Causal Diagnosability Optimization Design for UAVs Based on Maximum Mean Covariance Difference and the Gray Wolf Optimization Algorithm

Abstract

1. Introduction

2. Proposed Methodology

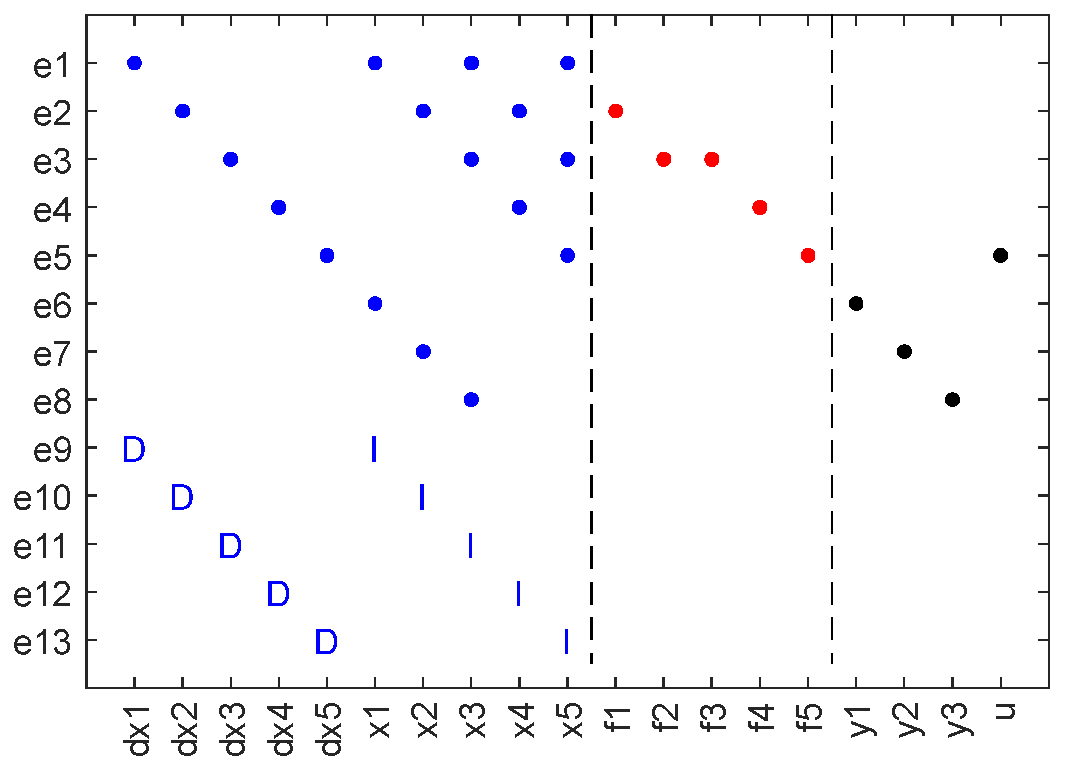

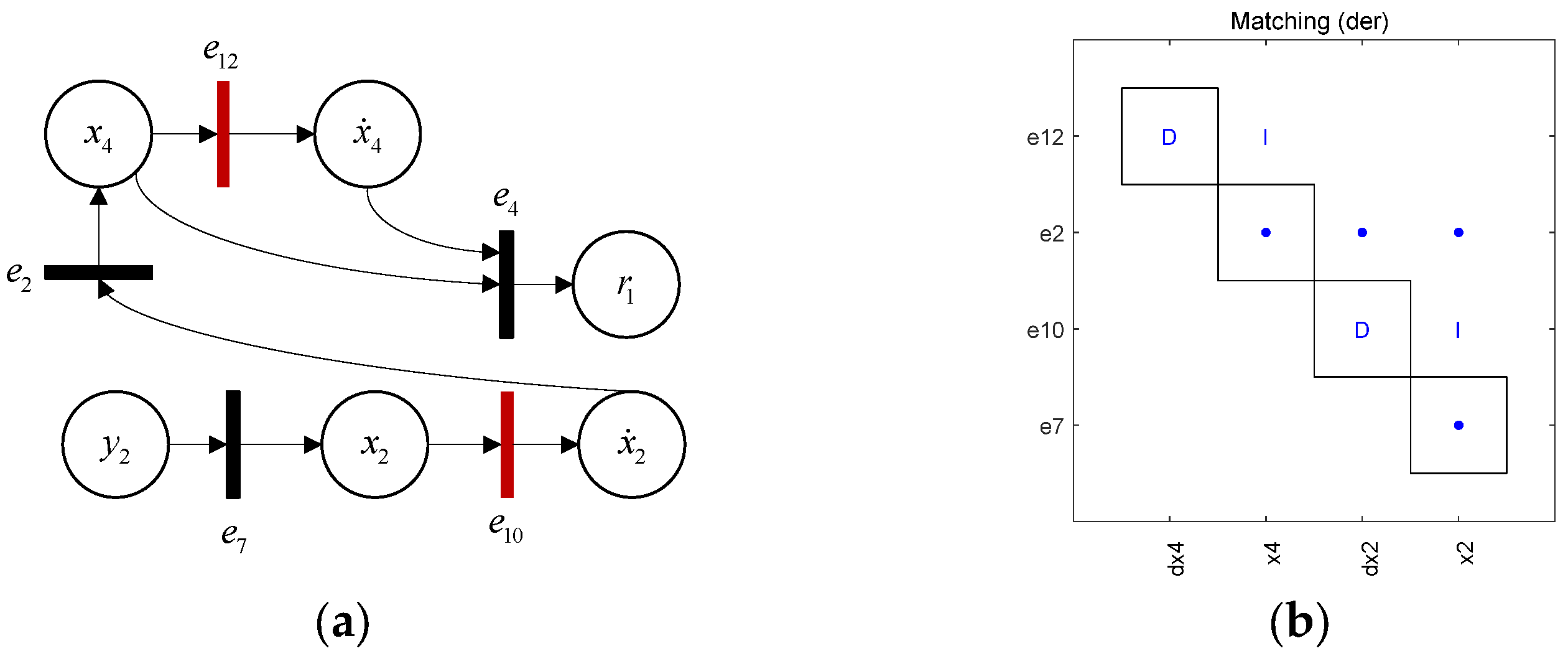

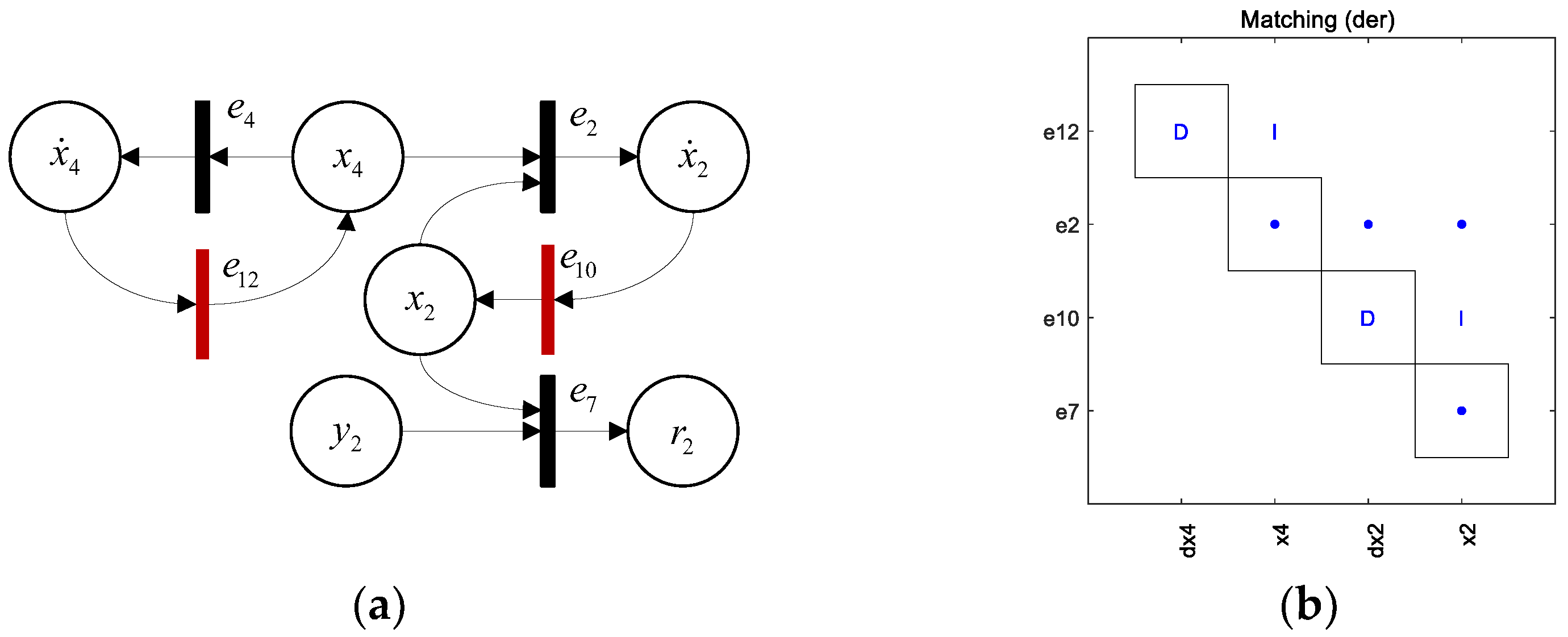

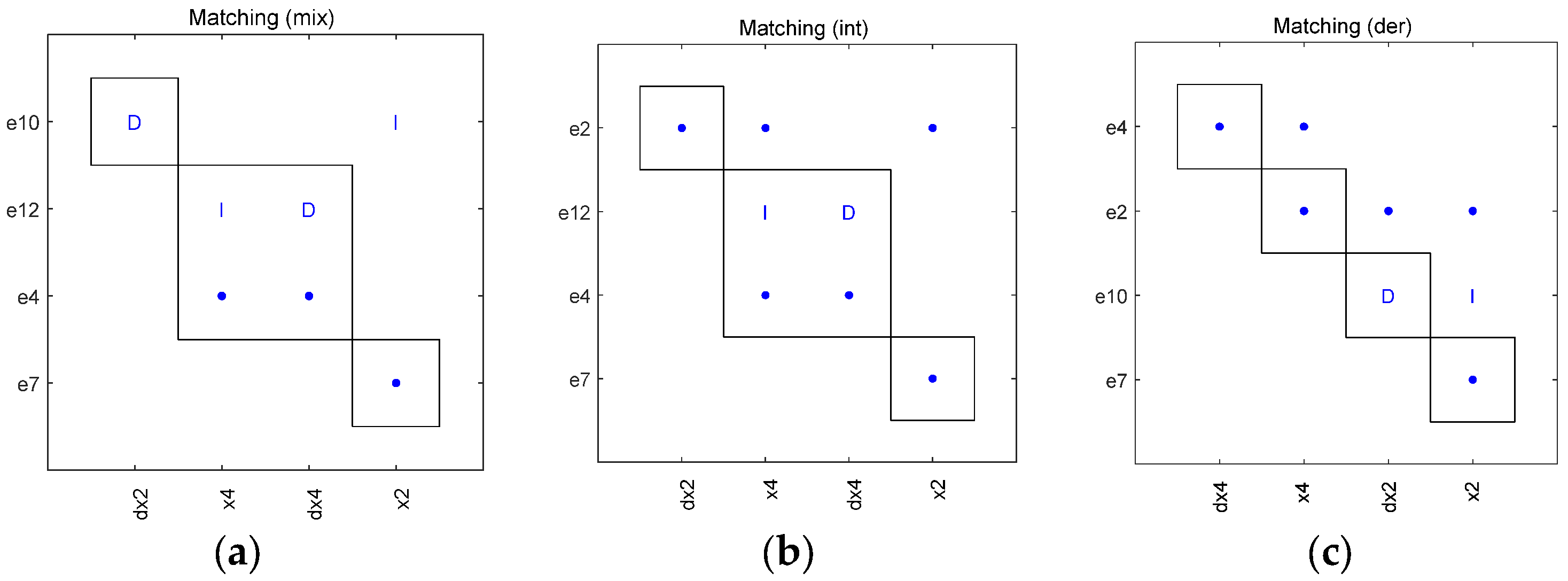

2.1. Causal Diagnosability Based on Structural Analysis

2.1.1. Structural Model

2.1.2. Causal Diagnosability

2.2. Quantitative Assessment of Diagnosability Based on MMCD

2.2.1. MMCD

2.2.2. Quantitative Assessment

2.3. Diagnosability Optimization Design Using GWO Algorithm

2.3.1. Optimization Design Model

- Step 1: Build the system structure model ;

- Step 2: Using the causal MSO algorithm from the literature [27], obtain the under different causal conditions;

- Step 3: Design the residual set that satisfies the diagnosability requirement;

- Step 4: Construct the vector ;

- Step 5: Assume that the design cost of is . Then, the design cost of is expressed as follows:

2.3.2. Diagnosability Optimization Design Strategy Based on the GWO Algorithm

- Step 1: For parameter initialization, set the gray wolf population as , maximum iteration number , and parameters , , and . The parameters of MMCD are selected from the optimal parameter settings verified in the literature [40];

- Step 2: Based on Equation (26), initialize the position of the gray wolf population ;

- Step 3: If the constraints shown in Equation (29) are satisfied, calculate its fitness value based on Equation (28); otherwise, its fitness value is infinity. Second, determine the wolf, wolf, and wolf according to the merit of fitness;

- Step 4: Update the location of the gray wolf population based on Equation (35);

- Step 5: Update the parameters , , and ;

- Step 6: Judge whether the maximum number of iterations has been reached. If so, stop the algorithm and return as the optimal solution ; otherwise, return to step 3.

