Hydrocyclones have been widely applied in industries such as petroleum and chemical engineering due to their structural simplicity, small footprint, and absence of moving parts. A typical hydrocyclone consists of five major components: inlet section, cylindrical section, conical section, vortex finder, and spigot [

1,

2,

3]. When multiphase flow enters the hydrocyclone under the high pressure induced by a plunger pump, particle classification occurs under the combined action of centrifugal force, pressure gradient force, and other classification forces. The classification process can be described as follows: coarse particles migrate toward the wall under centrifugal force and are discharged through the spigot, achieving axial settling; meanwhile, fine particles migrate toward the center under the pressure gradient and are discharged through the overflow outlet, completing radial settling under the guidance of the vortex finder. The ideal classification scenario involves all coarse particles exiting through the spigot and all fine particles being collected at the overflow outlet. However, due to inherent structural limitations and the influence of intense turbulent fluctuations, the internal flow field of the hydrocyclone becomes highly complex. Phenomena such as short-circuit flow, circulating flow, and secondary flow coexist, leading to particle trajectory deviations and a significant degree of particle misplacement—one of the main reasons for the low classification sharpness of hydrocyclones. As the discharge channel for fine particles, the vortex finder plays a crucial role in determining the classification performance. Therefore, rational design of the vortex finder geometry is considered one of the key strategies to enhance hydrocyclone classification efficiency [

4,

5].

