Advances in Design and Fabrication of Micro-Structured Solid Targets for High-Power Laser-Matter Interaction

Abstract

1. Introduction

2. 2D Targets

2.1. Foils Targets

2.2. Multilayer Target

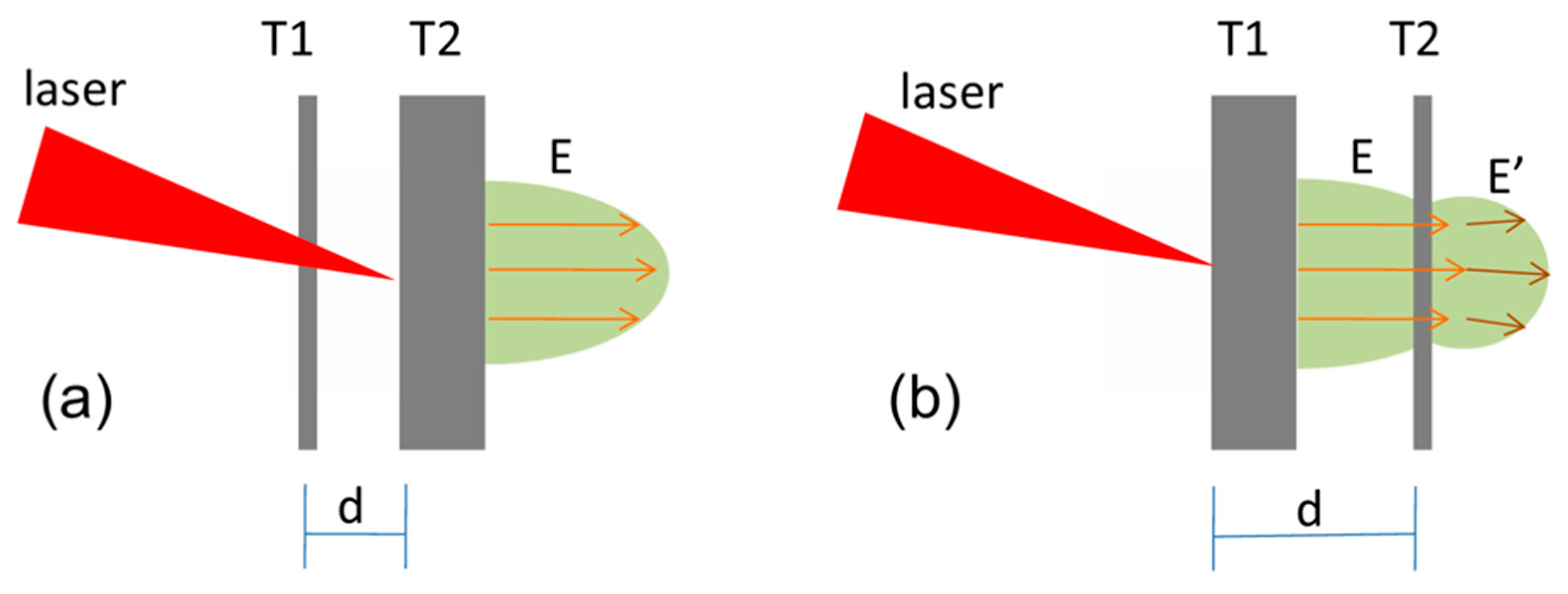

2.3. Double-Foil Target Design

3. 3D Targets

3.1. Foams Targets

3.2. Cone-Shaped Targets Fabrication

4. Numerical Simulation of Targets in Ultra-Intense Laser Irradiation Regime

4.1. Particle-in-Cell (PIC)

4.2. Finite-Difference Time-Domain (FDTD)

4.3. Raytracing Numerical Modeling

5. Challenges and Future Perspective

5.1. Repetition Rate Barrier

5.2. Energy Distribution Selection

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Esarey, E.; Schroeder, C.B.; Leemans, W.P. Physics of Laser-Driven Plasma-Based Electron Accelerators. Rev. Mod. Phys. 2009, 81, 1229–1285. [Google Scholar] [CrossRef]

- Fernández, J.; Albright, B.; Beg, F.; Foord, M.; Hegelich, B.; Honrubia, J.; Roth, M.; Stephens, R.; Yin, L. Fast Ignition with Laser-Driven Proton and Ion Beams. Nucl. Fusion 2014, 54, 054006. [Google Scholar] [CrossRef]

- Asavei, T.; Tomut, M.; Bobeica, M.; Aogaki, S.; Cernaianu, M.; Ganciu, M.; Kar, S.; Manda, G.; Mocanu, N.; Neagu, L.; et al. Materials in extreme environments for energy, accelerators and space applications at ELI-NP. Rom. Rep. Phys. 2016, 68, S275–S347. [Google Scholar]

