Burst-Mode 355 nm UV Laser Based on a QCW LD-Side-Pumped Electro-Optical Q-Switched Nd: YAG Laser

Abstract

1. Introduction

2. Experimental Section

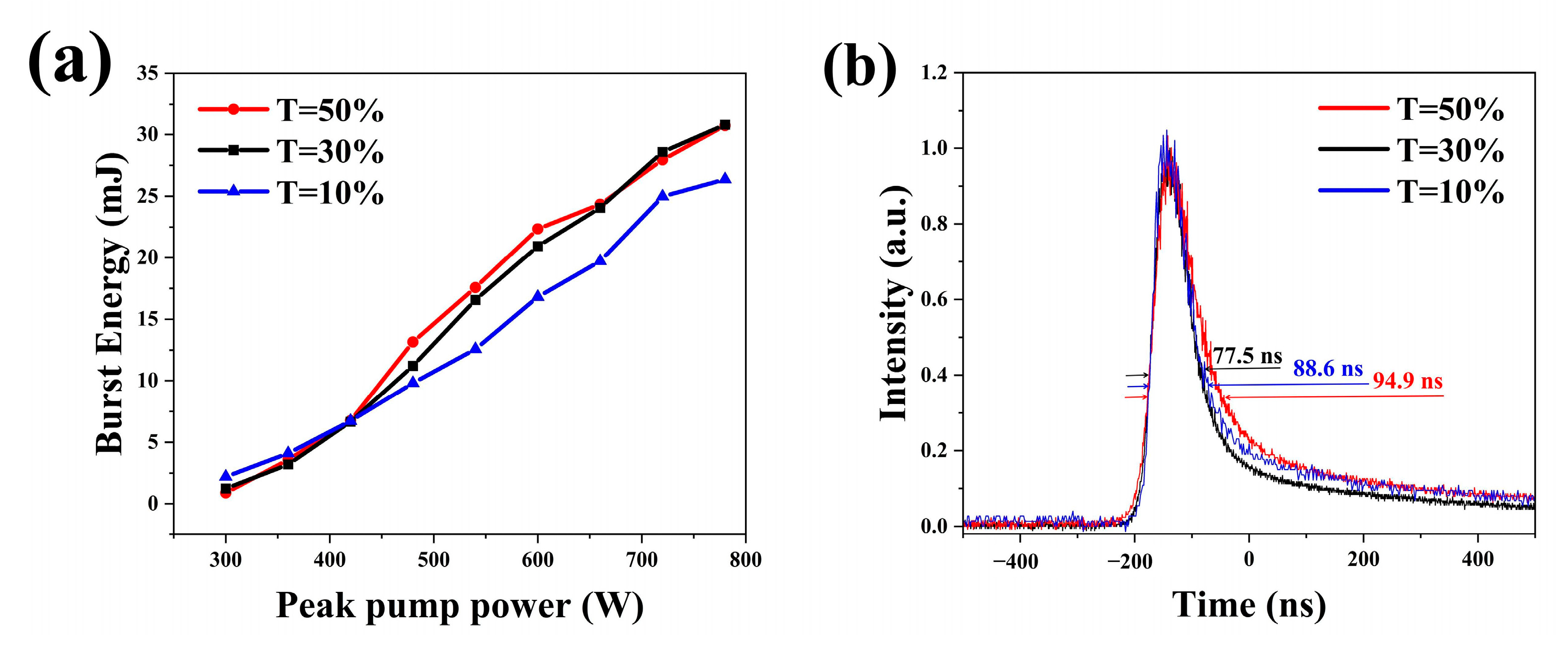

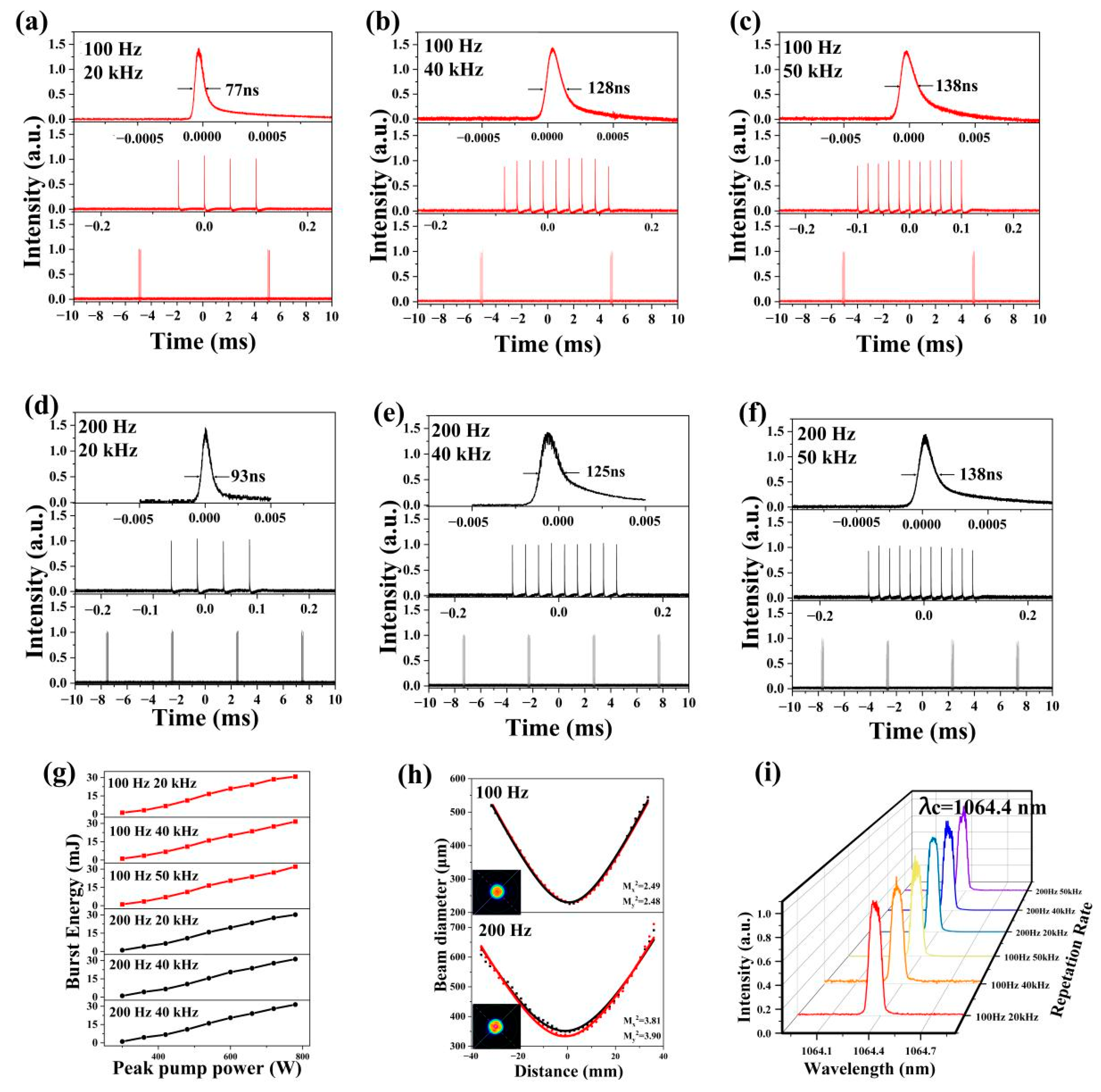

