An Adaptive Absolute Phase Correction Method with Row–Column Constraints for Projected Fringe Profilometry

Abstract

1. Introduction

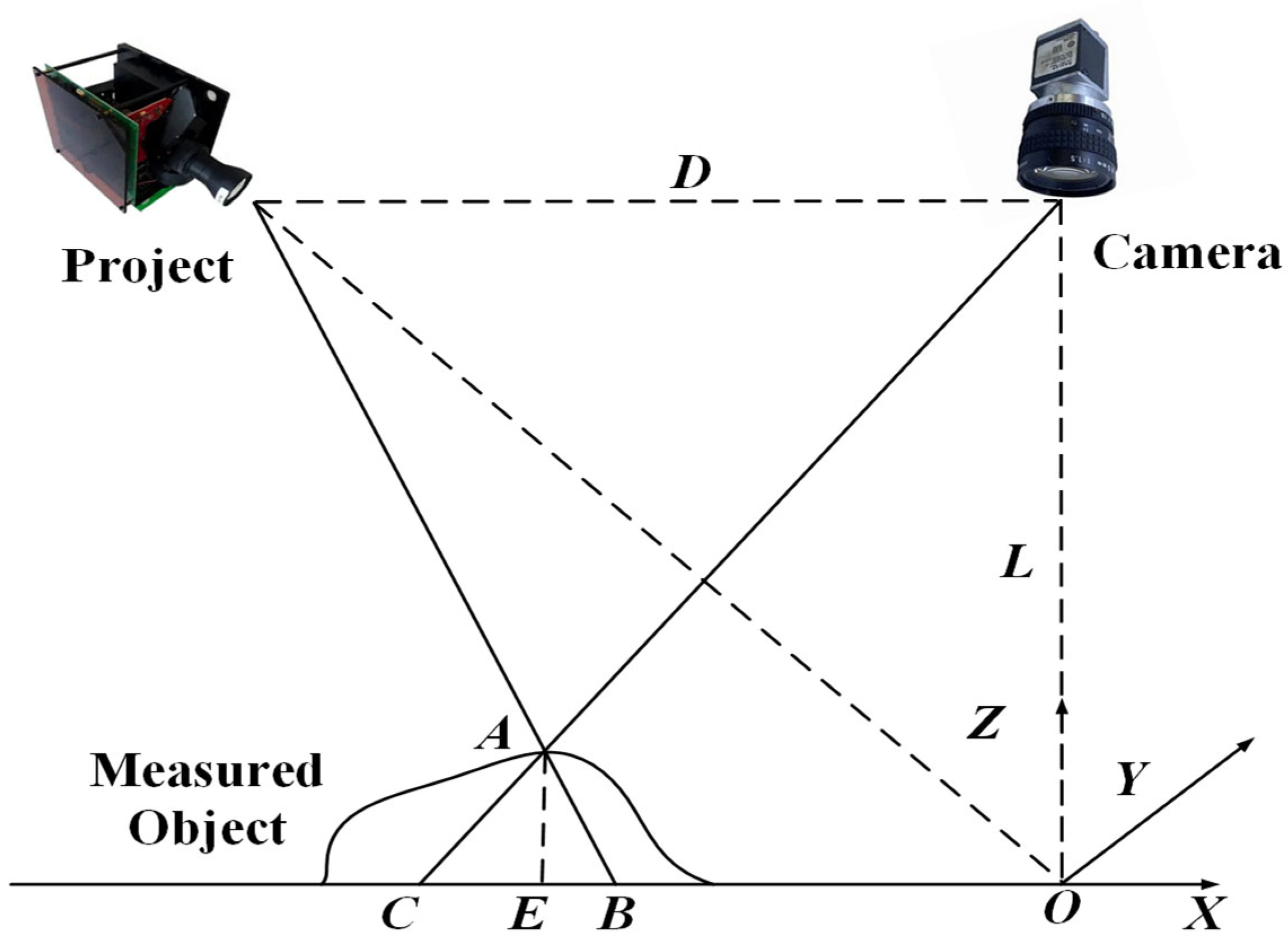

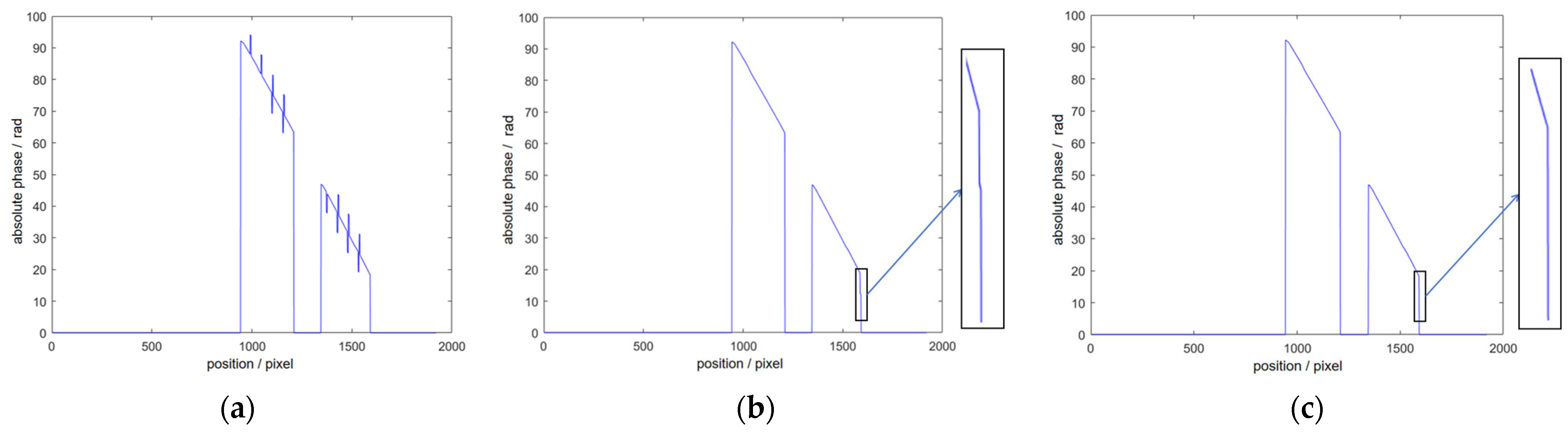

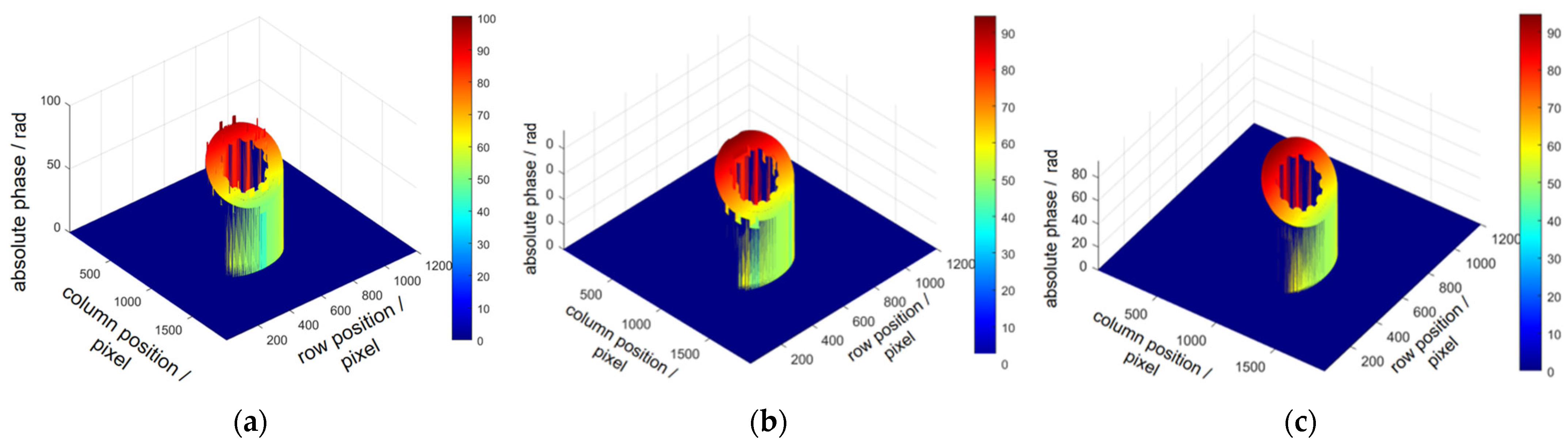

2. Dual-Frequency Outlier Principle

Acquisition of Phase Principal Value

3. Phase Unwrapping Error Correction Method

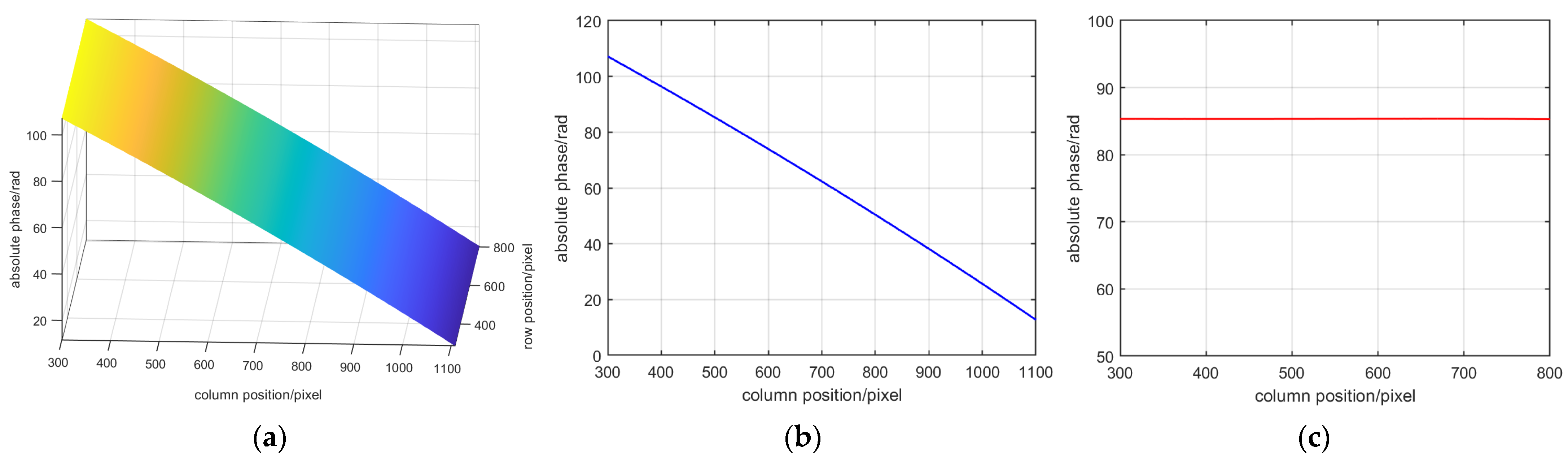

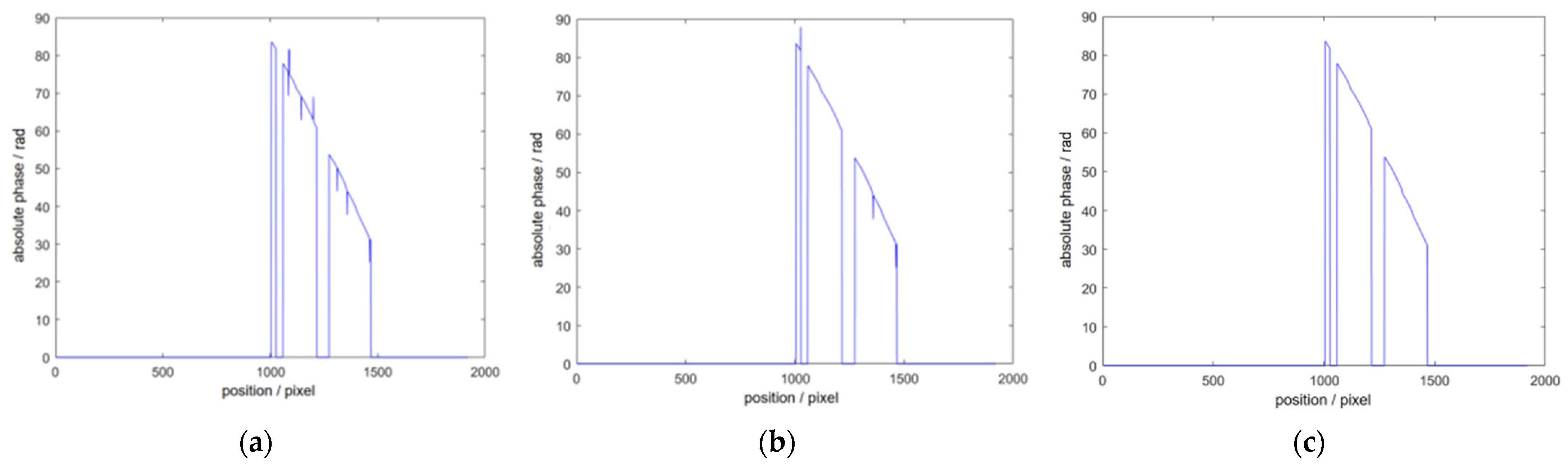

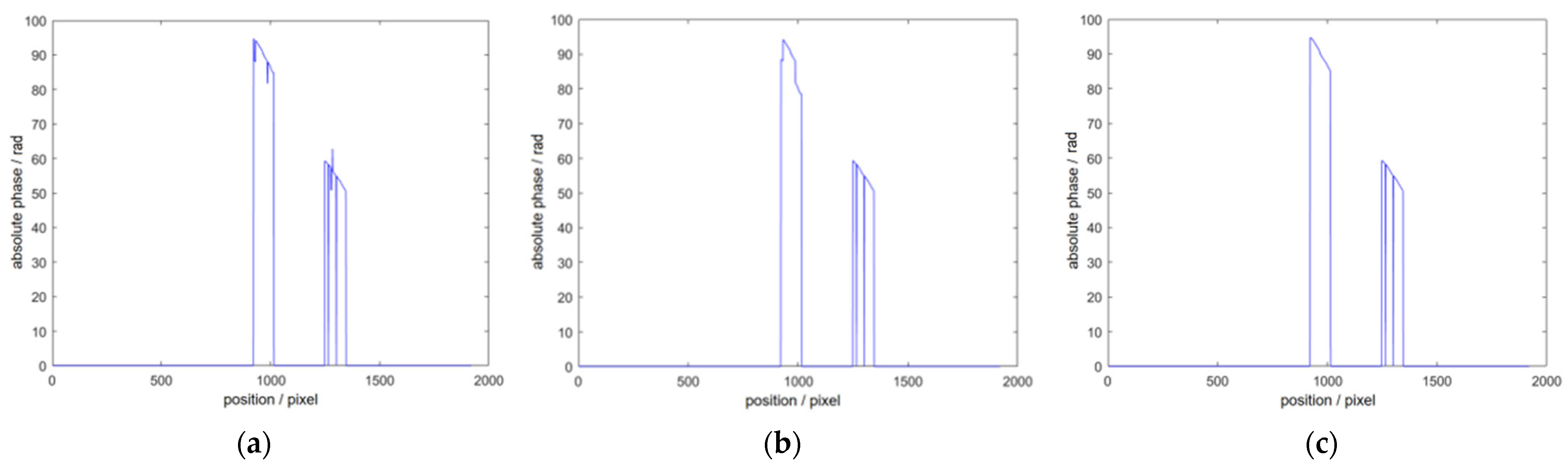

3.1. Row and Column Vector Analysis of Absolute Phase

3.2. Principle of the Improvement Method

- (1)

- Separate the continuous non-zero region (region of interest) and the zero-value region (null or background) in each row, always treating the zero value as the natural boundary and not operating across segments;

- (2)

- Inside each non-zero segment, starting from the third point, calculate the “difference between the first two points” and the “difference from the current point to the next point”. If the difference between the first two points is very small (indicating that the curve is smooth at that point) and the subsequent difference is very large, exceeding the set threshold value of 2π, then a phase jump has occurred, and the next point is judged to be an “abnormal jump point”;

- (3)

- Instead of replacing the point judged as abnormal with a fixed value, the increment (i.e., local slope) of the previous two points is used to smoothly calculate the new value of the point so as to ensure that the corrected data not only retains the original trend but also suppresses the phase jump;

- (4)

- All corrections are made only within the same continuous non-zero segment, the zero value is skipped immediately when encountered, and the void region is kept in its original state; the end of the segment and the beginning of the segment are smoothed and connected with the data in their respective segments so that the data in different segments will not be mixed or continued.

