2.1. Broad-Spectrum Moiré Fringe Alignment Theory

The alignment method based on the Moiré fringe utilizes the superposition of projected line gratings to generate a multiplicative Moiré fringe. The principle is that as the grating is displaced, the corresponding Moiré fringe also shifts, According to the principle of the Moiré fringe [

14], this change is reflected in the phase distribution of the Moiré fringe. By analyzing the phase distribution of the Moiré fringe, it is possible to calculate actual the deviation between the mask and wafer. The field distribution after double grating diffraction is determined via the superposition of all the harmonic components in the diffraction, using a rectangular line grating as an example.

represents the field intensity distribution of the diffracted beam passing through two gratings. The spatial frequencies of two rectangular line gratings are denoted as and , while represents the spatial frequency on the frequency spectrum. According to the Angular Spectrum theory, the propagation of the n-th order to the z plane introduces a nonlinear phase factor .

If the incident light is an incoherent white light broad–spectrum source, the light intensity distribution of the interference fringe in its diffraction field can be expressed as:

represents the weighted sum of the intensity distribution of the Moiré fringe produced by different wavelengths in a white light broad–spectrum. is the weight factor of the corresponding wavelength in the spectrum. represents the background light intensity of the Moiré fringe signal, and represents the amplitude of the Moiré fringe signal.

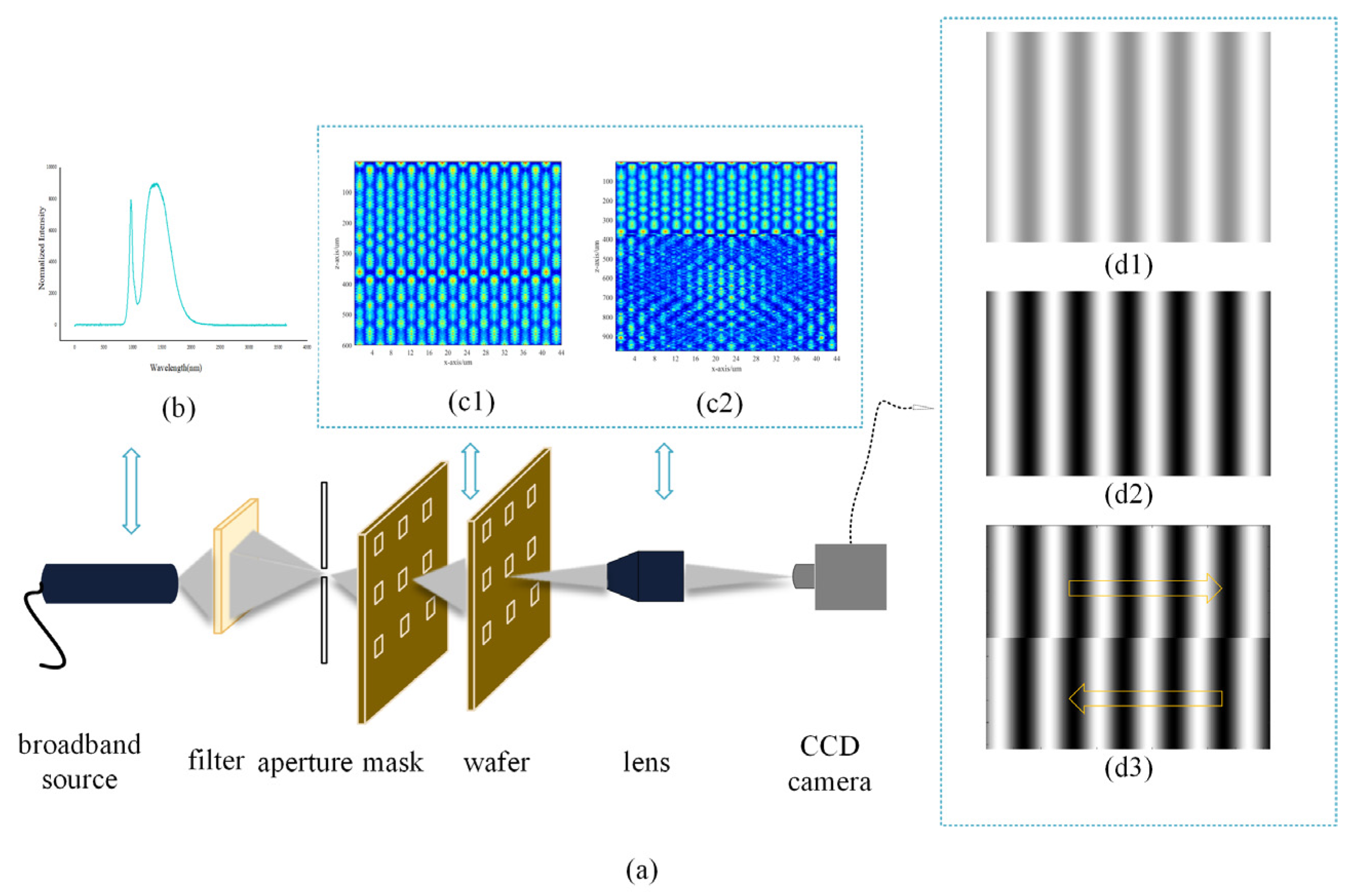

The schematic diagram in

Figure 1a illustrates the process. A white light broad–spectrum source is used, and the GA–PSO hybrid algorithm is used to determine the optimal wavelength ratio and form an optimized white light broad–spectrum source through a combination of filters with different wavelengths, and different transmittance light is diffracted through the mask and wafer separately, after passing through the collimated beam expansion system. The diffracted light is absorbed by the objective lens and transmitted to a CCD camera. The illumination spectrum is shown in

Figure 1b and is white light. Among them, the four bands with the highest energy proportion in the white light spectrum (405 nm, 532 nm, 633 nm, and 780 nm) are selected as the targets for optimizing the wavelength ratio. The light field x–z cross-sectional distribution of the diffraction field formed by the optimized white light plane wave is diffracted in the Z direction toward the rectangular line grating mask with a period of 4 μm and a duty cycle of 1:1, as shown in

Figure 1(c1). The self-imaging effect will result in a periodic frequency doubling effect in relation to the mask [

19]. The distribution passes through the rectangular line grating mask and is diffracted 300 um in the Z direction onto a rectangular line grating with a period of 2 μm and a duty cycle of 1:1, as shown in

Figure 1(c2). When the different wavelength components of the white light spectrum are not at their respective Talbot distance, their superpositions will affect the imaging contrast of the Moiré fringe, as shown in

Figure 1(d1). Under the illumination of the optimized white light source, the alignment mark of the rectangular line grating on the mask and wafer are overlapped and superimposed to achieve improved Moiré fringe imaging quality, as shown in

Figure 1(d2). The relative deviation between the mask and wafer is calculated using the phase distribution of the Moiré fringe, as illustrated in

Figure 1(d3).

