Low-Power-Consumption and Broadband 16-Channel Variable Optical Attenuator Array Based on Polymer/Silica Hybrid Waveguide

Abstract

1. Introduction

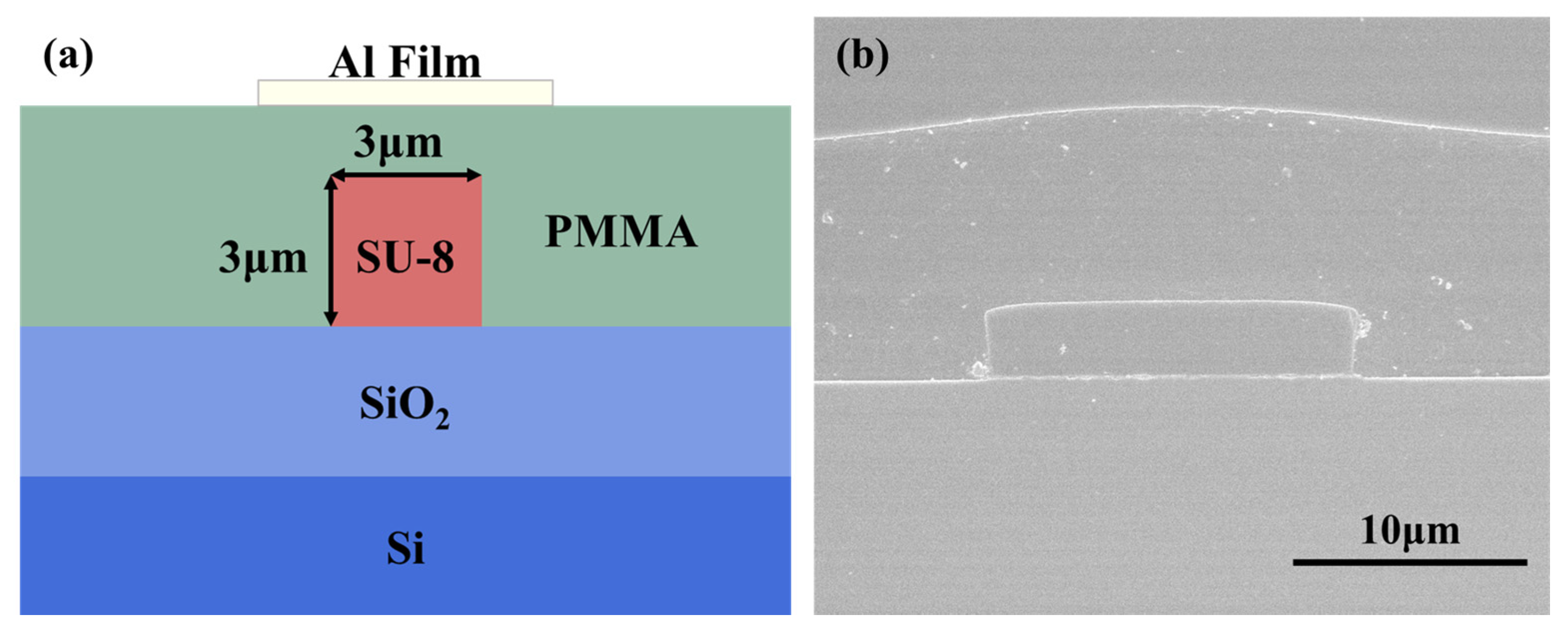

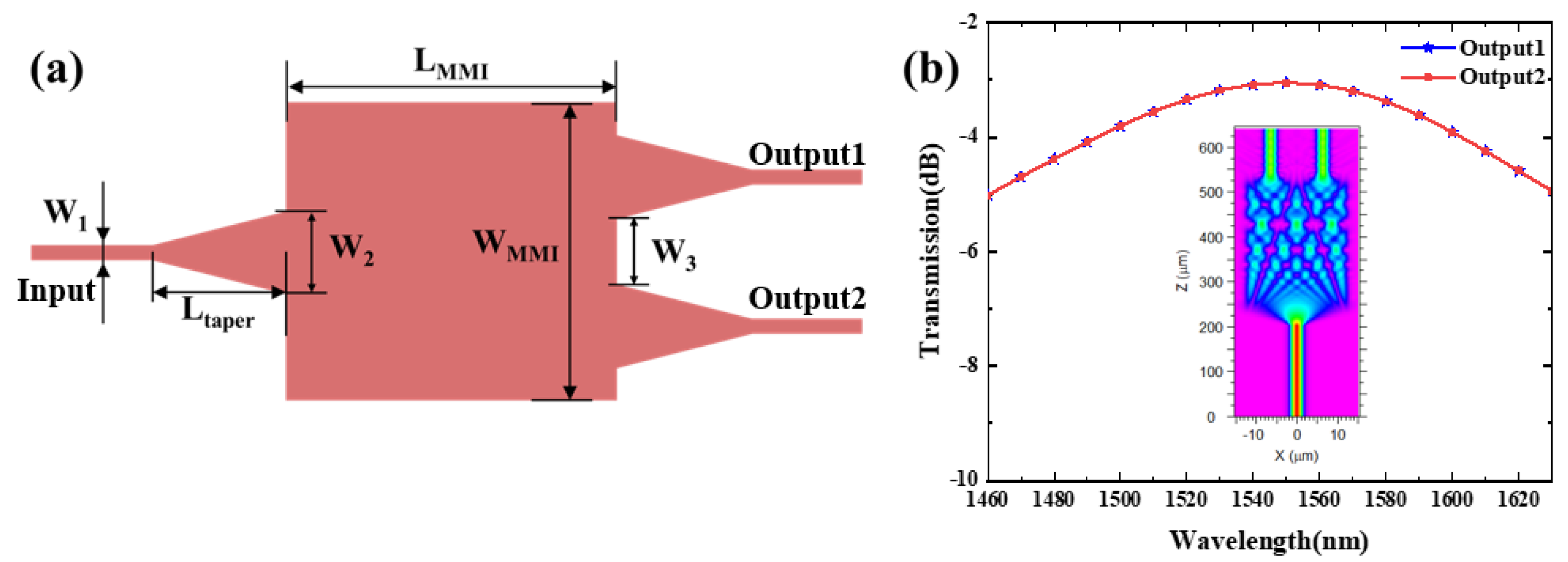

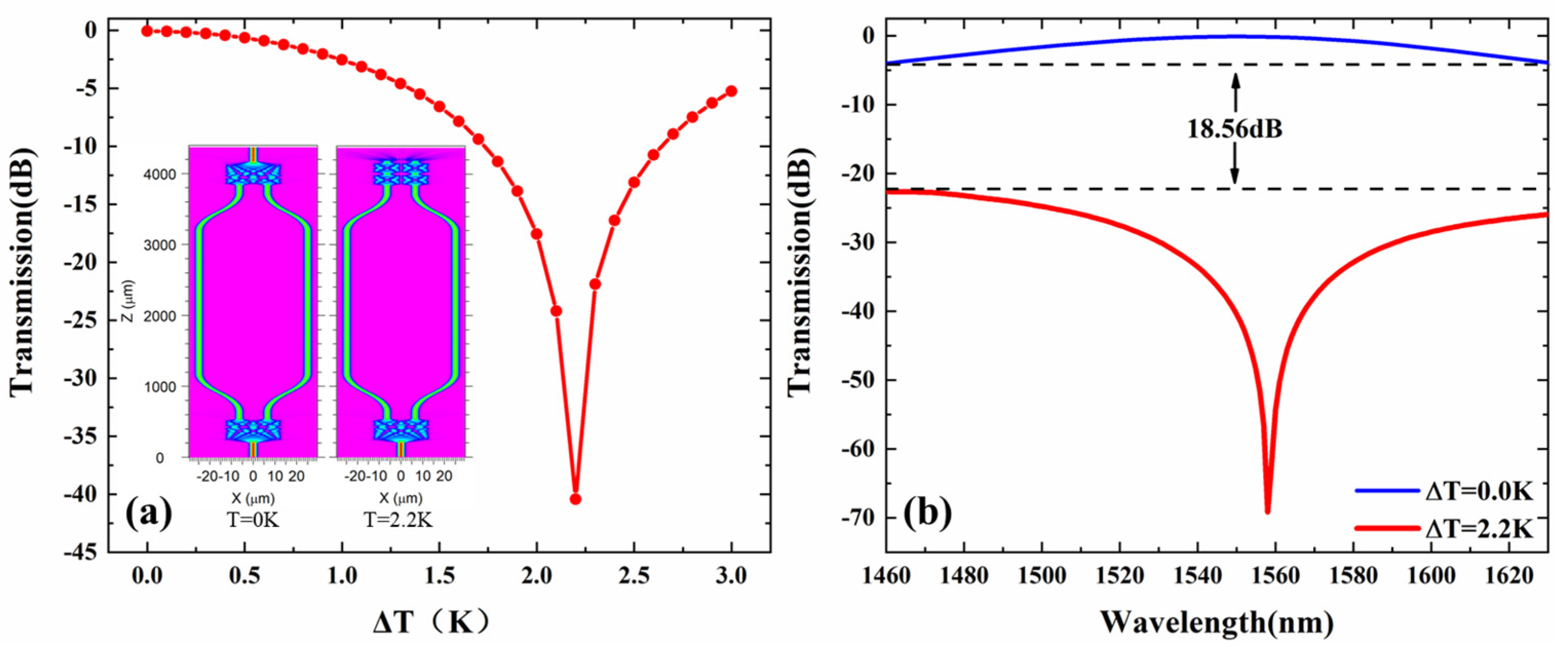

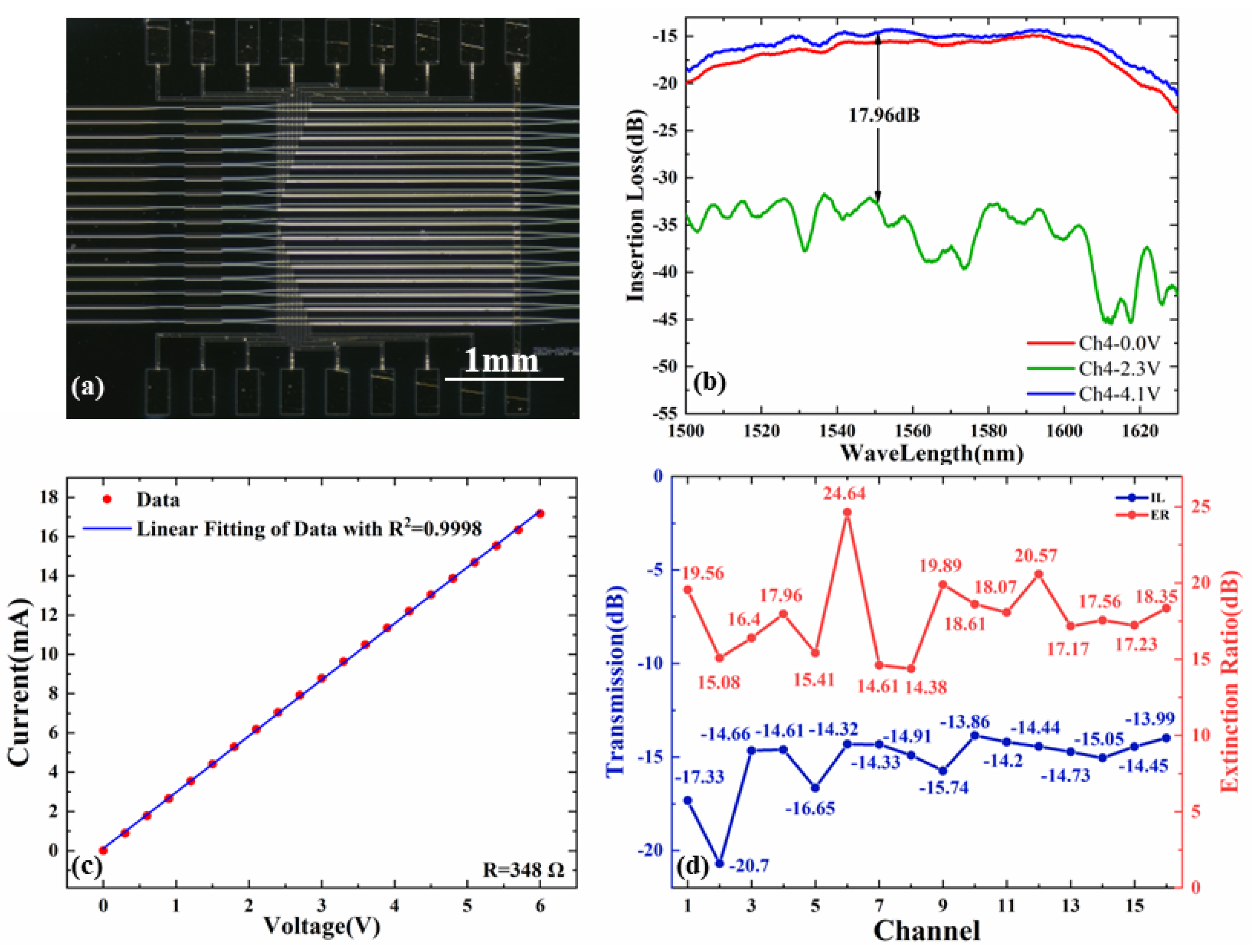

2. Design and Simulation