- Hatchett, S.P.; Brown, C.G.; Cowan, T.E.; Henry, E.A.; Johnson, J.S.; Key, M.H.; Koch, J.A.; Langdon, A.B.; Lasinski, B.F.; Lee, R.W.; et al. Electron, Photon, and Ion Beams from the Relativistic Interaction of Petawatt Laser Pulses with Solid Targets. Phys. Plasmas 2000, 7, 2076–2082. [Google Scholar] [CrossRef]

- Robinson, A.P.L.; Zepf, M.; Kar, S.; Evans, R.G.; Bellei, C. Radiation Pressure Acceleration of Thin Foils with Circularly Polarized Laser Pulses. New J. Phys. 2008, 10, 013021. [Google Scholar] [CrossRef]

- Galloudec, N.R.-L.; D’Humieres, E. New micro-cones targets can efficiently produce higher energy and lower divergence particle beams. Laser Part. Beams 2010, 28, 513–519. [Google Scholar] [CrossRef]

- Bradford, P.; Woolsey, N.C.; Scott, G.G.; Liao, G.; Liu, H.; Zhang, Y.; Zhu, B.; Armstrong, C.; Astbury, S.; Brenner, C.; et al. EMP Control and Characterization on High-Power Laser Systems. High. Power Laser Sci. Eng. 2018, 6, e21. [Google Scholar] [CrossRef]

- Lübcke, A.; Andreev, A.A.; Höhm, S.; Grunwald, R.; Ehrentraut, L.; Schnürer, M. Prospects of Target Nanostructuring for Laser Proton Acceleration. Sci. Rep. 2017, 7, 44030. [Google Scholar] [CrossRef]

- Călin, B.Ș.; Dobrea, C.; Tiseanu, I.; Zamfirescu, M. Laser microfabrication of conical microtargets for laser driven particle acceleration. J. Laser Appl. 2021, 33, 012054. [Google Scholar] [CrossRef]

- Budrigă, O.; D’Humières, E. Modeling the Ultra-High Intensity Laser Pulse—Cone Target Interaction for Ion Acceleration at CETAL Facility. Laser Part. Beams 2017, 35, 458–466. [Google Scholar] [CrossRef]

- Ionel, L. Characterizing spatiotemporal aspects of chirped pulse amplification laser micro-cone target interaction. Laser Phys. 2022, 32, 035301. [Google Scholar] [CrossRef]

- Wu, Y.; Jain, G.; Sizyuk, T.; Wang, X.; Hassanein, A. Dynamics of laser produced plasma from foam targets for future nano-lithography devices and X-ray sources. Sci. Rep. 2021, 11, 13677. [Google Scholar]

- Brabetz, C.; Busold, S.; Cowan, T.; Deppert, O.; Jahn, D.; Kester, O.; Roth, M.; Schumacher, D.; Bagnoud, V. Laser-Driven Ion Acceleration with Hollow Laser Beams. Phys. Plasmas 2015, 22, 013105. [Google Scholar] [CrossRef]

- Nuter, R.; Korneev, P.; Dmitriev, E.; Thiele, I.; Tikhonchuk, V.T. Gain of Electron Orbital Angular Momentum in a Direct Laser Acceleration Process. Phys. Rev. E 2020, 101, 053202. [Google Scholar] [CrossRef]

- Lécz, Z.; Andreev, A.; Seryi, A. Plasma Rotation with Circularly Polarized Laser Pulse. Laser Part. Beams 2016, 34, 31–42. [Google Scholar] [CrossRef]

- Jipa, F.; Dinescu, A.; Filipescu, M.; Anghel, I.; Zamfirescu, M.; Dabu, R. Laser Parallel Nanofabrication by Single Femtosecond Pulse Near-Field Ablation Using Photoresist Masks. Opt. Express 2014, 22, 3356. [Google Scholar] [CrossRef] [PubMed]

- Bol’shov, L.A.; Burdonskii, I.N.; Velikovich, A.L.; Gavrilov, V.V.; Gol’tsov, A.Y.; Zhuzhukalo, E.V.; Zabyalets, S.V.; Kiselev, V.P.; Koval’skii, N.G.; Liberman, M.A.; et al. Acceleration of foils by a pulsed laser beam. Sov. Phys. JETP 1987, 65, 1160–1169. [Google Scholar]

- Ripin, B.H.; Whitlock, P.R.; Young, F.C.; Obenschain, S.P.; McLean, E.A.; Decoste, R. Long-Pulse Laser-Plasma Interactions at 1012–1015 W/cm2. Phys. Rev. Lett. 1979, 43, 350. [Google Scholar] [CrossRef]

