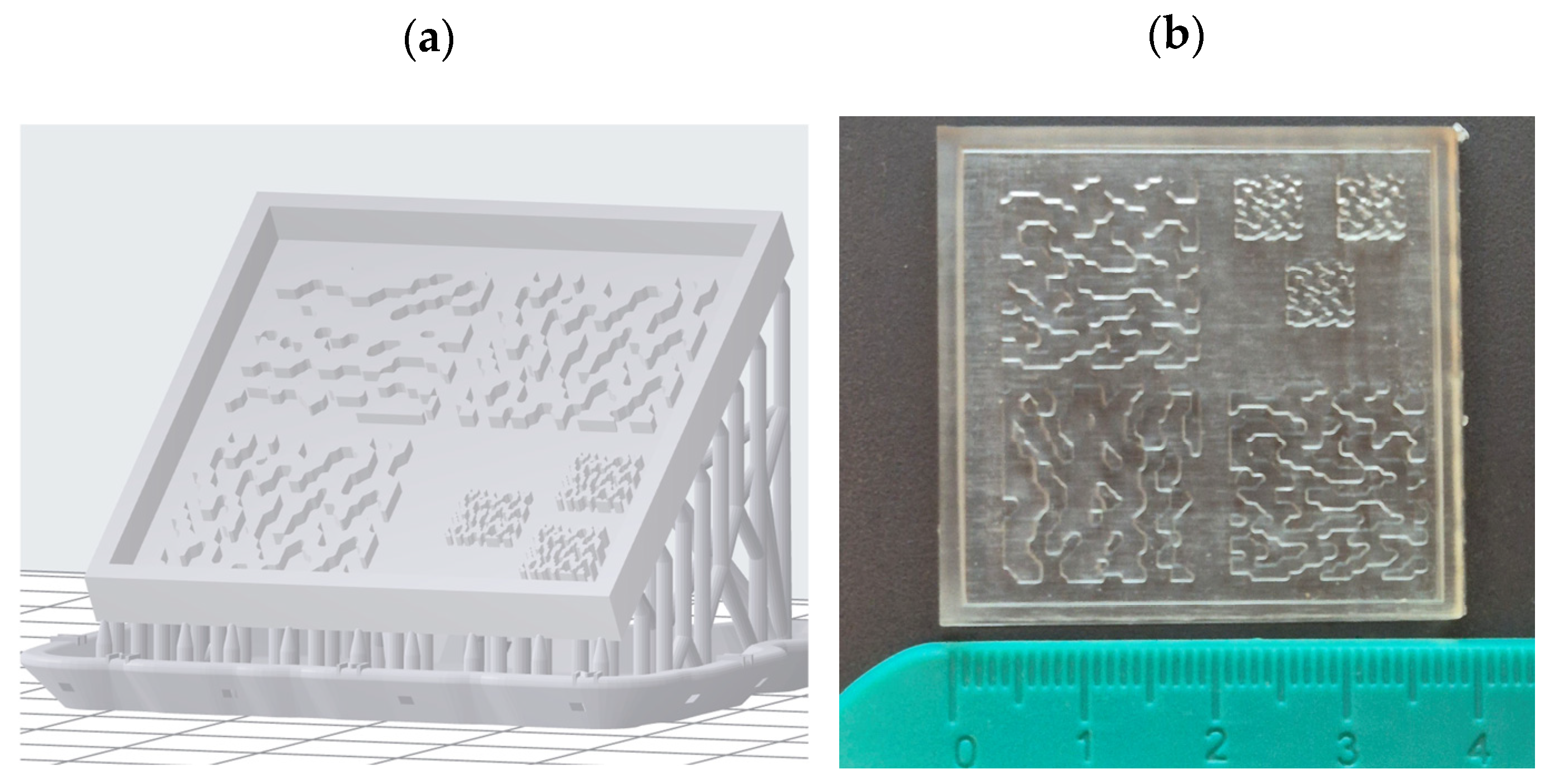

Because the CGH layout is non-periodic, a single pitch is not defined. We therefore report the minimum resolved feature width and inter-feature gap. In this study, the lateral (x–y) resolution is limited primarily by the laser spot diameter of the SLA 3D-printing system and lateral cure spread in the photopolymer (effective spot ≈80 μm). Across the 1.5 cm × 1.5 cm area, the smallest feature width that printed with intact edges was ≈420 μm, and the smallest inter-feature gap that remained open was ≈380 μm. In exploratory prints, clearances <≈120 μm exhibited bridging. Downscaled variants (0.5 cm × 0.5 cm;

Figure 2) were also fabricated. At this scale the narrowest gaps approached the process limit, so we used the 1.5 cm × 1.5 cm layout in all experiments, which provided sufficient edge contrast for reliable digital-microscope imaging and downstream analysis. Intermediate clearances (≈150–300 μm) were achievable locally in exploratory prints, but they did not resolve uniformly across the full 1.5 cm × 1.5 cm field due to spot overlap and lateral cure spread, with increased edge rounding after post-cure and cleaning.

