Group Control of Photo-Responsive Colloidal Motors with a Structured Light Field

Abstract

1. Introduction

2. Materials and Experimental System

2.1. Materials

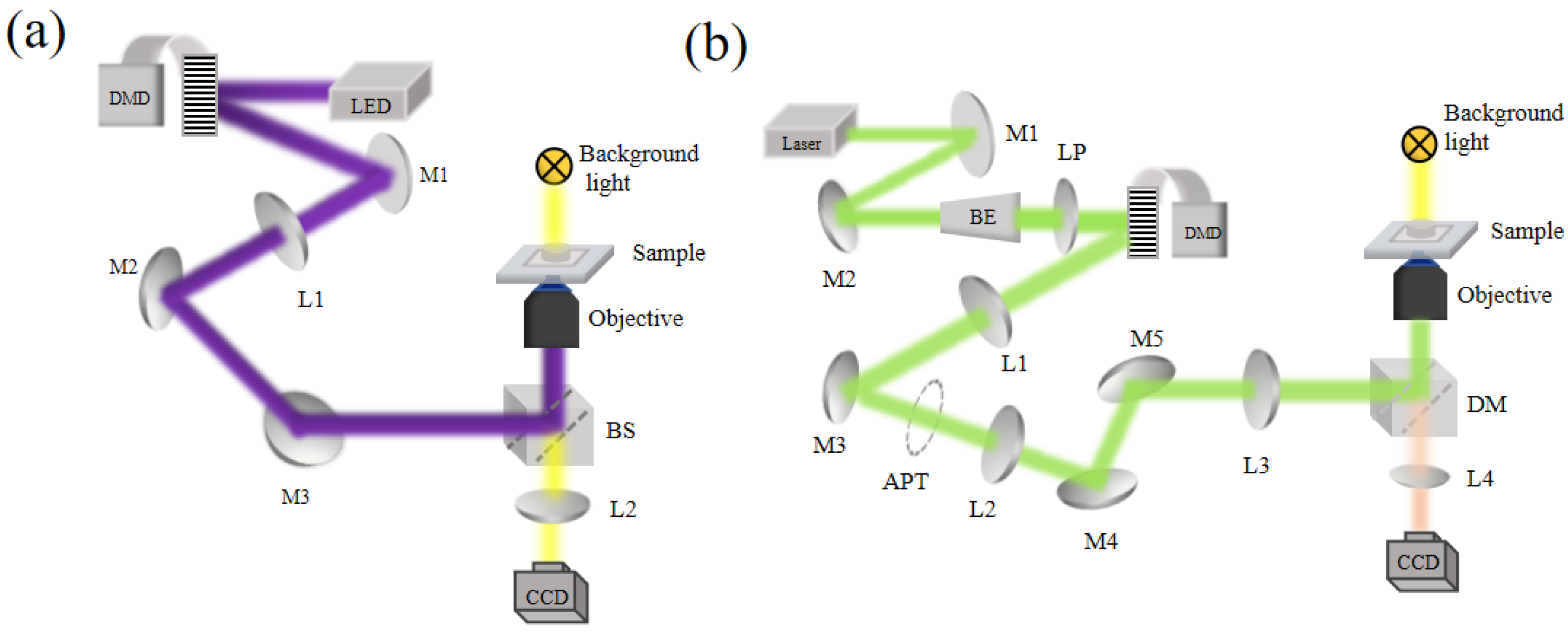

2.2. Experimental System

3. Experiment Results and Discussion

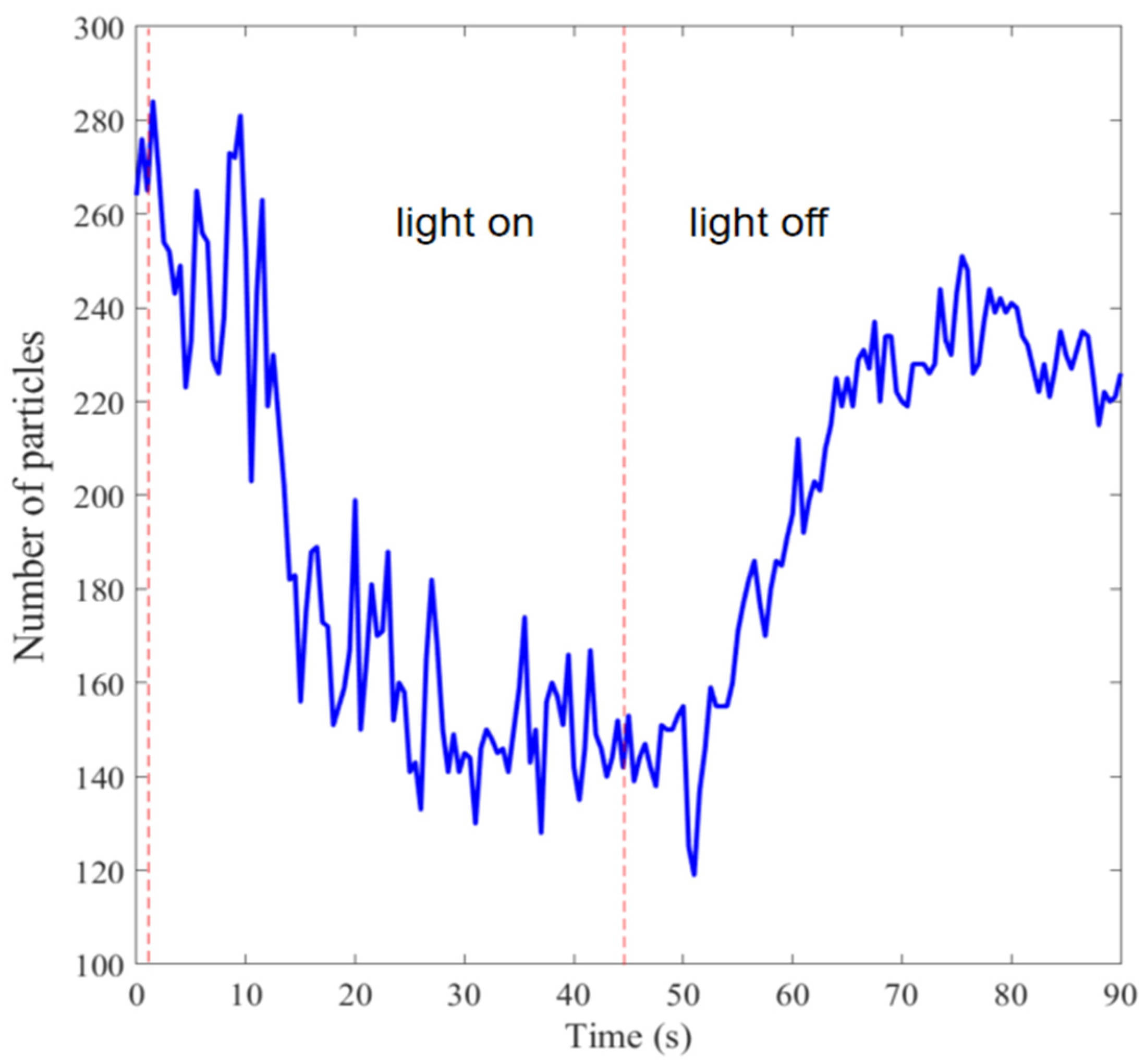

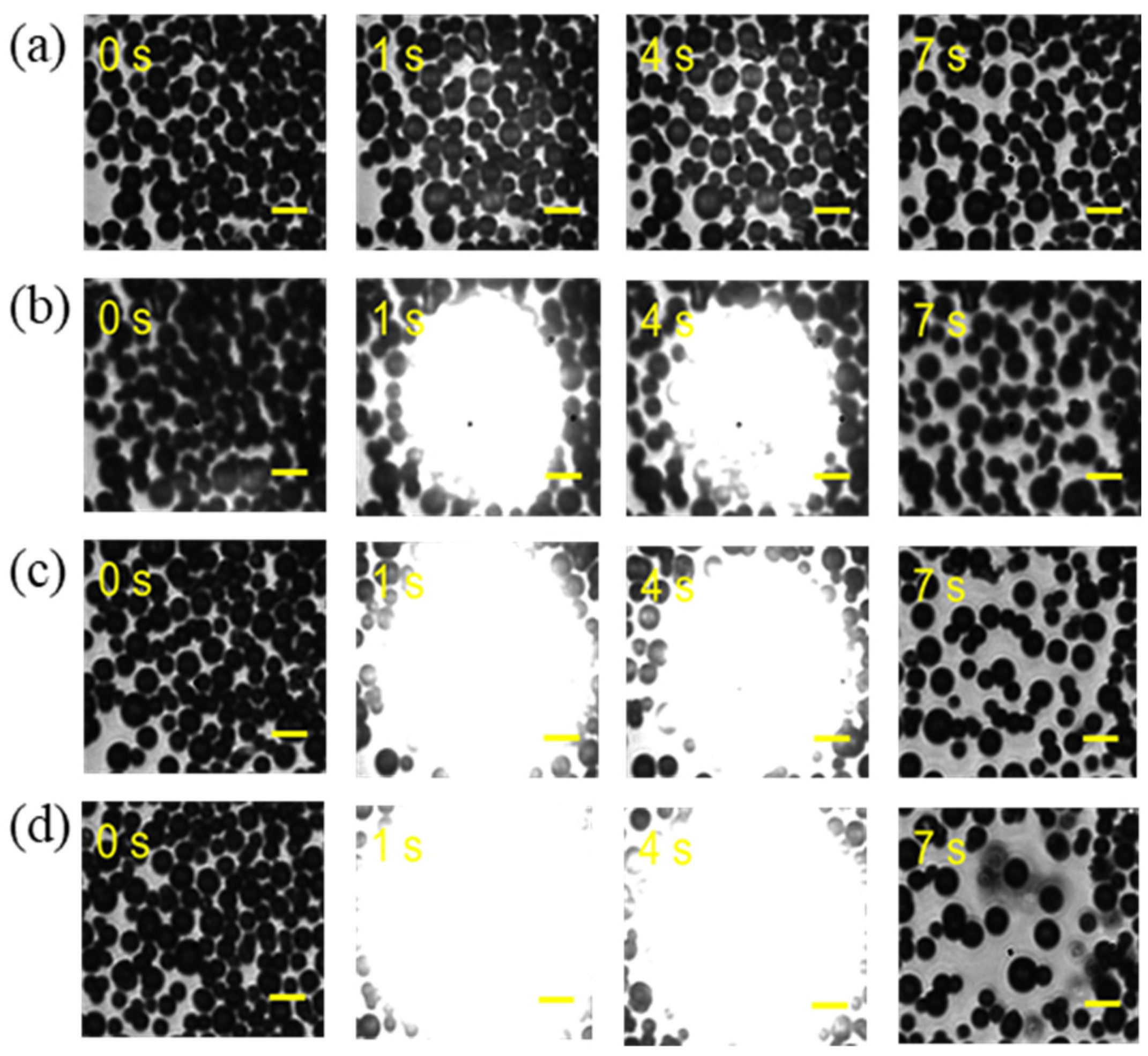

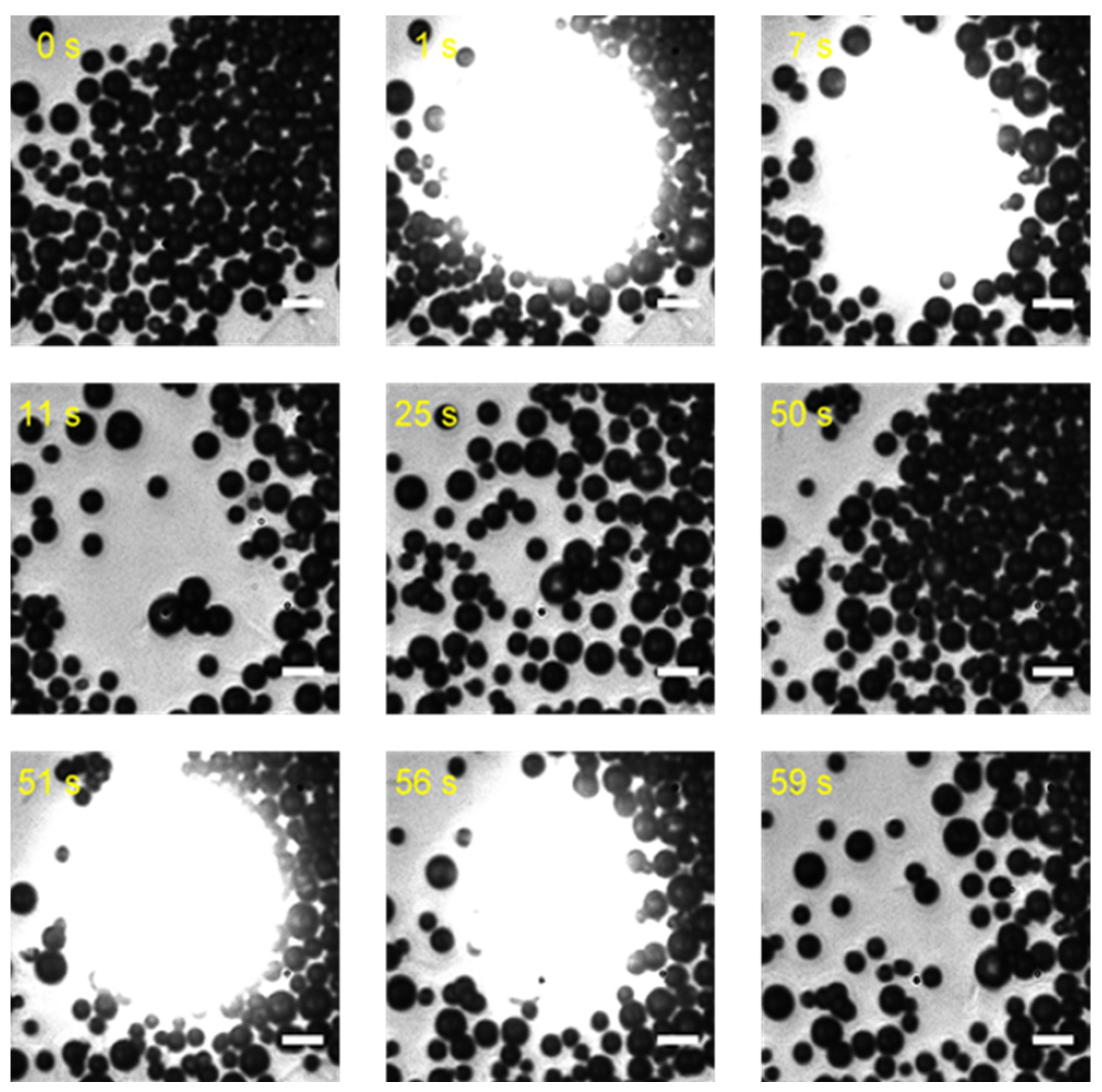

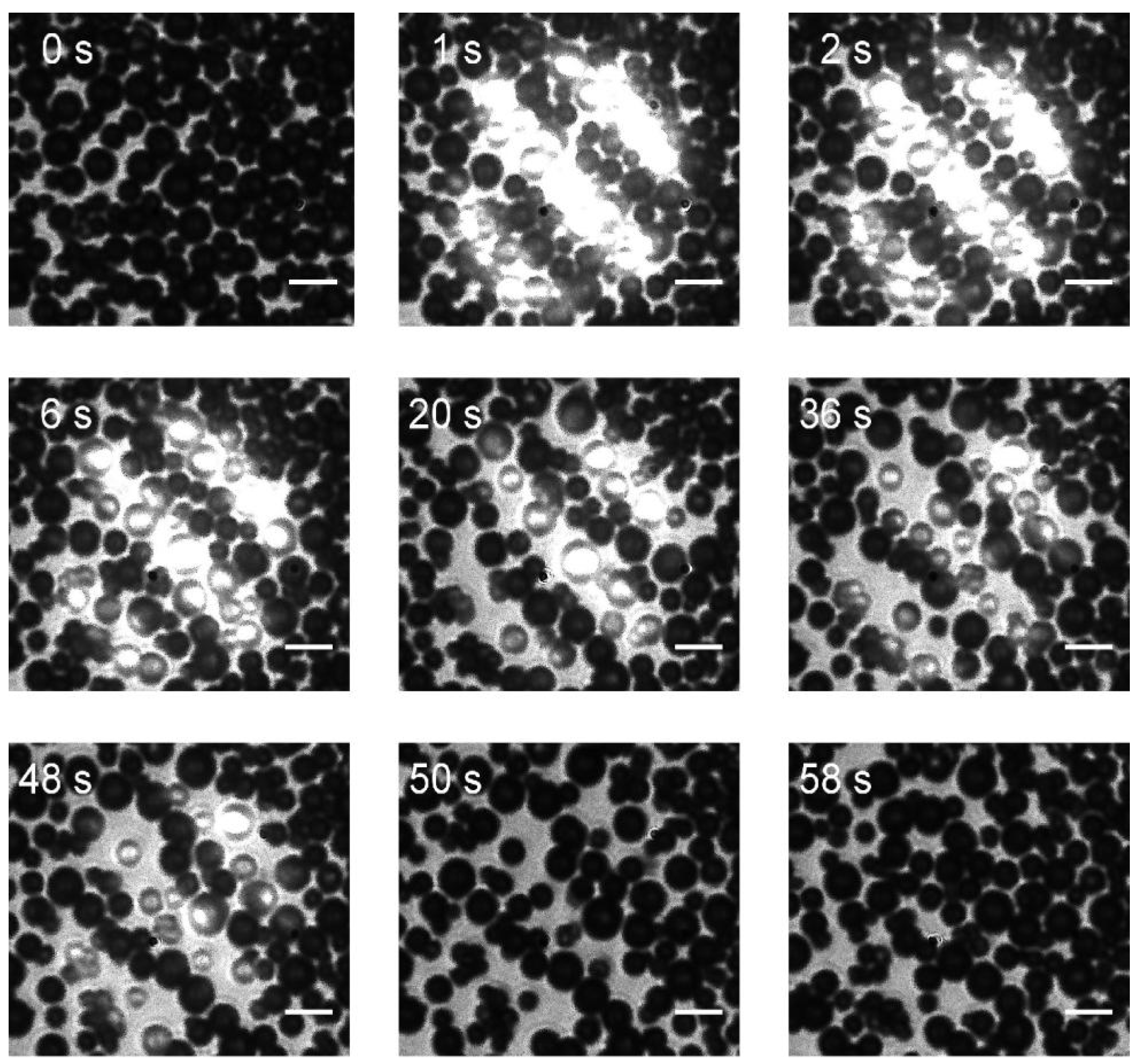

3.1. Group Spreading Behaviors of Colloidal Motors

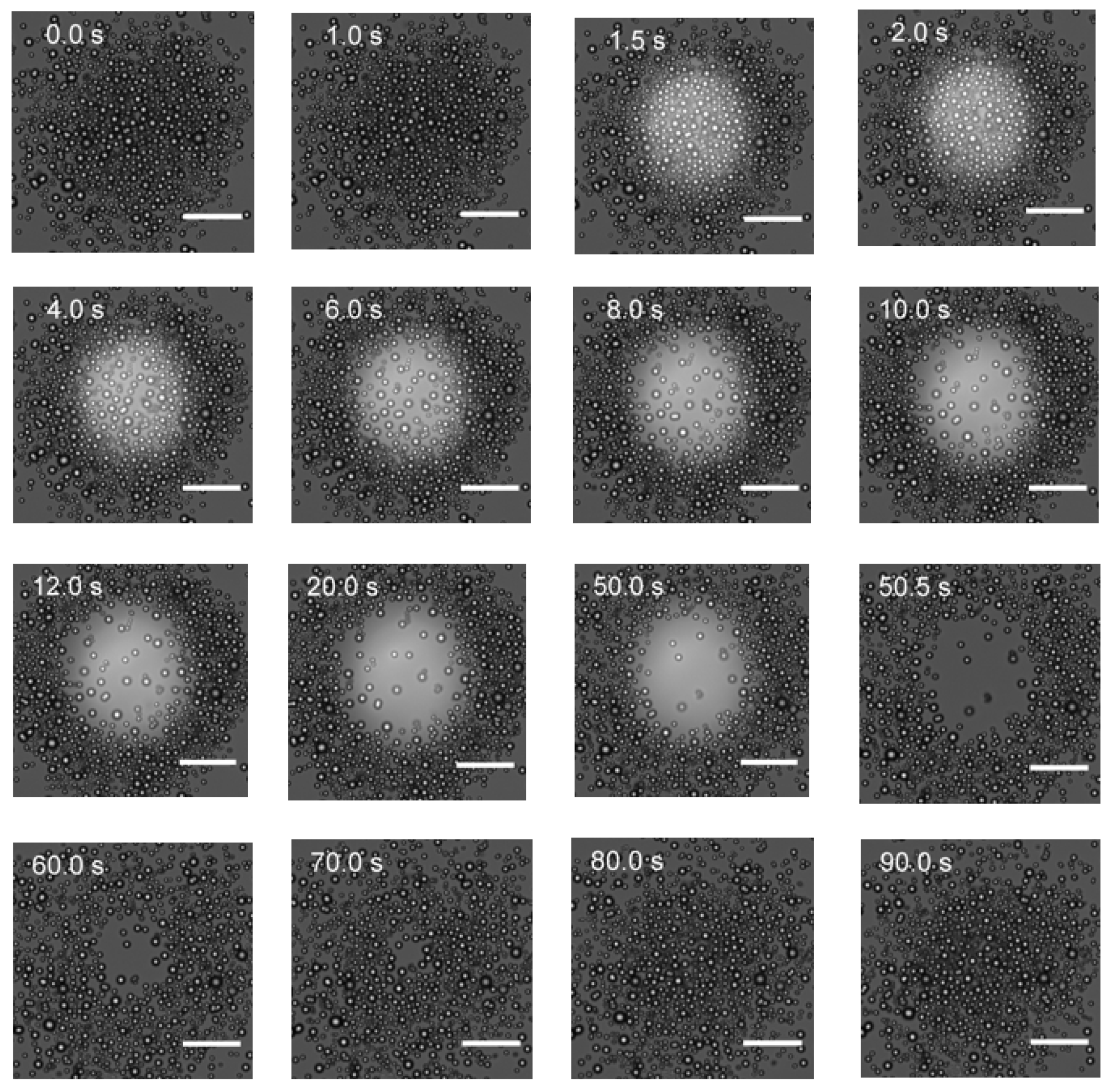

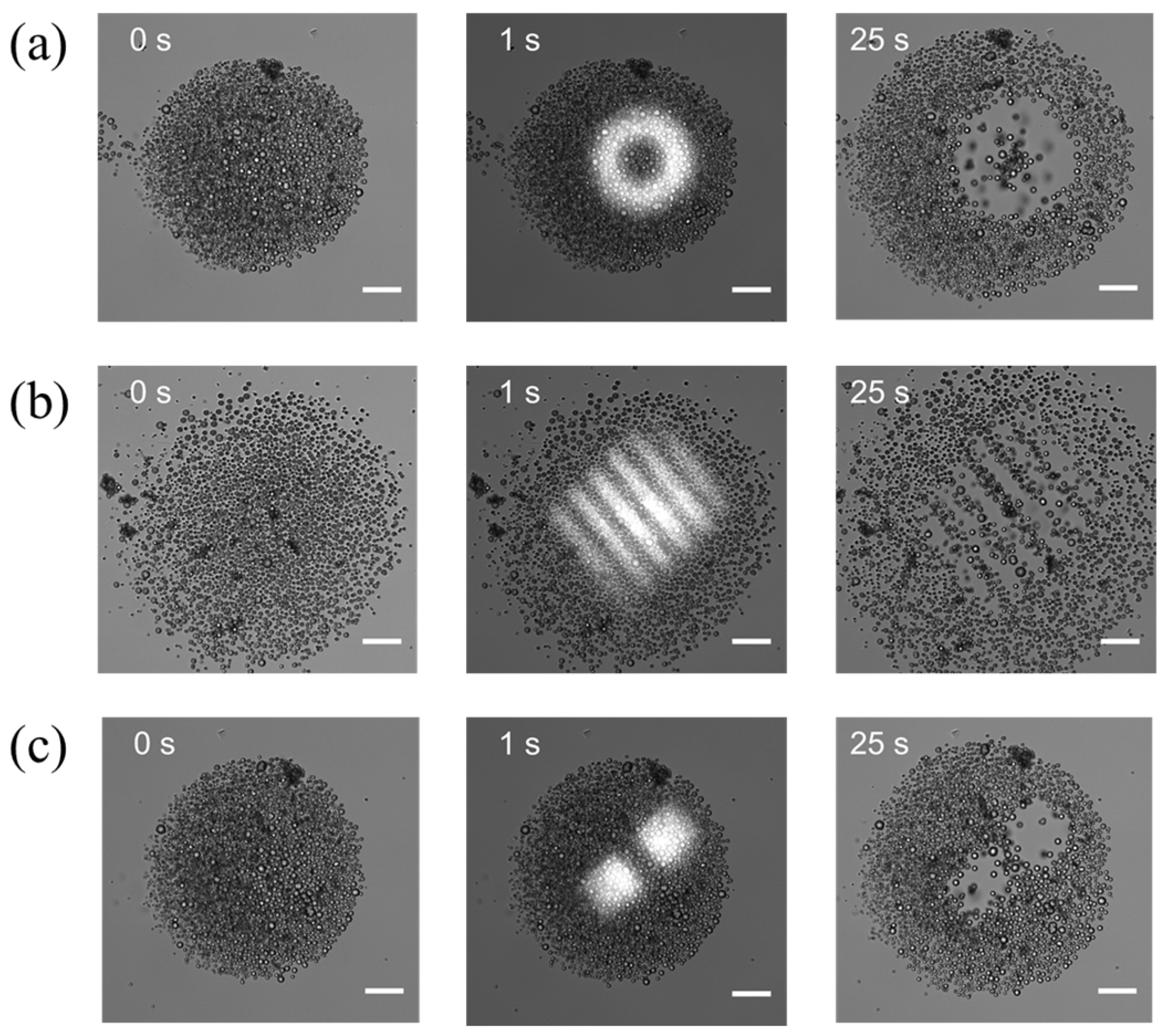

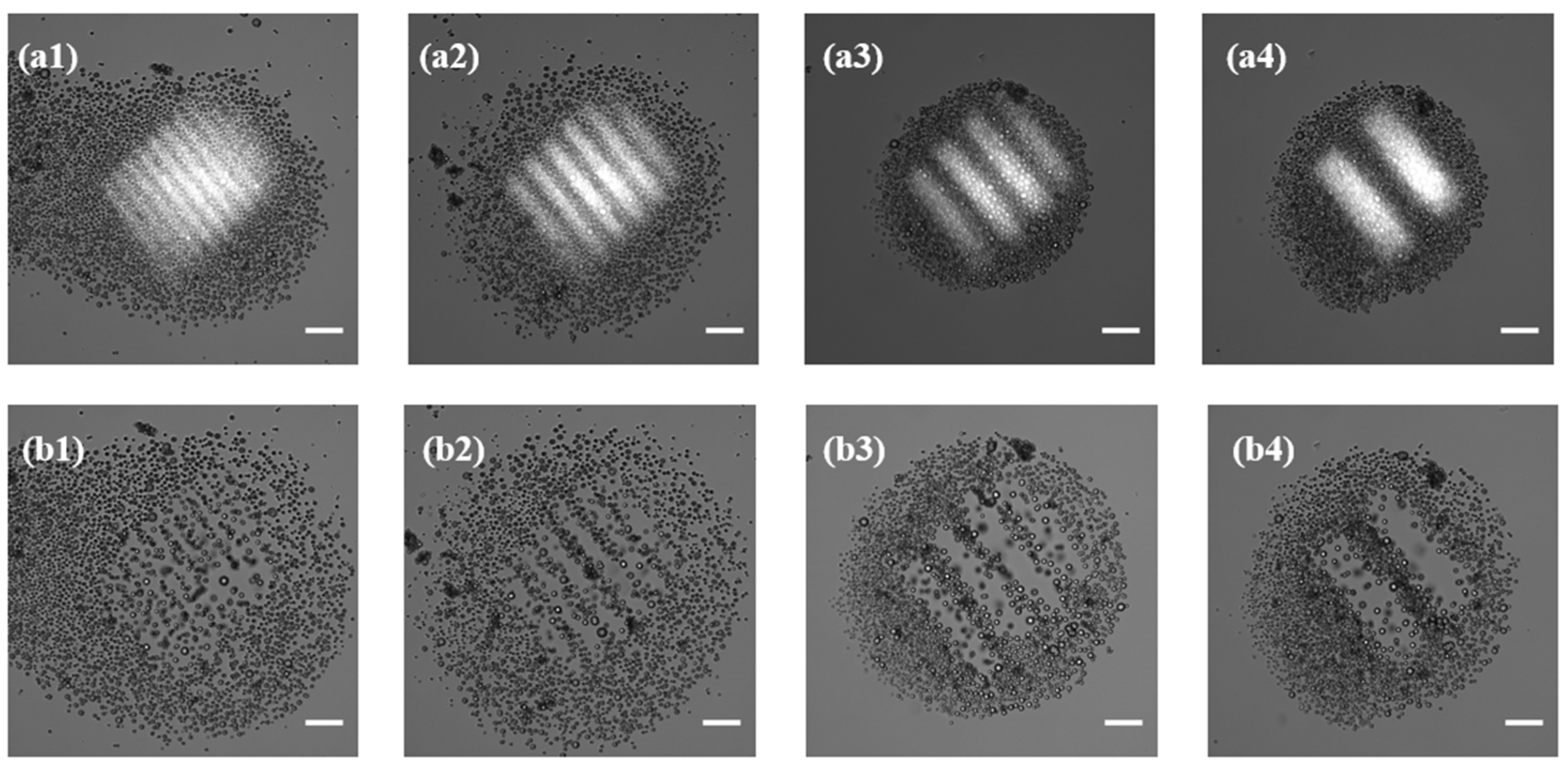