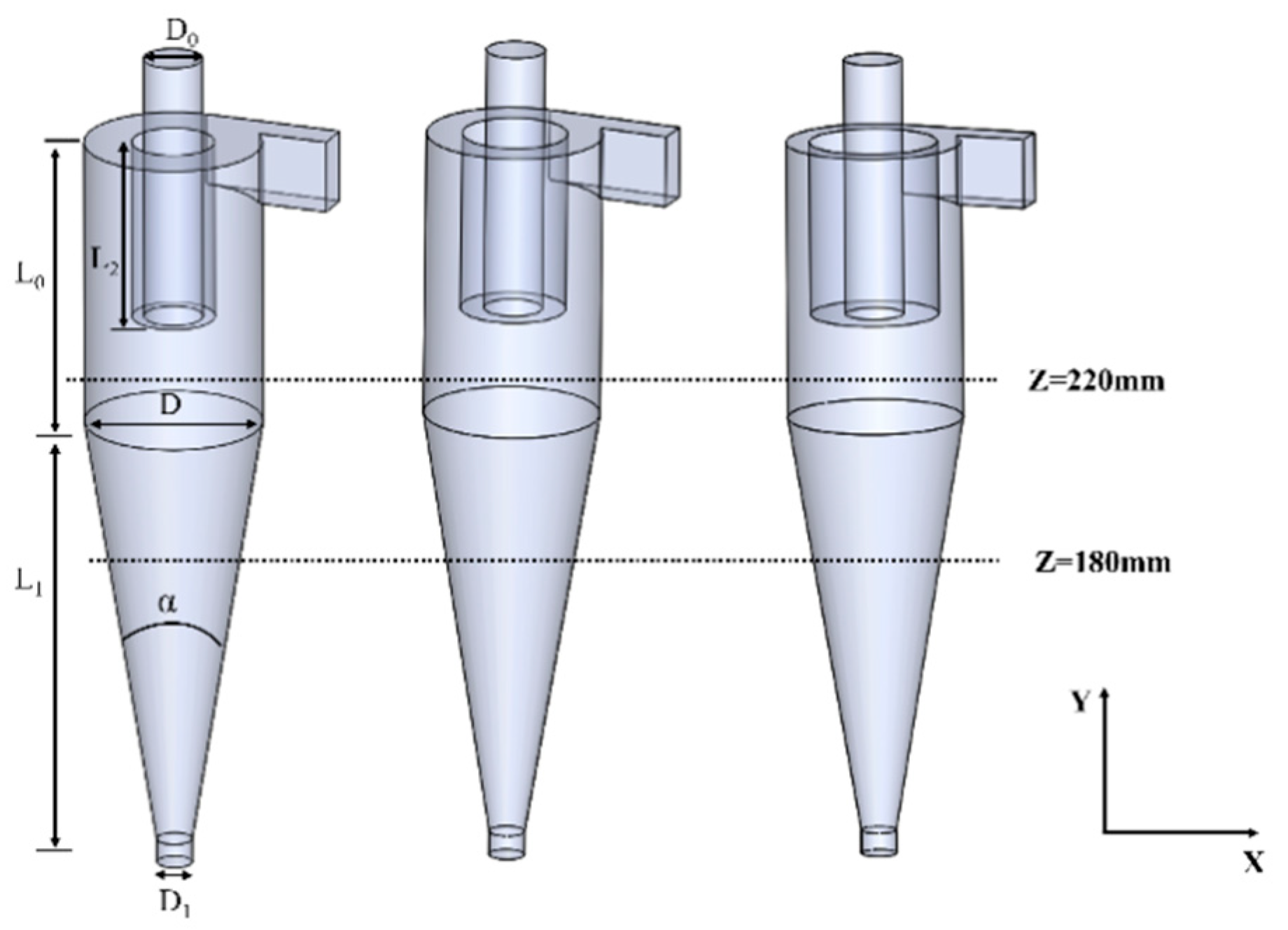

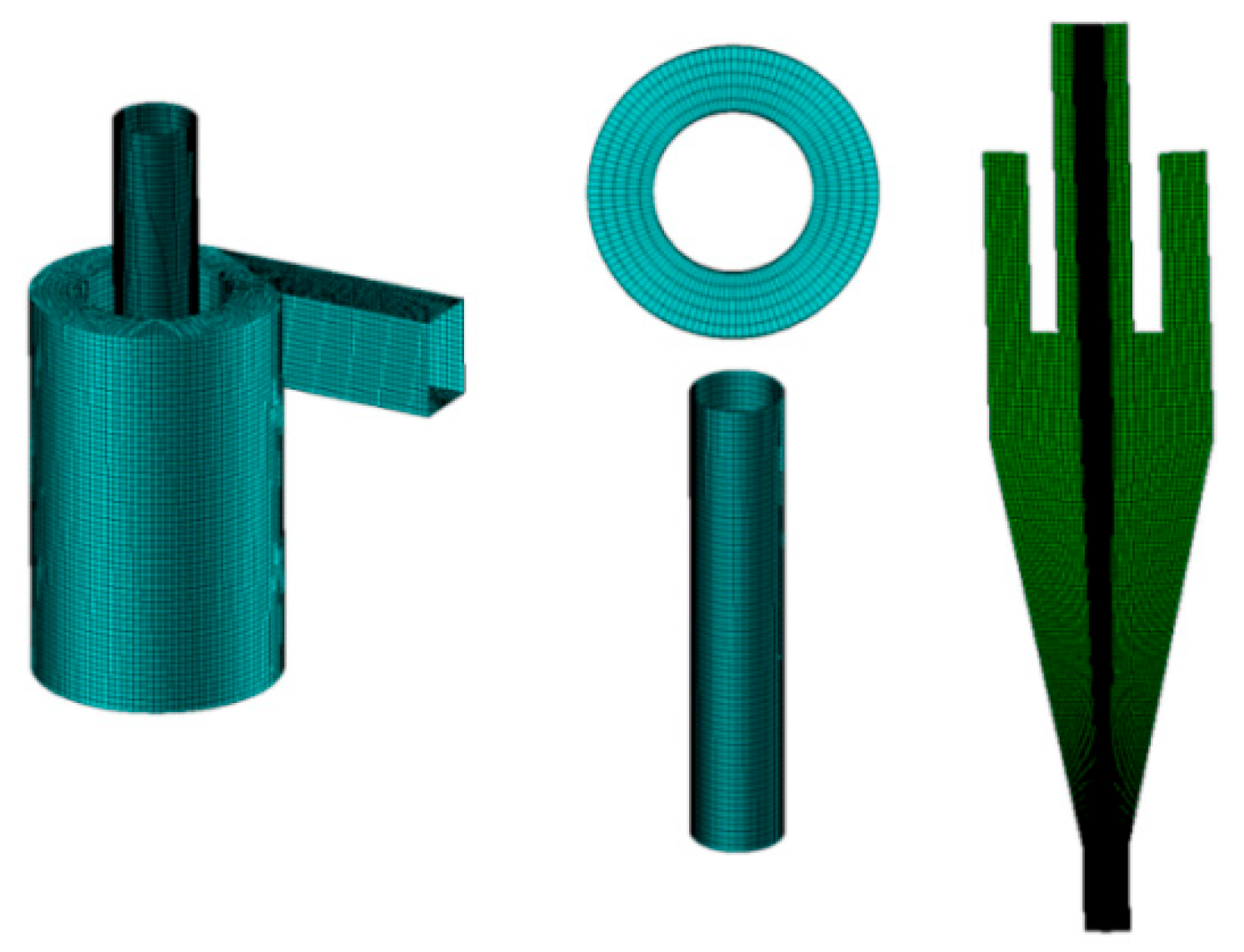

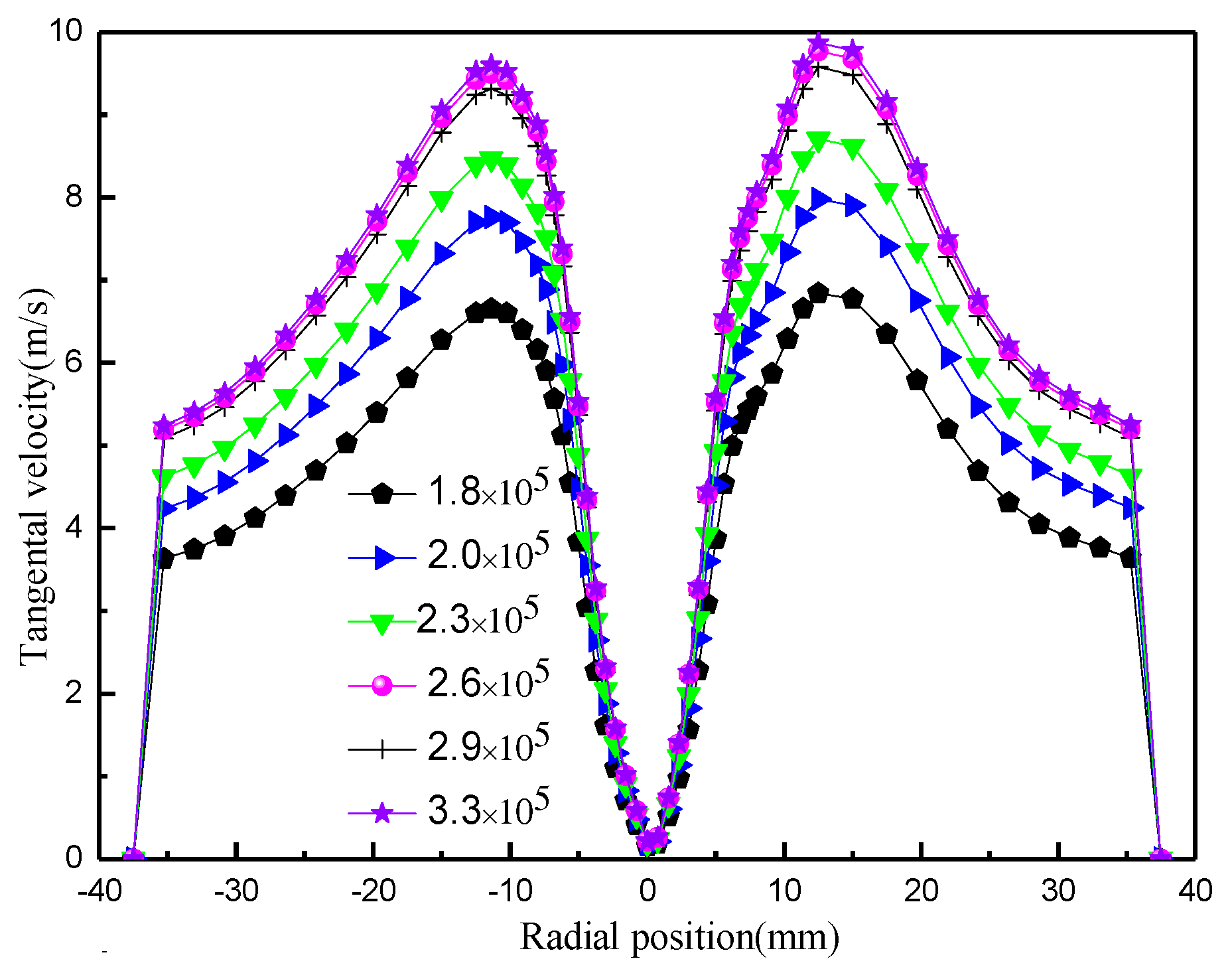

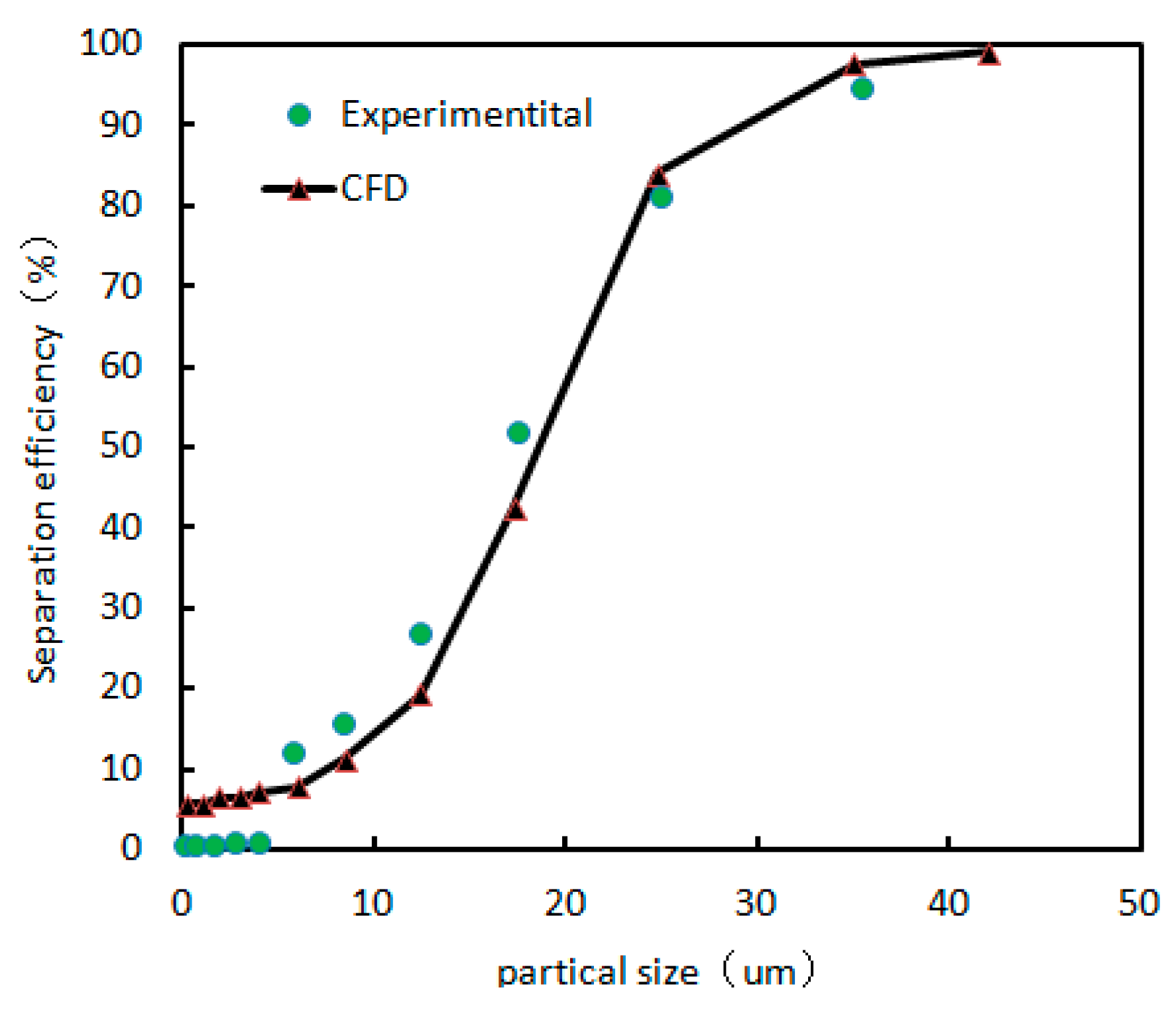

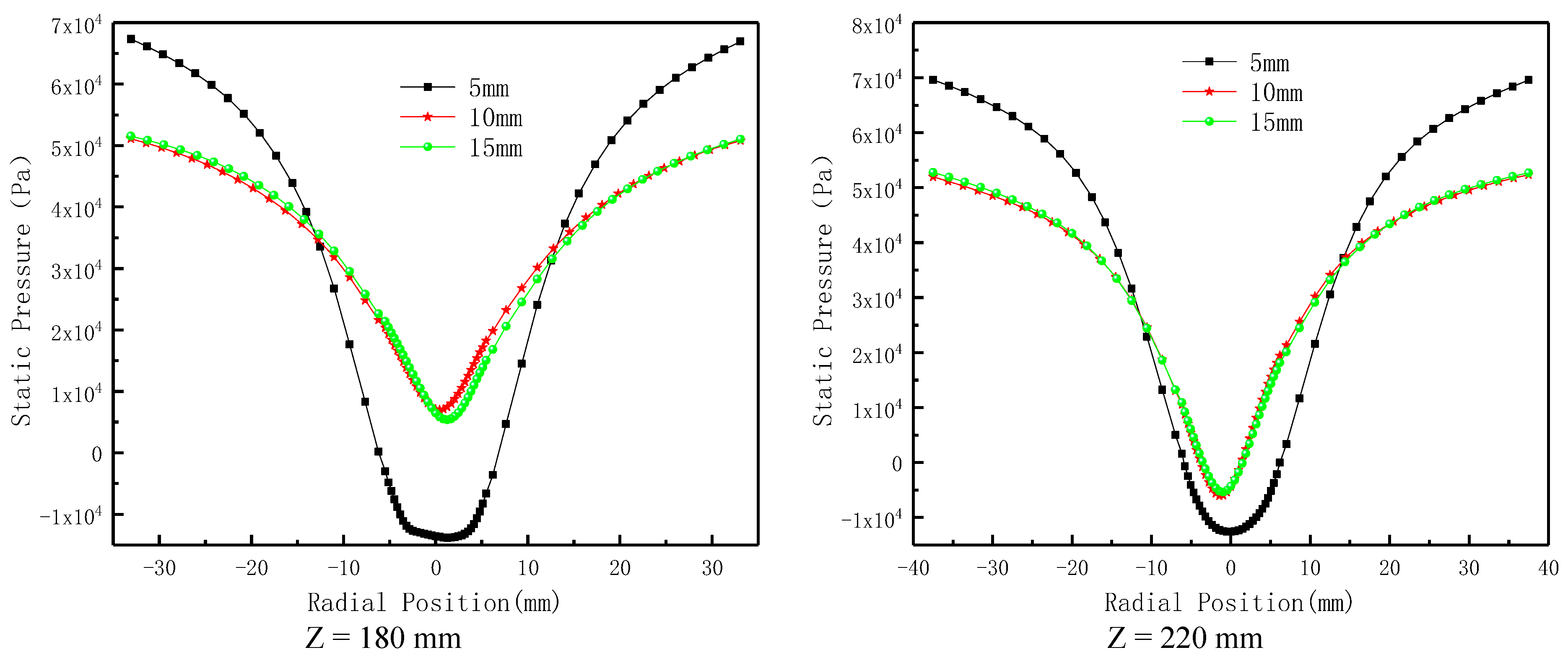

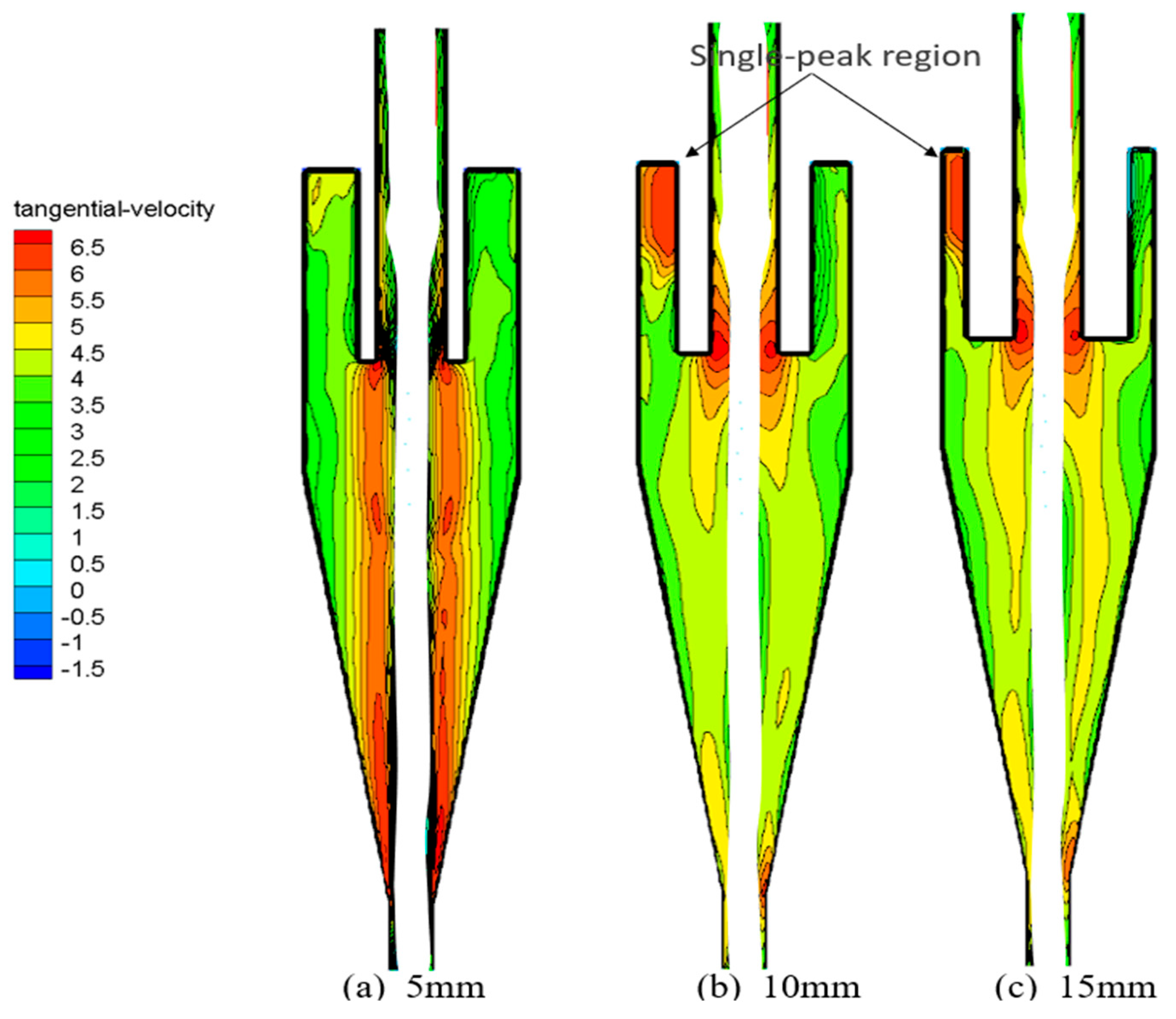

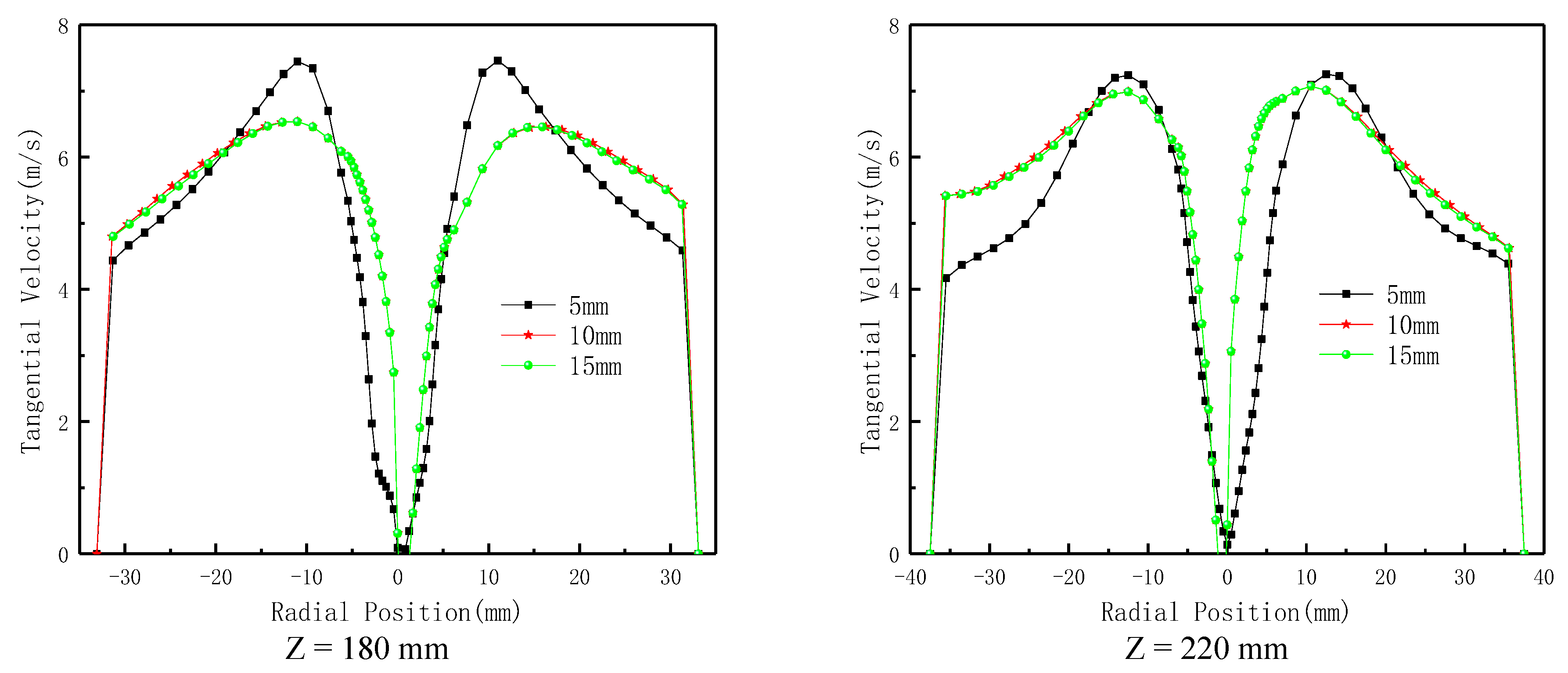

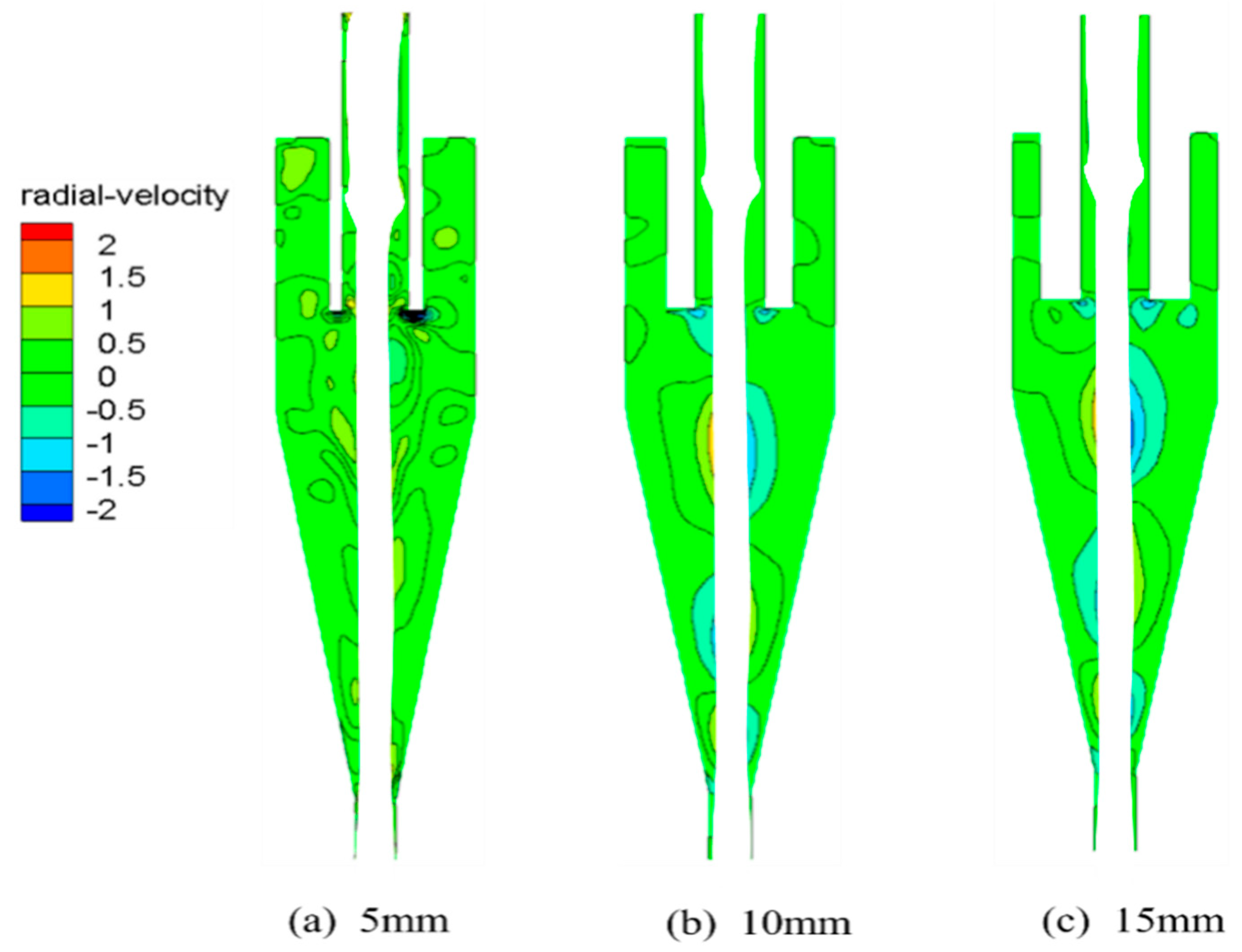

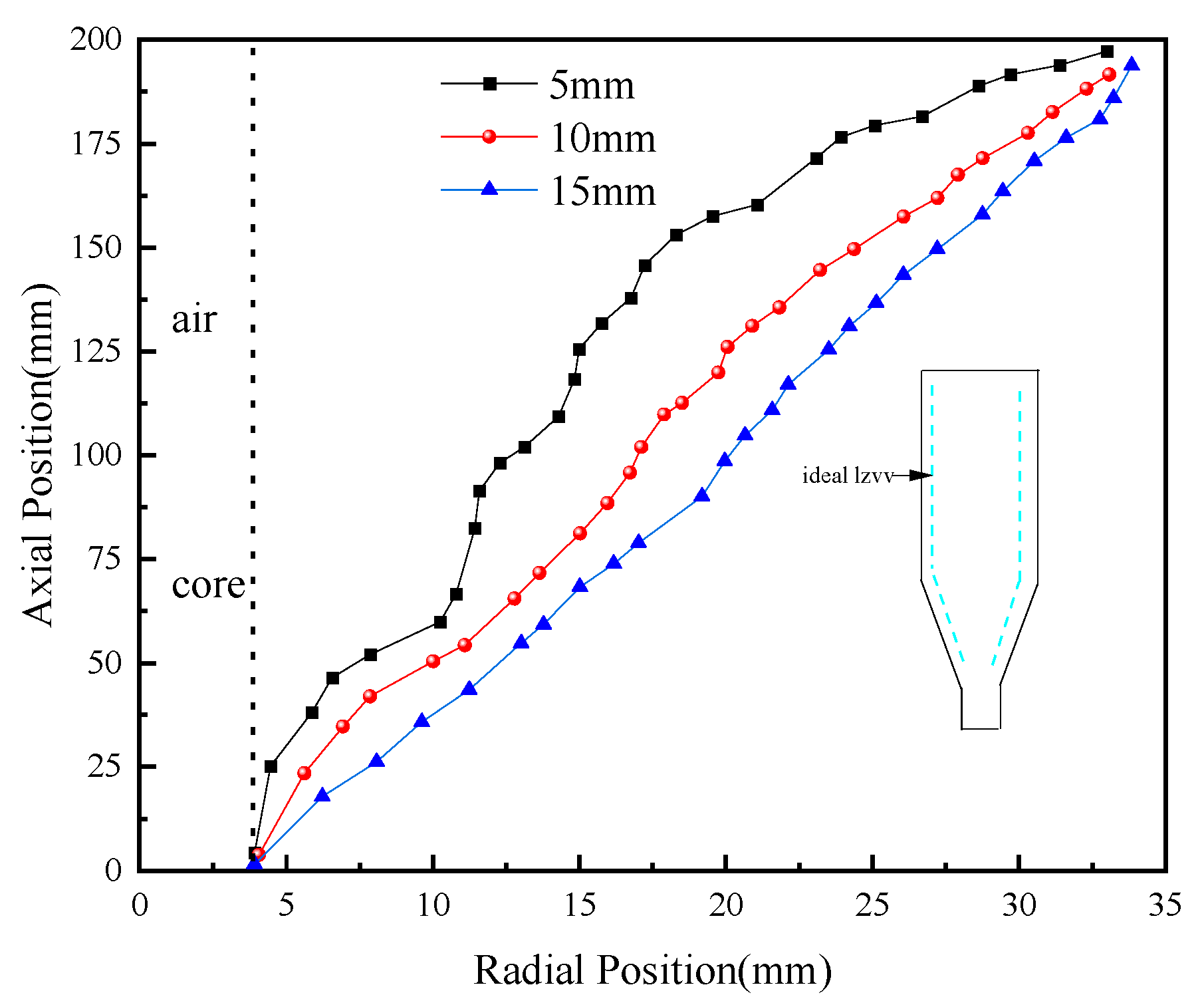

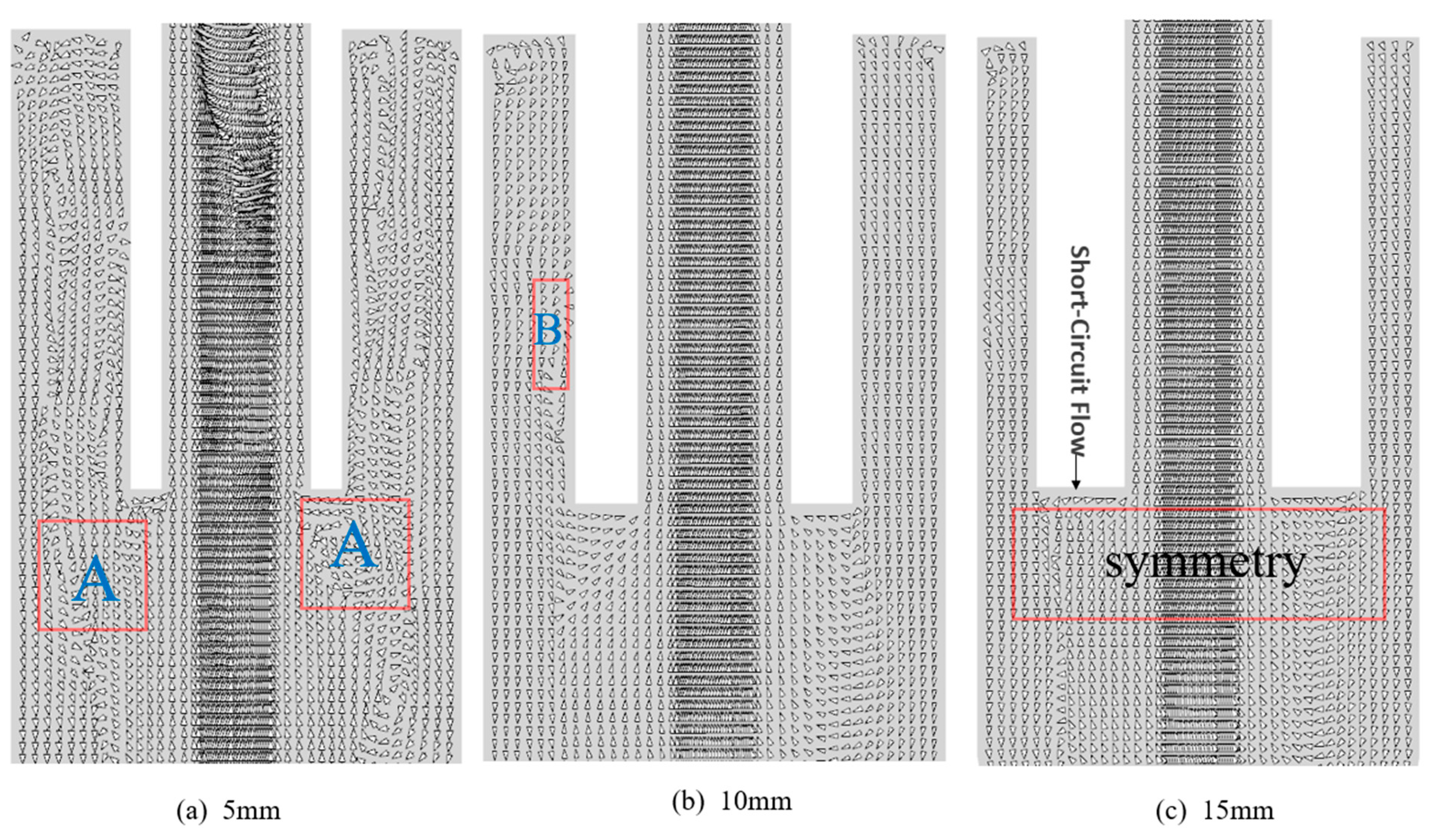

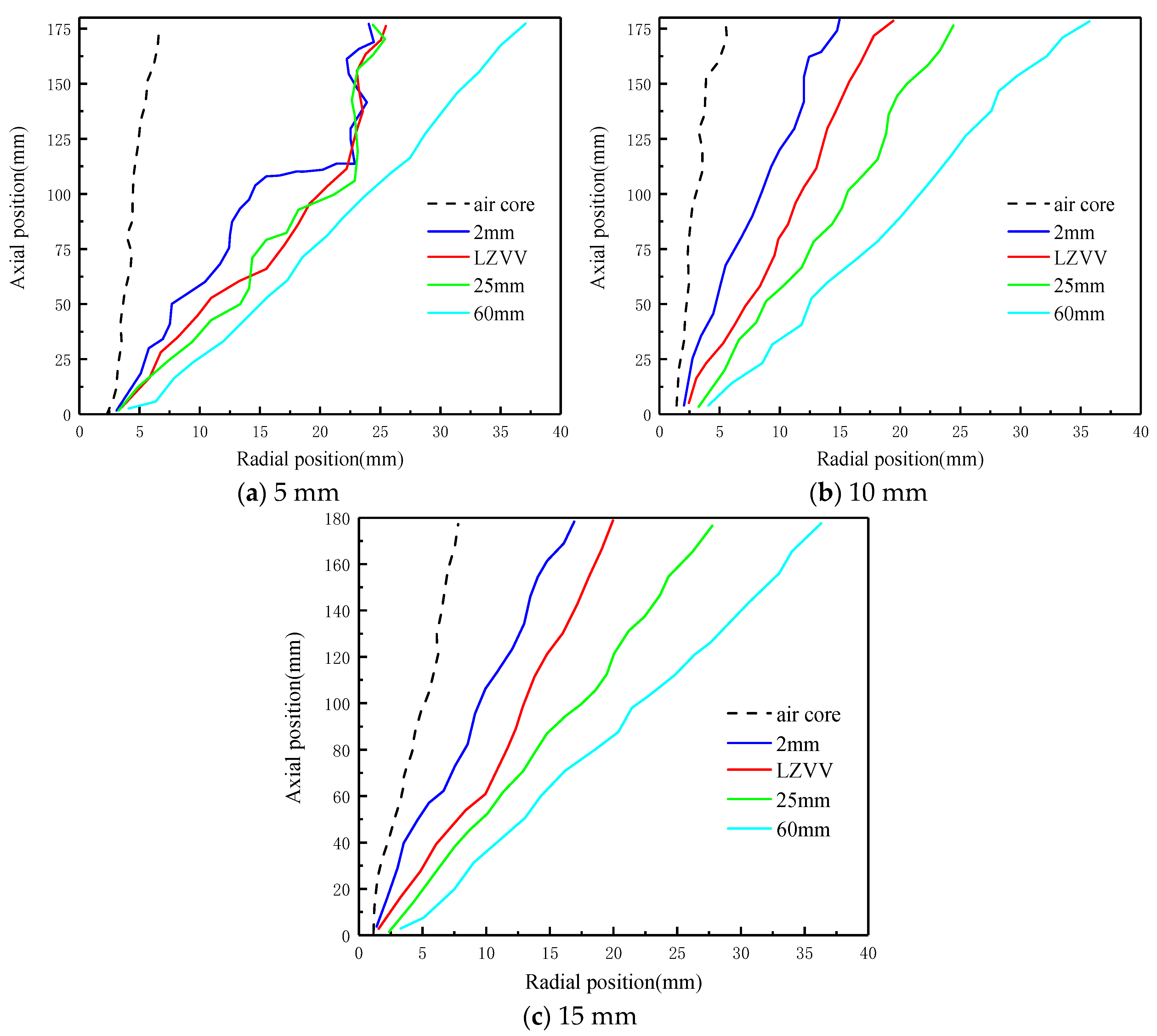

The cylindrical section of the hydrocyclone, functioning as a pre-separation zone, plays a decisive role in energy distribution and the development and stabilization of the internal flow field. The vortex finder