To further extend the applicability of this method, UV-NIL was employed to enable the replication of the 3D-printed security tags onto flexible substrates. This not only introduces substrate versatility but also allows integration with scalable manufacturing methods such as injection moulding and roll-to-roll NIL [

28], enhancing the potential for industrial adoption. Given the printed feature height of 1 mm and the minimum resolved lateral feature width of approximately 420 µm, the aspect ratio was ≈2.4:1. This geometry was preserved after replication, indicating effective pattern transfer fidelity in the NIL process.

The mould shown in

Figure 2 corresponds to the same 1.5 cm × 1.5 cm CGH structure presented in

Figure 3a, which served as the master for the NIL replication process.

Although the present structures fall within the microscale rather than the nanoscale, the same UV-NIL principles apply. This process is often referred to as microimprinting in similar contexts, yet the underlying mechanism (UV-assisted curing of a resist under conformal contact) remains identical to conventional NIL. The results confirm that UV-NIL can accurately replicate high-relief microstructures under mild conditions, highlighting its versatility beyond the nanoscale. In comparison to hot embossing, the UV-based process avoids thermal stress and enables replication on flexible polymer substrates, making it well suited for scalable production of optical tag structures.

3.2. Characterization

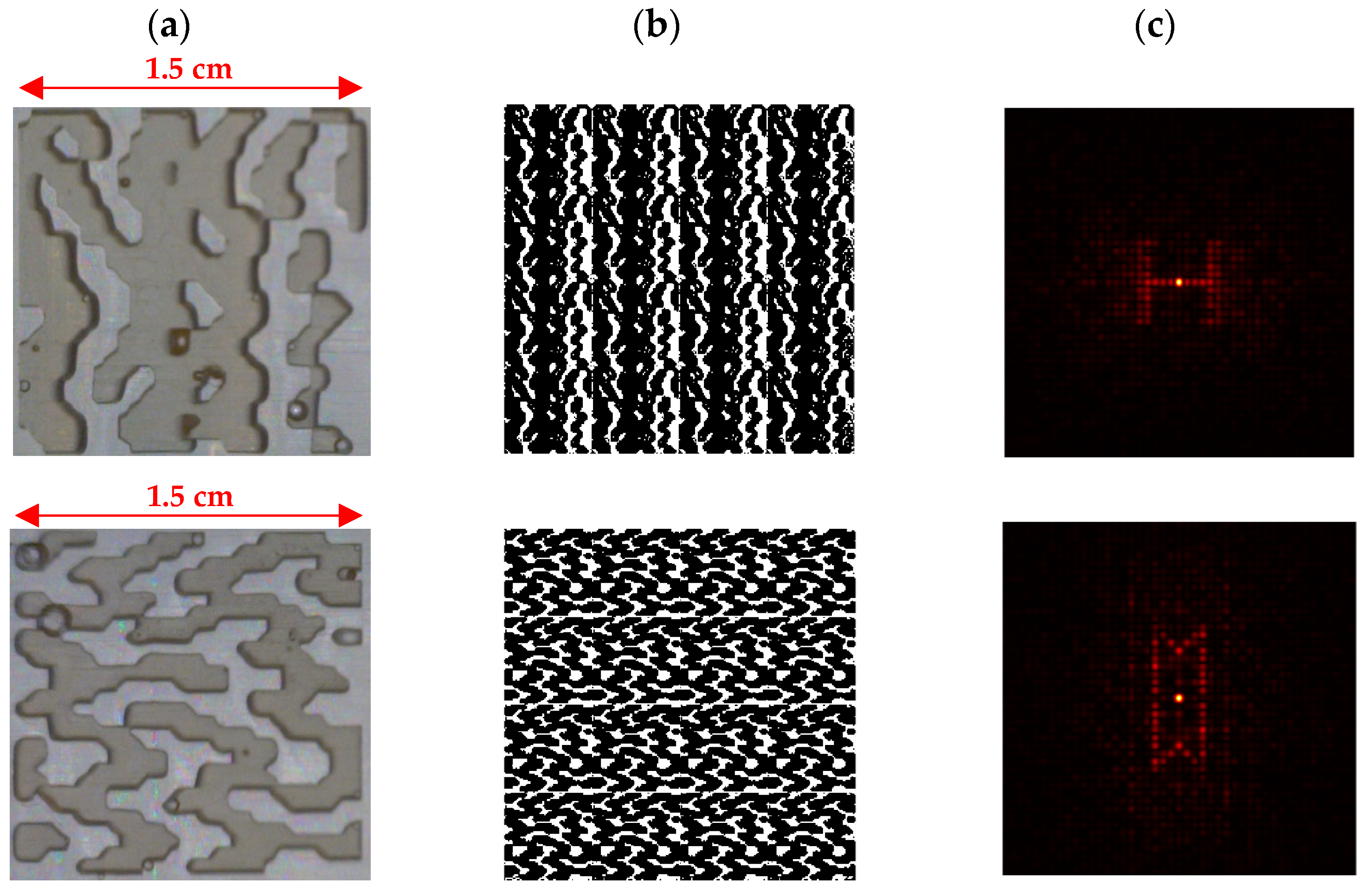

The 3D printed and replicated via NIL CGHs were optically characterized using a handheld digital microscope. The recorded RGB images were converted into grayscale for Fourier-based digital reconstruction.

