High Power Ytterbium-Doped Fiber Lasers Employing Longitudinal Vary Core Diameter Active Fibers

Abstract

1. Introduction

2. Basic Concept of Vary Core Diameter Ytterbium-Doped Fiber

2.1. Classification of Vary Core Diameter Ytterbium-Doped Fiber

2.2. Advantages of VCAF

2.2.1. High Nonlinear Effect Threshold

2.2.2. Good Mode Control Ability

2.2.3. Excellent ASE Inhibition

2.3. Fabrication Process of VCAF

2.3.1. Preform Form Control Method

2.3.2. Variable-Speed Drawing Method

2.3.3. Combination of Preform Form Control and Variable-Speed Drawing Method

3. Simulation of SRS and TMI Characteristics of VCAF

3.1. SRS in VCAF- and CCAF-Based Fiber Laser Oscillator

3.2. Theoretical Comparison of TMI in Fiber Laser Amplifier Based on VCAF and CCAF

4. Experimental Study on High-Power CW Fiber Laser Based on VCAF

4.1. Fiber Laser Based on TF with Constant Core-to-Cladding Ratio (TF-CCCR)

4.1.1. High-Power Fiber Laser Oscillator Based on TF-CCCR

4.1.2. High-Power Fiber Laser Amplifier Based on TF-CCCR

4.1.3. Summary

4.2. Fiber Laser Based on SAF

4.2.1. Fiber Laser Oscillator Based on SAF with Tapered Core and Constant Cladding

4.2.2. Fiber Laser Amplifier Based on SAF with Tapered Core and Constant Cladding

4.2.3. Summary

4.3. Fiber Laser Based on SPF

4.3.1. Fiber Laser Employing SPF with Constant Core-to-Cladding Ratio (SPF-CCCR)

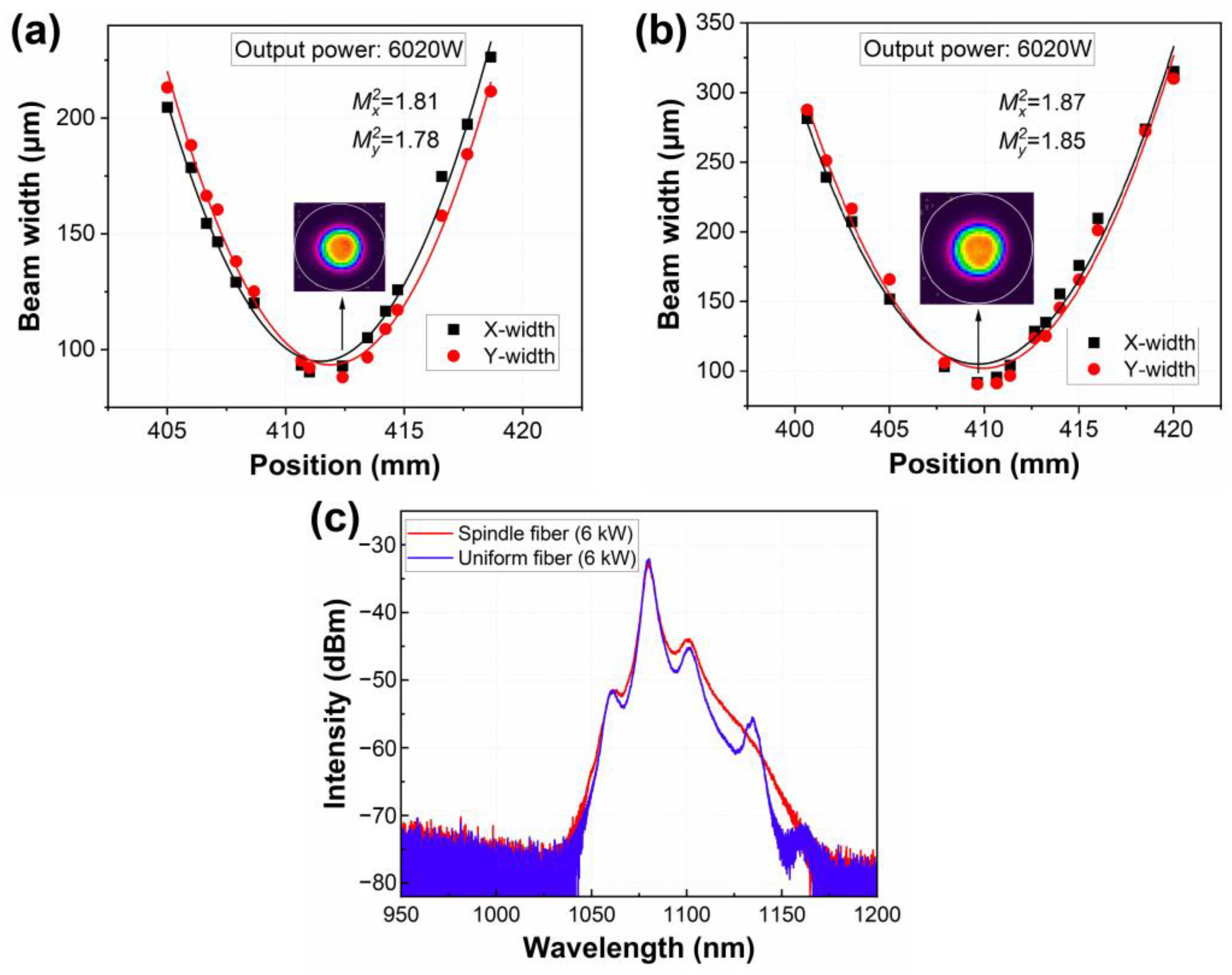

4.3.2. Fiber Laser Based on SPF with Constant Cladding Diameter (SPF-CCD)

4.3.3. Comparison of SRS of Fiber Laser Amplifier Based on SPF-CCCR and CCAF

4.3.4. Comparison of TMI of Fiber Laser Amplifier Based on SPF-CCD and CCAF

4.3.5. Summary

5. Application of VCAF in Novel Fiber Lasers

5.1. Quasi-Continuous Wave Fiber Laser Based on TF and SPF

5.1.1. Peak Power of 6.4 kW for QCW Fiber Laser Based on TF-CCCR

5.1.2. Peak Power of 7.3 kW for QCW Fiber Laser Based on SPF-CCCR

5.2. Optimization of Output Characteristics of Oscillating–Amplifying Integrated Fiber Laser Employing SPF-CCCR

5.3. Bidirectional-Output Fiber Laser Oscillator (2 × 3 kW) Based on SPF-CCCR

5.4. Summary

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Jauregui, C.; Limpert, J.; Tünnermann, A. High-power fibre lasers. Nat. Photonics 2013, 7, 861–867. [Google Scholar] [CrossRef]

- Zuo, J.; Lin, X. High-Power Laser Systems. Laser Photonics Rev. 2022, 16, 2100741. [Google Scholar] [CrossRef]

- Wang, Y.; Rintaro, K.; Kiyoyama, W.; Shirakura, Y.; Kurihara, T.; Nakanishi, Y.; Yamamoto, T.; Nakayama, M.; Ikoma, S.; Shima, K. 8-kW single-stage all-fiber Yb-doped fiber laser with a BPP of 0.50 mm-mrad. In Proceedings of the Fiber Lasers XVII: Technology and Systems, San Francisco, CA, USA, 1–6 February 2020. [Google Scholar]