- Boehly, T.; Yaakobi, B.; Shvarts, D.; Meyerhofer, D.; Audebert, P.; Wang, J.; Russotto, M.; Boswell, B.; Epstein, R.; Craxton, R.S.; et al. X-Ray Laser Experiments Using Double Foil Nickel Targets. Appl. Phys. B 1990, 50, 165–172. [Google Scholar] [CrossRef]

- Nishimura, H.; Takabe, H.; Kondo, K.; Endo, T.; Shiraga, H.; Sugimoto, K.; Nishikawa, T.; Kato, Y.; Nakai, S. X-Ray emission and transport in gold plasmas generated by 351-nm laser irradiation. Phys. Rev. A 1991, 43, 3073–3085. [Google Scholar] [CrossRef]

- Snavely, R.A.; Key, M.H.; Hatchett, S.P.; Cowan, T.E.; Roth, M.; Phillips, T.W.; Stoyer, M.A.; Henry, E.A.; Sangster, T.C.; Singh, M.S.; et al. Intense High-Energy Proton Beams from Petawatt-Laser Irradiation of Solids. Phys. Rev. Lett. 2000, 85, 2945–2948. [Google Scholar] [CrossRef] [PubMed]

- Wilks, S.C.; Langdon, A.B.; Cowan, T.E.; Roth, M.; Singh, M.; Hatchett, S.; Key, M.H.; Pennington, D.; MacKinnon, A.; Snavely, R.A. Energetic proton generation in ultra-intense laser–solid interactions. Phys. Plasmas 2001, 8, 542–549. [Google Scholar] [CrossRef]

- Esarey, E.; Schroeder, C.B.; Bulanov, S.V.; Esirkepov, T.Z.; Kando, M.; Pegoraro, F.; Leemans, W.P. Radiation pressure acceleration: The factors limiting maximum attainable ion energy. Phys. Plasmas 2016, 23, 056703. [Google Scholar] [CrossRef]

- Silva, L.O.; Marti, M.; Davies, J.R.; Fonseca, R.A.; Ren, C.; Tsung, F.S.; Mori, W.B. Proton Shock Acceleration in Laser-Plasma Interactions. Phys. Rev. Lett. 2004, 92, 015002. [Google Scholar] [CrossRef] [PubMed]

- Haberberger, D.; Tochitsky, S.; Fiuza, F.; Gong, C.; Fonseca, R.A.; Silva, L.O.; Mori, W.B.; Joshi, C. Collisionless shocks in laser-produced plasma generate monoenergetic high-energy proton beams. Nat. Phys. 2012, 8, 95–99. [Google Scholar] [CrossRef]

- Ditmire, T.; Tisch, J.W.G.; Springate, E.; Mason, M.B.; Hay, N.; Smith, R.A.; Marangos, J.; Hutchinson, M.H.R. High-energy ions produced in explosions of superheated atomic clusters. Nature 1997, 386, 54–56. [Google Scholar] [CrossRef]

- Yin, L.; Albright, B.J.; Hegelich, B.M.; Fernández, J.C. GeV laser ion acceleration from ultrathin targets: The laser break-out afterburner. Laser Part. Beams 2006, 24, 291–298. [Google Scholar] [CrossRef]

- Nakamura, T.; Bulanov, S.V.; Esirkepov, T.Z.; Kando, M. High-Energy Ions from Near-Critical Density Plasmas via Magnetic Vortex Acceleration. Phys. Rev. Lett. 2010, 105, 135002. [Google Scholar] [CrossRef]

- Kar, S.; Kakolee, K.F.; Qiao, B.; Macchi, A.; Cerchez, M.; Doria, D.; Geissler, M.; McKenna, P.; Neely, D.; Osterholz, J.; et al. Ion Acceleration in Multispecies Targets Driven by Intense Laser Radiation Pressure. Phys. Rev. Lett. 2012, 109, 185006. [Google Scholar] [CrossRef]

- Qiao, B.; Kar, S.; Geissler, M.; Gibbon, P.; Zepf, M.; Borghesi, M. Dominance of Radiation Pressure in Ion Acceleration with Linearly Polarized Pulses at Intensities of 1021 W/cm2. Phys. Rev. Lett. 2012, 108, 115002. [Google Scholar] [CrossRef]

- Higginson, A.; Gray, R.J.; King, M.; Dance, R.J.; Williamson, S.D.R.; Butler, N.M.H.; Wilson, R.; Capdessus, R.; Armstrong, C.; Green, J.S.; et al. Near-100 MeV protons via a laser-driven transparency-enhanced hybrid acceleration scheme. Nat. Commun. 2018, 9, 724. [Google Scholar] [CrossRef] [PubMed]

- Tong, S.-F.; Sheng, Z.-M.; Yu, M.Y. Target normal sheath acceleration of protons using triple-layer target with long preplasma. Phys. Rev. Accel. Beams 2018, 21, 051303. [Google Scholar] [CrossRef]

