Ultra-High Voltage NV Center Magnetic Sensing System Based on Power over Fiber

Abstract

1. Introduction

2. Materials and Methods

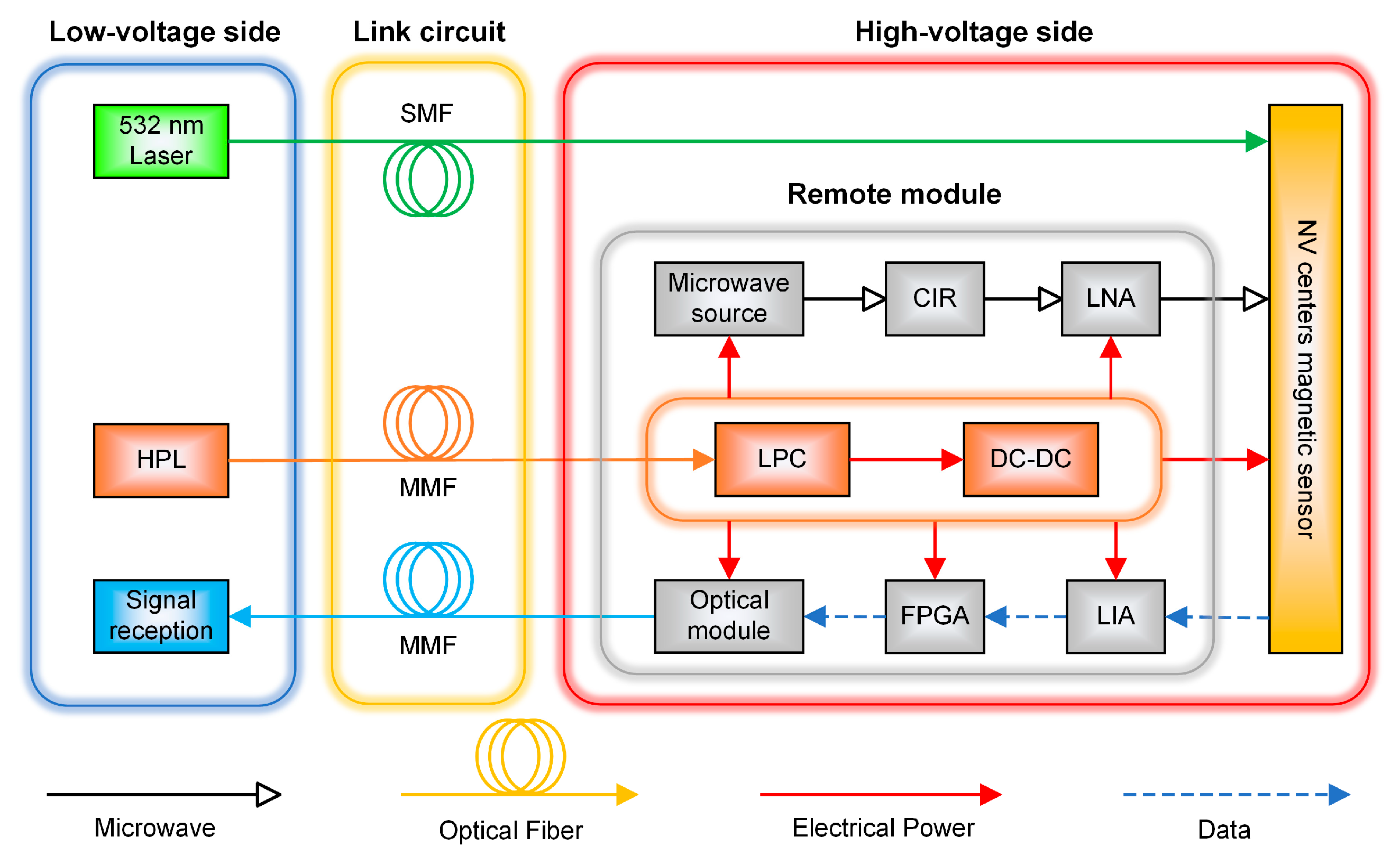

2.1. A UHV NV Center Magnetic Sensing System

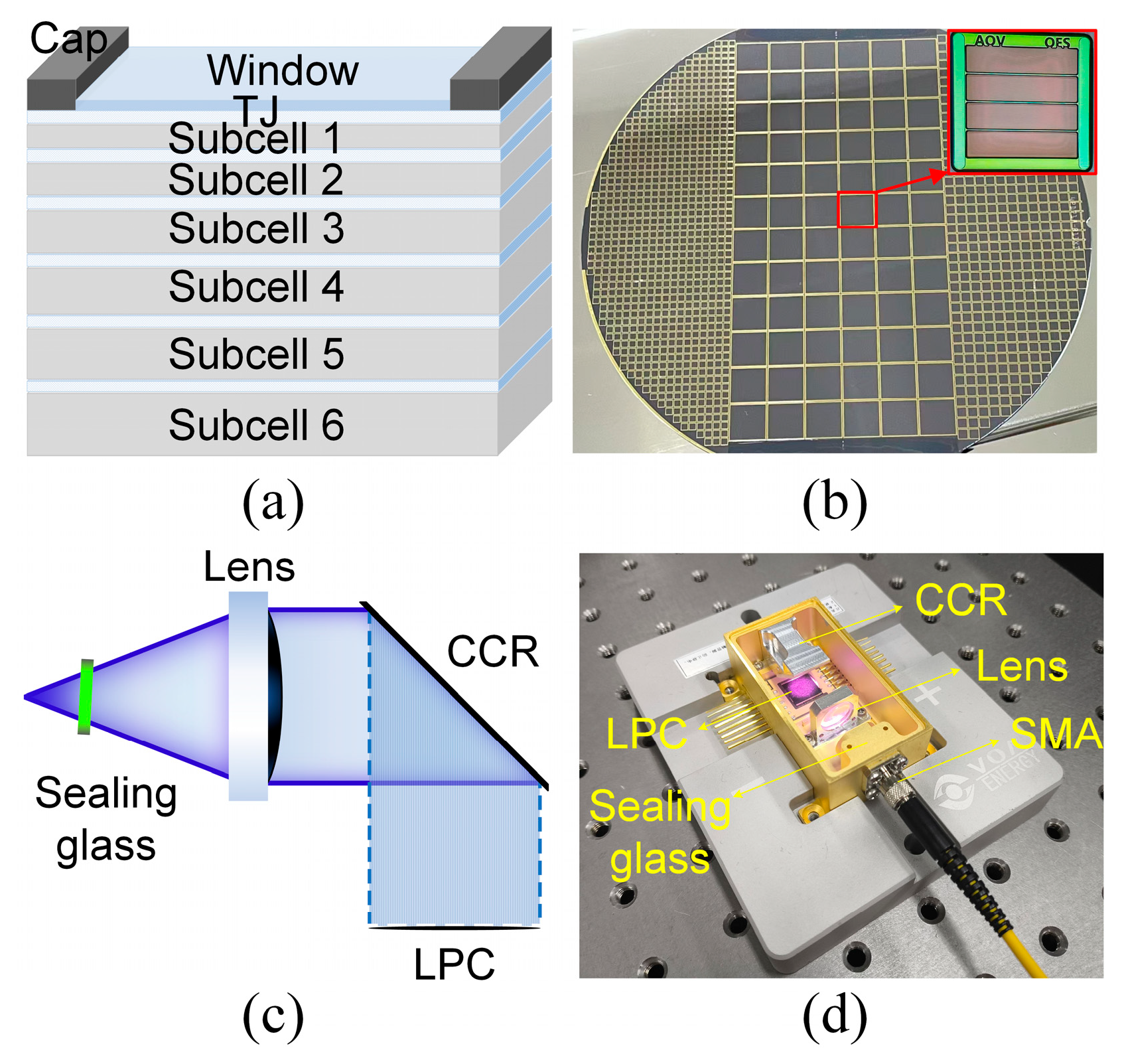

2.2. Design of the LPC Assembly

3. Results

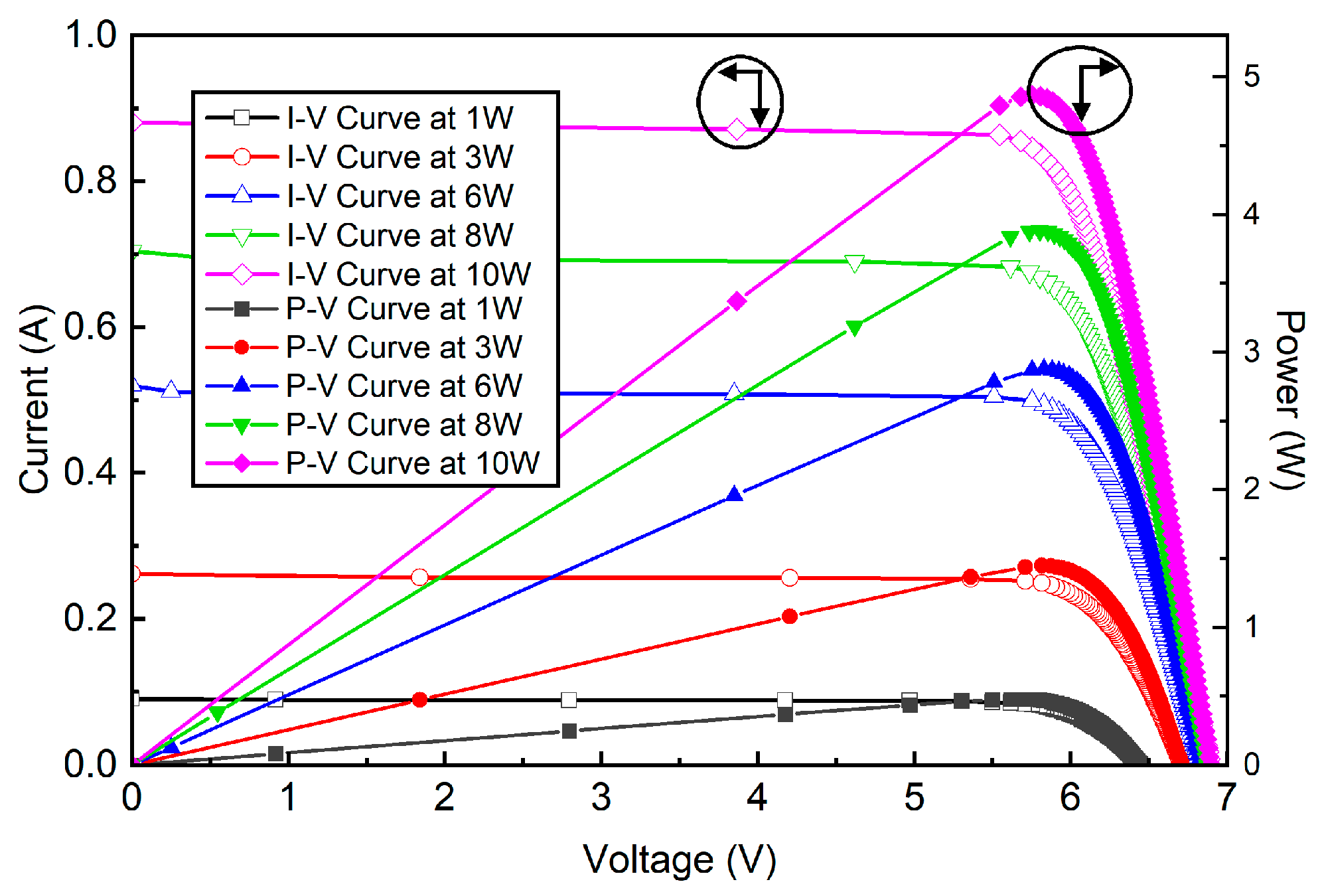

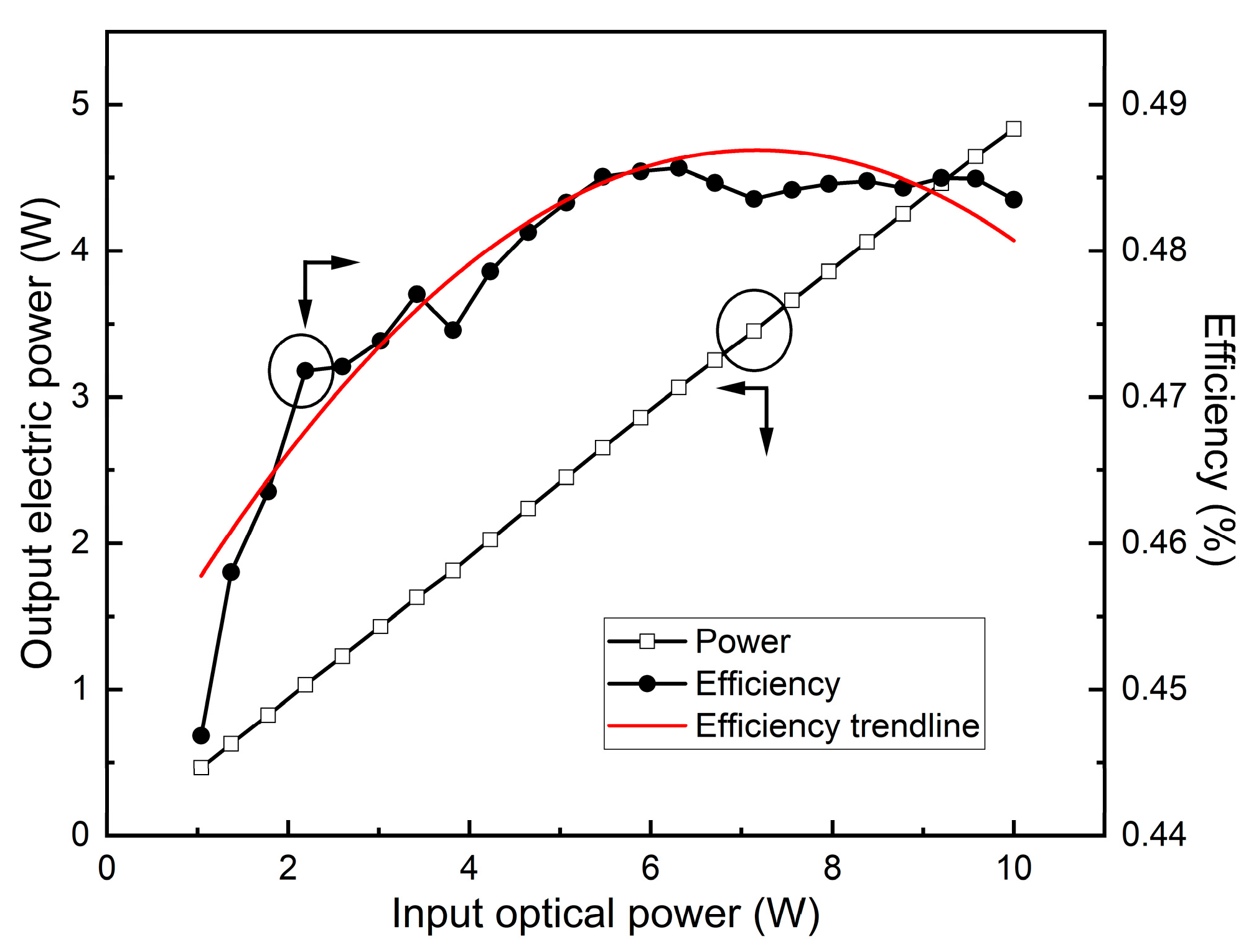

3.1. Characteristic of LPC Component

3.2. System Application

3.3. System Performance

4. Discussion

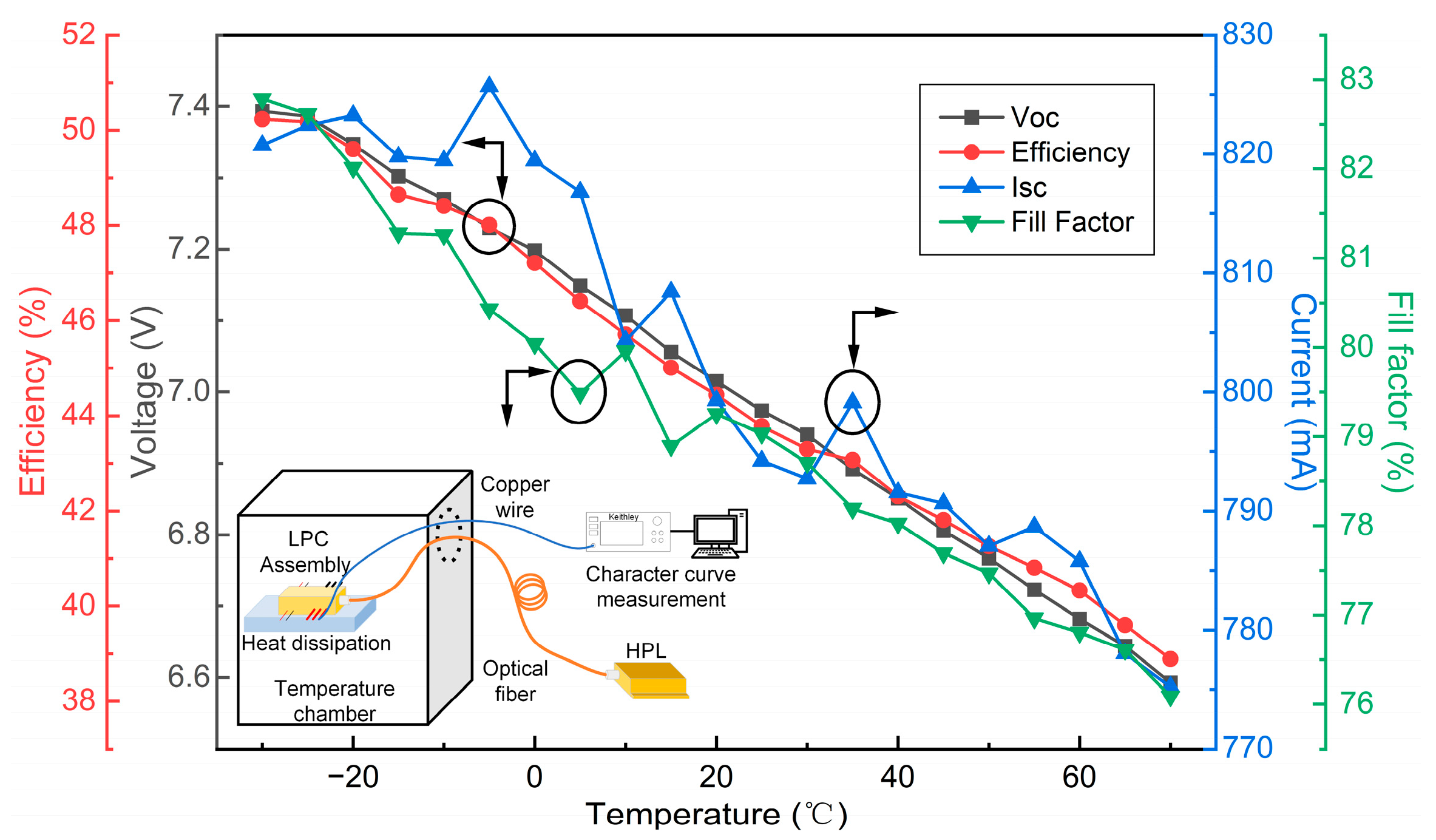

4.1. Full Temperature Operating Characteristics of the LPC Assembly

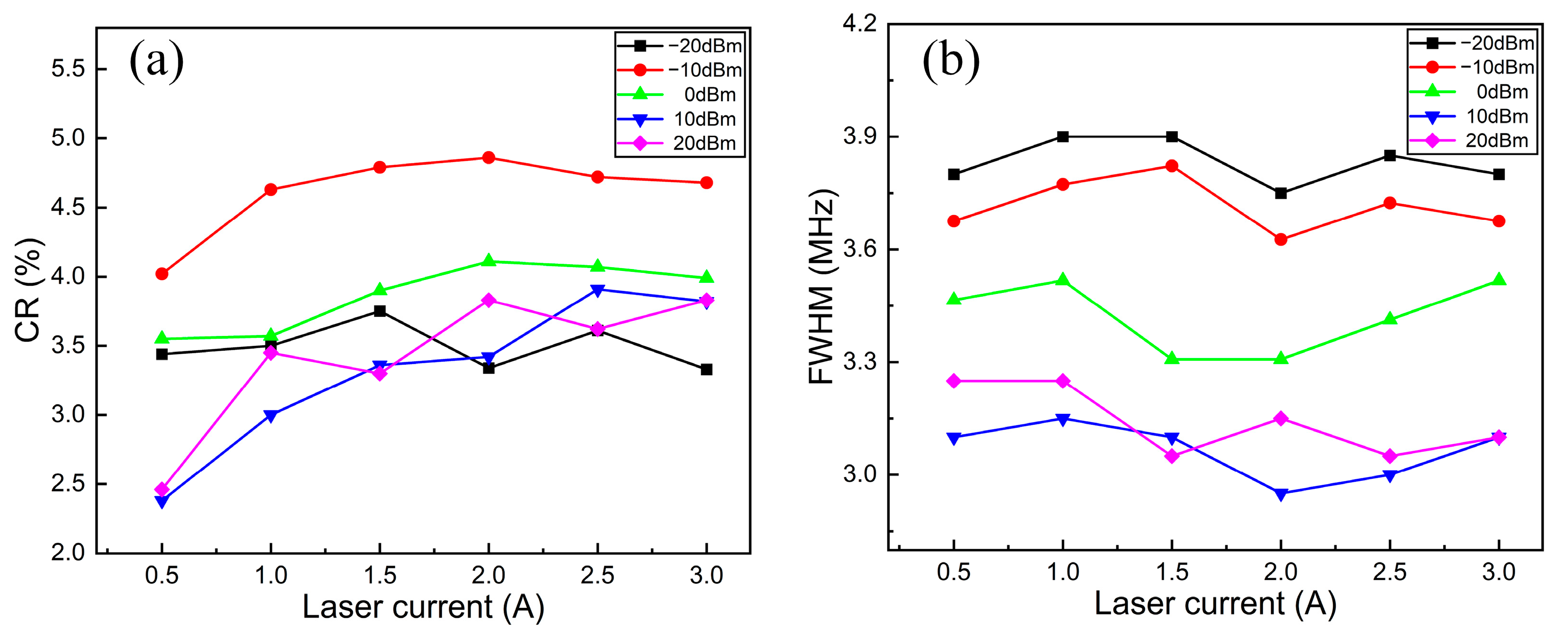

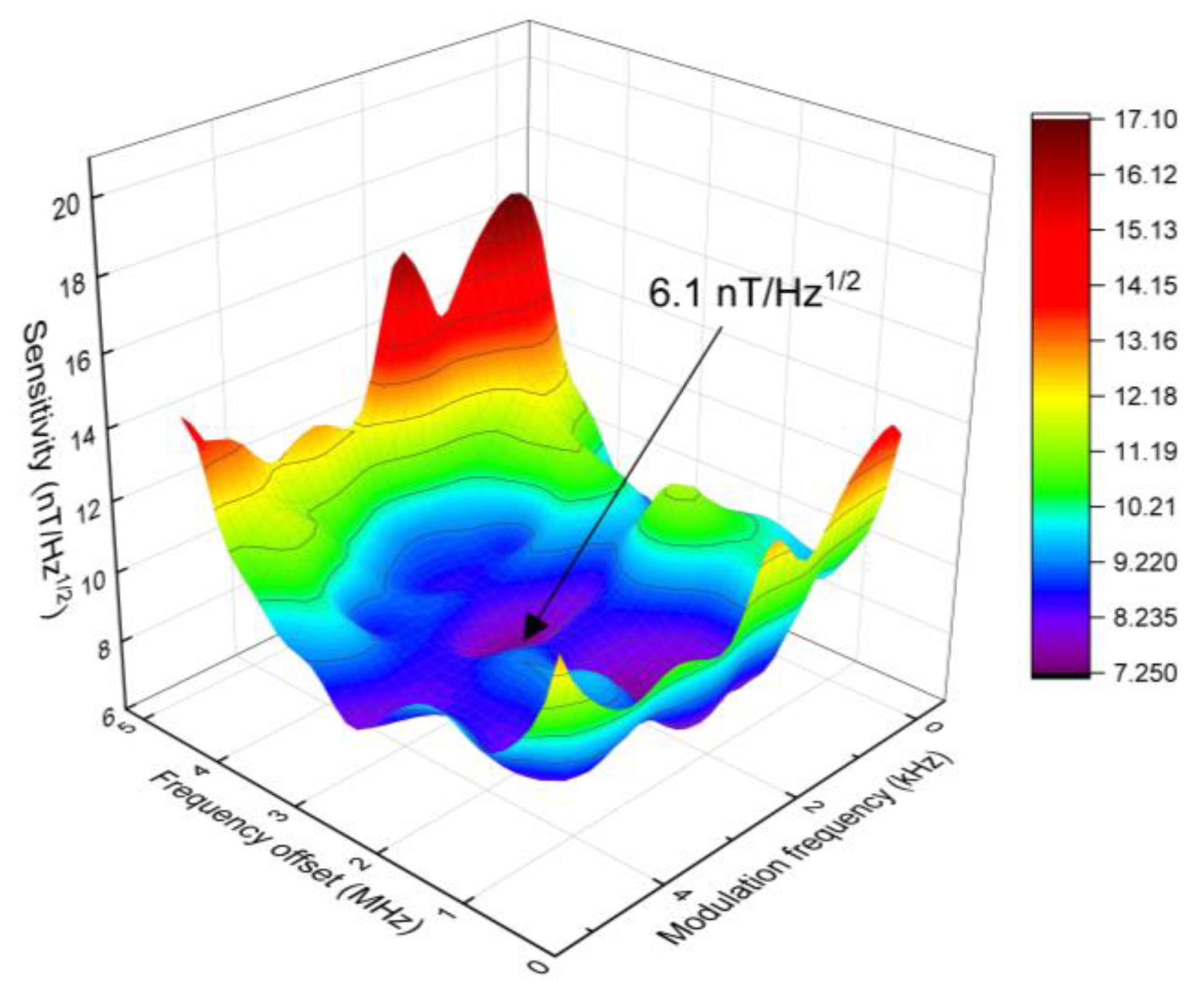