2.2. Depth of Focus Calculation Theory

According to scalar diffraction theory, a monochromatic plane wave passes through the periodic micro–nano structure mask along the direction of light field propagation at a distance with a period of

. It will produce self-images of a periodic object.

-phase–shifted images will also occur at

, where m is a positive integer,

p is the periodic constant of the mask, and

is the incident wavelength. Additionally, at halfway through each propagation period, self–images with

-phase–shifted images will also appear. This phenomenon is known as the Talbot effect. It is important to note that this effect is a result of diffraction imaging rather than lens imaging; hence, it is also referred to as the ‘self-imaging effect’. In addition, between self-images and

-phase–shifted images, there is also a sub–image of frequency–doubling self–images with weak light intensity. Compared to a grating mask with a period constant of 4 μm, its period is halved, resulting in a doubling of its fringe resolution. This phenomenon is known as the ‘frequency-doubling effect’ [

19].

When the self–imaging effect and frequency–doubling effect are used as an alignment mode in the field of lithography, the depth of focus (DOF) becomes an important parameter. The depth of focus (DOF) is defined as the range along the optical axis within which clear imaging can be achieved, representing the actual imaging in the optical system. The tolerance between the surface and the ideal imaging plane. The alignment method based on the Moiré fringe is limited by the Talbot effect, resulting in a small tolerance for the gap between the mask and wafer [

15]. It requires precise control of the gap tolerance, i.e., the available DOF, which is an important factor affecting the process requirements of the alignment system.

According to the Talbot effect and frequency–doubling effect theory, for a mask with the same periodic constant, the distribution positions of self–images and

