An Ultrabroadband and Cost-Effective Edge Coupler for Efficient Thin Film Lithium Niobate Photonics

Abstract

:1. Introduction

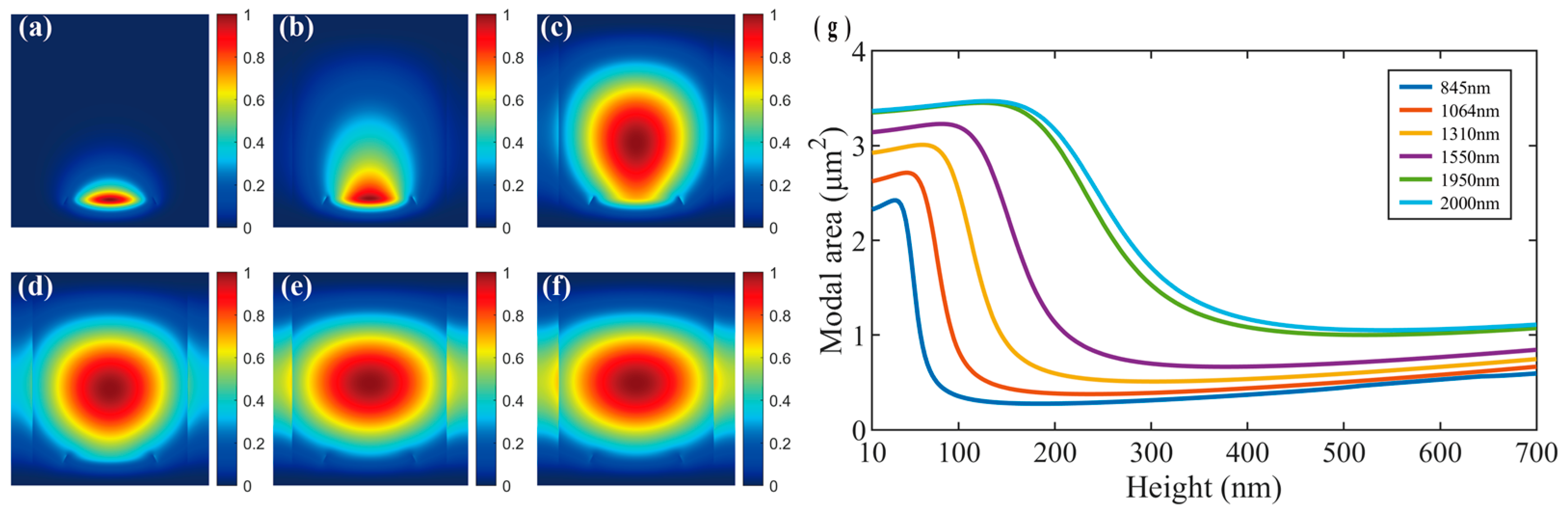

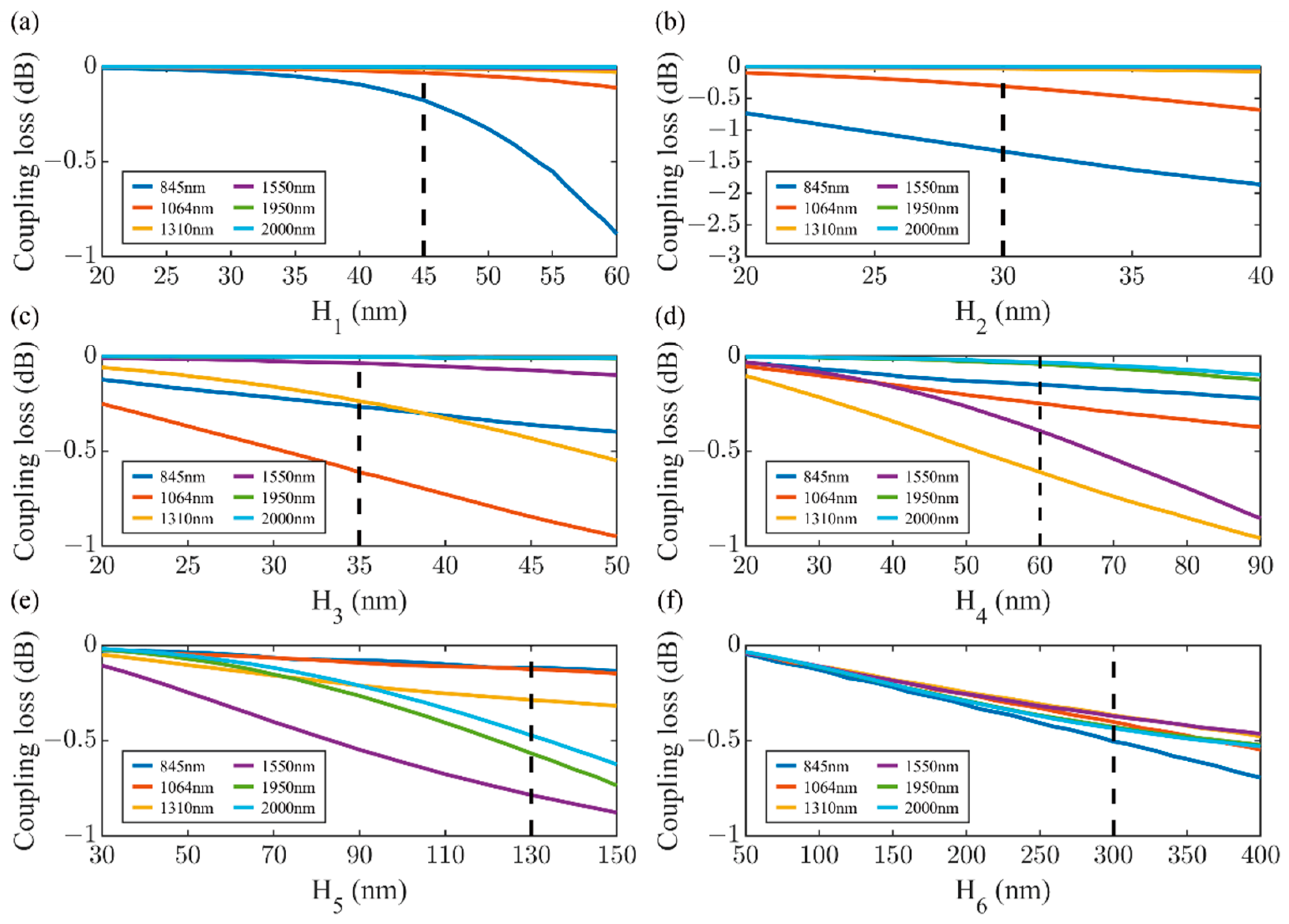

2. Principle of the Multilayer Coupler

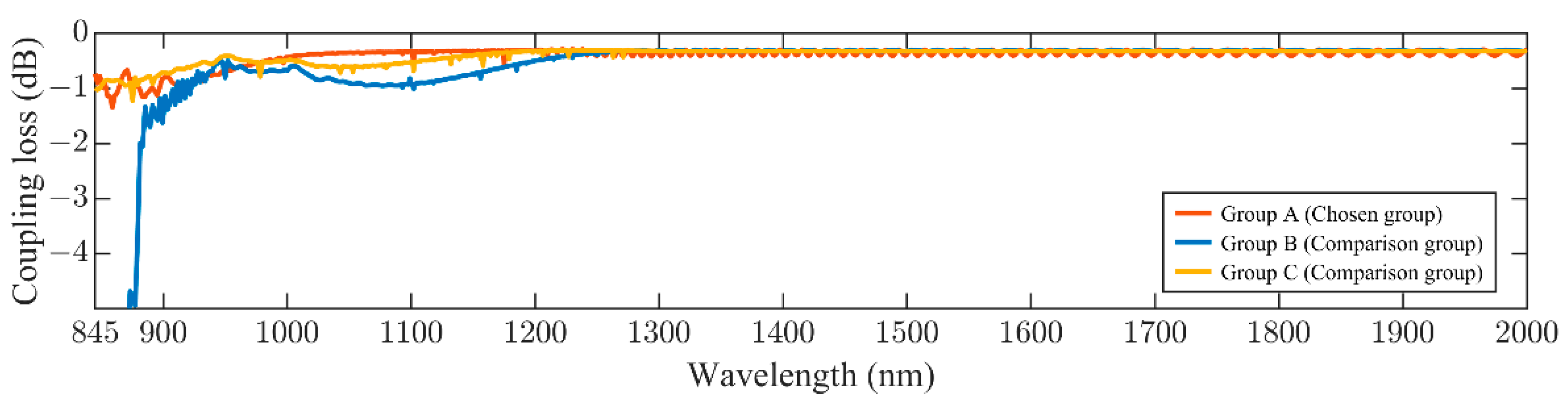

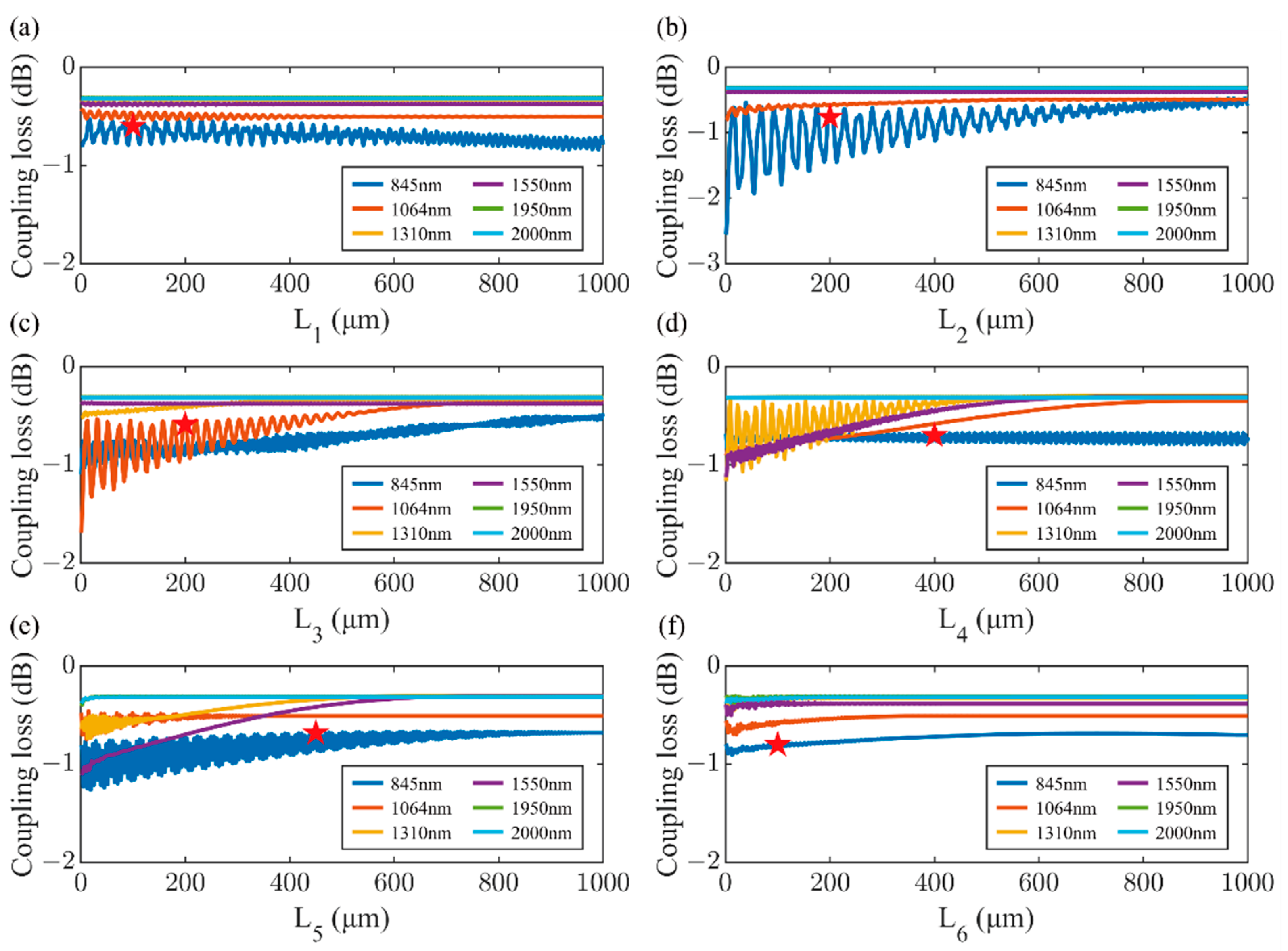

3. Simulation and Optimization

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Jalali, B.; Fathpour, S. Silicon Photonics. J. Light. Technol. 2006, 24, 4600–4615. [Google Scholar] [CrossRef]

