Flotation Behaviours of Ilmenite and Associated Solution Chemistry Properties Using Saturated Fatty Acids as the Collector

Abstract

1. Introduction

2. Materials and Methods

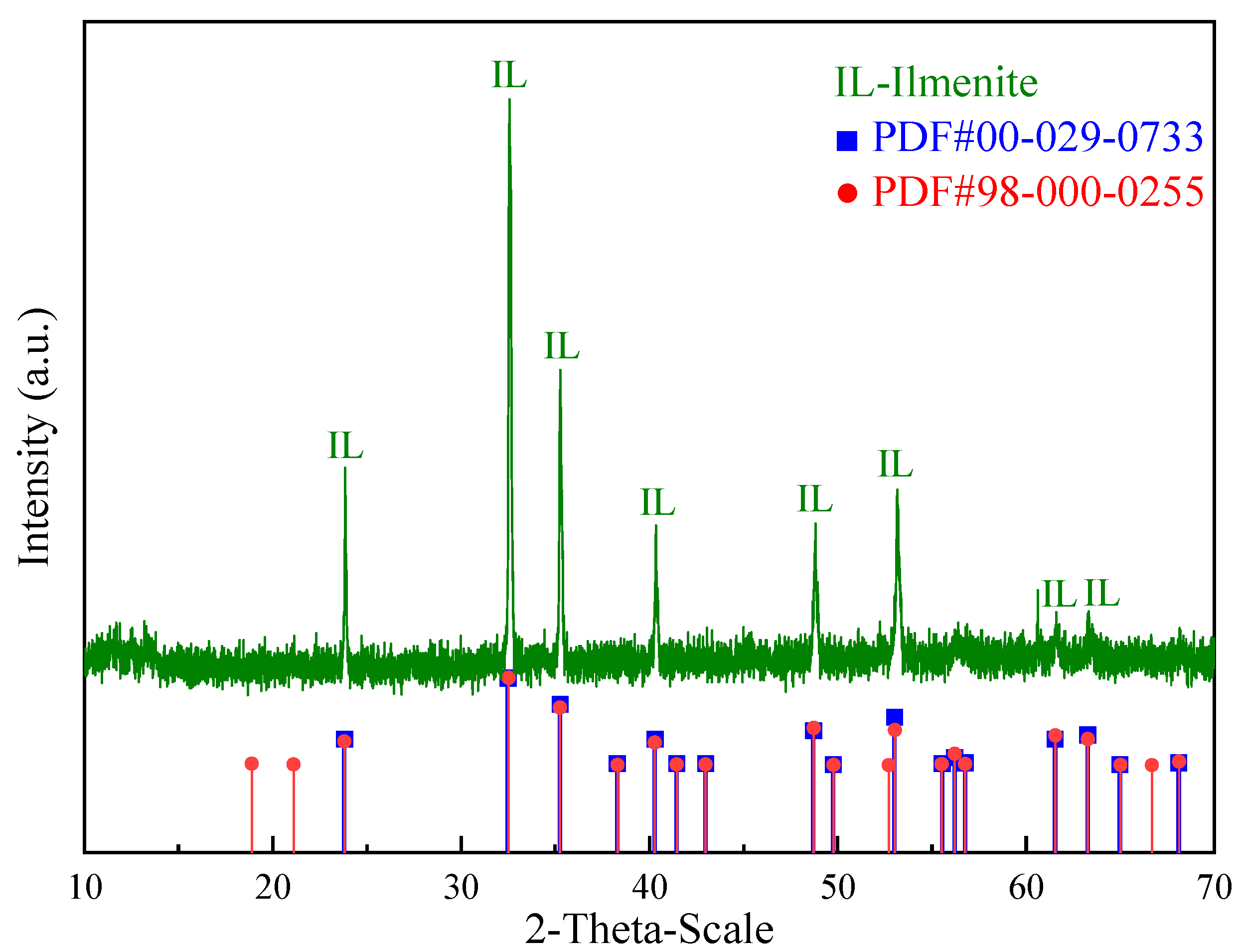

2.1. Materials and Reagents

2.2. Flotation Tests

2.3. Surface Tension Measurements

2.4. Surface Characterisation Techniques

3. Results and Discussion

3.1. Micro-Flotation Analysis

3.2. Surface Tension Analysis

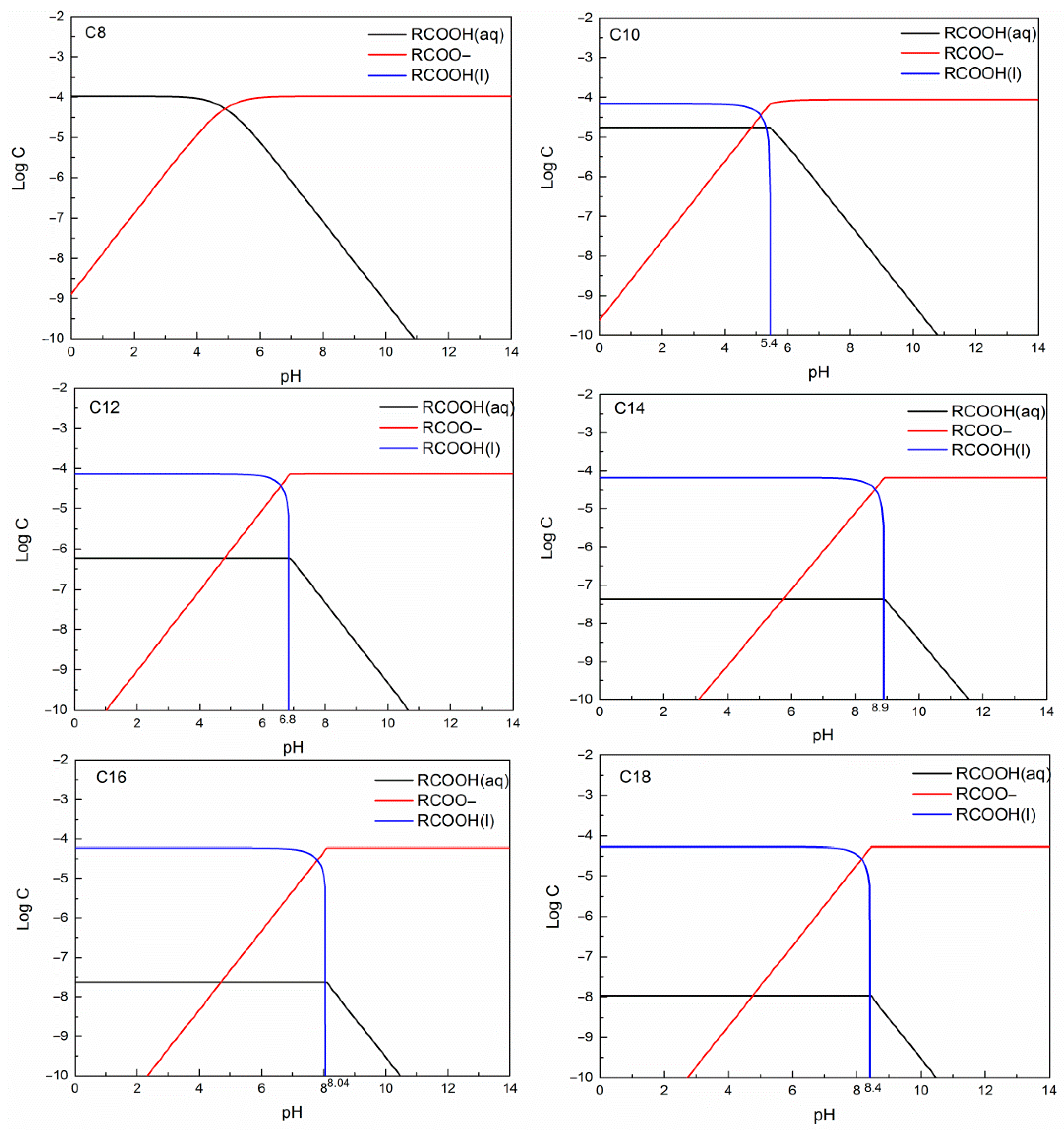

3.3. Solution Chemistry Diagram Analysis

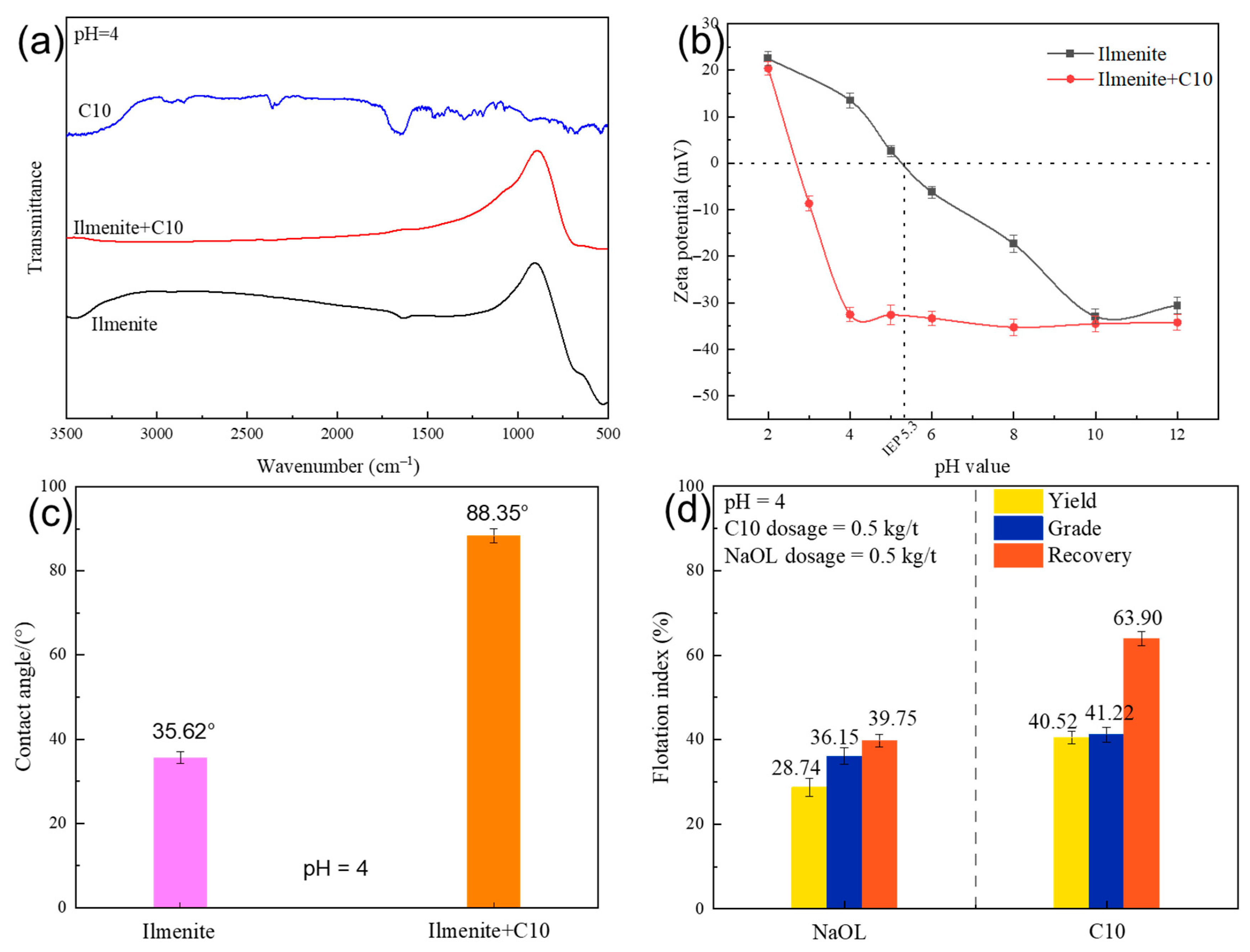

3.4. Adsorption Mechanism of Decanoic Acid on Ilmenite Surface

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Somasundaran, P.; Wang, D. Solution Chemistry: Minerals and Reagents; Elsevier: Amsterdam, The Netherlands, 2006. [Google Scholar]