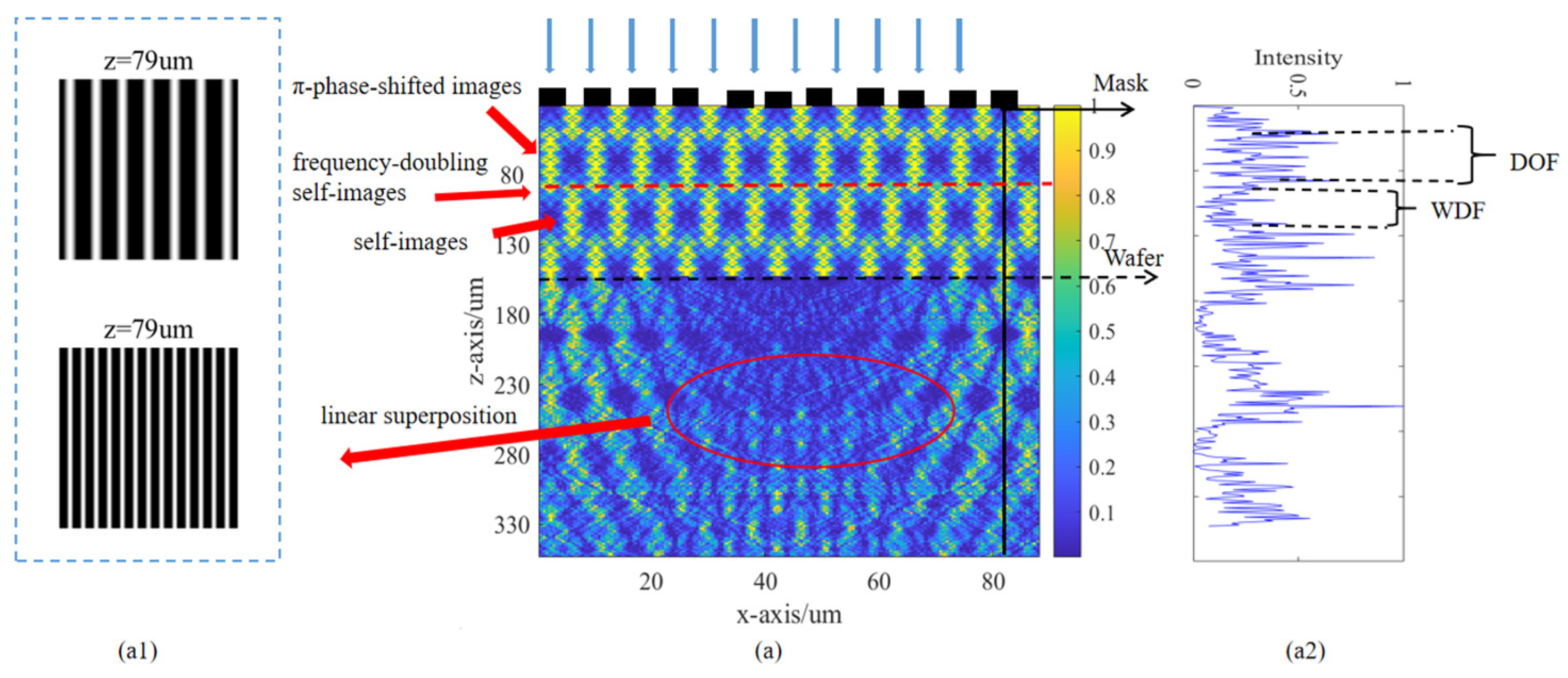

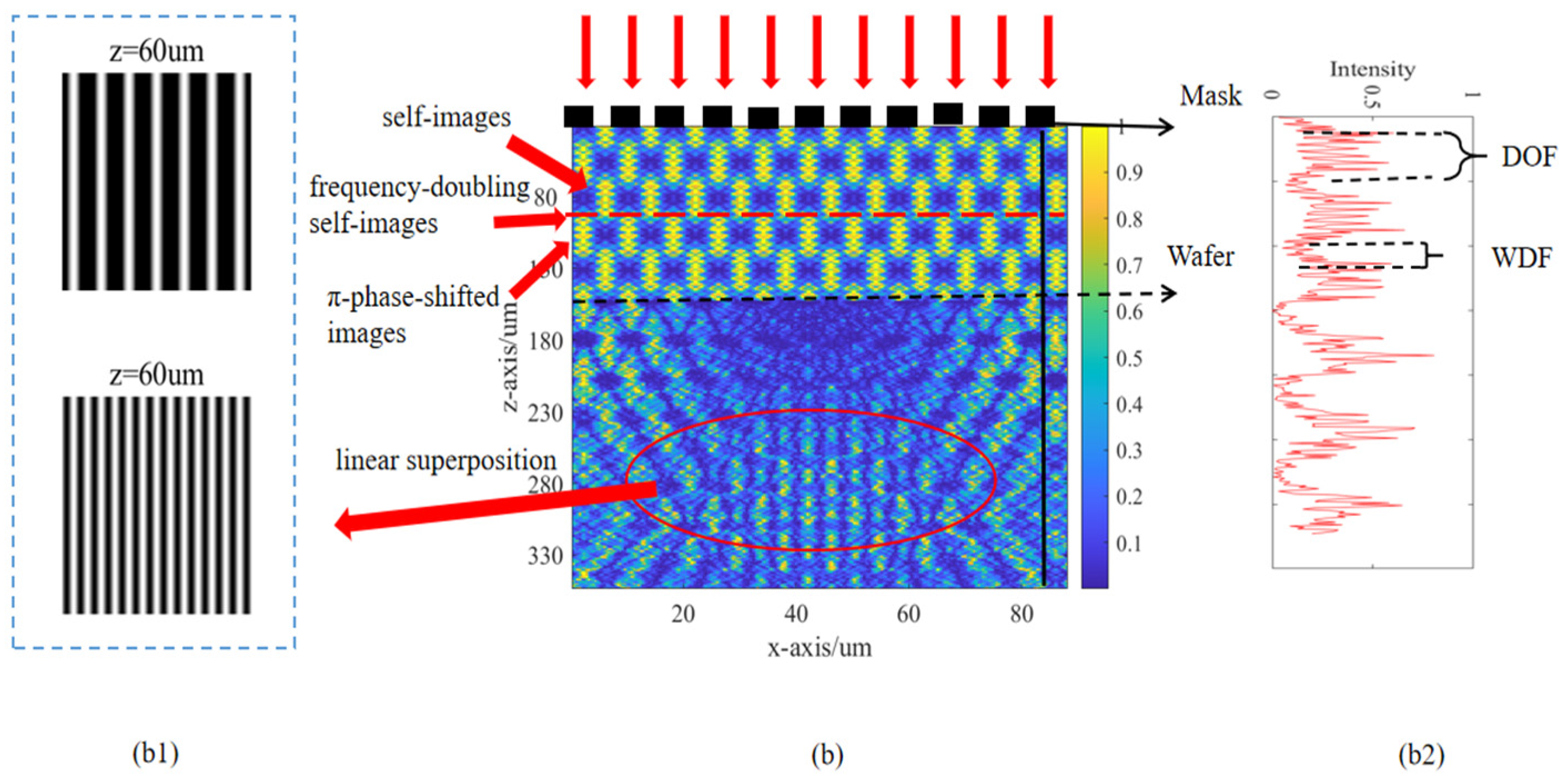

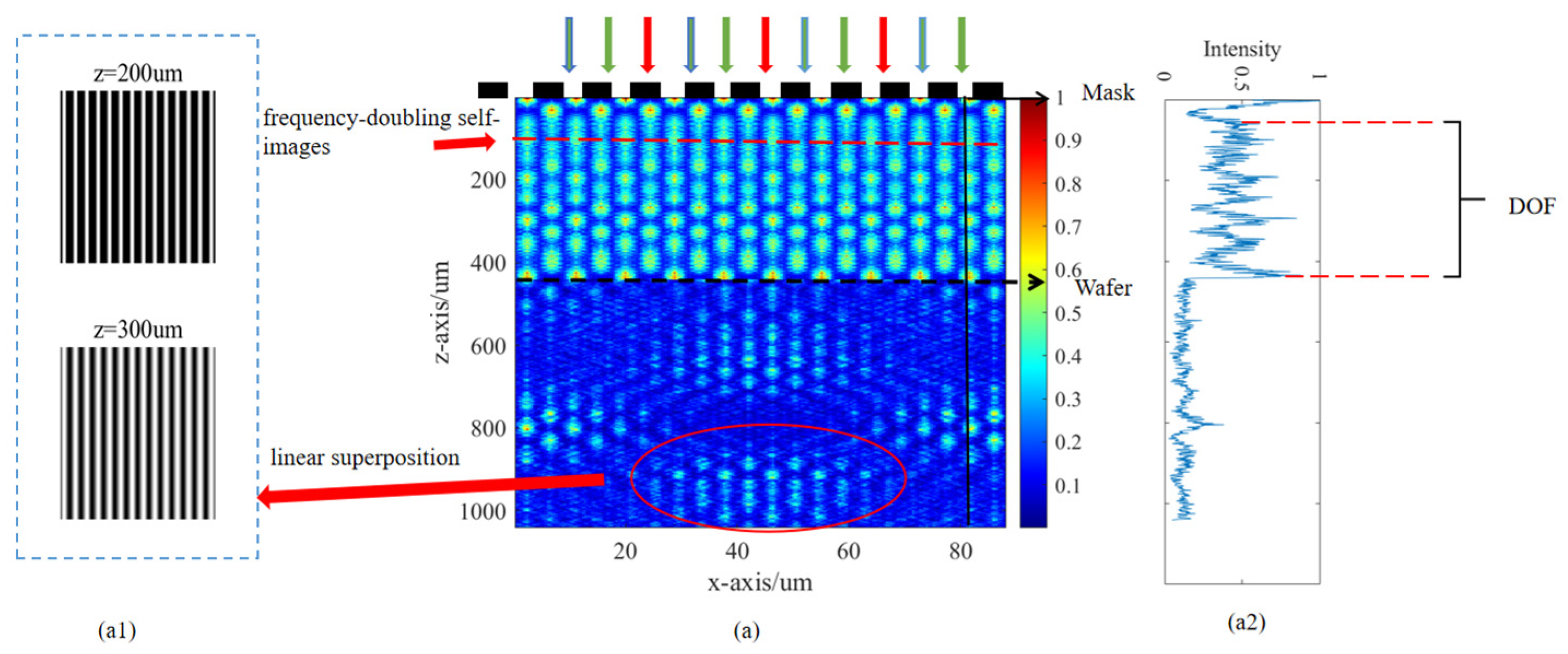

-phase–shifted images in the optical axis direction will change accordingly if the incident wavelength is different. As shown in

Figure 2a,b, the light field x–z cross–sectional distribution of the diffraction field formed by

and

, respectively, pass through the rectangular line grating mask with a period of 4 μm and a duty cycle of 1:1, along the Z direction, and then pass through a rectangular line grating wafer with a period of 4.4 μm and a duty cycle of 1:1 at the same diffraction distance. It can be observed that the

-phase–shifted images and self–images and frequency–doubling self–images, among them, as shown in

Figure 2(a1,b1), after passing through the grating mask,

and