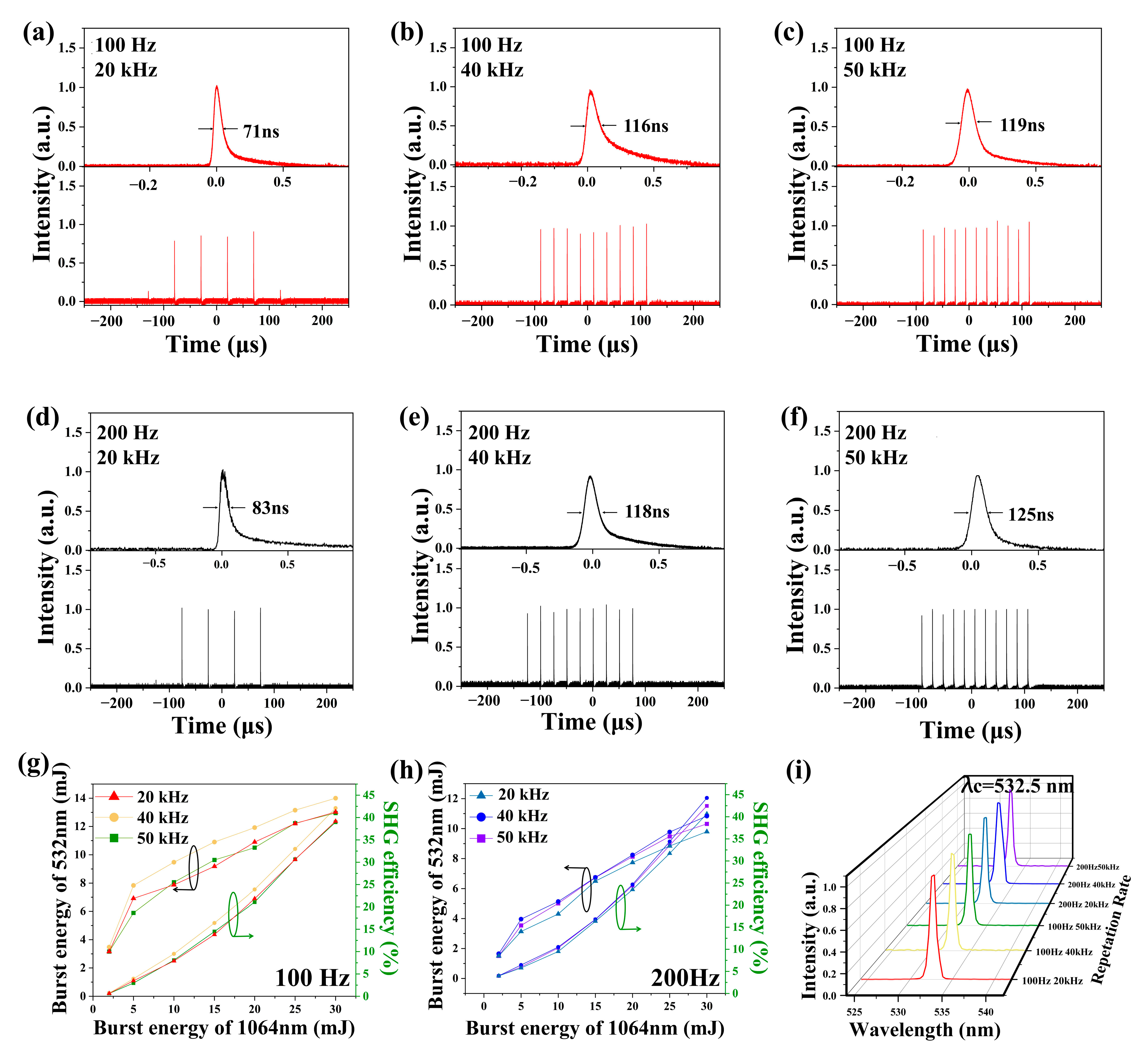

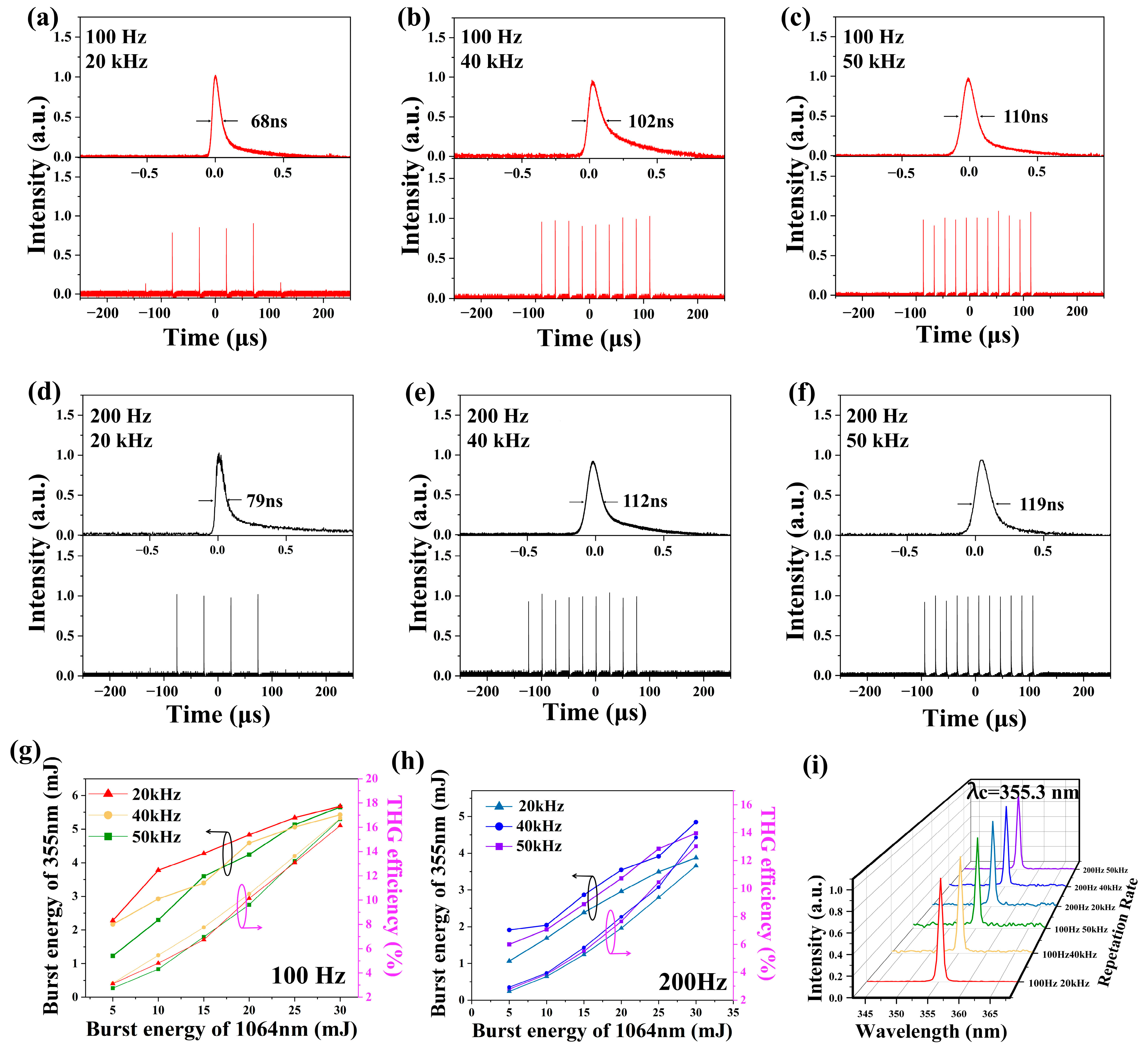

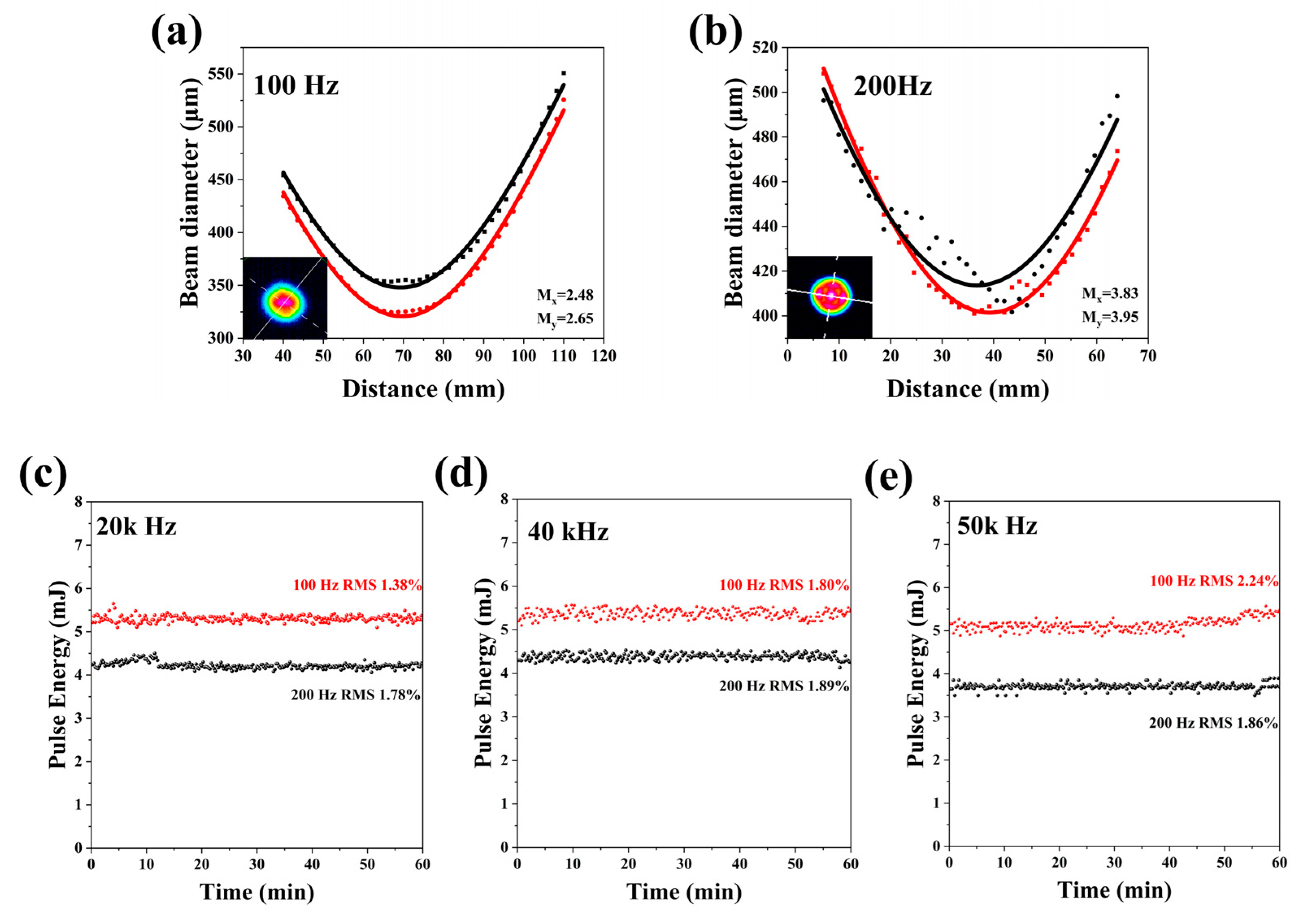

3. Results and Discussions

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wang, S.; Yu, Y.; Li, S.; Feng, Y.; Li, J.; Yang, C.; Li, W. Laser debonding application in ultra-thin device processing. Appl. Opt. 2023, 62, 6140–6146. [Google Scholar] [CrossRef] [PubMed]

