High-Resolution Laser in Widely Tunable Range (4.16–7.13 µm) Based on Mid-Infrared BaGa4Se7 Optical Parametric Oscillator Pumped at 1064 nm

Abstract

:1. Introduction

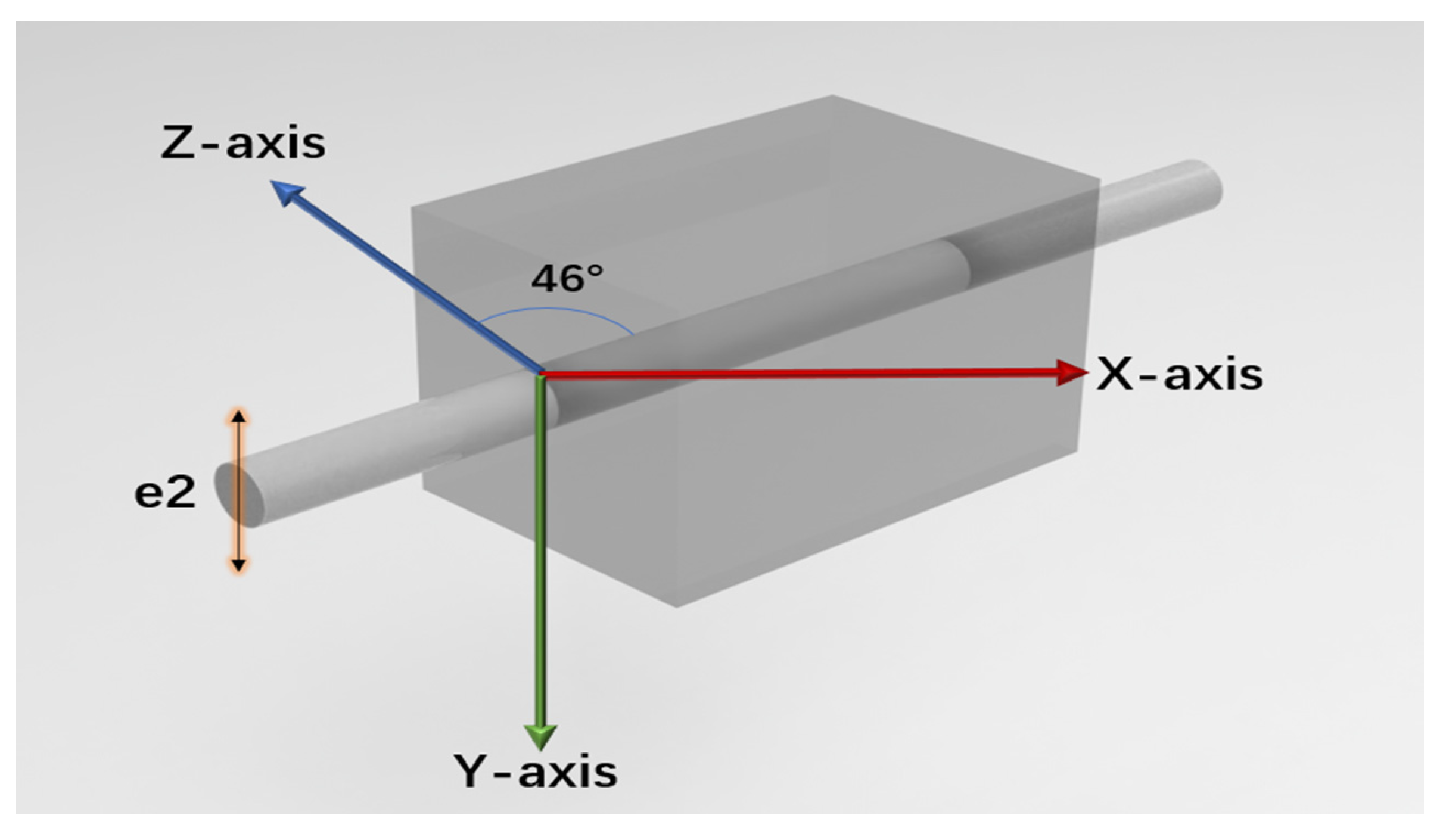

2. Experimental Setup

3. Results and Discussion

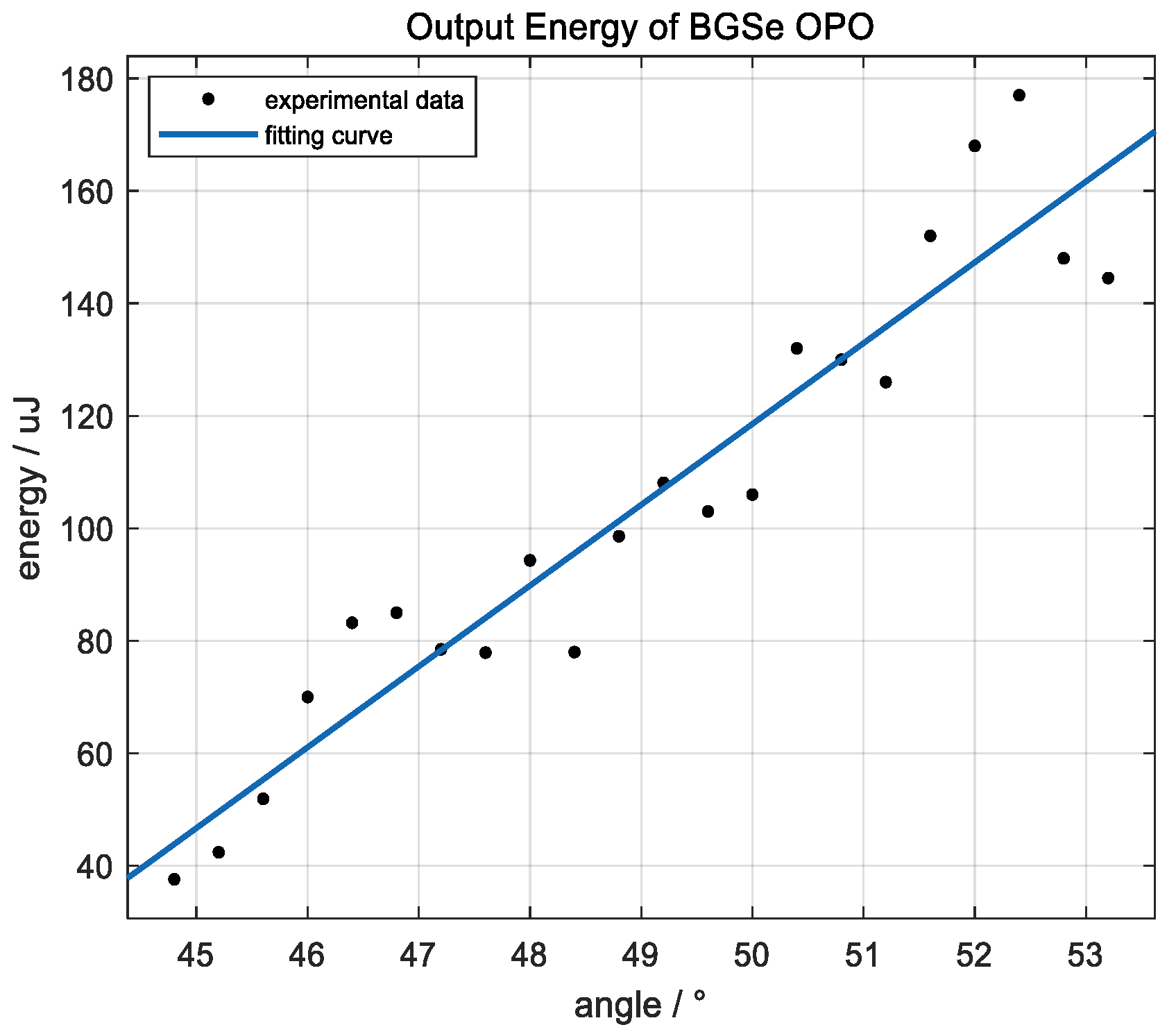

3.1. Conversion Efficiency at 30 °C and Different Incidence Angles

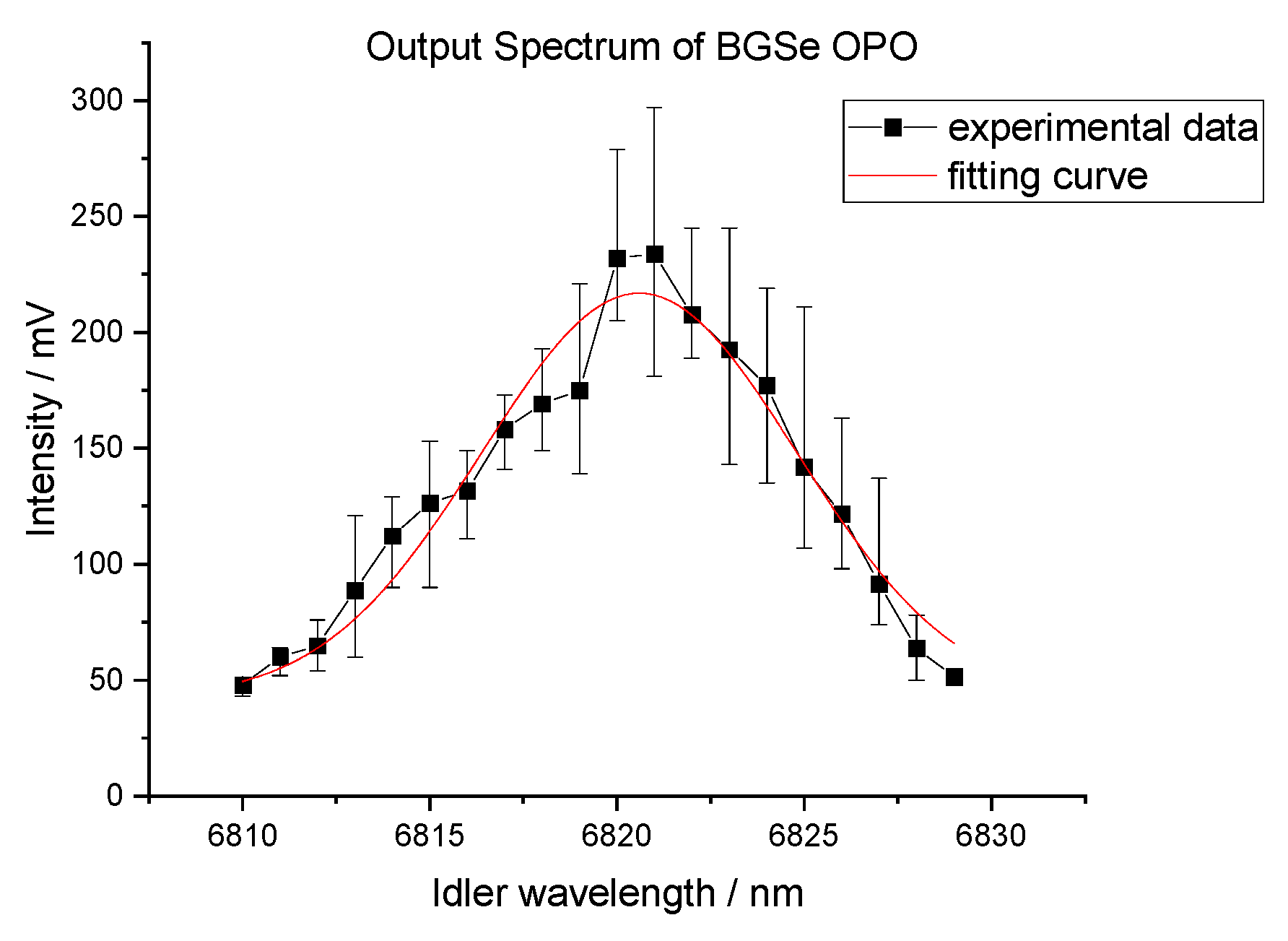