- Leuthold, J.; Koos, C.; Freude, W. Nonlinear silicon photonics. Nat. Photonics 2010, 4, 535–544. [Google Scholar] [CrossRef]

- Xiang, C.; Jin, W.; Bowers, J.E. Silicon nitride passive and active photonic integrated circuits: Trends and prospects. Photonics Res. 2022, 10, A82–A96. [Google Scholar] [CrossRef]

- Riley, F.L. Silicon Nitride and Related Materials. J. Am. Ceram. Soc. 2000, 83, 245–265. [Google Scholar] [CrossRef]

- Adachi, S. GaAs, AlAs, and AlxGa1−xAs: Material parameters for use in research and device applications. J. Appl. Phys. 1985, 58, R1–R29. [Google Scholar] [CrossRef]

- Weis, R.; Gaylord, T. Lithium niobate: Summary of physical properties and crystal structure. Appl. Phys. A 1985, 37, 191–203. [Google Scholar] [CrossRef]

- Boes, A.; Corcoran, B.; Chang, L.; Bowers, J.; Mitchell, A. Status and potential of lithium niobate on insulator (LNOI) for photonic integrated circuits. Laser Photonics Rev. 2018, 12, 1700256. [Google Scholar] [CrossRef]

- Vazimali, M.G.; Fathpour, S. Applications of thin-film lithium niobate in nonlinear integrated photonics. Adv. Photonics 2022, 4, 034001. [Google Scholar] [CrossRef]

