Simulation of Helical-Baffle Inlet Structure Cyclone Separator

Abstract

1. Introduction

2. Mathematical Models and Simulation Methodology

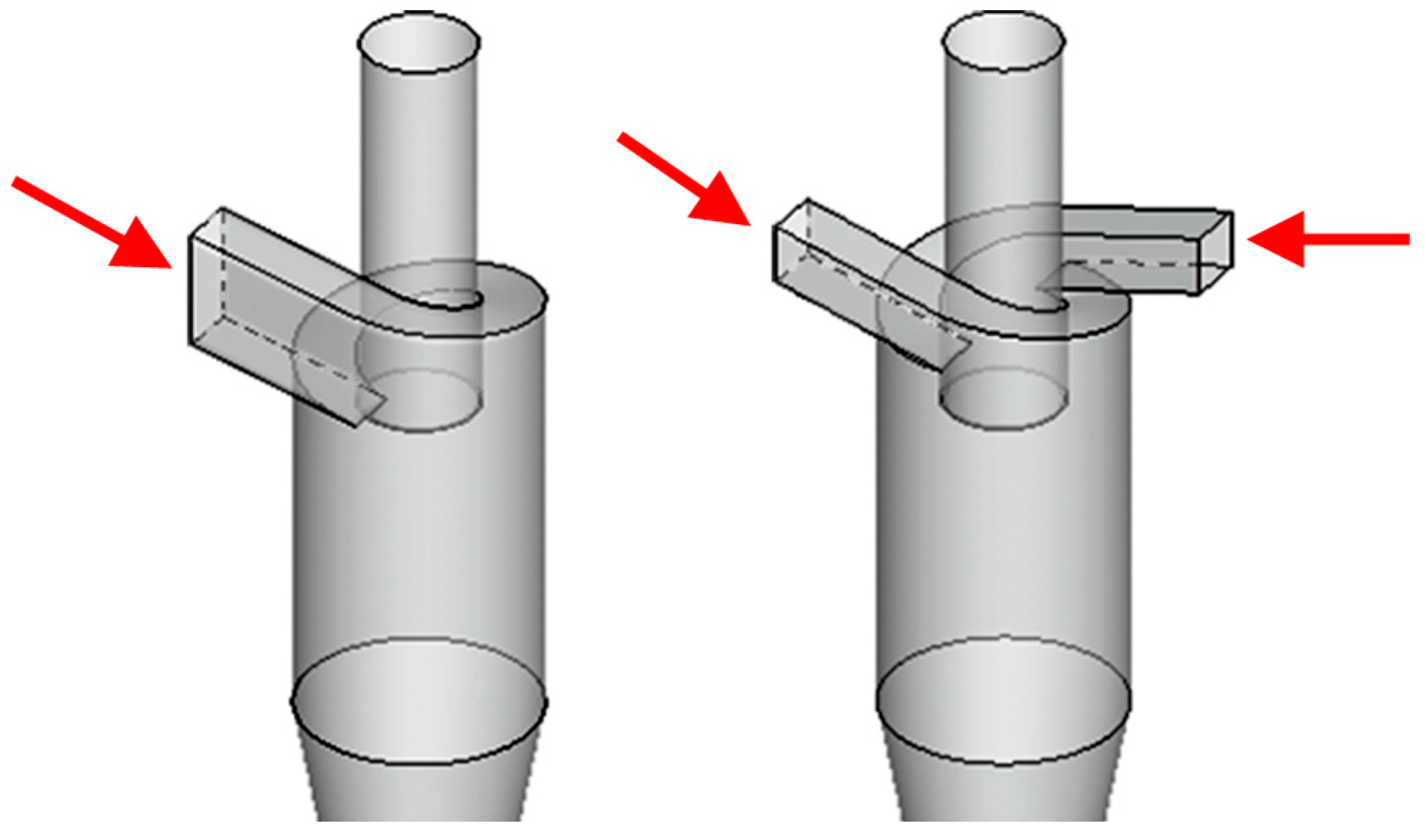

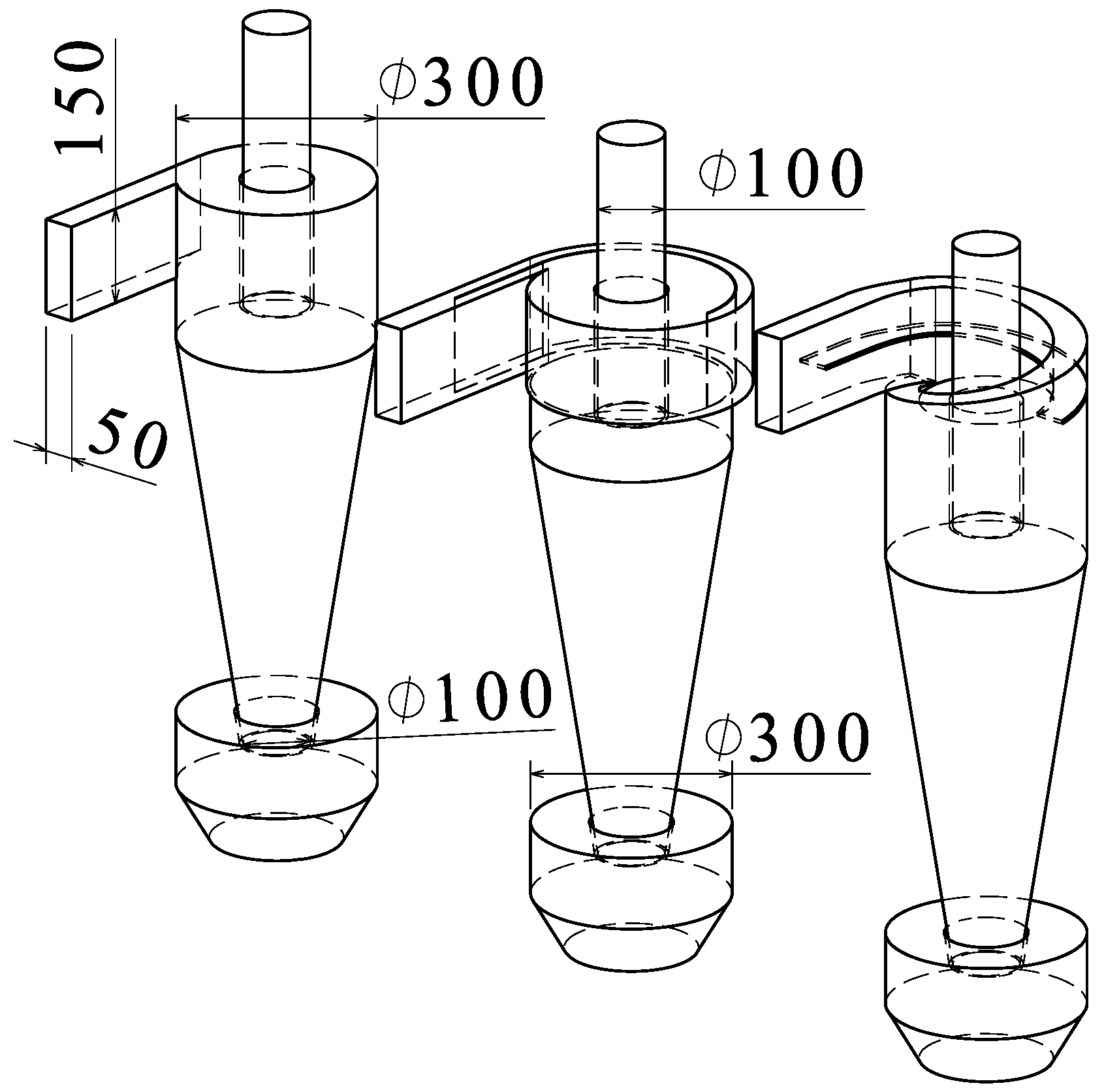

