Study on the Physical Characteristics of Plasma and Its Relationship with Pore Formation during Laser-Metal Active Gas Arc Hybrid Welding of 42CrMo Steel

Abstract

:1. Introduction

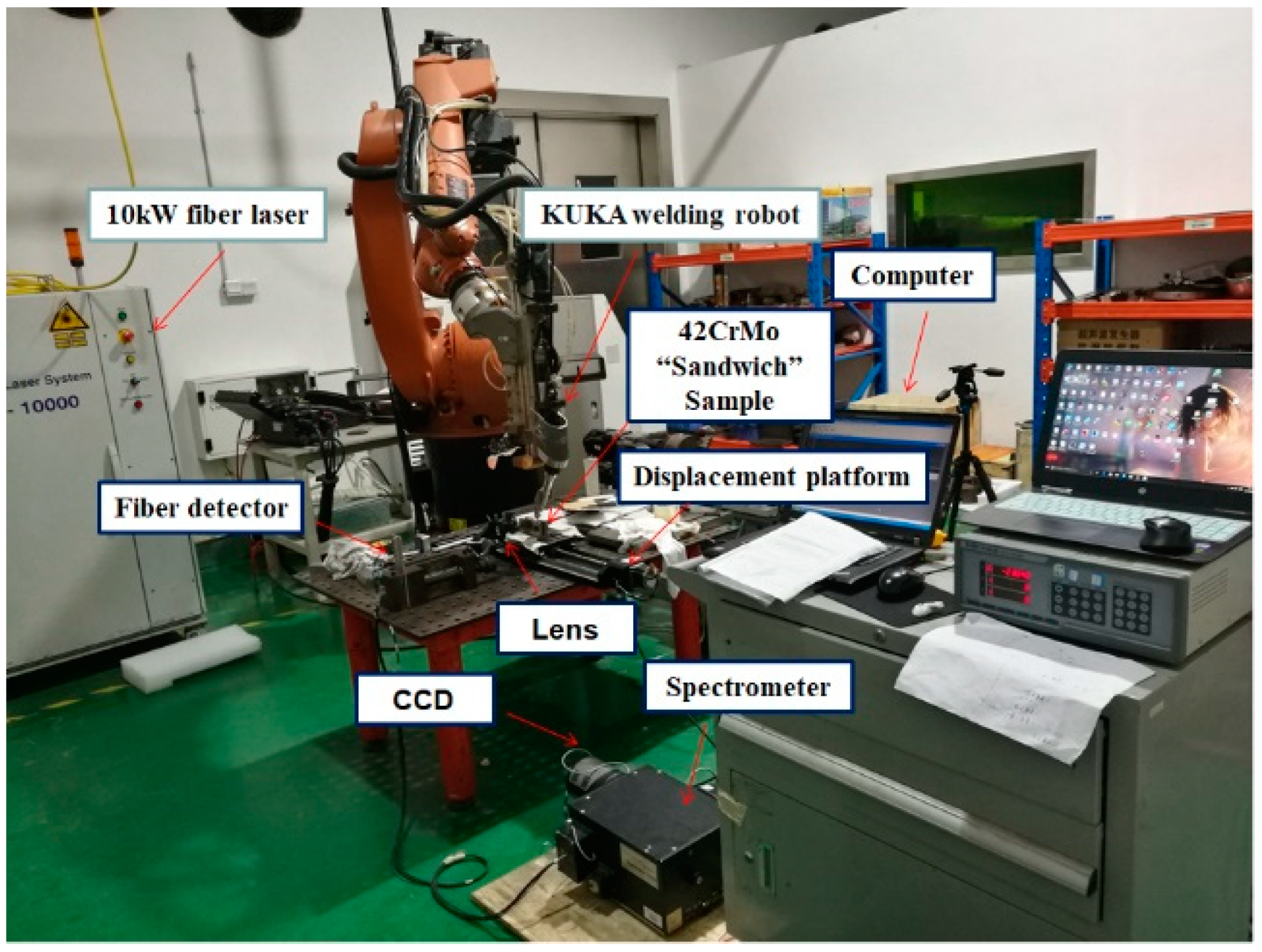

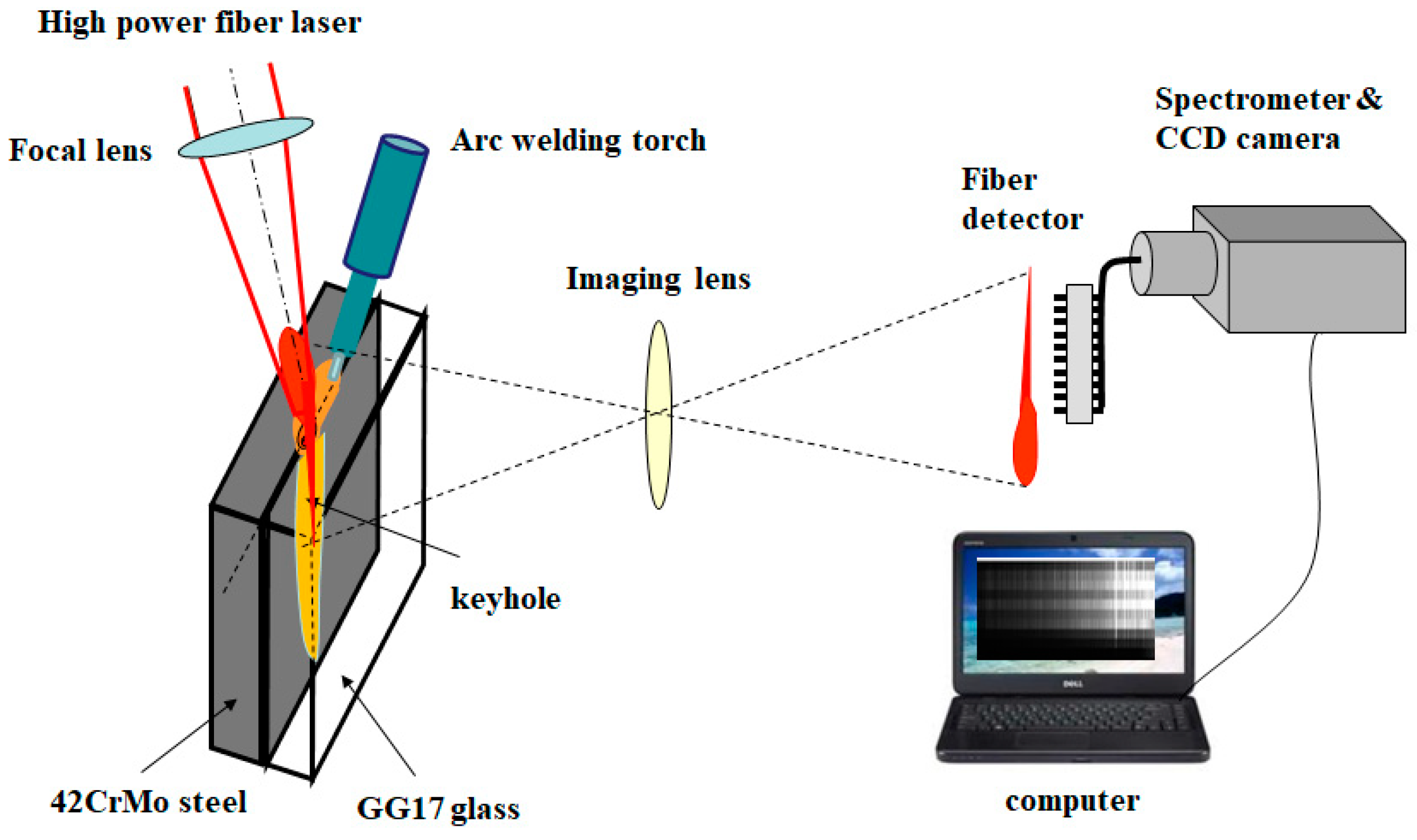

2. Experimental Procedure

3. Results and Discussion

