Development of a Voltammetric Methodology Based on a Methacrylic Molecularly Imprinted Polymer-Modified Carbon-Paste Electrode for the Determination of Aflatoxin B1

Abstract

1. Introduction

2. Materials and Methods

2.1. Reagents

2.2. Instrumentation

2.3. Synthesis of the MAA-MIP

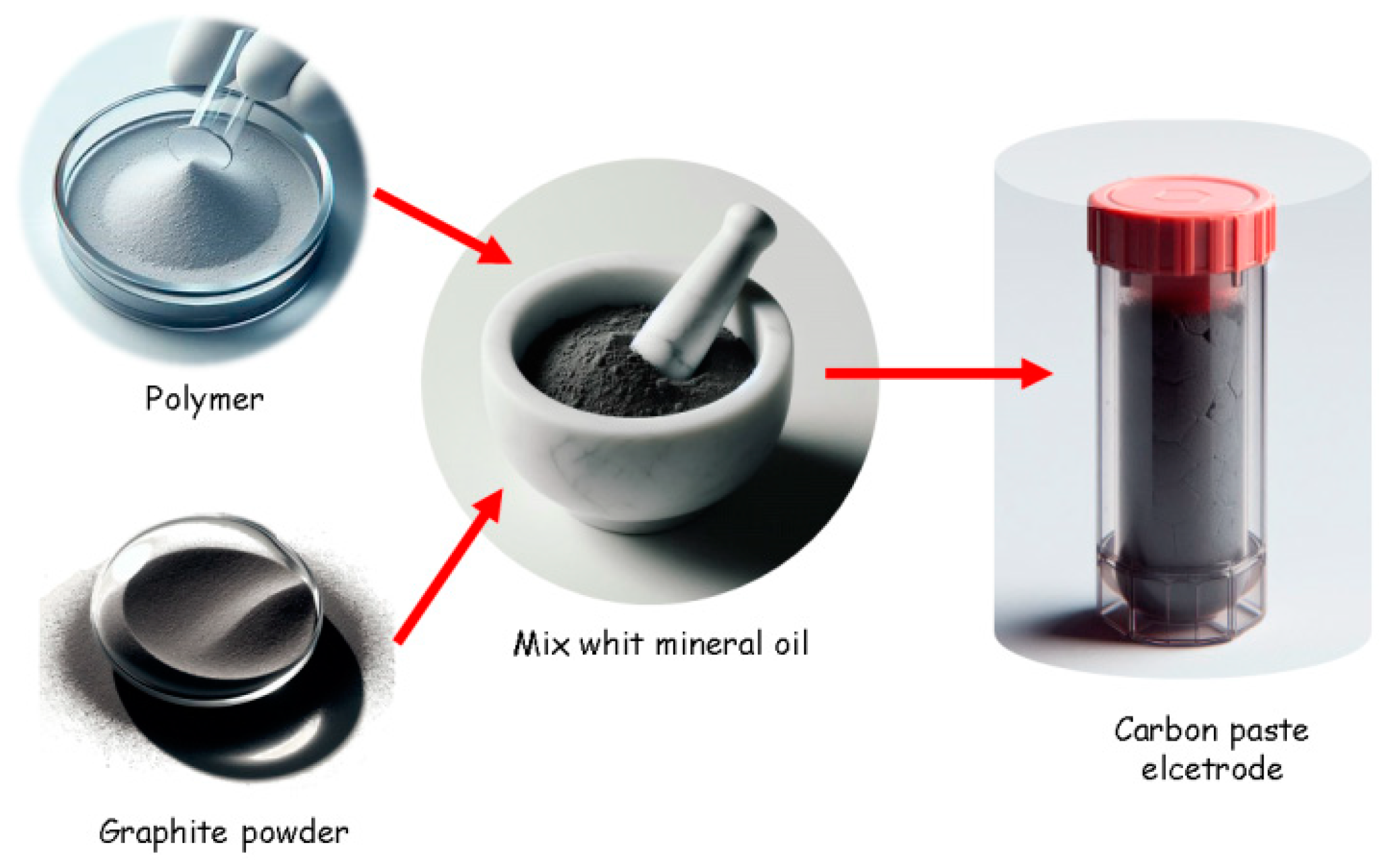

2.4. Construction of the Modified Carbon-Paste Electrodes