Figure 3a shows the 3D printed CGHs samples which have undergone the digital reconstruction process. Digital reconstruction using Fourier optics successfully retrieved the encoded letter ‘H’ and ‘M’ (

Figure 3c), confirming that the CGHs function as intended. The reconstructed hologram showed a high contrast ratio between the encoded pattern and the background. UV-NIL maintains the optical performance of the holographic structures. The same protocol was used for the evaluation of the NIL replicated CGHs (

Figure 4), where reconstructed holograms were also visible.

The fabricated CGHs were evaluated using optical microscopy and digital reconstruction techniques. The digital reconstruction process successfully retrieved the encoded holographic information, demonstrating machine-based authentication feasibility. The holographic patterns produced a distinct diffraction signature, making them difficult to replicate without access to the original fabrication process flow, as the latter involves multiple steps, parameters and techniques.

As can be seen in

Figure 3 and

Figure 4, the imaging conditions, i.e., the contrast between the edges of the CGH and the substrate background, play a decisive role in the quality of the reconstruction images. In particular, it is obvious that the contrast between the CGH structure and the background influences the image processing during black and white conversion, as the edges of the CGH structure determine the overall structure of the hologram perceived during this process. The absence of visible background texture or scattering in the bright and dark regions of the images confirmed that the surface roughness was adequate for the intended optical reconstruction.