- Lin, H.; Xu, L.; Li, C.; Shu, Q.; Chu, Q.; Xie, L.; Guo, C.; Zhao, P.; Li, Z.; Wang, J.; et al. 10.6 kW high-brightness cascade-end-pumped monolithic fiber lasers directly pumped by laser diodes in step-index large mode area double cladding fiber. Results Phys. 2019, 14, 102479. [Google Scholar] [CrossRef]

- Yang, B.; Wang, P.; Zhang, H.; Xi, X.; Shi, C.; Wang, X.; Xu, X. 6 kW single mode monolithic fiber laser enabled by effective mitigation of the transverse mode instability. Opt. Express 2021, 29, 26366. [Google Scholar] [CrossRef]

- Ackermann, M.; Rehmann, G.; Lange, R.; Witte, U.; Safarzadeh, F.; Boden, B.; Weber, H.; Netz, D.; Perne, C.; Kösters, A.; et al. Extraction of more than 10 kW from a single ytterbium-doped MM-fiber. In Proceedings of the Fiber Lasers XVI: Technology and Systems, San Francisco, CA, USA, 2–7 February 2019. [Google Scholar]

- Wen, Y.; Wang, P.; Xi, X.; Zhang, H.; Huang, L.; Yang, H.; Yan, Z.; Yang, B.; Shi, C.; Pan, Z.; et al. LD Direct Counter-Pumped 10 kW Fiber Laser Amplifier with Good Beam Quality. Acta Phys. Sin. 2022, 71, 2442202. [Google Scholar] [CrossRef]

- Eidam, T.; Hanf, S.; Seise, E.; Andersen, T.V.; Gabler, T.; Wirth, C.; Schreiber, T.; Limpert, J.; Tunnermann, A. Femtosecond fiber CPA system emitting 830 W average output power. Opt. Lett. 2010, 35, 94–96. [Google Scholar] [CrossRef] [PubMed]

- Smith, A.V.; Smith, J.J. Mode instability in high power fiber amplifiers. Opt. Express 2011, 19, 10180–10192. [Google Scholar] [CrossRef] [PubMed]

- Zervas, M.N. Transverse mode instability, thermal lensing and power scaling in Yb3+-doped high-power fiber amplifiers. Opt. Express 2019, 27, 19019–19041. [Google Scholar] [CrossRef] [PubMed]

- Jauregui, C.; Stihler, C.; Limpert, J. Transverse mode instability. Adv. Opt. Photonics 2020, 12, 429–484. [Google Scholar] [CrossRef]

- Rezaei-Nasirabad, R.; Azizi, S.; Paygan, D.; Tavassoli, M.; Abedinajafi, A.; Roohforouz, A.; Chenar, R.E.; Golshan, A.H.; Hejaz, K.; Vatani, V. 2.5 kW TMI-free co-pump Yb-doped fiber oscillator by 971.5 nm pumping wavelength. Opt. Laser Technol. 2023, 157, 108652. [Google Scholar] [CrossRef]

- Wan, Y.; Yang, B.; Xi, X.; Zhang, H.; Wang, P.; Wang, X.; Xu, X. Comparison and Optimization on Transverse Mode Instability of Fiber Laser Amplifier Pumped by Wavelength-Stabilized and Non-Wavelength-Stabilized 976 nm Laser Diode. IEEE Photonics J. 2022, 14, 1–5. [Google Scholar] [CrossRef]

- Wan, Y.; Xi, X.; Yang, B.; Zhang, H.; Wang, X. Enhancement of TMI Threshold in Yb-Doped Fiber Laser by Optimizing Pump Wavelength. IEEE Photonics Technol. Lett. 2021, 33, 656–659. [Google Scholar] [CrossRef]

- Tao, R.; Ma, P.; Wang, X.; Zhou, P.; Liu, Z. Mitigating of modal instabilities in linearly-polarized fiber amplifiers by shifting pump wavelength. J. Opt. 2015, 17, 45504. [Google Scholar] [CrossRef]

- Roohforouz, A.; Chenar, R.E.; Azizi, S.; Abad, R.R.N.; Hejaz, K.; Najafi, A.A.; Vatani, V.; Nabavi, S.H. Effect of pumping configuration on the transverse mode instability power threshold in a 3.02 kW fiber laser oscillator. In Proceedings of the Advanced Solid State Lasers, Vienna, Austria, 29 September–3 October 2019. [Google Scholar]

- Shi, C.; Su, R.T.; Zhang, H.W.; Yang, B.L.; Wang, X.L.; Zhou, P.; Xu, X.J.; Lu, Q.S. Experimental Study of Output Characteristics of Bi-Directional Pumping High Power Fiber Amplifier in Different Pumping Schemes. IEEE Photonics J. 2017, 9, 1–10. [Google Scholar] [CrossRef]

- Jauregui, C.; Otto, H.; Breitkopf, S.; Limpert, J.; Tünnermann, A. Optimizing high-power Yb-doped fiber amplifier systems in the presence of transverse mode instabilities. Opt. Express 2016, 24, 7879–7892. [Google Scholar] [CrossRef]

- Sanjabi Eznaveh, Z.; López-Galmiche, G.; Antonio-López, E.; Amezcua Correa, R.; Shaw, L.B. Bi-directional pump configuration for increasing thermal modal instabilities threshold in high power fiber amplifiers. In Proceedings of the Fiber Lasers XII: Technology, Systems, and Applications, San Francisco, CA, USA, 7–12 February 2015. [Google Scholar]

- Luo, X.; Tao, R.; Shi, C.; Zhang, H.; Wang, X.; Zhou, P.; Xu, X. Power of all-fiber amplifier increasing from 1030 W to 2280 W through suppressing mode instability by increasing the seed power. Chin. Phys. B 2019, 28, 24208. [Google Scholar] [CrossRef]

- Tao, R.; Wang, X.; Zhou, P.; Liu, Z. Seed power dependence of mode instabilities in high-power fiber amplifiers. J. Opt 2017, 19, 65202. [Google Scholar] [CrossRef]

- Ma, X.; Zhu, C.; Hu, I.; Kaplan, A.; Galvanauskas, A. Single-mode chirally-coupled-core fibers with larger than 50µm diameter cores. Opt. Express 2014, 22, 9206–9219. [Google Scholar] [CrossRef]

- Stutzki, F.; Jansen, F.; Eidam, T.; Steinmetz, A.; Jauregui, C.; Limpert, J.; Tunnermann, A. High average power large-pitch fiber amplifier with robust single-mode operation. Opt. Lett. 2011, 36, 689–691. [Google Scholar] [CrossRef]

- Hejaz, K.; Norouzey, A.; Poozesh, R.; Heidariazar, A.; Roohforouz, A.; Rezaei Nasirabad, R.; Tabatabaei Jafari, N.; Hamedani Golshan, A.; Babazadeh, A.; Lafouti, M. Controlling mode instability in a 500 W ytterbium-doped fiber laser. Laser Phys. 2014, 24, 25102. [Google Scholar] [CrossRef]

- Huang, Z.; Shu, Q.; Luo, Y.; Tao, R.; Feng, X.; Liu, Y.; Lin, H.; Wang, J.; Jing, F. 3.5 kW narrow-linewidth monolithic fiber amplifier at 1064 nm by employing a confined doping fiber. J. Opt. Soc. Am. B 2021, 38, 2945–2952. [Google Scholar] [CrossRef]