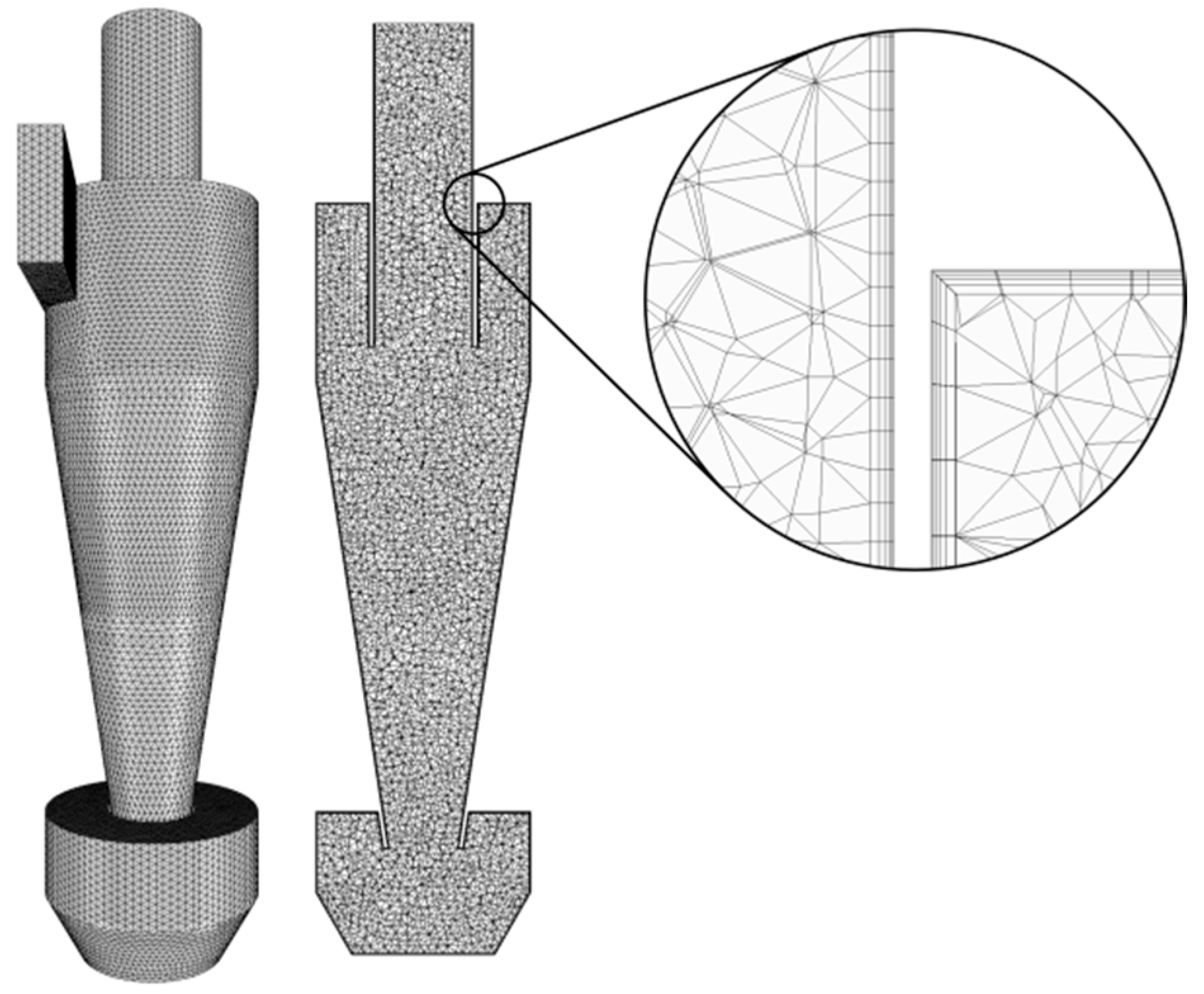

2.1. Geometric Modeling and Meshing

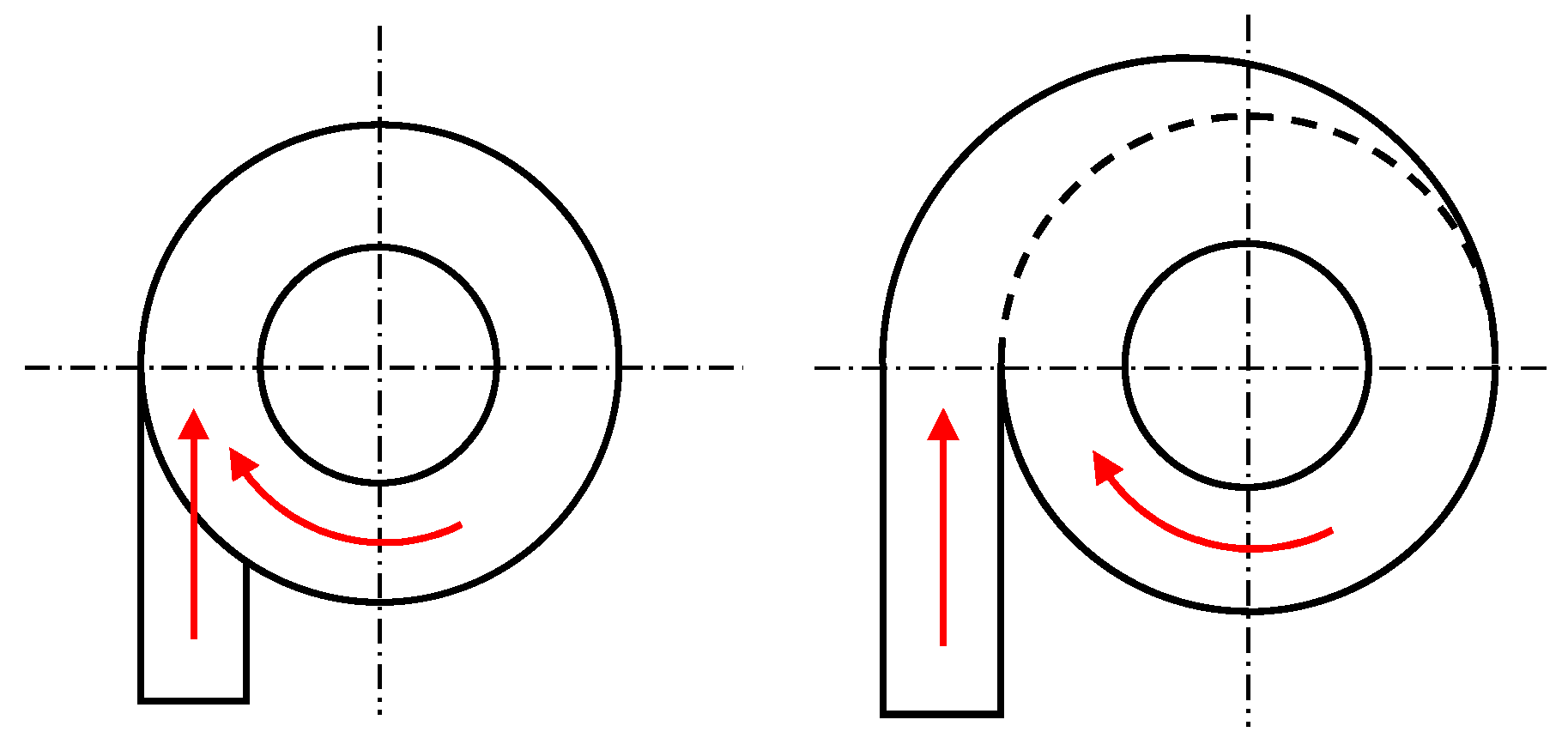

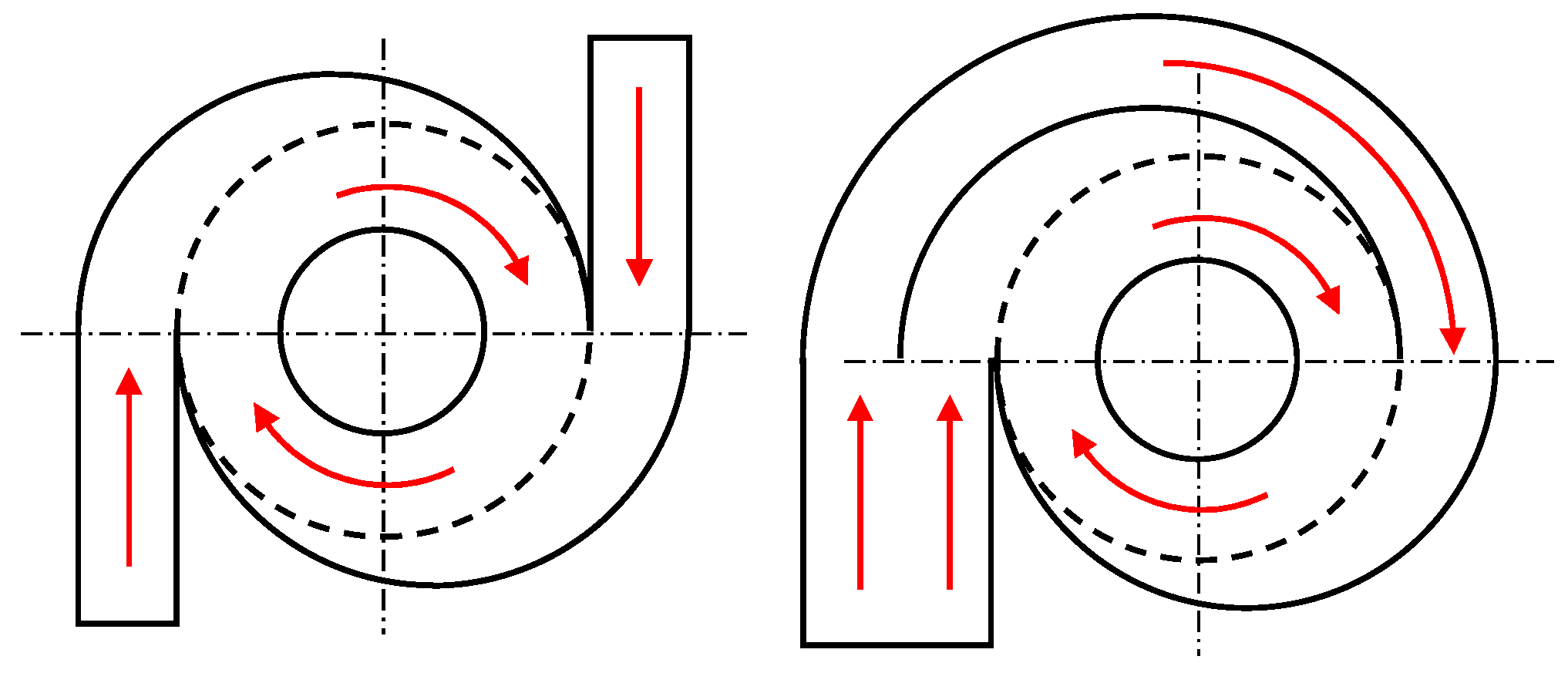

- Conventional: Tangential penetration through barrel sidewall.

- Volute-baffle inlet: Equidistant helical volute channel bifurcated by an internal splitter plate.

- Helical-baffle inlet: Downward-deflected inlet circumferentially encircling vortex finder with helical splitter plate.