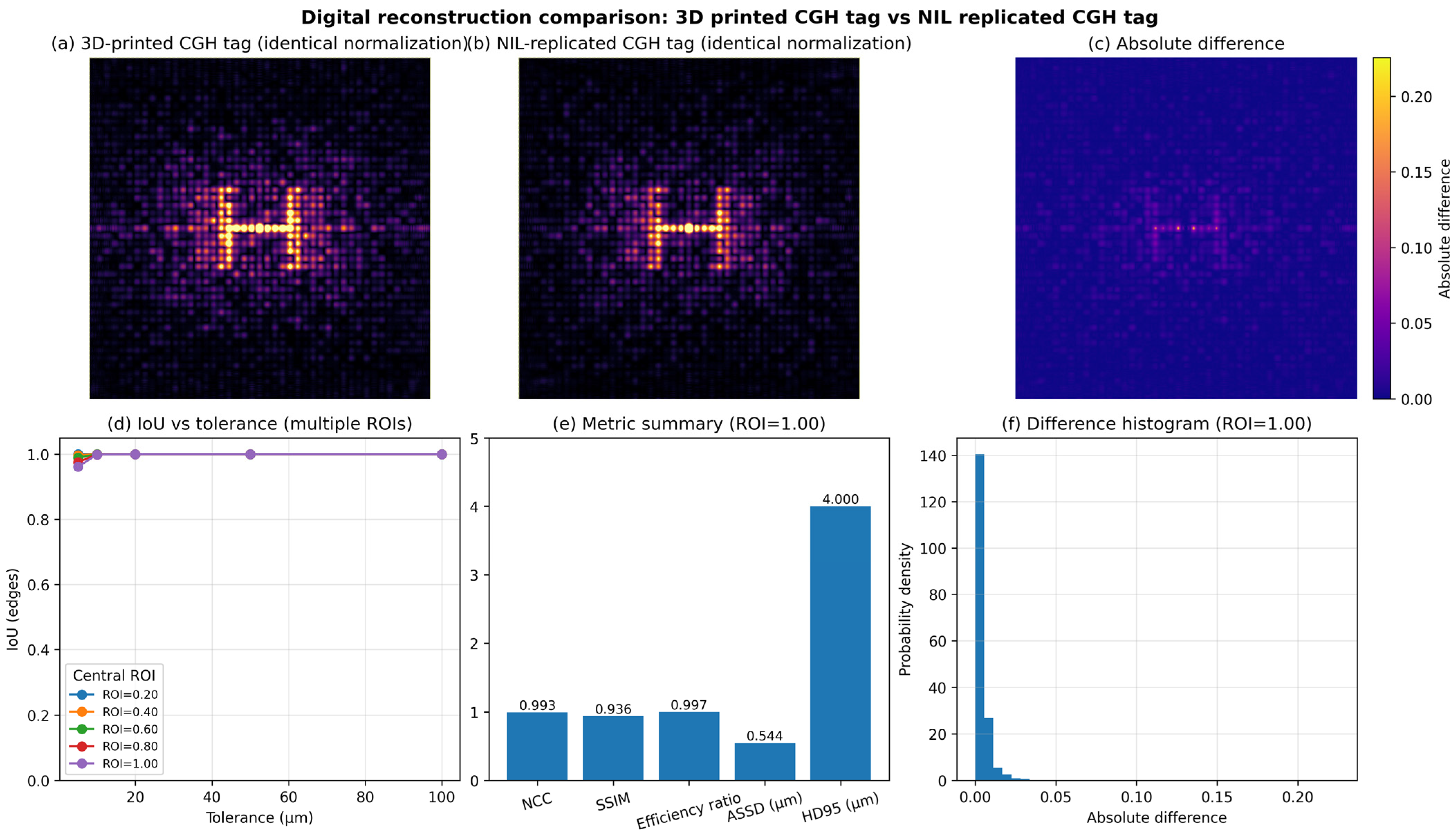

To quantitatively evaluate the reconstruction quality of the NIL-replicated tags and compare them with the 3D printed tags, the digitally reconstructed intensity maps of both were analysed using an in-house Python-based image comparison framework (Python v3.13).

Each reconstruction was normalized identically to enable direct pixel wise comparison, and an absolute difference map was calculated to visualize local intensity variations. Edge-based similarity was quantified using the intersection-over-union (IoU) metric for multiple central regions of interest (ROIs) ranging from 0.2 to 1.0 of the image area. Multiple ROIs were selected to verify whether the level of agreement between the two reconstructions remains consistent across both the central and peripheral regions of the diffraction pattern.

For the global quantitative metrics (e.g., the normalized cross-correlation (NCC) [

29], structural similarity index (SSIM) [

30], optical efficiency ratio, average symmetric surface distance (ASSD), and 95th-percentile Hausdorff distance (HD95) [

31]), the full image (ROI = 1) was analysed to include both the main diffraction pattern and the surrounding background. This approach ensures that the comparison accounts for the complete reconstructed optical field rather than only its high intensity region.