- Jia, K.; Ding, R.; Chen, Y.; Lu, T.; Li, G.; Cao, Y.; Wang, C. Green, multiple-ligand collector sodium myristoyl glutamate for flotation of smithsonite. Appl. Surf. Sci. 2024, 660, 159932. [Google Scholar] [CrossRef]

- Slabov, V.; Jain, G.; Larsen, E.; Kota, H.R.; Chernyshova, I. Eco-friendly collectors for flotation of fine hematite and malachite particles. Min. Metall. Explor. 2023, 40, 475–492. [Google Scholar] [CrossRef]

- Wills, B.A.; Finch, J. Wills’ Mineral Processing Technology: An Introduction to the Practical Aspects of Ore Treatment and Mineral Recovery; Butterworth-Heinemann: Oxford, UK, 2015. [Google Scholar]

- Zhai, J.; Niu, X.; Chen, P.; Fan, C.; Chen, Z.; Yang, Y. Lithium refinery residue reuse in construction materials production: Status, challenges and further perspectives. J. Environ. Manag. 2025, 379, 124801. [Google Scholar] [CrossRef] [PubMed]

- Gao, Y.; Gao, Z.; Sun, W.; Yin, Z.; Wang, J.; Hu, Y. Adsorption of a novel reagent scheme on scheelite and calcite causing an effective flotation separation. J. Colloid Interface Sci. 2018, 512, 39–46. [Google Scholar] [CrossRef] [PubMed]

- Satur, J.V.; Calabia, B.P.; Hoshino, M.; Morita, S.; Seo, Y.; Kon, Y.; Takagi, T.; Watanabe, Y.; Mutele, L.; Foya, S. Flotation of rare earth minerals from silicate–hematite ore using tall oil fatty acid collector. Miner. Eng. 2016, 89, 52–62. [Google Scholar] [CrossRef]

- Cook, B.K.; Gibson, C.E. A review of fatty acid collectors: Implications for spodumene flotation. Minerals 2023, 13, 212. [Google Scholar] [CrossRef]

- Zhang, C.; Liu, P.; Zhang, W.; Dai, H.; Tian, Y.; Tian, M.; Sun, W. Study on the adsorption selectivity of a novel fatty acid collector on apatite, dolomite, and calcite surfaces for improved flotation. Miner. Eng. 2025, 232, 109523. [Google Scholar] [CrossRef]

- Kulkarni, R.; Somasundaran, P. Flotation chemistry of hematite/oleate system. Colloids Surf. 1980, 1, 387–405. [Google Scholar] [CrossRef]

- Quast, K. Flotation of hematite using C6–C18 saturated fatty acids. Miner. Eng. 2006, 19, 582–597. [Google Scholar] [CrossRef]

- Xu, L.; Hu, Y.; Tian, J.; Wu, H.; Wang, L.; Yang, Y.; Wang, Z. Synergistic effect of mixed cationic/anionic collectors on flotation and adsorption of muscovite. Colloids Surf. A Physicochem. Eng. Asp. 2016, 492, 181–189. [Google Scholar] [CrossRef]