2.2. Mathematical Model

2.3. Boundary Conditions

2.4. Declaration of Software Usage

3. Numerical Simulation Results

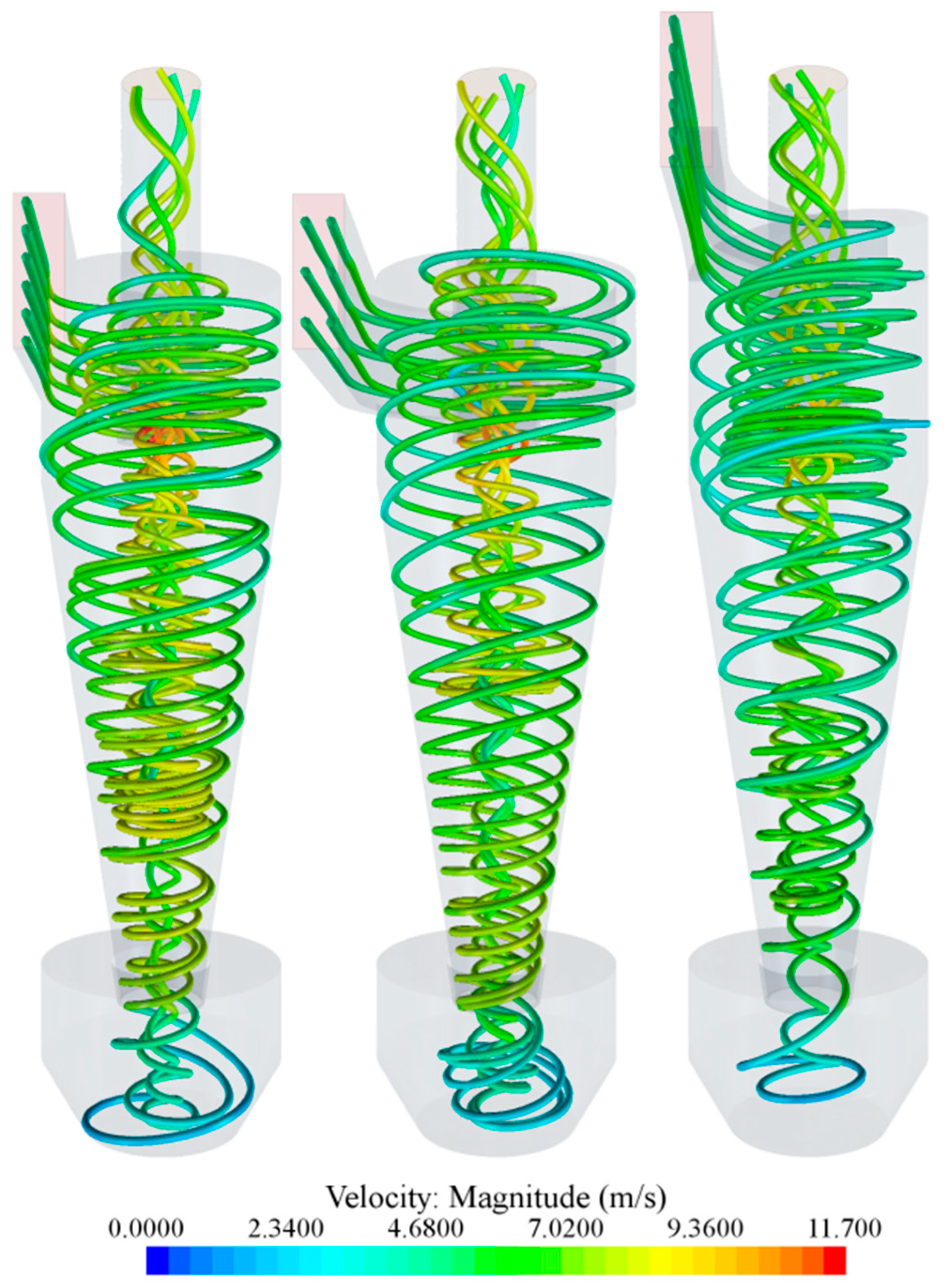