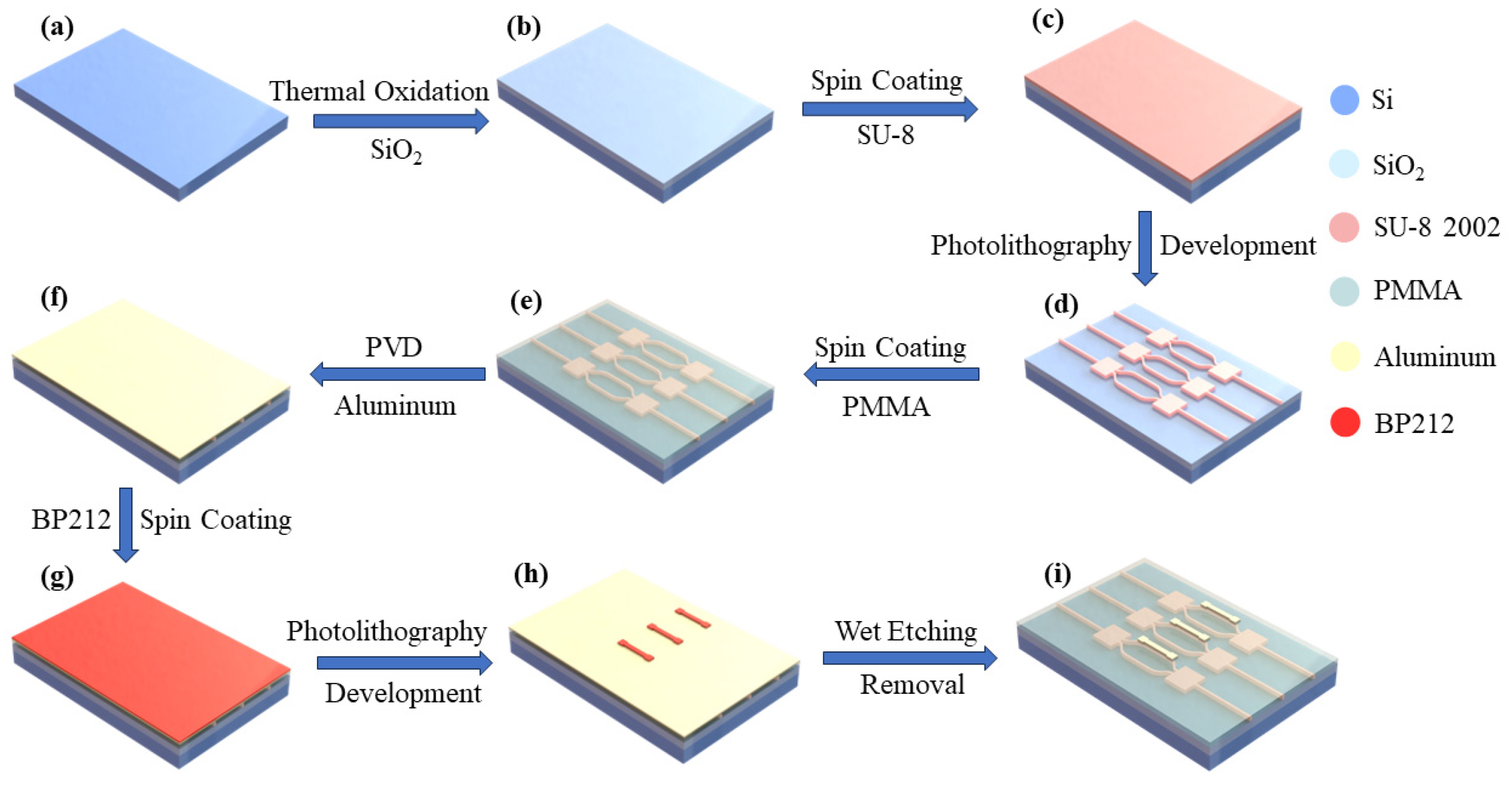

3. Fabrication and Characterizing

4. Discussion

| Ref. | Platform | IL (dB) | ER (dB) | PC (mW) | Work Range (nm) | Size | Ch |

|---|---|---|---|---|---|---|---|

| [3] | SOI | 4.54 4.87 | 59.08 (3.2 V) 60.11 (33 V) | 292.6 mW (29.71 dB) 486 mW (29.77 dB) | 1550 | N.A. | 1 |

| [22] | SOI | 0.5 | 20 | 60.74 mA | 1544–1556 | 2.9 mm × 1 mm (With AWG) | 16 |

