Enhancing Recovery of Low-Productivity Coalbed Methane Wells in Medium-Shallow Reservoirs by CO2 Huff-and-Puff

Abstract

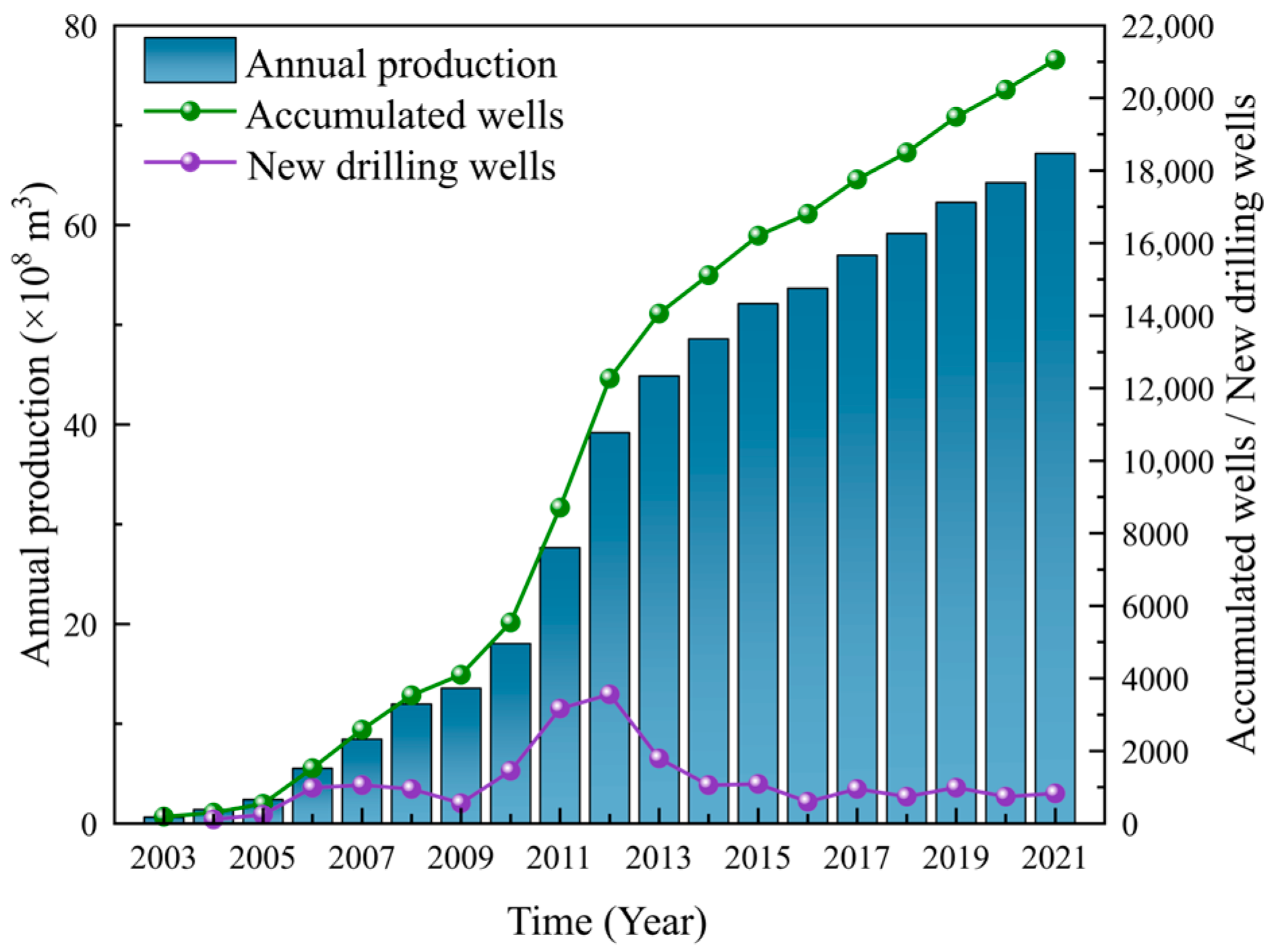

1. Introduction

2. Derivation of Mathematical Model for CO2 Huff-and-Puff Technology

2.1. Basic Assumptions

2.2. Governing Equations of Fluid Transport

2.3. Governing Equation of the Mechanical Field

2.4. Dynamic Porosity-Permeability Model for Coal Seam Fractures

3. Numerical Simulation of CO2 Huff-and-Puff Technology

3.1. Geological Model

3.2. Simulation Schemes

4. Results and Discussion

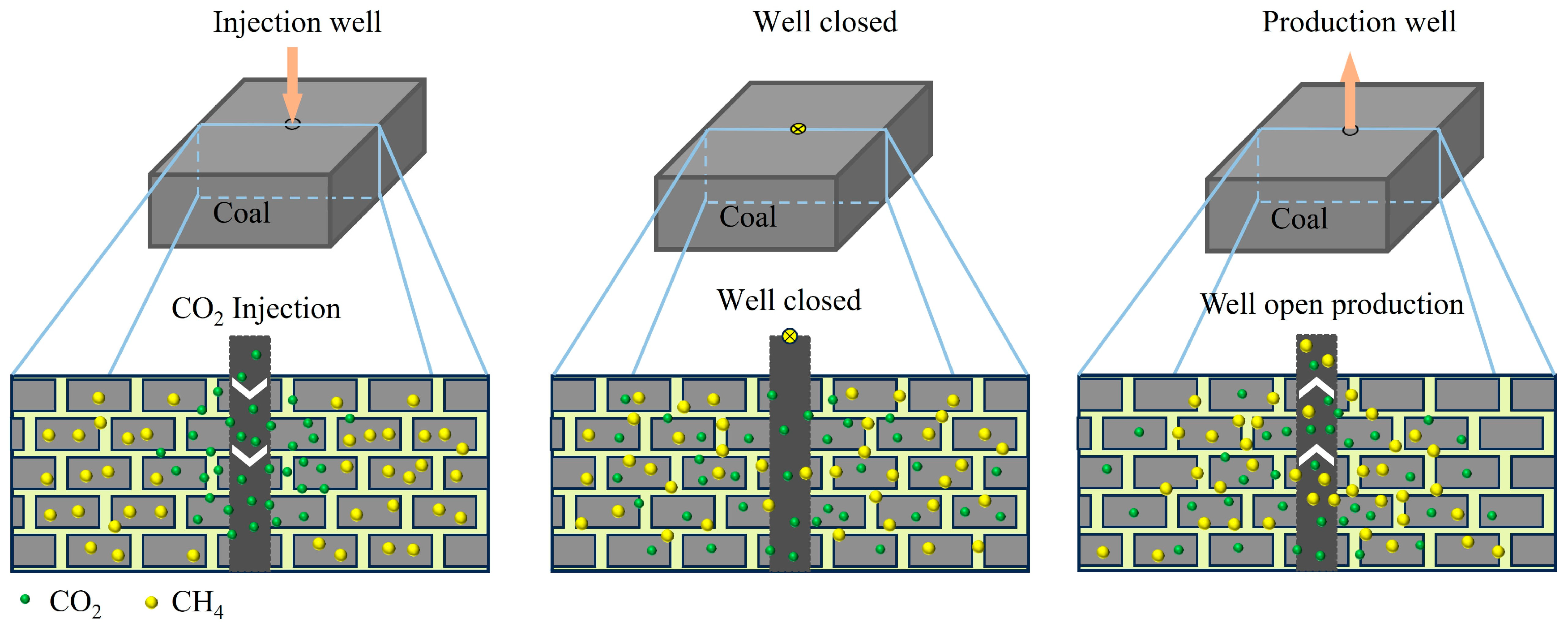

4.1. Mechanisms of CO2 Huff-and-Puff ECBM Recovery

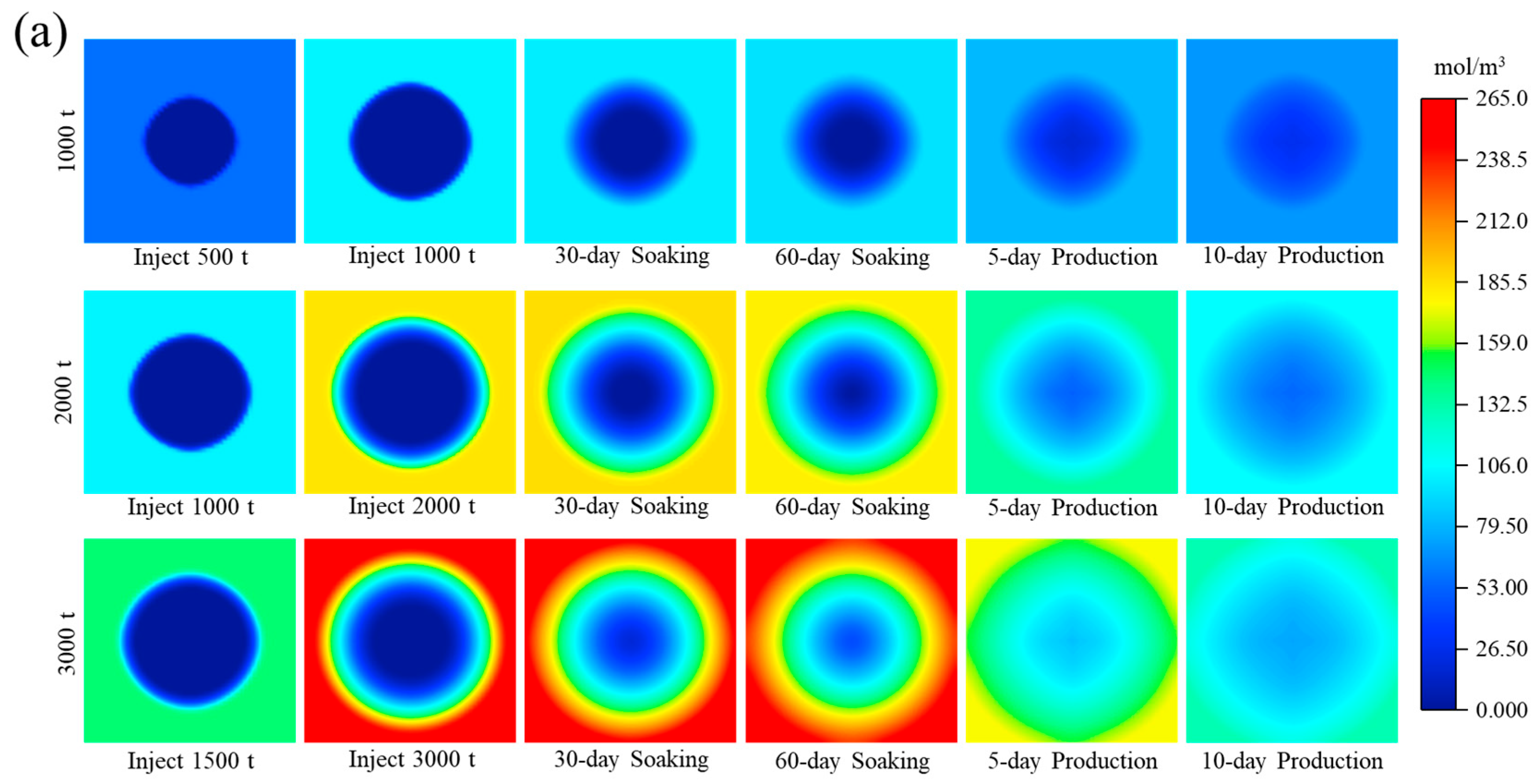

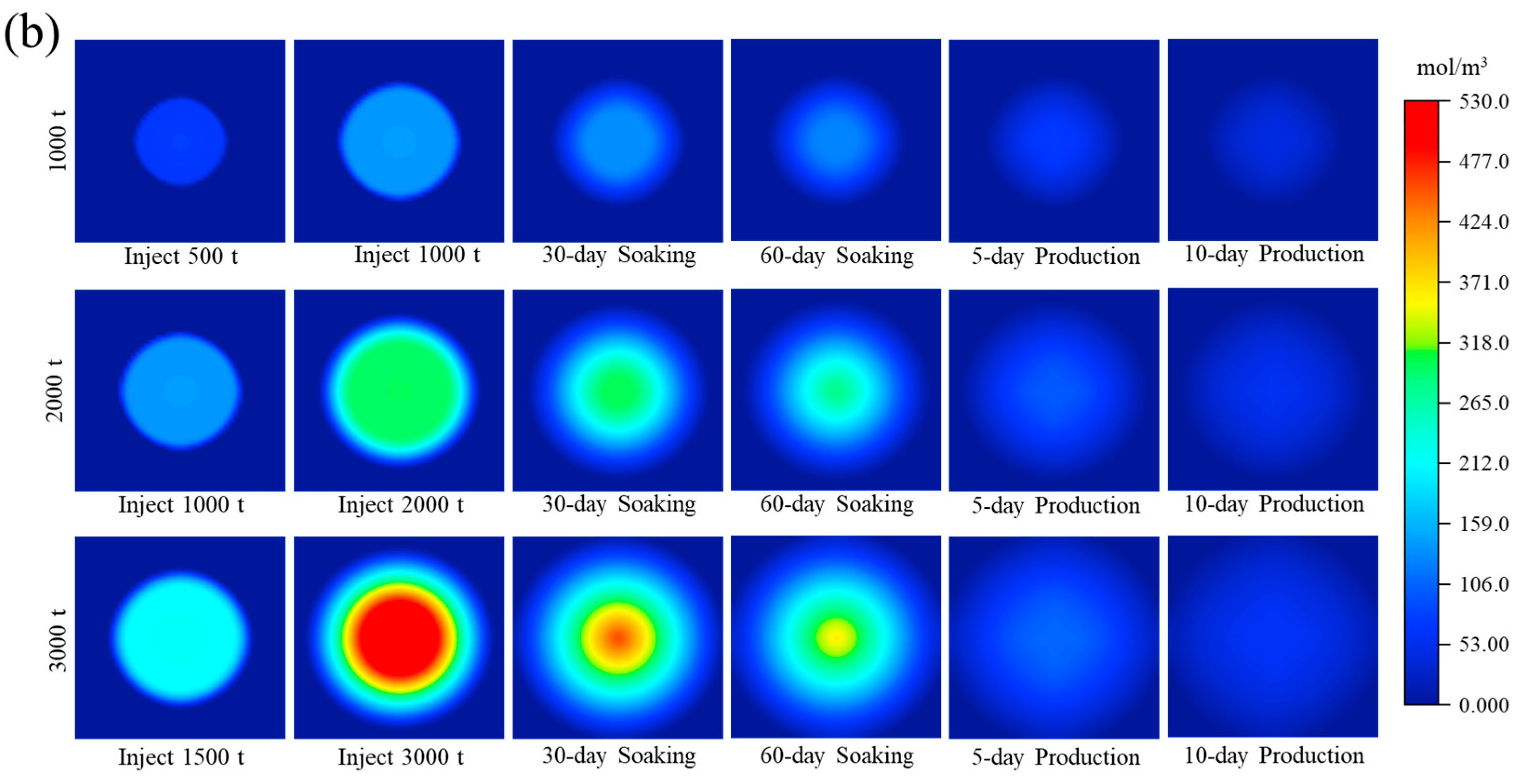

4.1.1. Transformation Between Adsorbed and Free Gas During CO2 Huff-and-Puff

- (1)

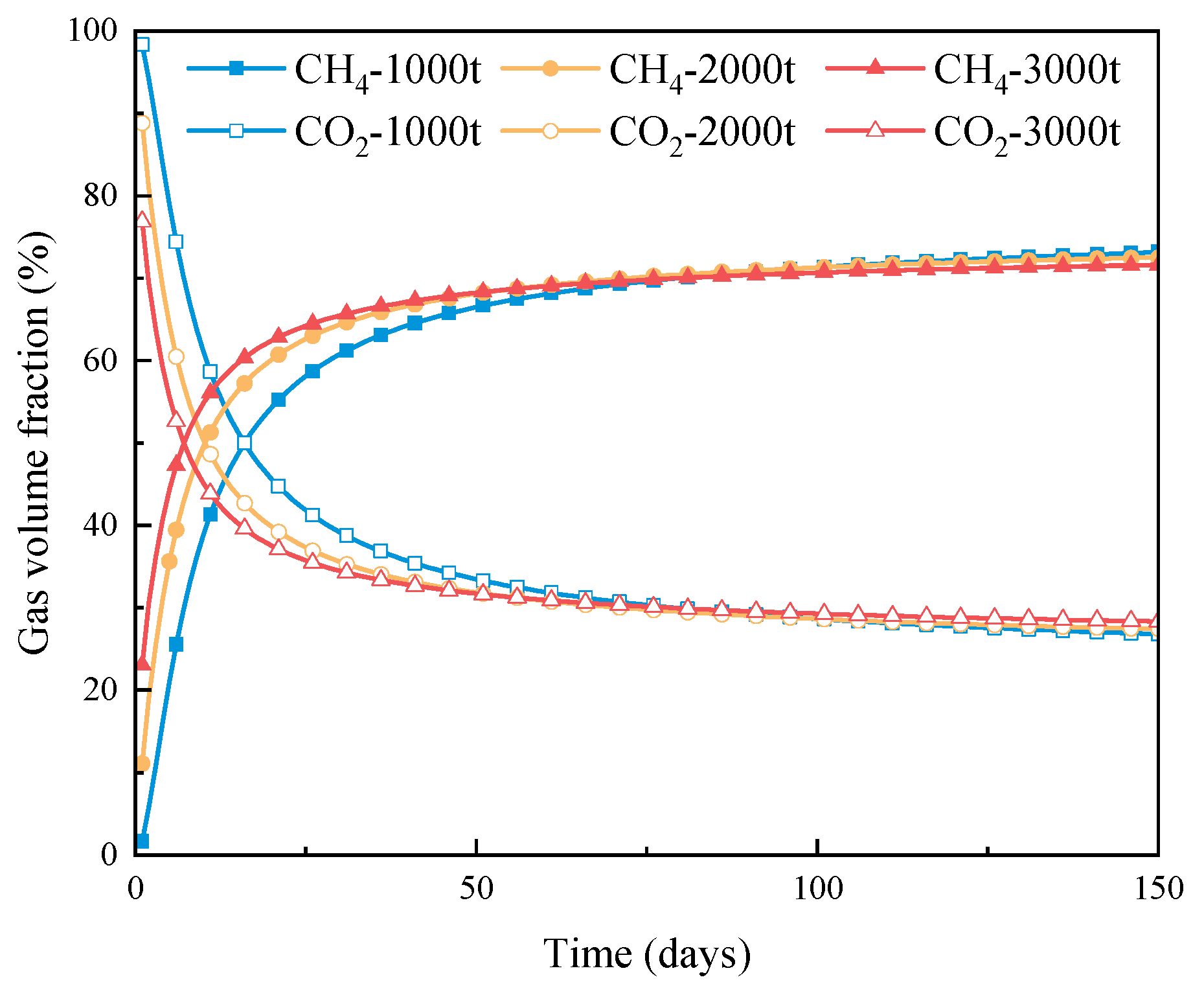

- During the gas injection phase, the free CH4 content within fractures demonstrates progressive accumulation, with CH4 near the wellbore experiences displacement by injected CO2, migrating toward peripheral regions. Simultaneously, significant CO2 accumulation occurs near the wellbore, with the high-concentration zone expanding proportionally with injection volume.

- (2)

- During the soaking phase, free CH4 exhibits concentration gradient-driven back-migration toward the wellbore. Continuous CO2 diffusion from fractures into the coal matrix occurs, accompanied by adsorption phenomena. This dual process leads to continuous reduction in free CO2 content, diminution of the wellbore-proximal high-CO2-concentration zone, and progressive expansion of the CO2-CH4 mixing zone. Notably, the extent of the mixed zone increases significantly with higher CO2 injection volumes. This is due to the higher injection volume leading to an increase in coal seam pore pressure, resulting in an increase in concentration gradients in the coal seam, thus accelerating the diffusion and mixing of CO2 and CH4 molecules.