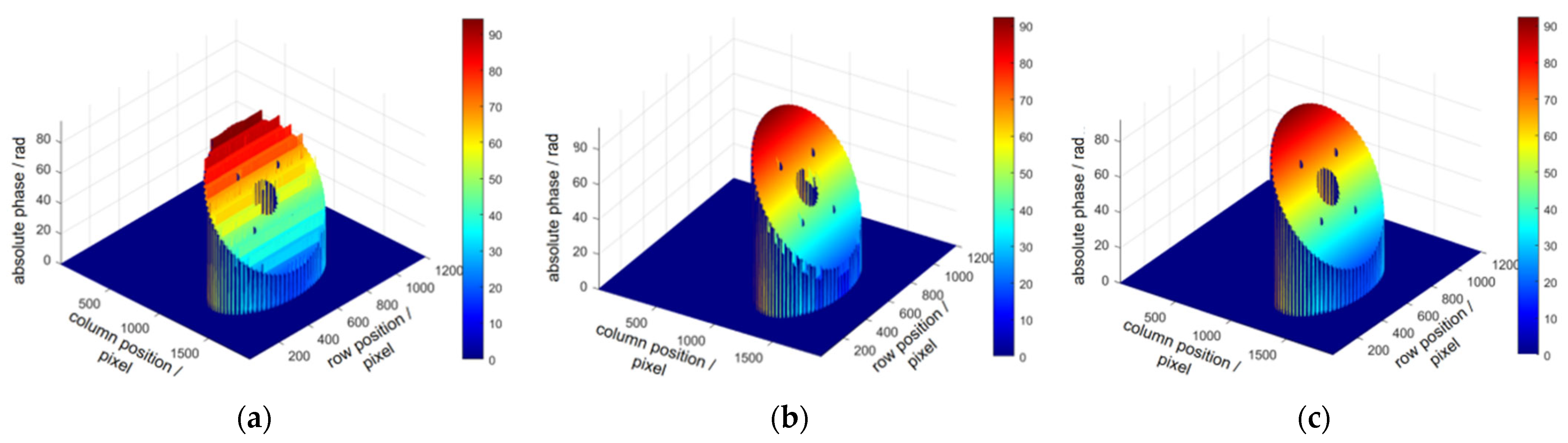

4. Experiment and Result Analysis

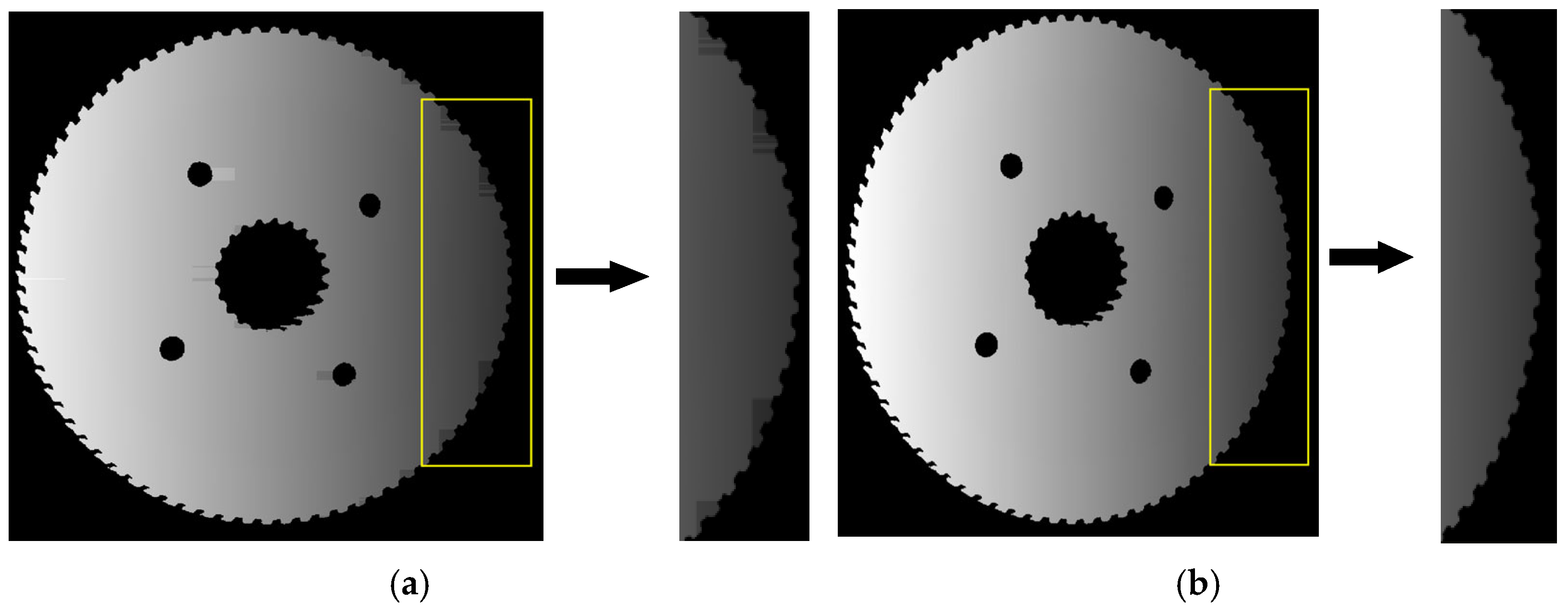

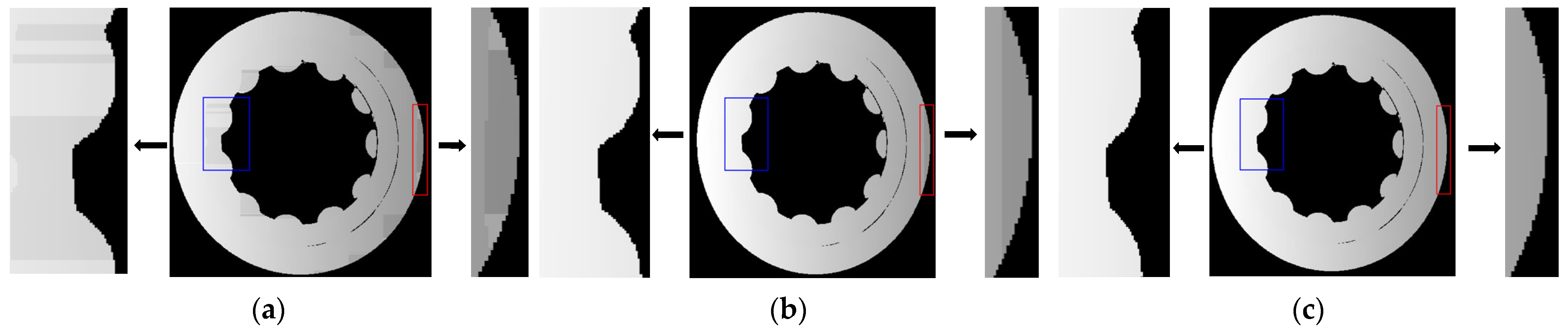

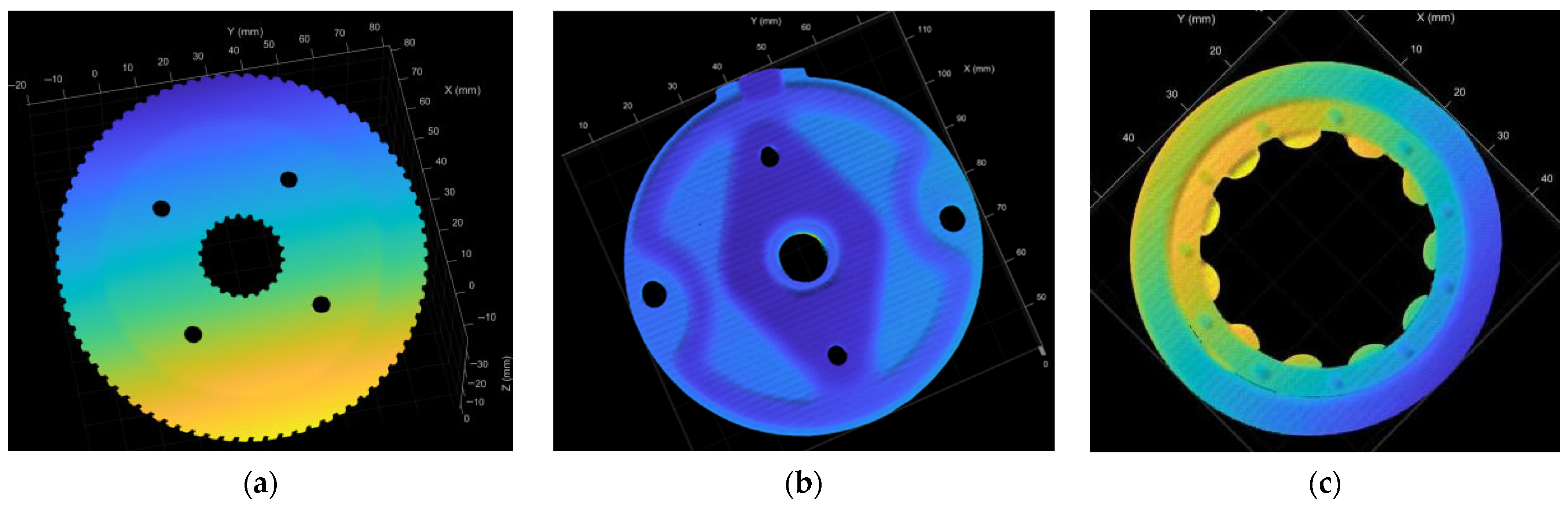

4.1. Comparative Measurement Experiments with Multiple Samples

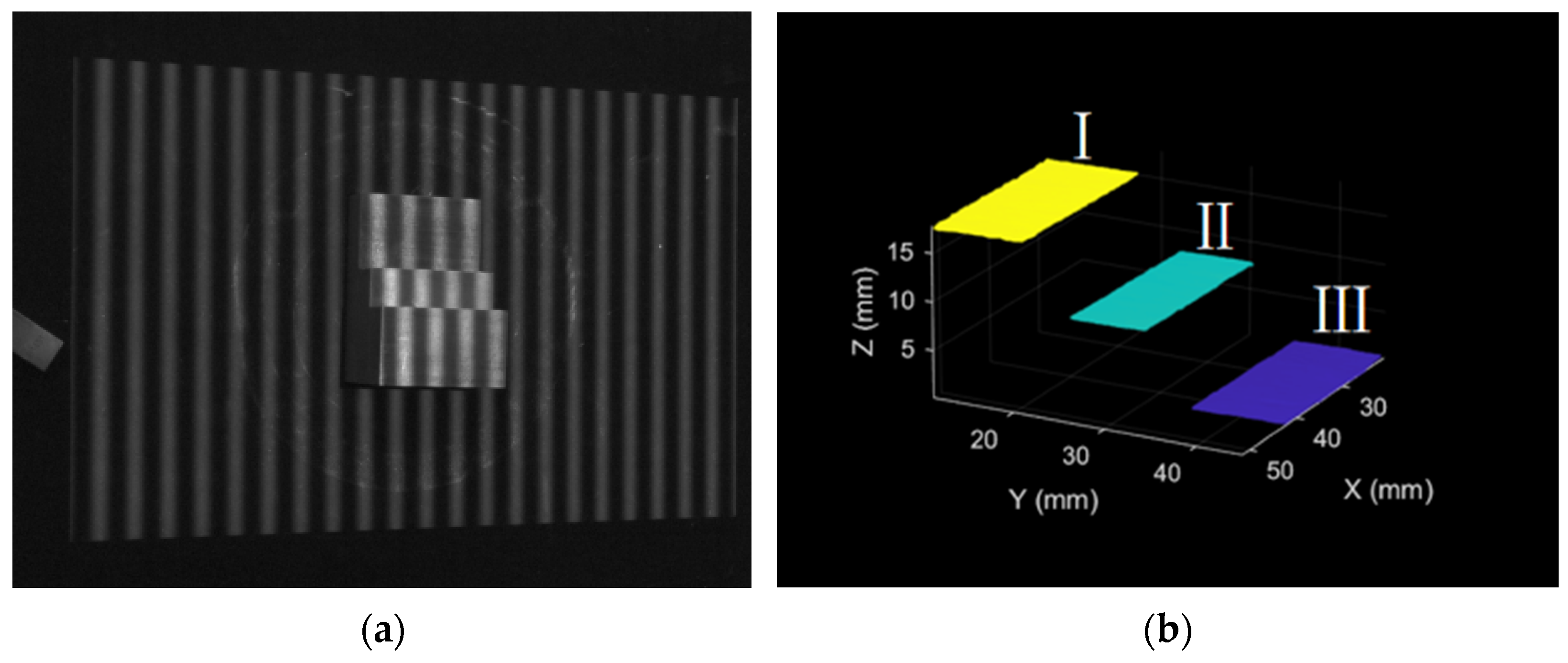

4.2. Accuracy Verification

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Xu, J.; Zhang, S. Status, challenges, and future perspectives of fringe projection profilometry. Opt. Lasers Eng. 2020, 135, 106193. [Google Scholar] [CrossRef]