| [18] | Silica | 0.04 (Sim) | 20–26 | 6–8 V | 1536.5–1560.5 | N.A. | 16 |

| [23] | Silica | 3.2–3.9 | 20 | 110 | 1530–1560 | 25 mm × 25 mm | 40 |

| [10] | Silica | 0.8 | 15 | 98 | N.A. | N.A. | 24 |

| [24] | Silica | 1.6 | 10 | 160 | 1520–1620 | 15 μm × 10 μm | 24 |

| [25] | Polymer | 0.7–0.9 | 41 | 17 | 1550 | 10 mm × 7 mm | 10 |

| [26] | Polymer | ~1 | 25 | 25 | 1525–1560 | 220 mm × 135 mm (With ROADM) | 40 |

| [15] | Polymer/Silica | 12.43 | 23.65 | 8.72 | 1260–1360 | N.A. | 1 |

| This work | Polymer/Silica | 15.2 | 15.5 (C + L) | 15.53 | 1500–1630 | 5 mm × 2 mm | 16 |

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Sgambelluri, A.; Izquierdo-Zaragoza, J.-L.; Giorgetti, A.; Gifre, L.; Velasco, L.; Paolucci, F.; Sambo, N.; Fresi, F.; Castoldi, P.; Piat, A.C.; et al. Fully Disaggregated ROADM White Box with NETCONF/YANG Control, Telemetry, and Machine Learning-based Monitoring. In Proceedings of the Optical Fiber Communication Conference, San Diego, CA, USA, 11–15 March 2018; OSA: San Diego, CA, USA, 2018; p. Tu3D.12. [Google Scholar]