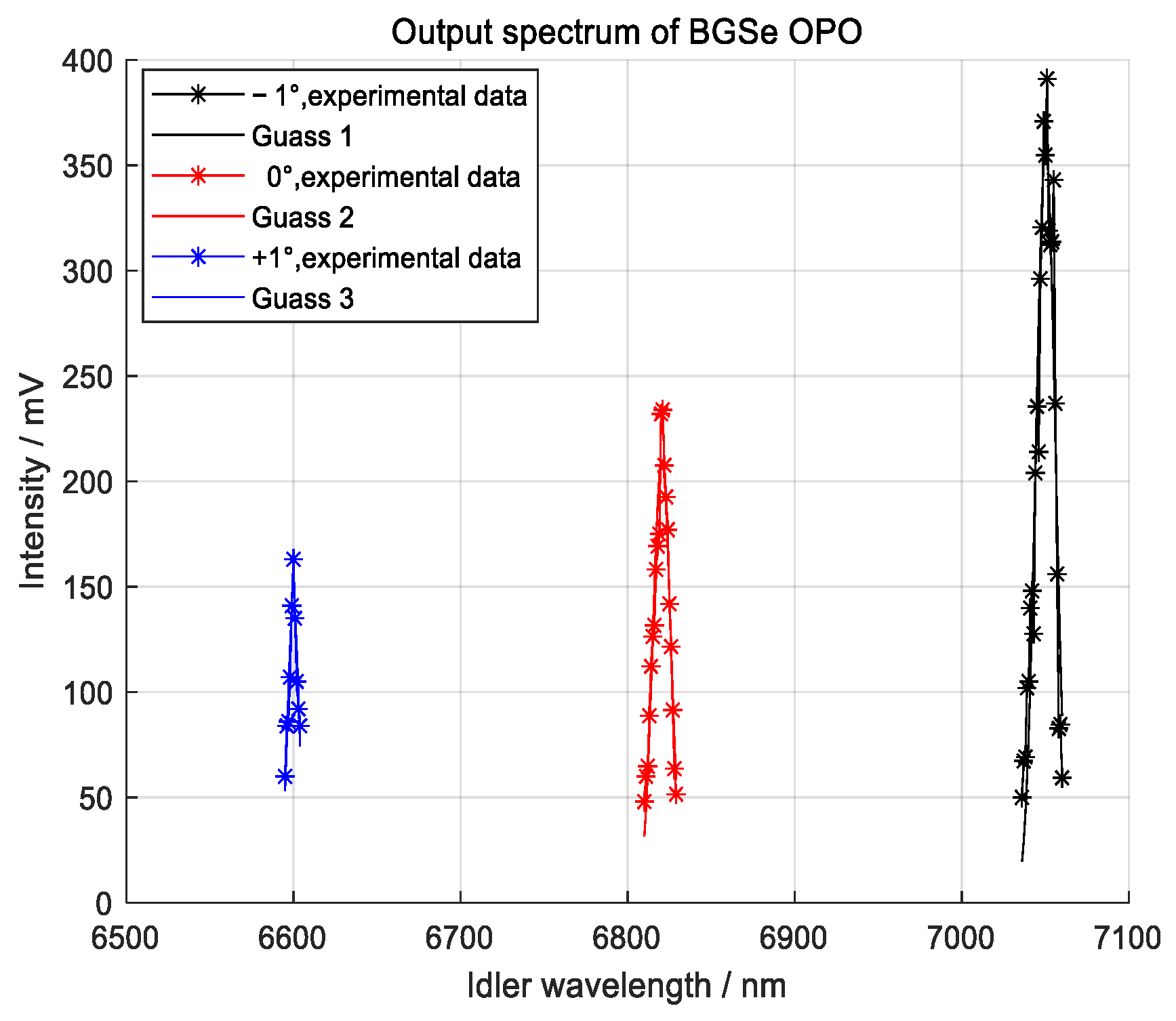

3.2. Output Spectra at 30 °C and Different Incidence Angles

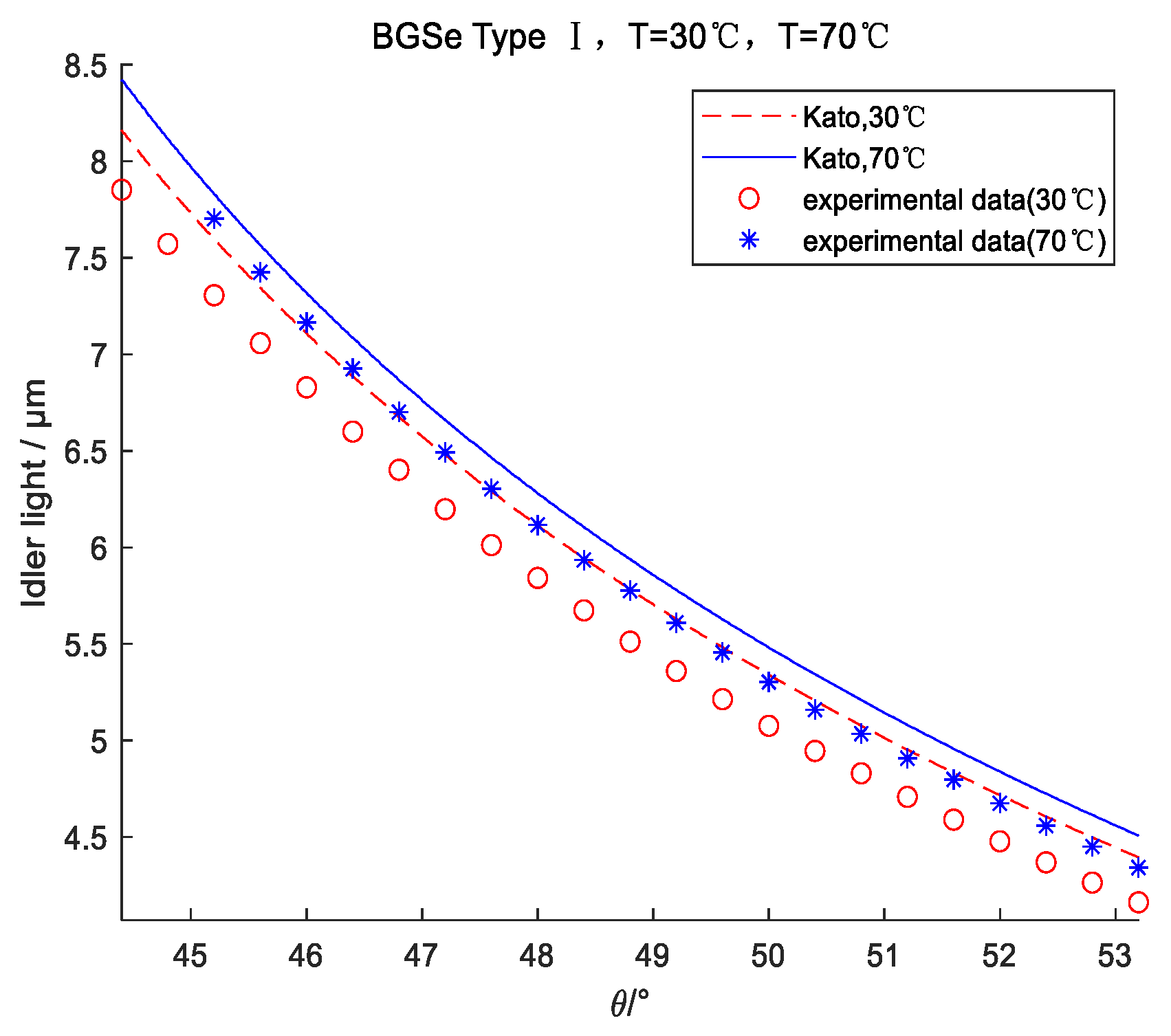

3.3. BGSe (44.4–53.2°) Output Wavelength at 30–70 °C

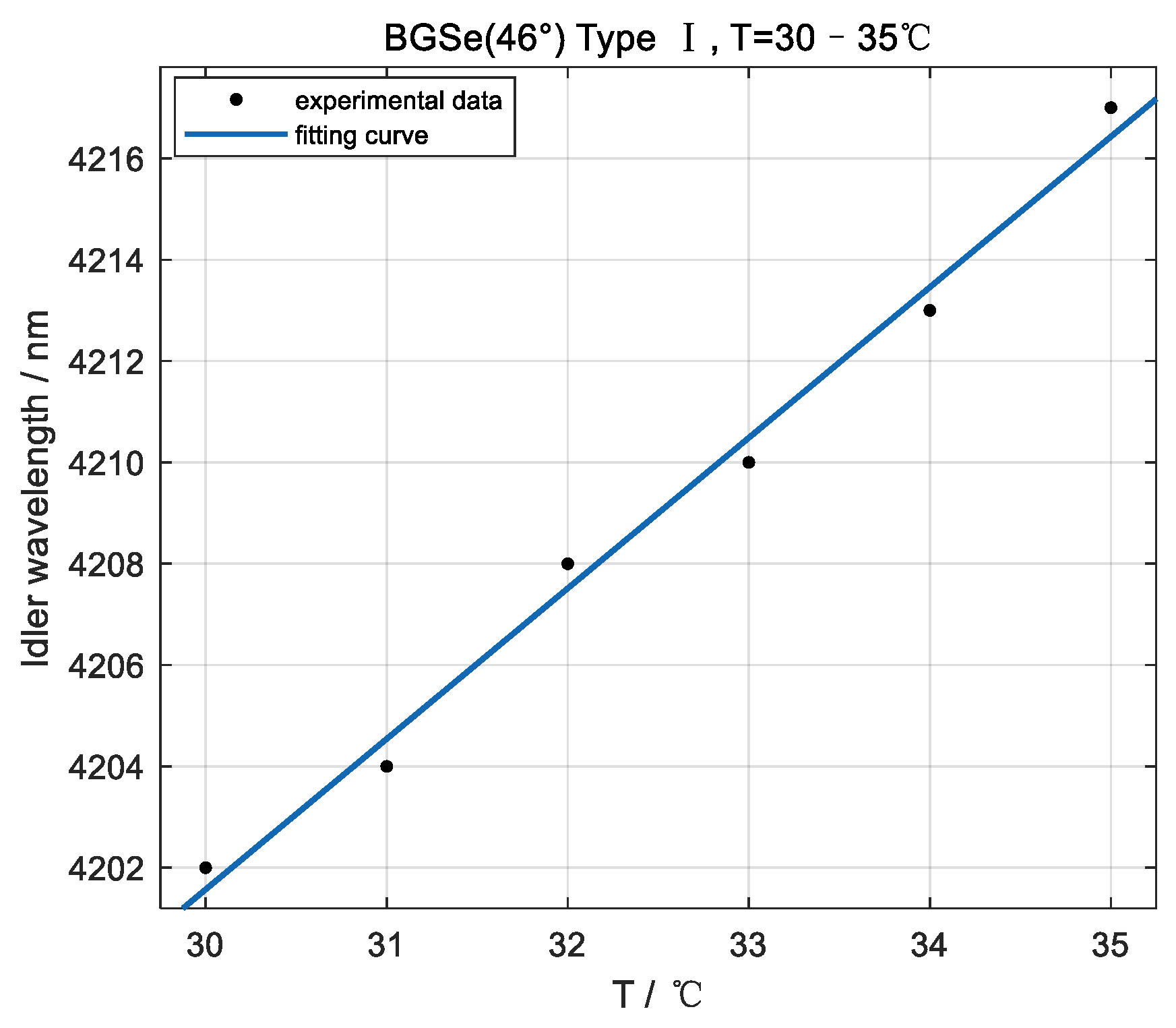

3.4. Temperature Tuning at a Fixed Angle (θ = 46°)

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ngai, A.K.Y.; Persijn, S.; Basum, G.; Harren, F. Automatically