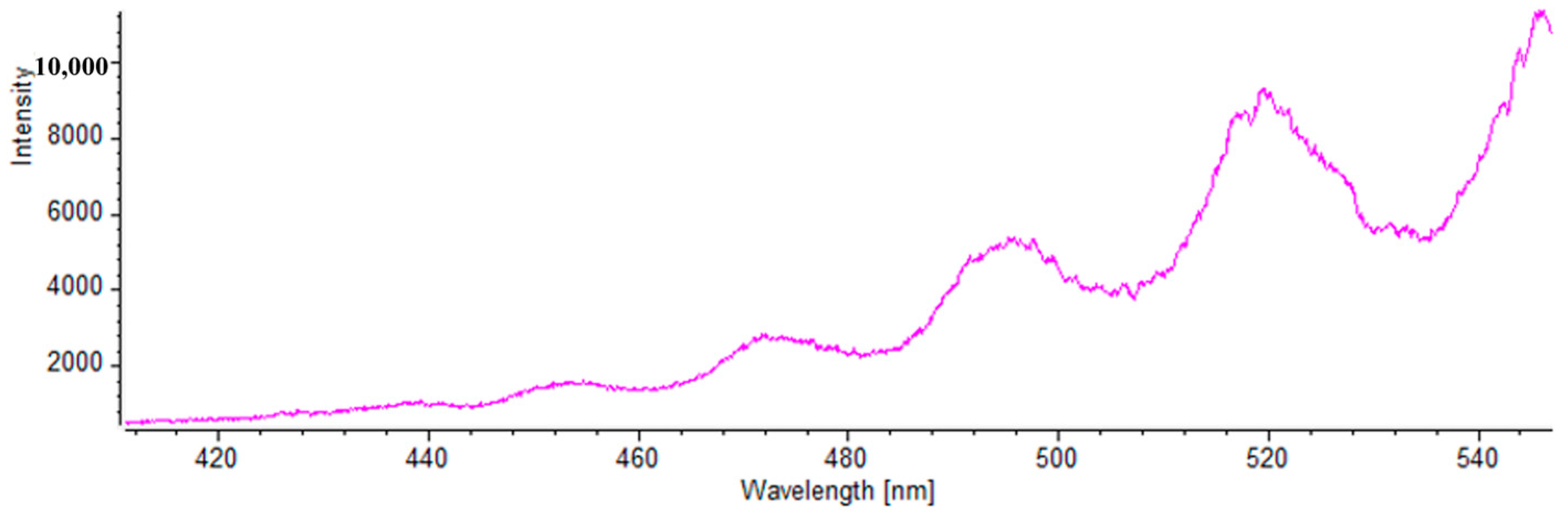

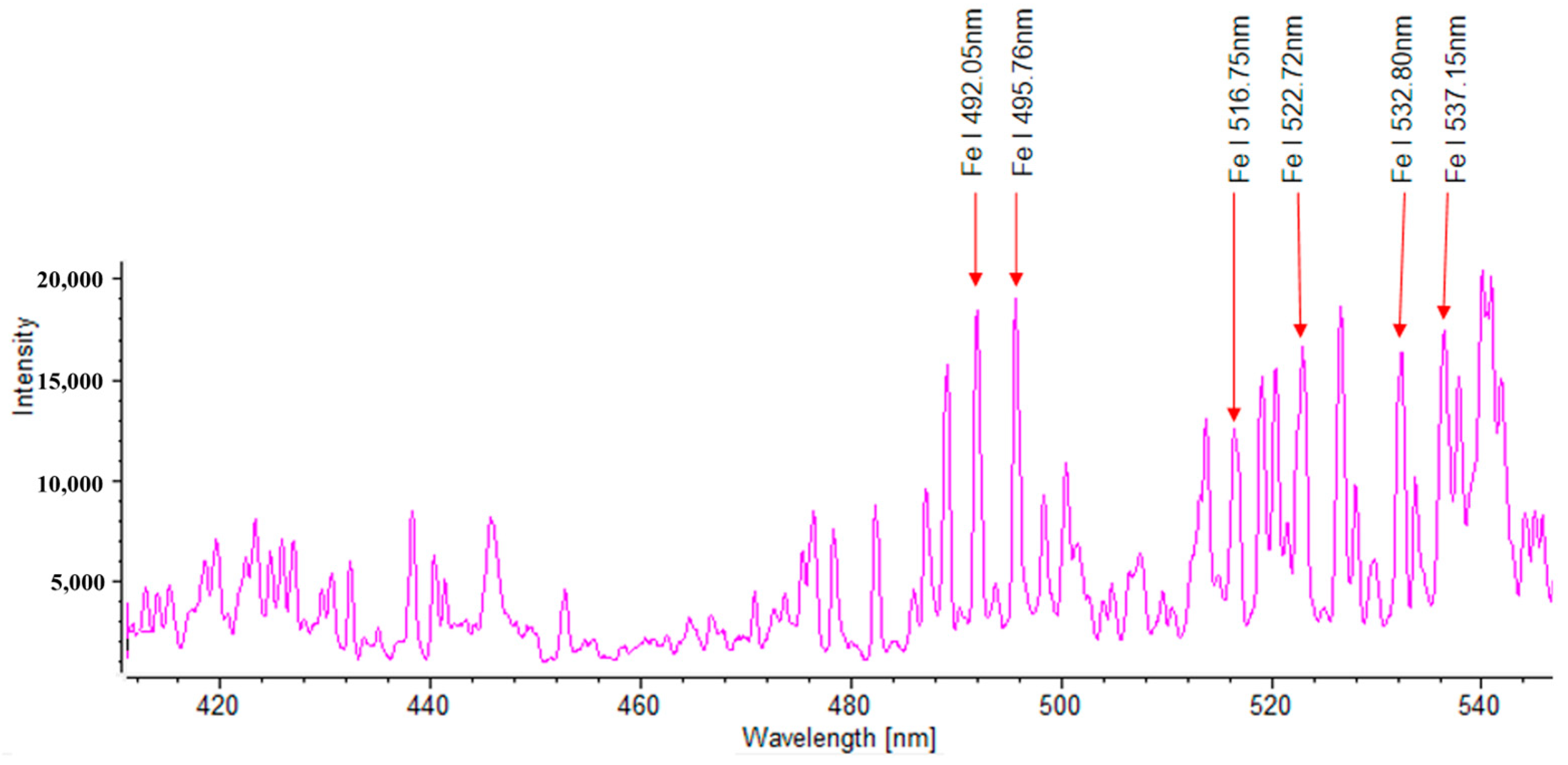

3.1. Calculation Results and Analysis of Plasma’s Physical Parameters in Laser-MAG Hybrid Welding

3.2. Relationship between the Plasma’s Physical Behavior and Pore Formation in Laser-MAG Hybrid Welding

4. Conclusions

- (1)