- Zhang, F.; Wang, Y.; Lin, X.; Cheng, Y.; Zhang, Z.; Liu, Y.; Liao, L.; Xing, Y.; Yang, L.; Dai, N.; et al. Gain-tailored Yb/Ce codoped aluminosilicate fiber for laser stability improvement at high output power. Opt. Express 2019, 27, 20824–20836. [Google Scholar] [CrossRef] [PubMed]

- Liao, L.; Zhang, F.; He, X.; Chen, Y.; Wang, Y.; Li, H.; Peng, J.; Yang, L.; Dai, N.; Li, J. Confined-doped fiber for effective mode control fabricated by MCVD process. Appl. Opt. Opt. Technol. Biomed. Opt. 2018, 57, 3244–3249. [Google Scholar] [CrossRef] [PubMed]

- Yuan, M.; Sui, Y.; Bai, Z.; Fan, Z. Recent Advances in Chirally-Coupled Core Fibers. Front. Phys. 2022, 10, 950492. [Google Scholar] [CrossRef]

- Hochheim, S.; Brockmuller, E.; Wessels, P.; Koponen, J.; Lowder, T.; Novotny, S.; Willke, B.; Neumann, J.; Kracht, D. Single-Frequency 336 W Spliceless All-Fiber Amplifier Based on a Chirally-Coupled-Core Fiber for the Next Generation of Gravitational Wave Detectors. J. Light. Technol. 2022, 40, 2136–2143. [Google Scholar] [CrossRef]

- Zhan, H.; Liu, Q.; Wang, Y.; Ke, W.; Ni, L.; Wang, X.; Peng, K.; Gao, C.; Li, Y.; Lin, H.; et al. 5kW GTWave fiber amplifier directly pumped by commercial 976nm laser diodes. Opt. Express 2016, 24, 27087–27095. [Google Scholar] [CrossRef]

- Filippov, V.; Chamorovskii, Y.; Kerttula, J.; Golant, K.; Pessa, M.; Okhotnikov, O.G. Double clad tapered fiber for high power applications. Opt. Express 2008, 16, 1929–1944. [Google Scholar] [CrossRef]

- Trikshev, A.I.; Kurkov, A.S.; Tsvetkov, V.B.; Filatova, S.A.; Kertulla, J.; Filippov, V.; Chamorovskiy, Y.K.; Okhotnikov, O.G. A 160 W single-frequency laser based on an active tapered double-clad fiber amplifier. Laser Phys. Lett. 2013, 10, 65101. [Google Scholar] [CrossRef]

- Zhou, Z.; Zhang, H.; Wang, X.; Pan, Z.; Su, R.; Yang, B.; Zhou, P.; Xu, X. All-fiber-integrated single frequency tapered fiber amplifier with near diffraction limited output. J. Opt. 2016, 18, 65504. [Google Scholar] [CrossRef]

- Pierre, C.; Guiraud, G.; Vincont, C.; Traynor, N.; Santarelli, G.; Boullet, J. 120W single frequency laser based on short active double clad tapered fiber. In Proceedings of the European Conference on Lasers and Electro-Optics 2017, Munich, Germany, 25–29 June 2017. [Google Scholar]

- Noronen, T.; Fedotov, A.; Rissanen, J.; Gumenyuk, R.; Butov, O.; Chamorovskii, Y.; Golant, K.; Odnoblyudov, M.; Filippov, V.; Hartl, I.; et al. Ultra-large mode area single frequency anisotropic MOPA with double clad Yb-doped tapered fiber. In Proceedings of the Fiber Lasers XV: Technology and Systems, San Francisco, CA, USA, 27 January–1 February 2018. [Google Scholar]

- Huang, L.; Zhou, Z.; Shi, C.; Tao, R.; Ma, P.; Wang, X.; Zhou, P. Towards tapered-fiber-based all-fiberized high power narrow linewidth fiber laser. Sci. China. Technol. Sci. 2018, 61, 971–981. [Google Scholar] [CrossRef]

- Lai, W.; Ma, P.; Liu, W.; Huang, L.; Li, C.; Ma, Y.; Zhou, P. 550 W single frequency fiber amplifiers emitting at 1030 nm based on a tapered Yb-doped fiber. Opt. Express 2020, 28, 20908–20919. [Google Scholar] [CrossRef] [PubMed]

- Huang, L.; Lai, W.; Ma, P.; Wang, J.; Su, R.; Ma, Y.; Li, C.; Zhi, D.; Zhou, P. Tapered Yb-doped fiber enabled monolithic high-power linearly polarized single-frequency laser. Opt. Lett. 2020, 45, 4001–4004. [Google Scholar] [CrossRef] [PubMed]

- Kerttula, J.; Filippov, V.; Chamorovskii, Y.; Golant, K.; Okhotnikov, O.G. Actively Q-switched 1.6-mJ tapered double-clad ytterbium-doped fiber laser. Opt. Express 2010, 18, 18543–18549. [Google Scholar] [CrossRef] [PubMed]

- Gumenyuk, R.; Filippov, V.; Vorotinskii, A.; Okhotnikov, O.G.; Chamorovskii, Y.; Golant, K. All-fiber, high-power, picosecond Yb double clad tapered fiber amplifier. In Proceedings of the 2014 International Conference Laser Optics, St. Petersburg, Russia, 30 June–4 July 2014. [Google Scholar]

- Koptev, M.Y.; Anashkina, E.A.; Bobkov, K.K.; Likhachev, M.E.; Levchenko, A.E.; Aleshkina, S.S.; Semjonov, S.L.; Denisov, A.N.; Bubnov, M.M.; Lipatov, D.S.; et al. Fibre amplifier based on an ytterbium-doped active tapered fibre for the generation of megawatt peak power ultrashort optical pulses. Quantum Electron. 2015, 45, 443–450. [Google Scholar] [CrossRef]

- Mu, X.; Steinvurzel, P.; Belden, P.; Rose, T.; Lotshaw, W.; Beck, S. Nanosecond-Pulsed, mJ-Level Single-Mode Fiber Master Oscillator Power Amplifier with Polarization Maintaining Tapered Gain Fiber. In Proceedings of the Lasers Congress 2016 (ASSL, LSC, LAC), Boston, MA, USA, 30 October–3 November 2016; OSA: Washington, DC, USA, 2016. [Google Scholar]

- Roy, V.; Paré, C.; Labranche, B.; Laperle, P.; Desbiens, L.; Boivin, M.; Taillon, Y.; Robin, C.A.; Hartl, I. Yb-doped large mode area tapered fiber with depressed cladding and dopant confinement. In Proceedings of the Fiber Lasers XIV: Technology and Systems, San Francisco, CA, USA, 28 January–2 February 2017. [Google Scholar]

- Zhu, Y.; Lorenz, M.; Leich, M.; Grimm, S.; Aichele, C.; Kobelke, J.; Bartelt, H.; Jager, M. Laser peak power scaling and beam quality improvement with a tapered ytterbium rod-type amplifier made by powder sinter technology. In Proceedings of the The European Conference on Lasers and Electro-Optics 2017, Munich, Germany, 25–29 June 2017. [Google Scholar]

- Zhu, Y.; Eschrich, T.; Leich, M.; Grimm, S.; Kobelke, J.; Lorenz, M.; Bartelt, H.; Jäger, M. Yb3+-doped rod-type amplifiers with local adiabatic tapers for peak power scaling and beam quality improvement. Laser Phys. 2017, 27, 105103. [Google Scholar] [CrossRef]