- Peng, M.; Ma, Y.-Y.; Li, B.-Y.; Tian, L.-C.; Jiang, J.; Zi, M.; Yang, X.-H. Enhancement of positron yields using multi-layer targets irradiated by laser-induced energetic electrons. Front. Phys. Sec. Fusion Plasma Phys. 2022, 10, 1038416. [Google Scholar] [CrossRef]

- Hegelich, M.; Karsch, S.; Pretzler, G.; Habs, D.; Witte, K.; Guenther, W.; Allen, M.; Blazevic, A.; Fuchs, J.; Gauthier, J.C.; et al. MeV Ion Jets from Short-Pulse-Laser Interaction with Thin Foils. Phys. Rev. Lett. 2002, 89, 085002. [Google Scholar] [CrossRef] [PubMed]

- Funk, R.K.; Stockham, A.L.; Laack, N.N.I. Basics of Radiation Therapy. In Clinal Cardio-Oncology; Elsevier: Amsterdam, The Netherlands, 2016; pp. 39–60. [Google Scholar]

- Ebert, N.; Tillner, F.; Baumann, M. Radiation Oncology. In Encyclopedia of Cancer, 3rd ed.; Paolo, B., Pierre, H., Eds.; Academic Press: London, UK, 2019; pp. 321–336. [Google Scholar]

- Ji, L.; Shen, B.; Zhang, X.; Wang, F.; Jin, Z.; Li, X.; Wen, M.; Cary, J.R. Generating Monoenergetic Heavy-Ion Bunches with Laser-Induced Electrostatic Shocks. Phys. Rev. Lett. 2008, 101, 164802. [Google Scholar] [CrossRef]

- Tayyab, M.; Bagchi, S.; Chakera, J.A.; Avasthi, D.K.; Ramis, R.; Upadhyay, A.; Ramakrishna, B.; Mandal, T.; Naik, P.A. Mono-energetic heavy ion acceleration from laser plasma based composite nano-accelerator. Phys. Plasmas 2018, 12, 123102. [Google Scholar] [CrossRef]

- Hadjikyriacou, A.; Psikal, J.; Giuffrida, L.; Kucharik, M. Novel approach to TNSA enhancement using multi-layered targets—A numerical study. Plasma Phys. Control. Fusion 2023, 65, 085002. [Google Scholar] [CrossRef]

- Nishiuchi, M.; Dover, N.P.; Hata, M.; Sakaki, H.; Kondo, K.; Lowe, H.F.; Miyahara, T.; Kiriyama, H.; Koga, J.K.; Iwata, N.; et al. Dynamics of laser-driven heavy-ion acceleration clarified by ion charge states. Phys. Rev. Res. 2020, 2, 033081. [Google Scholar] [CrossRef]

- Gizzi, L.A.; Boella, E.; Labate, L.; Baffigi, F.; Bilbao, P.J.; Brandi, F.; Cristoforetti, G.; Fazzi, A.; Fulgentini, L.; Giove, D.; et al. Enhanced laser-driven proton acceleration via improved fast electron heating in a controlled pre-plasma. Sci. Rep. 2021, 11, 13728. [Google Scholar] [CrossRef]

- Wang, P.; Gong, Z.; Lee, S.G.; Shou, Y.; Geng, Y.; Jeon, C.; Kim, I.J.; Lee, H.W.; Yoon, J.W.; Sung, J.H.; et al. Super-Heavy Ions Acceleration Driven by Ultrashort Laser Pulses at Ultrahigh Intensity. Phys. Rev. X 2021, 11, 021049. [Google Scholar] [CrossRef]

- Wei, W.Q.; Yuan, X.H.; Fang, Y.; Ge, Z.Y.; Ge, X.L.; Yang, S.; Liao, G.Q.; Zhang, Z.; Liu, F.; Chen, M.; et al. Plasma optical shutter in ultraintense laser-foil interaction. Phys. Plasmas 2017, 24, 113111. [Google Scholar] [CrossRef]

- An, H.H.; Wang, W.; Xiong, J.; Wang, C.; Pan, X.; Ouyang, X.P.; Jiang, S.; Xie, Z.Y.; Wang, P.P.; Yao, Y.L.; et al. Accelerated protons with energies up to 70 MeV based on the optimized SG-II Peta-watt laser facility. High. Power Laser Sci. Eng. 2023, 11, e63. [Google Scholar] [CrossRef]

- Braenzel, J.; Andreev, A.A.; Abicht, F.; Ehrentraut, L.; Platonov, K.; Schnürer, M. Amplification of Relativistic Electron Bunches by Acceleration in Laser Fields. Phys. Rev. Lett. 2017, 118, 014801. [Google Scholar] [CrossRef] [PubMed]