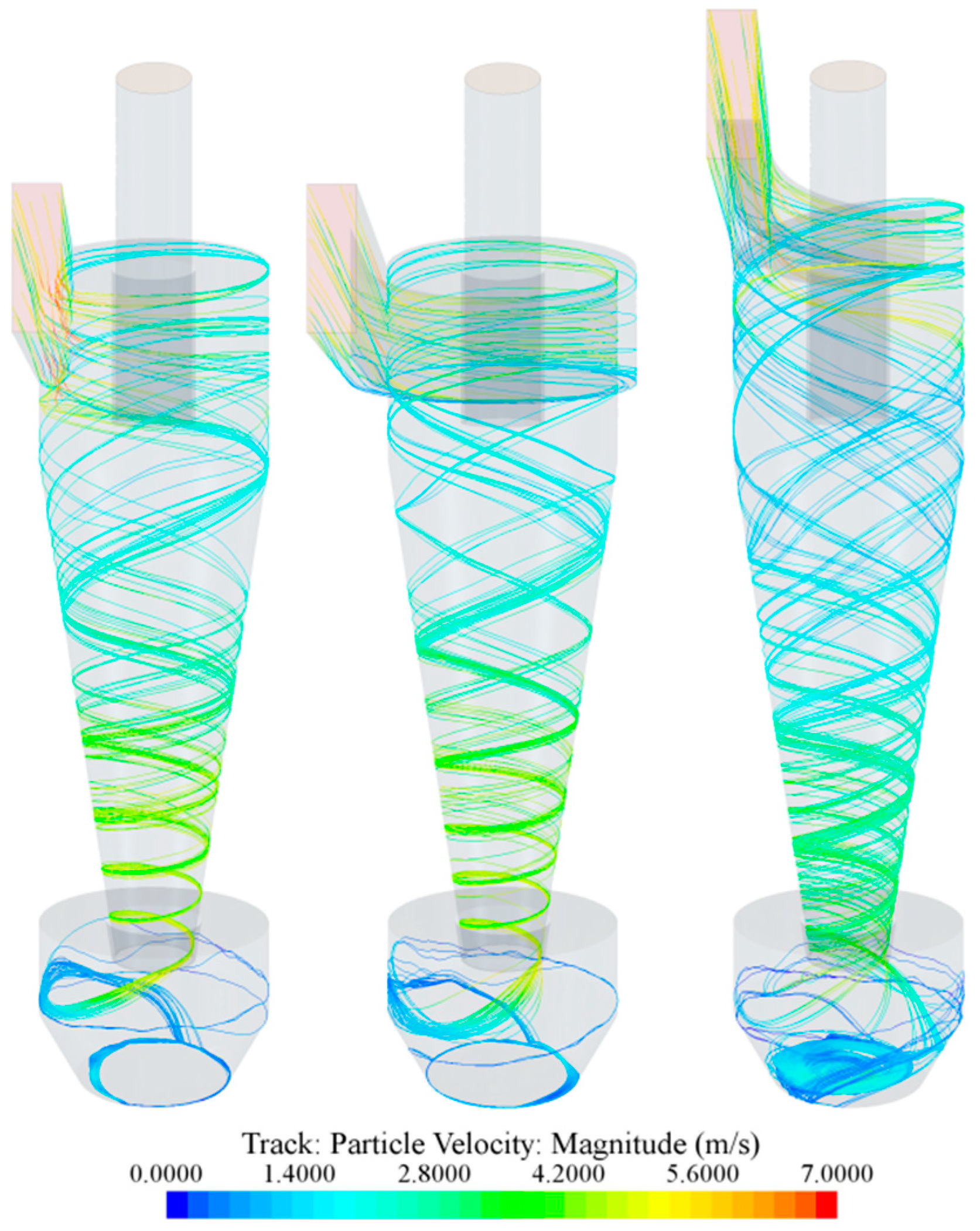

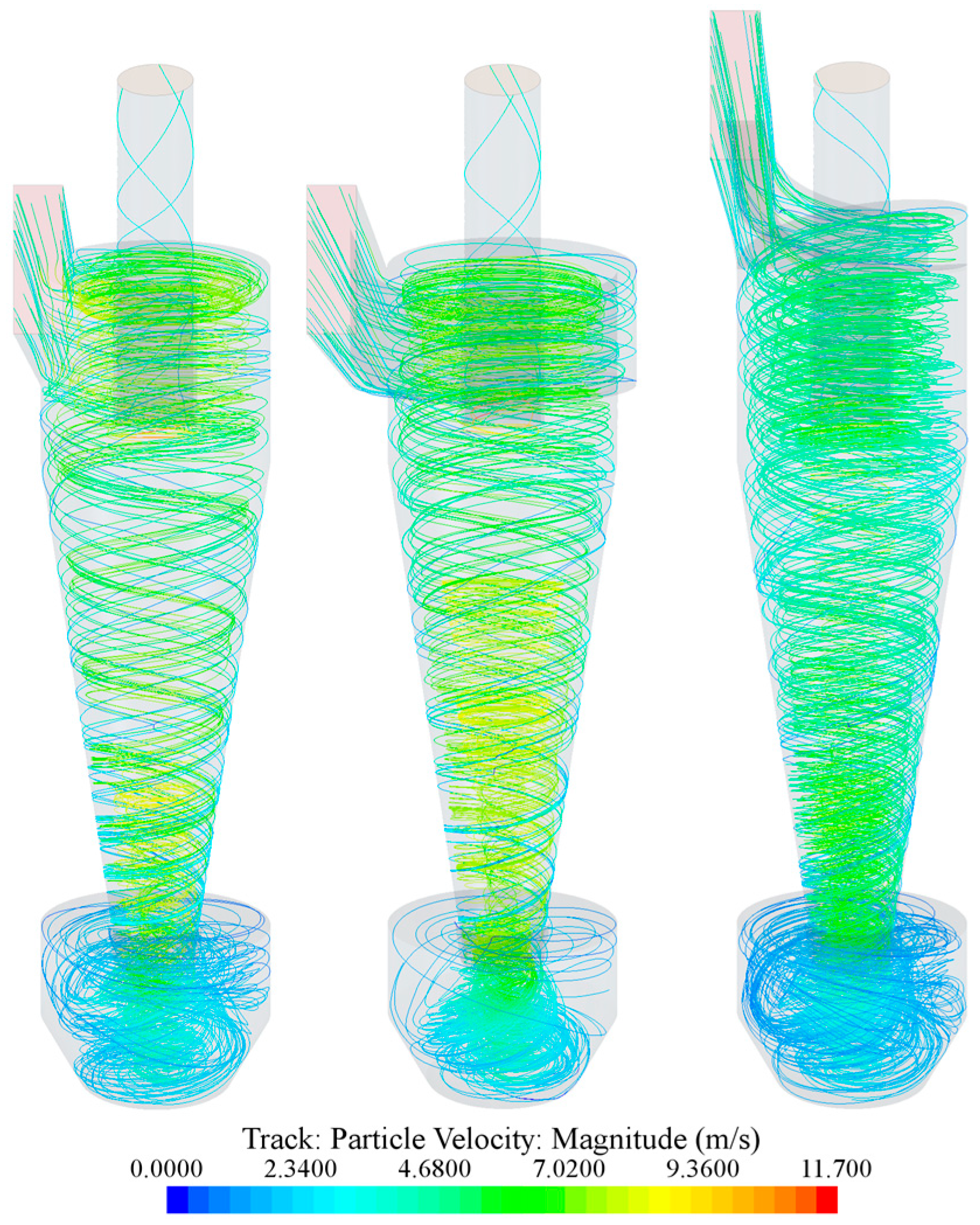

3.1. Three-Dimensional Streamline Visualization

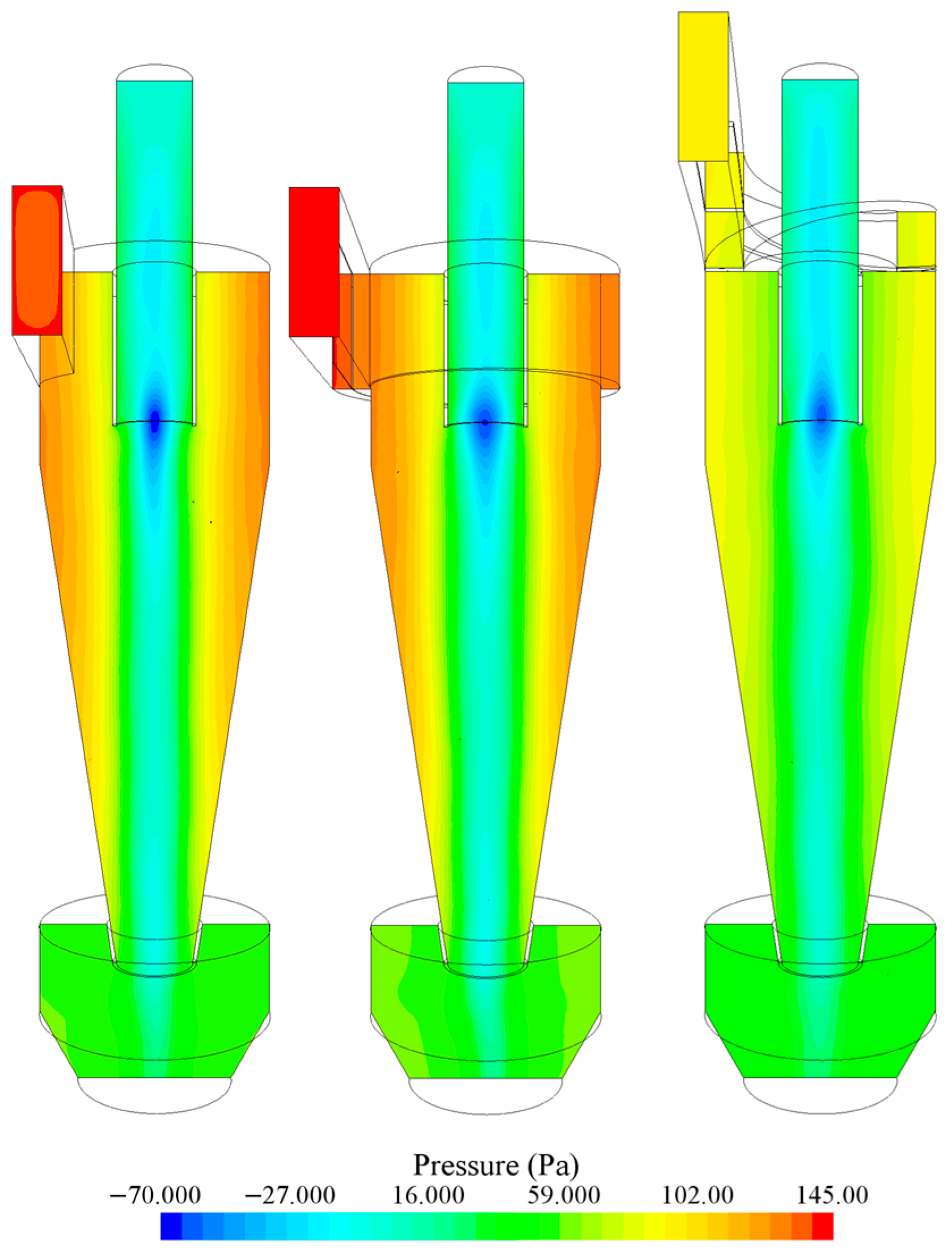