- Wu, Y.S.; Cheng, J.-H.; Peng, W.C.; Ouyang, H. Effects of laser sources on the reverse-bias leakages of laser lift-off GaN-based light-emitting diodes. Appl. Phys. Lett. 2007, 90, 251110. [Google Scholar] [CrossRef]

- Delmdahl, R.; Pätzel, R.; Brune, J. Large-Area Laser-Lift-Off Processing in Microelectronics. Phys. Procedia 2013, 41, 241–248. [Google Scholar] [CrossRef]

- Ziegelwanger, T.; Reisinger, M.; Matoy, K.; Medjahed, A.A.; Zalesak, J.; Gruber, M.; Meindlhumer, M.; Keckes, J. Backside metallization affects residual stress and bending strength of the recast layer in laser-diced Si. Mat. Sci. Semicon Proc. 2024, 181, 108579. [Google Scholar] [CrossRef]

- Marks, M.R.; Yong, F.K.; Cheong, K.Y.; Hassan, Z. Mechanism study of SiO2 layer formation and separation at the Si die sidewall during nanosecond laser dicing of ultrathin Si wafers with Cu backside layer. Appl. Phys. A 2020, 126, 138. [Google Scholar] [CrossRef]

- Park, C.; Shin, B.-S.; Kang, M.-S.; Ma, Y.-W.; Oh, J.-Y.; Hong, S.-M. Experimental study on micro-porous patterning using UV pulse laser hybrid process with chemical foaming agent. Int. J. Precis. Eng. Man. 2015, 16, 1385–1390. [Google Scholar] [CrossRef]

- Kim, Y.; Noh, Y.; Park, S.; Kim, B.-K.; June Kim, H. Ablation of polyimide thin-film on carrier glass using 355 nm and 37 ns laser pulses. Int. J. Heat. Mass. Tran. 2020, 147, 118896. [Google Scholar] [CrossRef]

- Ryoo, K.; Kim, M.; Sung, J.; Kim, K.; Kang, M. Maskless laser direct imaging lithography using a 355-nm UV light source in manufacturing of flexible fine dies. J. Mech. Sci. Technol. 2015, 29, 365–370. [Google Scholar] [CrossRef]

- Shin, J.; Nam, K. Groove Formation in Glass Substrate by a UV Nanosecond Laser. Appl. Sci. 2020, 10, 987. [Google Scholar] [CrossRef]

- Yang, X.; Zhang, M.; Huang, Y.; Wang, W.; Xing, H.; Fang, R.; Luo, J.; Luo, Q.; Yang, J.; Rong, K.; et al. Laser processing of glass plates using nanosecond lasers with three wavelengths. In AOPC 2022: Advanced Laser Technology and Applications; SPIE: St., Bellingham, WA, USA, 2023. [Google Scholar]

- Zakariyah, S.S.; Conway, P.P.; Hutt, D.A.; Selviah, D.R.; Wang, K.; Rygate, J.; Calver, J.; Kandulski, W. Fabrication of Polymer Waveguides by Laser Ablation Using a 355 nm Wavelength Nd:YAG Laser. J. Light. Technol. 2011, 29, 3566–3576. [Google Scholar] [CrossRef]

- Zhang, J.; Tao, S.; Wang, B.; Zhao, J.; Klotzbach, U.; Kling, R.; Watanabe, A. Development of industrial scale laser micro-processing solution for mobile devices. Proc. SPIE 2019, 10906. [Google Scholar] [CrossRef]

- Mason, P.; Barrett, H.; Banerjee, S.; Butcher, T.; Collier, J. Generation of Joule-level green bursts of nanosecond pulses from a DPSSL amplifier. Opt. Express 2023, 31, 19510–19522. [Google Scholar] [CrossRef] [PubMed]

