Fiber-Optic Hydraulic Sensor Based on an End-Face Fabry–Perot Interferometer with an Open Cavity

Abstract

:1. Introduction

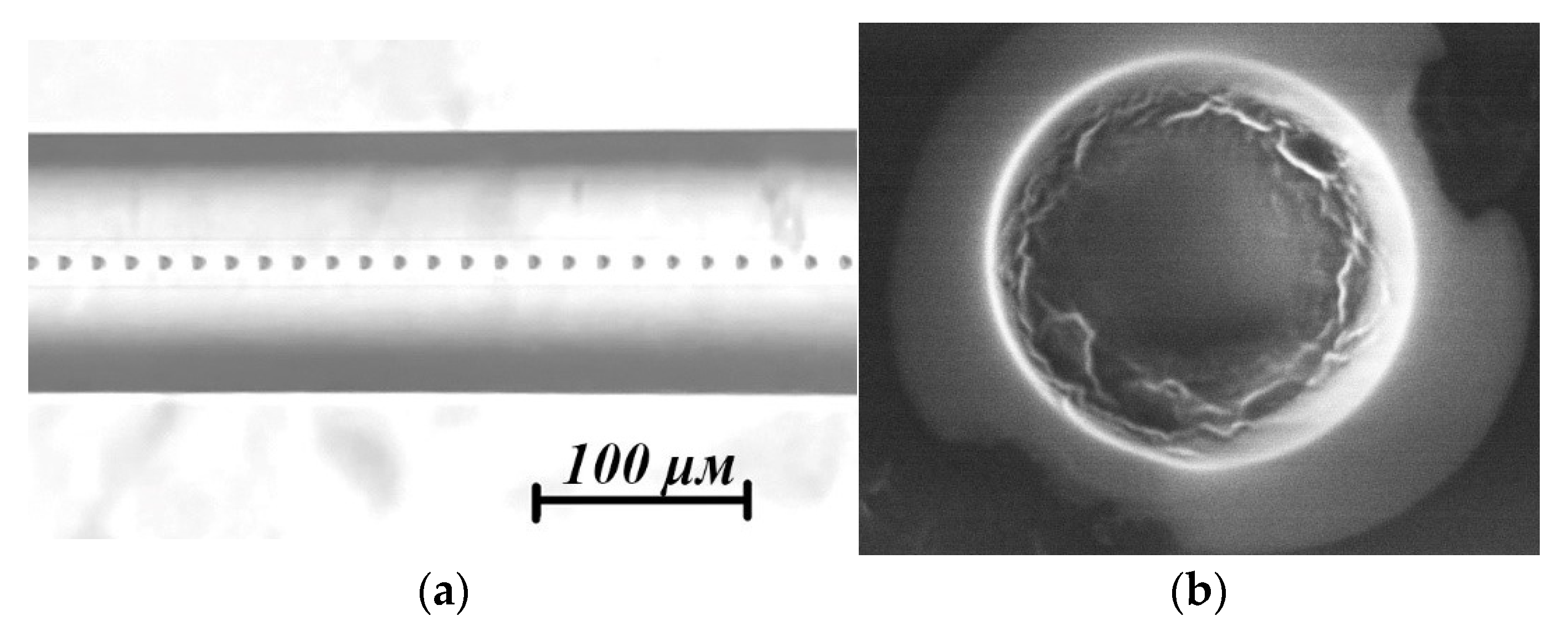

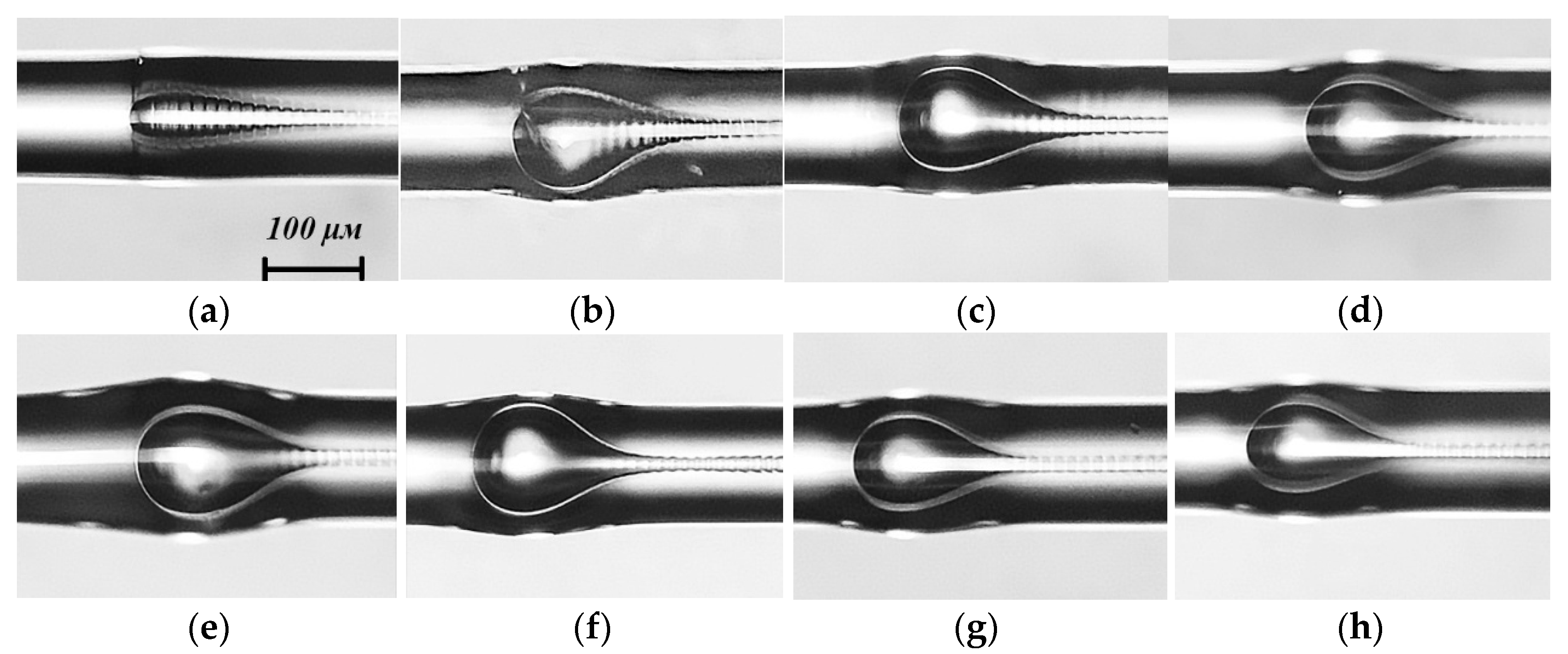

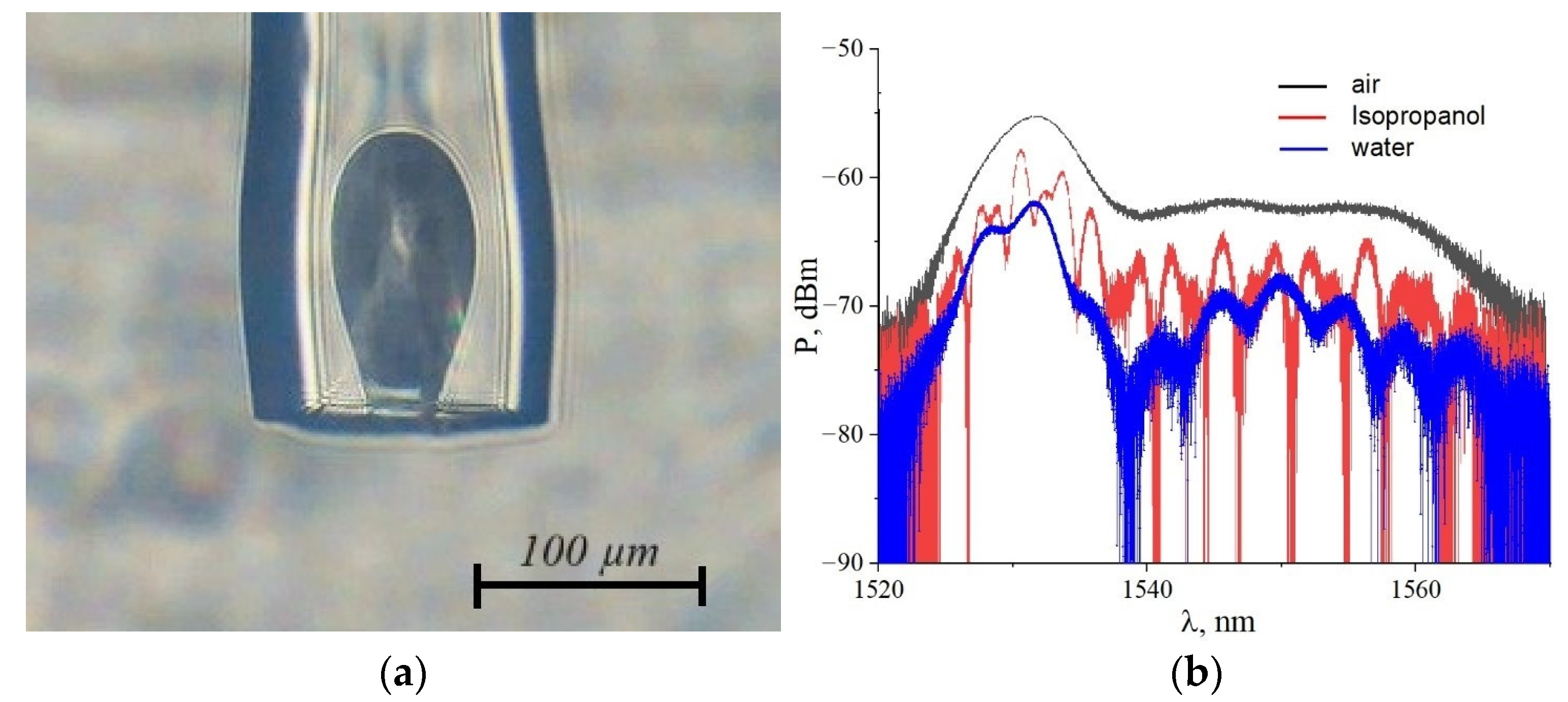

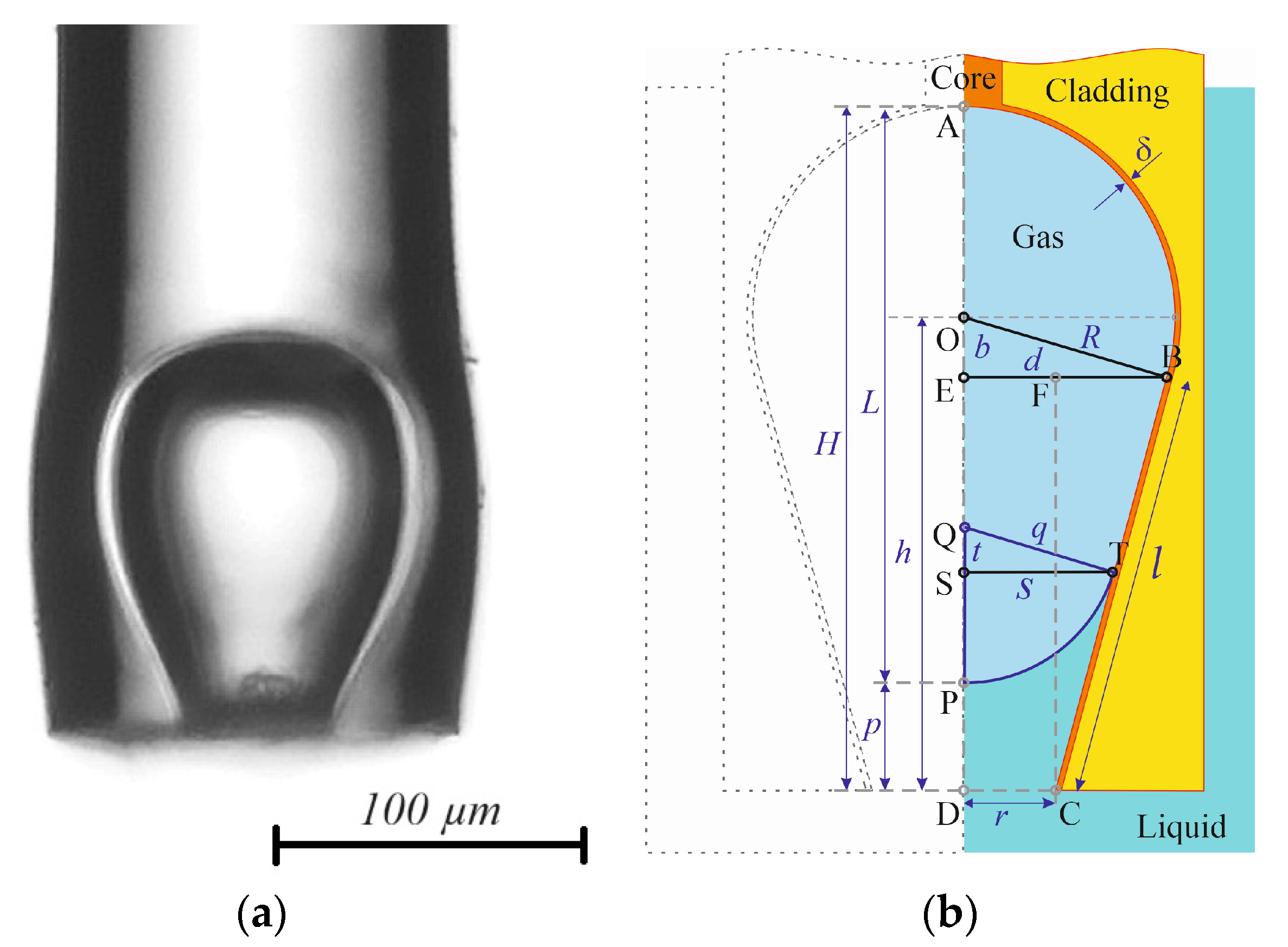

2. Open Cavity Formation at the End Face of an Optical Fiber

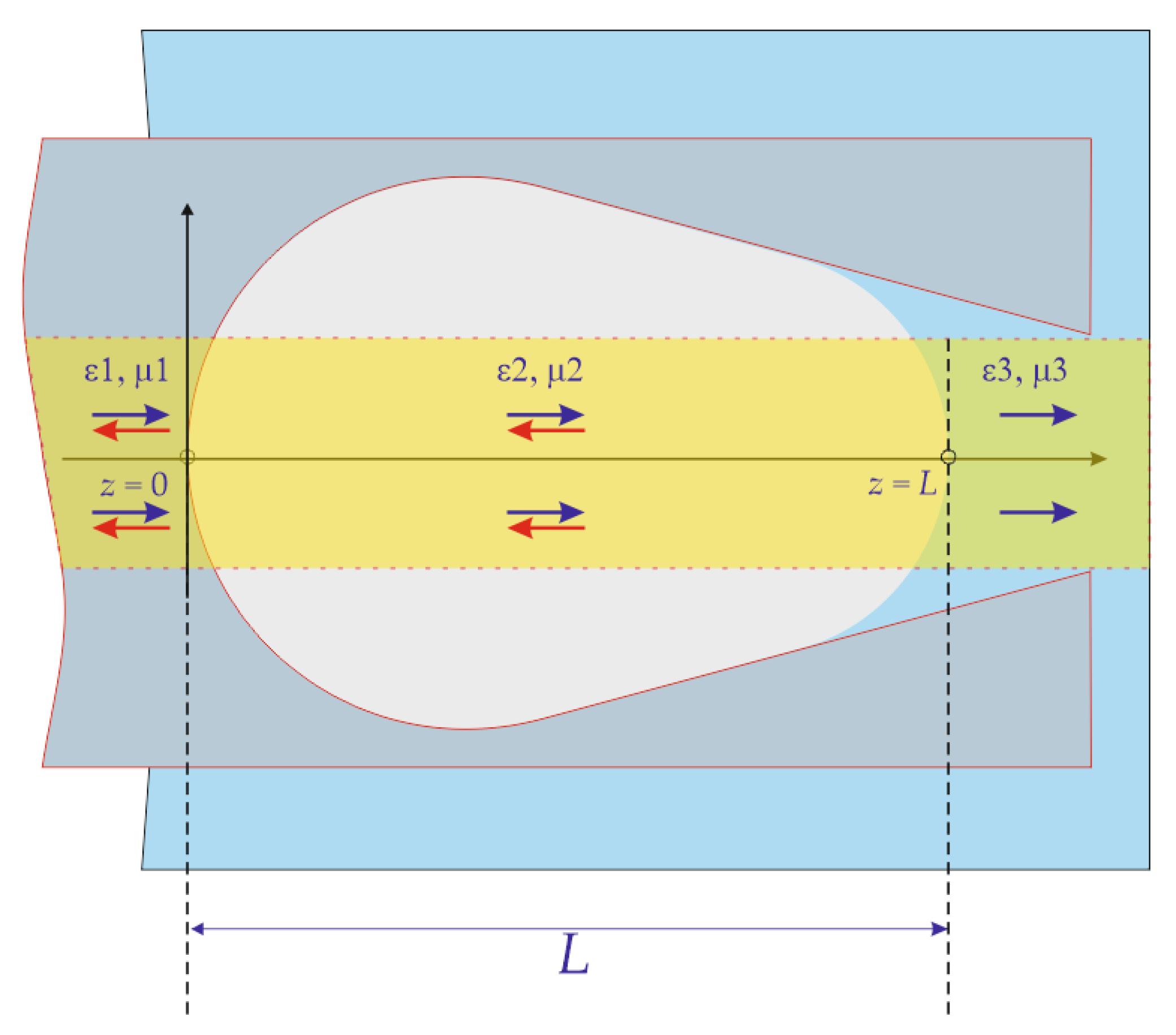

3. Mathematical Model of the Sensor

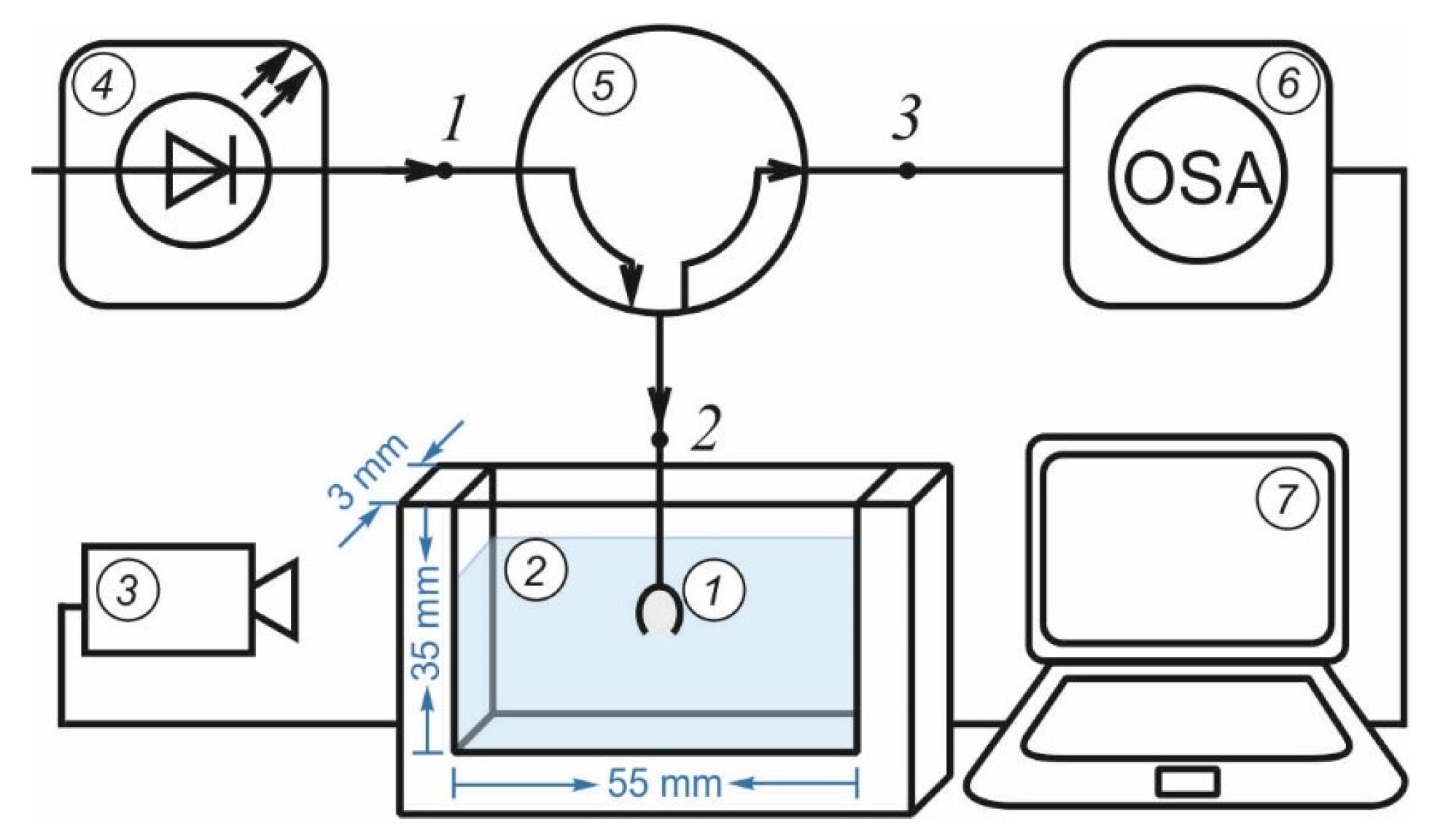

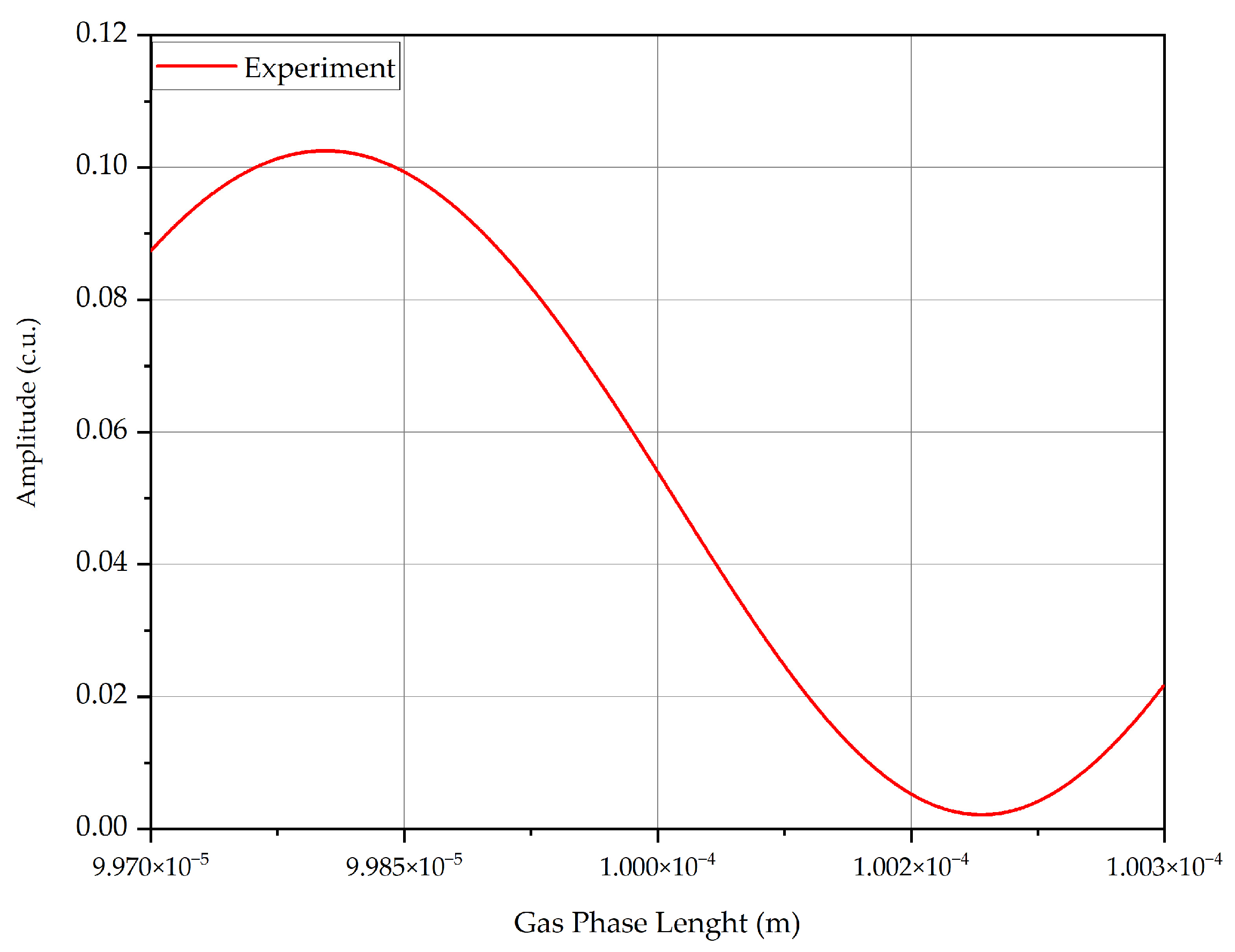

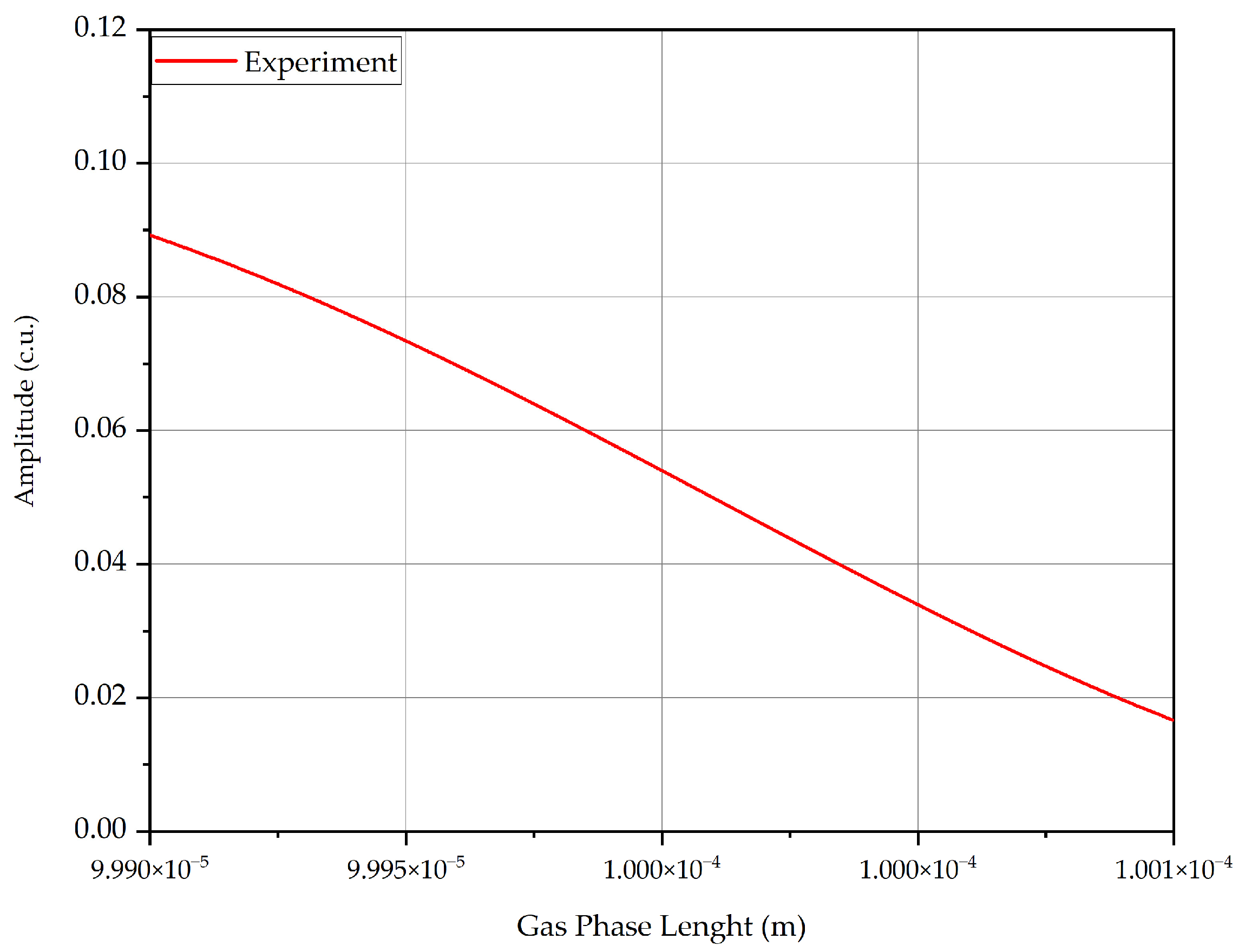

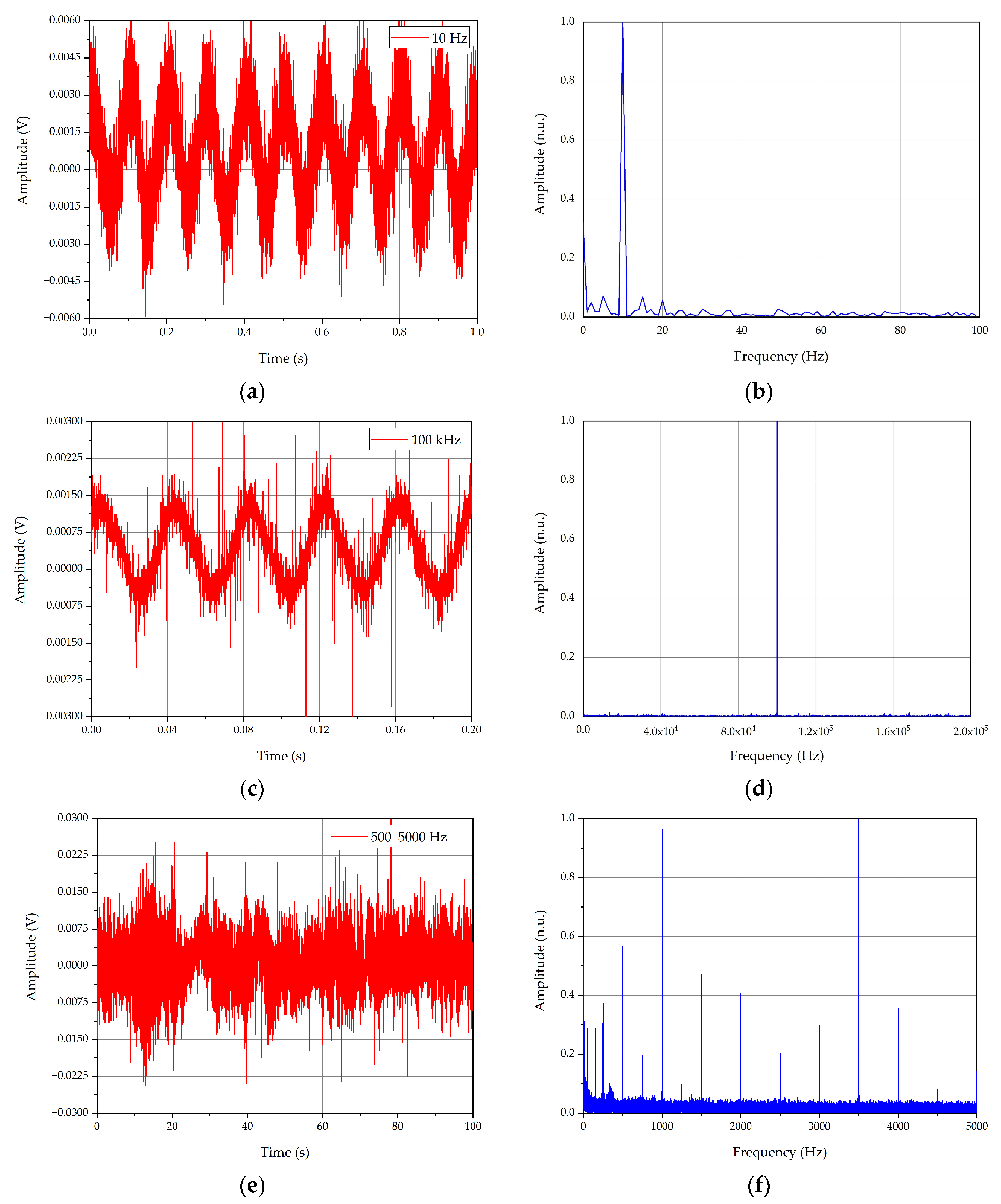

4. Detection of Acoustic Waves in a Liquid

5. Discussion

- The experiment satisfactorily verifies the mathematical model.