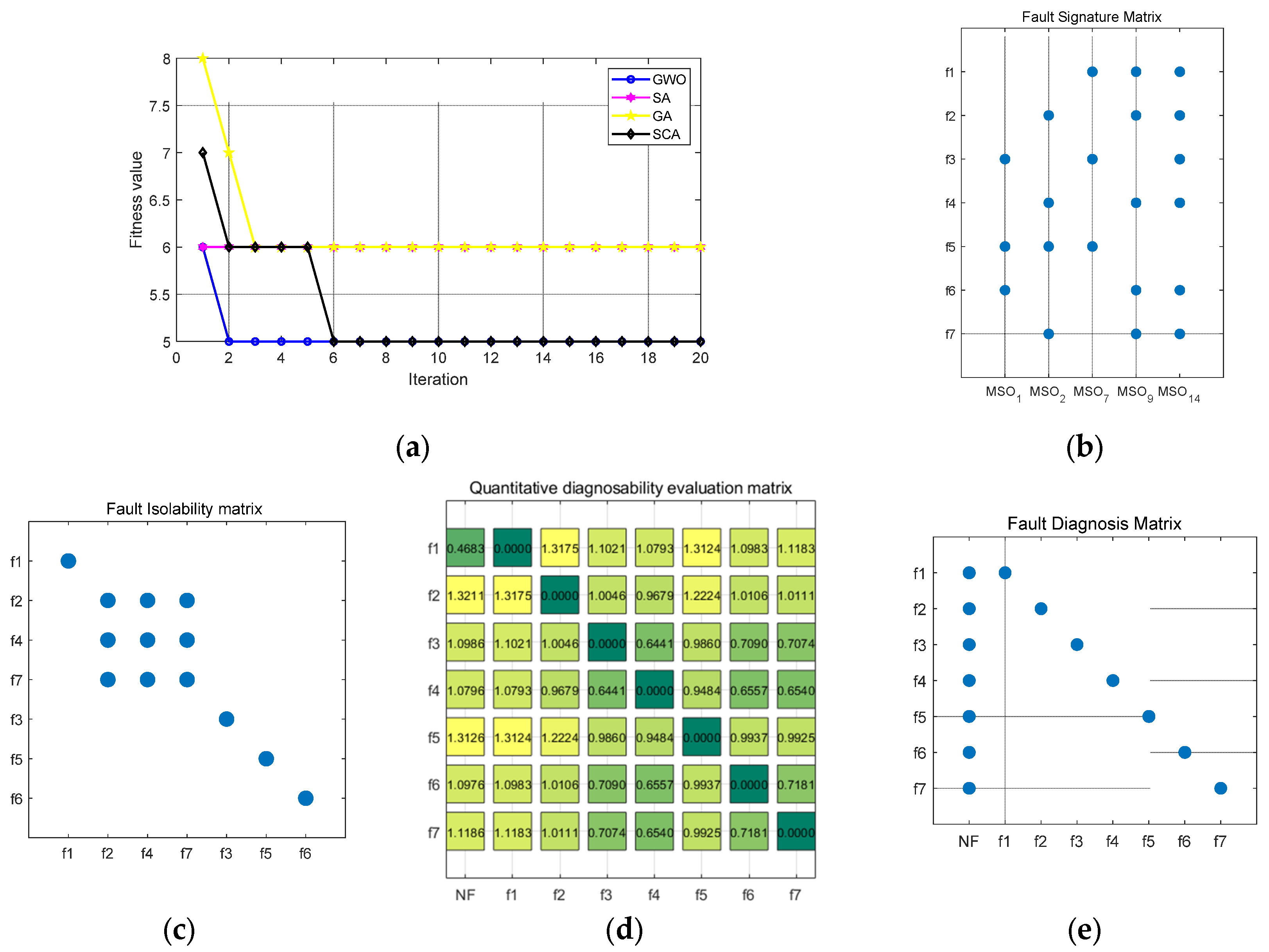

3. Results and Analysis

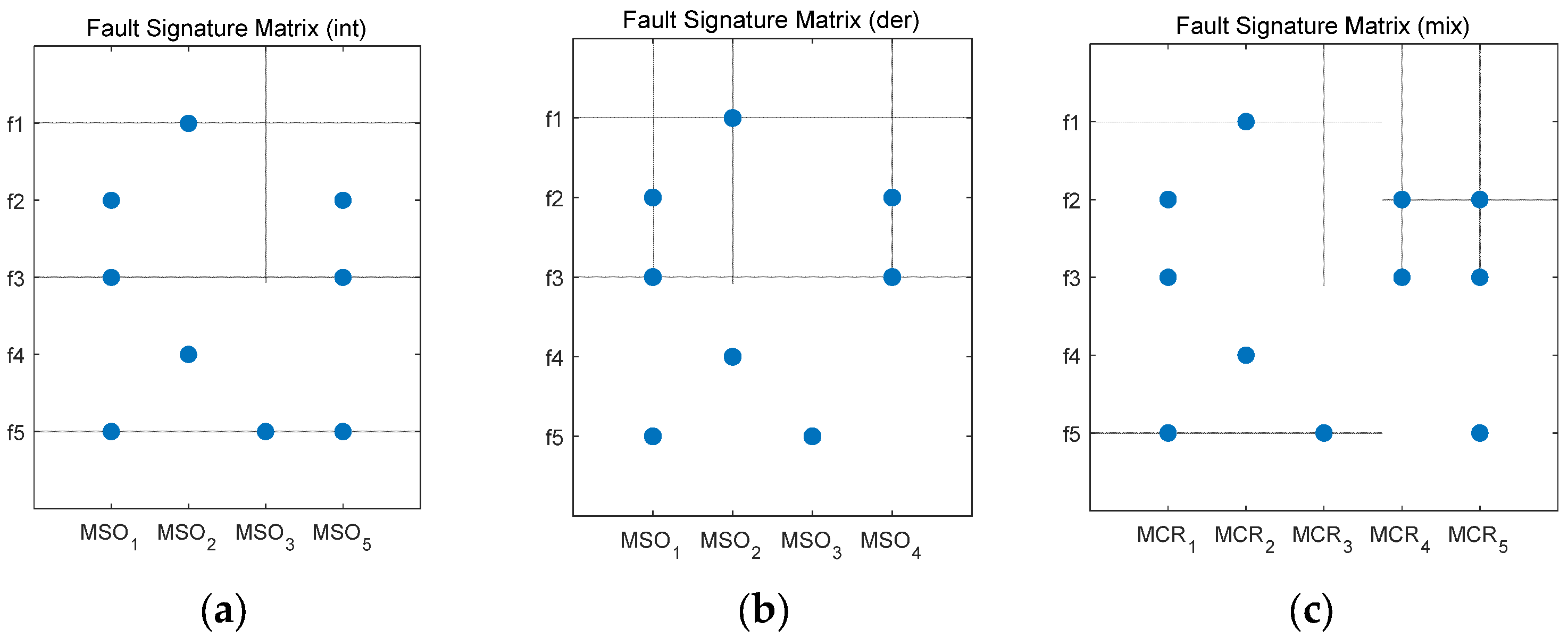

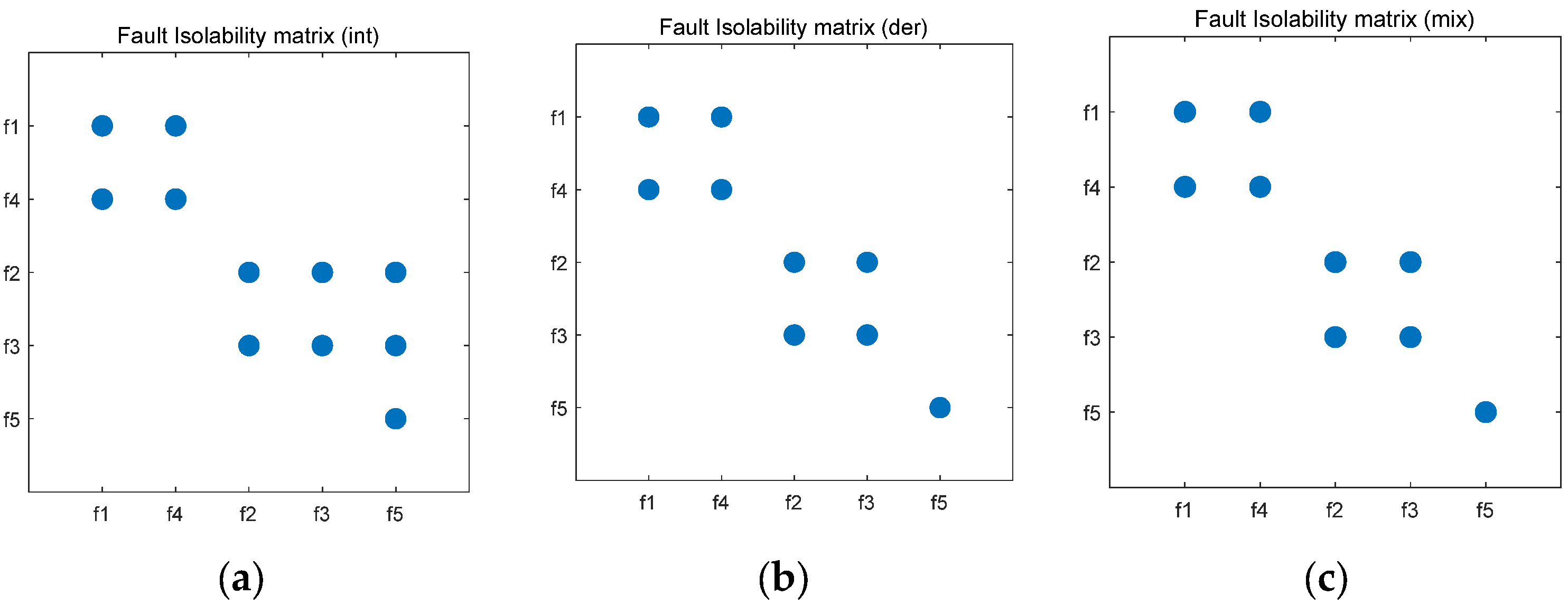

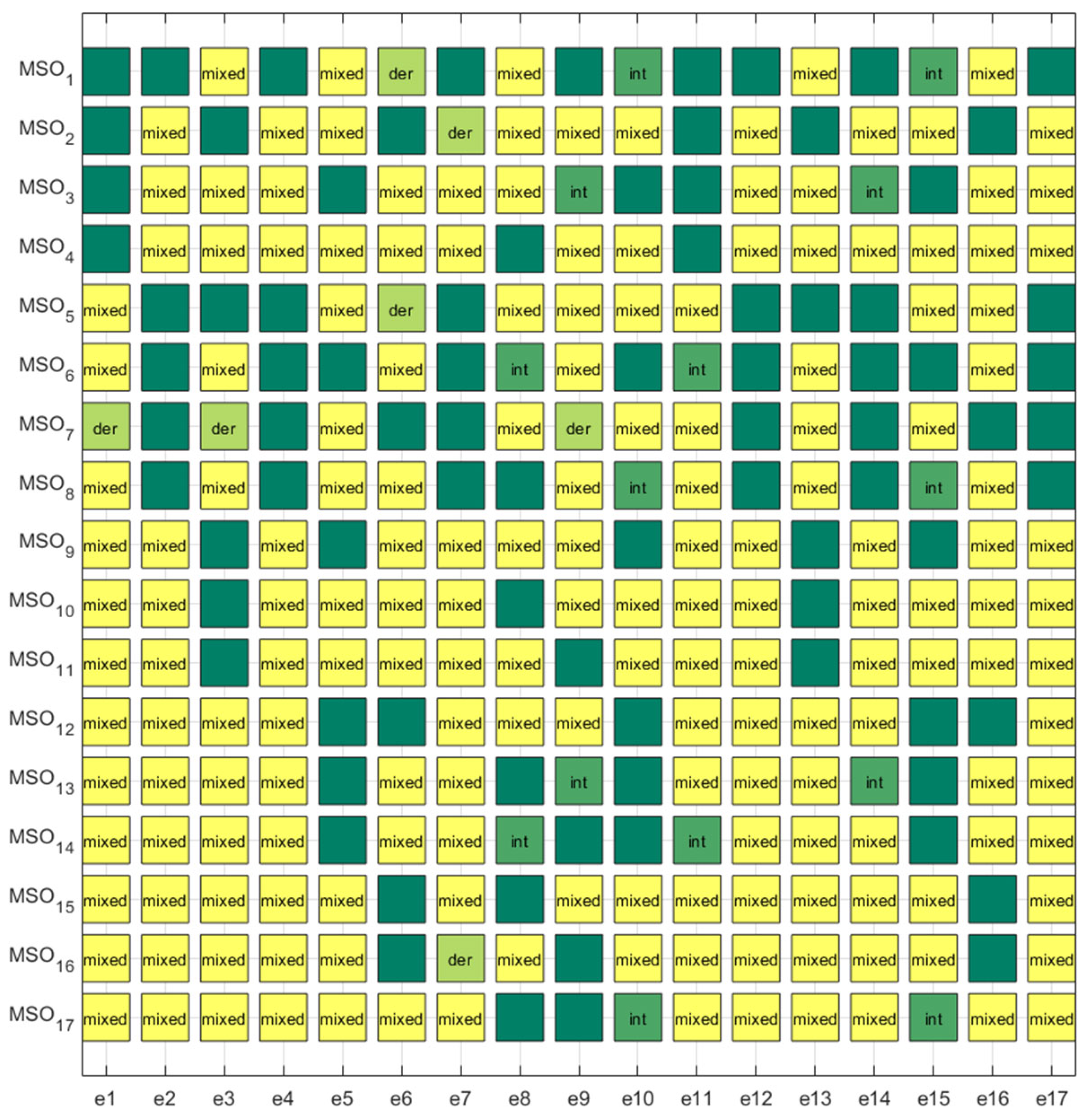

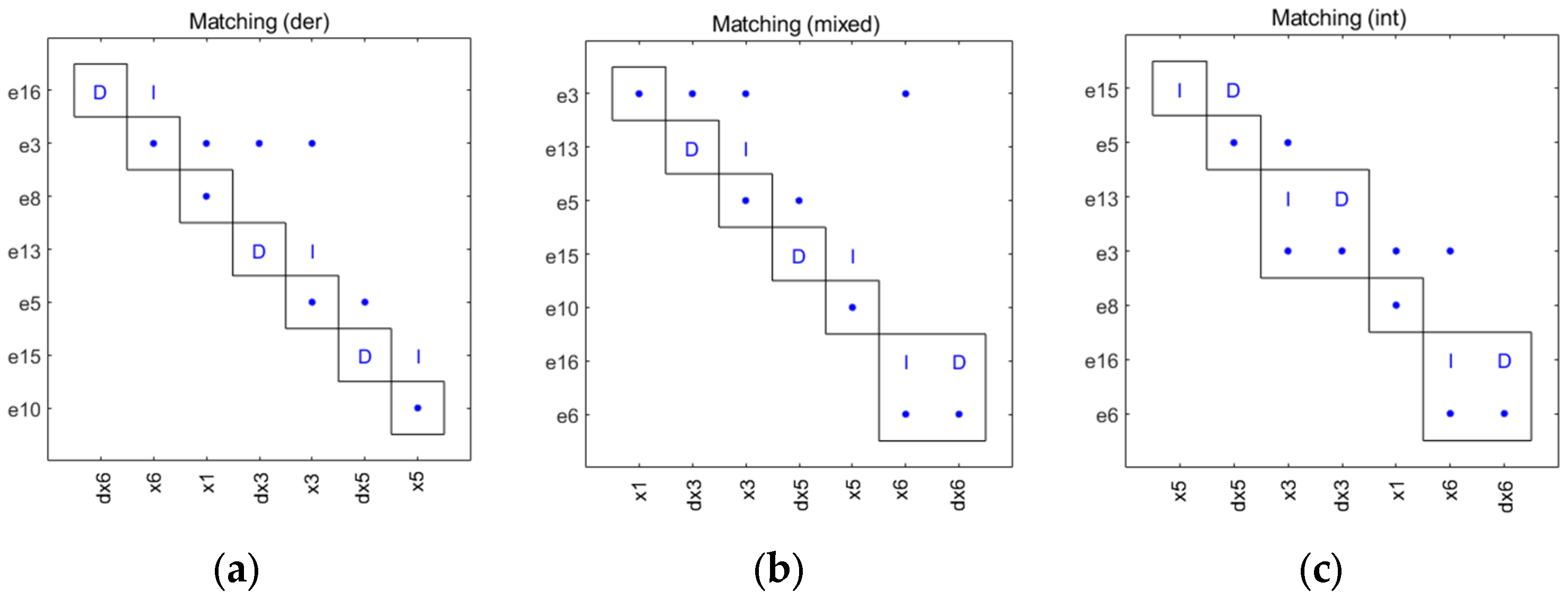

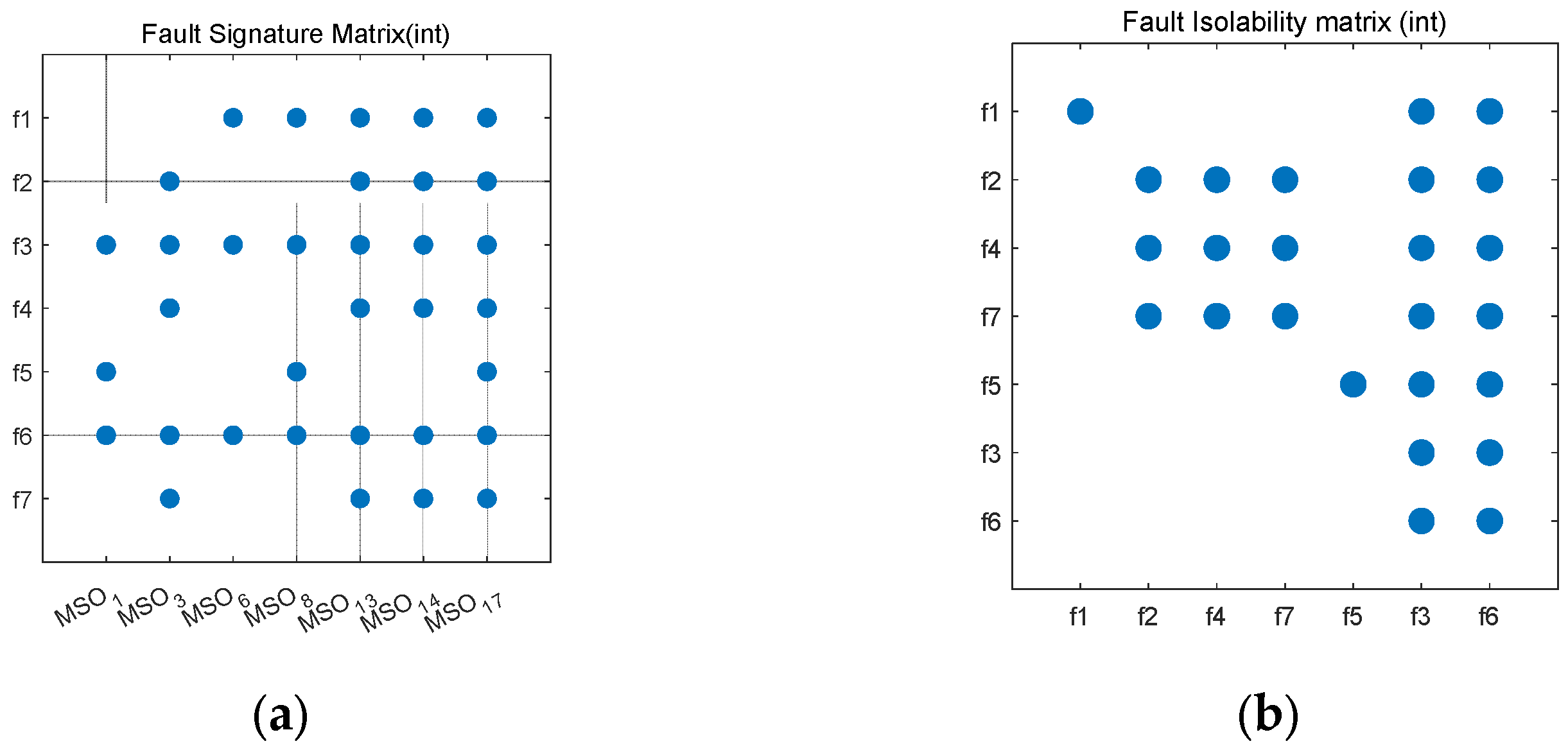

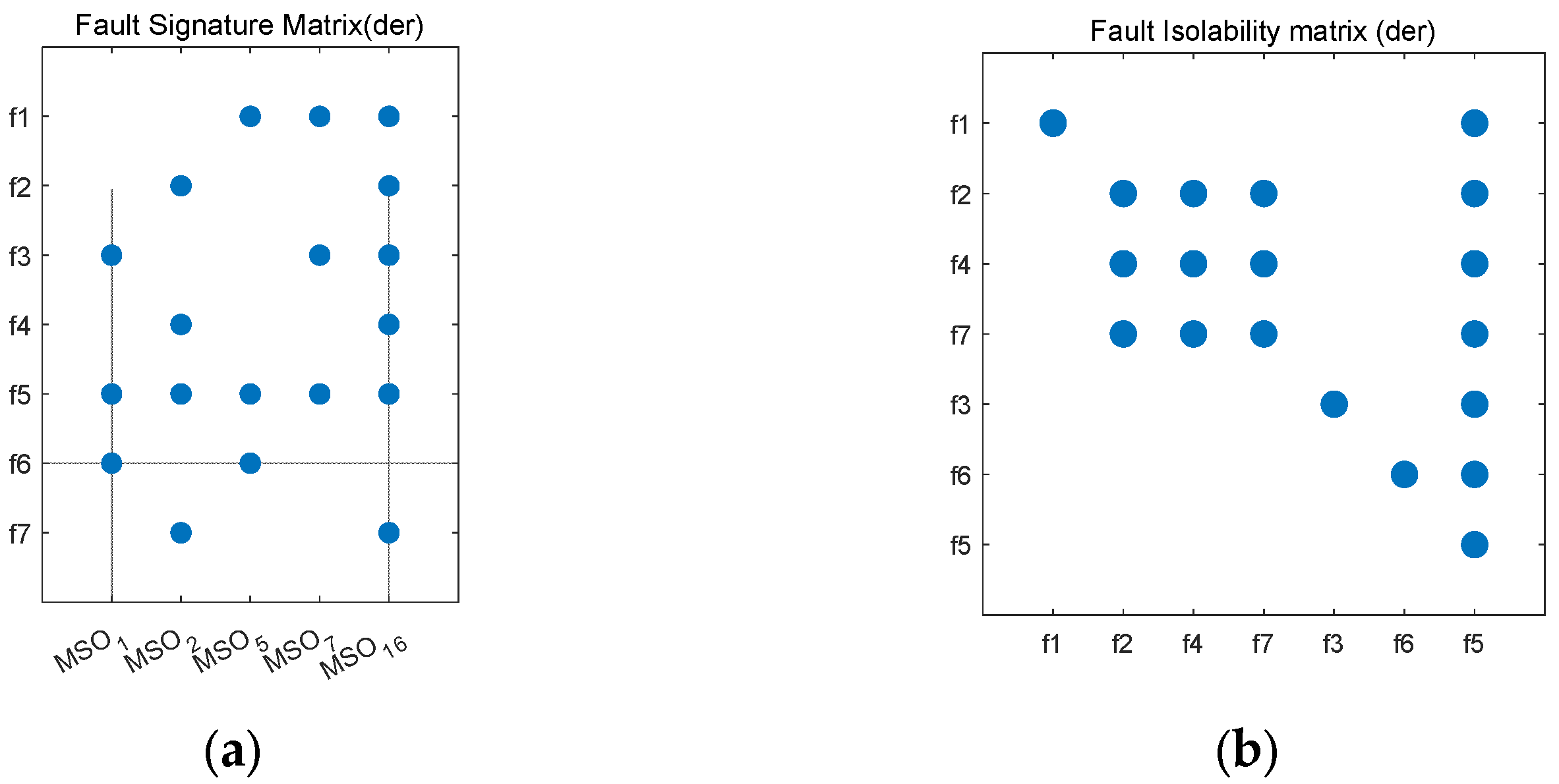

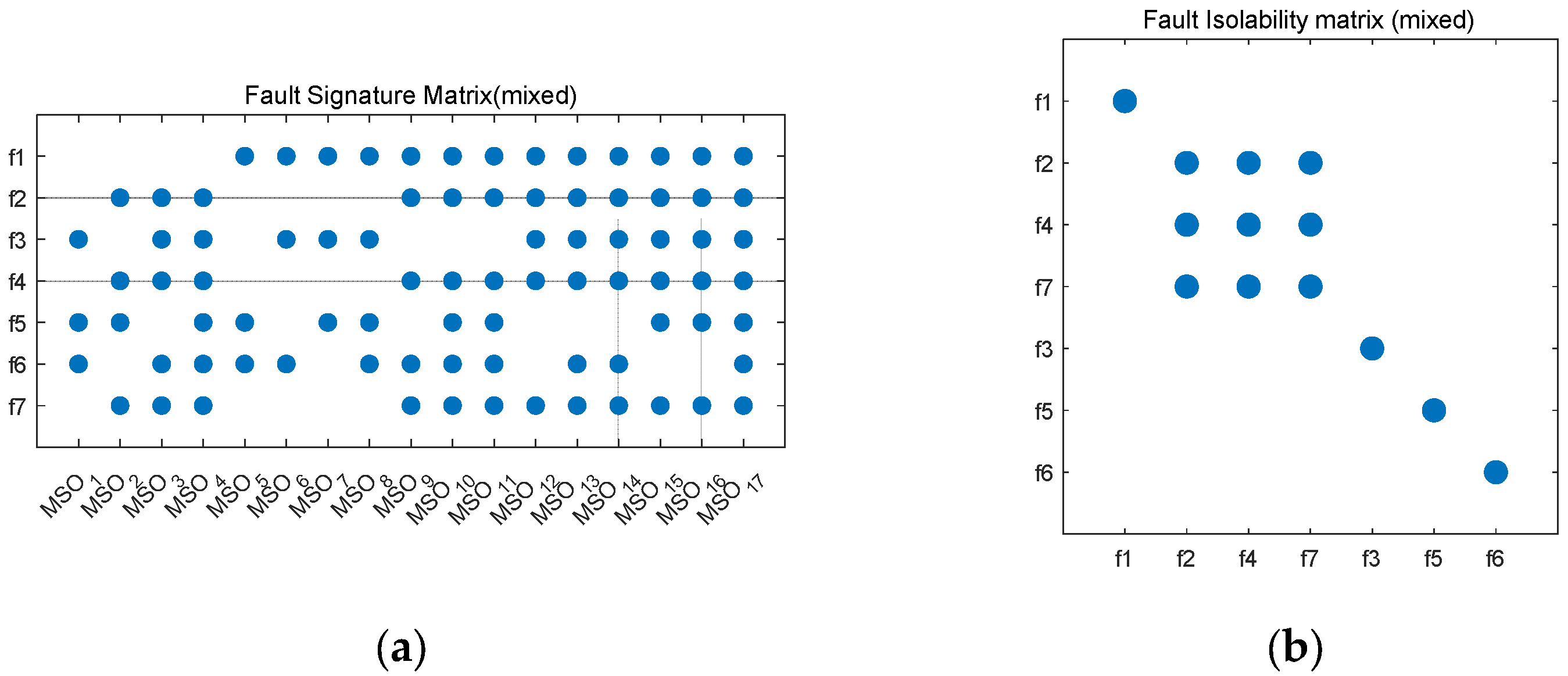

3.1. Causal Diagnosability of Fixed-Wing UAVs

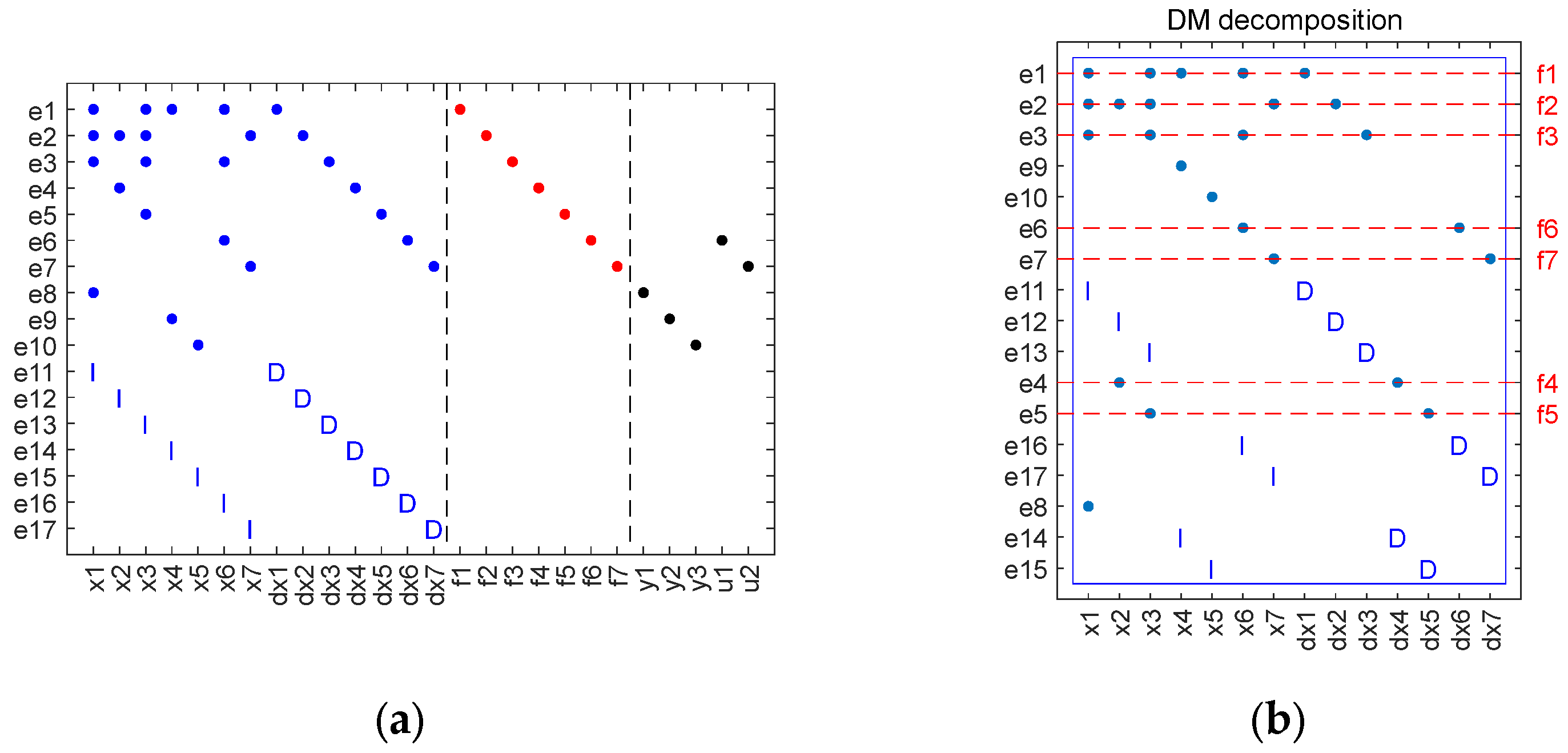

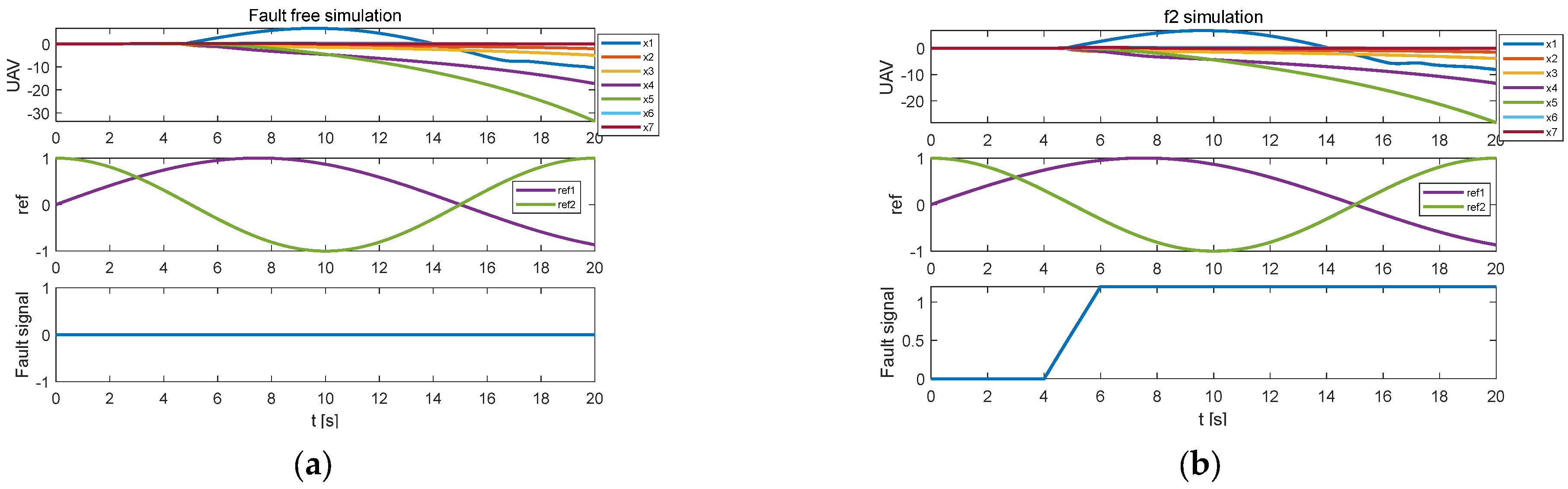

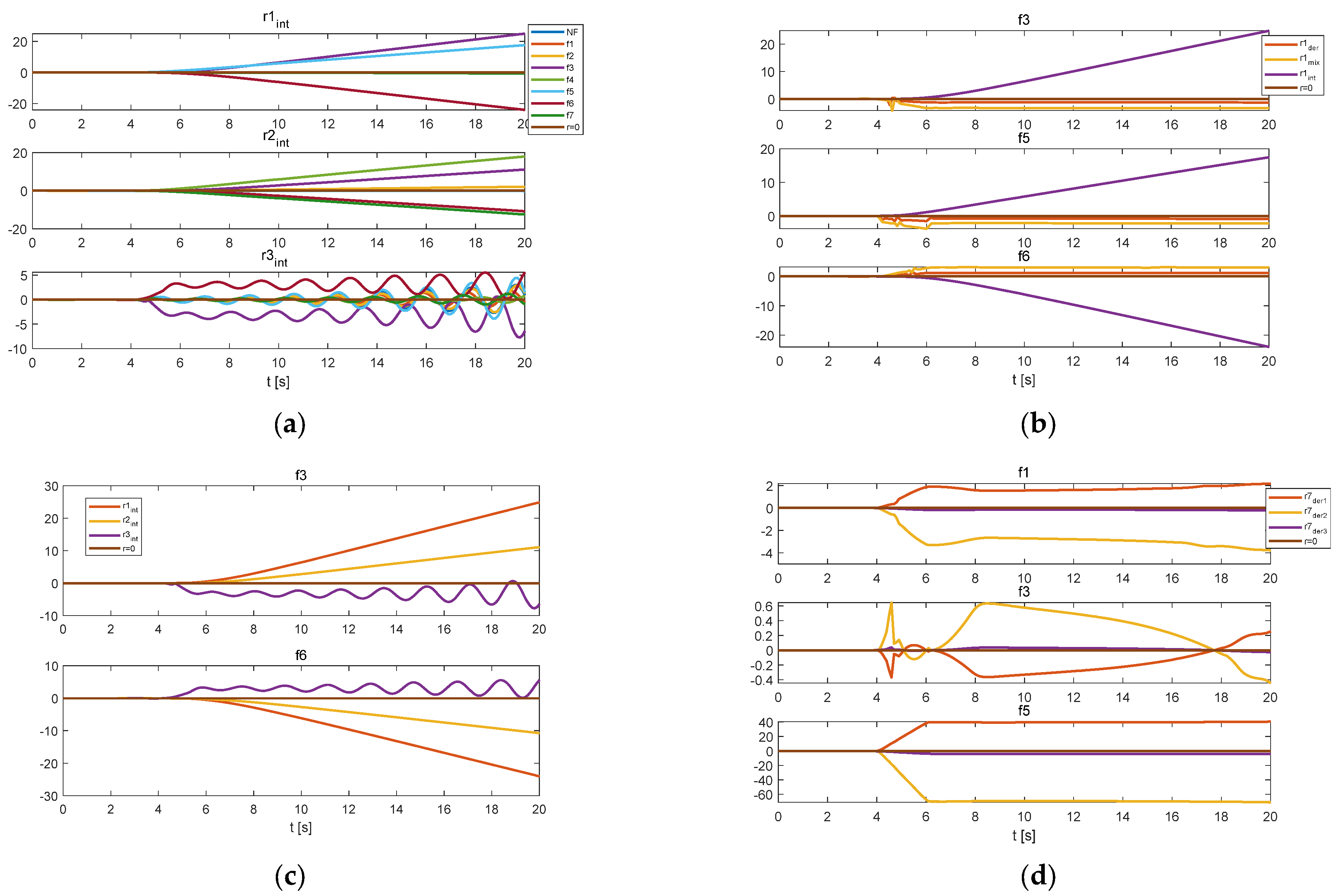

3.2. Diagnosability Impact Factor Analysis