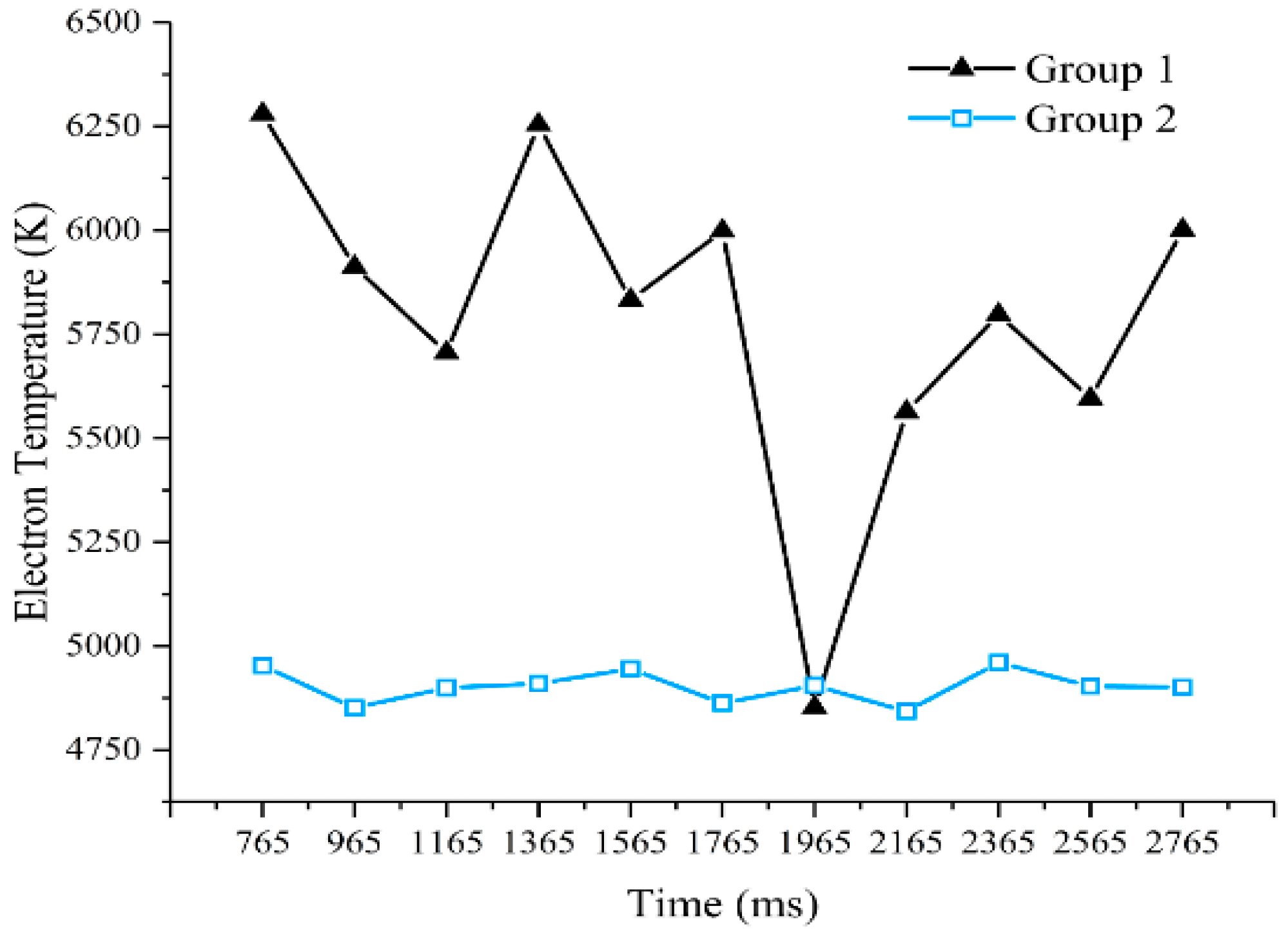

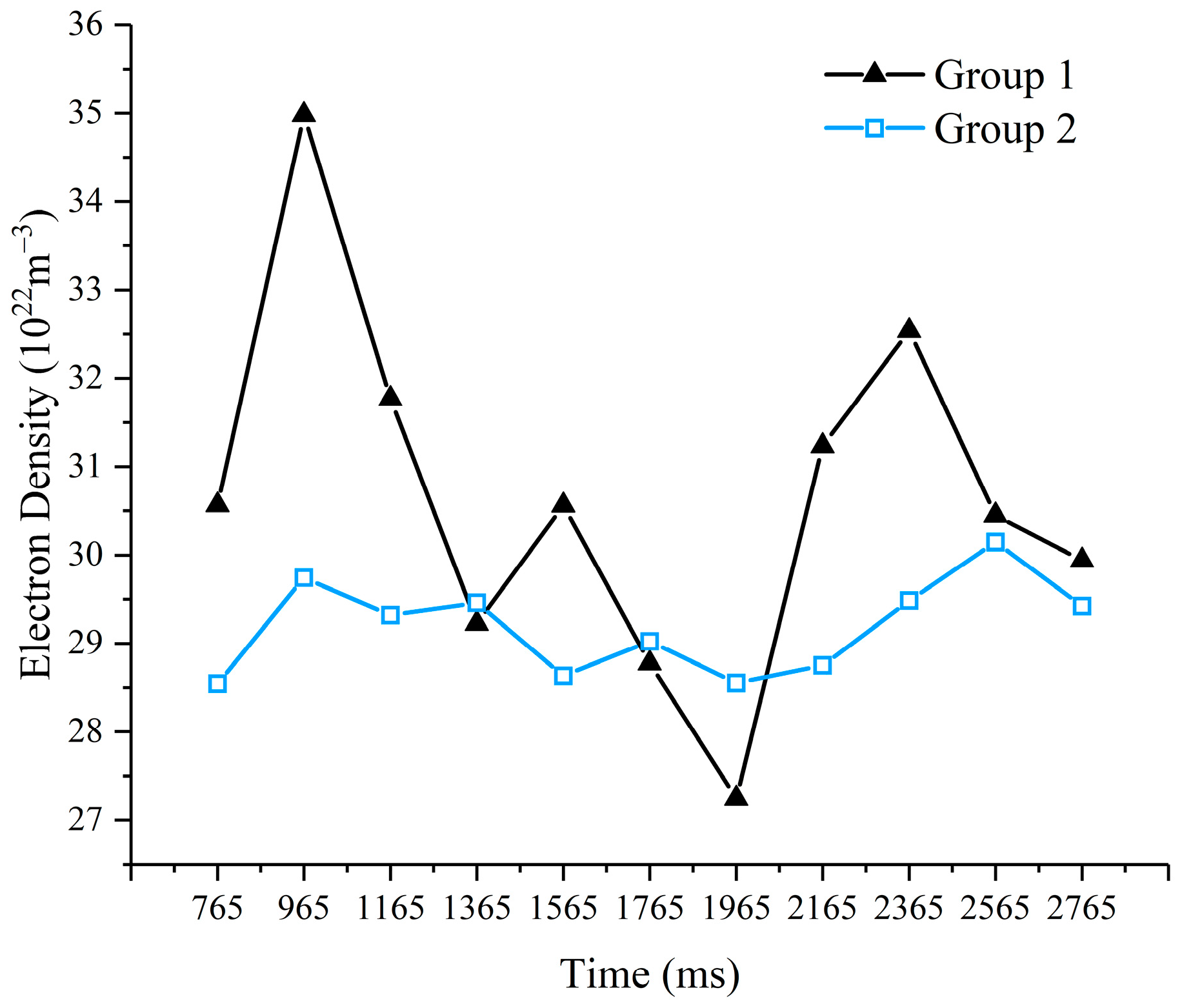

- When there is paraxial shielding gas blowing during the welding process, the laser welding of 42CrMo steel does not detect the plasma spectrum, but the hybrid welding can still detect the plasma spectrum. Regarding the welding parameters in this paper, the average plasma electron temperature and plasma electron density of the leading laser laser-MAG hybrid welding are, respectively, 4936 K and 26.9 × 1016 cm−3, and the leading arc laser-MAG hybrid welding are, respectively, 5621 K and 30.2 × 1016 cm−3;

- (2)

- The plasma electron temperature of each channel of the leading laser laser-MAG hybrid welding is generally lower than that of the leading arc laser-MAG hybrid welding; the average temperature is about 700 K lower, and the plasma electron density of the leading arc hybrid welding is also slightly higher;

- (3)

- The highest plasma electron density of both hybrid welding processes is in the third channel. Among them, the value of the leading laser laser-MAG hybrid welding process is 31.602 × 1016 cm−3, and the value of the leading arc laser-MAG hybrid welding process is 32.480 × 1016 cm−3;

- (4)