4.2. Sensitivity Optimization of the NV Center Sensor

4.3. Performance Comparison and Analysis

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Degen, C.L.; Reinhard, F.; Cappellaro, P. Quantum sensing. Rev. Mod. Phys. 2017, 89, 035002. [Google Scholar] [CrossRef]

- Schirhagl, R.; Chang, K.; Loretz, M.; Degen, C.L. Nitrogen-vacancy centers in diamond: Nanoscale sensors for physics and biology. Annu. Rev. Phys. Chem. 2014, 65, 83–105. [Google Scholar] [CrossRef]

- Rondin, L.; Tetienne, J.P.; Hingant, T.; Roch, J.-F.; Maletinsky, P.; Jacques, V. Magnetometry with nitrogen-vacancy defects in diamond. Rep. Prog. Phys. 2014, 77, 056503. [Google Scholar] [CrossRef]

- Webb, J.L.; Troise, L.; Hansen, N.W.; Achard, J.; Brinza, O.; Staacke, R.; Kieschnick, M.; Meijer, J.; Perrier, J.-F.; Berg-Sørensen, K.; et al. Optimization of a diamond nitrogen vacancy centre magnetometer for sensing of biological signals. Sensors 2020, 20, 4106. [Google Scholar] [CrossRef]

- Barry, J.F.; Schloss, J.M.; Bauch, E.; Turner, M.J.; Hart, C.A.; Pham, L.M.; Walsworth, R.L. Sensitivity optimization for NV-diamond magnetometry. Rev. Mod. Phys. 2020, 92, 015004. [Google Scholar] [CrossRef]

- Glenn, D.R.; Fu, R.R.; Kehayias, P.; Le Sage, D.; Lima, E.A.; Weiss, B.P.; Walsworth, R.L. Micrometer-scale magnetic imaging of geological samples