- Zhang, N.; Cheng, M.; Han, R.; Li, Z.; Zhou, A.; Wang, H. Enhanced flotation separation of coal gasification fine slag by composite collectors containing polar fatty acids. J. Environ. Chem. Eng. 2024, 12, 114890. [Google Scholar] [CrossRef]

- Rao, K.H.; Cases, J.; De Donato, P.; Forssberg, K. Mechanism of oleate interaction on salt-type minerals: IV. Adsorption, electrokinetic, and diffuse reflectance FT-IR studies of natural fluorite in the presence of sodium oleate. J. Colloid Interface Sci. 1991, 145, 314–329. [Google Scholar] [CrossRef]

- Somasundaran, P.; Ananthapadmanabhan, K.; Ivanov, I. Dimerization of oleate in aqueous solutions. J. Colloid Interface Sci. 1984, 99, 128–135. [Google Scholar] [CrossRef]

- Fu, X.; Gao, Y.; Peng, C.; Han, H.; Sun, W.; Yue, T. Adsorption mechanism of sodium oleate at hematite/quartz–water interfaces: A quantitative molecular insight. Miner. Eng. 2024, 216, 108904. [Google Scholar] [CrossRef]

- Quast, K. Flotation of hematite using 18-carbon fatty acids. Miner. Eng. 2021, 160, 106647. [Google Scholar] [CrossRef]

- Laskowski, J. Electrokinetic measurements in aqueous solutions of weak electrolyte type surfactants. J. Colloid Interface Sci. 1993, 159, 349–353. [Google Scholar] [CrossRef]

- Laskowski, J.; Yordan, J.; Yoon, R. Electrokinetic potential of microbubbles generated in aqueous solutions of weak electrolyte type surfactants. Langmuir 1989, 5, 373–376. [Google Scholar] [CrossRef]

- Chen, P.; Zhai, J.; Sun, W.; Hu, Y.; Yin, Z.; Lai, X. Adsorption mechanism of lead ions at ilmenite/water interface and its influence on ilmenite flotability. J. Ind. Eng. Chem. 2017, 53, 285–293. [Google Scholar] [CrossRef]

- Arun, J.; Nachiappan, S.; Rangarajan, G.; Alagappan, R.P.; Gopinath, K.; Lichtfouse, E. Synthesis and application of titanium dioxide photocatalysis for energy, decontamination and viral disinfection: A review. Environ. Chem. Lett. 2023, 21, 339–362. [Google Scholar] [CrossRef] [PubMed]

- García-Muñoz, P.; López-Maxías, C.; Guerra-Rodríguez, S.; Carbajo, J.; Casas, J.A.; Rodríguez-Chueca, J. Photocatalytic activation of peroxymonosulfate using ilmenite (FeTiO3) for Enterococcus faecalis inactivation. J. Environ. Chem. Eng. 2022, 10, 108231. [Google Scholar] [CrossRef]

- Zhai, J.; Chen, P.; Sun, W.; Chen, W.; Wan, S. A review of mineral processing of ilmenite by flotation. Miner. Eng. 2020, 157, 106558. [Google Scholar] [CrossRef]

- Zheng, X.; Du, L.; Li, S.; Jing, Z.; Lu, D.; Jia, K.; Cadiere, K.; Peng, B.; Wang, Y. A novel method for efficient recovery of ilmenite by high gradient magnetic separation coupling with magnetic fluid. Miner. Eng. 2023, 202, 108279. [Google Scholar] [CrossRef]

- Song, Q.; Tsai, S.C. Flotation of ilmenite using benzyl arsonic acid and acidified sodium silicate. Int. J. Miner. Process. 1989, 26, 111–121. [Google Scholar] [CrossRef]

- Xu, H.; Zhong, H.; Tang, Q.; Wang, S.; Zhao, G.; Liu, G. A novel collector 2-ethyl-2-hexenoic hydroxamic acid: Flotation performance and adsorption mechanism to ilmenite. Appl. Surf. Sci. 2015, 353, 882–889. [Google Scholar] [CrossRef]