- During the laser-MAG hybrid welding of 42CrMo steel, the stability of the plasma’s physical characteristics is closely related to the formation of pores. When the physical characteristics of the plasma fluctuate greatly over time, a large number of pores will be generated, and when the physical characteristics of the plasma are relatively stable, there will be fewer pores in the welding. For 42CrMo steel, which is prone to welding porosity that is difficult to detect, the porosity generation in the weld bead of 42CrMo steel can be monitored online by identifying the fluctuation in the plasma electron temperature and electron density.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Li, P. The present situation and development trend of the automobile engine piston design. Automob. Technol. Mater. 2008, 1, 5–8. [Google Scholar]

- Zhang, M.; Chen, G.; Zhou, Y.; Li, S. Direct observation of keyhole characteristics in deep penetration laser welding with a 10 kW fiber laser. Opt. Express. 2013, 21, 19997–20004. [Google Scholar] [CrossRef] [PubMed]

- Chen, G.; Zhang, M.; Zhao, Z.; Zhang, Y.; Li, S. Measurements of laser-induced plasma temperature field in deep penetration laser welding. Opt. Laser Technol. 2013, 45, 551–557. [Google Scholar] [CrossRef]

- Li, S.; Chen, G.; Zhang, Y.; Zhang, M.; Zhou, Y.; Deng, H. Investigation of keyhole plasma during 10 kW high power fiber laser welding. Laser Phys. 2014, 24, 106003. [Google Scholar] [CrossRef]