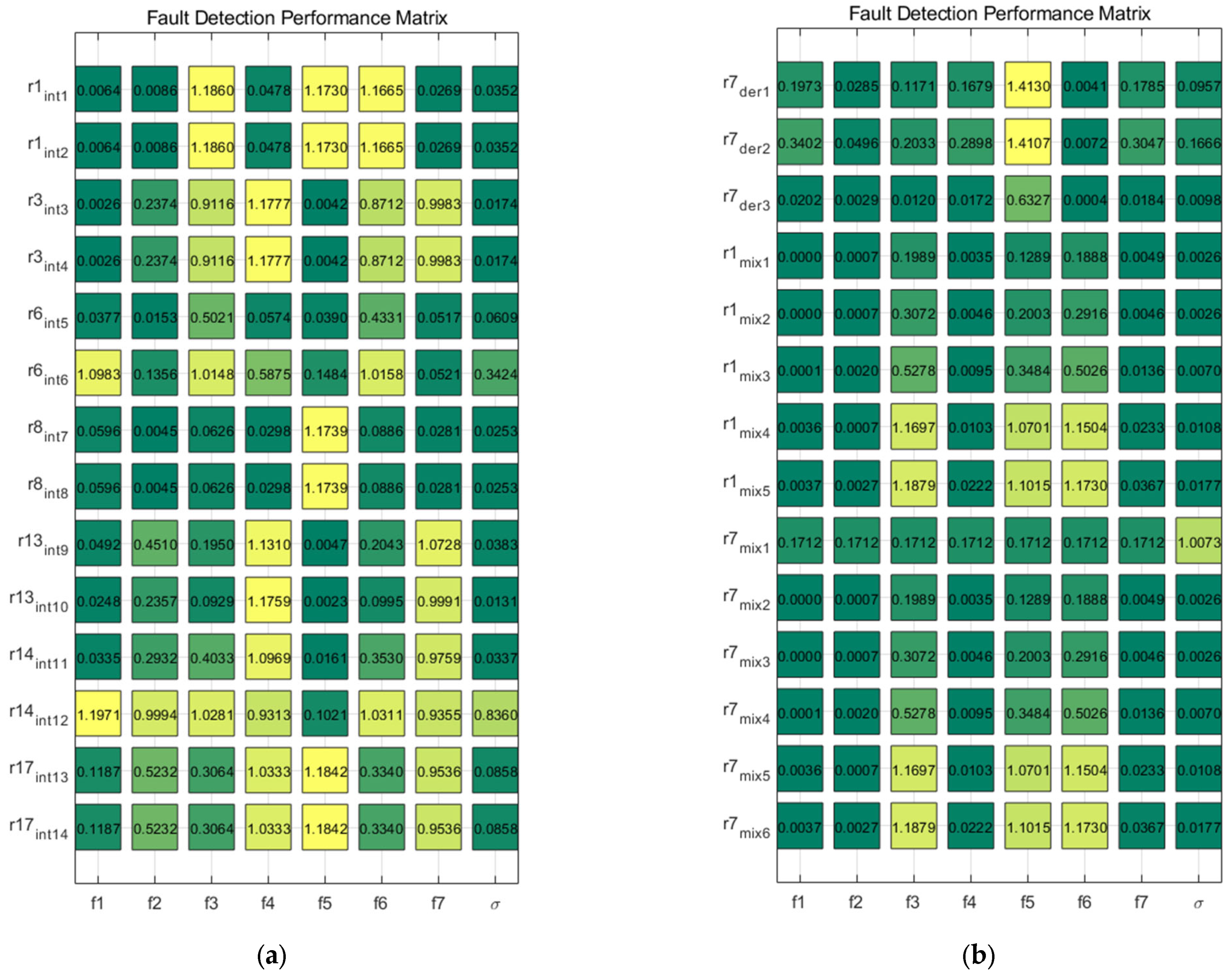

3.3. MMCD-Based Diagnosability Quantitative Assessment

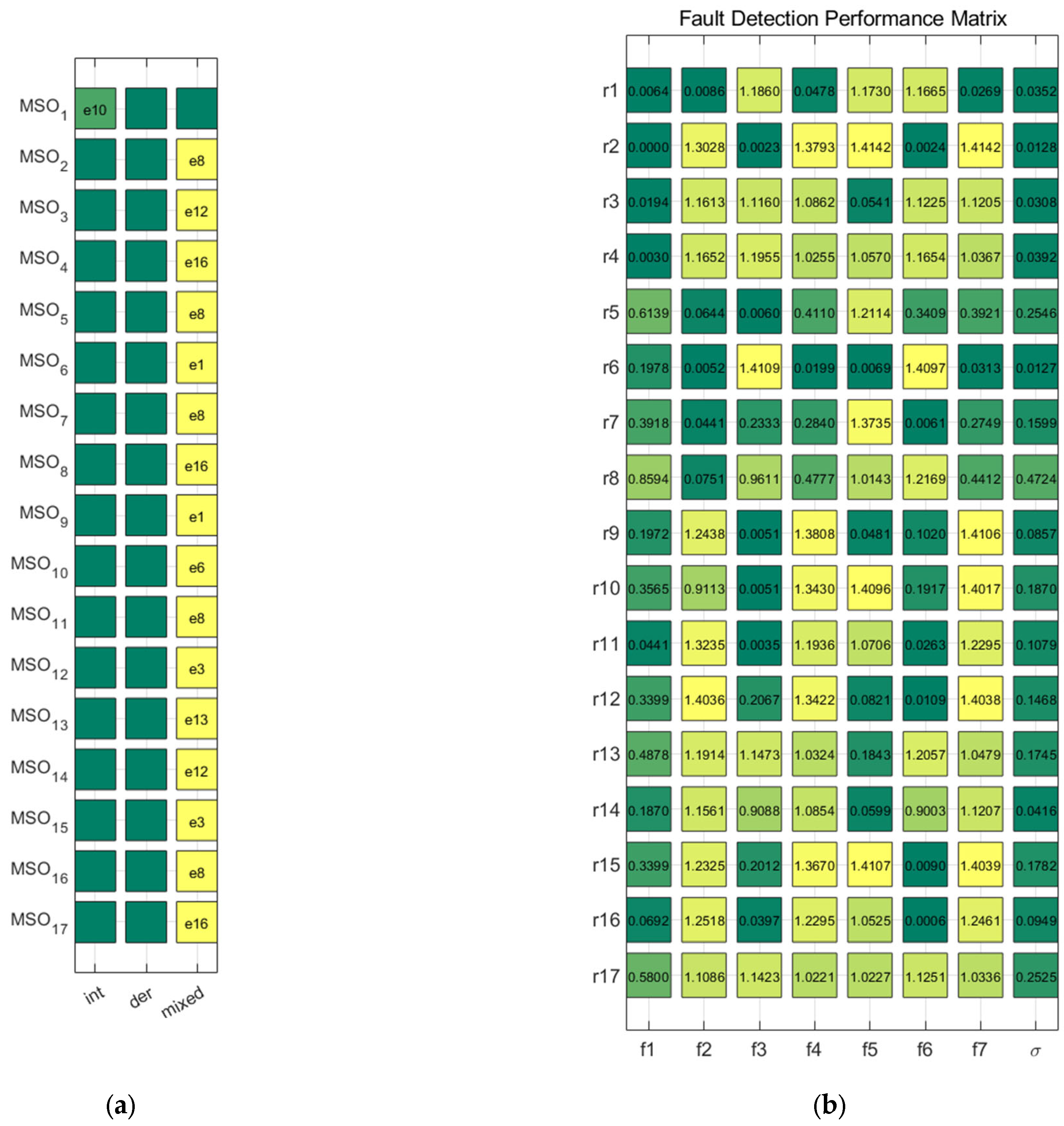

3.4. Diagnosability Optimization Design Based on the GWO Algorithm

4. Summary

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Mohsan, S.A.H.; Khan, M.A.; Noor, F.; Ullah, I.; Alsharif, M.H. Towards the Unmanned Aerial Vehicles (UAVs): A Comprehensive Review. Drones 2022, 6, 147. [Google Scholar] [CrossRef]

- del Cerro, J.; Cruz Ulloa, C.; Barrientos, A.; de León Rivas, J. Unmanned Aerial Vehicles in Agriculture: A Survey. Agronomy 2021, 11, 203. [Google Scholar] [CrossRef]