- Zhu, Y.; Zhang, G.; Feng, Q.; Yan, D.; Wang, W. Effect of surface dissolution on flotation separation of fine ilmenite from titanaugite. Trans. Nonferrous Met. Soc. China 2011, 21, 1149–1154. [Google Scholar] [CrossRef]

- Zhai, J.; Chen, P.; Wang, H.; Yang, Y.; Guan, C. Eco-friendly sophorolipid enabling the selective and efficient flotation separation of ilmenite from titanaugite. Miner. Eng. 2025, 232, 109567. [Google Scholar] [CrossRef]

- Pan, C.; Liu, J.-y.; Li, W.-s.; Zhai, J.-h.; Yang, Y.-h. Flotation behavior of ilmenite using 1, 10-phenanthroline as novel collector. Trans. Nonferrous Met. Soc. China 2024, 34, 995–1002. [Google Scholar]

- Chen, P.; Zhai, J.; Sun, W.; Hu, Y.; Yin, Z. The activation mechanism of lead ions in the flotation of ilmenite using sodium oleate as a collector. Miner. Eng. 2017, 111, 100–107. [Google Scholar] [CrossRef]

- Mehdilo, A.; Irannajad, M.; Rezai, B. Effect of crystal chemistry and surface properties on ilmenite flotation behavior. Int. J. Miner. Process. 2015, 137, 71–81. [Google Scholar] [CrossRef]

- Gao, Z.; Li, C.; Sun, W.; Hu, Y. Anisotropic surface properties of calcite: A consideration of surface broken bonds. Colloids Surf. A: Physicochem. Eng. Asp. 2017, 520, 53–61. [Google Scholar] [CrossRef]

- Jiang, W.; Gao, Z.; Khoso, S.A.; Gao, J.; Sun, W.; Pu, W.; Hu, Y. Selective adsorption of benzhydroxamic acid on fluorite rendering selective separation of fluorite/calcite. Appl. Surf. Sci. 2018, 435, 752–758. [Google Scholar] [CrossRef]

- Von Rybinski, W.; Schwuger, M. Adsorption of surfactant mixtures in froth flotation. Langmuir 1986, 2, 639–643. [Google Scholar] [CrossRef]

- de Castro, F.H.B.; Borrego, A.G. Modification of surface tension in aqueous solutions of sodium oleate according to temperature and pH in the flotation bath. J. Colloid Interface Sci. 1995, 173, 8–15. [Google Scholar] [CrossRef]

- Pugh, R.; Weissenborn, P.; Paulson, O. Flotation in inorganic electrolytes; the relationship between recover of hydrophobic particles, surface tension, bubble coalescence and gas solubility. Int. J. Miner. Process. 1997, 51, 125–138. [Google Scholar] [CrossRef]

- Yarar, B.; Kaoma, J. Estimation of the critical surface tension of wetting of hydrophobic solids by flotation. Colloids Surf. 1984, 11, 429–436. [Google Scholar] [CrossRef]

- Pugh, R.; Stenius, P. Solution chemistry studies and flotation behaviour of apatite, calcite and fluorite minerals with sodium oleate collector. Int. J. Miner. Process. 1985, 15, 193–218. [Google Scholar] [CrossRef]

- Man, X.; Wang, C.; Yu, S.; Yang, X.; Liu, J.; Fu, Y.; Dong, Z.; Zhi, H.; Ou, L. Low-Temperature Flotation Separation of Diaspore from Kaolinite by Using a Mixed Collector. Minerals 2022, 12, 891. [Google Scholar] [CrossRef]

- Sun, W.; Lan, L.; Zeng, H.; Zhou, J.; Khoso, S.A.; Wang, L. Study on the flotation separation mechanism of diaspore from kaolinite using mixed NaOL/BHA collector. Miner. Eng. 2022, 186, 107719. [Google Scholar] [CrossRef]