- De Vido, M.; Quinn, G.; Clarke, D.; McHugh, L.; Mason, P.; Spear, J.; Smith, J.M.; Divoky, M.; Pilar, J.; Denk, O.; et al. Demonstration of stable, long-term operation of a nanosecond pulsed DPSSL at 10 J, 100 Hz. Opt. Express 2024, 32, 11907–11915. [Google Scholar] [CrossRef] [PubMed]

- Knappe, R.; Haloui, H.; Seifert, A.; Weis, A.; Nebel, A. Scaling ablation rates for picosecond lasers using burst micromachining. Proc. SPIE 2010, 7585, 150–155. [Google Scholar] [CrossRef]

- Žemaitis, A.; Gudauskytė, U.; Steponavičiūtė, S.; Gečys, P.; Gedvilas, M. The ultrafast burst laser ablation of metals: Speed and quality come together. Opt. Laser Technol. 2025, 180, 111458. [Google Scholar] [CrossRef]

- Kerse, C.; Kalaycioglu, H.; Elahi, P.; Cetin, B.; Kesim, D.K.; Akcaalan, O.; Yavas, S.; Asik, M.D.; Oktem, B.; Hoogland, H.; et al. Ablation-cooled material removal with ultrafast bursts of pulses. Nature 2016, 537, 84–88. [Google Scholar] [CrossRef]

- Metzner, D.; Lickschat, P.; Weißmantel, S. Optimization of the ablation process using ultrashort pulsed laser radiation in different burst modes. J. Laser Appl. 2021, 33, 012057. [Google Scholar] [CrossRef]

- Brian, T.; Naibo, J.; Mo, S.; Walter, L. Narrow-linewidth megahertz-rate pulse-burst laser for high-speed flow diagnostics. Appl. Opt. 2004, 43, 5064–5073. [Google Scholar]

- Li, G.; Zhou, Q.; Xu, G.; Wang, X.; Han, W.; Wang, J.; Zhang, G.; Zhang, Y.; Yuan, Z.A.; Song, S.; et al. Lidar-radar for underwater target detection using a modulated sub-nanosecond Q-switched laser. Opt. Laser Technol. 2021, 142, 107234. [Google Scholar] [CrossRef]

- Smyser, M.E.; Rahman, K.A.; Slipchenko, M.N.; Roy, S.; Meyer, T.R. Compact burst-mode Nd:YAG laser for kHz-MHz bandwidth velocity and species measurements. Opt. Lett. 2018, 43, 735–738. [Google Scholar] [CrossRef]

- Liu, X.; Wang, Y.; Wang, Z.; Qi, F. Single camera 20 kHz two-color formaldehyde PLIF thermometry using a dual-wavelength-switching burst mode laser. Opt. Lett. 2021, 46, 5149–5152. [Google Scholar] [CrossRef]

- Michael, J.B.; Venkateswaran, P.; Miller, J.D.; Slipchenko, M.N.; Gord, J.R.; Roy, S.; Meyer, T.R. 100 kHz thousand-frame burst-mode planar imaging in turbulent flames. Opt. Lett. 2014, 39, 739–742. [Google Scholar] [CrossRef]

- Yang, H.; Chen, Y.; Ding, K.; Jia, F.; Li, K.; Copner, N. 3.5 ps burst mode pulses based on all-normal dispersion harmonic mode-locked. Appl. Phys. B 2020, 126, 127. [Google Scholar] [CrossRef]

- Wei, K.-H.; Jiang, P.-P.; Wu, B.; Chen, T.; Shen, Y.-H. Fiber laser pumped burst-mode operated picosecond mid-infrared laser. Chin. Phys. B 2015, 24, 024217. [Google Scholar] [CrossRef]

- Jung, M.; Lee, J.; Melkumov, M.; Khopin, V.F.; Dianov, E.M.; Lee, J.H. Burst-mode pulse generation from a bismuth-doped germanosilicate fiber laser through self Q-switched mode-locking. Laser Phys. Lett. 2014, 11, 125102. [Google Scholar] [CrossRef]