- Zheng, J.; Sheng, Z.-M.; Liu, J.-L.; Zhou, W.-M.; Xu, H.; Zhang, J. Efficient generation of proton bunches by intense laser pulse with a double-slice-foil target. J. Plasma Phys. 2012, 78, 491–496. [Google Scholar] [CrossRef]

- Rahman, O.; Sheng, Z.-M. High-density quasi-monoenergetic proton beam generation from vacuum sandwiched target. Phys. Plasmas 2023, 30, 123102. [Google Scholar] [CrossRef]

- Willingale, L.; Mangles, S.P.D.; Nilson, P.M.; Clarke, R.J.; Dangor, A.E.; Kaluza, M.C.; Karsch, S.; Lancaster, K.L.; Mori, W.B.; Najmudin, Z.; et al. Collimated Multi-MeV Ion Beams from High-Intensity Laser Interactions with Underdense Plasma. Phys. Rev. Lett. 2006, 96, 245002. [Google Scholar] [CrossRef]

- Yogo, A.; Daido, H.; Bulanov, S.V.; Nemoto, K.; Oishi, Y.; Nayuki, T.; Fujii, T.; Ogura, K.; Orimo, S.; Sagisaka, A.; et al. Laser ion acceleration via control of the near-critical density target. Phys. Rev. E 2008, 77, 016401. [Google Scholar] [CrossRef]

- Dong, Y.; Zhang, L.; Yang, J.; Shang, W. Detailed energy distributions in laser-produced plasmas of solid gold and foam gold planar targets. Phys. Plasmas 2013, 20, 123102. [Google Scholar] [CrossRef]

- Nagai, K.; Miyamoto, K.; Iyoda, T.; Pan, C.; Gu, Z. Monolithic and low-density (<50 mg/cm3) metal oxides fabricated using electrospinning: Vanadium oxide and copper oxide examples. Fusion. Sci. Technol. 2011, 59, 216–220. [Google Scholar] [CrossRef]

- Tanabe, M.; Hiroaki Nishimura, H.; Fujioka, S.; Nagai, K.; Yamamoto, N.; Gu, Z.Z.; Pan, C.; Girard, F.; Primout, M.; Villette, B.; et al. Titanium dioxide nanofiber-cotton targets for efficient multi-keV X-ray generation. Appl. Phys. Lett. 2008, 93, 051505. [Google Scholar] [CrossRef]

- Fazeli, R. Tuning laser plasma X-ray source for single shot microscopy using nano-porous targets. Opt. Lett. 2016, 41, 5250. [Google Scholar] [CrossRef] [PubMed]

- Jones, O.S.; Kemp, G.E.; Langer, S.H.; Winjum, B.J.; Berger, R.L.; Oakdale, J.S.; Belyaev, M.A.; Biener, J.; Biener, M.M.; Mariscal, D.A.; et al. Experimental and calculational investigation of la-ser-heated additive manufactured foams. Phys. Plasmas 2021, 28, 022709. [Google Scholar] [CrossRef]

- Wiste, T.; Maliuk, O.; Tikhonchuk, V.; Lastovicka, T.; Homola, J.; Chadt, K.; Weber, S. Additive manufactured foam targets for experiments on high-power laser–matter interaction. J. Appl. Phys. 2023, 4, 043101. [Google Scholar] [CrossRef]

- Liu, Y.; Campbell, J.H.; Stein, O.; Jiang, L.; Hund, J.; Lu, Y. Deformation Behavior of Foam Laser Targets Fabricated by Two-Photon Polymerization. Nanomaterials 2018, 8, 498. [Google Scholar] [CrossRef]

- Prencipe, I.; Sgattoni, A.; Dellasega, D.; Fedeli, L.; Cialfi, L.; Choi, I.W.; Kim, I.J.; A Janulewicz, K.; Kakolee, K.F.; Lee, H.W.; et al. Development of foam-based layered targets for laser-driven ion beam production. Plasma Phys. Control. Fusion 2016, 58, 034019. [Google Scholar] [CrossRef]

- Wang, P.; Qi, G.; Pan, Z.; Kong, D.; Shou, Y.; Liu, J.; Cao, Z.; Mei, Z.; Xu, S.; Liu, Z.; et al. Fabrication of large-area uniform carbon nanotube foams as near-critical-density targets for laser–plasma experiments. High. Power Laser Sci. Eng. 2021, 9, e29. [Google Scholar] [CrossRef]

- Carr, A.; Sechrest, Y.; Mertes, K.; Patterson, B.M.; Wohlberg, B.; Hancock, L.; Sirica, N.; Sandberg, R.; Sweeney, C.; Hunter, J.; et al. Morphology of Copper Nanofoams for Radiation Hydrodynamics and Fusion Applications Investigated by 3D Ptychotomography. Nano Lett. 2024, 32, 9916–9922. [Google Scholar] [CrossRef]