3.2. Group Patterning Behaviors of Colloidal Motors

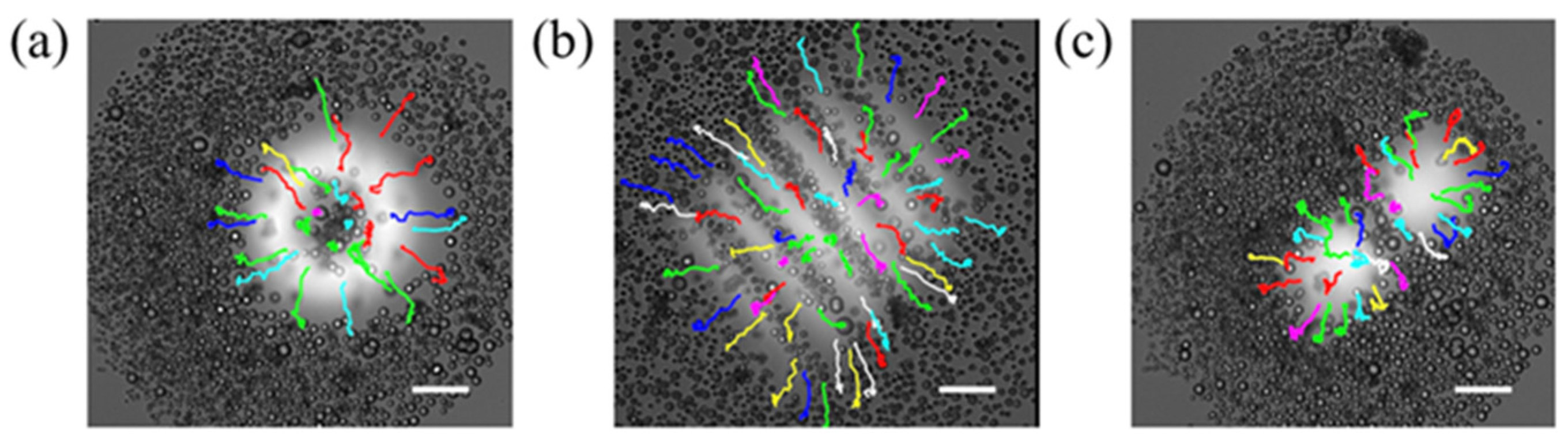

3.3. Group Migration Behaviors of Colloidal Motors

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

References

- Bechinger, C.; Di Leonardo, R.; Löwen, H.; Reichhardt, C.; Volpe, G.; Volpe, G. Active Particles in Complex and Crowded Environments. Rev. Mod. Phys. 2016, 88, 045006. [Google Scholar] [CrossRef]

- Marchetti, M.C.; Joanny, J.F.; Ramaswamy, S.; Liverpool, T.B.; Prost, J.; Rao, M.; Simha, R.A. Hydrodynamics of Soft Active Matter. Rev. Mod. Phys. 2013, 85, 1143–1189. [Google Scholar] [CrossRef]