- Zonghua, Z.; Yanling, L.; Feng, G.; Nan, G.; Zhaozong, M.; Xiangqian, J. Phase unwrapping technology for structured light three-dimensional measurement: A review. Infrared Laser Eng. 2023, 52, 20230126-1–20230126-23. [Google Scholar] [CrossRef]

- Suqin, W.; Taiqin, C.; Feng, Z.; Min, S.; Dengming, Z. High-precision 3D reconstruction method for topography measurement of complex mechanical parts. Infrared Laser Eng. 2022, 51, 20210730-1–20210730-11. [Google Scholar]

- Chuangwei, G.; Yang, W.; Wenzhe, Z.; Yuqing, G.; Yujie, Z.; Liqin, L.; Zhishan, G.; Lihua, L. Study of phase correction method based on multi-frequency heterodyne principle. Infrared Laser Eng. 2023, 52, 20220697-1–20220697-8. [Google Scholar]

- Chen, S.L.; Zhao, J.; Xia, R. Improvement of the phase unwrapping method based on multi-frequency heterodyne principle. Acta Opt. Sin. 2016, 36, 147–157. [Google Scholar]

- Liu, F.; Li, J.; Lai, J.; He, C. Full-frequency phase unwrapping algorithm based on multi-frequency heterodyne principle. Laser Optoelectron. Prog. 2019, 56, 011202. [Google Scholar]

- Liu, Q.; Li, L.L.; Huang, X.J.; Zhang, H.; Yue, X.B. Hierarchical phase unwrapping for dual-wavelength digital holographic microscopy. J. Opt. 2020, 22, 045701. [Google Scholar] [CrossRef]