- Filippov, V.; Vorotynskii, A.; Noronen, T.; Gumenyuk, R.; Chamorovskii, Y.; Golant, K.; Robin, C.A.; Hartl, I. Picosecond MOPA with ytterbium doped tapered double clad fiber. In Proceedings of the Fiber Lasers XIV: Technology and Systems, San Francisco, CA, USA, 28 January–2 February 2017. [Google Scholar]

- Bobkov, K.; Andrianov, A.; Koptev, M.; Muravyev, S.; Levchenko, A.; Velmiskin, V.; Aleshkina, S.; Semjonov, S.; Lipatov, D.; Guryanov, A.; et al. Sub-MW peak power diffraction-limited chirped-pulse monolithic Yb-doped tapered fiber amplifier. Opt. Express 2017, 25, 26958–26972. [Google Scholar] [CrossRef]

- Noronen, T.; Gumenyuk, R.; Chamorovskii, Y.; Golant, K.; Odnoblyudov, M.; Filippov, V. Ultrafast picosecond MOPA With Yb-doped tapered double clad fiber. In Proceedings of the 2017 Conference on Lasers and Electro Optics Europe & European Quantum lectronics Conference (CLEO/Europe-EQEC), Munich, Germany, 25–29 June 2017. [Google Scholar]

- Bobkov, K.; Levchenko, A.; Aleshkina, S.; Semenov, S.; Denisov, A.; Bubnov, M.; Lipatov, D.; Laptev, A.; Guryanov, A.; Likhachev, M. 1.5 MW peak power diffraction limited monolithic Yb-doped tapered fiber amplifier. In Proceedings of the 2017 Conference on Lasers and Electro-Optics Europe & European Quantum Electronics Conference (CLEO/Europe-EQEC), Munich, Germany, 25–29 June 2017. [Google Scholar]

- Noronen, T.; Gumenyuk, R.; Chamorovskii, Y.; Golant, K.; Odnoblyudov, M.; Filippov, V. Anisotropic Ultra-Large Mode Area Yb-doped Tapered Double Clad Fiber For Ultrafast Amplifiers. In Proceedings of the Laser Congress 2017 (ASSL, LAC), Nagoya, Aichi, Japan, 1–5 October 2017. [Google Scholar]

- Fedotov, A.; Noronen, T.; Gumenyuk, R.; Ustimchik, V.; Chamorovskii, Y.; Golant, K.; Odnoblyudov, M.; Rissanen, J.; Niemi, T.; Filippov, V. Ultra-large core birefringent Yb-doped tapered double clad fiber for high power amplifiers. Opt. Express 2018, 26, 6581–6592. [Google Scholar] [CrossRef]

- Khudyakov, M.M.; Levchenko, A.E.; Velmiskin, V.V.; Bobkov, K.K.; Lipatov, D.S.; Guryanov, A.N.; Bubnov, M.M.; Likhachev, M.E.; Likhachev, B.A.M.E. 107-kW-Peak-Power 2-ns Pulse Tapered Er-doped Fiber Amplifier. In Proceedings of the 2018 International Conference Laser Optics (ICLO), St. Petersburg, Russia, 4–8 June 2018. [Google Scholar]

- Huang, L.; Lai, W.; Su, R.; Ma, P.; Jiang, M.; Wu, J.; Ma, Y.; Zhou, P. Monolithic Linearly Polarized Nanosecond Fiber Laser with Record Peak Power and Near-Transform-Limited Linewidth. In Proceedings of the 18th International Conference on Optical Communications and Networks, Huangshan, China, 5–8 August 2019. [Google Scholar]

- Bobkov, K.K.; Levchenko, A.E.; Velmiskin, V.V.; Kochergina, T.A.; Aleshkina, S.S.; Bubnov, M.M.; Lipatov, D.S.; Guryanov, A.N.; Likhachev, M.E. High Peak and Average Power Yb-Doped Tapered Fiber Amplifier. In Proceedings of the CLEO: Sci-ence and Innovations 2019, San Jose, CA, USA, 5–10 May 2019. [Google Scholar]

- Rissanen, J.; Fedotov, A.; Noronen, T.; Gumenyuk, R.; Chamorovskiy, Y.; Kolosovskii, A.; Voloshin, V.; Vorobev, I.; Odnoblyudov, M.; Filippov, V.; et al. Large-mode-area double clad ytterbium-doped tapered fiber with circular birefringence. In Proceedings of the Fiber Lasers XVI: Technology and Systems, San Francisco, CA, USA, 4–7 February 2019. [Google Scholar]

- Andrianov, A.V.; Koptev, M.Y.; Anashkina, E.A.; Muravyev, S.V.; Kim, A.V.; Lipatov, D.S.; Velmiskin, V.V.; Levchenko, A.E.; Bubnov, M.M.; Likhachev, M.E. Tapered erbium-doped fibre laser system delivering 10 MW of peak power. Quantum Electron. 2019, 49, 1093–1099. [Google Scholar] [CrossRef]

- Bobkov, K.K.; Likhachev, M.E.; Levchenko, A.E.; Velmiskin, V.V.; Kochergina, T.A.; Aleshkina, S.S.; Bubnov, M.M.; Lipatov, D.S.; Laptev, A.Y.; Guryanov, A.N. 71 W Average Power Sub-MW Peak Power Diffraction-Limited Monolithic Tapered Fiber Amplifier. In Proceedings of the 2019 Conference on Lasers and Electro-Optics Europe & European Quantum Electronics Conference (CLEO/Europe-EQEC), Munich, Germany, 23–27 June 2019. [Google Scholar]

- Leich, M.; Kalide, A.; Eschrich, T.; Lorenz, M.; Lorenz, A.; Wondraczek, K.; Schönfeld, D.; Langner, A.; Schötz, G.; Jäger, M. 2 MW peak power generation in fluorine co-doped Yb fiber prepared by powder-sinter technology. Opt. Lett. 2020, 45, 4404–4407. [Google Scholar] [CrossRef]

- Petrov, A.; Odnoblyudov, M.; Gumenyuk, R.; Minyonok, L.; Chumachenko, A.; Filippov, V. Picosecond Yb-doped tapered fiber laser system with 1.26 MW peak power and 200 W average output power. Sci. Rep. 2020, 10, 17781. [Google Scholar] [CrossRef]

- Guesmi, K.; Mugnier, A.; Canat, G.; Canal, C.; Maine, P.; Zervas, M.N.; Jauregui-Misas, C. Simple design for high energy femtosecond tapered double clad fiber amplifier. In Proceedings of the Fiber Lasers XVIII: Technology and Systems, Online Only, 6–11 March 2021. [Google Scholar]

- Scol, F.; Bouwmans, G.; Hugonnot, E. High-energy, narrow-linewidth, flat-top temporal profile nanosecond-pulses from ytterbium-doped tapered fiber amplifier with chirped-diode seeding. OSA Contin. 2021, 4, 1162–1169. [Google Scholar] [CrossRef]

- Petrov, A.; Mikhailovsky, G.; Gorbatchev, A.; Odnoblyudov, M.; Kozlyakov, M.; Rissanen, J.; Gumenyuk, R.; Filippov, V.; Zervas, M.N.; Jauregui-Misas, C. High-power and pulse energy picosecond narrow linewidth laser system based on tapered fiber amplifier for second harmonic generation. In Proceedings of the Fiber Lasers XVIII: Technology and Systems, Online Only, 6–11 March 2021. [Google Scholar]