- (3)

- During the production phase, after reopening the well, rapid co-extraction of the mixed CH4 and CO2 occurs, causing a rapid decline in the content of both CH4 and CO2 within the fracture system. Meanwhile, CH4 located farther from the wellbore migrates toward the wellbore. Due to the relatively limited shut-in duration, some of the injected CO2 has not been fully adsorbed by the coal matrix, resulting in partial CO2 being re-extracted after reopening the well.

- (1)

- During the CO2 injection phase, competitive adsorption between CO2 and CH4 induces rapid desorption of CH4 near the wellbore. Additionally, free CH4 in fractures is displaced to regions farther from the wellbore, leading to a reduction in CH4 partial pressure in the near-wellbore region. According to the Langmuir equation, this decrease in partial pressure results in a reduction of CH4 adsorption capacity.

- (2)

- During the soaking phase, CO2 adsorption continues to increase, forming a high-concentration CO2 adsorption zone near the wellbore. After 60 days of soaking, the spatial extent of this CO2-rich zone expands with higher injection volumes.

- (3)

- During the production phase, extraction of free CO2 from fractures slightly reduces adsorbed CO2 content. Meanwhile, as CH4 migrates toward the wellbore, a portion of CH4 is re-adsorbed by the coal matrix during this flow process, leading to a localized increase in CH4 adsorption near the wellbore. Overall, after CO2 huff-and-puff, the adsorbed CH4 content around the wellbore remains significantly lower than the initial state, confirming effective displacement. Moreover, substantial CO2 storage is achieved, with both the storage capacity and spatial distribution of CO2 increasing proportionally with injection volume.

4.1.2. Evolution of Gas Volume Fraction in Production Well

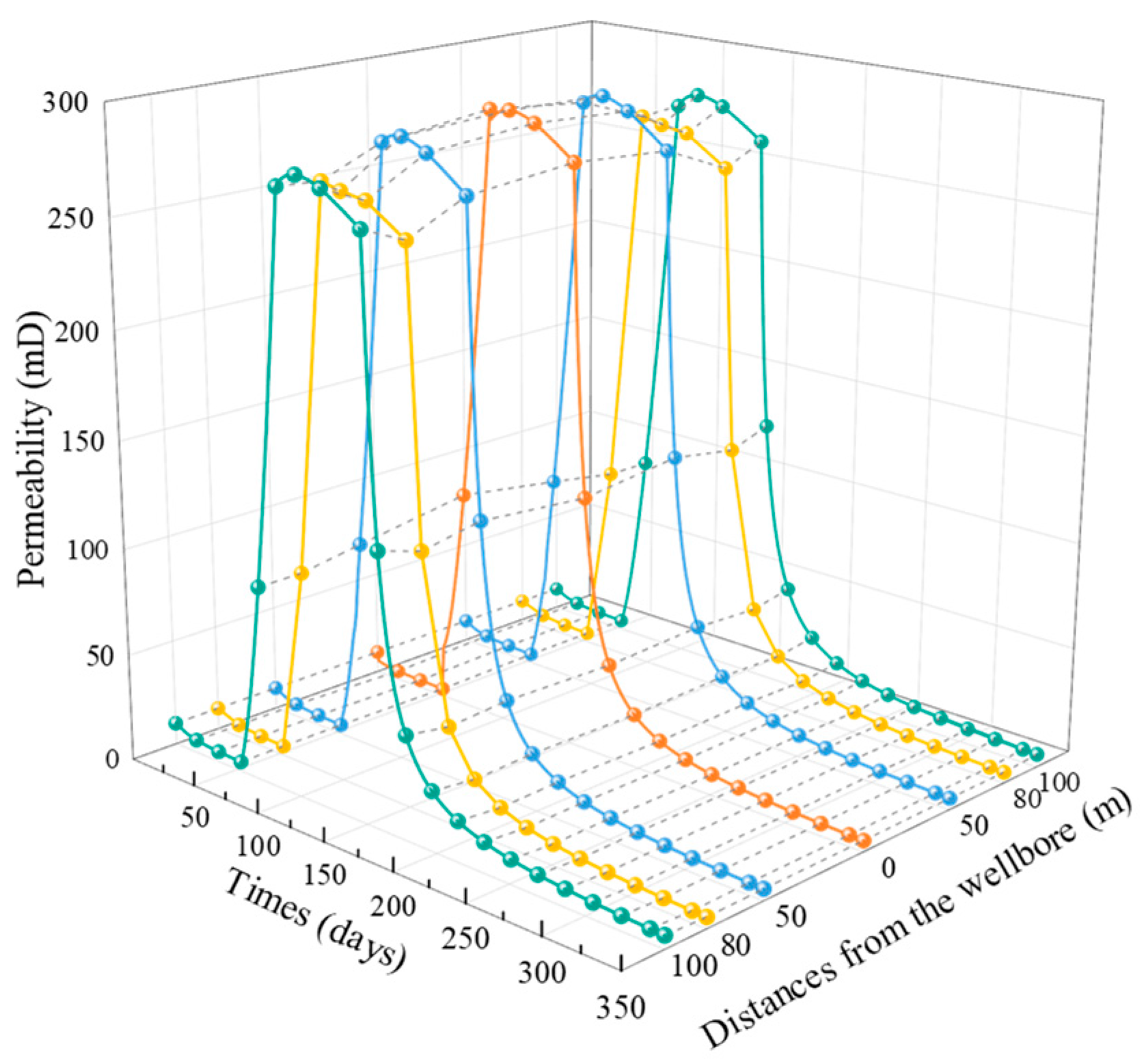

4.1.3. Evolution of Coal Seam Permeability

- (1)