using a quantum diamond microscope. Geochem. Geophys. Geosystems 2017, 18, 3254–3267. [Google Scholar] [CrossRef]

- Rizzato, R.; von Grafenstein, N.R.; Bucher, D.B. Quantum sensors in diamonds for magnetic resonance spectroscopy: Current applications and future prospects. Appl. Phys. Lett. 2023, 123, 260501. [Google Scholar] [CrossRef]

- Zhang, S.C.; Zhao, L.; Qiu, R.J.; Geng, J.-Q.; Tian, T.; Zhao, B.-W.; Liu, Y.; Shan, L.-K.; Chen, X.-D.; Guo, G.-C.; et al. High-voltage current sensing with nitrogen-vacancy centers in diamond. APL Photonics 2025, 10, 030701. [Google Scholar] [CrossRef]

- Crawford, S.E.; Shugayev, R.A.; Paudel, H.P.; Lu, P.; Syamlal, M.; Ohodnicki, P.R.; Chorpening, B.; Gentry, R.; Duan, Y. Quantum sensing for energy applications: Review and perspective. Adv. Quantum Technol. 2021, 4, 2100049. [Google Scholar] [CrossRef]

- Liu, Q.; Nie, S.; Peng, X.; Zhu, Y.; Wang, N.; Hu, Y.; Luo, X.; Li, C.; Jing, M.; Zhang, C.; et al. Fiber-integrated diamond quantum sensor for high-voltage current measurements. Adv. Sens. Res. 2025, 4, 2400106. [Google Scholar] [CrossRef]

- Zhu, H.B.; Huang, Y.H. The world’s first UHV DC quantum current sensor put into operation. China Science Daily, 10 April 2025; p. 3. [Google Scholar] [CrossRef]

- Zhang, S.; Fan, Y.; Lei, Q.; Wang, J.; Liu, Y.; Zhan, T. Insulation structure design and electric field simulation of 500 kV isolation energy supply transformer for HVDC breaker. High Volt. 2022, 7, 185–196. [Google Scholar] [CrossRef]

- Okabe, S. Research in high voltage and insulation engineering of UHV-class electric power equipment. IEEJ Trans. Electr. Electron. Eng. 2023, 18, 1384–1397. [Google Scholar] [CrossRef]

- Matsuura, M. Recent advancement in power-over-fiber technologies. Photonics 2021, 8, 335. [Google Scholar] [CrossRef]

- Algora, C.; García, I.; Delgado, M.; Peña, R.; Vázquez, C.; Hinojosa, M.; Rey-Stolle, I. Beaming power: Photovoltaic laser power converters for power-by-light. Joule 2022, 6, 340–368. [Google Scholar] [CrossRef]

