Mask-Shifting-Based Projection Lithography for Microlens Array Fabrication

Abstract

:1. Introduction

2. Methodology

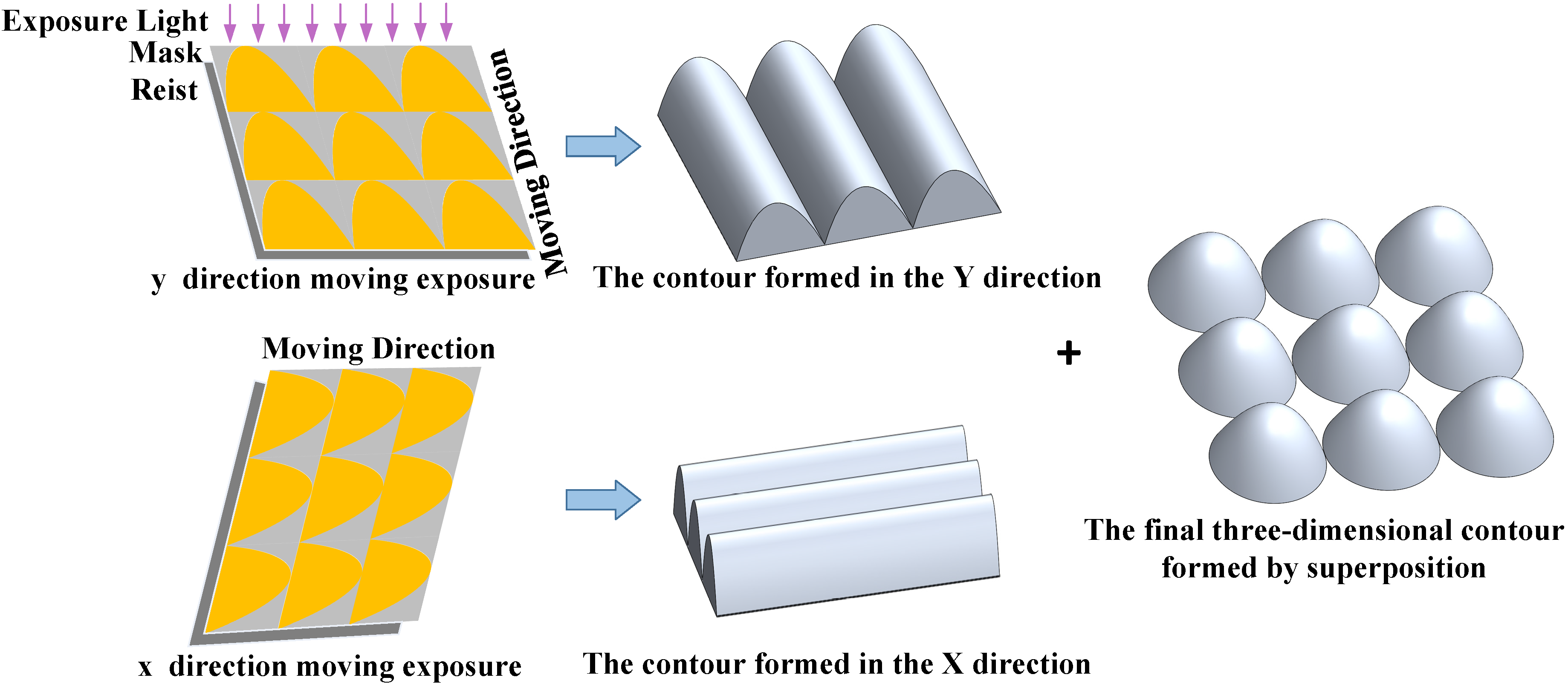

2.1. Mask-Shifting Principle

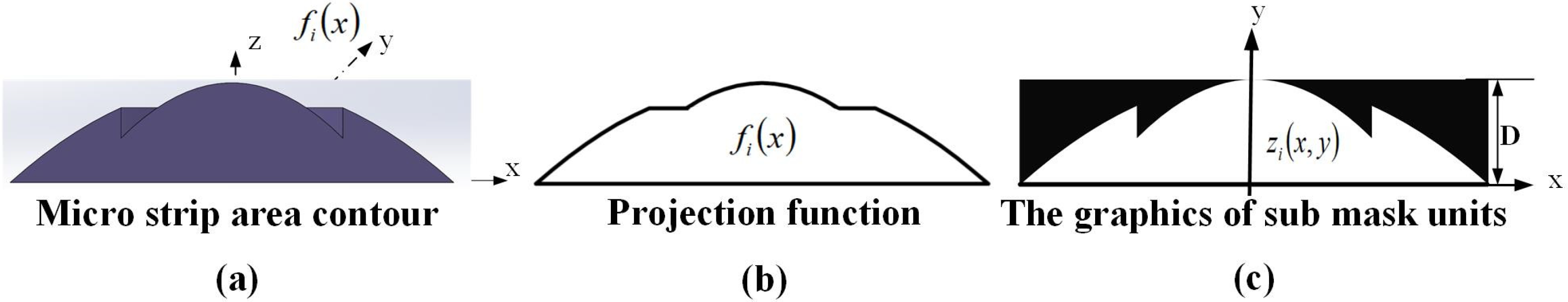

2.2. Mask-Shift Filtering Technique

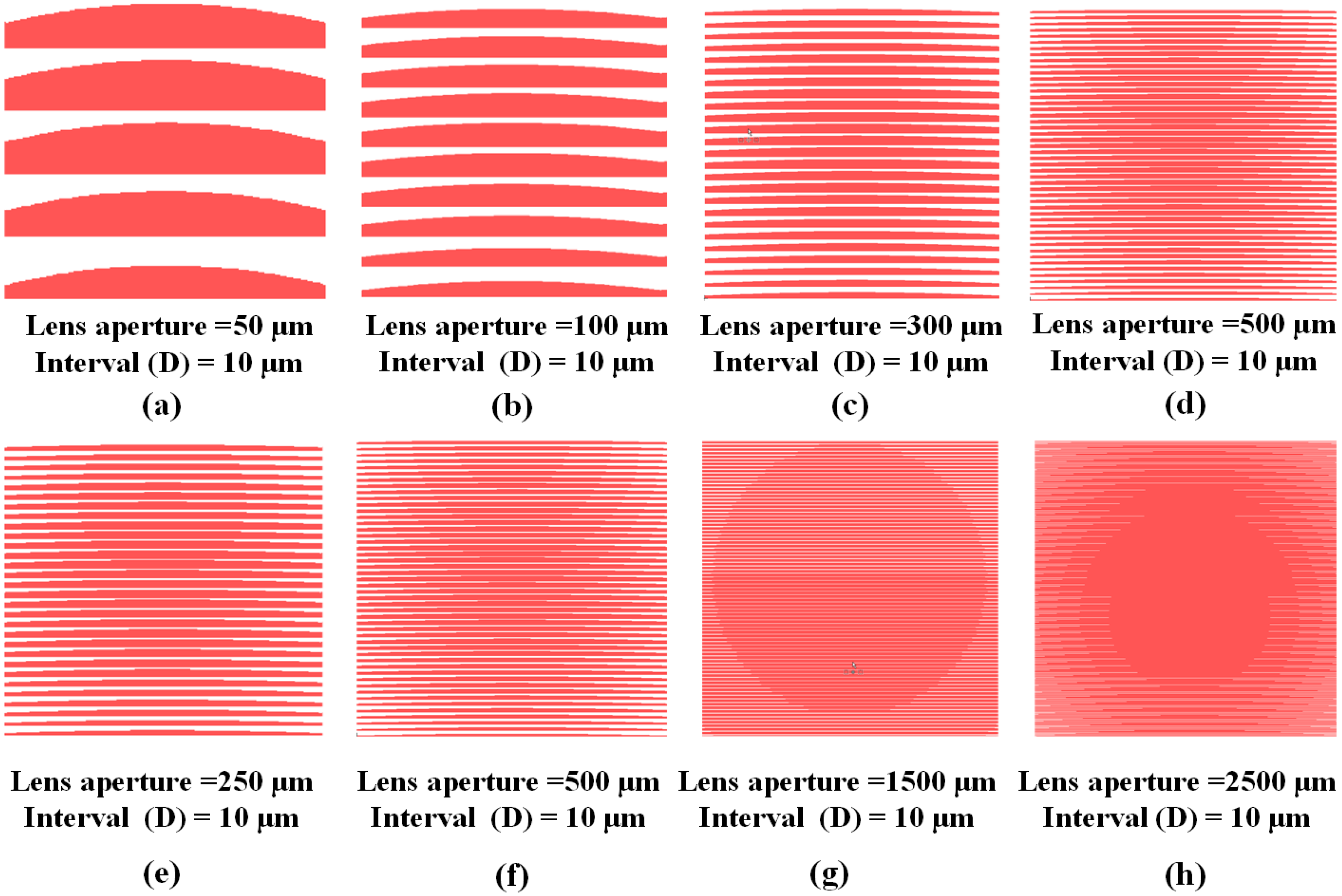

2.3. Impact of Mask Preparation Accuracy on the Microstructure’s Surface Figure

3. Experiment and Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Dong, X.; Du, C.; Wang, C.; Deng, Q.; Zhang, Y.; Luo, X. Mask-shift filtering for forming microstructures with irregular profile. Appl. Phys. Lett. 2006, 89, 261105. [Google Scholar] [CrossRef]