- During the initial phase of conventional extraction, the abrupt pressure drops near the wellbore after well opening causes a rapid increase in effective stress, resulting in a sharp decline in permeability. In contrast, regions farther from the wellbore exhibit a moderate permeability increase primarily due to coal matrix shrinkage caused by CH4 desorption. As extraction progresses, the sustained reduction in coal seam gas pressure elevates effective stress, inducing compressive deformation and an overall downward permeability trend. By the end of conventional extraction, the permeability reaches a minimum of 3.42 mD.

- (2)

- During the injection phase, CO2 injection increases fracture pressure, which reduces effective stress and consequently enhances permeability. During the subsequent soaking phase, permeability initially increases before declining. This transient increase occurs because CO2 continues displacing adsorbed CH4 early in the soaking period, thereby improving flow pathways. However, as displacement weakens, ongoing CO2 diffusion and adsorption reduce free gas in fractures, lowering pore pressure and permeability. A notably permeability reduction is observed at 80 m from the wellbore during soaking. This phenomenon occurs because permeability in this region, where pore pressure remains relatively stable, is predominantly governed by matrix adsorption characteristics. Situated within the CH4–CO2 transition zone, the coal matrix exists in a mixed-gas adsorption state. According to the extended Langmuir strain model, matrix swelling under mixed-gas adsorption exceeds that under single-component adsorption. This leads to a greater pore structure contraction and thus lower permeability compared to adjacent zones under pure adsorption states.

- (3)

- Following well reopening, continuous reservoir pressure depletion leads to a sustained permeability decline, causing the production to drop rapidly after reaching its peak. By the 97th day of extraction, the coal seam permeability reverts to its initial value of 10 mD. Continued extraction further reduces the minimum permeability to 8.51 mD by the end of production—below the initial permeability level.