- Lin, J.; Bo, F.; Cheng, Y.; Xu, J. Advances in on-chip photonic devices based on lithium niobate on insulator. Photonics Res. 2020, 8, 1910–1936. [Google Scholar] [CrossRef]

- Boes, A.; Chang, L.; Langrock, C.; Yu, M.; Zhang, M.; Lin, Q.; Lončar, M.; Fejer, M.; Bowers, J.; Mitchell, A. Lithium niobate photonics: Unlocking the electromagnetic spectrum. Science 2023, 379, eabj4396. [Google Scholar] [CrossRef]

- Parameswaran, K.R.; Route, R.K.; Kurz, J.R.; Roussev, R.V.; Fejer, M.M.; Fujimura, M. Highly efficient second-harmonic generation in buried waveguides formed by annealed and reverse proton exchange in periodically poled lithium niobate. Opt. Lett. 2002, 27, 179–181. [Google Scholar] [CrossRef] [Green Version]

- Roussev, R.V.; Langrock, C.; Kurz, J.R.; Fejer, M.M. Periodically poled lithium niobate waveguide sum-frequency generator for efficient single-photon detection at communication wavelengths. Opt. Lett. 2004, 29, 1518–1520. [Google Scholar] [CrossRef] [PubMed]

- Suntsov, S.; Rüter, C.E.; Brüske, D.; Kip, D. Watt-level 775 nm SHG with 70% conversion efficiency and 97% pump depletion in annealed/reverse proton exchanged diced PPLN ridge waveguides. Opt. Express 2021, 29, 11386–11393. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Jiao, X.; Wang, B.; Liu, Y.; Xie, X.-P.; Zheng, M.-Y.; Zhang, Q.; Pan, J.-W. Quantum frequency conversion and single-photon detection with lithium niobate nanophotonic chips. NPJ Quantum Inf. 2023, 9, 38. [Google Scholar] [CrossRef]

- Wang, C.; Langrock, C.; Marandi, A.; Jankowski, M.; Zhang, M.; Desiatov, B.; Fejer, M.M.; Lončar, M. Ultrahigh-efficiency wavelength conversion in nanophotonic periodically poled lithium niobate waveguides. Optica 2018, 5, 1438–1441. [Google Scholar] [CrossRef] [Green Version]

- Chen, J.-Y.; Ma, Z.-H.; Sua, Y.M.; Li, Z.; Tang, C.; Huang, Y.-P. Ultra-efficient frequency conversion in quasi-phase-matched lithium niobate microrings. Optica 2019, 6, 1244–1245. [Google Scholar] [CrossRef]

- Lu, J.; Surya, J.B.; Liu, X.; Bruch, A.W.; Gong, Z.; Xu, Y.; Tang, H.X. Periodically poled thin-film lithium niobate microring resonators with a second-harmonic generation efficiency of 250,000%/W. Optica 2019, 6, 1455–1460. [Google Scholar] [CrossRef] [Green Version]

- Zhao, J.; Rüsing, M.; Javid, U.A.; Ling, J.; Li, M.; Lin, Q.; Mookherjea, S. Shallow-etched thin-film lithium niobate waveguides for highly-efficient second-harmonic generation. Opt. Express 2020, 28, 19669–19682. [Google Scholar] [CrossRef]

- Niu, Y.; Lin, C.; Liu, X.; Chen, Y.; Hu, X.; Zhang, Y.; Cai, X.; Gong, Y.-X.; Xie, Z.; Zhu, S. Optimizing the efficiency of a periodically poled LNOI waveguide using in situ monitoring of the ferroelectric domains. Appl. Phys. Lett. 2020, 116, 101104. [Google Scholar] [CrossRef]

- Park, T.; Stokowski, H.S.; Ansari, V.; McKenna, T.P.; Hwang, A.Y.; Fejer, M.; Safavi-Naeini, A.H. High-efficiency second harmonic generation of blue light on thin-film lithium niobate. Opt. Lett. 2022, 47, 2706–2709. [Google Scholar] [CrossRef]

- Wu, X.; Zhang, L.; Hao, Z.; Zhang, R.; Ma, R.; Bo, F.; Zhang, G.; Xu, J. Broadband second-harmonic generation in step-chirped periodically poled lithium niobate waveguides. Opt. Lett. 2022, 47, 1574–1577. [Google Scholar] [CrossRef] [PubMed]

- Lin, J.; Yao, N.; Hao, Z.; Zhang, J.; Mao, W.; Wang, M.; Chu, W.; Wu, R.; Fang, Z.; Qiao, L. Broadband quasi-phase-matched harmonic generation in an on-chip monocrystalline lithium niobate microdisk resonator. Phys. Rev. Lett. 2019, 122, 173903. [Google Scholar] [CrossRef] [PubMed]