- Kawano, T.; Koyama, R.; Kuroda, A.; Uematsu, T.; Fukai, C.; Watanabe, H.; Ogushi, I. Power-over-fiber system with intermittent operation based on capacitor voltage estimation for high-efficiency energy charging. IEEE Access 2024, 12, 54999–55006. [Google Scholar] [CrossRef]

- Green, M.A.; Dunlop, E.D.; Hohl-Ebinger, J.; Yoshita, M.; Kopidakis, N.; Hao, X. Solar cell efficiency tables (Version 58). Prog. Photovolt. Res. Appl. 2021, 29, 657–667. [Google Scholar] [CrossRef]

- Guan, C.G.; Li, L.; Ji, H.M.; Luo, S.; Xu, P.; Gao, Q.; Lv, H.; Liu, W. Fabrication and characterization of a high-power assembly with a 20-junction monolithically stacked laser power converter. IEEE J. Photovolt. 2018, 8, 1355–1362. [Google Scholar] [CrossRef]

- López-Cardona, J.D.; Vázquez, C.; Montero, D.S.; Lallana, P.C. Remote optical powering using fiber optics in hazardous environments. J. Light. Technol. 2017, 36, 748–754. [Google Scholar] [CrossRef]

- Li, A.; Miao, Y.; Feng, C.; Fan, G. Research on optical fiber energy supply technology suitable for power system. In Proceedings of the 2022 International Conference on Electronics and Devices, Computational Science (ICEDCS), Marseille, France, 20–22 September 2022; IEEE: New York, NY, USA, 2022; pp. 230–233. [Google Scholar]

- Budelmann, C. Opto-electronic sensor network powered over fiber for harsh industrial applications. IEEE Trans. Ind. Electron. 2017, 65, 1170–1177. [Google Scholar] [CrossRef]

- Li, Y.; Xiao, Z.; Zhang, Z.; Li, L. A novel remote multi-sensing energy management system based on power-over-fiber transmission. In Proceedings of the 2021 4th International Conference on Energy, Electrical and Power Engineering (CEEPE), Chongqing, China, 23–25 April 2021; IEEE: New York, NY, USA, 2021; pp. 125–129. [Google Scholar]

- Liu, C.; Qin, H.; Guan, C.; Chen, X.; Li, J.; Zhan, L.; Wang, W.; Xiao, Y.; Hu, S.; Huang, J.; et al. Passive bidirectional audio over fiber system integrating sensing, power supply and communication. IEEE Sens. J. 2024, 24, 6543–6552. [Google Scholar] [CrossRef]

- Wuhan AOV Energy LLC.; Jiangsu Huaxing Laser Technology Co., Ltd. High-Power Monochromatic Light Photovoltaic Cell Device and Monochromatic Light Photovoltaic Cell Assembly. CN Patent No. 201611241266.0, 28 May 2019. [Google Scholar]

- Zhang, Y.; Guan, C.; Chu, W.; Zhou, Y.; Zhou, R.; Yao, Y. Optimal I–V curve scan time for a GaAs laser power converter. Photonics 2023, 10, 762. [Google Scholar] [CrossRef]

- El-Ella, H.A.R.; Ahmadi, S.; Wojciechowski, A.M.; Huck, A.; Andersen, U.L. Optimised frequency modulation for continuous-wave optical magnetic resonance sensing using nitrogen-vacancy ensembles. Opt. Express 2017, 25, 14809–14821. [Google Scholar] [CrossRef]

- Liu, Q.; Xie, F.; Peng, X.; Hu, Y.; Wang, N.; Zhang, Y.; Wang, Y.; Li, L.; Chen, H.; Cheng, J.; et al. Millimeter-scale temperature self-calibrated diamond-based quantum sensor for high-precision current sensing. Adv. Quantum Technol. 2023, 6, 2300210. [Google Scholar] [CrossRef]

- Peng, X.; Xie, F.; Zhu, Y.; Luo, X.; Liu, Q.; Wang, D.; Hu, Y.; Han, J.; Li, L.; Liu, J.; et al. A highly integrated three-axis vector diamond quantum magnetometer with a compact electrical package. Appl. Phys. Lett. 2025, 126, 081101. [Google Scholar] [CrossRef]

- Pogorzelski, J.; Horsthemke, L.; Homrighausen, J.; Stiegekötter, D.; Gregor, M.; Glösekötter, P. Compact and fully integrated LED quantum sensor based on NV centers in diamond. Sensors 2024, 24, 743. [Google Scholar] [CrossRef]

- Stürner, F.M.; Brenneis, A.; Kassel, J.; Wostradowski, U.; Rölver, R.; Fuchs, T.; Nakamura, K.; Sumiya, H.; Onoda, S.; Isoya, J.; et al. Compact integrated magnetometer based on nitrogen-vacancy centres in diamond. Diam. Relat. Mater. 2019, 93, 59–65. [Google Scholar] [CrossRef]

- Ibrahim, M.I.; Foy, C.; Englund, D.R.; Han, R. High-scalability CMOS quantum magnetometer with spin-state excitation and detection of diamond color centers. IEEE J. Solid-State Circuits 2020, 56, 1001–1014. [Google Scholar] [CrossRef]