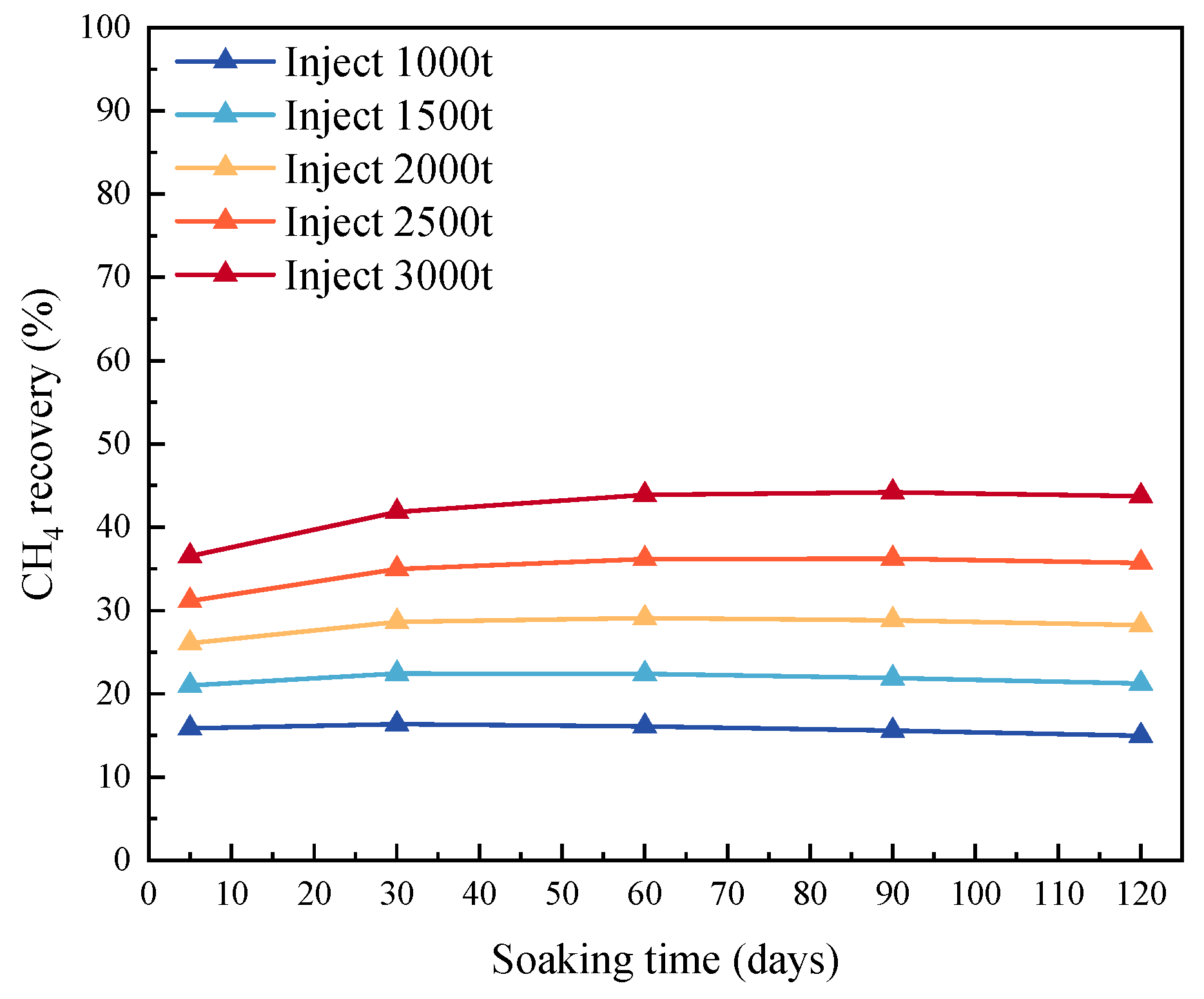

4.2. Effects of CO2 Injection Volume and Soaking Time on CH4 Enhancement and CO2 Storage Performance

4.2.1. Variation of CH4 Production

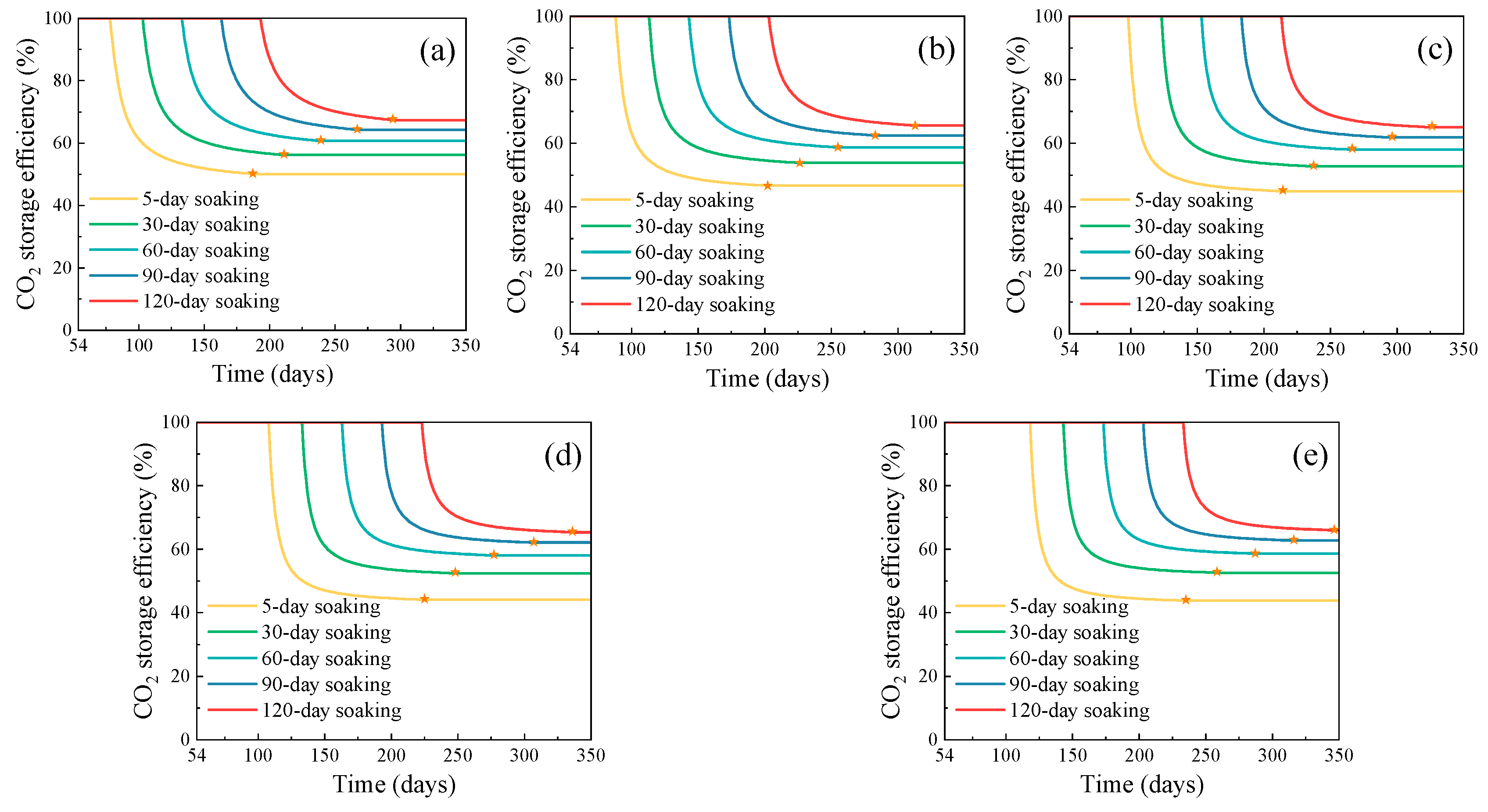

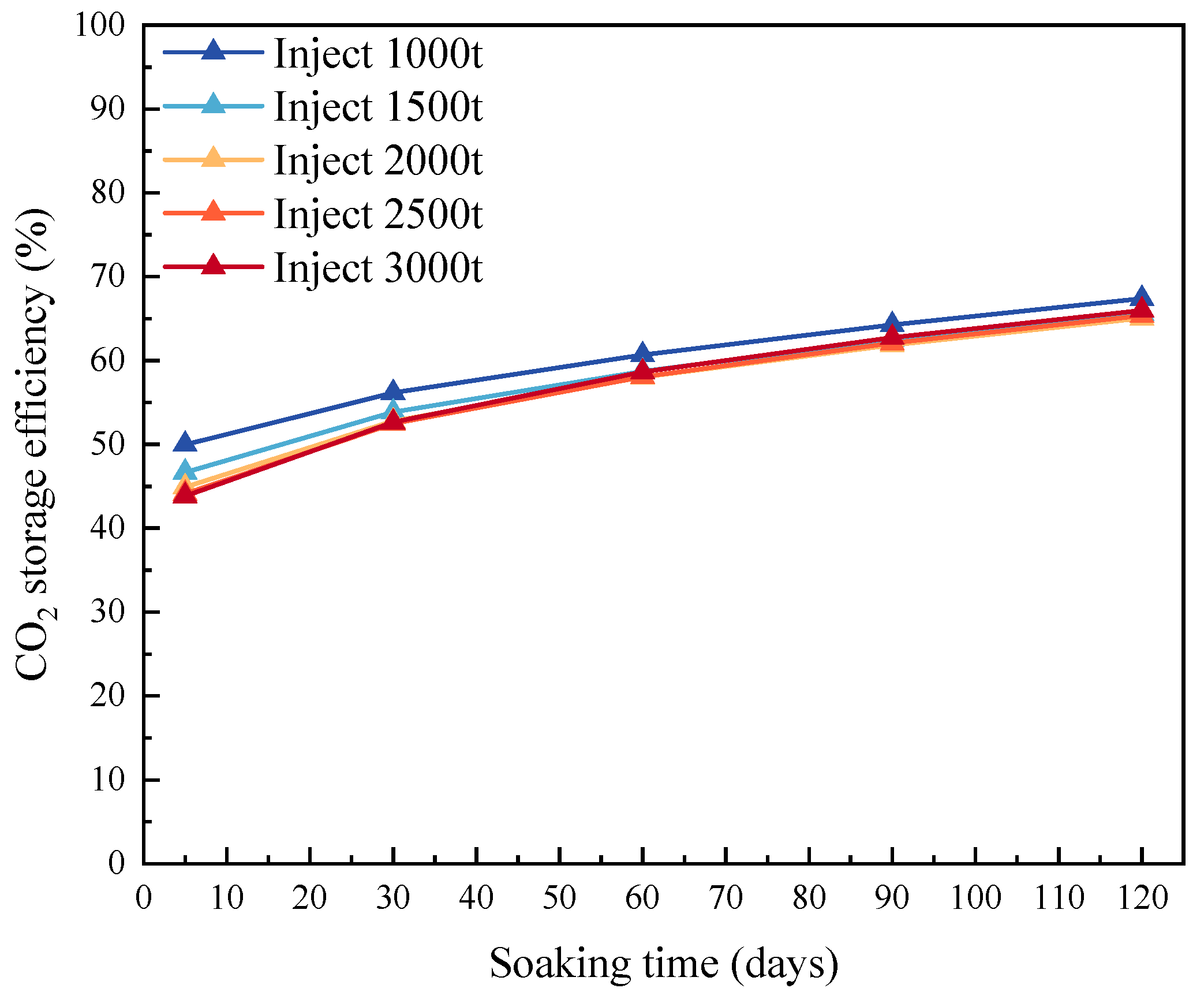

4.2.2. CO2 Storage Efficiency

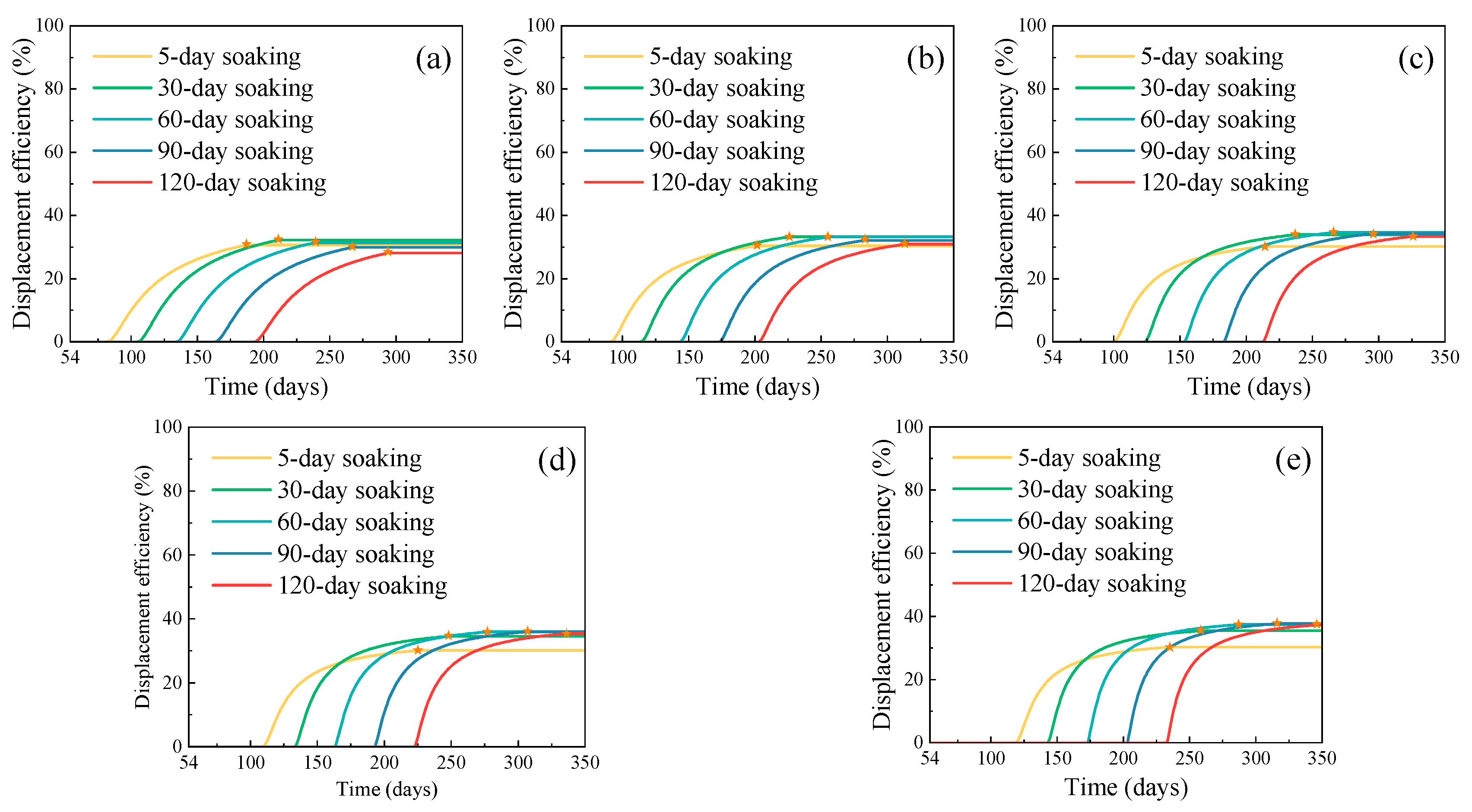

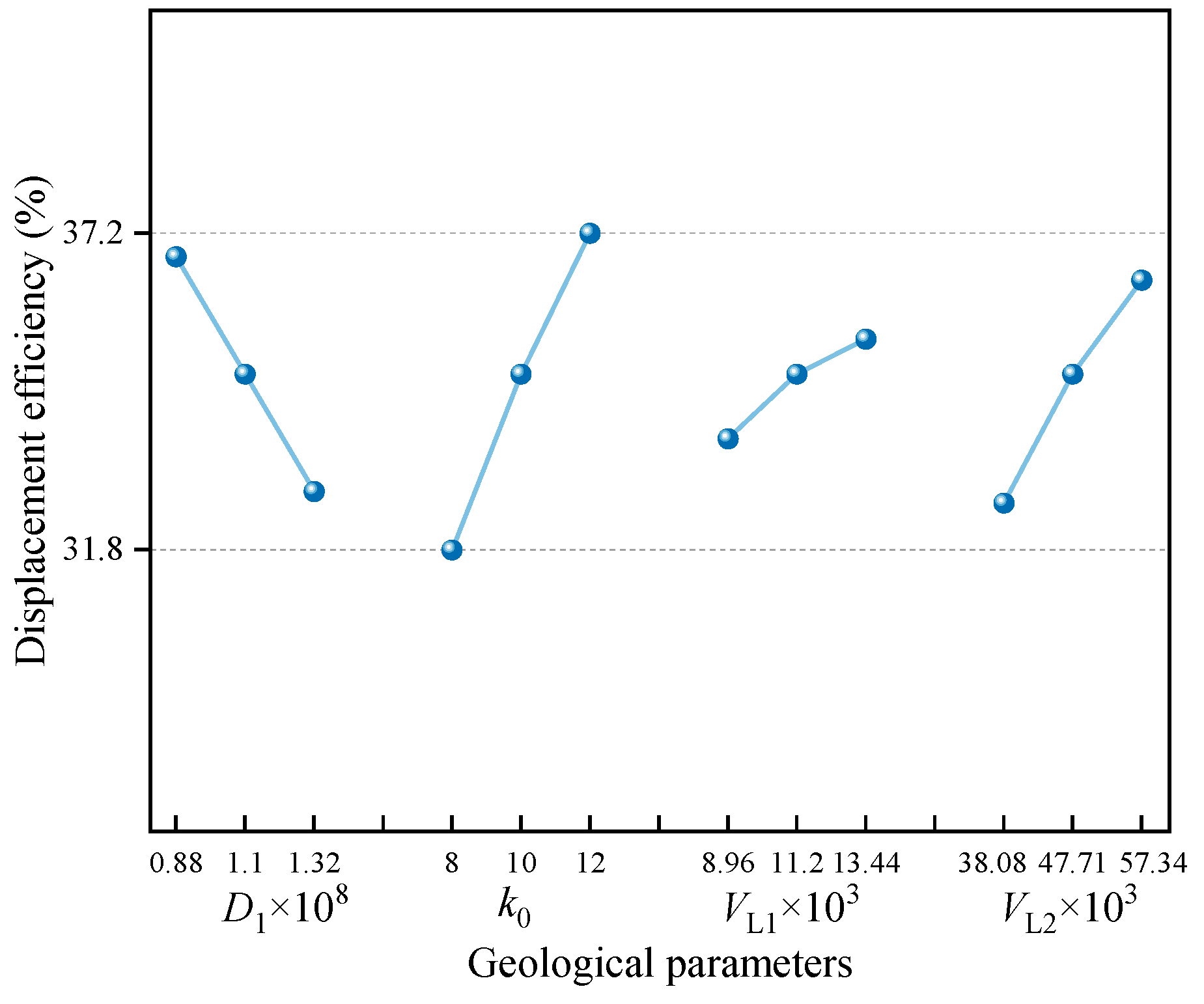

4.2.3. Displacement Efficiency

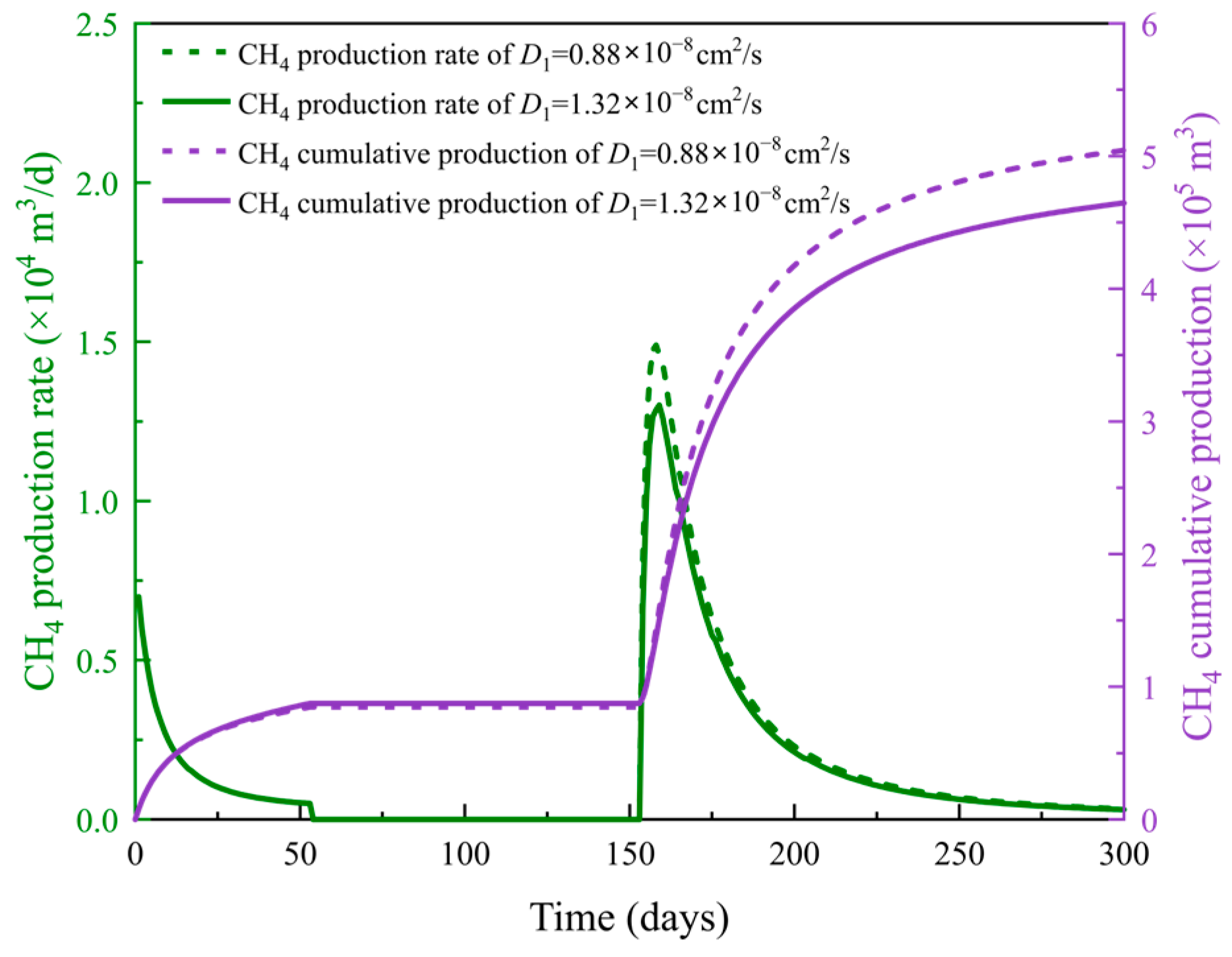

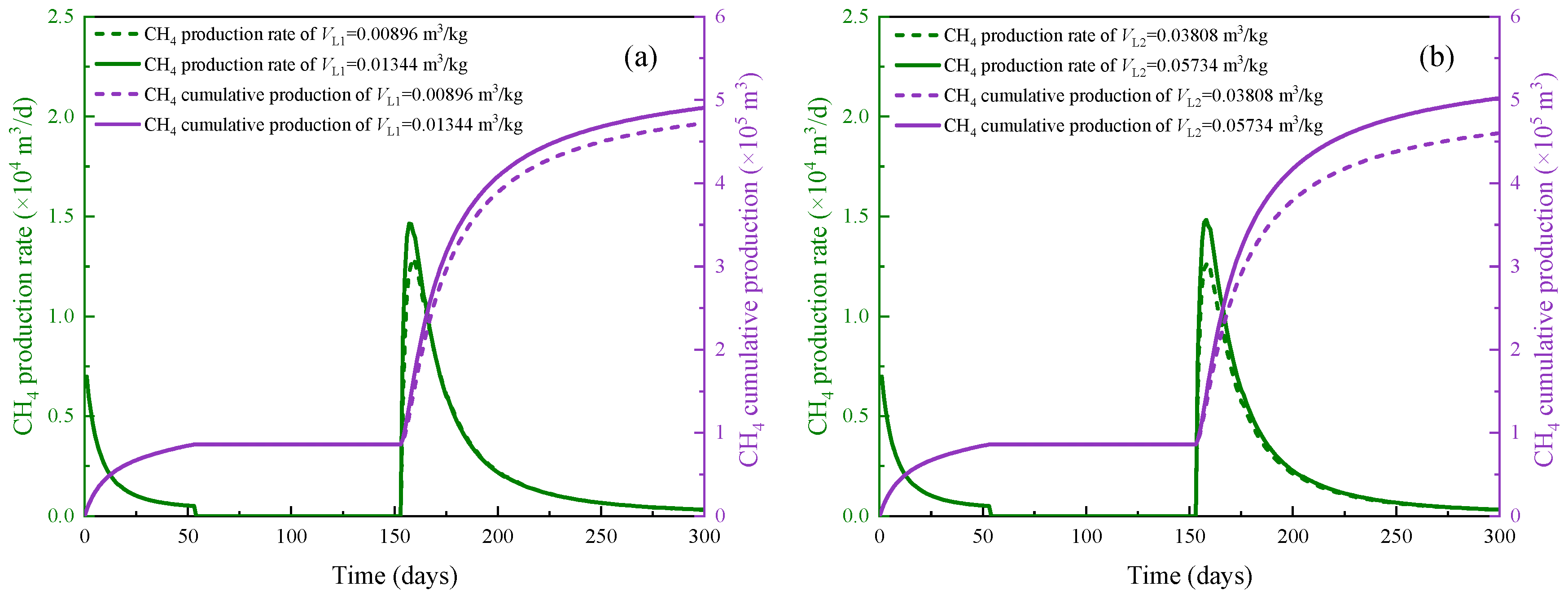

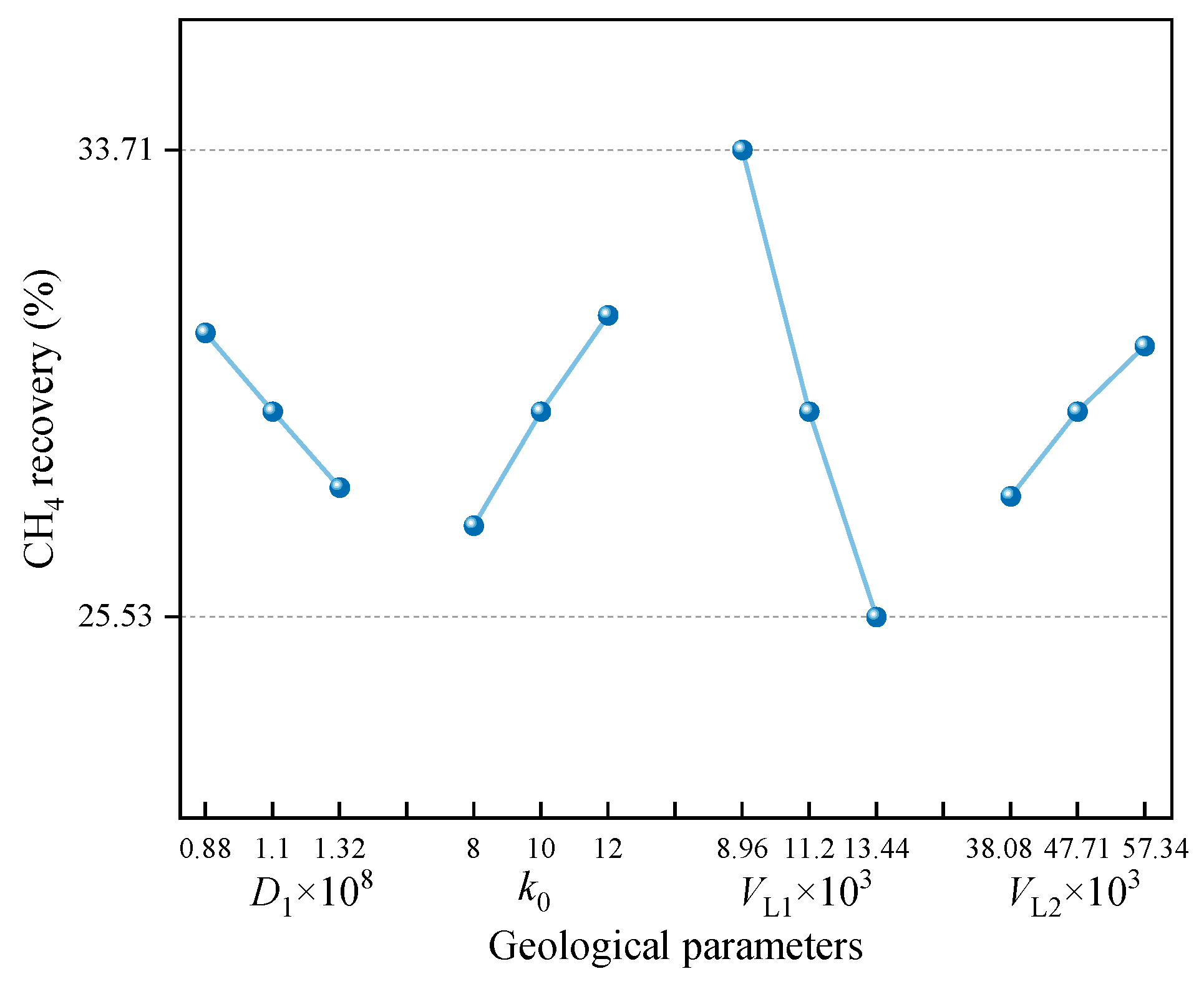

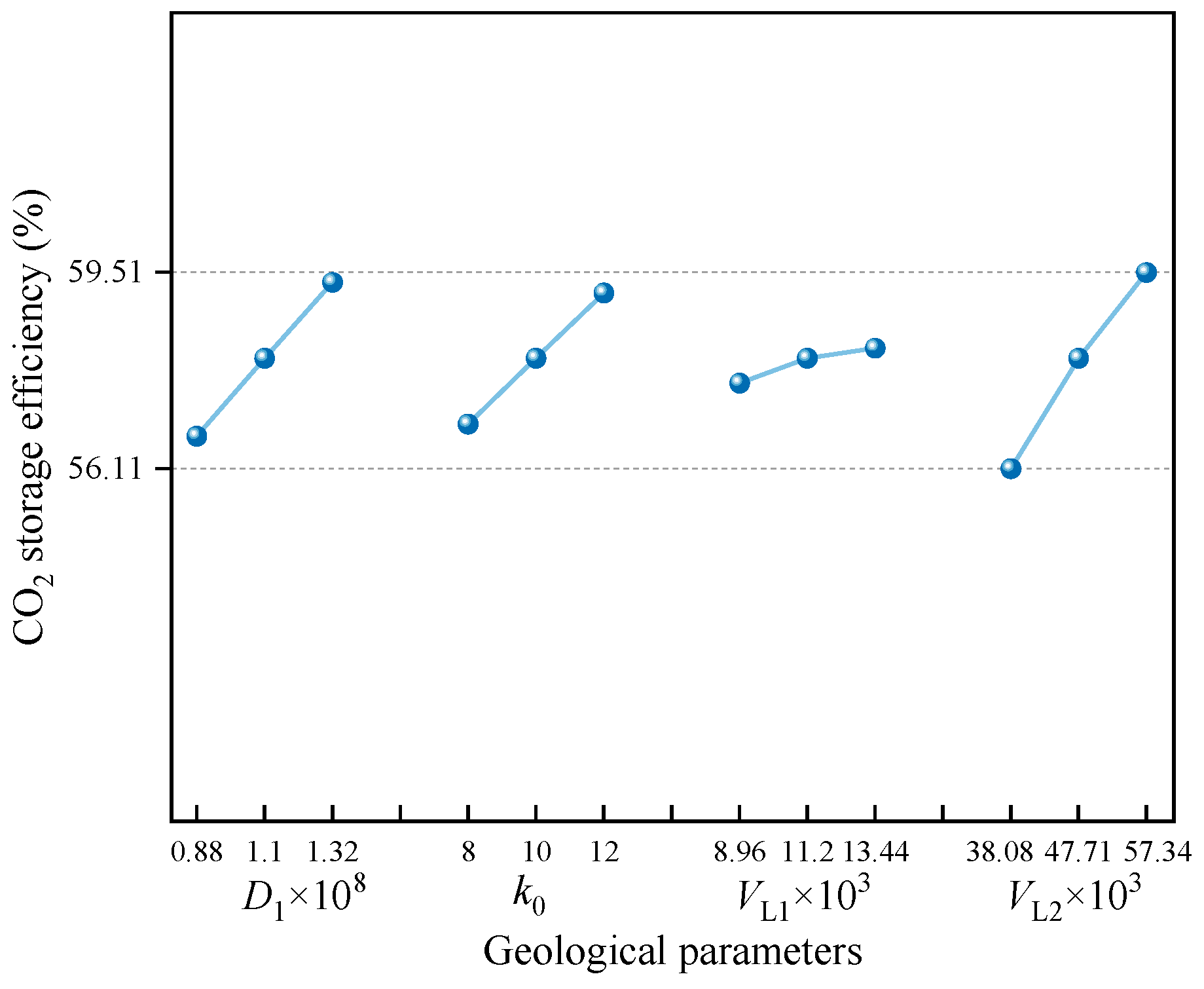

4.3. Effects of Key Geological Parameters on CO2 Huff-and-Puff Performance

4.3.1. Effects of Key Geological Parameters on CH4 Production

4.3.2. Effects of Key Geological Parameters on CO2 Storage

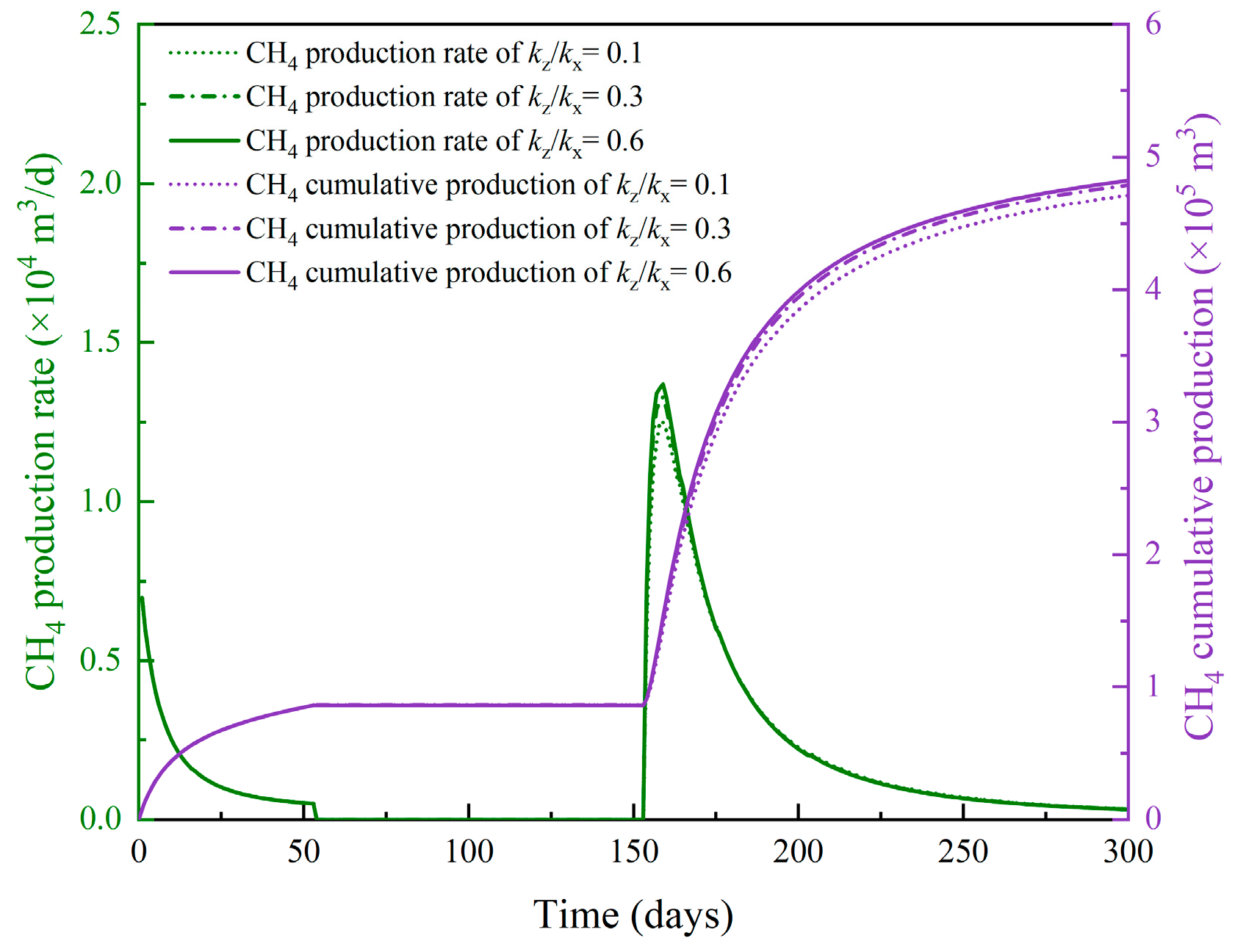

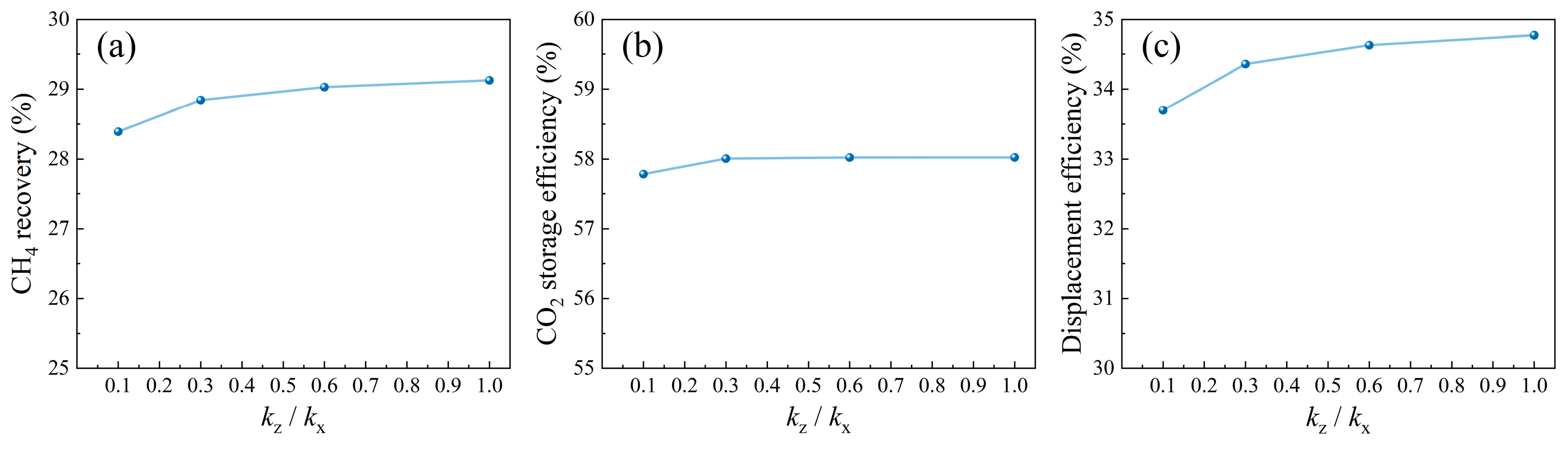

4.4. Effects of Coal Seam Anisotropy

5. Conclusions

- CO2 huff-and-puff enhances CH4 recovery through competitive adsorption, where CO2 displaces CH4 from the coal matrix, and reservoir pressure maintenance. The process involves three phases—injection, soaking, and production, wherein soaking time critically influences CH4 desorption and CO2 storage.

- Higher CO2 injection volumes (e.g., 2000–3000 t) significantly enhance CH4 production. Soaking times of 30–90 days maximize economic returns, while excessive soaking diminishes gains due to energy depletion.

- CH4 recovery is most sensitive to the CH4 Langmuir volume constant and initial fracture permeability, whereas CO2 storage efficiency is primarily controlled by the CO2 Langmuir constant. Lower diffusion coefficients enhance CH4 retention in fractures.