- Shokitaa, S.; Yogo, A.; Mirfayzia, S.R.; Honokia, Y.; Golovina, D.; Ishimotoa, T.; Lana, Z.; Matsuoa, K.; Moria, T.; Okamotoa, K.; et al. Observation of MeV-energy ions from the in-teraction of over picosecond laser pulses with near-critical density foam targets. High. Energy Density Phys. 2020, 36, 100821. [Google Scholar] [CrossRef]

- Kodama, R.; Sentoku, Y.; Chen, Z.L.; Kumar, G.R.; Hatchett, S.P.; Toyama, Y.; Cowan, T.E.; Freeman, R.R.; Fuchs, J.; Izawa, Y.; et al. Plasma Devices to Guide and Collimate a High Density of MeV Electrons. Nature 2004, 432, 1005–1008. [Google Scholar] [CrossRef]

- Atzeni, S.; Schiavi, A.; Honrubia, J.J.; Ribeyre, X.; Schurtz, G.; Nicolaï, P.; Olazabal-Loumé, M.; Bellei, C.; Evans, R.G.; Davies, J.R. Fast Ignitor Target Studies for the HiPER Project. Phys. Plasmas 2008, 15, 056311. [Google Scholar] [CrossRef]

- Ebert, T.; Heber, R.; Abel, T.; Bieker, J.; Schaumann, G.; Roth, M. Targets with cone-shaped microstructures from various ma-terials for enhanced high-intensity laser–matter interaction. High. Power Laser Sci. Eng. 2021, 9, e24. [Google Scholar] [CrossRef]

- Kluge, T.; A Gaillard, S.; A Flippo, K.; Burris-Mog, T.; Enghardt, W.; Gall, B.; Geissel, M.; Helm, A.; Kraft, S.D.; Lockard, T.; et al. High Proton Energies from Cone Targets: Electron Acceleration Mechanisms. New J. Phys. 2012, 14, 023038. [Google Scholar] [CrossRef]

- Chen, C.; Galitskiy, S.; Mishra, A.; Dongare, A.M. Modeling laser interactions with aluminum and tantalum targets using a hybrid atomistic-continuum model. J. Appl. Phys. 2023, 133, 105901. [Google Scholar] [CrossRef]

- Zeng, Q.; Chen, B.; Zhang, S.; Kang, D.; Wang, H.; Yu, X.; Dai, J. Full-scale ab initio simulations of laser-driven atomistic dy-namics. Comput. Mater. 2023, 9, 213. [Google Scholar] [CrossRef]

- Yong, G. Coupling of material point method and molecular dynamics for modeling ultrafast laser interaction with metals. Eng. Anal. Bound. Elem. 2020, 110, 104–111. [Google Scholar]

- Benlliure, J.; Cortina-Gil, D.; Llerena, J.; Ruiz, C. Validation of the radiation shielding for the Laser Laboratory for Acceleration and Applications. Nucl. Instrum. Methods Phys. Res. Sect. A Accel. Spectrometers Detect. Assoc. Equip. 2018, 916, 158–168. [Google Scholar] [CrossRef]

- Qiu, R.; Song, H. Review of bremsstrahlung photon dose generated from ultra-intense and ultra-short laser target interactions. Radiat. Phys. Chem. 2023, 217, 111465. [Google Scholar] [CrossRef]

- Hadjisolomou, P.; Jeong, T.; Valenta, P.; Kolenaty, D.; Versaci, R.; Olšovcová, V.; Ridgers, C.; Bulanov, S. Gamma-ray flash in the interaction of a tightly focused single-cycle ultra-intense laser pulse with a solid target. J. Plasma Phys. 2022, 88, 905880104. [Google Scholar] [CrossRef]

- Barberio, M.; Scisciò, M.; Vallières, S.; Cardelli, F.; Chen, S.N.; Famulari, G.; Gangolf, T.; Revet, G.; Schiavi, A.; Senzacqua, M.; et al. Laser-accelerated particle beams for stress testing of materials. Nat. Commun. 2018, 9, 372. [Google Scholar] [CrossRef]

- Smith, J.R.; Orban, C.; Morrison, J.T.; George, K.M.; Ngirmang, G.K.; A Chowdhury, E.; Roquemore, W.M. Optimizing laser-plasma interactions for ion acceleration using particle-in-cell simulations and evolutionary algorithms. New J. Phys. 2020, 22, 103067. [Google Scholar] [CrossRef]

- Sundström, A.; Gremillet, L.; Siminos, E.; Pusztai, I. Collisional effects on the electrostatic shock dynamics in thin-foil targets driven by an ultraintense short pulse laser. Plasma Phys. Control. Fusion 2020, 62, 085015. [Google Scholar] [CrossRef]