- The effect of sensitivity to acoustic vibrations in a liquid of a proposed Fabry-Perot cavity is shown.

- It was initially demonstrated that sensitivity in a certain frequency range is qualitatively observed tens of times from launch to launch of the system, which determines further research paths. The study observed the sensor’s response to frequencies up to 100 kHz, with high repeatability.

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Fabry, C.; Pérot, A. Sur Les Franges Des Lames Minces Argentées et Leur Application à La Mesure de Petites Épaisseurs d’air. Ann. Chim. Phys. 1897, 12, 459–501. [Google Scholar]

- Gong, Y.-J.R.; Zeng-Ling, R. Yuan Fiber-Optic Fabry-Perot Sensors: An Introduction; CRC Press: Boca Raton, FL, USA, 2017; ISBN 978-1-315-12099-7. [Google Scholar]

- Islam, M.R.; Ali, M.; Lai, M.-H.; Lim, K.-S.; Ahmad, H. Chronology of Fabry-Perot Interferometer Fiber-Optic Sensors and Their Applications: A Review. Sensors 2014, 14, 7451–7488. [Google Scholar] [CrossRef] [PubMed]

- Totsu, K.; Haga, Y.; Esashi, M. Ultra-Miniature Fiber-Optic Pressure Sensor Using White Light Interferometry. J. Micromech. Microeng. 2004, 15, 71. [Google Scholar] [CrossRef]

- Wang, W.; Wu, N.; Tian, Y.; Niezrecki, C.; Wang, X. Miniature All-Silica Optical Fiber Pressure Sensor with an Ultrathin Uniform Diaphragm. Opt. Express 2010, 18, 9006–9014. [Google Scholar] [CrossRef]