- This study preliminarily demonstrates the feasibility of large-scale CO2 huff-and-puff for enhancing production in low-productivity CBM wells. However, further research under field-world conditions is essential for large-scale deployment. CO2 huff-and-puff offers a sustainable solution for CBM extraction and carbon storage, aligning with China’s “dual carbon” strategy. The integration of this technology with carbon capture, utilization, and storage (CCUS) promises a sustainable pathway for energy production and emission reduction.

- In this study, the coal seam is assumed to be a homogeneous and isotropic medium. The results presented above are based on idealized homogeneous coal properties and must be calibrated against field pilot tests before practical implementation. Key uncertainties, including the neglect of thermal effects, simplified boundary conditions, coal heterogeneity, permeability anisotropy, and the long-term security of CO2 storage, will be addressed in future research.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Bai, G.; Su, J.; Zhang, Z.; Lan, A.; Zhou, X.; Gao, F.; Zhou, J. Effect of CO2 injection on CH4 desorption rate in poor permeability coal seams: An experimental study. Energy 2022, 238, 121674. [Google Scholar] [CrossRef]

- Lin, J.; Ren, T.; Wang, G.; Booth, P.; Nemcik, J. Experimental investigation of N2 injection to enhance gas drainage in CO2-rich low permeable seam. Fuel 2018, 215, 665–674. [Google Scholar] [CrossRef]

- Zhang, C.; Wang, E.; Li, B.; Kong, X.; Xu, J.; Peng, S.; Chen, Y. Laboratory experiments of CO2-enhanced coalbed methane recovery considering CO2 sequestration in a coal seam. Energy 2023, 262, 125473. [Google Scholar] [CrossRef]

- Tu, Z.; Li, L.; Wang, F.; Zhang, Y. Review on separation of coalbed methane by hydrate method. Fuel 2024, 358, 130224. [Google Scholar] [CrossRef]