serves as the fine-particle outlet and exerts a significant influence on the hydrocyclone separation performance; accordingly, it has been extensively investigated by numerous researchers. Cui [

6] used CFD to investigate the interaction between feed size distribution and vortex finder diameter on hydrocyclone separation performance. It was demonstrated that, when the vortex finder diameter falls within an optimal range, the hydrocyclone can self-adjust its zero-axial-velocity envelope surface and particle equilibrium radius to accommodate varying feed size distributions; however, the optimal diameter was not determined in that study. Ghodrat [

7] employed numerical analysis to assess the effects of vortex finder diameter, length, and geometry on separation performance. It was found that, by varying diameter or geometry, a compromise optimum can be identified that minimizes inlet pressure drop; moreover, the influence of vortex finder length on separation efficiency was shown to be far less significant than that of diameter and shape. Arman Raoufi [

8] used CFD to predict and evaluate the impact of vortex finder shape and diameter on hydrocyclone performance and internal flow. The results show that increasing the vortex finder diameter reduces the tangential velocity in the hydrocyclone’s internal region, which in turn leads to lower separation efficiency in hydrocyclones equipped with larger vortex finders. Among the structural parameters, the wall thickness of the vortex finder directly determines the space available for flow development in the cylindrical section, thereby exerting a significant influence on the classification performance of the hydrocyclone [

9,

10,

11]. Meanwhile, an increased wall thickness of the vortex finder prolongs the trajectory of the short-circuit flow, allowing more particles to re-enter the separation zone, which is beneficial for improving classification efficiency. However, few studies have focused on the effects of vortex finder wall thickness on the internal flow field and classification characteristics. This study, based on fluid dynamics theory, applies the Reynolds Stress Model (RSM) to predict variations in the turbulent field within the hydrocyclone. The Mixture model is employed to capture the behavioral patterns of the particle phase [

12,

13]. The numerical results are validated through comparison with Hsieh’s [

14] classical experimental data, confirming the accuracy of the simulation [

15]. On this basis, the study quantitatively analyzes how changes in vortex finder wall thickness affect key evaluation parameters such as the pressure field, velocity field, and classification efficiency.