- Yuan, P.; Wang, Y.; Wu, Y.; An, J.; Zhu, L. Monolithic integration of a wavelength division multiplexer/demultiplexer and electro-absorption VOAs based on 3 μm-SOI. Infrared Laser Eng. 2019, 48, 818004. [Google Scholar] [CrossRef]

- Huang, Y.; Lu, L.; Chen, G.; Xu, Y.; Zhu, L. Design and optimization of an SOI-based electro-absorption-type VOA. Appl. Opt. 2023, 62, 6316. [Google Scholar] [CrossRef] [PubMed]

- Zhao, Y.; Liu, S.; Shi, Y.; Hao, L.; Ma, Y.; Dai, P.; Liu, G.; Ni, Y.; Chen, X. Compact mode converter on SOI based on a polygonal subwavelength grating structure. Opt. Lett. 2024, 49, 834. [Google Scholar] [CrossRef] [PubMed]

- Wu, S.; Su, Y.; Zhang, L.; Gu, X.; Feng, T.; Xiao, J.; Yao, X.S. Local-field engineering in slot waveguide for fabricating on-chip Bragg grating filters with high reflectivity across a flat broadband. Opt. Express 2024, 32, 4684. [Google Scholar] [CrossRef] [PubMed]

- Ai, X.; Zhang, Y.; Hsu, W.-L.; Veilleux, S.; Dagenais, M. Broadband 2 × 2 multimode-interference coupler on the silicon-nitride platform. Opt. Express 2024, 32, 9405. [Google Scholar] [CrossRef] [PubMed]

- Pita, J.; Nabki, F.; Ménard, M. Inverse-designed silicon nitride reflectors. Opt. Lett. 2024, 49, 786. [Google Scholar] [CrossRef] [PubMed]

- Sato, T.; Wada, M.; Mori, T.; Sakamoto, T.; Imada, R.; Matsui, T.; Nakajima, K.; Saitoh, K. Broadband design of silica-PLC mode-dependent-loss equalizer for 2LP-mode transmission systems. Opt. Express 2023, 31, 39965. [Google Scholar] [CrossRef] [PubMed]

- Zeng, G.; Yin, Y.; Ding, Y.; Yang, J.; Yan, J.; Sun, X.; Zhang, D. Temperature-insensitive and fabrication-tolerant coarse wavelength division (de)multiplexing on a silica platform using an angled multimode interferometer. Opt. Express 2023, 31, 21161. [Google Scholar] [CrossRef] [PubMed]

- Wu, X.; Liu, W.; Yuan, Z.; Liang, X.; Chen, H.; Xu, X.; Tang, F. Low Power Consumption VOA Array with Air Trenches and Curved Waveguide. IEEE Photonics J. 2018, 10, 7201308. [Google Scholar] [CrossRef]

- Hu, C.; Shi, Y.; Zhou, T.; Xu, C.; Zhu, A. A Small Size On-chip Temperature Sensor Based on a Microring Resonator. Silicon 2022, 14, 5847–5854. [Google Scholar] [CrossRef]

- Li, J.; Mao, B.; Xu, B.; Shen, C.; Xu, R.; Wang, L.; Wang, D.; Zhao, C. PDMS-filled Fabry–Perot interferometer-based multipoint temperature measurement using an array-waveguide grating. Appl. Opt. 2020, 59, 9773. [Google Scholar] [CrossRef] [PubMed]

- Ning, N.; Huang, Q.; Zhang, Q.; Wei, Z.; Xia, P.; Wang, Y.; Yang, J.; Yu, H. Narrow-band Add-Drop Filters Based on Silicon Nitride Multimode Waveguide Bragg Grating. IEEE Photonics Technol. Lett. 2024, 1, 1. [Google Scholar] [CrossRef]