- Dong, X.; Du, C.; Li, S.; Wang, C.; Fu, Y. Control approach for form accuracy of microlenses with continuous relief. Opt. Express 2005, 13, 1353–1360. [Google Scholar] [CrossRef] [PubMed]

- Zhang, W.; Zhu, G.; Zhu, X.; Du, C. Ultraprecision replication technology for fabricating spiral-structure metamaterial. Front. Phys. 2020, 8, 555729. [Google Scholar] [CrossRef]

- Zhang, W.; Xia, L.; Gao, M.; Du, C. Laser beam homogenization with random distributed freeform cylindrical microlens. Opt. Eng. 2020, 59, 065103. [Google Scholar] [CrossRef]

- Zhang, S.; Zhao, L.; He, Y. Lithography alignment method based on image rotation matching. J. Phys. Conf. Ser. 2021, 1939, 012039. [Google Scholar] [CrossRef]

- Gopal, V.; Radmilovic, V.R.; Daraio, C.; Jin, S.; Yang, P.; Stach, E.A. Rapid prototyping of site-specific nanocontacts by electron and ion beam assisted direct-write nanolithography. Nano Lett. 2004, 4, 2059–2063. [Google Scholar] [CrossRef]

- Bhuvana, T.; Kulkarni, G.U.U. Highly conducting patterned Pd nanowires by direct-write electron beam lithography. ACS Nano 2008, 2, 457–462. [Google Scholar] [CrossRef]

- Ekberg, M.; Nikolajeff, F.; Larsson, M.; Hård, S. Proximity-compensated blazed transmission grating manufacture with direct-writing, electron-beam lithography. Appl. Opt. 1994, 33, 103–107. [Google Scholar] [CrossRef]

- Lee, L.P.; Berger, S.A.; Liepmann, D.; Pruitt, L. High aspect ratio polymer microstructures and cantilevers for bioMEMS using low energy ion beam and photolithography. Sens. Actuators A 1998, 71, 144–149. [Google Scholar] [CrossRef]

- Gonin, Y.; Munnik, F.; Benninger, F.; Mikhaïlov, S. Creating sub-surface channels in PMMA with ion beam lithography in only one step. Appl. Surf. Sci. 2003, 217, 289–293. [Google Scholar] [CrossRef]

- Leon, J.A.; Alves, E.S.; Elias, D.C.; Brant, J.C.; Barbosa, T.C.; Malard, L.M.; Pimenta, M.A.; Ribeiro, G.M.; Plentz, F. Rapid fabrication of bilayer graphene devices using direct laser writing photolithography. J. Vac. Sci. Technol. B 2011, 29, 021204. [Google Scholar] [CrossRef]

- Xianfan, X. Laser direct write of silicon nanowires. Opt. Eng. 2011, 50, 475–480. [Google Scholar]

- Lee, C.H.; Yoshida, H.; Miura, Y.; Fujii, A.; Ozaki, M. Local liquid crystal alignment on patterned micrograting structures photofabricated by two photon excitation direct laser writing. Appl. Phys. Lett. 2008, 93, 173509. [Google Scholar] [CrossRef]

- Liu, X.; Chen, Q.; Guan, K.; Ma, Z.; Yu, Y.; Li, Q.; Tian, Z.; Sun, H. Dry-etching-assisted femtosecond laser machining. Laser Photonics Rev. 2017, 11, 1600115. [Google Scholar] [CrossRef]

- Liu, X.; Yu, L.; Yang, S.; Chen, Q.; Wang, L.; Juodkazis, S.; Sun, H. Optical Nanofabrication of Concave Microlens Arrays. Laser Photonics Rev. 2019, 13, 1800272. [Google Scholar] [CrossRef]

- Liu, J.; Liu, J.; Deng, Q.; Feng, J.; Zhou, S.; Hu, S. Intensity modulation based optical proximity optimization for the maskless lithography. Opt. Express 2020, 28, 548–557. [Google Scholar] [CrossRef]

- Artyukov, I.; Balakireva, L.; Bijkerk, F.; Vinogradov, A.; Zorev, N.; Kozhevnikov, I.; Kondratenko, V.; Ogurtsov, O.; Ponomarenko, A.; Fedorenko, A. Projection X-ray-lithography on the basis of oint sources. Kvantovaya Electron. 1992, 19, 114–127. [Google Scholar]