- Zhu, Y.; Leich, M.; Lorenz, M.; Eschrich, T.; Aichele, C.; Kobelke, J.; Bartelt, H.; Jäger, M. Yb-doped large mode area fiber for beam quality improvement using local adiabatic tapers with reduced dopant diffusion. Opt. Express 2018, 26, 17034–17043. [Google Scholar] [CrossRef] [PubMed]

- Filippov, V.; Chamorovskii, Y.; Kerttula, J.; Kholodkov, A.; Okhotnikov, O.G. Single-mode 212 W tapered fiber laser pumped by a low-brightness source. Opt. Lett. 2008, 33, 1416–1418. [Google Scholar] [CrossRef]

- Filippov, V.; Chamorovskii, Y.; Kerttula, J.; Kholodkov, A.; Okhotnikov, O.G. 600 W power scalable single transverse mode tapered double-clad fiber laser. Opt. Express 2009, 17, 1203–1214. [Google Scholar] [CrossRef] [PubMed]

- Filippova, V.; Chamorovskiib, Y.; Kerttula, J.; Kholodkov, A.; Okhotnikova, O.G. High-power single-mode tapered double-clad ytterbium fiber laser pumped by diode-laser bar. In Proceedings of the Fiber Lasers VI: Technology, Systems, and Applications, San Jose, CA, USA, 24–29 January 2009. [Google Scholar]

- Filippov, V.; Kerttula, J.; Chamorovskii, Y.; Golant, K.; Okhotnikov, O.G. Highly efficient 750 W tapered double-clad ytterbium fiber laser. Opt. Express 2010, 18, 12499–12512. [Google Scholar] [CrossRef]

- Lin, X.; Zhang, Z.; Chu, Y.; Wang, Y.; Xing, Y.; Chen, G.; Peng, J.; Li, H.; Dai, N.; Li, J. Fabrication and laser performance of cladding uniform core tapered fiber. Opt. Fiber Technol. 2021, 64, 102561. [Google Scholar] [CrossRef]

- Lin, X.; Ye, Y.; Zhang, Z.; Wang, X.; Xing, Y.; Chen, G.; Peng, J.; Li, H.; Dai, N.; Li, J. 2.7 kW co-pumped fiber amplifier based on constant-cladding tapered-core fiber. Opt. Fiber Technol. 2022, 68, 102773. [Google Scholar] [CrossRef]

- Zeng, L.; Xi, X.; Ye, Y.; Zhang, H.; Wang, X.; Pan, Z.; Wang, Z.; Xu, X. Near-single-mode 3 kW monolithic fiber oscillator based on a longitudinally spindle-shaped Yb-doped fiber. Opt. Lett. 2020, 45, 5792–5795. [Google Scholar] [CrossRef]

- Zeng, L.; Xi, X.; Ye, Y.; Lin, X.; Wang, X.; Li, J.; Shi, C.; Yang, B.; Zhang, H.; Wang, P.; et al. A novel fiber laser oscillator employing saddle-shaped core ytterbium-doped fiber. Appl. Phys. B 2020, 126, 185. [Google Scholar] [CrossRef]

- Ye, Y.; Lin, X.; Xi, X.; Shi, C.; Yang, B.; Zhang, H.; Wang, X.; Li, J.; Xu, X. Novel constant-cladding tapered-core ytterbium-doped fiber for high-power fiber laser oscillator. High Power Laser Sci. 2021, 9, 142–148. [Google Scholar] [CrossRef]

- Ye, Y.; Lin, X.; Xi, X.; Zhang, H.; Yang, B.; Shi, C.; Wang, X.; Li, J.; Xu, X. Demonstration of constant-cladding tapered-core Yb-doped fiber for mitigating thermally-induced mode instability in high-power monolithic fiber amplifiers. Opt. Express 2022, 30, 24936–24947. [Google Scholar] [CrossRef] [PubMed]

- An, Y.; Yang, H.; Xiao, H.; Chen, X.; Huang, L.; Pan, Z.; Wang, X.; Xi, X.; Ma, P.; Wang, Z. 4-kW single-mode laser output using homemade double-tapered fiber. Chin. J. Lasers 2020, 1, 115002. [Google Scholar]

- Song, J.; Ren, S.; Wang, G.; Yang, H.; Chen, Y.; Ma, P.; Liu, W.; Huang, L.; Pan, Z.; Zhou, P. High power narrow-linewidth fiber laser based on double-tapered fiber. J. Light. Technol. 2022, 40, 5668–5672. [Google Scholar] [CrossRef]

- Zhang, Z.; Lin, X.; Zhang, X.; Luo, Y.; Liao, S.; Wang, X.; Chen, G.; Xing, Y.; Li, H.; Peng, J.; et al. Low-numerical aperture confined-doped long-tapered Yb-doped silica fiber for a single-mode high-power fiber amplifier. Opt. Express 2022, 30, 32333–32346. [Google Scholar] [CrossRef]

- Zeng, L.; Yang, H.; Xi, X.; Ye, Y.; Huang, L.; Yang, B.; Zhang, H.; Yan, Z.; Wang, X.; Pan, Z.; et al. Optimization and demonstration of 6 kW oscillating-amplifying integrated fiber laser employing spindle-shaped fiber to suppress SRS and TMI. Opt. Laser Technol. 2023, 159, 108903. [Google Scholar] [CrossRef]

- Kerttula, J.; Filippov, V.; Chamorovskii, Y.; Ustimchik, V.; Golant, K.; Okhotnikov, O.G. Tapered fiber amplifier with high gain and output power. Laser Phys. 2012, 22, 1734–1738. [Google Scholar] [CrossRef]

- Filippov, V.; Chamorovskii, Y.K.; Golant, K.M.; Vorotynskii, A.; Okhotnikov, O.G.; Ballato, J. Optical Amplifiers and Lasers Based on Tapered Fiber Geometry for Power and Energy Scaling with Low Signal Distortion. In Proceedings of the Fiber Lasers XIII: Technology, Systems, and Applications, San Francisco, CA, USA, 13–18 February 2016. [Google Scholar]

- Shi, C.; Zhang, H.; Wang, X.; Zhou, P.; Xu, X. kW-class high power fiber laser enabled by active long tapered fiber. High Power Laser Sci. 2018, 6, 1–5. [Google Scholar] [CrossRef]

- Zhang, H.; Yang, B.; Wang, X.; Shi, C.; Zhou, P.; Xu, X. High Power All-Fiberized Oscillator Based on Tapered Fiber. In Proceedings of the Conference on Lasers and Electro-Optics/Pacific Rim 2018, Hong Kong, China, 29 July–3 August 2018. [Google Scholar]

- Patokoski, K.; Rissanen, J.; Noronen, T.; Gumenyuk, R.; Chamorovskii, Y.; Filippov, V.; Toivonen, J. Single-frequency 100 ns/05 mJ laser pulses from all-fiber double clad ytterbium doped tapered fiber amplifier. Opt. Express 2019, 27, 31532–31541. [Google Scholar] [CrossRef]

- Huang, L.; Ma, P.; Su, R.; Lai, W.; Ma, Y.; Zhou, P. Comprehensive investigation on the power scaling of a tapered Yb-doped fiber-based monolithic linearly polarized high-peak-power near-transform-limited nanosecond fiber laser. Opt. Express 2021, 29, 761–782. [Google Scholar] [CrossRef]

- Yang, B.; Zhang, H.; Shi, C.; Wang, X.; Pan, Z.; Wang, Z.; Zhou, P.; Xu, X. High power monolithic tapered ytterbium-doped fiber laser oscillator. Opt. Express 2019, 27, 7585–7592. [Google Scholar] [CrossRef]