- Li, J.; Zhang, Y.; Liu, W.; Li, B.; Yin, X.; Chen, C. Prediction of penetration based on plasma plume and spectrum characteristics in laser welding. J. Manuf. Process. 2022, 75, 593–604. [Google Scholar] [CrossRef]

- Gong, J.; Peng, G.; Li, L.; Xia, H.; Meng, S.; Wang, J. Effect of plasma plume produced by vacuum laser welding on energy transmission. Opt. Laser Technol. 2021, 136, 106744. [Google Scholar] [CrossRef]

- Qiu, W.; Yang, L.; Zhao, S.; Yang, R.; Liu, T. A study on plasma plume fluctuation characteristic during A304 stainless steel laser welding. J. Manuf. Process. 2018, 33, 1–9. [Google Scholar] [CrossRef]

- Huang, Y.; Xu, S.; Yang, L.; Zhao, S.; Shi, Y. Defect detection during laser welding using electrical signals and high-speed photography. J. Mater. Process. Technol. 2019, 271, 394–403. [Google Scholar] [CrossRef]

- Luo, Y.; Zhu, L.; Han, J.; Xie, X.; Wan, R.; Zhu, Y. Study on the acoustic emission effect of plasma plume in pulsed laser welding. Mech. Syst. Signal Process. 2019, 124, 715–723. [Google Scholar] [CrossRef]

- Gao, Z.; Jiang, P.; Shao, X.; Cao, L.; Mi, G. Numerical analysis of hybrid plasma in fiber laser-arc welding. J. Phys. D Appl. Phys. 2018, 52, 025206. [Google Scholar] [CrossRef]

- Liu, T.; Yang, L.; Zhao, S.; Huang, Y. Electrical Characteristics of Plasma Plume During Pulse Wave Laser Welding. Trans. Tianjin Univ. 2019, 25, 420–428. [Google Scholar] [CrossRef]

- Tang, G.; Chen, H.; Yang, X.; Shen, L. Effects of different welding process on the electronic temperature of plasma and weld shape during laser-MIG hybrid welding of A7N01P-T4 aluminum alloy. J. Laser Appl. 2018, 30, 022002. [Google Scholar] [CrossRef]

- Liu, W.; Ma, J.; Yang, G.; Kovacevic, R. Hybrid laser-arc welding of advanced high-strength steel. J. Mater. Process. Technol. 2014, 214, 2823–2833. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, S.; Chen, G.; Zhang, H.; Zhang, M. Characteristics of zinc behavior during laser welding of zinc “sandwich” sample. Opt. Laser Technol. 2012, 44, 2340–2346. [Google Scholar] [CrossRef]

- Liu, L.; Huang, R.; Song, G.; Hao, X. Behavior and spectrum analysis of welding arc in low-power YAG-laser–MAG hybrid-welding process. IEEE Trans. Plasma Sci. 2008, 36, 1937–1943. [Google Scholar] [CrossRef]

- Gao, M.; Chen, C.; Hu, M.; Guo, L.; Wang, Z.; Zeng, X. Characteristics of plasma plume in fiber laser welding of aluminum alloy. Appl. Surf. Sci. 2015, 326, 181–186. [Google Scholar] [CrossRef]

- Tenner, F.; Brock, C.; Klämpfl, F.; Schmidt, M. Analysis of the correlation between plasma plume and keyhole behavior in laser metal welding for the modeling of the keyhole geometry. Opt. Laser Eng. 2015, 64, 32–41. [Google Scholar] [CrossRef]

- Liu, L.; Hao, X. Study of the effect of low-power pulse laser on arc plasma and magnesium alloy target in hybrid welding by spectral diagnosis technique. J. Phys. D Appl. Phys. 2008, 41, 205202. [Google Scholar] [CrossRef]

- Li, Z.; Wang, W.; Wang, X.; Li, H. A study of the radiation of a Nd: YAG laser–MIG hybrid plasma. Opt. Laser Technol. 2010, 42, 132–140. [Google Scholar] [CrossRef]

- Shaikh, N.M.; Rashid, B.; Hafeez, S.; Jamil, Y.; Baig, M.A. Measurement of electron density and temperature of a laser-induced zinc plasma. J. Phys. D Appl. Phys. 2006, 39, 1384–1391. [Google Scholar] [CrossRef]