2.5. Electrochemical Measurements

3. Results and Discussion

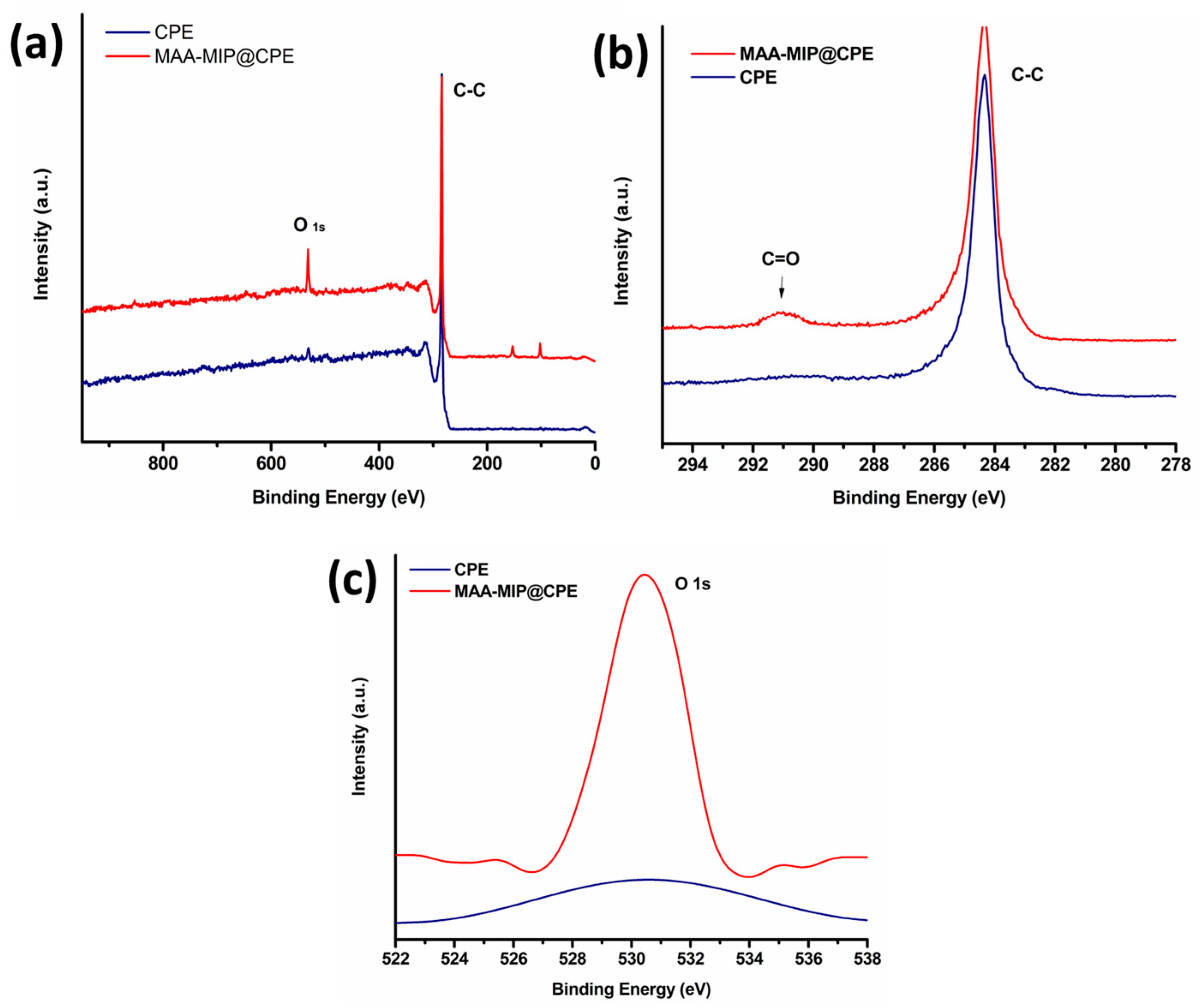

3.1. Characterization of the MIP and the Modified Electrode

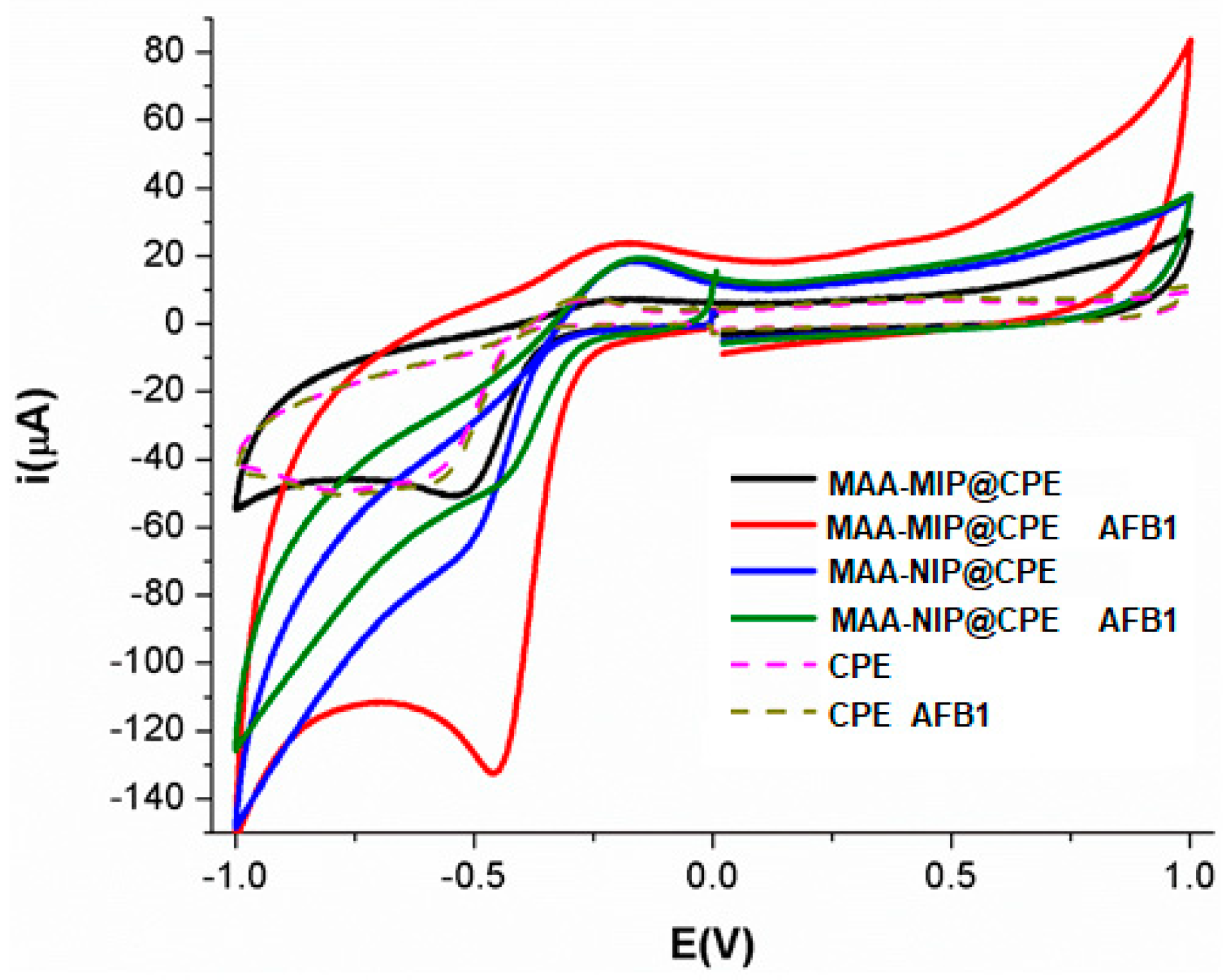