- Jia, W.; Jiao, F.; Zhu, H.; Xu, L.; Qin, W. Mitigating the negative effects of feldspar slime on spodumene flotation using mixed anionic/cationic collector. Miner. Eng. 2021, 168, 106813. [Google Scholar] [CrossRef]

- Morgan, L.; Somasundaran, P.; Partyka, S. Adsorption of hydrolyzable surfactants: Effect of precipitation on adsorption of oleate on hematite. Colloids Surf. 1987, 27, 15–27. [Google Scholar] [CrossRef]

- Morgan, L.J.; Ananthapadmanabhan, K.; Somasundaran, P. Oleate adsorption on hematite: Problems and methods. Int. J. Miner. Process. 1986, 18, 139–152. [Google Scholar] [CrossRef]

- Quast, K. Direct measurement of oleate adsorption on hematite and its consequences for flotation. Miner. Eng. 2018, 118, 122–132. [Google Scholar] [CrossRef]

- Antti, B.-M.; Forssberg, E. Pulp chemistry in industrial mineral flotation. Studies of surface complex on calcite and apatite surfaces using FTIR spectroscopy. Miner. Eng. 1989, 2, 217–227. [Google Scholar] [CrossRef]

- Jung, R.F.; James, R.O.; Healy, T.W. Adsorption, precipitation, and electrokinetic processes in the iron oxide (Goethite)—Oleic acid—Oleate system. J. Colloid Interface Sci. 1987, 118, 463–472. [Google Scholar] [CrossRef]

- Guan, C.; Yin, Z.; Zhai, J.; Hu, Y.; Chen, P.; Sun, W. Surface modification of ilmenite by a novel surfactant dodecyliminodimethylenediphosphoinc acid and its sequent influence on ilmenite floatability. Sep. Sci. Technol. 2019, 55, 358–368. [Google Scholar] [CrossRef]

- Zhai, J.; Chen, P.; Wang, H.; Hu, Y.; Sun, W. Flotability improvement of ilmenite using attrition-scrubbing as a pretreatment method. Minerals 2017, 7, 13. [Google Scholar] [CrossRef]

- Vurdela, R.; Laskowski, J. Positively charged colloidal species in aqueous anionic surfactant solutions. Colloids Surf. 1987, 22, 77–80. [Google Scholar] [CrossRef]

- Yoon, R.-h.; Mao, L. Application of Extended DLVO Theory, IV: Derivation of Flotation Rate Equation from First Principles. J. Colloid Interface Sci. 1996, 181, 613–626. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhai, J.; He, H.; Chen, P.; Song, L.; Yao, X.; Zhang, H. Flotation Behaviours of Ilmenite and Associated Solution Chemistry Properties Using Saturated Fatty Acids as the Collector. Separations 2025, 12, 191. https://doi.org/10.3390/separations12080191

Zhai J, He H, Chen P, Song L, Yao X, Zhang H. Flotation Behaviours of Ilmenite and Associated Solution Chemistry Properties Using Saturated Fatty Acids as the Collector. Separations. 2025; 12(8):191. https://doi.org/10.3390/separations12080191

Chicago/Turabian StyleZhai, Jihua, Hao He, Pan Chen, Lin Song, Xiaohai Yao, and Hongxian Zhang. 2025. "Flotation Behaviours of Ilmenite and Associated Solution Chemistry Properties Using Saturated Fatty Acids as the Collector" Separations 12, no. 8: 191. https://doi.org/10.3390/separations12080191

APA StyleZhai, J., He, H., Chen, P., Song, L., Yao, X., & Zhang, H. (2025). Flotation Behaviours of Ilmenite and Associated Solution Chemistry Properties Using Saturated Fatty Acids as the Collector. Separations, 12(8), 191. https://doi.org/10.3390/separations12080191