tunable continuous-wave optical parametric oscillator for high-resolution spectroscopy and sensitive trace-gas detection. Appl. Phys. B 2006, 85, 173–180. [Google Scholar] [CrossRef]

- Gabrieli, A.; Wright, R.; Lucey, P.G.; Porter, J.N.; Garbeil, H.; Pilger, E.; Wood, M. Characterization and initial field test of an 8–14 μm thermal infrared hyperspectral imager for measuring SO2 in volcanic plumes. Bull. Volcanol. 2016, 78, 73. [Google Scholar]

- Bowles, N.E.; Tecza, M.; Barstow, J.K.; Temple, J.M.; Irwin, P.G.J.; Fletcher, L.N.; Calcutt, S.; Hurley, J.; Ferlet, M.; Freeman, D.J.E.A. The Long wave (11–16 μm) spectrograph for the EChO M3 Mission Candidate study. Exp. Astron. 2015, 40, 801–811. [Google Scholar] [CrossRef]

- Sijan, A. Development of military lasers for optical countermeasures in the mid-IR. In Proceedings of the Technologies for Optical Countermeasures VI, Berlin, Germany, 31 August–1 September 2009. [Google Scholar]

- Naranjo, E.; Baliga, S.; Bernascolle, P. IR gas imaging in an industrial setting. In Thermosense Xxxii; SPIE: Bellingham, WA, USA, 2010; p. 7661. [Google Scholar]

- Yao, J.; Mei, D.; Bai, L.; Lin, Z.; Yin, W.; Fu, P.; Wu, Y. BaGa4Se7: A New Congruent-Melting IR Nonlinear Optical Material. Inorg. Chem. 2010, 49, 9212–9216. [Google Scholar] [CrossRef] [PubMed]

- Kostyukova, N.Y.; Boyko, A.A.; Badikov, V.; Badikov, D.; Shevyrdyaeva, G.; Panyutin, V.; Marchev, G.M.; Kolker, D.B.; Petrov, V. Widely tunable in the mid-IR BaGa4Se7 optical parametric oscillator pumped at 1064 nm. Opt. Lett. 2016, 41, 3667–3670. [Google Scholar] [CrossRef] [PubMed]