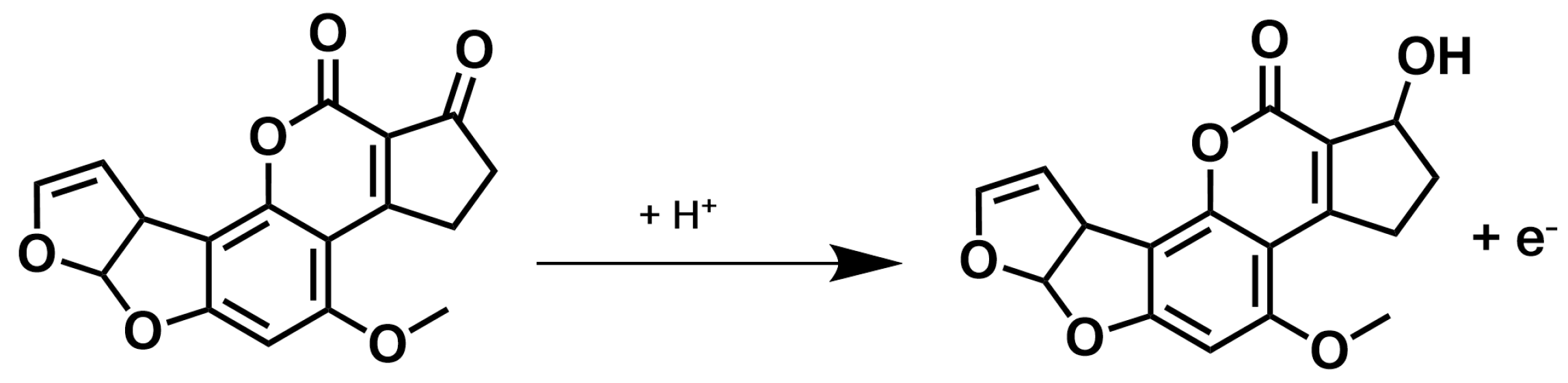

3.2. Electrochemical Behavior in the Absence and Presence of AFB1

3.3. Effect of pH on the Electrochemical Response

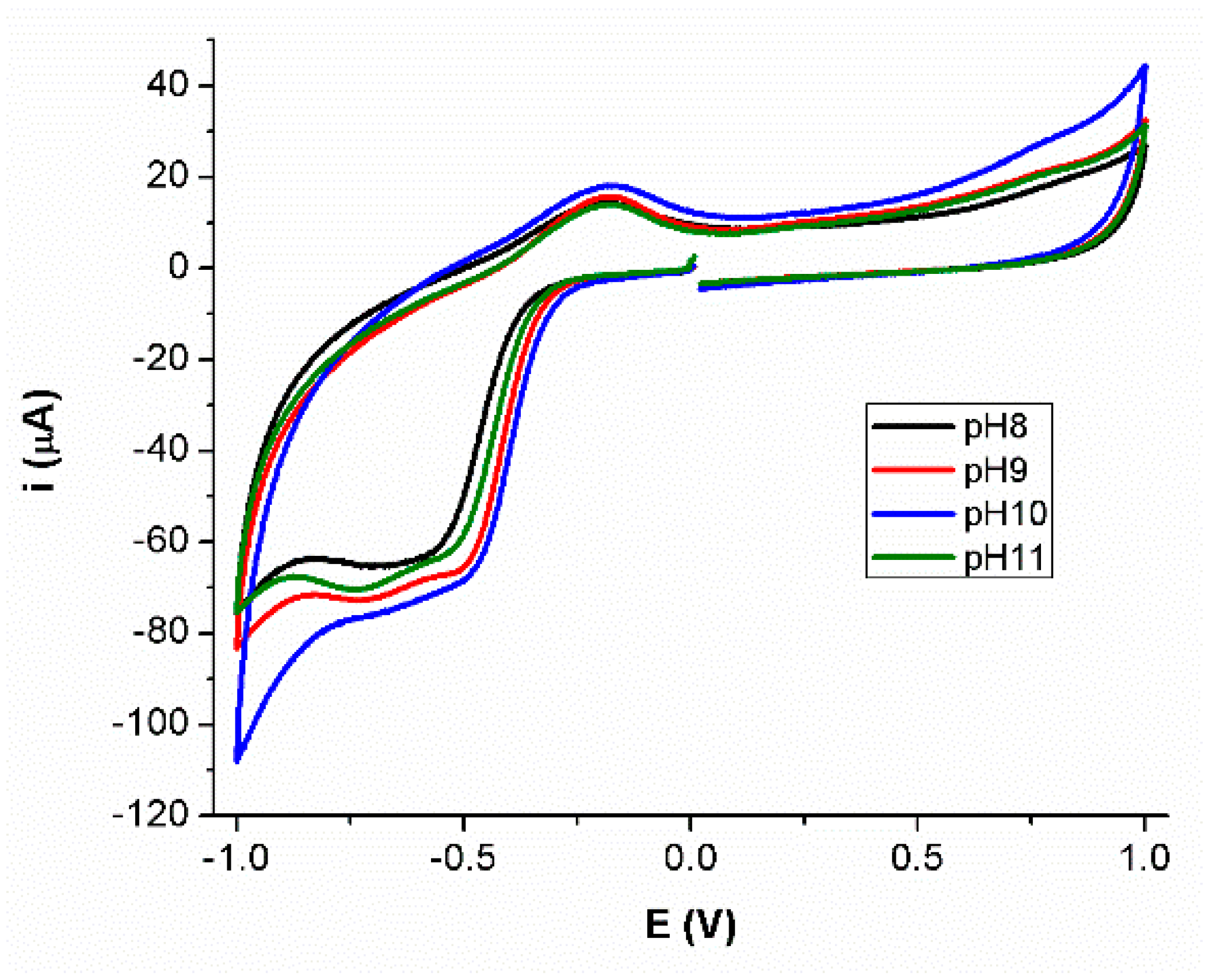