- Sato, H.; Miura, H.; Qiu, F.; Spring, A.M.; Kashino, T.; Kikuchi, T.; Ozawa, M.; Nawata, H.; Odoi, K.; Yokoyama, S. Low driving voltage Mach-Zehnder interference modulator constructed from an electro-optic polymer on ultra-thin silicon with a broadband operation. Opt. Express 2017, 25, 768. [Google Scholar] [CrossRef]

- Yin, Y.; Yao, M.; Ding, Y.; Xu, X.; Li, Y.; Wu, Y.; Zhang, D. Polymer/Silica Hybrid Waveguide Thermo-Optic VOA Covering O-Band. Micromachines 2022, 13, 511. [Google Scholar] [CrossRef]

- Gaso, P.; Pudis, D.; Seyringer, D.; Kuzma, A.; Gajdosova, L.; Mizera, T.; Goraus, M. 3D Polymer Based 1x4 Beam Splitter. J. Light. Technol. 2021, 39, 154–161. [Google Scholar] [CrossRef]

- Shang, Y.; Zhou, J.; Jiang, H.; He, X.; Ye, X.; Li, C. Optimal design of a 4 × 4 MMI thermal optical switch with trapezoidal air trenches. Appl. Opt. 2023, 62, 1521. [Google Scholar] [CrossRef] [PubMed]

- Wang, W.; Zhao, Z.; Han, X.; Wang, Y.; An, J.; Liu, J. Low Loss 16-Channel Photodetector Array Receiving Module with Fine Tuning Ability. IEEE Photonics J. 2022, 14, 6656406. [Google Scholar] [CrossRef]

- Liu, Q.-H.; Pan, P.; You, J.; Zhang, J.-S.; Wang, Y.; Wang, Y.-T.; Wang, L.-L.; An, J.-M.; Cui, D.-J.; Zhou, L.; et al. Four-stage cascaded variable optical attenuator with large attenuation range for quantum key distribution. Chin. Phys. B 2023, 32, 054207. [Google Scholar] [CrossRef]

- Li, F.; Bai, Y.; Hu, H.; Li, L.; Li, L.; Zhang, F.; Luo, X.; Zhang, X. Elastoplastic contact model of pitch-based rough surface and its polishing characteristics. Opt. Express 2023, 31, 42150–42164. [Google Scholar] [CrossRef]

- Noh, Y.-O.; Lee, C.-H.; Kim, J.-M.; Hwang, W.-Y.; Won, Y.-H.; Lee, H.-J.; Han, S.-G.; Oh, M.-C. Polymer waveguide variable optical attenuator and its reliability. Opt. Commun. 2004, 242, 533–540. [Google Scholar] [CrossRef]

- Yuan, P.; Wu, Y.; Wang, Y.; An, J.; Hu, X. Monolithic integration of a 16-channel VMUX on SOI platform. J. Semicond. 2015, 36, 084005. [Google Scholar] [CrossRef]

- Itoh, M.; Watanabe, K.; Nasu, Y.; Yamazaki, H.; Kamei, S.; Ogawa, I.; Kaneko, A.; Inoue, Y. 1-square-inch 100 GHz 40 ch VMUX/DEMUX based on single-chip PLC integration with 2.5%- silica-based waveguides. In Proceedings of the 33rd European Conference and Exhibition on Optical Communication—ECOC 2007, Berlin, Germany, 6–20 September 2007; IEE: Berlin, Germany, 2007; Volume 2007, p. 251. [Google Scholar]

- Ma, J.; Wang, L.; Zhang, J.; Wang, Y.; Chen, J.; Sun, B.; Zhou, T.; Cui, P.; Wu, Y.; An, J. Compactly integrated polarization insensitive 24-channel variable optical attenuator arrays using silica-based. Opt. Commun. 2023, 549, 129932. [Google Scholar] [CrossRef]