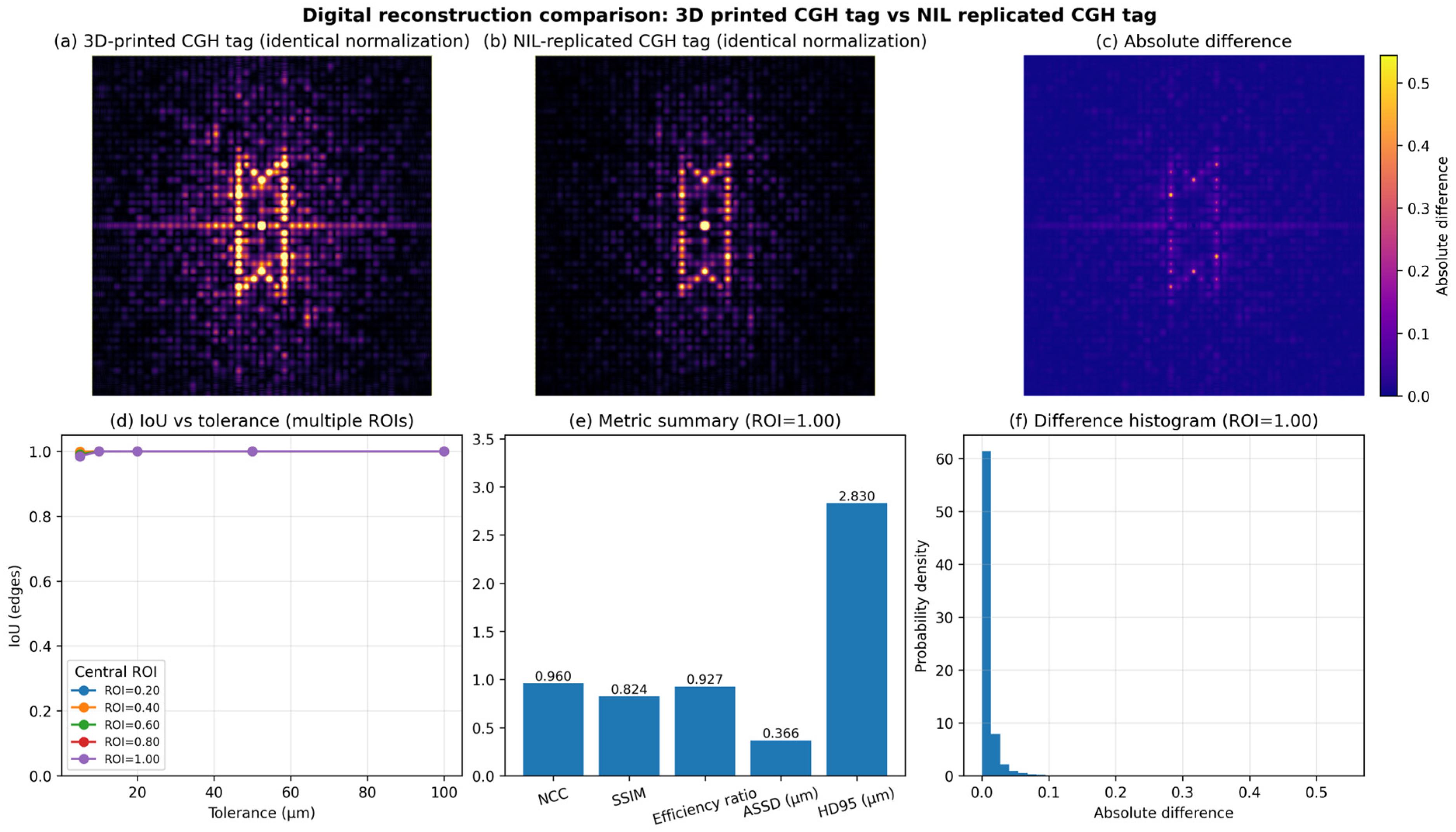

Figure 5 shows the quantitative comparison between the digital reconstructions of the 3D-printed and NIL-replicated “H” tag.

Figure 5a,b present the normalized reconstructions of the 3D printed and NIL replicated tags, respectively, while

Figure 5c displays their absolute difference map.

Figure 5d shows the IoU as a function of positional tolerance for different ROIs, and

Figure 5e summarizes the calculated quantitative metrics. The corresponding histogram of pixel-wise absolute differences is shown in

Figure 5f. The IoU values above 0.96 across all ROIs demonstrate that the reconstructed optical fields of both tags are highly consistent throughout the reconstruction area. For the “H” tag, the high NCC (0.993) and SSIM (0.936) confirm strong global and local agreement, while the efficiency ratio (0.997) indicates that the replicated tag preserves almost the same optical response as the original. The ASSD (0.54 µm) and HD95 (4.0 µm) values show sub-micrometer average deviations and minimal local differences, confirming that the optical reconstruction of the NIL replicated tag closely matches that of the 3D-printed master.