- Katayama, S.; Kawahito, Y.; Mizutani, M. Elucidation of laser welding phenomena and factors affecting weld penetration and welding defects. Phys. Procedia 2010, 5, 9–17. [Google Scholar] [CrossRef]

- Tsukamoto, S. High speed imaging technique Part 2—High speed imaging of power beam welding phenomena. Sci. Technol. Weld. Join. 2011, 16, 44–55. [Google Scholar] [CrossRef]

- Kawahito, Y.; Mizutani, M.; Katayama, S. Elucidation of high-power fibre laser welding phenomena of stainless steel and effect of factors on weld geometry. J. Phys. D Appl. Phys. 2007, 40, 5854–5859. [Google Scholar] [CrossRef]

| C | Si | Mn | S | P | Cr | Ni | Cu | Mo |

|---|---|---|---|---|---|---|---|---|

| 0.44 | 0.23 | 0.76 | 0.017 | 0.011 | 0.99 | 0.042 | 0.04 | 0.17 |

| Wavelength (nm) | Transition Probability (s−1) | Energy of the Upper Level (eV) | Statistical Weight |

|---|---|---|---|

| 492.05 | 3.58 × 10−7 | 5.3516 | 9 |

| 495.76 | 4.22 × 10−7 | 5.3085 | 11 |

| 516.75 | 2.72 × 10−6 | 3.8835 | 7 |

| 522.72 | 2.89 × 10−6 | 3.9286 | 5 |

| 532.80 | 1.15 × 10−6 | 3.2410 | 7 |

| 537.15 | 1.05 × 10−6 | 3.2657 | 5 |

| Channel | Position Inside and Outside the Keyhole (mm) | Electron Temperature (, K) | Electron Density (, 1016 cm−3) |

|---|---|---|---|

| first channel | +2.5 | 4718.22 | 24.515 |

| second channel | +1.5 | 4919.44 | 27.857 |

| third channel | +0.5 | 4903.44 | 31.602 |

| fourth channel | −0.5 | 5089.90 | 29.138 |

| fifth channel | −1.5 | 4917.36 | 26.834 |

| sixth channel | −2.5 | 5067.67 | 21.511 |

| Channel | Position Inside and Outside the Keyhole (mm) | Electron Temperature (, K) | Electron Density (, 1016 cm−3) |

|---|---|---|---|

| first channel | +2.5 | 5251.12 | 27.071 |

| second channel | +1.5 | 5745.03 | 30.652 |

| third channel | +0.5 | 5799.73 | 32.480 |

| fourth channel | −0.5 | 5688.71 | 30.733 |

| Test Number | Weld Appearance | CT Photograph | Number of Pores |

|---|---|---|---|

| 1 |  |  | 44 |

| 2 |  |  | 3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Y.; Li, H.; Mi, X.; Zhou, H.; Zhang, M.; Wan, Z.; Tang, L. Study on the Physical Characteristics of Plasma and Its Relationship with Pore Formation during Laser-Metal Active Gas Arc Hybrid Welding of 42CrMo Steel. Photonics 2023, 10, 1246. https://doi.org/10.3390/photonics10111246

Zhang Y, Li H, Mi X, Zhou H, Zhang M, Wan Z, Tang L. Study on the Physical Characteristics of Plasma and Its Relationship with Pore Formation during Laser-Metal Active Gas Arc Hybrid Welding of 42CrMo Steel. Photonics. 2023; 10(11):1246. https://doi.org/10.3390/photonics10111246

Chicago/Turabian StyleZhang, Yan, Hao Li, Xin Mi, Hongzhi Zhou, Mingjun Zhang, Zhongmin Wan, and Liyuan Tang. 2023. "Study on the Physical Characteristics of Plasma and Its Relationship with Pore Formation during Laser-Metal Active Gas Arc Hybrid Welding of 42CrMo Steel" Photonics 10, no. 11: 1246. https://doi.org/10.3390/photonics10111246

APA StyleZhang, Y., Li, H., Mi, X., Zhou, H., Zhang, M., Wan, Z., & Tang, L. (2023). Study on the Physical Characteristics of Plasma and Its Relationship with Pore Formation during Laser-Metal Active Gas Arc Hybrid Welding of 42CrMo Steel. Photonics, 10(11), 1246. https://doi.org/10.3390/photonics10111246