- Costa, G.; Torrisi, L. Particle-in-cell simulation for experimental ion acceleration by fs laser-generated plasma. Radiat. Eff. Defects Solids 2019, 174, 985–997. [Google Scholar] [CrossRef]

- Martiş, M.; Budrigă, O.; D’humières, E.; E Ionel, L.; Carabaş, M. Modeling the interaction of an ultra-high intensity laser pulse with an ultra-thin nanostructured foil target. Plasma Phys. Control. Fusion 2020, 62, 095014. [Google Scholar] [CrossRef]

- Brantov, A.V.; Bychenkov, V.Y. Proton acceleration from thin foils by extremely short PW laser pulse. Phys. Plasmas 2021, 28, 063106. [Google Scholar] [CrossRef]

- Zhu, X.-L.; Liu, W.Y.; Chen, M.; Weng, S.-M.; McKenna, P.; Sheng, Z.-M.; Zhang, J. Bunched Proton Acceleration from a La-ser-Irradiated Cone Target. Phys. Rev. Appl. 2022, 18, 044051. [Google Scholar] [CrossRef]

- Budriga, O.; D’Humières, E.; E Ionel, L.; Martis, M.; Carabas, M. Modeling the interaction of an ultra-high intensity laser pulse with nano-layered flat-top cone targets for ion acceleration. Plasma Phys. Control. Fusion 2019, 61, 085007. [Google Scholar] [CrossRef]

- Zou, D.B.; Zhuo, H.B.; Yang, X.H.; Yu, T.P.; Shao, F.Q.; Pukhov, A. Control of target-normal-sheath-accelerated protons from a guiding cone. Phys. Plasmas 2015, 22, 063103. [Google Scholar] [CrossRef]

- Chintalwad, S.; Krishnamurthy, S.; Ramakrishna, B.; Ridgers, C.P. Photon emission enhancement studies from the interaction of ultraintense laser pulses with shaped targets. Phys. Rev. E 2022, 105, 025205. [Google Scholar] [CrossRef]

- Budriga, O.; Ionel, L.E.; Tatomirescu, D.; Tanaka, K.A. Enhancement of laser-focused intensity greater than 10 times through a re-entrant cone in the petawatt regime. Opt. Lett. 2020, 45, 3454–3457. [Google Scholar] [CrossRef]

- Rocca, J.J.; Capeluto, M.G.; Hollinger, R.C.; Wang, S.; Wang, Y.; Kumar, G.R.; Lad, A.D.; Pukhov, A.; Shlyaptsev, V.N. Ultra-intense femtosecond laser interactions with aligned nanostructures. Optica 2024, 11, 437–453. [Google Scholar] [CrossRef]

- Dozières, M.; Petrov, G.M.; Forestier-Colleoni, P.; Campbell, P.; Krushelnick, K.; Maksimchuk, A.; McGuffey, C.; Kaymak, V.; Pukhov, A.; Capeluto, M.G.; et al. Optimization of laser-nanowire target interaction to increase the proton acceleration efficiency. Plasma Phys. Control. Fusion 2019, 61, 065016. [Google Scholar] [CrossRef]

- Houng, F.; Hoh, S.; Ong, J. Ionisation in nanowire by ultra-short relativistic laser pulse. Fundam. Plasma Phys. 2024, 10, 100045. [Google Scholar] [CrossRef]

- Vallières, S.; Salvadori, M.; Permogorov, A.; Cantono, G.; Svendsen, K.; Chen, Z.; Sun, S.; Consoli, F.; D’humières, E.; Wahlström, C.-G.; et al. Enhanced laser-driven proton acceleration using nanowire targets. Sci. Rep. 2021, 11, 2226. [Google Scholar] [CrossRef]

- Ionel, L. Spatio-temporal analysis of high-power laser micro-structured targets interaction. Phys. Scr. 2020, 95, 105501. [Google Scholar] [CrossRef]

- Floquet, V.; Klimo, O.; Psikal, J.; Velyhan, A.; Limpouch, J.; Proska, J.; Novotny, F.; Stolcova, L.; Macchi, A.; Sgattoni, A.; et al. Micro-sphere layered targets efficiency in laser driven proton acceleration. J. Appl. Phys. 2013, 114, 083305. [Google Scholar] [CrossRef]

- Lin, Z.; Chen, X.; Ding, P.; Qiu, W.; Pu, J. Modeling the ponderomotive interaction of high-power laser beams with collisional plasma: The FDTD-based approach. Opt. Express 2017, 25, 8440–8449. [Google Scholar] [CrossRef] [PubMed]

- Ionel, L.; Ursescu, D. Spatial extension of the electromagnetic field from tightly focused ultra-short laser pulses. Laser Part. Beams 2014, 32, 89–97. [Google Scholar] [CrossRef]