- Ye, Y.; Xi, X.; Shi, C.; Yang, B.; Wang, X.; Zhang, H.; Zhou, P.; Xu, X. Comparative study on transverse mode instability of fiber amplifiers based on long tapered fiber and conventional uniform fiber. Laser Phys. Lett. 2019, 16, 85109. [Google Scholar] [CrossRef]

- Fedotov, A.; Ustimchik, V.; Chamorovskii, Y.; Gumenyuk, R.; Filippov, V. Low-birefringence Active Tapered Fibers for High-power Applications. In Proceedings of the Specialty Optical Fibers 2020, Washington, DC, USA, 13–16 July 2020. [Google Scholar]

- Zeng, L.; Xi, X.; Ye, Y.; Wang, X.; Yang, B.; Pan, Z.; Shi, C.; Zhang, H.; Wang, P.; Wang, Z.; et al. A 1.8 kW fiber laser oscillator employing a section of spindle-shaped core ytterbium-doped fiber. Laser Phys. Lett. 2020, 17, 95104. [Google Scholar] [CrossRef]

- Ye, Y.; Lin, X.; Xi, X.; Zeng, L.; Yang, B.; Zhang, H.; Wang, X.; Li, J.; Xu, X. 2 kW monolithic fiber amplifier based on constant-cladding tapered-core Yb-doped fiber. In Proceedings of the 24th National Laser Conference & Fifteenth National Conference on Laser Technology and Optoelectronics, Shanghai, China, 17–20 October 2020. [Google Scholar]

- Fedotov, A.; Ustimchik, V.; Rissanen, J.; Kolosovskii, A.; Voloshin, V.; Vorob Ev, I.; Gumenyuk, R.; Chamorovskiy, Y.; Filippov, V. Active tapered double-clad fiber with low birefringence. Opt. Express 2021, 29, 16506–16519. [Google Scholar] [CrossRef] [PubMed]

- Fedotov, A.; Ustimchik, V.; Rissanen, J.; Noronen, T.; Gumenyuk, R.; Chamorovskii, Y.; Kolosovskii, A.; Voloshin, V.; Vorob’Ev, I.; Filippov, V.; et al. Large mode area double-clad ytterbium-doped tapered fiber with low birefringence. In Proceedings of the Fiber Lasers XVIII: Technology and Systems, Online Only, 6–12 March 2021. [Google Scholar]

- Bobkov, K.K.; Aleshkina, S.S.; Khudyakov, M.M.; Lipatov, D.S.; Likhachev, M.E.; Kalli, K.; Mendez, A.; Peterka, P. Active tapered fibers for high peak power fiber lasers. In Proceedings of the SPIE Optics + Optoelectronics, Online Only, 19–30 April 2021. [Google Scholar]

- Zeng, L.; Pan, Z.; Xi, X.; Yang, H.; Ye, Y.; Huang, L.; Zhang, H.; Wang, X.; Wang, Z.; Zhou, P.; et al. 5 kW monolithic fiber amplifier employing homemade spindle-shaped ytterbium-doped fiber. Opt. Lett. 2021, 46, 1393–1396. [Google Scholar] [CrossRef] [PubMed]

- Li, W.; Ma, P.; Lai, W.; Song, J.; Wang, T.; Ren, B.; Liu, W.; Zhou, P.; Si, L. Tapered active fiber simultaneously enabled 141 W high average and 1.3 MW high peak power via all-fiber and polarization-maintained picosecond amplifier. Opt. Laser Technol. 2022, 152, 108166. [Google Scholar] [CrossRef]

- Li, W.; Ma, P.; Chen, Y.; Song, J.; Lai, W.; Liu, W.; Zhou, P.; Si, L. 694 W sub-GHz polarization-maintained tapered fiber amplifier based on spectral and pump wavelength optimization. Opt. Express 2022, 30, 26875–26885. [Google Scholar] [CrossRef]

- Ye, Y.; Lin, X.; Yang, B.; Xi, X.; Shi, C.; Zhang, H.; Wang, X.; Li, J.; Xu, X. Tapered Yb-doped fiber enabled a 4 kW near-single-mode monolithic fiber amplifier. Opt. Lett. 2022, 47, 2162–2165. [Google Scholar] [CrossRef]

- Wang, L.; Zhang, H.; Wang, P.; Yang, B.; Wang, X.; Ning, Y.; Xu, X. A 6.4-kW peak power near-single-mode quasi-continuous wave fiber laser oscillator employing spindle-shaped ytterbium-doped fiber. Opt. Laser Technol. 2022, 154, 108338. [Google Scholar] [CrossRef]

- Wang, L.; Zhang, H.; Wang, P.; Yang, B.; Wang, X.; Ning, Y.; Xu, X. Theoretical and Experimental Study of High-Peak-Power High-Brightness Quasi-CW Fiber Laser. IEEE Photonics J. 2022, 14, 1–6. [Google Scholar]

- Shiraki, K.; Ohashi, M.; Tateda, M. Suppression of stimulated Brillouin scattering in a fibre by changing the core radius. Electron. Lett. 1995, 31, 668–669. [Google Scholar] [CrossRef]

- Filippov, V.; Kerttula, J.; Chamorovskii, Y.; Golant, K.; Okhotnikova, O.G. Actively Q-switched ytterbium tapered fiber laser. In Proceedings of the Fiber Lasers VIII: Technology, Systems, and Applications, San Francisco, CA, USA, 22–27 January 2011. [Google Scholar]

- Zeng, L.; Shi, C.; Xi, X.; Zhang, H.; Wang, X.; Xu, X.; Zhao, Y. Study on stimulated Raman scattering in fiber amplifier employing tapered Yb3+ doped fiber. In Proceedings of the Fifth International Symposium on Laser Interaction with Matter, Changsha, China, 11–14 November 2018. [Google Scholar]

- SeeFiberLaser. Available online: http://www.seelight.net/html/SFLaser/index.html (accessed on 1 December 2022).

- Shi, C.; Wang, X.; Zhou, P.; Xu, X.; Lu, Q. Theoretical study of mode evolution in active long tapered multimode fiber. Opt. Express 2016, 24, 19473–19490. [Google Scholar] [CrossRef] [PubMed]

- Ye, Y.; Lin, X.; Xi, X.; Zhang, H.; Wang, X.; Li, J.; Xu, X. Large mode area saddle-shaped core Yb-doped fiber enabled monolithic high-power, high-efficiency, near-diffraction-limited MOPA laser. In Proceedings of the Thirteenth International Conference on Information Optics and Photonics (CIOP 2022), Xi’an, China, 7–10 August 2022. [Google Scholar]

- Yang, B.; Zhang, H.; Shi, C.; Tao, R.; Su, R.; Ma, P.; Wang, X.; Zhou, P.; Xu, X.; Lu, Q. 3.05 kW monolithic fiber laser oscillator with simultaneous optimizations of stimulated Raman scattering and transverse mode instability. J. Opt. 2018, 20, 25802. [Google Scholar] [CrossRef]

- Hong, Z.; Wan, Y.; Xi, X.; Zhang, H.; Wang, X.; Xu, X. High-peak-power pump-modulated quasi-CW fiber laser. Appl. Opt. 2022, 61, 1826–1833. [Google Scholar] [CrossRef] [PubMed]