- Xu, W.-T.; Wang, Y.-y.; Xu, D.-G.; Li, C.; Yao, J.-Y.; Yan, C.; He, Y.-X.; Nie, M.-t.; Wu, Y.-C.; Yao, J.-q. High-pulse-energy mid-infrared optical parametric oscillator based on BaGa4Se7 crystal pumped at 1.064 μm. Appl. Phys. B 2017, 123, 80. [Google Scholar] [CrossRef]

- Zhao, B.; Chen, Y.; Yao, B.; Yao, J.; Guo, Y.; Wang, R.; Dai, T.; Duan, X. High-efficiency, tunable 8–9 μm BaGa4Se7 optical parametric oscillator pumped at 21 μm. Opt. Mater. Express 2018, 8, 3332–3337. [Google Scholar] [CrossRef]

- Kang, M.; Deng, Y.; Yan, X.; Zeng, X.; Guo, Y.; Yao, J.; Zeng, F.; Zheng, J.; Zhou, K.; Qu, C.; et al. A compact and efficient 4.25 μm BaGa4Se7 optical parametric oscillator. Chin. Opt. Lett. 2019, 17, 121402. [Google Scholar] [CrossRef]

- Zhang, Y.; Liu, Y.; Jia, D.; Yu, T.; Huang, Y.; Zhang, Z.; Wang, R.; Zhou, P.; Lin, X.; Cai, Y.; et al. Electrically controlled tunable optical parametric oscillator (3.0–6.7 μm) based on BaGa4Se7 crystal pumped by a Q-switch Nd:YAG laser. In Proceedings of the AOPC 2020: Advanced Laser Technology and Application, Beijing, China, 30 November–2 December 2020. [Google Scholar]

- Xu, D.; Zhang, J.; Wang, Y.; Yao, J.; Guo, Y.; Chen, K.; Yan, C.; Yao, J.; Jiang, S.; Hartl, I.; et al. Widely-tuned longwave mid-infrared optical parametric oscillator based on BaGa4Se7 crystal. In Proceedings of the Advanced Lasers, High-Power Lasers, and Applications XII, Nantong, China, 10–20 October 2021. [Google Scholar]

- He, Y.; Yan, C.; Chen, K.; Xu, D.; Li, J.; Zhong, K.; Wang, Y.; Yao, R.; Yao, J.; Yao, J. High Repetition Rate, Tunable Mid-Infrared BaGa4Se7 Optical Parametric Oscillator Pumped by a 1 μm Nd:YAG Laser. Appl. Sci. 2022, 12, 7197. [Google Scholar] [CrossRef]

- Kong, H.; Bian, J.; Yao, J.; Ye, Q.; Sun, X. Temperature tuning of BaGa4Se7 optical parametric oscillator. Chin. Opt. Lett. 2021, 19, 021901. [Google Scholar] [CrossRef]

- Yang, K.; Yao, B.; Li, C.; Yao, J.; Mi, S.; Tang, J.; Wei, D.; Li, J.; Xiao Hua, X.; Duan, X.; et al. High efficiency non-critical phase-matching 9.3–10.6 μm optical parametric oscillator in BaGa4Se7 crystal. Opt. Laser Technol. 2023, 160, 109082. [Google Scholar] [CrossRef]

- Kato, K.; Miyata, K.; Petrov, V. Phase-matching properties of BaGa4Se7 for SHG and SFG in the 0901–105910 μm range. Appl. Opt. 2017, 56, 2978–2981. [Google Scholar] [CrossRef] [PubMed]

| Years | Authors | Tuning Method | Tuning Range (μm) | Tuning Slope (nm/° or nm/°C) |

|---|---|---|---|---|

| 2016 | Kostyukova et al. [7] | angular tuning | 2.70–17.00 | 680 |

| 2017 | Xu et al. [8] | angular tuning | 3.12–5.16 | 212 |

| 2018 | Zhao et al. [9] | angular tuning | 8.00–9.00 | 327 |

| 2020 | Zhang et al. [11] | angular tuning | 3.00–6.70 | 294 |

| 2021 | Xu et al. [12] | angular tuning | 8.24–13.30 | 1581 |

| 2021 | Kong et al. [14] | temperature tuning | 3.00–5.00 | 3.2 |

| 2022 | He et al. [13] | angular tuning | 3.42–4.73 | 305 |

| 2023 | Yang et al. [15] | temperature tuning | 9.39–10.63 | 31.0 |

| No. of Colored Lines | Peak Wavelength (nm) | ) | ) | Linewidth (nm) |

|---|---|---|---|---|

| 1 | 6600 | +1 | 46.4 | 8.37 |

| 2 | 6821 | 0 | 46 | 12.62 |

| 3 | 7051 | −1 | 45.6 | 13.86 |

| No. of Angle Points | of BGSe (°) | Output Wavelength (nm) | Temperature Tuning Slope (nm/°C) | Difference between Rotation Angle and 90° (°) | ||