A similar analysis was performed for the “M” tag, as shown in

Figure 6. The results show comparable behaviour. The NCC (0.96) and SSIM (0.824) demonstrate good global and local correspondence, and the efficiency ratio (0.93) indicates a small reduction in reconstructed intensity compared with the master. The ASSD (0.37 µm) and HD95 (2.8 µm) again confirm very limited spatial deviation. Because the reconstruction is performed digitally, illumination nonuniformity cannot contribute to these differences. The intensity variations observed are therefore attributed to small replication defects introduced during the NIL process.

Table 1 summarizes the quantitative comparison of the digital reconstructions obtained from the printed and NIL-replicated CGH tags.

These observations confirm that the NIL process successfully replicated the CGH patterns and that the replicated tags produce clear and accurate reconstructions. The optical performance of the replicas is very close to that of the 3D printed masters, supporting their use as functional optical tags.

3.3. Scalability

The scalability of the proposed method is supported by the quantitative correspondence between the 3D printed and NIL-replicated CGHs. The high similarity metrics (NCC > 0.96, SSIM > 0.82, IoU > 0.96 across all regions) confirm reliable pattern transfer and reproducible optical performance, indicating that the process can be extended to high-throughput production.

NIL offers a rapid, large-area replication process that is compatible with scalable manufacturing methods such as roll-to-roll and injection molding [

32,

33]. This combination of additive manufacturing and UV-NIL enables cost-efficient, flexible, and reproducible fabrication of optical security tags.

Furthermore, the integration of additional unique identifiers, such as physical unclonable functions (PUFs) [

34], could further enhance the security and anti-counterfeiting potential of the proposed approach in industrial scale implementations.

4. Discussion

The proposed method represents a scalable and cost-effective fabrication route for optical tags. It focuses on the rapid and flexible production of holographic structures that yield clear optical reconstructions. Combining 3D printing with UV-NIL provides a practical route for the fabrication of tags, making it ideally suited for applications within the FMCG, pharmaceutical, and financial sectors, where secure and cost-efficient product marking is essential.

The optical characterization of the imprinted CGHs confirms their functional integrity and reconstruction accuracy. Quantitative comparison between the 3D printed and NIL replicated tags showed strong global and local correspondence, with NCC and SSIM values above 0.96 and 0.82, respectively, and intersection-over-union (IoU) values exceeding 0.96 across all evaluated regions. The sub-micrometer average deviations (ASSD < 0.6 µm) and low maximum deviations (HD95 < 4 µm) indicate that the NIL process preserved the encoded optical information with minimal distortion. The reconstructed intensity distributions of the replicated tags closely matched those of their 3D printed masters, confirming that replication defects had only a minor influence on the optical output.

The high degree of optical consistency between master and replica reconstructions demonstrates that the hybrid fabrication route effectively transfers the designed holographic features while maintaining their optical functionality. This confirms the robustness of the process for accurate, repeatable production of functional optical elements.

Overall, this study highlights the technical feasibility, economic viability, and security potential of CGHs produced by combining additive manufacturing with nanoimprint lithography. The proposed workflow supports large scale replication of 3D printed optical masters while maintaining high reconstruction quality, representing a significant step toward next generation, low-cost optical security features that are both robust and commercially scalable.

5. Conclusions

This study presents a novel hybrid approach for the design, fabrication, and evaluation of anti-counterfeiting tags using computer-generated holograms integrated onto the surface of 3D printed components and replicated by nanoimprint lithography. The method combines the design flexibility and rapid prototyping capabilities of 3D printing with the high-throughput replication efficiency of UV-NIL to produce unique optical security features. This combination enables scalable, cost-effective, and adaptable integration of CGH-based tags into plastic components across multiple industries.

Direct integration of CGHs onto the surface of 3D printed components eliminates the need for post-processing and allows seamless incorporation of optical security features during fabrication. This embedded configuration improves durability and protects the tags from physical wear and surface damage. By leveraging both additive manufacturing and NIL, the approach enhances the scalability and manufacturability of functional holographic elements, enabling large-scale production of secure and reproducible optical tags.

Quantitative analysis of the digital reconstructions confirmed that the NIL replicated CGH tags closely reproduce the optical response of their 3D printed masters. The high similarity of metrics and submicrometer spatial deviations demonstrate that replication defects introduced during NIL have negligible impact on the reconstructed optical patterns. The proposed digital reconstruction-based evaluation framework thus provides a robust tool for verifying optical performance and product authenticity. Overall, this hybrid process offers a commercially viable and scalable route toward next generation optical security features for anti-counterfeiting applications.