3.4. Effect of Stirring Rate and Time in the Pre-Concentration Stage

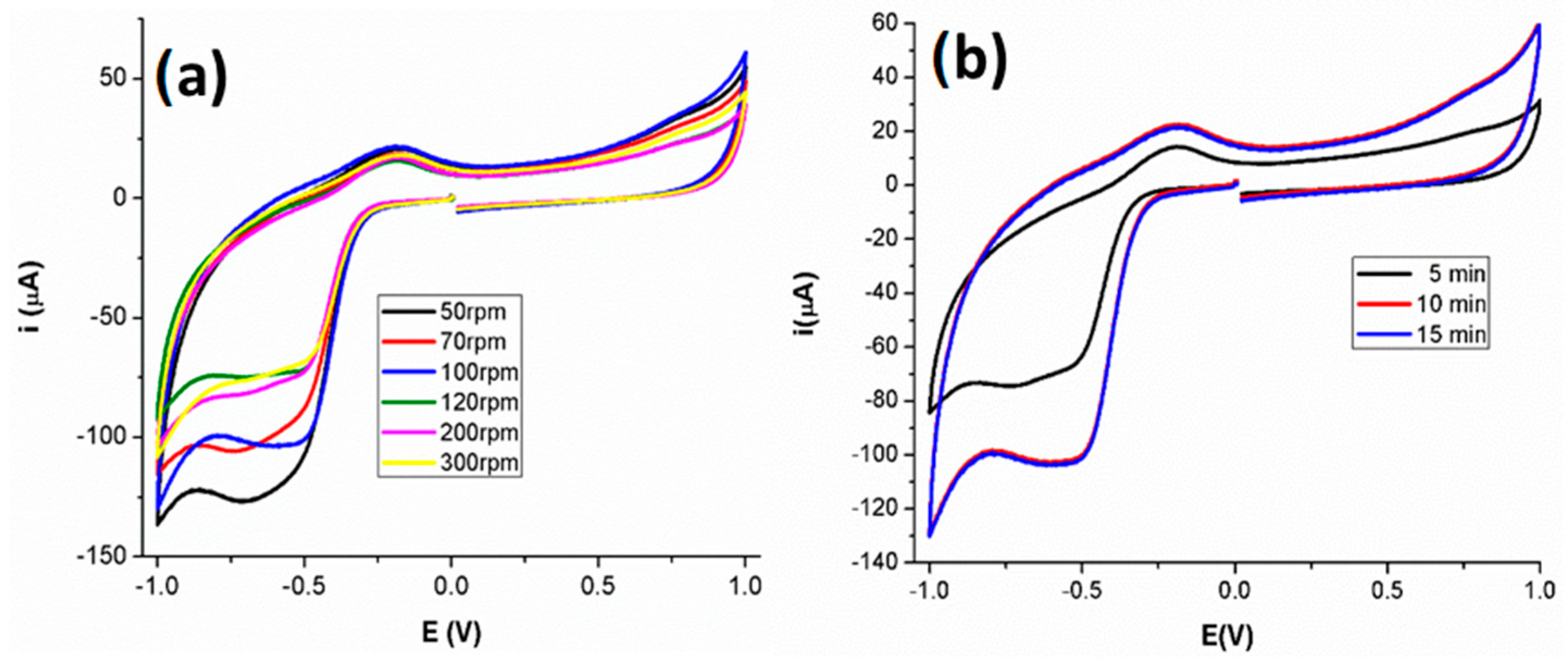

3.5. Optimization of the MIP Ratio in the Composite Mixture

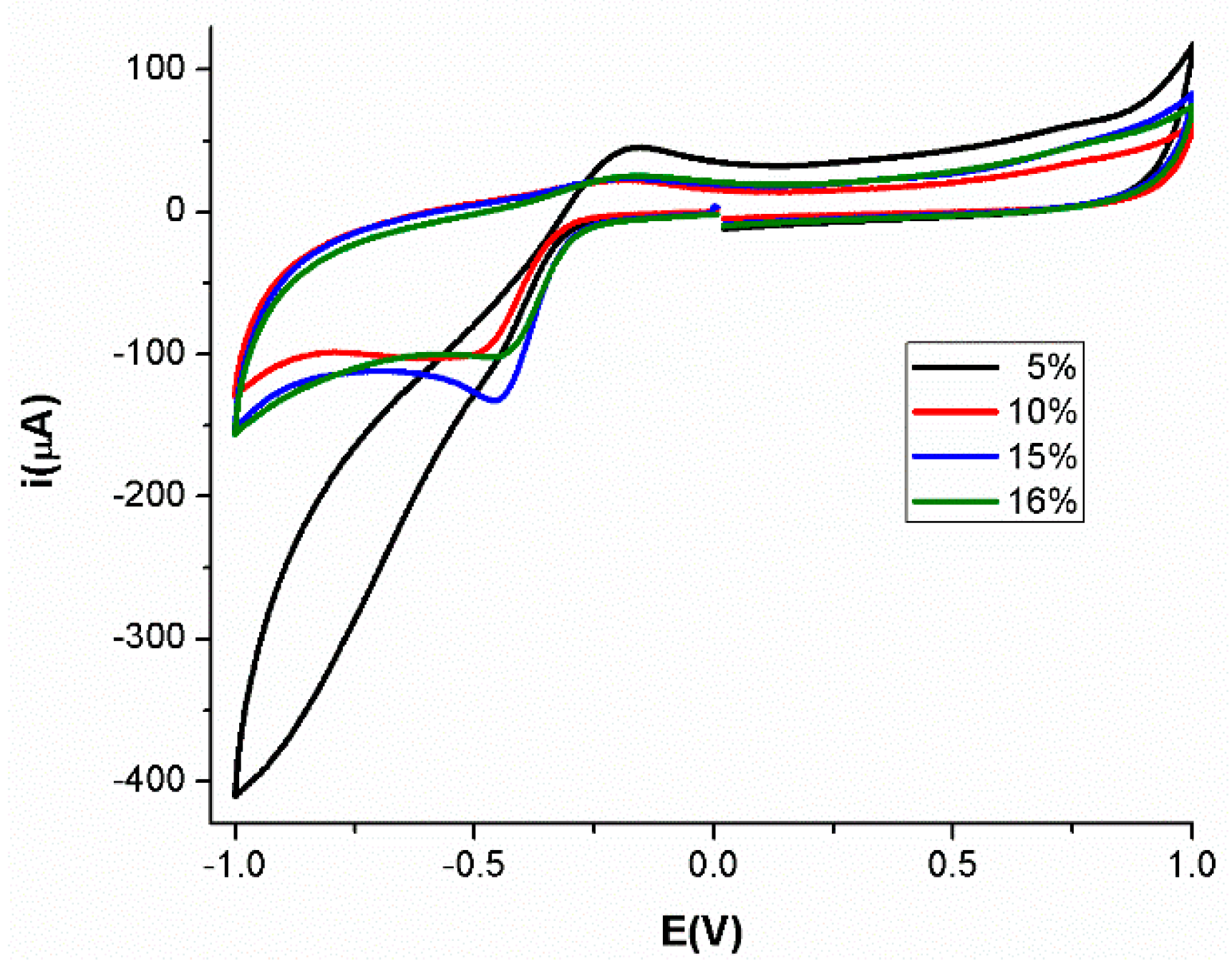