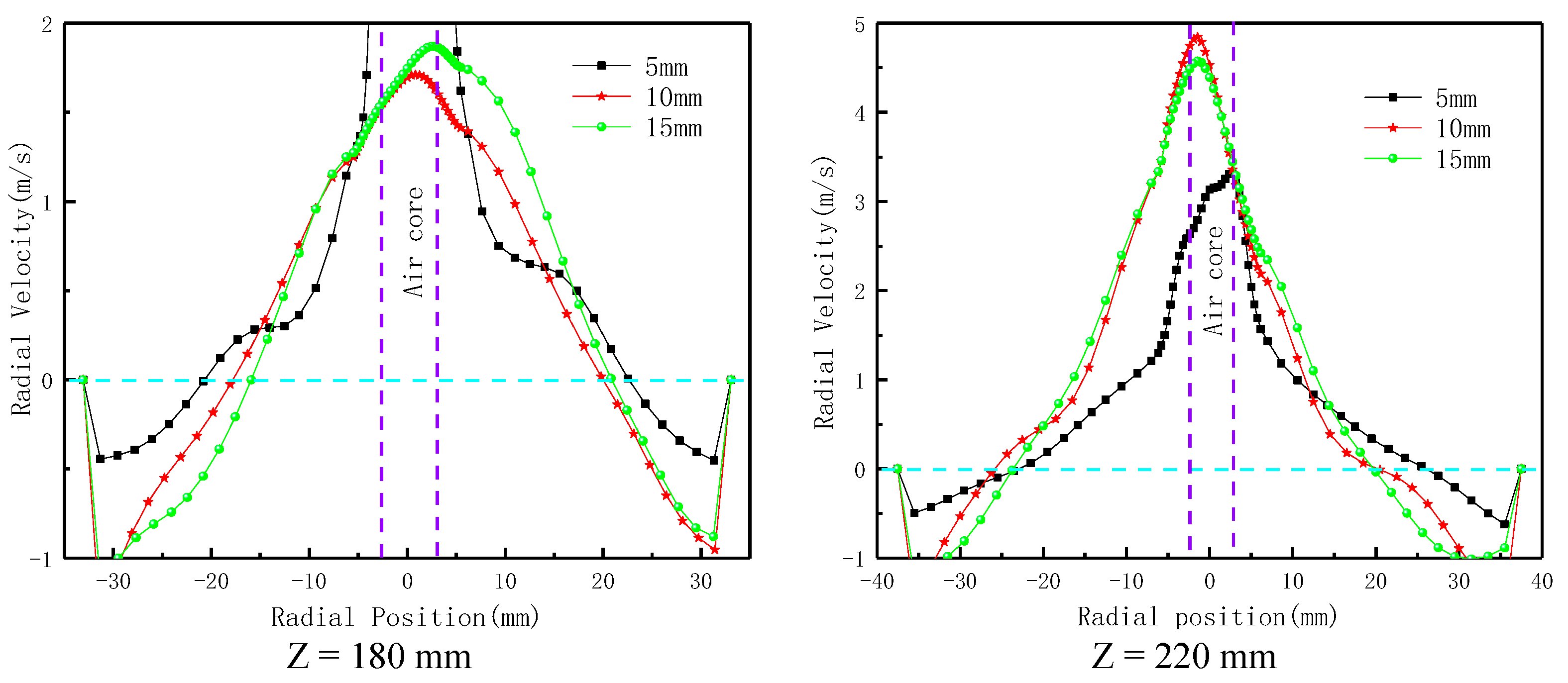

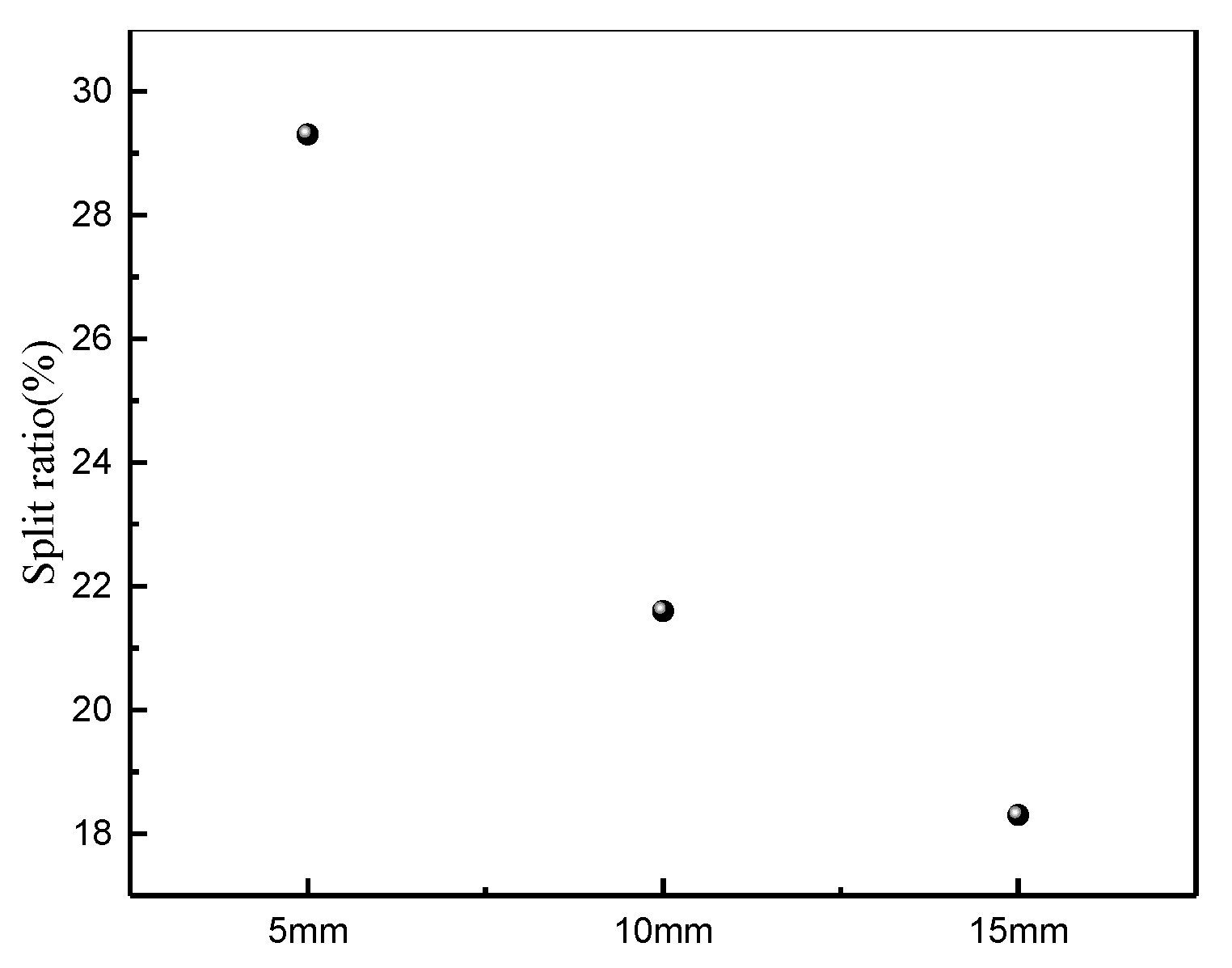

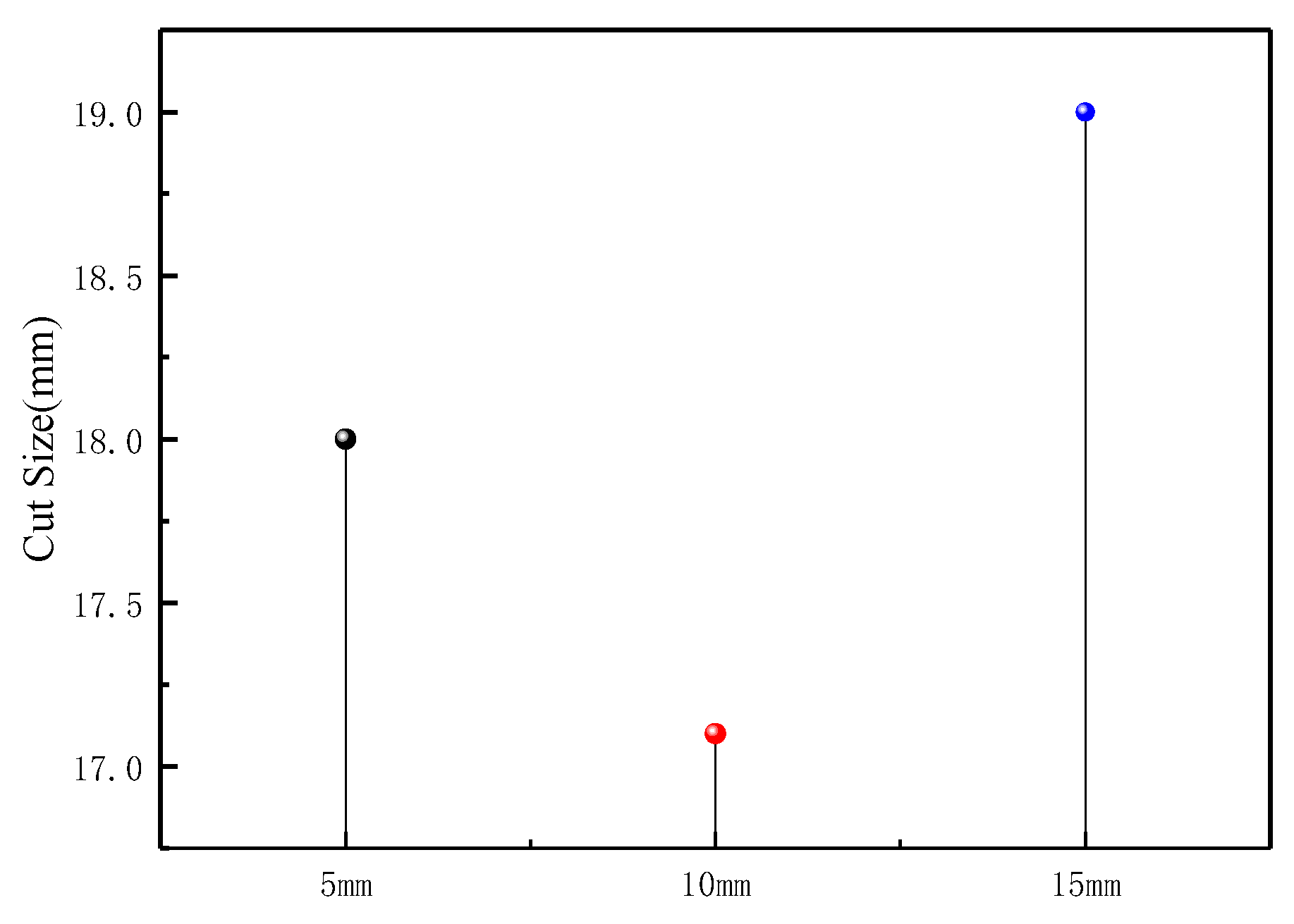

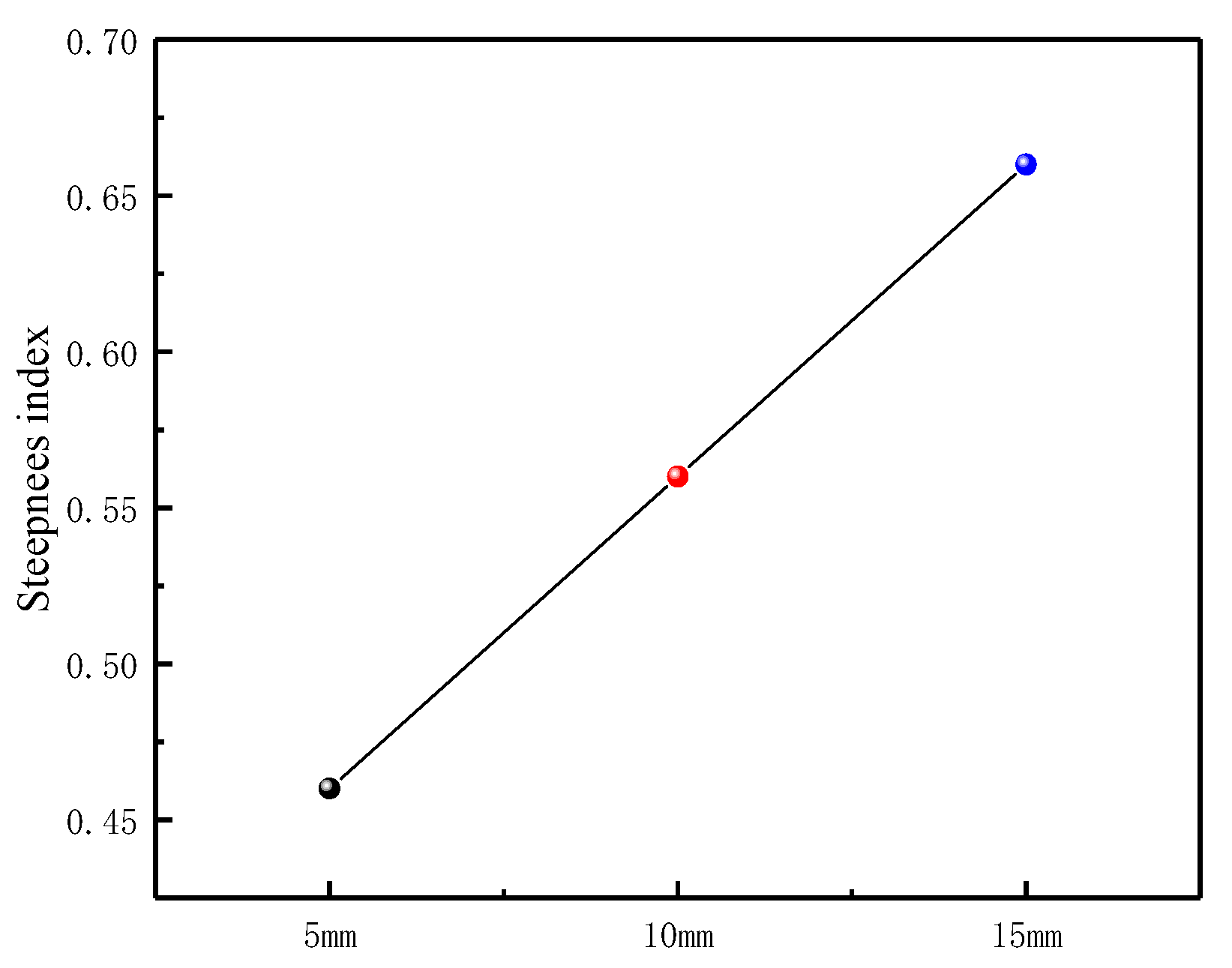

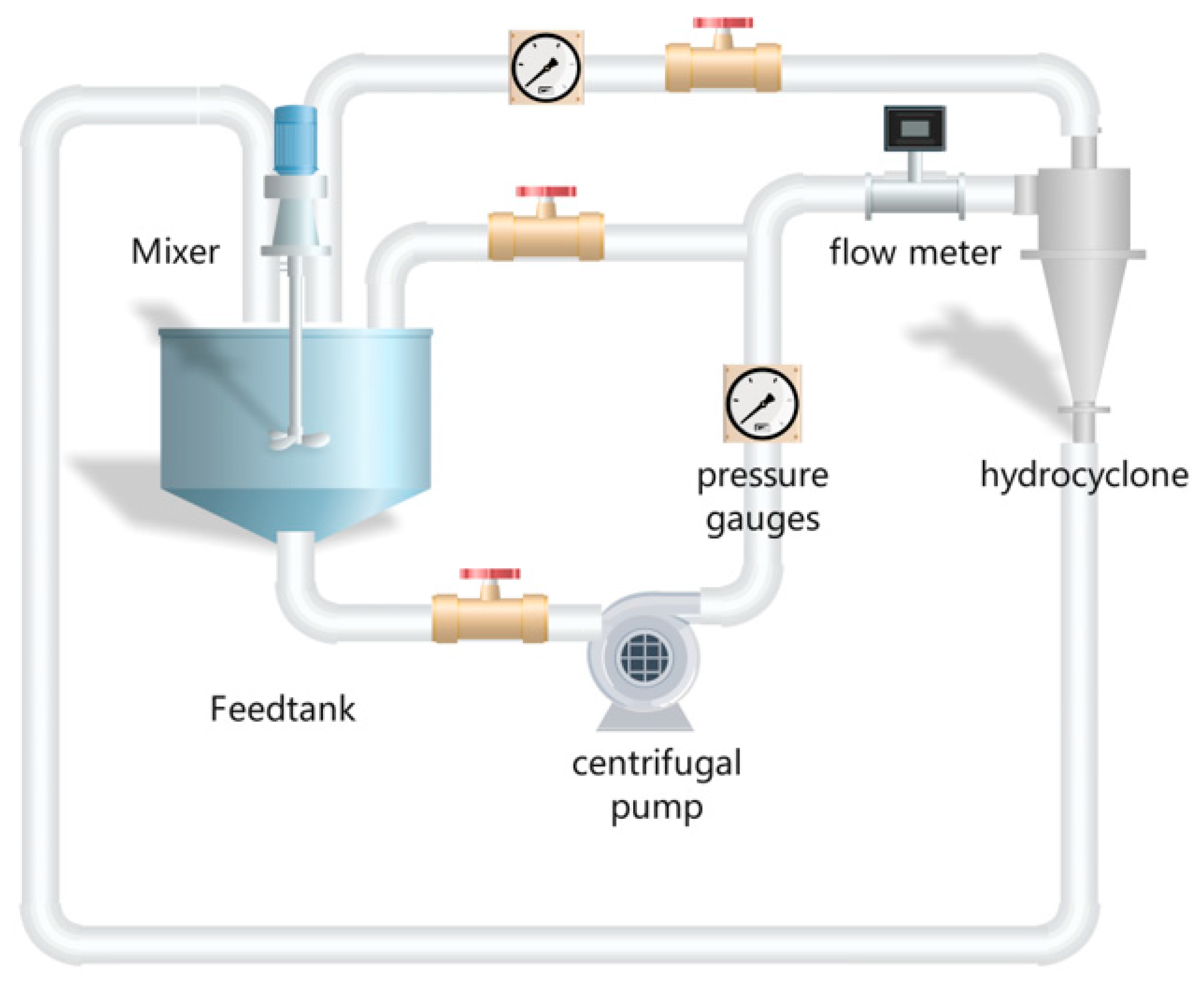

This study investigates the influence of vortex finder wall thickness on the internal flow field and classification performance of a hydrocyclone using both numerical analysis (CFD) and experimental methods. The effects were examined in terms of key evaluation indicators such as pressure field, velocity field, turbulence field, and classification efficiency, thereby revealing the underlying mechanisms of how vortex finder wall thickness impacts these factors. Laboratory experiments were conducted to obtain the characteristics of how vortex finder wall thickness affects particle-phase classification. The evolution of flow structures and the spatial distribution characteristics of the particle phase are illustrated. The results provide important theoretical and practical guidance for the future design of advanced vortex finder structures.