, respectively, correspond to a wafer grating with a period of 4.4 μm and a duty cycle of 1:1, and a wafer grating with a period of 2 μm and a duty cycle of 1:1. The superposition of these gratings generates a Moiré fringe pattern. It can be seen from the pattern that it is consistent with what is described by the frequency doubling effect. Moreover, there is a width of dark field (WDF) between the

k-th order image and the

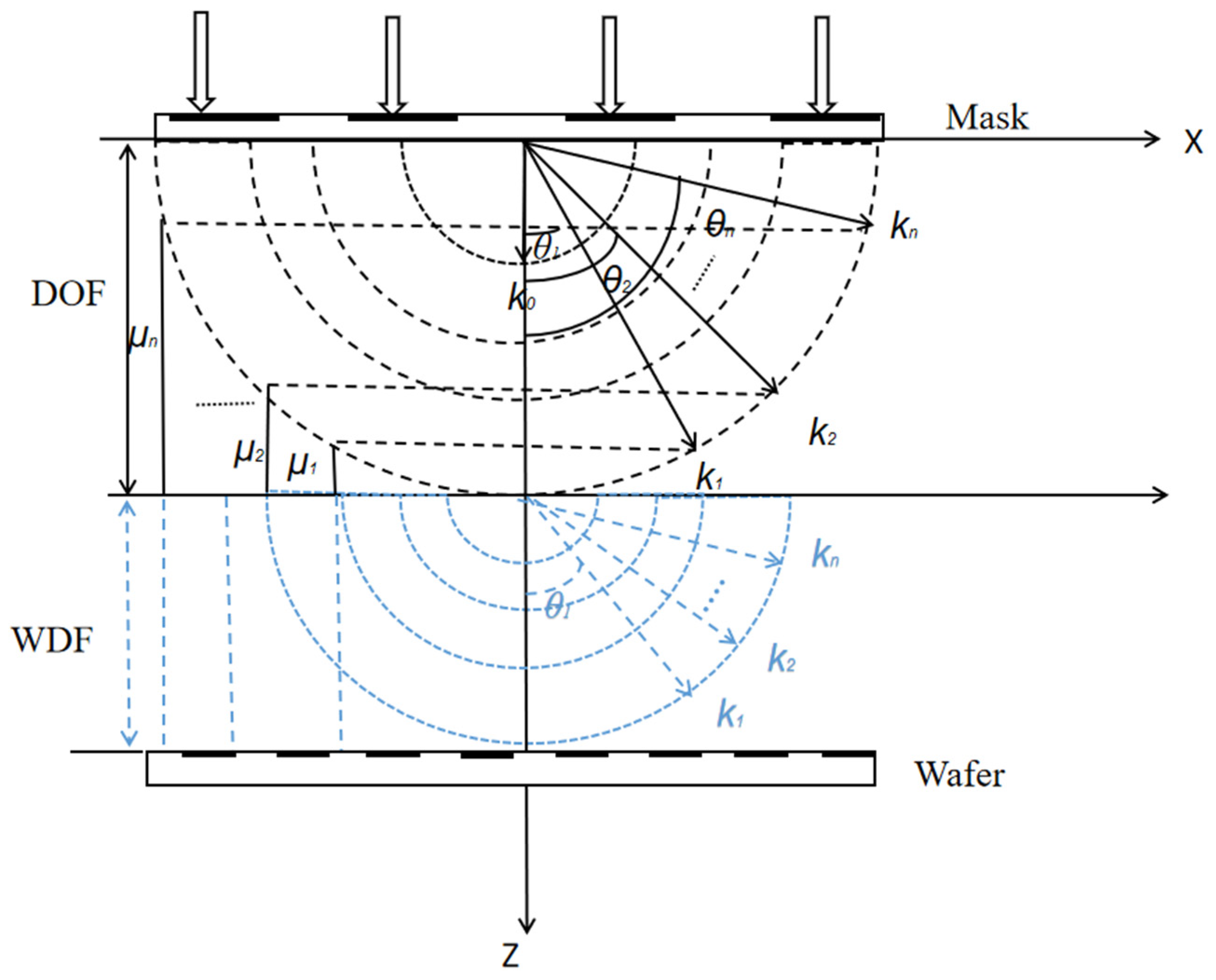

k + 1-th order image. That is, the relative light intensity distribution in this area is insignificant. The self–imaging effect will result in wavefront distortion at the actual imaging surface of the wafer. This wavefront distortion can be considered as the linear recombination of the diffraction field generated by each harmonic after the second grating after the incident plane wave is diffracted by the first grating. As shown in

Figure 3, it can also be expressed as the outcome of the interaction of the diffraction orders of all the distinct wave vectors.