- Ghamari, M.; Rangel, P.; Mehrubeoglu, M.; Tewolde, G.S.; Sherratt, R.S. Unmanned Aerial Vehicle Communications for Civil Applications: A Review. IEEE Access 2022, 10, 102492–102531. [Google Scholar] [CrossRef]

- Zuo, Z.; Liu, C.; Han, Q.-L.; Song, J. Unmanned Aerial Vehicles: Control Methods and Future Challenges. IEEE/CAA J. Autom. Sin. 2022, 9, 601–614. [Google Scholar] [CrossRef]

- Gu, X.; Shi, X. A review of research on diagnosability of control systems. Energy Rep. 2024, 11, 2174–2188. [Google Scholar] [CrossRef]

- Fourlas, G.K.; Karras, G.C. A Survey on Fault Diagnosis Methods for UAVs. In Proceedings of the 2021 International Conference on Unmanned Aircraft Systems (ICUAS), Athens, Greece, 15–18 June 2021; pp. 394–403. [Google Scholar] [CrossRef]

- Fourlas, G.K.; Karras, G.C. A Survey on Fault Diagnosis and Fault-Tolerant Control Methods for Unmanned Aerial Vehicles. Machines 2021, 9, 197. [Google Scholar] [CrossRef]

- Iannace, G.; Ciaburro, G.; Trematerra, A. Fault Diagnosis for UAV Blades Using Artificial Neural Network. Robotics 2019, 8, 59. [Google Scholar] [CrossRef]

- Liang, S.; Zhang, S.; Huang, Y.; Zheng, X.; Cheng, J.; Wu, S. Data-driven fault diagnosis of FW-UAVs with consideration of multiple operation conditions. ISA Trans. 2022, 126, 472–485. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, S.; Zhang, A.; An, X. FW-UAV fault diagnosis based on knowledge complementary network under small sample. Mech. Syst. Signal Process. 2024, 215, 111418. [Google Scholar] [CrossRef]

- Hua, L.; Zhang, J.; Li, D.; Xi, X.; Shah, M.A. Sensor Fault Diagnosis and Fault Tolerant Control of Quadrotor UAV Based on Genetic Algorithm. J. Sens. 2022, 2022, 8626722. [Google Scholar] [CrossRef]