- Duraibabu, D.B.; Poeggel, S.; Omerdic, E.; Capocci, R.; Lewis, E.; Newe, T.; Leen, G.; Toal, D.; Dooly, G. An Optical Fibre Depth (Pressure) Sensor for Remote Operated Vehicles in Underwater Applications. Sensors 2017, 17, 406. [Google Scholar] [CrossRef] [PubMed]

- Wang, W.; Li, F. Large-Range Liquid Level Sensor Based on an Optical Fibre Extrinsic Fabry–Perot Interferometer. Opt. Lasers Eng. 2014, 52, 201–205. [Google Scholar] [CrossRef]

- Liu, S.; Wang, Y.; Liao, C.; Wang, Y.; He, J.; Fu, C.; Yang, K.; Bai, Z.; Zhang, F. Nano Silica Diaphragm In-Fiber Cavity for Gas Pressure Measurement. Sci. Rep. 2017, 7, 787. [Google Scholar] [CrossRef]

- Cibula, E.; Ðonlagić, D. Miniature Fiber-Optic Pressure Sensor with a Polymer Diaphragm. Appl. Opt. 2005, 44, 2736–2744. [Google Scholar] [CrossRef]

- Xu, F.; Ren, D.; Shi, X.; Li, C.; Lu, W.; Lu, L.; Lu, L.; Yu, B. High-Sensitivity Fabry–Perot Interferometric Pressure Sensor Based on a Nanothick Silver Diaphragm. Opt. Lett. 2012, 37, 133–135. [Google Scholar] [CrossRef]

- Ma, J.; Jin, W.; Ho, H.L.; Dai, J.Y. High-Sensitivity Fiber-Tip Pressure Sensor with Graphene Diaphragm. Opt. Lett. 2012, 37, 2493–2495. [Google Scholar] [CrossRef]

- Cheng, L.; Wang, C.; Huang, Y.; Liang, H.; Guan, B.-O. Silk Fibroin Diaphragm-Based Fiber-Tip Fabry-Perot Pressure Sensor. Opt. Express 2016, 24, 19600–19606. [Google Scholar] [CrossRef] [PubMed]

- Luo, C.; Liu, X.; Liu, J.; Shen, J.; Li, H.; Zhang, S.; Hu, J.; Zhang, Q.; Wang, G.; Huang, M. An Optimized PDMS Thin Film Immersed Fabry-Perot Fiber Optic Pressure Sensor for Sensitivity Enhancement. Coatings 2019, 9, 290. [Google Scholar] [CrossRef]

- Wei, X.; Song, X.; Li, C.; Hou, L.; Li, Z.; Li, Y.; Ran, L. Optical Fiber Gas Pressure Sensor Based on Polydimethylsiloxane Microcavity. J. Light. Technol. 2021, 39, 2988–2993. [Google Scholar] [CrossRef]

- Cheng, X.; Dash, J.N.; Gunawardena, D.S.; Htein, L.; Tam, H.-Y. Silicone Rubber Based Highly Sensitive Fiber-Optic Fabry–Perot Interferometric Gas Pressure Sensor. Sensors 2020, 20, 4927. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Zhang, S.; Gao, H.; Xu, D.; Gao, Z.; Hou, Z.; Shen, J.; Li, C. A High Precision Fiber Optic Fabry–Perot Pressure Sensor Based on AB Epoxy Adhesive Film. Photonics 2021, 8, 581. [Google Scholar] [CrossRef]