- Huang, Z.; Luo, K.; Feng, Z.; Zhang, Z.; Li, Y.; Qiu, W.; Guan, H.; Xu, Y.; Li, X.; Lu, H. Resonant enhancement of second harmonic generation in etchless thin film lithium niobate heteronanostructure. Sci. China Phys. Mech. Astron. 2022, 65, 104211. [Google Scholar] [CrossRef]

- Wang, C.; Zhang, M.; Stern, B.; Lipson, M.; Lončar, M. Nanophotonic lithium niobate electro-optic modulators. Opt. Express 2018, 26, 1547–1555. [Google Scholar] [CrossRef] [Green Version]

- Wang, C.; Zhang, M.; Chen, X.; Bertrand, M.; Shams-Ansari, A.; Chandrasekhar, S.; Winzer, P.; Lončar, M. Integrated lithium niobate electro-optic modulators operating at CMOS-compatible voltages. Nature 2018, 562, 101–104. [Google Scholar] [CrossRef]

- He, M.; Xu, M.; Ren, Y.; Jian, J.; Ruan, Z.; Xu, Y.; Gao, S.; Sun, S.; Wen, X.; Zhou, L.; et al. High-performance hybrid silicon and lithium niobate Mach–Zehnder modulators for 100 Gbit s−1 and beyond. Nat. Photonics 2019, 13, 359–364. [Google Scholar] [CrossRef] [Green Version]

- Zhang, M.; Buscaino, B.; Wang, C.; Shams-Ansari, A.; Reimer, C.; Zhu, R.; Kahn, J.M.; Lončar, M. Broadband electro-optic frequency comb generation in a lithium niobate microring resonator. Nature 2019, 568, 373–377. [Google Scholar] [CrossRef] [Green Version]

- Pelc, J.S.; Yu, L.; De Greve, K.; McMahon, P.L.; Natarajan, C.M.; Esfandyarpour, V.; Maier, S.; Schneider, C.; Kamp, M.; Höfling, S.; et al. Downconversion quantum interface for a single quantum dot spin and 1550-nm single-photon channel. Opt. Express 2012, 20, 27510–27519. [Google Scholar] [CrossRef] [Green Version]

- Yu, Y.; Ma, F.; Luo, X.-Y.; Jing, B.; Sun, P.-F.; Fang, R.-Z.; Yang, C.-W.; Liu, H.; Zheng, M.-Y.; Xie, X.-P.; et al. Entanglement of two quantum memories via fibres over dozens of kilometres. Nature 2020, 578, 240–245. [Google Scholar] [CrossRef]

- Yao, N.; Yao, Q.; Xie, X.-P.; Liu, Y.; Xu, P.; Fang, W.; Zheng, M.-Y.; Fan, J.; Zhang, Q.; Tong, L. Optimizing up-conversion single-photon detectors for quantum key distribution. Opt. Express 2020, 28, 25123–25133. [Google Scholar] [CrossRef]

- Chen, Z.; Wang, Y.; Zhang, H.; Hu, H. Silicon grating coupler on a lithium niobate thin film waveguide. Opt. Mater. Express 2018, 8, 1253–1258. [Google Scholar] [CrossRef]

- Jian, J.; Xu, P.; Chen, H.; He, M.; Wu, Z.; Zhou, L.; Liu, L.; Yang, C.; Yu, S. High-efficiency hybrid amorphous silicon grating couplers for sub-micron-sized lithium niobate waveguides. Opt. Express 2018, 26, 29651–29658. [Google Scholar] [CrossRef]

- Krasnokutska, I.; Chapman, R.J.; Tambasco, J.-L.J.; Peruzzo, A. High coupling efficiency grating couplers on lithium niobate on insulator. Opt. Express 2019, 27, 17681–17685. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ruan, Z.; Hu, J.; Xue, Y.; Liu, J.; Chen, B.; Wang, J.; Chen, K.; Chen, P.; Liu, L. Metal based grating coupler on a thin-film lithium niobate waveguide. Opt. Express 2020, 28, 35615–35621. [Google Scholar] [CrossRef] [PubMed]

- Kang, S.; Zhang, R.; Hao, Z.; Jia, D.; Gao, F.; Bo, F.; Zhang, G.; Xu, J. High-efficiency chirped grating couplers on lithium niobate on insulator. Opt. Lett. 2020, 45, 6651–6654. [Google Scholar] [CrossRef]

- Liu, Y.; Huang, X.; Li, Z.; Guan, H.; Wei, Q.; Fan, Z.; Han, W.; Li, Z. Efficient grating couplers on a thin film lithium niobate-silicon rich nitride hybrid platform. Opt Lett 2020, 45, 6847–6850. [Google Scholar] [CrossRef]