- Gu, X.; Shi, X. A Review of Research on Diagnosability of Control Systems Based on Structural Analysis. Appl. Sci. 2023, 13, 12241. [Google Scholar] [CrossRef]

- Chen, Z.; Xu, J.; Peng, T.; Yang, C. Graph Convolutional Network-Based Method for Fault Diagnosis Using a Hybrid of Measurement and Prior Knowledge. IEEE Trans. Cybern. 2022, 52, 9157–9169. [Google Scholar] [CrossRef] [PubMed]

- Cheng, Y.; D’Arpino, M.; Rizzoni, G. Fault Diagnosis in Lithium-ion Battery of Hybrid Electric Aircraft based on Structural Analysis. In Proceedings of the 2022 IEEE Transportation Electrification Conference & Expo (ITEC), Anaheim, CA, USA, 15–17 June 2022; pp. 997–1004. [Google Scholar] [CrossRef]

- Li, X.; Xu, J.; Chen, Z.; Xu, S.; Liu, K. Real-Time Fault Diagnosis of Pulse Rectifier in Traction System Based on Structural Model. IEEE Trans. Intell. Transp. Syst. 2022, 23, 2130–2143. [Google Scholar] [CrossRef]

- Yin, C.; He, Z.; Wang, J.; Zhou, H. A method for fault diagnosability evaluation of spacecraft control system. In Proceedings of the 2016 Joint International Information Technology, Mechanical and Electronic Engineering, Xi’an, China, 4–5 October 2016; Xu, B., Chen, Y.N., Zhao, L.H., Eds.; Atlantis Press: Paris, France, 2016; Volume 59, pp. 611–614. [Google Scholar]

- Cui, Y.; Shi, J.; Wang, Z. System-level operational diagnosability analysis in quasi real-time fault diagnosis: The probabilistic approach. J. Process Control 2014, 24, 1444–1453. [Google Scholar] [CrossRef]

- Cheng, Y.; Liu, Y.; Yang, S.; Wu, J. Multi-sensor optimal placement of rotor-bearing system based on fault diagnosability. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2023, 237, 1510–1521. [Google Scholar] [CrossRef]

- Reppa, V.; Timotheou, S.; Polycarpou, M.M.; Panayiotou, C. Performance Index for Optimizing Sensor Fault Detection of a Class of Nonlinear Systems. IFAC-PapersOnLine 2018, 51, 1387–1394. [Google Scholar] [CrossRef]

- Fu, F.; Xue, T.; Wu, Z.; Wang, D. A Fault Diagnosability Evaluation Method for Dynamic Systems Without Distribution Knowledge. IEEE Trans. Cybern. 2022, 52, 5113–5123. [Google Scholar] [CrossRef]

- Wang, Z.; Tang, Z.; Chen, F. Quantitative Evaluation of Sensor Fault Diagnosability of F-16 High Maneuvering Fighter. In Proceedings of the 2022 IEEE 5th International Conference on Automation, Electronics and Electrical Engineering (AUTEEE), Shenyang, China, 18–20 November 2022; pp. 102–108. [Google Scholar] [CrossRef]

- Liu, Q.; Wang, Z.; Zhang, J.; Zhou, D. Necessary and Sufficient Conditions for Fault Diagnosability of Linear Open- and Closed-Loop Stochastic Systems Under Sensor and Actuator Faults. IEEE Trans. Autom. Control 2022, 67, 4178–4185. [Google Scholar] [CrossRef]

- Qu, R.; Jiang, B.; Cheng, Y. Research on the Diagnosability of a Satellite Attitude Determination System on a Fault Information Manifold. Appl. Sci. 2022, 12, 12835. [Google Scholar] [CrossRef]

- Stiefelmaier, J.; Gienger, A.; Böhm, M.; Sawodny, O.; Tarín, C. A Bayesian Approach to Fault Diagnosability Analysis in Adaptive Structures. IFAC-PapersOnLine 2022, 55, 347–352. [Google Scholar] [CrossRef]

- Zhang, W.; Zhang, X.; Lan, L.; Luo, Z. Maximum Mean and Covariance Discrepancy for Unsupervised Domain Adaptation. Neural Process Lett. 2020, 51, 347–366. [Google Scholar] [CrossRef]

- Yang, C.; Jia, M.; Li, Z.; Gabbouj, M. Enhanced hierarchical symbolic dynamic entropy and maximum mean and covariance discrepancy-based transfer joint matching with Welsh loss for intelligent cross-domain bearing health monitoring. Mech. Syst. Signal Process. 2022, 165, 108343. [Google Scholar] [CrossRef]

- Gu, X.; Shi, X. Diagnosability-optimization design of fixed-wing unmanned aerial vehicle based on causal matching and tree seed algorithm. Meas. Control 2024, 00202940241307629. [Google Scholar] [CrossRef]

- Katoch, S.; Chauhan, S.S.; Kumar, V. A review on genetic algorithm: Past, present, and future. Multimed. Tools Appl. 2021, 80, 8091–8126. [Google Scholar] [CrossRef]

- Cunha, M.; Marques, J. A New Multiobjective Simulated Annealing Algorithm—MOSA-GR: Application to the Optimal Design of Water Distribution Networks. Water Resour. Res. 2020, 56, e2019WR025852. [Google Scholar] [CrossRef]

- Li, W.; Yan, X.; Huang, Y. Cooperative-Guided Ant Colony Optimization with Knowledge Learning for Job Shop Scheduling Problem. Tsinghua Sci. Technol. 2024, 29, 1283–1299. [Google Scholar] [CrossRef]

- Gad, A.G. Particle Swarm Optimization Algorithm and Its Applications: A Systematic Review. Arch. Comput. Methods Eng. 2022, 29, 2531–2561. [Google Scholar] [CrossRef]

- Kaya, E.; Gorkemli, B.; Akay, B.; Karaboga, D. A review on the studies employing artificial bee colony algorithm to solve combinatorial optimization problems. Eng. Appl. Artif. Intell. 2022, 115, 105311. [Google Scholar] [CrossRef]

- Qiu, Y.; Yang, X.; Chen, S. An improved gray wolf optimization algorithm solving to functional optimization and engineering design problems. Sci. Rep. 2024, 14, 14190. [Google Scholar] [CrossRef]

- Pan, H.; Chen, S.; Xiong, H. A high-dimensional feature selection method based on modified Gray Wolf Optimization. Appl. Soft Comput. 2023, 135, 110031. [Google Scholar] [CrossRef]

- Wang, J.; Xu, Y.-P.; She, C.; Xu, P.; Bagal, H.A. Optimal parameter identification of SOFC model using modified gray wolf optimization algorithm. Energy 2022, 240, 122800. [Google Scholar] [CrossRef]

- Emary, E.; Zawbaa, H.M.; Grosan, C. Experienced Gray Wolf Optimization Through Reinforcement Learning and Neural Networks. IEEE Trans. Neural Netw. Learn. Syst. 2018, 29, 681–694. [Google Scholar] [CrossRef] [PubMed]

- Kumar, A.; Pant, S.; Ram, M. System Reliability Optimization Using Gray Wolf Optimizer Algorithm. Qual. Reliab. Eng. Int. 2017, 33, 1327–1335. [Google Scholar] [CrossRef]

- Dulmage, A.L.; Mendelsohn, N.S. Coverings of Bipartite Graphs. Can. J. Math. 1958, 10, 517–534. [Google Scholar] [CrossRef]

- Krysander, M.; Aslund, J.; Nyberg, M. An Efficient Algorithm for Finding Minimal Overconstrained Subsystems for Model-Based Diagnosis. IEEE Trans. Syst. Man Cybern. A 2008, 38, 197–206. [Google Scholar] [CrossRef]

- Gu, X.; Shi, X. Diagnosability-optimized design of unmanned aerial vehicles based on structural analysis and maximum mean covariance differences. Measurement 2024, 238, 115334. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gu, X.; Shi, X. Causal Diagnosability Optimization Design for UAVs Based on Maximum Mean Covariance Difference and the Gray Wolf Optimization Algorithm. Math. Comput. Appl. 2025, 30, 55. https://doi.org/10.3390/mca30030055

Gu X, Shi X. Causal Diagnosability Optimization Design for UAVs Based on Maximum Mean Covariance Difference and the Gray Wolf Optimization Algorithm. Mathematical and Computational Applications. 2025; 30(3):55. https://doi.org/10.3390/mca30030055

Chicago/Turabian StyleGu, Xuping, and Xianjun Shi. 2025. "Causal Diagnosability Optimization Design for UAVs Based on Maximum Mean Covariance Difference and the Gray Wolf Optimization Algorithm" Mathematical and Computational Applications 30, no. 3: 55. https://doi.org/10.3390/mca30030055

APA StyleGu, X., & Shi, X. (2025). Causal Diagnosability Optimization Design for UAVs Based on Maximum Mean Covariance Difference and the Gray Wolf Optimization Algorithm. Mathematical and Computational Applications, 30(3), 55. https://doi.org/10.3390/mca30030055