Using zero–order diffraction as a reference:

Therefore, the wavefront distortion introduced by all the diffraction orders can be expressed as:

In the Formula (4),

m is the largest diffraction order. At the same time, the depth of focus (DOF) is defined as the wavefront distortion caused by defocus, which cannot exceed one–quarter of the wavelength. Therefore, the depth of focus can be expressed as:

Substituting the diffraction equation

into above the Formula (5), the DOF can be expressed as:

It can be seen from

Figure 2a,b that the WDF formed between two self–images in the z direction at wavelength

is approximately filled by the width of dark field (WDF) at wavelength

.

Among them,

N is the number of periods during which the light intensity distribution is continuous along the

Z–axis. For a rectangular grating mask, the longest WDF can be approximately equal to half of the longest self–imaging distance in the broad-spectrum. The above Formula (7) be approximately derived as:

Among them, . represents the continuous and constant starting distance of light field along the Z axis.

Finally, lithography uses the white light broad–spectrum illumination of , and if Equation (8) is satisfied, the WDF at N times the self–images’ distance from the mask grating will be filled by the superposition of different diffraction light fields. That is, weighted incoherent superposition. This greatly expands the imaging DOF of the longitudinal light field, and at the same time, produces this weighted incoherent superposition on both the self–images and -phase–shifted images and frequency-doubling effect.

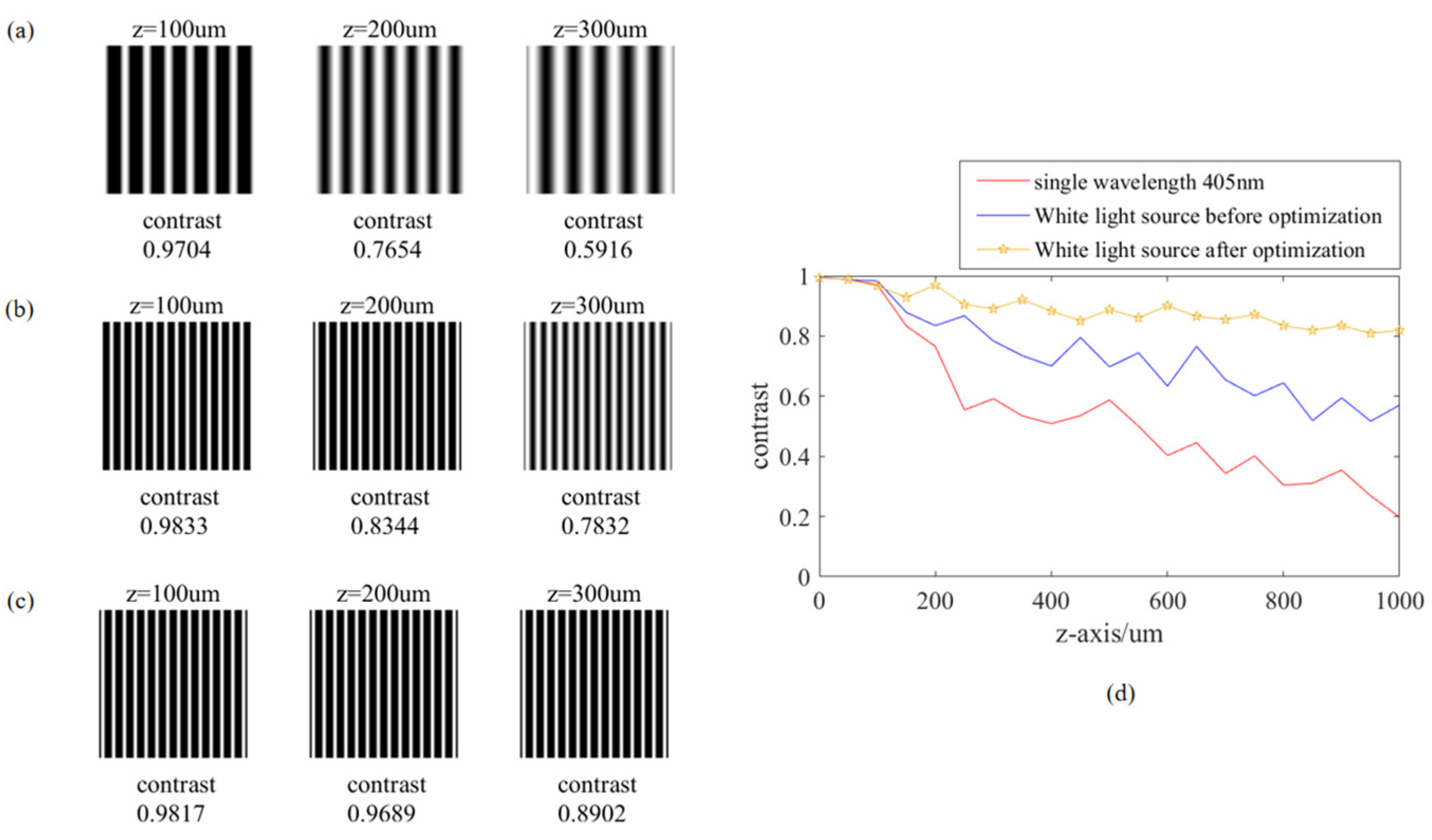

By measuring the white light spectrum, the bands with the highest energy proportion are 405 nm, and 532 nm, and 633 nm, and 780 nm. Under ideal circumstances, assuming that the relative light intensity between the four bands is consistent, the self-imaging light fields of the four bands perform incoherent superposition. They pass through the rectangular line grating mask with a period of 4 μm and a duty cycle of 1:1. In the area of

, an ultra–long depth of focus will be formed (relative to the single wavelength case) along the Z direction 420 μm, and then pass through a rectangular line grating wafer with a period of 2 μm and a duty cycle of 1:1. The superposition of these gratings generates a Moiré fringe pattern at the different diffraction distance. The light field x–z cross-sectional distribution shown in

Figure 4(a,a1,a2) illustrates that the radio of various wavelengths in the white light source before optimization lead to a depth–DOF but also create a scattered width of dark field, which impacts the contrast of the Moiré fringe. In addition, a depth DOF produced by the broad-spectrum will also result in the frequency doubling effect. Therefore, the period of the wafer should be half of the mask period to achieve a high-quality Moiré fringe.