- Shankar, S.; Souslov, A.; Bowick, M.J.; Marchetti, M.C.; Vitelli, V. Topological Active Matter. Nat. Rev. Phys. 2022, 4, 380–398. [Google Scholar] [CrossRef]

- De Gennes, P.G. Soft Matter. Science 1992, 256, 495–497. [Google Scholar] [CrossRef]

- Vicsek, T.; Zafeiris, A. Collective Motion. Phys. Rep. 2012, 517, 71–140. [Google Scholar] [CrossRef]

- Nsamela, A.; Garcia Zintzun, A.I.; Montenegro-Johnson, T.D.; Simmchen, J. Colloidal Active Matter Mimics the Behavior of Biological Microorganisms—An Overview. Small 2023, 19, 2202685. [Google Scholar] [CrossRef] [PubMed]

- Chen, X.; Zhou, C.; Wang, W. Colloidal Motors 101: A Beginner’s Guide to Colloidal Motor Research. Chem.—Asian J. 2019, 14, 2388–2405. [Google Scholar] [CrossRef] [PubMed]

- Wang, L.; Li, L.; Li, T.; Zhang, G.; Sun, Q. Locomotion of Chemically Powered Autonomous Nanowire Motors. Appl. Phys. Lett. 2015, 107, 063102. [Google Scholar] [CrossRef]

- Zhan, Z.; Wei, F.; Zheng, J.; Yang, W.; Luo, J.; Yao, L. Recent Advances of Light-Driven Micro/Nanomotors: Toward Powerful Thrust and Precise Control. Nanotechnol. Rev. 2018, 7, 555–581. [Google Scholar] [CrossRef]