3.6. Electroactive Surface Area Determination

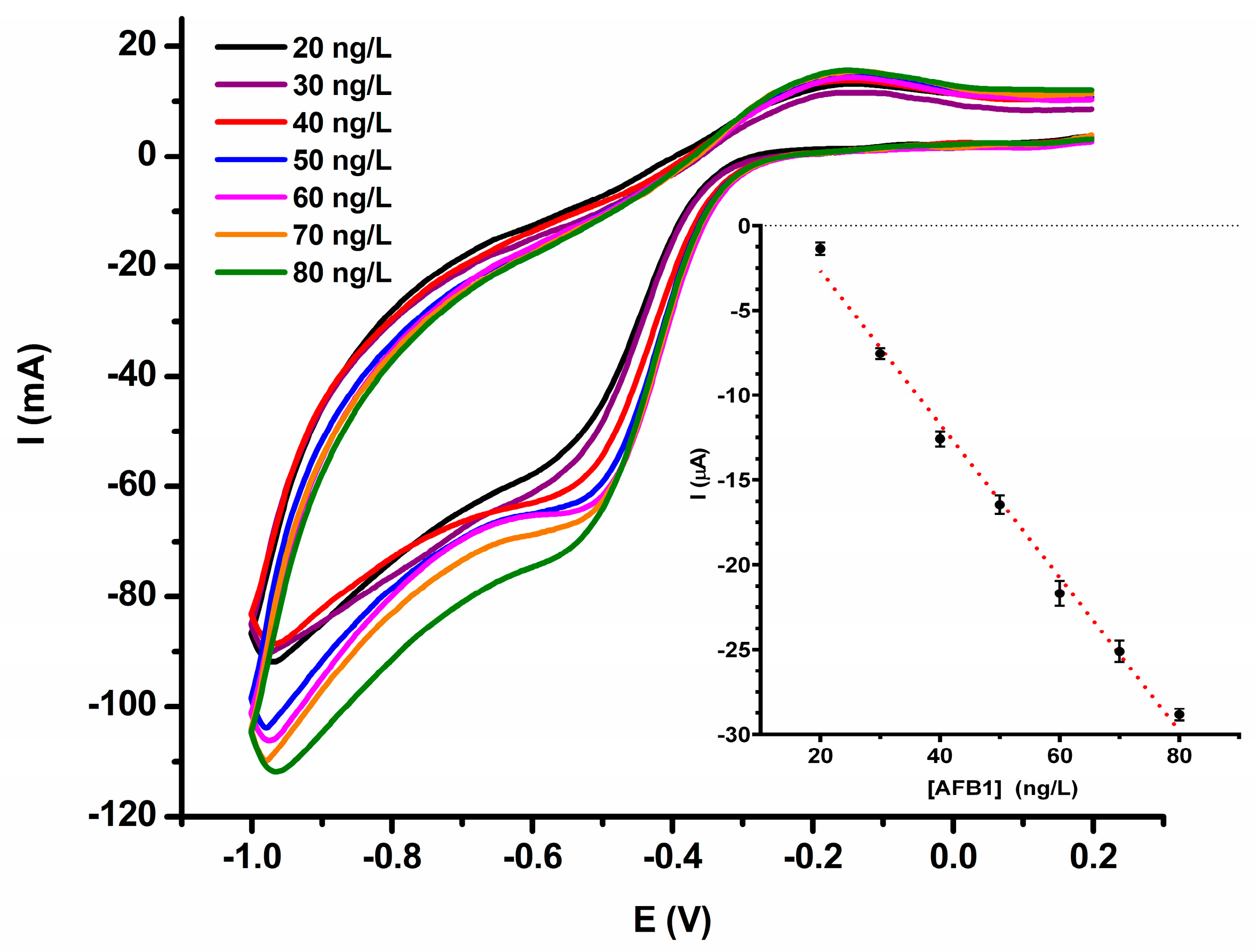

3.7. Analytical Performance of the Proposed Methodology for the Determination of AFB1