- Xu, F.; Hou, W.; Xiong, X.; Xu, B.; Wu, P.; Wang, H.; Feng, K.; Yun, J.; Li, S.; Zhang, L.; et al. The status and development strategy of coalbed methane industry in China. Pet. Explor. Dev. 2023, 50, 765–783. [Google Scholar] [CrossRef]

- Heng, X.; Li, H.; Li, Q.; Fu, J.; Yao, C.; Ye, P.; Zhang, S.; Niu, Y. Investigation of an adsorption model of wet coal that considers coal seam gas pressure and temperature effects. ACS Omega 2025, 10, 5634–5644. [Google Scholar] [CrossRef]

- Tang, X.; Wang, Z.; Ripepi, N.; Kang, B.; Yue, G. Adsorption affinity of different types of coal: Mean isosteric heat of adsorption. Energy Fuels 2015, 29, 3609–3615. [Google Scholar] [CrossRef]

- Zhu, Q.; Du, X.; Zhang, T.; Yu, H.; Liu, X. Investigation into the variation characteristics and influencing factors of coalbed methane gas content in deep coal seams. Sci. Rep. 2024, 14, 18813. [Google Scholar] [CrossRef]

- Yin, G.; Deng, B.; Li, M.; Zhang, D.; Wang, W.; Li, W.; Shang, D. Impact of injection pressure on CO2–enhanced coalbed methane recovery considering mass transfer between coal fracture and matrix. Fuel 2017, 196, 288–297. [Google Scholar] [CrossRef]

- Gao, L.; Mastalerz, M.; Schimmelmann, A. The origin of coalbed methane. In Coal Bed Methane; Elsevier: Amsterdam, The Netherlands, 2020; pp. 3–34. [Google Scholar]

- Li, D.; Gao, X.; Liu, Z.; Zan, X.; Zheng, Z.; Jia, J.; Wu, J. Comparison and revelation of coalbed methane resources distribution characteristics and development status between China and America. Coal Sci. Technol. 2018, 46, 252–261. [Google Scholar]

- Ma, T.; Liu, J.; Fu, J.; Wu, B. Drilling and completion technologies of coalbed methane exploitation: An overview. Int. J. Coal Sci. Technol. 2022, 9, 68. [Google Scholar] [CrossRef]

- Palmer, I. Coalbed methane completions: A world view. Int. J. Coal Geol. 2010, 82, 184–195. [Google Scholar] [CrossRef]