- Xiao, Z.; Duan, S.; Xu, P.; Cui, J.; Zhang, H.; Wang, W. Synergistic Speed Enhancement of an Electric-Photochemical Hybrid Micromotor by Tilt Rectification. ACS Nano 2020, 14, 8658–8667. [Google Scholar] [CrossRef]

- Li, T.; Li, J.; Zhang, H.; Chang, X.; Song, W.; Hu, Y.; Shao, G.; Sandraz, E.; Zhang, G.; Li, L.; et al. Magnetically Propelled Fish-Like Nanoswimmers. Small 2016, 12, 6098–6105. [Google Scholar] [CrossRef] [PubMed]

- Li, Z.; Zhang, H.; Wang, D.; Gao, C.; Sun, M.; Wu, Z.; He, Q. Reconfigurable Assembly of Active Liquid Metal Colloidal Cluster. Angew. Chem. Int. Ed. 2020, 59, 19884–19888. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Xiong, Z.; Zheng, J.; Zhan, X.; Tang, J. Light-Driven Micro/Nanomotor for Promising Biomedical Tools: Principle, Challenge, and Prospect. Acc. Chem. Res. 2018, 51, 1957–1965. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Xiong, Z.; Tang, J. The Encoding of Light-Driven Micro/Nanorobots: From Single to Swarming Systems. Adv. Intell. Syst. 2021, 3, 2000170. [Google Scholar] [CrossRef]

- Palacios-Corella, M.; Rojas, D.; Pumera, M. Photocatalytic Pt/Ag3VO4 Micromotors with Inherent Sensing Capabilities for Corroding Environments. J. Colloid Interface Sci. 2023, 631, 125–134. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Z.; Yan, H.; Li, S.; Liu, Y.; Ran, P.; Chen, W.; Li, X. Janus Rod-like Micromotors to Promote the Tumor Accumulation and Cell Internalization of Therapeutic Agents. Chem. Eng. J. 2021, 404, 127073. [Google Scholar] [CrossRef]

- Wu, Z.; Si, T.; Gao, W.; Lin, X.; Wang, J.; He, Q. Superfast Near-Infrared Light-Driven Polymer Multilayer Rockets. Small 2016, 12, 577–582. [Google Scholar] [CrossRef] [PubMed]

- Maggi, C.; Saglimbeni, F.; Dipalo, M.; De Angelis, F.; Di Leonardo, R. Micromotors with Asymmetric Shape That Efficiently Convert Light into Work by Thermocapillary Effects. Nat. Commun. 2015, 6, 7855. [Google Scholar] [CrossRef]