2.3. Wavelength Weight Optimization Theory

In order to achieve the optimal DOF range of the broad–spectrum Moiré fringe imaging model, this paper discusses the GA–PSO hybrid algorithm, which utilizes gradient–free operations, employs the extended depth of field (DOF) in the wavelength weight ratio model used as the objective function, and uses the ratio of the wavelength part with the highest energy in white light (405 nm, 532 nm, 633 nm, 780 nm) as a variable to accurately assess the optimization of the wavelength weight ratio process. The general structure of the optimization process is as follows:

Among them, Formula (9) represents the physical relationship between the depth of focus and wavelength in the broad-spectrum fringe imaging model. represents different wavelengths in white light that exist in the white light spectrum in different ratios . of this paper is mainly taken as the four bands with the highest energy proportion in the white light spectrum (405 nm, 532 nm, 633 nm, and 780 nm), and T represents the period of grating. The function in Formula (10) reaches close to the global maximum during iteration process, with representing the matrix variable of each active light source, which is continuously updated as the algorithm iterates and loops. .

Formulas (11) and (12) represent the constraints and each design variable type for solving the maximization problem of Formula (10). Formula (11) represents that the sum of all the wavelength weight ratio factors is 1. Formula (12) represents the lower bound set for the design wavelength variable, and represents the upper bound set for the design wavelength variable.

Previous research has shown that using a method that combines multiple heuristic algorithms is more effective than applying these heuristic algorithms individually [

20]. This paper utilizes the GA–PSO hybrid algorithm to address the engineering optimization problem of the wavelength weight ratio design variables. In the hybrid algorithm proposed in this paper, the mutation and crossover operations of the genetic algorithm (GA) are utilized to broaden the search range of the wavelength weight ratio variable. The objective of incorporating the GA is to enhance the diversity of the initial population. Subsequently, these updated variables undergo a PSO cycle. By applying the PSO search process, the fitness value of individuals in the population can be improved, enabling the PSO to quickly obtain the optimal solution. Furthermore, the populations with higher fitness values achieved after the GA and PSO cycles are restricted in order to attain the optimal solution that satisfies the conditions.