- Salmachi, A.; Rajabi, M.; Wainman, C.; Mackie, S.; McCabe, P.; Camac, B.; Clarkson, C. History, Geology, In Situ Stress Pattern, Gas Content and Permeability of Coal Seam Gas Basins in Australia: A Review. Energies 2021, 14, 2651. [Google Scholar] [CrossRef]

- Xu, F.; Wang, B.; Zhao, X.; Yun, J.; Zhang, S.; Wang, H.; Yang, Y. Thoughts and suggestions on promoting high quality development of China’s CBM business under the goal of “double carbon”. China Pet. Explor. 2021, 26, 9–18. [Google Scholar]

- Sang, S.; Liu, S.; Han, S.; Zheng, S.; Liu, T.; Zhou, X.; Wang, R.; Wang, M. Coal methane control and its emission reduction potential in China. Coal Geol. Explor. 2023, 51, 159–175. [Google Scholar]

- YI, Y. Research on the Production Characteristics and Drainage Control of CBM Wells in the Shizhuangnan Block of Qinshui Basin. Master’s Thesis, China University of Geosciences, Beijing, China, 2020. [Google Scholar]

- Feng, Y. Analysis on the Low-yield Genesis of Coalbed Methane Stripper Wells and Key Stimulation Technologies. Master’s Thesis, Henan Polytechnic University, Jiaozuo, China, 2021. [Google Scholar]

- Wang, T. Key Factors of Low Production of Coalbed Methane Vertical Well in Fanzhuang Block and Its Secondary Fracturing Reconstruction. Master’s Thesis, China University of Mining and Technology, Beijing, China, 2020. [Google Scholar]

- Dong, K. Study on Geological Conditions Affected to Production of Coalbed Methane Well of Broken Soft Coal Reservoir. Ph.D. Thesis, China Coal Research Institute, Beijing, China, 2019. [Google Scholar]

- Zhao, L. Research on the genesis Mechanism and Development Technology of Low Temperature and Low Pressure Coalbed Methane Reservoirs in Yangquan Mining Area. Ph.D. Thesis, Henan Polytechnic University, Jiaozuo, China, 2023. [Google Scholar]

- Wang, D. The Research of Affective Facts of Production and Enrichment of CBM in Linfen Block. Ph.D. Thesis, China University of Geosciences, Beijing, China, 2015. [Google Scholar]

- Wang, W. Analysis on effect of gas production and influence factors of CBM separate layer pressure control and multi-layer drainage in tectonic coal mining area. Coal Sci. Technol. 2019, 47, 120–124. [Google Scholar]

- Zhang, Z. Controlling Factors of Productivity Difference of Coalbed Methane Wells in Eastern Yunnan and Western Guizhou. Ph.D. Thesis, China University of Mining and Technology, Beijing, China, 2022. [Google Scholar]

- Sun, H. Development status and prospect of CBM fracturing technology in China. China Offshore Oil Gas 2021, 33, 120–128. [Google Scholar]

- Huang, Z.; Li, Z.; Li, G.; Yang, R.; Mei, Y.; Niu, J.; Li, Z.; Wu, C.; Wen, H.; Cong, R. Oriented and sand control hydra-jet fracturing in coalbed methane horizontal wells and field applications. J. China Coal Soc. 2022, 47, 2687–2697. [Google Scholar]

- Zhang, W.; Si, L.; Guo, Q.; Tian, K.; Zhang, R. Study on mechanism and application of liquid nitrogen injection combined with fracturing to enhance permeability in CBM wells. Coal Sci. Technol. 2019, 47, 97–102. [Google Scholar]

- Qin, L.; Li, S.; Zhai, C.; Lin, H.; Zhao, P.; Shi, Y.; Bai, Y. Changes in the pore structure of lignite after repeated cycles of liquid nitrogen freezing as determined by nitrogen adsorption and mercury intrusion. Fuel 2020, 267, 117214. [Google Scholar] [CrossRef]

- Cao, Y.; Shi, B.; Zhou, D.; Wu, H.; Liu, T.; Tian, L.; Cao, Y.; Jia, M. Study and application of stimulation technology for low production CBM well through high pressure N2 Injection-soak. J. China Coal Soc. 2019, 44, 2556–2565. [Google Scholar]

- Lin, X.; Liu, Z.; Zhu, W.; Si, L.; Qu, B.; Liu, S.; Zhang, Y. Mechanism of matrix–fracture equilibrium time lag property inducing coal sub-matrix mass transfer behavior and its effect on the coal seepage characteristics in CO2 sequestration. Phys. Fluids 2025, 37, 016601. [Google Scholar] [CrossRef]

- Wang, Z.; Fu, X.; Pan, J.; Deng, Z. Effect of N2/CO2 injection and alternate injection on volume swelling/shrinkage strain of coal. Energy 2023, 275, 127377. [Google Scholar] [CrossRef]

- Zhou, F.; Hussain, F.; Cinar, Y. Injecting pure N2 and CO2 to coal for enhanced coalbed methane: Experimental observations and numerical simulation. Int. J. Coal Geol. 2013, 116–117, 53–62. [Google Scholar] [CrossRef]

- Fang, Z.; Yang, C.; Wang, R. Monitoring technologies for CO2 storage in coal seams and enhanced coalbed methane recovery: A review of field applications. Fuel Process. Technol. 2025, 276, 108274. [Google Scholar] [CrossRef]

- Shen, S.C.; Fang, Z.M.; Li, X.C.; Jiang, Q.; Shen, H.M.; Shi, L. Enhanced coalbed methane recovery from lignite using CO2 and N2. Energy Fuels 2025, 39, 10394–10409. [Google Scholar] [CrossRef]

- Lin, K.; Jing, T.; Wei, N.; Chen, Q.; Zhao, W.; Zhou, J.; Ali, M.; Wang, W.; Li, X. A Comprehensive Analysis of the Mutual Feedback Mechanisms between CO2 Geological Storage and Underground Coal Mining in the Ordos Basin. Energy Fuels 2025, 39, 5802–5817. [Google Scholar] [CrossRef]

- Fang, H.; Sang, S.; Wang, Z.; Guo, J.; Liu, H.; Xu, H.; Chen, R. Numerical analysis of temperature effect on CO2 storage capacity and CH4 production capacity during the CO2-ECBM process. Energy 2024, 289, 130022. [Google Scholar] [CrossRef]

- Zhang, S.; Sang, S.; Wu, J.; Zhou, X.; Zhang, B.; Yang, R.; Guo, J.; Liu, X.; Zhang, W.; Li, Y. Progress and application of key technologies for CO2 enhancing coalbed methane. J. China Coal Soc. 2022, 47, 3952–3964. [Google Scholar]

- Lin, K.; Wei, N.; Jiang, D.; Zhang, Y. Progress and perspectives in source-sink matching for CCUS: A critical review. Renew. Sustain. Energy Rev. 2026, 226, 116313. [Google Scholar] [CrossRef]

- Li, Z.; Ni, G.; Wen, Y.; Jiang, H.; Liu, Y.; Huang, Q.; Huang, W. Analysis of permeability evolution mechanism during CO2 enhanced coalbed methane recovery based on impact factor method. Fuel 2021, 304, 121389. [Google Scholar] [CrossRef]

- Wang, L.; Hu, L.; Guo, H.; Wang, Z.; Xiao, Y.; Zhang, Z. Differences in CH4 Displacement Efficiency by CO2/N2 Injection in Anthracite under Isobaric and High Pressures: Molecular Dynamics Insights. Energy Fuels 2025, 39, 1959–1970. [Google Scholar] [CrossRef]

- Ye, D.; Liu, G.; Gao, F.; Wang, X.; Wei, M.; Liu, Z.; Li, D. A novel interdisciplinary model for optimizing coalbed methane recovery and carbon dioxide sequestration: Fracture dynamics, gas mechanics, and its application. Phys. Fluids 2024, 36, 076607. [Google Scholar] [CrossRef]

- Matkivskyi, S. Optimization of gas recycling technique in development of gas-condensate fields. Min. Miner. Deposits 2023, 17, 101–107. [Google Scholar] [CrossRef]

- Wong, S.; Law, D.; Deng, X.H.; Robinson, J.; Kadatz, B.; Gunter, W.D.; Ye, J.P.; Feng, S.L.; Fan, Z.Q. Enhanced coalbed methane and CO2 storage in anthracitic coals-Micro-pilot test at South Qinshui, Shanxi, China. Int. J. Greenh. Gas Control 2007, 1, 215–222. [Google Scholar] [CrossRef]

- Liu, S.; Huang, F.; Du, R.; Chen, S.; Guan, Y.; Liu, Y.; Wang, T. Progress and typical case analysis of demonstration projects of the geological sequestration and utilization of CO2. Coal Geol. Explor. 2023, 51, 158–174. [Google Scholar] [CrossRef]

- Lee, J.H.; Cho, J.; Lee, K.S. Effects of aqueous solubility and geochemistry on CO2 injection for shale gas reservoirs. Sci. Rep. 2020, 10, 2071. [Google Scholar] [CrossRef] [PubMed]

- Fathi, E.; Akkutlu, I.Y. Multi-component gas transport and adsorption effects during CO2 injection and enhanced shale gas recovery. Int. J. Coal Geol. 2014, 123, 52–61. [Google Scholar] [CrossRef]

- Eshkalak, M.O.; Al-Shalabi, E.W.; Sanaei, A.; Aybar, U.; Sepehrnoori, K. Simulation study on the CO2-driven enhanced gas recovery with sequestration versus the re-fracturing treatment of horizontal wells in the U.S. nconventional shale reservoirs. J. Nat. Gas Sci. Eng. 2014, 21, 1015–1024. [Google Scholar] [CrossRef]

- Kim, T.H.; Cho, J.; Lee, K.S. Evaluation of CO2 injection in shale gas reservoirs with multi-component transport and geomechanical effects. Appl. Energy 2017, 190, 1195–1206. [Google Scholar] [CrossRef]

- Su, E.; Zhu, X.; Chen, X.; Su, W.; Wang, L.; Ye, X.; Wang, T. Gas transport behavior of tectonic and intact coal reservoirs during CO2-enhanced coalbed methane recovery. Phys. Fluids 2025, 37, 076652. [Google Scholar] [CrossRef]

- Fang, H.; Ye, K.; Yu, S.; Wang, Y.; Wang, Z. Determining the Starting Time of CO2 Injection and Its Implications for the CO2-ECBM Process. ACS Omega 2024, 10, 1591–1609. [Google Scholar] [CrossRef] [PubMed]

- Ma, T.; Rutqvist, J.; Oldenburg, C.M.; Liu, W. Coupled thermal–hydrological–mechanical modeling of CO2-enhanced coalbed methane recovery. Int. J. Coal Geol. 2017, 179, 81–91. [Google Scholar] [CrossRef]

- Liu, X.; Sang, S.; Zhou, X.; Wang, Z. Coupled adsorption-hydro-thermo-mechanical-chemical modeling for CO2 sequestration and well production during CO2-ECBM. Energy 2023, 262, 125306. [Google Scholar] [CrossRef]

- Fan, C.; Elsworth, D.; Li, S.; Chen, Z.; Luo, M.; Song, Y.; Zhang, H. Modelling and optimization of enhanced coalbed methane recovery using CO2/N2 mixtures. Fuel 2019, 253, 1114–1129. [Google Scholar] [CrossRef]

- Yang, L.; Fan, C.-J.; Luo, M.-K.; Wen, H.-O.; Sun, H.; Zhou, L.-J.; Cheng, Z.-H.; Zhang, Z.-P. Geological parameters and gas mixture composition on enhanced coalbed methane recovery: A THM modeling approach. Pet. Sci. 2025, 22, 2078–2095. [Google Scholar] [CrossRef]

- Hou, Y.; Huang, S.; Han, J.; Liu, X.; Han, L.; Fu, C. Numerical Simulation of the Effect of Injected CO2 Temperature and Pressure on CO2-Enhanced Coalbed Methane. Appl. Sci. 2020, 10, 1385. [Google Scholar] [CrossRef]