- Han, X.; Jiang, Y.; Frigg, A.; Xiao, H.; Zhang, P.; Boes, A.; Nguyen, T.G.; Yang, J.; Ren, G.; Su, Y.; et al. Single-step etched grating couplers for silicon nitride loaded lithium niobate on insulator platform. APL Photonics 2021, 6, 086108. [Google Scholar] [CrossRef]

- Chen, B.; Ruan, Z.; Fan, X.; Wang, Z.; Liu, J.; Li, C.; Chen, K.; Liu, L. Low-loss fiber grating coupler on thin film lithium niobate platform. APL Photonics 2022, 7, 076103. [Google Scholar] [CrossRef]

- He, L.; Zhang, M.; Shams-Ansari, A.; Zhu, R.; Wang, C.; Marko, L. Low-loss fiber-to-chip interface for lithium niobate photonic integrated circuits. Opt. Lett. 2019, 44, 2314–2317. [Google Scholar] [CrossRef]

- Krasnokutska, I.; Tambasco, J.J.; Peruzzo, A. Nanostructuring of LNOI for efficient edge coupling. Opt. Express 2019, 27, 16578–16585. [Google Scholar] [CrossRef] [Green Version]

- Hu, C.; Pan, A.; Li, T.; Wang, X.; Liu, Y.; Tao, S.; Zeng, C.; Xia, J. High-efficient coupler for thin-film lithium niobate waveguide devices. Opt. Express 2021, 29, 5397–5406. [Google Scholar] [CrossRef]

- Ying, P.; Tan, H.; Zhang, J.; He, M.; Xu, M.; Liu, X.; Ge, R.; Zhu, Y.; Liu, C.; Cai, X. Low-loss edge-coupling thin-film lithium niobate modulator with an efficient phase shifter. Opt. Lett. 2021, 46, 1478–1481. [Google Scholar] [CrossRef] [PubMed]

- Deng, J.Y.; Wang, M.K.; Ma, X.X.; Li, H.J.; Wu, J.Y.; Chen, K.X. Spot-Size Converter Based on Long-Period Grating. IEEE Photonics J. 2022, 14, 1–5. [Google Scholar] [CrossRef]

- Liu, X.; Gao, S.; Zhang, C.; Pan, Y.; Ma, R.; Zhang, X.; Liu, L.; Xie, Z.; Zhu, S.; Yu, S. Ultra-broadband and low-loss edge coupler for highly efficient second harmonic generation in thin-film lithium niobate. Adv. Photonics Nexus 2022, 1, 16001. [Google Scholar] [CrossRef]

- Yang, P.; Sun, S.; Xue, H.; Zheng, Q.; He, H.; Meng, X.; Liu, F.; Cao, L. Efficient and scalable edge coupler based on silica planar lightwave circuits and lithium niobate thin films. Opt. Laser Technol. 2023, 158, 108867. [Google Scholar] [CrossRef]

- He, L.; Feng, H.; Wang, C.; Chan, H.P. Cost-effective fiber-to-lithium niobate chip coupling using a double-side irradiation self-written waveguide. Opt. Lett. 2023, 48, 283–286. [Google Scholar] [CrossRef]

- Wang, M.K.; Li, J.H.; Yao, H.; Long, Y.J.; Zhang, F.; Chen, K.X. A Cost-Effective Edge Coupler With High Polarization Selectivity for Thin Film Lithium Niobate Modulators. J. Light. Technol. 2022, 40, 1105–1111. [Google Scholar] [CrossRef]

- Zhu, X.; Li, G.; Wang, X.; Li, Y.; Davidson, R.; Little, B.E.; Chu, S.T. Low-loss fiber-to-chip edge coupler for silicon nitride integrated circuits. Opt. Express 2023, 31, 10525–10532. [Google Scholar] [CrossRef] [PubMed]