- Yan, L.P.; Zhang, H.Y.; Zhang, R.; Xie, X.; Chen, B.Y. A robust phase unwrapping algorithm based on reliability mask and weighted minimum least-squares method. Opt. Lasers Eng. 2019, 112, 39–45. [Google Scholar] [CrossRef]

- Zhang, A.; Sun, Y.; Gao, N.; Meng, Z.; Zhang, Z. Fringe projection profilometry by ternary-gray encoded phase unwrapping method. Opt. Precis. Eng. 2022, 30, 518–526. [Google Scholar] [CrossRef]

- Gu, Q.; Lv, S.; Jiang, M.; Zhang, L.; Zhang, F.; Sui, Q. Wrapped phase demodulation algorithm based on dual-frequency heterodyne and phase-shifting method for structured light imaging. Instrum. Technol. Sens. 2020, 3, 105–109. [Google Scholar]

- Xu, Z.; Forsberg, E.; Guo, Y.; Cai, F.; He, S. Light-sheet microscopy for surface topography measurements and quantitative analysis. Sensors 2020, 20, 2842. [Google Scholar] [CrossRef] [PubMed]

- Luo, L.; Chen, X.; Xu, Z.; Li, S.; Sun, Y.; He, S. A parameter-free calibration process for a Scheimpflug LIDAR for volumetric profiling. Prog. Electromagn. Res. 2020, 169, 117–127. [Google Scholar] [CrossRef]

- He, X.; Kemao, Q. A comparative study on temporal phase unwrapping methods in high-speed fringe projection profilometry. Opt. Lasers Eng. 2021, 142, 106613. [Google Scholar] [CrossRef]

- Ha, M.; Xiao, C.; Pham, D.; Ge, J. Complete grid pattern decoding method for a one-shot structured light system. Appl. Opt. 2020, 59, 2674–2685. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y.; Han, X.; Zhang, P.; Fu, Y.; Zhong, K.; Zhang, W. 3D measurement method based on S-shaped segmental phase encoding. Opt. Laser Technol. 2020, 121, 105781. [Google Scholar] [CrossRef]

- Wu, B.; Liu, K. Few-image projected fringe profilometry using frequency encoding. Laser Optoelectron. Prog. 2024, 61, 2011024-1–2011024-9. [Google Scholar]

- Liu, Y.; Wu, Y.; Liu, F. Study on class imbalance based on wrapped optical phase. Opt. Optoelectron. Technol. 2021, 19, 37–44. [Google Scholar]

- Deng, G.; Wu, S.; Zhou, S.; Chen, B.; Liao, Y. A robust discontinuous phase unwrapping based on least-squares orientation estimator. Electronics 2021, 10, 2871. [Google Scholar] [CrossRef]

| 1 | 2 | 3 | 4 | 5 | |

|---|---|---|---|---|---|

| Difference in height between I and II/mm | 9.9544 | 9.9635 | 9.9579 | 10.0351 | 9.9691 |

| Absolute error between I and II/mm | 0.0456 | 0.0365 | 0.0421 | 0.03511 | 0.0301 |

| Difference in height between II and III/mm | 9.9693 | 10.0477 | 9.9627 | 9.9763 | 9.9574 |

| Absolute error between II and III/mm | 0.0307 | 0.0477 | 0.0373 | 0.0237 | 0.0426 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yu, Y.; Zhang, Q.; Feng, P.; Qian, L.; Li, C. An Adaptive Absolute Phase Correction Method with Row–Column Constraints for Projected Fringe Profilometry. Photonics 2025, 12, 956. https://doi.org/10.3390/photonics12100956

Yu Y, Zhang Q, Feng P, Qian L, Li C. An Adaptive Absolute Phase Correction Method with Row–Column Constraints for Projected Fringe Profilometry. Photonics. 2025; 12(10):956. https://doi.org/10.3390/photonics12100956

Chicago/Turabian StyleYu, Yuyang, Qin Zhang, Pengfei Feng, Lei Qian, and Chucheng Li. 2025. "An Adaptive Absolute Phase Correction Method with Row–Column Constraints for Projected Fringe Profilometry" Photonics 12, no. 10: 956. https://doi.org/10.3390/photonics12100956

APA StyleYu, Y., Zhang, Q., Feng, P., Qian, L., & Li, C. (2025). An Adaptive Absolute Phase Correction Method with Row–Column Constraints for Projected Fringe Profilometry. Photonics, 12(10), 956. https://doi.org/10.3390/photonics12100956