- Fan, N.; Wang, J.; Deng, C.; Fan, Y.; Mu, Y.; Wang, T. Numerical study on enhancing coalbed methane recovery by injecting N2/CO2 mixtures and its geological significance. Energy Sci. Eng. 2019, 8, 1104–1119. [Google Scholar] [CrossRef]

- Fan, Y.P.; Deng, C.B.; Zhang, X.; Li, F.Q.; Wang, X.Y.; Qiao, L. Numerical study of CO2-enhanced coalbed methane recovery. Int. J. Greenh. Gas Control 2018, 76, 12–23. [Google Scholar] [CrossRef]

- Fang, H.-H.; Sang, S.-X.; Liu, S.-Q. Numerical simulation of enhancing coalbed methane recovery by injecting CO2 with heat injection. Pet. Sci. 2019, 16, 32–43. [Google Scholar] [CrossRef]

- Liu, S.; Fang, H.; Sang, S.; Ashutosh, T.; Wu, J.; Zhang, S.; Zhang, B. CO2 injectability and CH4 recovery of the engineering test in qinshui Basin, China based on numerical simulation. Int. J. Greenh. Gas Control 2020, 95, 102980. [Google Scholar] [CrossRef]

- Wei, X.R.; Wang, G.X.; Massarotto, P.; Golding, S.D.; Rudolph, V. Numerical simulation of multicomponent gas diffusion and flow in coals for CO2 enhanced coalbed methane recovery. Chem. Eng. Sci. 2007, 62, 4193–4203. [Google Scholar] [CrossRef]

- Lin, J.; Ren, T.; Wang, G.; Nemcik, J. Simulation investigation of N2-injection enhanced gas drainage: Model development and identification of critical parameters. J. Nat. Gas Sci. Eng. 2018, 55, 30–41. [Google Scholar] [CrossRef]

- Kumar, H.; Elsworth, D.; Mathews, J.P.; Liu, J.; Pone, D. Effect of CO2 injection on heterogeneously permeable coalbed reservoirs. Fuel 2014, 135, 509–521. [Google Scholar] [CrossRef]

- Mu, Y.; Fan, Y.; Wang, J.; Fan, N. Numerical study on injection of flue gas as a heat carrier into coal reservoir to enhance CBM recovery. J. Nat. Gas Sci. Eng. 2019, 72, 103017. [Google Scholar] [CrossRef]

- Fang, H.; Sang, S.; Liu, S. The coupling mechanism of the thermal-hydraulic-mechanical fields in CH4-bearing coal and its application in the CO2-enhanced coalbed methane recovery. J. Pet. Sci. Eng. 2019, 181, 106177. [Google Scholar] [CrossRef]

- Liu, T.; Lin, B.; Yang, W.; Zhai, C.; Liu, T. Coal permeability evolution and gas migration under non-equilibrium state. Transp. Porous Media 2017, 118, 393–416. [Google Scholar] [CrossRef]

- Shen, S. Study on Gas Displacement of Coalbed Methane in Low-Rank Coal Seams in Jiergalangtu Area, Inner Mongolia. Ph.D. Thesis, Institute of Rock and Soil Mechanics, Chinese Academy of Sciences, Beijing, China, 2024. [Google Scholar]

- Huo, B.; Jing, X.; Fan, C.; Han, Y. Numerical investigation of flue gas injection enhanced underground coal seam gas drainage. Energy Sci. Eng. 2019, 7, 3204–3219. [Google Scholar] [CrossRef]

- Zhou, L.; Zhou, X.; Fan, C.; Bai, G.; Yang, L.; Wang, Y. Modelling of flue gas injection promoted coal seam gas extraction incorporating heat-fluid-solid interactions. Energy 2023, 268, 126664. [Google Scholar] [CrossRef]

- Zhou, L.; Zhou, X.; Fan, C.; Bai, G. Coal permeability evolution triggered by variable injection parameters during gas mixture enhanced methane recovery. Energy 2022, 252, 124065. [Google Scholar] [CrossRef]

- Palmer, I.; Mansoori, J. How permeability depends on stress and pore pressure in coalbeds: A new model. SPE Reserv. Eval. Eng. 1998, 1, 539–544. [Google Scholar] [CrossRef]

- Wu, Y.; Liu, J.; Elsworth, D.; Miao, X.; Mao, X. Development of anisotropic permeability during coalbed methane production. J. Nat. Gas Sci. Eng. 2010, 2, 197–210. [Google Scholar] [CrossRef]

- Cui, X.; Bustin, R.M. Volumetric strain associated with methane desorption and its impact on coalbed gas production from deep coal seams. AAPG Bull. 2005, 89, 1181–1202. [Google Scholar] [CrossRef]

- Fang, Z.; Shen, S. Optimizing enhanced coalbed methane recovery in thick lignite formations: An integrated technical and economic evaluation. Results Eng. 2025, 27, 106733. [Google Scholar] [CrossRef]

- Fan, C.; Elsworth, D.; Li, S.; Zhou, L.; Yang, Z.; Song, Y. Thermo-hydro-mechanical-chemical couplings controlling CH4 production and CO2 sequestration in enhanced coalbed methane recovery. Energy 2019, 173, 1054–1077. [Google Scholar] [CrossRef]

- Ye, J.; Hou, S.; Zhang, S. Progress of coalbed methane exploration and development in China during the 13th Five-Year Plan period and the next exploration direction. Coal Geol. Explor. 2022, 50, 15–22. [Google Scholar]

- Gao, Y.; Zhang, C.; Zhao, L.; Jia, H.; Qin, M.; Zhang, W.; Ji, Y.; Yuan, S. Application of drainage technology for L-shaped coalbed methane horizontal well in Southern Qinshui Basin. Coal Sci. Technol. 2025, 53, 304–314. [Google Scholar] [CrossRef]

- Li, S.; Fan, C.; Han, J.; Luo, M.; Yang, Z.; Bi, H. A fully coupled thermal-hydraulic-mechanical model with two-phase flow for coalbed methane extraction. J. Nat. Gas Sci. Eng. 2016, 33, 324–336. [Google Scholar] [CrossRef]

- Wu, Y.; Liu, J.; Chen, Z.; Elsworth, D.; Pone, D. A dual poroelastic model for CO2-enhanced coalbed methane recovery. Int. J. Coal Geol. 2011, 86, 177–189. [Google Scholar] [CrossRef]

- Fang, Z.; Li, X.; Li, H.; Chen, H. Feasibility study of gas mixture enhanced coalbed methane recovery technology. Rock Soil Mech. 2010, 31, 3223–3229. [Google Scholar]

- Hou, X. Study on Gas Controlling Mechanism and Coupled Accumulation of Deep Coal Measure Gases in Qinshui Basin. Ph.D. Thesis, China University of Mining and Technology, Beijing, China, 2020. [Google Scholar]

- Hu, B. Methane Adsorption Behavior Characteristics of Multi-scale Pore Structure in Coal and Its Microscopic Influencing Mechanism. Ph.D. Thesis, China University of Mining and Technology, Beijing, China, 2022. [Google Scholar]

- Gao, Y. Study on Nitrogen Injection and Production Increasing Technology in Coalbed Methane Wells. Master’s Thesis, China University of Petroleum, Beijing, China, 2018. [Google Scholar]

| Region | Period | Number of Wells | Production Status | |

|---|---|---|---|---|

| Qinshui Basin | Shizhuangnan Block [17] | by the end of 2019 | 950+ | 278 (29.3%) non-producing wells, 536 (56.4%) have an average production below 500 m3/d, only 38 wells (4%) maintain an average production exceeding 1000 m3/d |

| Xishan Block [18] | 2011–2021 | 700+ | with an overall average production <300 m3/d, nearly 90% of wells (89.31%) produce below 500 m3/d | |

| Fanzhuang Block [19] | 2006–2020 | 1426 vertical wells | 463 wells (32%) demonstrate average production rates below 500 m3/d | |

| Zhaozhuang Block [20] | 2006–2018 | 283 | 42.8% of wells (121) remain productive, maintaining an average output of 124 m3/d | |

| Yangquan Block [21] | - | 85 | 22 wells (25.9%) are non-productive, with an additional 40 wells (47.1%) producing at average rates less than 200 m3/d | |

| Ordos Basin | Liulin County | by the end of 2019 | 570 | 46.7% of wells (266) maintain production at an average rate of 1052 m3/d, whereas the unfractured wells (304, 53.3%) remain non-productive |

| Linfen Block [22] | 2013–2015 | 164 | 79.3% of active wells exhibited sustained production rates below 500 m3/d | |

| Henan | Pingdingshan Block [23] | 2011–2013 | 5 | overall average production rate of 157.6 m3/d, with a maximum peak production reaching 586 m3/d |

| Yunnan | Enhong Block [24] | 2005–2018 | 4 | overall average production rate of 302 m3/d, with a maximum peak production reaching 750.31 m3/d |

| Laochang Block [24] | 2011–2018 | 11 | overall average production rate of 682 m3/d, with a maximum peak production reaching 1864 m3/d | |

| Parameters | Value | Refs |

|---|---|---|

| Initial porosity of matrix (φm0) | 0.05 | [77] |

| Initial porosity of fracture (φf0) | 0.02 | [77] |

| Initial fracture permeability (k0, mD) | 10 | [78] |

| Coal density (ρc, kg/m3) | 1400 | [79] |

| Temperature (T, K) | 298.15 | [66] |

| Fracture compressibility (cf, 1/kPa) | 2.4 × 10−4 | [66] |

| Poisson’s ratio (υ) | 0.35 | [74] |

| CH4 Langmuir pressure constant (pL1, MPa) | 3.5 | [80] |

| CH4 Langmuir volume constant (VL1, m3/kg) | 0.0112 | [80] |

| CO2 Langmuir pressure constant (pL2, MPa) | 1.38 | [74] |

| CO2 Langmuir volume constant (VL2, m3/kg) | 0.04771 | [74] |

| CH4 Langmuir strain constant (εL1) | 0.0128 | [74] |

| CO2 Langmuir strain constant (εL2) | 0.0237 | [74] |

| CH4 Diffusion coefficient (D1, cm2/s) | 1.1 × 10−8 | [81] |

| CO2 Diffusion coefficient (D2, cm2/s) | 1.4 × 10−8 | [81] |

| Injection Volume (t) | Soaking Time (d) |

|---|---|

| 1000 | 5, 30, 60, 90, 120 |

| 1500 | |

| 2000 | |

| 2500 | |

| 3000 |

| Key Geological Parameters | Value Setting |

|---|---|

| CH4 Diffusion coefficient (D1 × 108, cm2/s) | 0.88, 1.1, 1.32 |

| Initial fracture permeability (k0, mD) | 8, 10, 12 |

| CH4 Langmuir volume constant (VL1 × 103, m3/kg) | 8.96, 11.2, 13.44 |

| CO2 Langmuir volume constant (VL2 × 103, m3/kg) | 38.08, 47.71, 57.34 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, C.; Fang, Z.; Shen, S.; Wang, H. Enhancing Recovery of Low-Productivity Coalbed Methane Wells in Medium-Shallow Reservoirs by CO2 Huff-and-Puff. Separations 2025, 12, 314. https://doi.org/10.3390/separations12110314

Yang C, Fang Z, Shen S, Wang H. Enhancing Recovery of Low-Productivity Coalbed Methane Wells in Medium-Shallow Reservoirs by CO2 Huff-and-Puff. Separations. 2025; 12(11):314. https://doi.org/10.3390/separations12110314

Chicago/Turabian StyleYang, Chenlong, Zhiming Fang, Shaicheng Shen, and Haibin Wang. 2025. "Enhancing Recovery of Low-Productivity Coalbed Methane Wells in Medium-Shallow Reservoirs by CO2 Huff-and-Puff" Separations 12, no. 11: 314. https://doi.org/10.3390/separations12110314

APA StyleYang, C., Fang, Z., Shen, S., & Wang, H. (2025). Enhancing Recovery of Low-Productivity Coalbed Methane Wells in Medium-Shallow Reservoirs by CO2 Huff-and-Puff. Separations, 12(11), 314. https://doi.org/10.3390/separations12110314