- Zeng, L.; Xi, X.; Zhang, H.; Yang, B.; Wang, P.; Wang, X.; Xu, X. Demonstration of the reliability of a 5-kW-level oscillating–amplifying integrated fiber laser. Opt. Lett. 2021, 46, 5778–5781. [Google Scholar] [CrossRef] [PubMed]

- Zhong, P.; Wang, L.; Yang, B.; Zhang, H.; Xi, X.; Wang, P.; Wang, X. 2 × 2 kW near-single-mode bidirectional high-power output from a single-cavity monolithic fiber laser. Opt. Lett. 2022, 47, 2806–2809. [Google Scholar] [CrossRef] [PubMed]

| Year | Fiber Type | Core/Cladding Diameter | Fiber Length | Power (Average/Peak Power) | Affiliation * | Reference |

|---|---|---|---|---|---|---|

| 2008 | TF | 5.6/174–27/834 µm | 10.5 m | 84 W @average | TUT | [31] |

| 2008 | TF | 6.5/200–27/834 µm | 12 m | 212 W @average | TUT | [64] |

| 2009 | TF | 10.8/145–65/835 µm | 24 m | 600 W @average | TUT | [65] |

| 2010 | TF | 15/160–83/880 µm | 6.3 m | 24.3 kW | TUT | [40] |

| 2010 | TF | 17.7/320–51.6/930 µm | 23.5 m | 750 W @average | TUT | [67] |

| 2012 | TF | 7.5/120–44μm/700 µm | 18 m | 110 W @average | TUT | [78] |

| 2013 | TF | 7.5/120–44/700 µm | 18 m | 160 W @average | RAS | [32] |

| 2014 | TF | 9/145–50/800 µm | 4 m | 60 W/0.4 MW | TUT | [40] |

| 2015 | TF | 10/80–45/430 µm | 2.1 m | 2.5 MW | RAS | [41] |

| 2016 | TF | 10/237.1–46.9/579.9 µm | 7 m | 53 W @average | NUDT | [33] |

| 2016 | TF | 25/250–60/600 µm | 2 m | 10.2 W/340 kW | The Aerospace Corporation | [42] |

| 2016 | TF | 13–100 µm (core diameter) | 6 m | 5 MW | TUT | [79] |

| 2017 | TF | 35/250–56/400 µm | 2.8 m | 1.5 MW | INO | [43] |

| 2017 | TF | 6.9/29–45/190 µm | 68 cm | 11.4 W/167 kW | IPHT | [44] |

| 2017 | TF | 6.5/53–56/460 µm | 60 cm | 10 W/230 kW | IPHT | [45] |

| 2017 | TF | 10/72.5–62/450 µm | 2 m | 0.76 MW 22 MW after compression | RAS | [48] |

| 2017 | TF | 18/145–100/800 µm | 4 m | 5 MW | Ampliconyx Ltd. | [48] |

| 2017 | TF | 20–67 µm (core diameter) | 2.2 m | 1.5 MW | RAS | [49] |

| 2017 | TF | 13.2/110–96/792 µm | 70 W @average | Ampliconyx Ltd. | [50] | |

| 2017 | TF | 9–22 µm (core diameter) | 2.5 m | 120 W @average | ALPhANOV | [34] |

| 2017 | TF | 35/250 to 56/400 µm | 2.8 m | 100 W @average | INO | [43] |

| 2017 | TF | 21.2/417.3–30.4/609.6 µm | 33 m | 1470 W @average | NUDT | [80] |

| 2018 | TF | 20/400–30/600 µm | 33 m | 260 W @average | NUDT | [81] |

| 2018 | TF | 13.3/110–96/792 µm | 3.6 m | 28 W/292 kW | TUT | [51] |

| 2018 | TF | 20/237.1–46.9/579.9 µm | 7.2 m | 260 W @average | NUDT | [36] |

| 2018 | TF | 22.5/90–86/350 µm | 2.5 m | 19 W/107 kW | MIPT | [52] |

| 2018 | TF | 12/53–45/200 µm | 50 cm | 15.5 W/375 kW | IPHT | [63] |

| 2019 | TF | 36/250–58/560 µm | 0.74 m | 8.8 W/30 kW | NUDT | [54] |

| 2019 | TF | 8.6/73–65/550 µm | 2.7 m | 44 W/550 kW | RAS | [55] |

| 2019 | TF | 22/75–75/256 µm | 3.2 m | 10 MW after compression | RAS | [56] |

| 2019 | TF | 7.2/57–43/344 µm | 3 m | 71 W/820 kW | RAS | [57] |

| 2019 | TF | 35/280–100/800 µm | 3.4 m | 55 W @average | Ampliconyx Ltd. | [56] |

| 2019 | TF | 17/170–49/490 µm | 1.2 m | 2.2 kW @PM, 4 kW @NPM | TU | [82] |

| 2019 | TF | 36/250–58/560 µm | 0.74 m | 8.8 W/30 kW | NUDT | [83] |

| 2019 | TF | 20/400–30/600 µm | 33 m | 1700 W @average | NUDT | [84] |

| 2019 | TF | 20/400–30/600 µm | 22 m | 2170 W @average | NUDT | [85] |

| 2020 | TF | 15/120–35/285 µm | 2.8 m | 72.5 W @average | TU | [86] |

| 2020 | TF | 10/100–50/100 µm | 2.5 m | 7.5 W/1.26 MW | SPbPU | [59] |

| 2020 | TF | 8.5/35.7–52/226.8 µm | 4 cm | 2.3 MW | IPHT | [58] |

| 2020 | SPF | 20/400–30/600–20/400 µm | 31 m | 1836 W @average | NUDT | [87] |

| 2020 | SPF | 24.08/400–31/400–23.36/400 µm | 25 m | 2023 W @average | NUDT | [88] |

| 2020 | SPF | 24.08/400–31/400–23.36/400 µm | 25 m | 3420 W @average | NUDT | [72] |

| 2020 | SPF | 20/400–30/600–20/400 µm | 30.5 m | 3004 W @average | NUDT | [70] |

| 2020 | SAF | 30.77/400–23.28/400–30.77/400 µm | 22.8 m | 1300 W @average | NUDT | [71] |

| 2021 | TF | 31.2/400–52.5/400 µm | 7 m | 364 W @average | HUST | [68] |

| 2021 | TF | 10/80–45/435 µm | 2.6 m | 97 MW after compression | Lumibird | [60] |

| 2021 | TF | 10/70–59/432 µm | 2.5 m | 170 kW | CEA | [61] |

| 2021 | TF | 10/100–50/500 µm | 3 m | 150 W/170 kW | SPbPU | [62] |

| 2021 | TF | 15/120–35/285 µm | 3 m | 50 W/47 kW | TU | [89] |

| 2021 | TF | 8/90–44/486 µm | 6.7 m | 64 W @average | TU | [90] |

| 2021 | TF | 9.5/68–46/330 µm | 2.45 m | 150 W/0.74 MW | RAS | [91] |

| 2021 | SPF | 22/413–32/600–22/413 µm | 21 m | 4000 W @average | NUDT | [74] |

| 2021 | SPF | 27/410–39.5/410–27/410 µm | 21 m | 5008 W @average | NUDT | [92] |

| 2022 | TF | 36.1/249.3–57.8/397.3 µm | 1.27 m | 141 W/1.3 MW | NUDT | [93] |

| 2022 | SPF | 20/400–30/600–20/400 µm | 19 m | 4180 W @average | NUDT | [75] |

| 2022 | TF | 35/250–56.2/400 µm | 3.8 m | 694 W @average | NUDT | [94] |

| 2022 | SPF | 25/400–37.5/600–25/400 µm | 27 m | 4180 W @average | HUST | [76] |