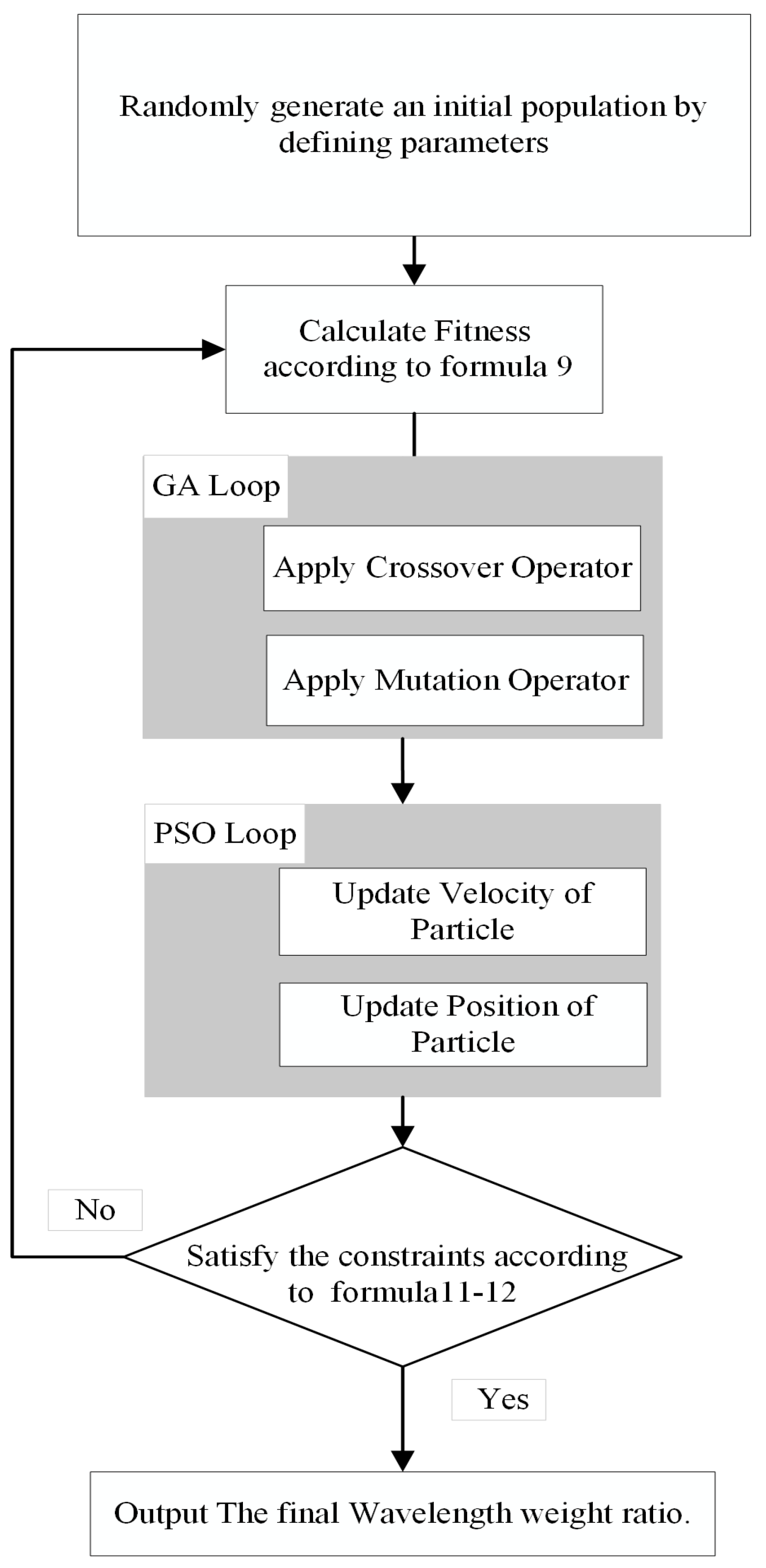

The GA–PSO hybrid optimization algorithm flow is shown in

Figure 5. The randomly generated initial population P is used to calculate the fitness function value of each particle in the population P, according to the wavelength weight ratio calculation model in Formula (9). To enhance the diversity of the hybrid algorithms, the genetic algorithm (GA) uses the mutation operation to introduce random updates over an increasing number of iterations. Through a multi-point crossover strategy, the randomness of the variable update process is enhanced, expanding the search scope. Furthermore, the population P resulting from the mutation and crossover operations of the GA is used as input for the particle swarm optimization model (PSO). Non-linear adaptive control in the PSO algorithm is used to enhance the search efficiency during the optimization process. Implementing this strategy can decrease the likelihood of becoming stuck in a local optimum. Combining GA and PSO can enhance both the exploration and exploitation capabilities simultaneously. By combining GA and PSO, the optimized weight ratio is applied to the constraints. The purpose of imposing constraints is to enhance the likelihood of finding an optimal solution.

For the optimal weight ratio problem, as shown in Algorithm 1, the detailed implementation process of the GA–PSO algorithm.

| Algorithm 1: | Flow of the GA–PSO hybrid algorithm in the wavelength weight ratio simulation. |

Input:

Output: | ;

);

|

| Step1: | t ← 1 (initialization);

) using the random function;

evaluate P(t) using (9); |

| Step2: | While

For

if η < η1, then//crossover operation

create G(t + 1) from P(t) by crossover routine;//

End

End

For i = 1 to NP

If then//mutation operation

create G(t + 1) from P(t) by mutation routine;//

End

End

For i = 1 to NP //PSO loop

End

End

For i = 1 to NP//Restrictions

End |

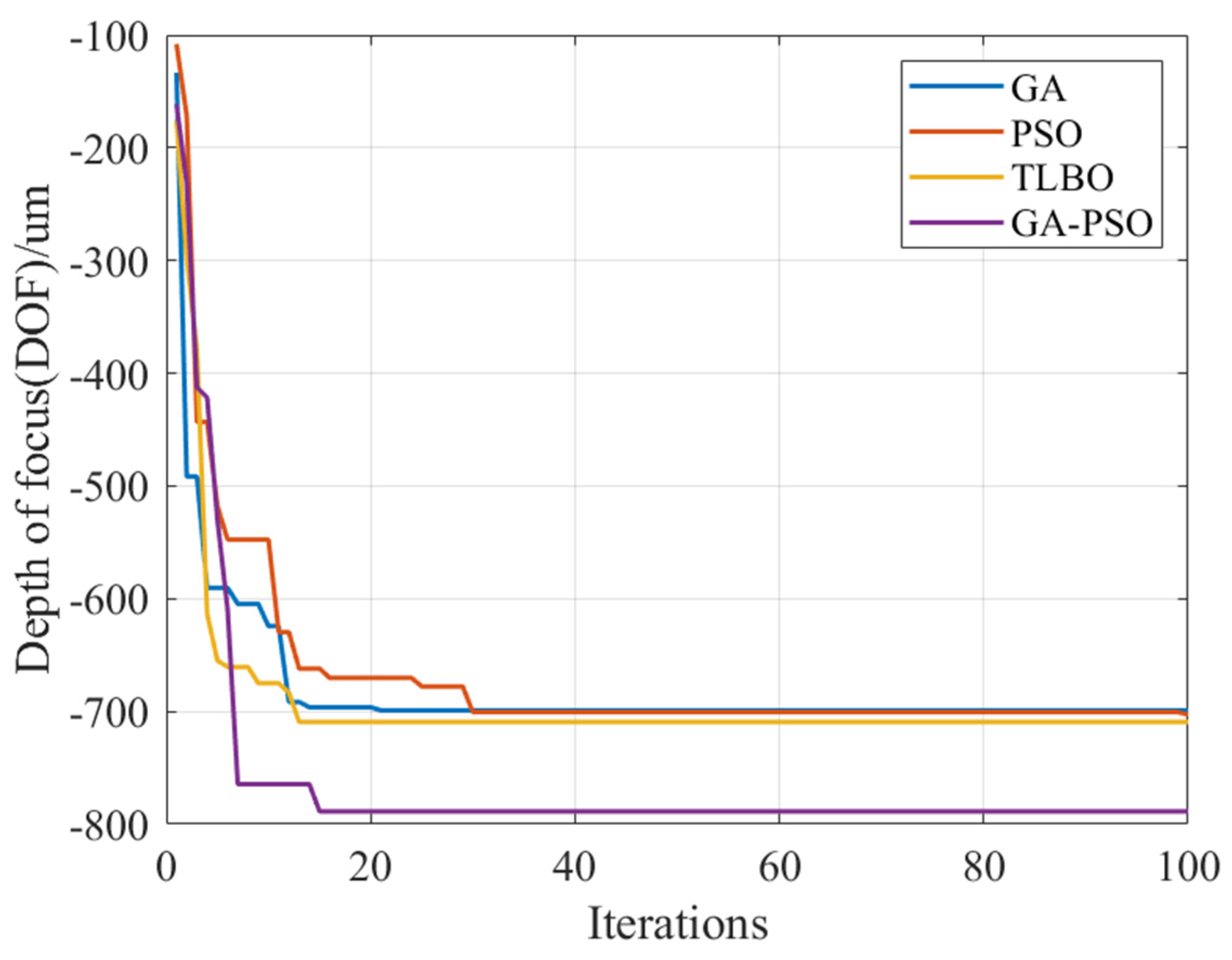

Using the optimization problem above, the initial variable is set as the ratio of the wavelength part with the highest energy in white light (405 nm, 532 nm, 633 nm, 780 nm). The number of iterations is set to 100, and these initial conditions are then substituted into the GA–PSO hybrid algorithm for comparative analysis of the optimization effects of several established individual heuristic algorithms currently in use.