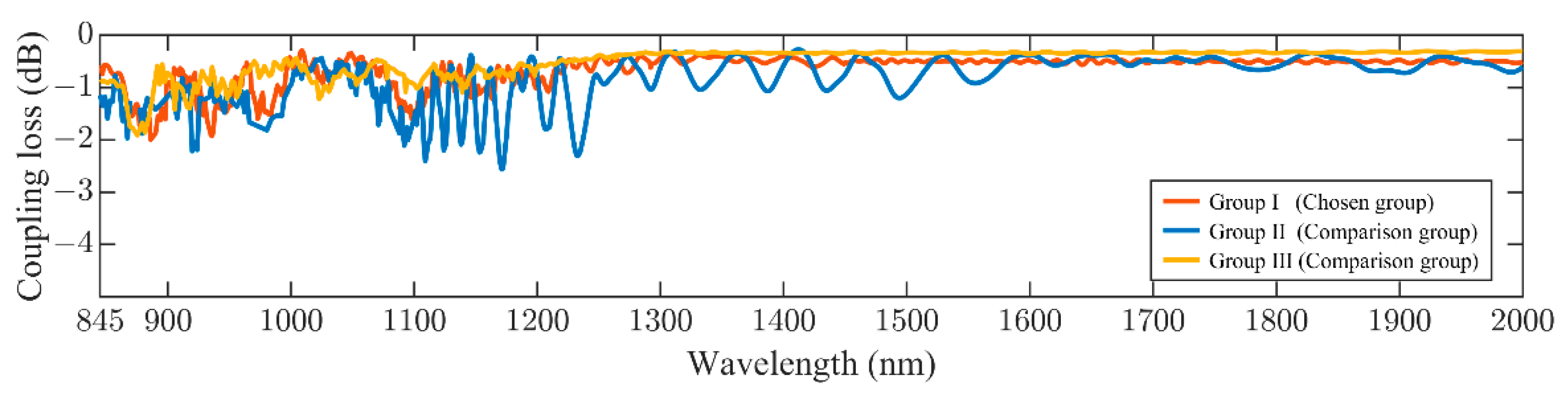

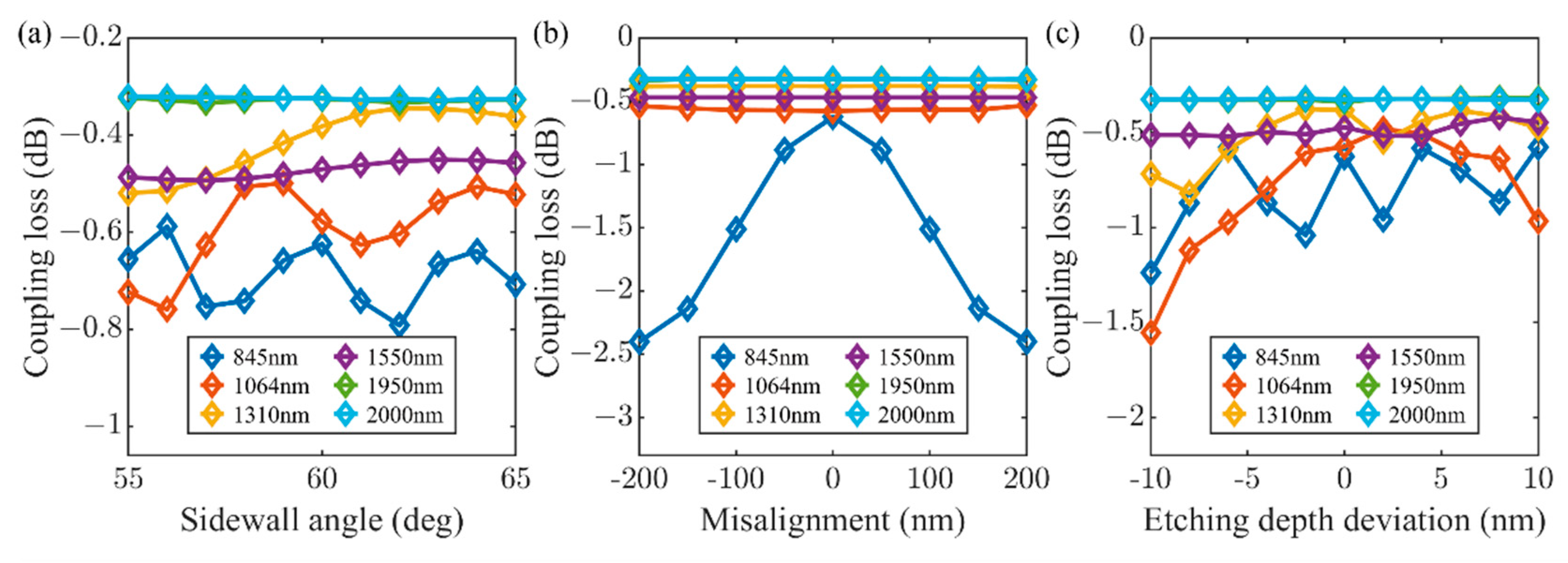

| Parameters | H1 (nm) | H2 (nm) | H3 (nm) | H4 (nm) | H5 (nm) | H6 (nm) | H7 (nm) |

|---|---|---|---|---|---|---|---|

| Group A (Chosen group) | 45 | 30 | 35 | 60 | 130 | 300 | - |

| Group B (Comparison group) | 50 | 50 | 70 | 130 | 300 | - | - |

| Group C (Comparison group) | 40 | 30 | 30 | 50 | 100 | 100 | 250 |

| Parameters | L1 (μm) | L2 (μm) | L3 (μm) | L4 (μm) | L5 (μm) | L6 (μm) | Ltotal (μm) |