|---|---|---|---|---|---|---|

| 30 °C | 70 °C | |||||

| 1 | 44.4 | 7852 | --- | --- | −1.6 | −4 |

| 2 | 44.8 | 7572 | --- | --- | −1.2 | −3 |

| 3 | 45.2 | 7306 | 7703 | 9.93 | −0.8 | −2 |

| 4 | 45.6 | 7058 | 7425 | 9.18 | −0.4 | −1 |

| 5 | 46.0 | 6829 | 7165 | 8.40 | 0 | 0 |

| 6 | 46.4 | 6600 | 6926 | 8.15 | 0.4 | 1 |

| 7 | 46.8 | 6402 | 6701 | 7.48 | 0.8 | 2 |

| 8 | 47.2 | 6198 | 6493 | 7.38 | 1.2 | 3 |

| 9 | 47.6 | 6012 | 6304 | 7.30 | 1.6 | 4 |

| 10 | 48.0 | 5842 | 6116 | 6.85 | 2.0 | 5 |

| 11 | 48.4 | 5674 | 5935 | 6.53 | 2.4 | 6 |

| 12 | 48.8 | 5512 | 5776 | 6.60 | 2.8 | 7 |

| 13 | 49.2 | 5360 | 5610 | 6.25 | 3.2 | 8 |

| 14 | 49.6 | 5214 | 5456 | 6.05 | 3.6 | 9 |

| 15 | 50.0 | 5076 | 5303 | 5.68 | 4.0 | 10 |

| 16 | 50.4 | 4946 | 5160 | 5.35 | 4.4 | 11 |

| 17 | 50.8 | 4830 | 5035 | 5.13 | 4.8 | 12 |

| 18 | 51.2 | 4708 | 4908 | 5.00 | 5.2 | 13 |

| 19 | 51.6 | 4590 | 4798 | 5.20 | 5.6 | 14 |

| 20 | 52.0 | 4478 | 4675 | 4.93 | 6.0 | 15 |

| 21 | 52.4 | 4369 | 4559 | 4.75 | 6.4 | 16 |

| 22 | 52.8 | 4264 | 4451 | 4.68 | 6.8 | 17 |

| 23 | 53.2 | 4162 | 4342 | 4.50 | 7.2 | 18 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, X.; Kong, H.; Zou, J.; Lv, G.; Bian, J.; Xu, H.; Wen, K.; Jiang, X.; Ma, Y. High-Resolution Laser in Widely Tunable Range (4.16–7.13 µm) Based on Mid-Infrared BaGa4Se7 Optical Parametric Oscillator Pumped at 1064 nm. Photonics 2023, 10, 1134. https://doi.org/10.3390/photonics10101134

Zhao X, Kong H, Zou J, Lv G, Bian J, Xu H, Wen K, Jiang X, Ma Y. High-Resolution Laser in Widely Tunable Range (4.16–7.13 µm) Based on Mid-Infrared BaGa4Se7 Optical Parametric Oscillator Pumped at 1064 nm. Photonics. 2023; 10(10):1134. https://doi.org/10.3390/photonics10101134

Chicago/Turabian StyleZhao, Xinqiang, Hui Kong, Jierui Zou, Guorui Lv, Jintian Bian, Haiping Xu, Kaihua Wen, Xiuhong Jiang, and Yunfan Ma. 2023. "High-Resolution Laser in Widely Tunable Range (4.16–7.13 µm) Based on Mid-Infrared BaGa4Se7 Optical Parametric Oscillator Pumped at 1064 nm" Photonics 10, no. 10: 1134. https://doi.org/10.3390/photonics10101134

APA StyleZhao, X., Kong, H., Zou, J., Lv, G., Bian, J., Xu, H., Wen, K., Jiang, X., & Ma, Y. (2023). High-Resolution Laser in Widely Tunable Range (4.16–7.13 µm) Based on Mid-Infrared BaGa4Se7 Optical Parametric Oscillator Pumped at 1064 nm. Photonics, 10(10), 1134. https://doi.org/10.3390/photonics10101134