3.2. Pressure Distribution

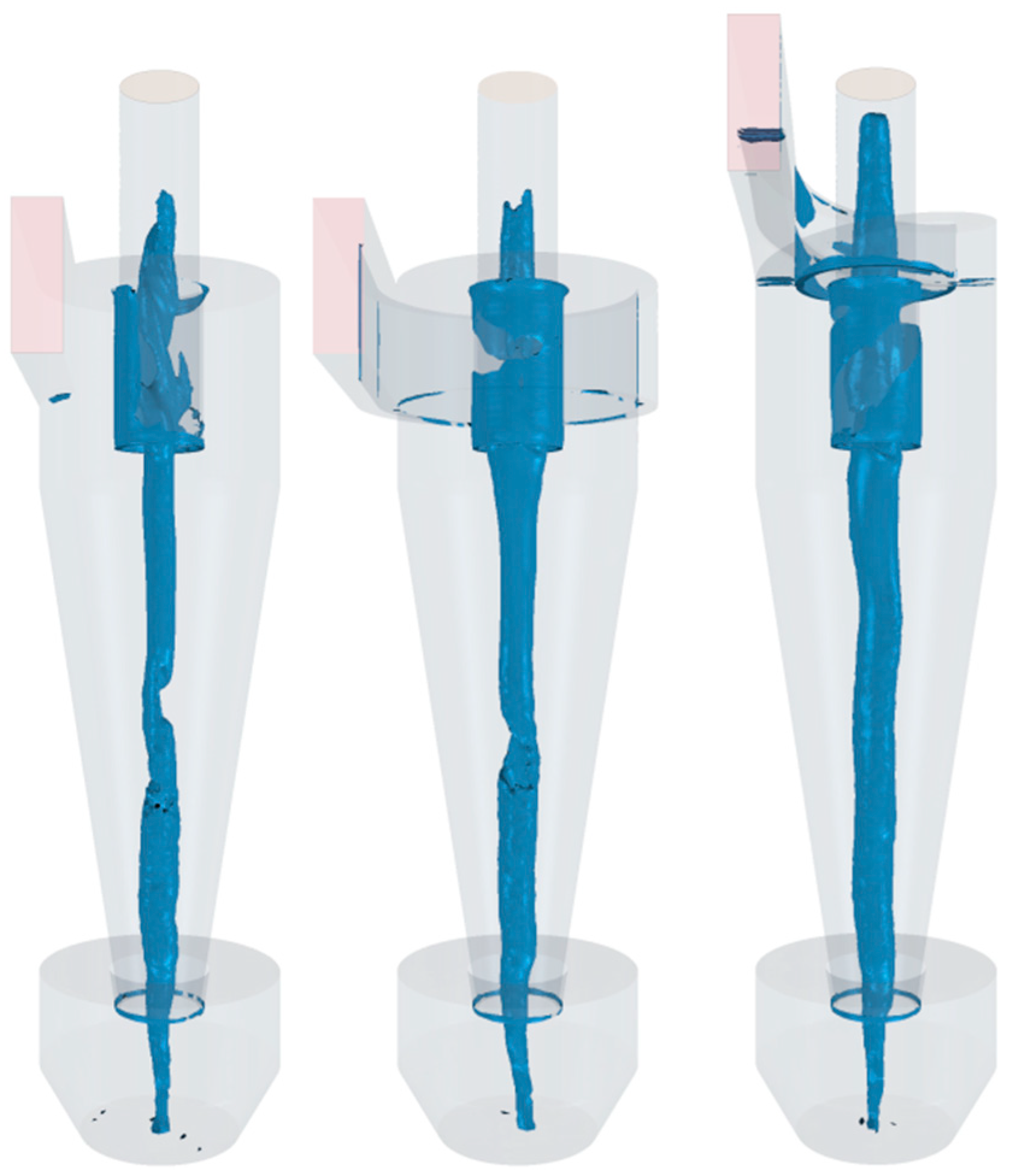

3.3. Vortex Core Morphology

3.4. Particle Trajectory

4. Discussion and Conclusions

- Inlet flow uniformity: The volute configuration mitigates inlet gas funneling, while the helical configuration eliminates it entirely, establishing axially consistent flow development.