- Han, Y.-T.; Shin, J.-U.; Park, S.-H.; Han, S.-P.; Lee, C.-H.; Noh, Y.-O.; Lee, H.-J.; Baek, Y. 10 channel polymer variable optical attenuator array for power monitoring and equalization in integrated PLC ROADM module. In Proceedings of the 2008 International Conference on Photonics in Switching, Sapporo, Japan, 4–7 August 2008; IEEE: Sapporo, Japan, 2008; pp. 1–2. [Google Scholar]

- Shin, J.-U.; Han, Y.-T.; Han, S.-P.; Park, S.-H.; Baek, Y.; Noh, Y.-O.; Park, K.-H. Reconfigurable Optical Add-Drop Multiplexer Using a Polymer Integrated Photonic Lightwave Circuit. ETRI J. 2009, 31, 770–777. [Google Scholar] [CrossRef]

- Li, S.; Zhang, J.; Wang, L.; You, J.; Wang, Y.; Yin, X.; Chen, J.; Sun, B.; An, J.; Wu, Y. The O-band 20-channel 800 GHz Arrayed Waveguide Grating based on silica platform for 1 Tb/s or higher-speed communication system. Opt. Laser Technol. 2022, 156, 108475. [Google Scholar] [CrossRef]

- Yue, J.; Wang, C.; Lin, H.; Ding, S.; Shi, Z.; Cui, Z.; Chen, C.; Zhang, D. Interlayer directional coupling thermo-optic waveguide switches based on functionalized epoxy-crosslinking polymers. Opt. Express 2022, 30, 13931. [Google Scholar] [CrossRef] [PubMed]

- Lee, E.-S.; Chun, K.-W.; Jin, J.; Lee, S.-S.; Oh, M.-C. Monolithic integration of polymer waveguide phase modulators with silicon nitride waveguides using adiabatic transition tapers. Opt. Express 2023, 31, 4760. [Google Scholar] [CrossRef] [PubMed]

- Deng, Z.; Ding, Z.; Chen, T.; Zhang, Z. Thermal Gradient Driven Variable Optical Attenuator with On-Chip CNT Absorber. IEEE Photonics Technol. Lett. 2024, 36, 243–246. [Google Scholar] [CrossRef]

- Gao, F.; Xie, W.; Tan, J.Y.S.; Leong, C.; Li, C.; Luo, X.; Lo, G.-Q. Comprehensive Investigation of Thermo-Optic Phase Shifters on a Multi-Layered SiN-on-SOI Platform. J. Light. Technol. 2023, 41, 3108–3114. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, S.; Yin, Y.; Wang, Z.; Li, Y.; Zhang, Y.; Yao, M.; Zhang, D.; Li, Y. Low-Power-Consumption and Broadband 16-Channel Variable Optical Attenuator Array Based on Polymer/Silica Hybrid Waveguide. Photonics 2024, 11, 547. https://doi.org/10.3390/photonics11060547

Zhang S, Yin Y, Wang Z, Li Y, Zhang Y, Yao M, Zhang D, Li Y. Low-Power-Consumption and Broadband 16-Channel Variable Optical Attenuator Array Based on Polymer/Silica Hybrid Waveguide. Photonics. 2024; 11(6):547. https://doi.org/10.3390/photonics11060547

Chicago/Turabian StyleZhang, Shengyuan, Yuexin Yin, Zihao Wang, Yafan Li, Yuan Zhang, Mengke Yao, Daming Zhang, and Ye Li. 2024. "Low-Power-Consumption and Broadband 16-Channel Variable Optical Attenuator Array Based on Polymer/Silica Hybrid Waveguide" Photonics 11, no. 6: 547. https://doi.org/10.3390/photonics11060547

APA StyleZhang, S., Yin, Y., Wang, Z., Li, Y., Zhang, Y., Yao, M., Zhang, D., & Li, Y. (2024). Low-Power-Consumption and Broadband 16-Channel Variable Optical Attenuator Array Based on Polymer/Silica Hybrid Waveguide. Photonics, 11(6), 547. https://doi.org/10.3390/photonics11060547