- Zhu, C.; Chen, Y.; Zhuang, Y.; Fang, G.; Liu, X.; Huang, J. Optical Interferometric Pressure Sensor Based on a Buckled Beam With Low-Temperature Cross-Sensitivity. IEEE Trans. Instrum. Meas. 2018, 67, 950–955. [Google Scholar] [CrossRef]

- Li, J.; Jia, P.; Fang, G.; Wang, J.; Qian, J.; Ren, Q.; Xiong, J. Batch-Producible All-Silica Fiber-Optic Fabry–Perot Pressure Sensor for High-Temperature Applications up to 800 °C. Sens. Actuators A Phys. 2022, 334, 113363. [Google Scholar] [CrossRef]

- Wu, J.; Yao, M.; Xiong, F.; Zhang, A.P.; Tam, H.-Y.; Wai, P.K.A. Optical Fiber-Tip Fabry–Pérot Interferometric Pressure Sensor Based on an In Situ μ-Printed Air Cavity. J. Light. Technol. 2018, 36, 3618–3623. [Google Scholar] [CrossRef]

- Cui, Q.; Thakur, P.; Rablau, C.; Avrutsky, I.; Cheng, M.M.-C. Miniature Optical Fiber Pressure Sensor With Exfoliated Graphene Diaphragm. IEEE Sens. J. 2019, 19, 5621–5631. [Google Scholar] [CrossRef]

- Domingues, M.F.; Paixão, T.; Mesquita, E.; Alberto, N.; Antunes, P.; Varum, H.; André, P.S. Hydrostatic Pressure Sensor Based on Micro-Cavities Developed by the Catastrophic Fuse Effect. In Proceedings of the 24th International Conference on Optical Fibre Sensors, Curitiba, Brazil, 28 September 2015; SPIE: Bellingham, WA, USA, 2015; Volume 9634, pp. 737–740. [Google Scholar]

- Martins, J.; Diaz, C.A.R.; Domingues, M.F.; Ferreira, R.A.S.; Antunes, P.; André, P.S. Low-Cost and High-Performance Optical Fiber-Based Sensor for Liquid Level Monitoring. IEEE Sens. J. 2019, 19, 4882–4888. [Google Scholar] [CrossRef]

- Ferreira, L.A.; Lobo Ribeiro, A.B.; Santos, J.L.; Farahi, F. Simultaneous Measurement of Displacement and Temperature Using a Low Finesse Cavity and a Fiber Bragg Grating. IEEE Photonics Technol. Lett. 1996, 8, 1519–1521. [Google Scholar] [CrossRef]

- Bremer, K.; Lewis, E.; Leen, G.; Moss, B.; Lochmann, S.; Mueller, I.A.R. Feedback Stabilized Interrogation Technique for EFPI/FBG Hybrid Fiber-Optic Pressure and Temperature Sensors. IEEE Sens. J. 2012, 12, 133–138. [Google Scholar] [CrossRef]

- Poeggel, S.; Duraibabu, D.; Kalli, K.; Leen, G.; Dooly, G.; Lewis, E.; Kelly, J.; Munroe, M. Recent Improvement of Medical Optical Fibre Pressure and Temperature Sensors. Biosensors 2015, 5, 432–449. [Google Scholar] [CrossRef] [PubMed]

- Wang, Q.; Yu, Q. Polymer Diaphragm Based Sensitive Fiber Optic Fabry-Perot Acoustic Sensor. Chin. Opt. Lett. COL 2010, 8, 266–269. [Google Scholar] [CrossRef]

- Gong, Z.; Chen, K.; Zhou, X.; Yang, Y.; Zhao, Z.; Zou, H.; Yu, Q. High-Sensitivity Fabry-Perot Interferometric Acoustic Sensor for Low-Frequency Acoustic Pressure Detections. J. Light. Technol. 2017, 35, 5276–5279. [Google Scholar] [CrossRef]

- Xu, F.; Shi, J.; Gong, K.; Li, H.; Hui, R.; Yu, B. Fiber-Optic Acoustic Pressure Sensor Based on Large-Area Nanolayer Silver Diaghragm. Opt. Lett. 2014, 39, 2838–2840. [Google Scholar] [CrossRef] [PubMed]

- Fan, P.; Yan, W.; Lu, P.; Zhang, W.; Zhang, W.; Fu, X.; Zhang, J. High Sensitivity Fiber-Optic Michelson Interferometric Low-Frequency Acoustic Sensor Based on a Gold Diaphragm. Opt. Express 2020, 28, 25238–25249. [Google Scholar] [CrossRef]

- Wang, S.; Lu, P.; Liu, L.; Liao, H.; Sun, Y.; Ni, W.; Fu, X.; Jiang, X.; Liu, D.; Zhang, J.; et al. An Infrasound Sensor Based on Extrinsic Fiber-Optic Fabry–Perot Interferometer Structure. IEEE Photonics Technol. Lett. 2016, 28, 1264–1267. [Google Scholar] [CrossRef]

- Liu, B.; Zheng, G.; Wang, A.; Gui, C.; Yu, H.; Shan, M.; Jin, P.; Zhong, Z. Optical Fiber Fabry–Perot Acoustic Sensors Based on Corrugated Silver Diaphragms. IEEE Trans. Instrum. Meas. 2020, 69, 3874–3881. [Google Scholar] [CrossRef]

- Ma, J.; Xuan, H.; Ho, H.L.; Jin, W.; Yang, Y.; Fan, S. Fiber-Optic Fabry–Pérot Acoustic Sensor With Multilayer Graphene Diaphragm. IEEE Photonics Technol. Lett. 2013, 25, 932–935. [Google Scholar] [CrossRef]

- Ni, W.; Lu, P.; Fu, X.; Zhang, W.; Shum, P.P.; Sun, H.; Yang, C.; Liu, D.; Zhang, J. Ultrathin Graphene Diaphragm-Based Extrinsic Fabry-Perot Interferometer for Ultra-Wideband Fiber Optic Acoustic Sensing. Opt. Express 2018, 26, 20758–20767. [Google Scholar] [CrossRef] [PubMed]