- Ionel, L. Numerical analysis of non-collinear coherently combined laser beams interaction with micro-structured targets. Opt. Commun. 2021, 498, 127234. [Google Scholar] [CrossRef]

- Gamaly, E. The physics of ultra-short laser interaction with solids at non-relativistic intensities. Phys. Rep. 2011, 508, 91–243. [Google Scholar] [CrossRef]

- Zhang, S.; Menoni, C.; Gruzdev, V.; Chowdhury, E. Ultrafast Laser Material Damage Simulation—A New Look at an Old Problem. Nanomaterials 2022, 12, 1259. [Google Scholar] [CrossRef]

- Ionel, L. Piston error effect on intensity at the interaction of coherently combined femtosecond laser beams with cone targets. UPB Sci. Bull. Ser. A 2024, 86, 179–190. [Google Scholar]

- Spindloe, C.; Arthur, G.; Hall, F.; Tomlinson, S.; Potter, R.; Kar, S.; Green, J.; Higginbotham, A.; Booth, N.; Tolley, M.K. High volume fabrication of laser targets using MEMS techniques. J. Phys. Conf. Ser. 2016, 713, 012002. [Google Scholar] [CrossRef]

- Zaffino, R.; Seimetz, M.; Quirión, D.; de la Cruz, A.R.; Sánchez, I.; Mur, P.; Benlliure, J.; Martín, L.; Roso, L.; Benlloch, J.M.; et al. Preparation and characterization of micro-nano engineered targets for high-power laser experiments. Microelectron Eng. 2018, 194, 67. [Google Scholar] [CrossRef]

- Peñas, J.; Bembibre, A.; Cortina-Gil, D.; Martín, L.; Reija, A.; Ruiz, C.; Seimetz, M.; Alejo, A.; Benlliure, J. A Multi-Shot Target Wheel Assembly for High-Repetition-Rate, Laser-Driven Proton Acceleration. High Power Laser Sci. Eng. 2024, 12, e22. [Google Scholar] [CrossRef]

- Lim, J.K.; Frigola, P.; Travish, G.; Rosenzweig, J.B.; Anderson, S.G.; Brown, W.J.; Jacob, J.S.; Robbins, C.L.; Tremaine, A.M. Adjustable, short focal length permanent-magnet quadrupole based electron beam final focus system. Phys. Rev. Spéc. Top. Accel. Beams 2005, 8, 072401. [Google Scholar] [CrossRef]

- Romano, F.; Schillaci, F.; Cirrone, G.; Cuttone, G.; Scuderi, V.; Allegra, L.; Amato, A.; Amico, A.; Candiano, G.; De Luca, G.; et al. The ELIMED transport and dosimetry beamline for laser-driven ion beams. Nucl. Instrum. Methods Phys. Res. Sect. A Accel. Spectrometers Detect. Assoc. Equip. 2016, 829, 153–158. [Google Scholar] [CrossRef]

- Brack, F.-E.; Kroll, F.; Gaus, L.; Bernert, C.; Beyreuther, E.; Cowan, T.E.; Karsch, L.; Kraft, S.; Kunz-Schughart, L.A.; Lessmann, E.; et al. Spectral and spatial shaping of laser-driven proton beams using a pulsed high-field magnet beamline. Sci. Rep. 2020, 10, 9118. [Google Scholar] [CrossRef]

- Reija, A.; Esteban, D.; Alejo, A.; Apiñaniz, J.I.; Bembibre, A.; Benlliure, J.; Ehret, M.; López, J.G.; Jiménez-Ramos, M.C.; Juan-Morales, J.; et al. Design and Implementation of an Energy Selector for Laser-Accelerated Protons. Instruments 2024, 8, 36. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jipa, F.; Ionel, L.; Zamfirescu, M. Advances in Design and Fabrication of Micro-Structured Solid Targets for High-Power Laser-Matter Interaction. Photonics 2024, 11, 1008. https://doi.org/10.3390/photonics11111008

Jipa F, Ionel L, Zamfirescu M. Advances in Design and Fabrication of Micro-Structured Solid Targets for High-Power Laser-Matter Interaction. Photonics. 2024; 11(11):1008. https://doi.org/10.3390/photonics11111008

Chicago/Turabian StyleJipa, Florin, Laura Ionel, and Marian Zamfirescu. 2024. "Advances in Design and Fabrication of Micro-Structured Solid Targets for High-Power Laser-Matter Interaction" Photonics 11, no. 11: 1008. https://doi.org/10.3390/photonics11111008

APA StyleJipa, F., Ionel, L., & Zamfirescu, M. (2024). Advances in Design and Fabrication of Micro-Structured Solid Targets for High-Power Laser-Matter Interaction. Photonics, 11(11), 1008. https://doi.org/10.3390/photonics11111008