- Flowing performance: Despite improved symmetry, the volute configuration exhibits a higher pressure drop (145 Pa) than conventional (138 Pa) due to extended flow paths. The helical configuration achieves the lowest pressure loss (98 Pa).

- Vortex stability: Helical vortex precession in conventional configuration causes energy dissipation. The helical configuration generates stable vortex cores without breakdown, evidenced by smooth Q-criterion iso-surfaces extending into the hopper.

- Separation efficiency: Top dust ring formation in conventional/volute cyclones reduces 4 μm particle capture (91.43–92.50%). The helical configuration eliminates recirculation zones, achieving 95.92% efficiency through shorter particle trajectories.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Cai, Z.; Qu, S. Space environment characteristics and key points in space environmental protection design for Mars probe mission. Spacecr. Environ. Eng. 2019, 36, 542–548. [Google Scholar]

- Jia, Y.; Li, Y.; Ji, L. Demands of Mars exploration missions on environmental simulation technologies. Spacecr. Environ. Eng. 2015, 32, 464–468. [Google Scholar]

- Wang, H.; Sun, C.; Ju, D.; Zhao, Y.; Wu, Y. Dust environmental detection in deep space explorations. Spacecr. Environ. Eng. 2019, 36, 549–557. [Google Scholar]

- Cui, H.; Guo, R.; Liu, R.; Xing, B.; Chen, L. The contamination of satellite optical device by space microparticles. Spacecr. Environ. Eng. 2017, 34, 566–570. [Google Scholar]

- Jiang, L.; Bai, Y. A Study on Effect of High-Speed Space Dust Collision on Transmittance of Optical Glass. Spacecr. Environ. Eng. 2005, 22, 215–218. [Google Scholar]

- Drolshagen, G. Impact effects from small size meteoroids and space debris. Adv. Space Res. 2008, 41, 1123–1131. [Google Scholar] [CrossRef]

- Stairmand, C.J. The design and performance of cyclone separators. Trans. Inst. Chem. Eng. 1951, 29, 356–383. [Google Scholar]

- Hoffmann, A.C. Gas cyclones and swirl tubes: Principles, design and operation. Appl. Mech. Rev. 2007, 56, B28. [Google Scholar] [CrossRef]

- Tian, P.; Li, S.; Zhang, Y.; Jin, Y.; Li, X.; Luo, Z. Experimental Analysis of High Efficiency, Low Resistance Cyclone Separator Inlet. China Powder Sci. Technol. 2010, 16, 7–11. [Google Scholar]

- He, H.; Huang, J. Numerical Simulations of Gas–Solid Flow in a Ramped Entrance Cyclone Separator. J. Combust. Sci. Technol. 2010, 16, 531–536. [Google Scholar]

- Song, J.; Wei, Y.; Shi, M. Analysis of Asymmetry of Gas-Phase Flow Field in Volute Cyclone. J. Chem. Ind. Eng. 2007, 58, 1091–1096. [Google Scholar]

- Wang, J.; Mao, Y.; Wang, J. Flow Characteristic in a Single Inlet Cyclone Separator With Double Passage. Acta Pet. Sin. Pet. Process. Sect. 2011, 27, 780–786. [Google Scholar]

- Liang, W.; Dai, S. Numerical simulation on flow field and separation efficiency of cyclone separator with helical-roof double inlet. Min. Process. Equip. 2018, 46, 6. [Google Scholar]

- Liu, W. Numerical Investigation on Performance of Vortex Tube Separator; Dalian Maritime University: Dalian, China, 2017. [Google Scholar]

- Dhakal, T.P.; Walters, D.K.; Strasser, W. Numerical study of gas-cyclone airflow: An investigation of turbulence modelling approaches. Int. J. Comput. Fluid Dyn. 2014, 28, 1–15. [Google Scholar] [CrossRef]

- Su, J.; Wang, L.; Gu, Z.; Zhang, Y. Simulation of cyclone separator using multiphase particle in cell method based on particle energy dissipation model. Chin. J. Environ. Eng. 2016, 10, 5735–5742. [Google Scholar]

- Hunt, J.C.; Wray, A.A.; Moin, P. Eddies stream and convergence zones in turbulent flows. Cent. Turbul. Res. Rep. CTR-S88 1988, 2, 193−208. [Google Scholar]

- Gao, Z.W.; Wang, J.; Wang, J.Y.; Mao, Y.; Li, J.; Wei, Y.D. Vortex Analysis for Cyclone Separators With Different Vortex Finder Diameters Based on Q Criterion. Acta Pet. Sin. Pet. Process. Sect. 2018, 34, 1172–1180. [Google Scholar]

| Conventional | Volute | Helical |

|---|---|---|

| 91.43% | 92.50% | 95.92% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, G.; Gong, J.; Wang, Z.; Liu, R. Simulation of Helical-Baffle Inlet Structure Cyclone Separator. Separations 2025, 12, 166. https://doi.org/10.3390/separations12060166

Li G, Gong J, Wang Z, Liu R. Simulation of Helical-Baffle Inlet Structure Cyclone Separator. Separations. 2025; 12(6):166. https://doi.org/10.3390/separations12060166

Chicago/Turabian StyleLi, Guohua, Jie Gong, Zijuan Wang, and Ran Liu. 2025. "Simulation of Helical-Baffle Inlet Structure Cyclone Separator" Separations 12, no. 6: 166. https://doi.org/10.3390/separations12060166

APA StyleLi, G., Gong, J., Wang, Z., & Liu, R. (2025). Simulation of Helical-Baffle Inlet Structure Cyclone Separator. Separations, 12(6), 166. https://doi.org/10.3390/separations12060166