It is evident from

Figure 6 that the GA–PSO hybrid method significantly improves the optimization in the initial stages, Among them, since the optimization goal is to expand the depth of focus, the abscissa represents the number of iterations, the ordinate represents the depth of focus range, and the negative sign on the ordinate represents the positive direction of

z-–axis diffraction. The GA and PSO and TLBO algorithms will complicate the optimization model by introducing a large number of optimization variables. This can cause the iterative process to prematurely converge to a local optimum and slow down the search speed of the method. Its performance in searching for GA is weaker compared to the weight ratio optimization results obtained via the genetic algorithm. The convergence curve of the GA–PSO algorithm indicates a tendency to maintain stability around iteration 40. The genetic algorithm has strong generalization ability. Combining PSO with the genetic algorithm in the weight ratio model can significantly enhance the optimized efficiency of the point variable matrix of light source. The search range can be expanded outward based on the local optimum, thereby bringing the variable matrix closer to the global optimal value. The optimization effect in

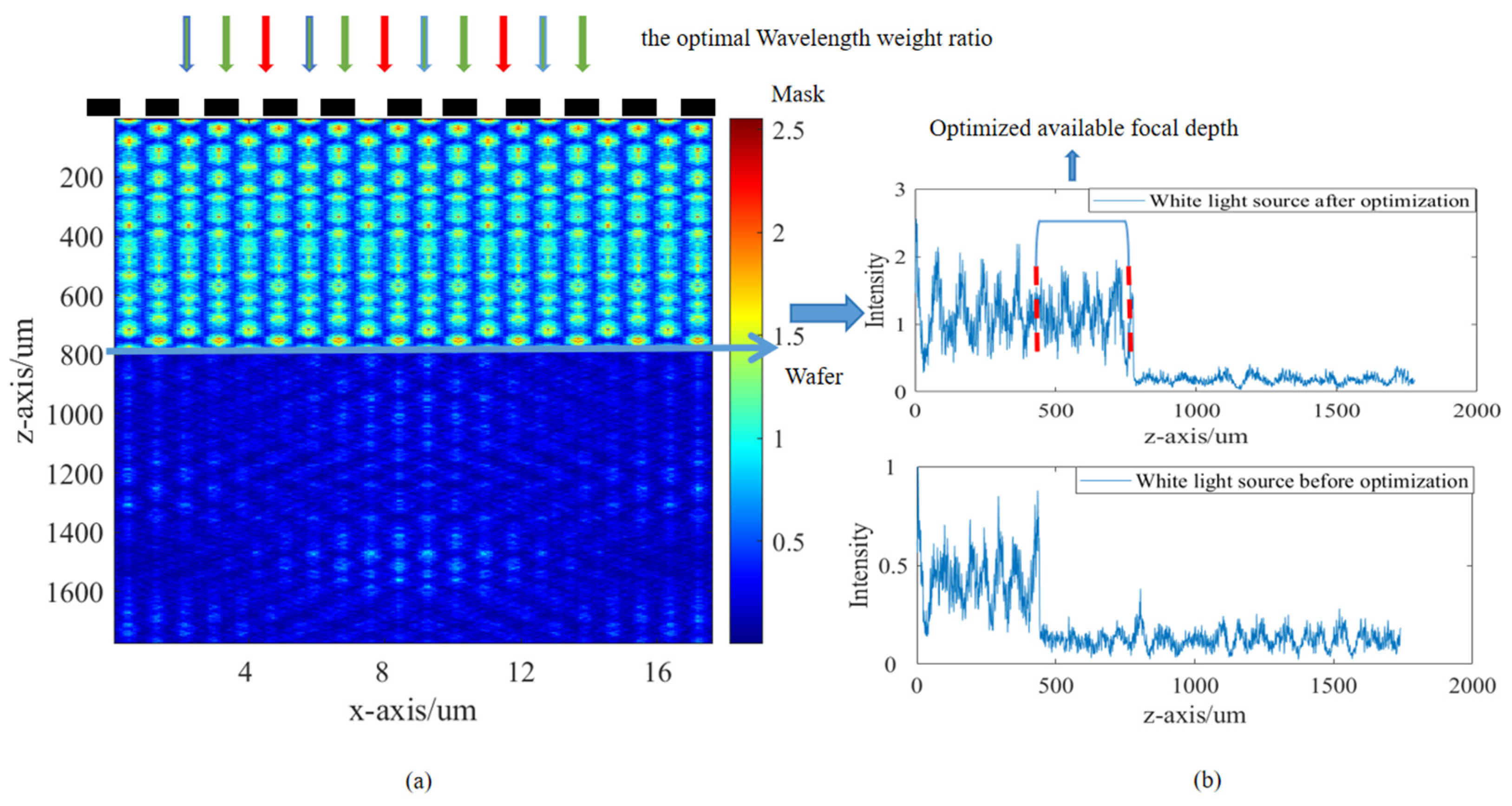

Figure 7 confirms that the combination of PSO and GA can enhance the optimization capability of the wavelength weight ratio model. The XZ cross–sectional distribution in

Figure 7a illustrates that the WDF formed between the self-images of different wavelengths is well covered, resulting in a continuous light field distribution. However, it should be noted that there will always be a frequency–doubling effect occurring simultaneously. Therefore, a periodic frequency–doubling grating relative to the mask grating needs to be placed on the wafer. The normalized distribution of the white light source before and after optimization can be seen in

Figure 7b. The comparison results show that, compared with the white light source before optimization, the white light source after optimization is more stable, and the DOF has also increased from 400 μm to 800 μm.