- Guo, M.; Chen, K.; Yang, B.; Li, C.; Zhang, B.; Yang, Y.; Wang, Y.; Li, C.; Gong, Z.; Ma, F.; et al. Ultrahigh Sensitivity Fiber-Optic Fabry–Perot Interferometric Acoustic Sensor Based on Silicon Cantilever. IEEE Trans. Instrum. Meas. 2021, 70, 1–8. [Google Scholar] [CrossRef]

- De Fatima, F.; Domingues, M.; De Brito Paixao, T.; Mesquita, E.F.T.; Alberto, N.; Frias, A.R.; Ferreira, R.A.S.; Varum, H.; Da Costa Antunes, P.F. Liquid Hydrostatic Pressure Optical Sensor Based on Micro-Cavity Produced by the Catastrophic Fuse Effect. IEEE Sens. J. 2015, 15, 5654–5658. [Google Scholar] [CrossRef]

- Xiao, Q.; Tian, J.; Yan, P.; Li, D.; Gong, M. Exploring the Initiation of Fiber Fuse. Sci. Rep. 2019, 9, 11655. [Google Scholar] [CrossRef] [PubMed]

- Rocha, A.M.; Da Costa Antunes, P.F.; De Fatima, F.; Domingues, M.; Facao, M.; De Brito Andre, P.S. Detection of Fiber Fuse Effect Using FBG Sensors. IEEE Sens. J. 2011, 11, 1390–1394. [Google Scholar] [CrossRef]

- Antunes, P.F.C.; Domingues, M.F.F.; Alberto, N.J.; Andre, P.S. Optical Fiber Microcavity Strain Sensors Produced by the Catastrophic Fuse Effect. IEEE Photonics Technol. Lett. 2014, 26, 78–81. [Google Scholar] [CrossRef]

- Domingues, F.; Frias, A.R.; Antunes, P.; Sousa, A.O.P.; Ferreira, R.A.S.; André, P.S. Observation of Fuse Effect Discharge Zone Nonlinear Velocity Regime in Erbium-Doped Fibres. Electron. Lett. 2012, 48, 1295. [Google Scholar] [CrossRef]

- Konin, Y.A.; Scherbakova, V.A.; Bulatov, M.I.; Malkov, N.A.; Lucenko, A.S.; Starikov, S.S.; Grachev, N.A.; Perminov, A.V.; Petrov, A.A. Structural Characteristics of Internal Microcavities Produced in Optical Fiber via the Fuse Effect. J. Opt. Technol. 2021, 88, 672. [Google Scholar] [CrossRef]

- Kashyap, R. The Fiber Fuse—From a Curious Effect to a Critical Issue: A 25^th Year Retrospective. Opt. Express 2013, 21, 6422. [Google Scholar] [CrossRef]

- Kutsche, I.; Gildehaus, G.; Schuller, D.; Schumpe, A. Oxygen Solubilities in Aqueous Alcohol Solutions. J. Chem. Eng. Data 1984, 29, 286–287. [Google Scholar] [CrossRef]

- Agliullin, T.; Anfinogentov, V.; Morozov, O.; Sakhabutdinov, A.; Valeev, B.; Niyazgulyeva, A.; Garovov, Y. Comparative Analysis of the Methods for Fiber Bragg Structures Spectrum Modeling. Algorithms 2023, 16, 101. [Google Scholar] [CrossRef]

- Zhu, Y.; Kang, J.; Sang, T.; Dong, X.; Zhao, C. Hollow Fiber-Based Fabry–Perot Cavity for Liquid Surface Tension Measurement. Appl. Opt. 2014, 53, 7814–7818. [Google Scholar] [CrossRef] [PubMed]

- Tian, Y.; Xu, B.; Chen, Y.; Duan, C.; Tan, T.; Chai, Q.; Carvajal Martí, J.J.; Zhang, J.; Yang, J.; Yuan, L. Liquid Surface Tension and Refractive Index Sensor Based on a Side-Hole Fiber Bragg Grating. IEEE Photonics Technol. Lett. 2019, 31, 947–950. [Google Scholar] [CrossRef]

- Tian, Y.; Xiao, G.; Luo, Y.; Zhang, J.; Yuan, L. Microhole Fiber-Optic Sensors for Nanoliter Liquid Measurement. Opt. Fiber Technol. 2022, 72, 102981. [Google Scholar] [CrossRef]

- Turov, A.T.; Barkov, F.L.; Konstantinov, Y.A.; Korobko, D.A.; Lopez-Mercado, C.A.; Fotiadi, A.A. Activation Function Dynamic Averaging as a Technique for Nonlinear 2D Data Denoising in Distributed Acoustic Sensors. Algorithms 2023, 16, 440. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Morozov, O.; Agliullin, T.; Sakhabutdinov, A.; Kuznetsov, A.; Valeev, B.; Qaid, M.; Ponomarev, R.; Nurmuhametov, D.; Shmyrova, A.; Konstantinov, Y. Fiber-Optic Hydraulic Sensor Based on an End-Face Fabry–Perot Interferometer with an Open Cavity. Photonics 2024, 11, 22. https://doi.org/10.3390/photonics11010022

Morozov O, Agliullin T, Sakhabutdinov A, Kuznetsov A, Valeev B, Qaid M, Ponomarev R, Nurmuhametov D, Shmyrova A, Konstantinov Y. Fiber-Optic Hydraulic Sensor Based on an End-Face Fabry–Perot Interferometer with an Open Cavity. Photonics. 2024; 11(1):22. https://doi.org/10.3390/photonics11010022

Chicago/Turabian StyleMorozov, Oleg, Timur Agliullin, Airat Sakhabutdinov, Artem Kuznetsov, Bulat Valeev, Mohammed Qaid, Roman Ponomarev, Danil Nurmuhametov, Anastasia Shmyrova, and Yuri Konstantinov. 2024. "Fiber-Optic Hydraulic Sensor Based on an End-Face Fabry–Perot Interferometer with an Open Cavity" Photonics 11, no. 1: 22. https://doi.org/10.3390/photonics11010022

APA StyleMorozov, O., Agliullin, T., Sakhabutdinov, A., Kuznetsov, A., Valeev, B., Qaid, M., Ponomarev, R., Nurmuhametov, D., Shmyrova, A., & Konstantinov, Y. (2024). Fiber-Optic Hydraulic Sensor Based on an End-Face Fabry–Perot Interferometer with an Open Cavity. Photonics, 11(1), 22. https://doi.org/10.3390/photonics11010022