- Wang, X.; Zheng, D.; Wang, X.; Liu, X.; Wang, Q.; Zhao, J.; Guo, H.; Qin, L.; Tang, J.; Ma, Z.; et al. Portable diamond NV magnetometer head integrated with 520 nm diode laser. IEEE Sens. J. 2022, 22, 5580–5587. [Google Scholar] [CrossRef]

| Component | Power Consumption (W) | Total Power Consumption (W) |

|---|---|---|

| LNA | 0.6 | 3.8 |

| RF microwave | 0.8 | |

| NV center sensor | 0.08 | |

| LIA | 0.8 | |

| FPGA | 0.8 | |

| Low-speed optical module | 0.72 |

| References | Sensitivity (nT/Hz1/2) | Power Supply Mode | Application Scenario | Advantages | Drawbacks |

|---|---|---|---|---|---|

| Peng X, Xie F, Zhu Y, et al. [28] | 2.25 | Electrically driven (with PCB-embedded copper block for heat dissipation) Total power consumption not specified, laser power of 100 mW | Handheld magnetic detection devices, industrial magnetic field monitoring, biomagnetic imaging (e.g., animal magnetocardiography), magnetically silent environment detection | Volume of only 2.72 cm3 Three-axis vector detection No obvious thermal drift | Near-surface NV center coherence to be optimized Relies on local power supply Laser noise requires a balance between detection efficiency and noise suppression |

| Our Work | 6.1 | Power over Fiber (PoF), 4 LPC modules connected in parallel Total power consumption of the high-voltage side is approximately 15.2 W | UHV current/magnetic field monitoring, strong electromagnetic interference environments (e.g., substations, converter stations) | All-fiber isolation design Adaptability to complex working conditions High precision under strong interference | Relatively high system power consumption Sensor thermal stability to be improved |

| Pogorzelski J, Horsthemke L, Homrighausen J, et al. [29] | 28.32 | Powered by 9 V battery, constant current source driving LED (30 mA) Total power consumption of approximately 0.1 W | Automotive current detection, switchgear magnetic field monitoring, temperature-magnetic field combined measurement, portable industrial on-site detection | Significant cost advantage, with cost ~90% lower than CVD diamonds Volume of only 0.42 cm3 Ultra-low power consumption | System performance dominated by LED noise Sensitivity limited by hardware Dynamic magnetic field detection deviation |

| Stürner F M, Brenneis A, Kassel J, et al. [30] | 31 | Powered by external wired power supply; total power consumption of 1.5 W (including LED and signal amplification circuit) | Industrial-grade vector magnetic measurement, equipment magnetic field calibration, low-cost quantum sensing prototype verification | First realization of an NV magnetometer integration without external optical equipment Vector detection capability | Prominent heat dissipation issue Obvious sensitivity bottleneck No active thermal control |

| Ibrahim M I, Foy C, Englund D R, et al. [31] | 245 | Electrically driven by CMOS circuit Total power consumption of 40 mW | Chip-level quantum sensing, integrated NMR spectroscopy, gradient magnetometers, atomic gyroscopes | Strong mass production compatibility Excellent green light suppression High microwave uniformity | Low NV center density Dependence on external microwave source Differential detection noise |

| Wang X, Zheng D, Wang X, et al. [32] | 20.77 | Laser diode driven by self-developed APC circuit (10 mW) Total power consumption < 200 mW | Portable magnetic detection (e.g., near-surface biomagnetism), industrial equipment magnetic field inspection, field magnetic field measurement | Adopts a small laser diode with volume < 10 cm3; Lightweight probe: Overall weight < 50 g, | Narrow bandwidth Low system integration Poor environmental adaptability |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhan, L.; Guan, C.; Dong, C.; Fan, X.; Guo, Q.; Wang, W.; Xiao, Y.; Chen, X.; Huang, J.; Zhang, X.; et al. Ultra-High Voltage NV Center Magnetic Sensing System Based on Power over Fiber. Photonics 2025, 12, 1093. https://doi.org/10.3390/photonics12111093

Zhan L, Guan C, Dong C, Fan X, Guo Q, Wang W, Xiao Y, Chen X, Huang J, Zhang X, et al. Ultra-High Voltage NV Center Magnetic Sensing System Based on Power over Fiber. Photonics. 2025; 12(11):1093. https://doi.org/10.3390/photonics12111093

Chicago/Turabian StyleZhan, Linfeng, Chenggang Guan, Chaoqiang Dong, Xuelong Fan, Qingtao Guo, Weiqi Wang, Yifan Xiao, Xuan Chen, Junchang Huang, Xueyou Zhang, and et al. 2025. "Ultra-High Voltage NV Center Magnetic Sensing System Based on Power over Fiber" Photonics 12, no. 11: 1093. https://doi.org/10.3390/photonics12111093

APA StyleZhan, L., Guan, C., Dong, C., Fan, X., Guo, Q., Wang, W., Xiao, Y., Chen, X., Huang, J., Zhang, X., Jiang, W., & Gong, J. (2025). Ultra-High Voltage NV Center Magnetic Sensing System Based on Power over Fiber. Photonics, 12(11), 1093. https://doi.org/10.3390/photonics12111093