- Chen, X.; Chen, X.; Elsayed, M.; Edwards, H.; Liu, J.; Peng, Y.; Zhang, H.P.; Zhang, S.; Wang, W.; Wheeler, A.R. Steering Micromotors via Reprogrammable Optoelectronic Paths. ACS Nano 2023, 17, 5894–5904. [Google Scholar] [CrossRef]

- Lin, L.; Zhang, J.; Peng, X.; Wu, Z.; Coughlan, A.C.H.; Mao, Z.; Bevan, M.A.; Zheng, Y. Opto-Thermophoretic Assembly of Colloidal Matter. Sci. Adv. 2017, 3, e1700458. [Google Scholar] [CrossRef]

- Yang, S.; Huang, M.; Zhao, Y.; Zhang, H.P. Controlling Cell Motion and Microscale Flow with Polarized Light Fields. Phys. Rev. Lett. 2021, 126, 058001. [Google Scholar] [CrossRef] [PubMed]

- Yuan, Y.; Abuhaimed, G.N.; Liu, Q.; Smalyukh, I.I. Self-Assembled Nematic Colloidal Motors Powered by Light. Nat. Commun. 2018, 9, 5040. [Google Scholar] [CrossRef] [PubMed]

- Trivedi, M.; Saxena, D.; Ng, W.K.; Sapienza, R.; Volpe, G. Self-Organized Lasers from Reconfigurable Colloidal Assemblies. Nat. Phys. 2022, 18, 939–944. [Google Scholar] [CrossRef]

- Xuan, M.; Shao, J.; Gao, C.; Wang, W.; Dai, L.; He, Q. Self-Propelled Nanomotors for Thermomechanically Percolating Cell Membranes. Angew. Chem. Int. Ed. 2018, 57, 12463–12467. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Q.; Dong, R.; Wu, Y.; Gao, W.; He, Z.; Ren, B. Light-Driven Au-WO 3 @C Janus Micromotors for Rapid Photodegradation of Dye Pollutants. ACS Appl. Mater. Interfaces 2017, 9, 4674–4683. [Google Scholar] [CrossRef] [PubMed]

- Guo, H.; Li, Z. Optical Tweezers Technique and Its Applications. Sci. China Phys. Mech. Astron. 2013, 56, 2351–2360. [Google Scholar] [CrossRef]

- Li, M.; Yan, S.; Liang, Y.; Zhang, P.; Yao, B. Spinning of Particles in Optical Double-Vortex Beams. J. Opt. 2018, 20, 025401. [Google Scholar] [CrossRef]

- Basharat, M.; Zhang, J.; Yu, N.; Li, R.; Zhang, Y.; Wang, Y.; Gao, Y. Reversible Assembly of Flexible and Switchable Active Colloidal Molecules from Binary Photoactive and Passive Spheres (Under Review).

- Popescu, M.N.; Uspal, W.E.; Dietrich, S. Self-Diffusiophoresis of Chemically Active Colloids. Eur. Phys. J. Spec. Top. 2016, 225, 2189–2206. [Google Scholar] [CrossRef]

- Usui, S. Interaction between Dissimilar Double Layers with like Signs under Charge Regulation on the Basis of the Gouy–Chapman–Stern–Grahame Model. J. Colloid Interface Sci. 2004, 280, 113–119. [Google Scholar] [CrossRef]

- Brown, A.; Poon, W. Ionic Effects in Self-Propelled Pt-Coated Janus Swimmers. Soft Matter 2014, 10, 4016–4027. [Google Scholar] [CrossRef]

- Zhou, X.; Wang, S.; Xian, L.; Shah, Z.H.; Li, Y.; Lin, G.; Gao, Y. Ionic Effects in Ionic Diffusiophoresis in Chemically Driven Active Colloids. Phys. Rev. Lett. 2021, 127, 168001. [Google Scholar] [CrossRef] [PubMed]

- Chen, M.; Lin, Z.; Xuan, M.; Lin, X.; Yang, M.; Dai, L.; He, Q. Programmable Dynamic Shapes with a Swarm of Light-Powered Colloidal Motors. Angew. Chem. Int. Ed. 2021, 60, 16674–16679. [Google Scholar] [CrossRef] [PubMed]

- Straube, A.V.; Pagès, J.M.; Ortiz-Ambriz, A.; Tierno, P.; Ignés-Mullol, J.; Sagués, F. Assembly and Transport of Nematic Colloidal Swarms above Photo-Patterned Defects and Surfaces. New J. Phys. 2018, 20, 075006. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, D.; Wei, H.; Fang, H.; Gao, Y. Group Control of Photo-Responsive Colloidal Motors with a Structured Light Field. Photonics 2024, 11, 421. https://doi.org/10.3390/photonics11050421

Li D, Wei H, Fang H, Gao Y. Group Control of Photo-Responsive Colloidal Motors with a Structured Light Field. Photonics. 2024; 11(5):421. https://doi.org/10.3390/photonics11050421

Chicago/Turabian StyleLi, Dianyang, Huan Wei, Hui Fang, and Yongxiang Gao. 2024. "Group Control of Photo-Responsive Colloidal Motors with a Structured Light Field" Photonics 11, no. 5: 421. https://doi.org/10.3390/photonics11050421

APA StyleLi, D., Wei, H., Fang, H., & Gao, Y. (2024). Group Control of Photo-Responsive Colloidal Motors with a Structured Light Field. Photonics, 11(5), 421. https://doi.org/10.3390/photonics11050421