| 2022 | TF | 24/400–31/400 µm | 16 m | 2704 W @average | HUST | [69] |

| 2022 | TF | 20/400–30/600 µm | 17 m | 4089 W @average | NUDT | [95] |

| 2022 | SPF | 20.8/600–36/600–20.3/600 µm | 28.5 m | 2494 W @average | NUDT | [73] |

| 2022 | SPF | 25/400–37.5/600–25/400 µm | 24 m | 6.4 kW QCW | NUDT | [96] |

| 2022 | SPF | 25/400–37.5/600–25/400 µm | 24 m | 7.3 kW QCW | NUDT | [97] |

| 2022 | SPF | 25/400–37.5/600–25/400 µm | 21 m | 6020 W @average | NUDT | [77] |

| Fiber | Core Diameter/µm | Cladding Diameter/µm | Length/m |

|---|---|---|---|

| fiber1 | 20 | 400 | 11 |

| fiber2 | 25 | 500 | 11 |

| fiber3 | 30 | 600 | 11 |

| fiber4 | 20–30–20 | 400–600–400 | 11 |

| Parameter | Value | Parameter | Value |

|---|---|---|---|

| Signal center wavelength | 1080 nm | Pump wavelength | 976 nm |

| Length of passive fiber | 10 m | Doping concentration | 1.26 × 1026 m−3 |

| Signal range | 1050 nm–1150 nm | Raman range | 1116 nm–1150 nm |

| Raman power | indicates signal power) | ||

| Raman ratio | |||

| Pump configuration and pump power | FP, 5000 W BP, 5000 W BIP, 2500 W for FP and 2500 W for BP | ||

| Fiber | Raman Power (W) | Raman Ratio (×10−5) | ||||

|---|---|---|---|---|---|---|

| FP | BP | BIP | FP | BP | BIP | |

| fiber1 | 2.87 | 0.368 | 0.673 | 59.58 | 7.80 | 14.17 |

| fiber2 | 0.20 | 0.051 | 0.089 | 4.09 | 1.08 | 1.89 |

| fiber3 | 0.05 | 0.025 | 0.03 | 1.09 | 0.521 | 0.74 |

| fiber4 | 0.45 | 0.107 | 0.16 | 9.23 | 2.28 | 3.35 |

| Fiber | TMI Threshold | Efficiency | M2 |

|---|---|---|---|

| TF-CCCR | >2170 W | 79.1% | 2.2 |

| CCAF (25/400 µm) | 1046 W | 80.3% | 3.2 |

| Section | Core Diameter/µm | Cladding Diameter/µm | Length/m |

|---|---|---|---|

| L1 | 30.77 | 400 | 1.5 |

| SA | 30.77-23.28-30.77 | 400 | 22.8 |

| L2 | 30.77 | 400 | 2.7 |

| Section | Core Diameter/µm | Cladding Diameter/µm | Length/m |

|---|---|---|---|

| L1 | 30.0 | 600 | 1.0 |

| SA | 30.0-20.8-30.0 | 600 | 32.0 |

| L2 | 30.0 | 600 | 1.0 |

| Fiber Type | Pump Wavelength/Configuration | Maximum Power | TMI | Fiber Length | SRS | Efficiency | M2 |

|---|---|---|---|---|---|---|---|

| 21/400 µm CCAF | 976 nm /bidirectional | 3050 W | >3050 W | 18 m | −29 dB | 73% | ~1.3 |

| SPF | 976 nm /bidirectional | 3004 W | >3004 W | 30.9 m | −34 dB | 78% | ~1.3 |

| Fiber Type | Core/Cladding Diameter | Core NA | Average Absorption Coefficient | Length |

|---|---|---|---|---|

| SPF-CCD | 20-36-20/600 µm | 0.065 | 0.78 dB/m | 28.5 m (11.1 m-6 m-11.4 m) |

| CCAF | 28/600 µm | 0.065 | 0.80 dB/m | 27.8 m |

| Fiber Type | Fiber Length | Equivalent Core Diameter | Bandwidth (HR/OC) | Pump Configuration | Peak Power | Efficiency | SRS | M2 |

|---|---|---|---|---|---|---|---|---|

| 30/400 CCAF | 15 m | 30 µm | 4.05/2.05 nm | Bidirectional | 9713 W | 61.6% | >24 dB | 2.40 |

| TF-CCCR | 17 m | 25 µm | 3.05/1.98 nm | Counter | 6420 W | 70.6% | 19.8 dB | 1.60 |

| SPF-CCCR | 24 m | 32.6 µm | 4.09/1.01 nm | Bidirectional (1:9.2) | 7398 W | 67.0% | 26 dB | 1.43 |

| Fiber Parameters | Power | SRS | TMI | M2 | ||

|---|---|---|---|---|---|---|

| OS | AS | |||||

| Ref. [106] | 22/400 µm 7.2 m | 25/400 µm 13.5 m | 5009 W | 14.7 dB | >5009 W | 2.83 |

| This work | 22/400 µm 4.32 m | SPF 21.0 m | 6020 W | 18.2 dB | >6060 W | 1.77 |

| Fiber Type | Laser Type | Maximum Power/W | Threshold of TMI/W | M2 | SRS/dB |

|---|---|---|---|---|---|

| TF | CW Amplifier | 6110 | ~5000 | 2.57 | >45 |

| SPF | CW Amplifier | 6020 | >6020 | 1.86 | 26.7 |

| OAIFL | 6060 | >6060 | 1.78 | 18.2 | |

| Bidirectional-output Fiber Laser Oscillator | 6096(3256 + 2840) | >6096 | 1.98/2.38 | >40 | |

| SAF | CW Oscillator | 1312 | >1312 | 2.01 | >40 |

| CW Amplifier | 1816 | 1797 | 1.50 | >40 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zeng, L.; Wang, X.; Ye, Y.; Wang, L.; Yang, B.; Xi, X.; Wang, P.; Pan, Z.; Zhang, H.; Shi, C.; et al. High Power Ytterbium-Doped Fiber Lasers Employing Longitudinal Vary Core Diameter Active Fibers. Photonics 2023, 10, 147. https://doi.org/10.3390/photonics10020147

Zeng L, Wang X, Ye Y, Wang L, Yang B, Xi X, Wang P, Pan Z, Zhang H, Shi C, et al. High Power Ytterbium-Doped Fiber Lasers Employing Longitudinal Vary Core Diameter Active Fibers. Photonics. 2023; 10(2):147. https://doi.org/10.3390/photonics10020147

Chicago/Turabian StyleZeng, Lingfa, Xiaolin Wang, Yun Ye, Li Wang, Baolai Yang, Xiaoming Xi, Peng Wang, Zhiyong Pan, Hanwei Zhang, Chen Shi, and et al. 2023. "High Power Ytterbium-Doped Fiber Lasers Employing Longitudinal Vary Core Diameter Active Fibers" Photonics 10, no. 2: 147. https://doi.org/10.3390/photonics10020147

APA StyleZeng, L., Wang, X., Ye, Y., Wang, L., Yang, B., Xi, X., Wang, P., Pan, Z., Zhang, H., Shi, C., Han, K., & Xu, X. (2023). High Power Ytterbium-Doped Fiber Lasers Employing Longitudinal Vary Core Diameter Active Fibers. Photonics, 10(2), 147. https://doi.org/10.3390/photonics10020147