|---|---|---|---|---|---|---|---|

| Group I (Chosen group) | 100 | 200 | 200 | 400 | 450 | 100 | 1450 |

| Group II (Comparison group) | 60 | 120 | 160 | 200 | 200 | 200 | 60 |

| Group III (Comparison group) | 100 | 280 | 300 | 500 | 600 | 120 | 1900 |

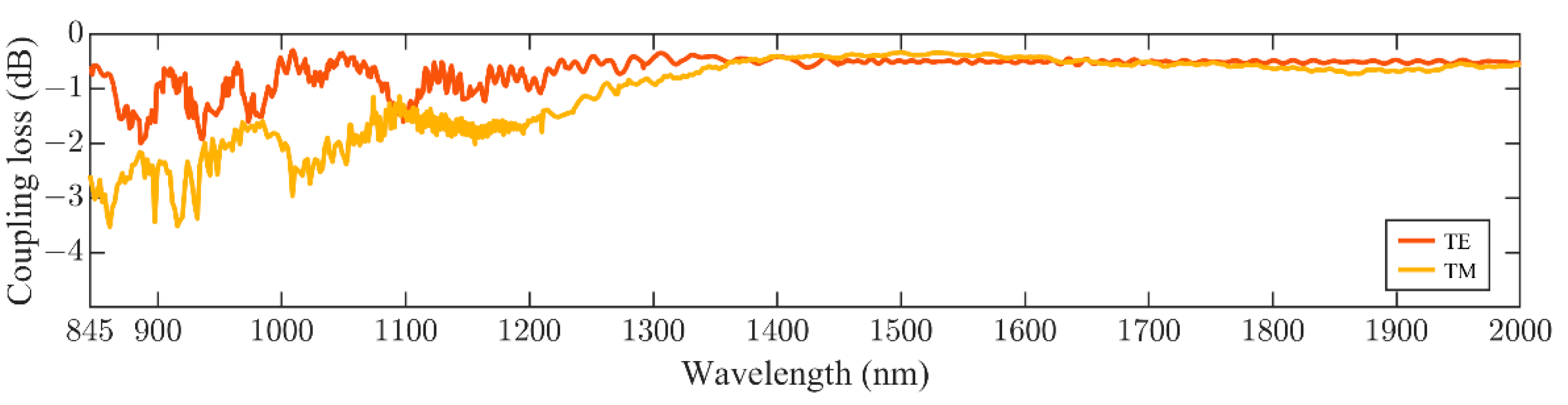

| Structure | Coupling Loss for TE (dB/Facet) | Coupling Loss for TM (dB/Facet) | Coupling Bandwidth for TE (nm) | Wafer-Scale Fabrication | ||

|---|---|---|---|---|---|---|

| Simulation | Experiment | Simulation | Experiment | |||

| Bilayer [39] | 0.5 @ 1550 nm a | 1.7 @ 1550 nm a | - | - | - | No |

| Bilayer [41] | 0.07 @ 1550 nm a | 0.54 @ 1550 nm | 0.06 @ 1550 nm a | 0.59 @ 1550 nm | 100 nm (CL < 1 dB/facet) c | No |

| Bilayer [42] | 0.1 @ 1550 nm a | 0.5 @ 1550 nm a | - | - | 35 nm (CL< 1.7 dB/facet) a,c | No |

| Tri-layers [44] | 1.0 @ 775 nm 0.5 @ 1550 nm | 3.0 @ 775 nm 1.0 @ 1550 nm | 7.0 @ 775 nm 3.0 @ 1550 nm | - | - | No |

| Multi- Layers [47] | 1.6 @ 1550 nm b | - | - | - | 120 nm (CL < 2 dB/facet) a,b | Yes |

| Multi- Layers (This work) | 0.62 @ 845 nm b 0.47 @ 1550 nm b | - | 0.38 @ 1550 nm b | - | 800 nm (CL < 1 dB/facet) b | Yes |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, H.; Ma, F.; Chen, K.; Dong, J. An Ultrabroadband and Cost-Effective Edge Coupler for Efficient Thin Film Lithium Niobate Photonics. Photonics 2023, 10, 760. https://doi.org/10.3390/photonics10070760

Chen H, Ma F, Chen K, Dong J. An Ultrabroadband and Cost-Effective Edge Coupler for Efficient Thin Film Lithium Niobate Photonics. Photonics. 2023; 10(7):760. https://doi.org/10.3390/photonics10070760

Chicago/Turabian StyleChen, Houhong, Fei Ma, Ke Chen, and Jianwen Dong. 2023. "An Ultrabroadband and Cost-Effective Edge Coupler for Efficient Thin Film Lithium Niobate Photonics" Photonics 10, no. 7: 760. https://doi.org/10.3390/photonics10070760

APA StyleChen, H., Ma, F., Chen, K., & Dong, J. (2023). An Ultrabroadband and Cost-Effective Edge Coupler for Efficient Thin Film Lithium Niobate Photonics. Photonics, 10(7), 760. https://doi.org/10.3390/photonics10070760