- Erdmann, A.; Fühner, T.; Evanschitzky, P.; Agudelo, V.; Freund, C.; Michalak, P.; Xu, D. Optical and EUV projection lithography: A computational view. Microelectron. Eng. 2015, 132, 21–34. [Google Scholar] [CrossRef]

- Vlad, A.; Huynen, I.; Melinte, S. Wavelength-scale lens microscopy viathermal reshaping of colloidal particles. Nanotechnology 2012, 23, 285708. [Google Scholar] [CrossRef]

- Veldkamp, W.B. Binary optics: A new approach to optical design and fabrication. Opt. News 1988, 14, 29–30. [Google Scholar] [CrossRef]

- Chang, C.-Y.; Yang, S.-Y.; Huang, L.-S.; Chang, J.-H. Fabrication of plastic microlens array using gas-assisted micro-hot-embossing with a silicon mold. Infrared Phys. Technol. 2006, 48, 163–173. [Google Scholar] [CrossRef]

- Liu, J.; Liu, J.; Deng, Q.; Liu, X.; He, Y.; Tang, Y.; Hu, S. Dose-modulated maskless lithography for the efficient fabrication of compound eyes with enlarged field-of-view. IEEE Photonics J. 2019, 11, 2400110. [Google Scholar] [CrossRef]

- Huang, P.; Dong, X.C.; He, C.W. Square-aperture microlens array fabrication by the moving mask technology. In Proceedings of the 2017 2nd International Seminar on Applied Physics, Optoelectronics and Photonics, Lancaster, PA, USA, 2017. [Google Scholar]

- Du, C.; Dong, X.; Qiu, C.; Deng, Q.; Zhou, C. Profile control technology for high performance microlens array. Opt. Eng. 2004, 44, 2595–2601. [Google Scholar] [CrossRef]

- Du, C.; Dong, X.C.; Deng, Q.; Luo, X. Micro-optical structures formed by a mask moving method. Optoelectron. Lett. 2007, 3, 95–98. [Google Scholar] [CrossRef]

- Cao, A.; Wang, J.; Pang, H.; Zhang, M.; Shi, L.; Deng, Q.; Hu, S. Design and fabrication of a multifocal bionic compound eye for imaging. Bioinspir. Biomim. 2018, 13, 026012. [Google Scholar] [CrossRef]

- Im, B.; Prasetyo, F.D.; Yudistira, H.T.; Khalil, S.M.; Cho, D.; Byun, D. Drop-on-Demand Electrohydrodynamic Jet Printing of Microlens Array on Flexible Substrates. ACS Appl. Polym. Mater. 2023, 5, 2264–2271. [Google Scholar] [CrossRef]

- Zhang, Q.; Schambach, M.; Schlisske, S.; Jin, Q.; Mertens, A.; Rainer, C.; Hernandez-Sosa, G.; Heizmann, M.; Lemmer, U. Fabrication of Microlens Arrays with High Quality and High Fill Factor by Inkjet Printing. Adv. Opt. Mater. 2022, 10, 2200677. [Google Scholar] [CrossRef]

- Shi, L.; Du, C.; Dong, X.; Deng, Q.; Luo, X. Effective formation method for an aspherical microlens array based on an aperiodic moving mask during exposure. Appl. Opt. 2007, 46, 8346–8350. [Google Scholar] [CrossRef]

- Li, Q.; Ji, M.G.; Chapagain, A.; Cho, I.H.; Kim, J. Curvature-Adjustable Polymeric Nanolens Fabrication Using UV-Controlled Nanoimprint Lithography. Micromachines 2022, 13, 2183. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gong, J.; Zhou, J.; Sun, H.; Hu, S.; Wang, J.; Liu, J. Mask-Shifting-Based Projection Lithography for Microlens Array Fabrication. Photonics 2023, 10, 1135. https://doi.org/10.3390/photonics10101135

Gong J, Zhou J, Sun H, Hu S, Wang J, Liu J. Mask-Shifting-Based Projection Lithography for Microlens Array Fabrication. Photonics. 2023; 10(10):1135. https://doi.org/10.3390/photonics10101135

Chicago/Turabian StyleGong, Jianwen, Ji Zhou, Haifeng Sun, Song Hu, Jian Wang, and Junbo Liu. 2023. "Mask-Shifting-Based Projection Lithography for Microlens Array Fabrication" Photonics 10, no. 10: 1135. https://doi.org/10.3390/photonics10101135

APA StyleGong, J., Zhou, J., Sun, H., Hu, S., Wang, J., & Liu, J. (2023). Mask-Shifting-Based Projection Lithography for Microlens Array Fabrication. Photonics, 10(10), 1135. https://doi.org/10.3390/photonics10101135