- Yu, H.; Qi, Y.; Zhang, J.; Zou, S.; Zhang, L.; He, C.; Chen, H.; Li, B.; Lin, X. 8.3 mJ, 166 W Burst Mode Pulse Fiber Amplifier Based on a Q-Switched Mode-Locked Fiber Seed Laser. IEEE J. Sel. Top. Quantum Electron. 2018, 24, 1–5. [Google Scholar] [CrossRef]

- Mackenzie, J.I.; JelÍnková, H.; Taira, T.; Abdou Ahmed, M.; Pan, H.; Yan, R.; Li, X.; Ma, Y.; Yu, X.; Chen, D. LD-pumped acousto-optical Q-switched burst-mode Nd:YAG laser. Proc. SPIE 2016, 9893, 165–170. [Google Scholar] [CrossRef]

- Yang, X.; Bo, Y.; Peng, Q.; Geng, A. QCW diode-pumped 654 W AO Q-switched Nd:YAG rod oscillator-amplifier laser. Optik 2011, 122, 467–470. [Google Scholar] [CrossRef]

- Li, C.Y.; Peng, Q.J.; Wang, B.S.; Bo, Y.; Cui, D.F.; Xu, Z.Y.; Feng, X.Q.; Pan, Y.B. QCW diode-side-pumped Nd:YAG ceramic laser with 247 W output power at 1123 nm. Appl Phys B 2010, 103, 285–289. [Google Scholar] [CrossRef]

- Wu, W.; Li, X.; Yan, R.; Zhou, Y.; Ma, Y.; Fan, R.; Dong, Z.; Chen, D. 100 kHz, 3.1 ns, 1.89 J cavity-dumped burst-mode Nd:YAG MOPA laser. Opt. Express 2017, 25, 26875–26884. [Google Scholar] [CrossRef]

- Li, X.; Xu, H.; Yan, R.; Jiang, Y.; Fan, R.; Dong, Z.; Chen, D. Burst-mode YVO4/Nd:YVO4 laser oscillator with pulse repetition rate up to 500 kHz. Optik 2021, 228, 165789. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guo, H.; Jia, C.; Ye, S.; Yao, Y.; Ma, T.; Zhang, J.; Bai, M.; Xia, J.; Nie, H.; Yao, B.; et al. Burst-Mode 355 nm UV Laser Based on a QCW LD-Side-Pumped Electro-Optical Q-Switched Nd: YAG Laser. Photonics 2024, 11, 1071. https://doi.org/10.3390/photonics11111071

Guo H, Jia C, Ye S, Yao Y, Ma T, Zhang J, Bai M, Xia J, Nie H, Yao B, et al. Burst-Mode 355 nm UV Laser Based on a QCW LD-Side-Pumped Electro-Optical Q-Switched Nd: YAG Laser. Photonics. 2024; 11(11):1071. https://doi.org/10.3390/photonics11111071

Chicago/Turabian StyleGuo, Haowen, Chunyan Jia, Shuai Ye, Yongping Yao, Tiejun Ma, Jiayu Zhang, Meng Bai, Jinbao Xia, Hongkun Nie, Bo Yao, and et al. 2024. "Burst-Mode 355 nm UV Laser Based on a QCW LD-Side-Pumped Electro-Optical Q-Switched Nd: YAG Laser" Photonics 11, no. 11: 1071. https://doi.org/10.3390/photonics11111071

APA StyleGuo, H., Jia, C., Ye, S., Yao, Y., Ma, T., Zhang, J., Bai, M., Xia, J., Nie, H., Yao, B., He, J., & Zhang, B. (2024). Burst-Mode 355 nm UV Laser Based on a QCW LD-Side-Pumped Electro-Optical Q-Switched Nd: YAG Laser. Photonics, 11(11), 1071. https://doi.org/10.3390/photonics11111071