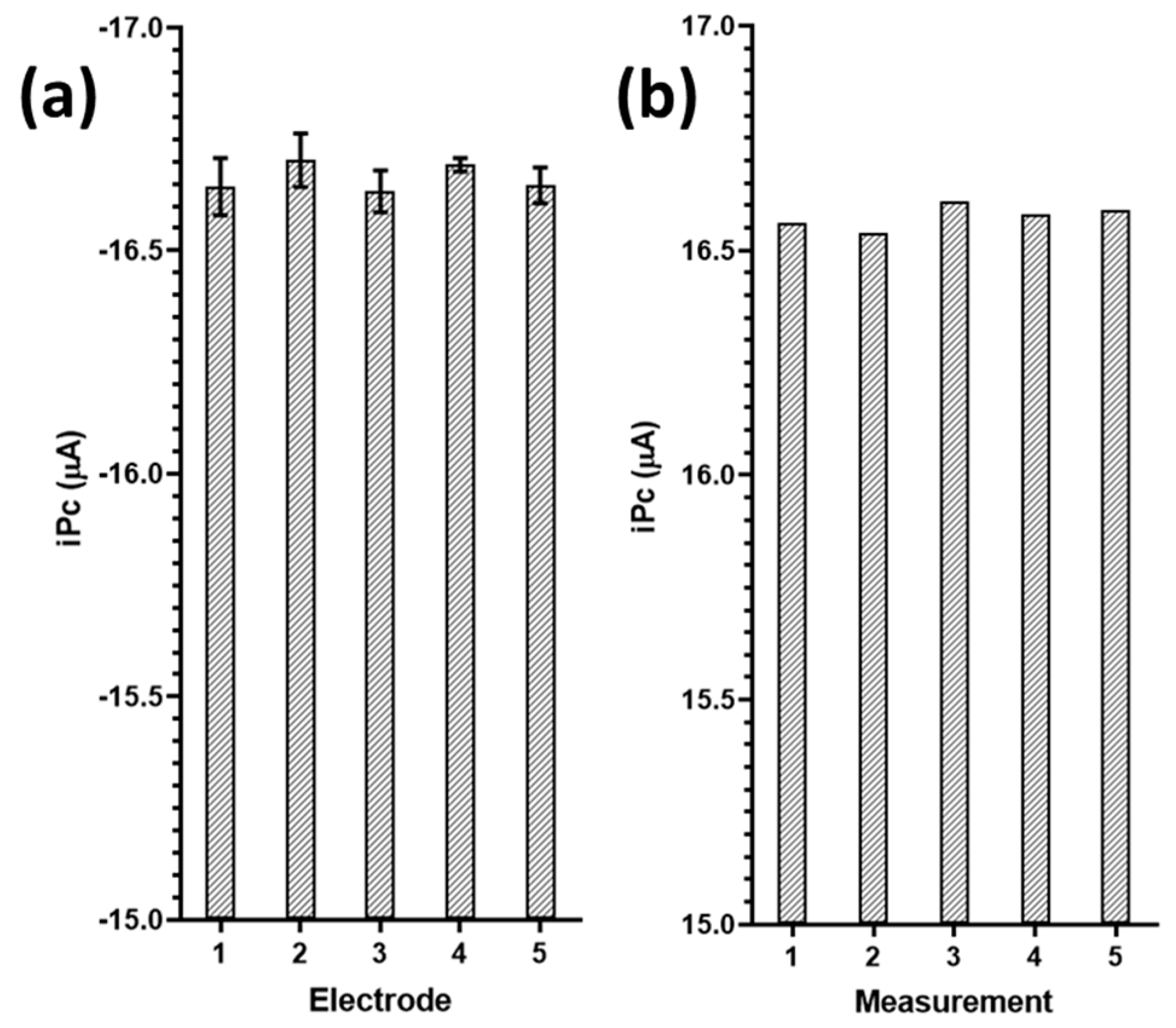

3.8. Reproducibility and Repeatability

3.9. Analysis of Real Samples

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Rushing, B.R.; Selim, M.I. Aflatoxin B1: A Review on Metabolism, Toxicity, Occurrence in Food, Occupational Exposure, and Detoxification Methods. Food Chem. Toxicol. 2019, 124, 81–100. [Google Scholar] [CrossRef] [PubMed]

- McKean, C.; Tang, L.; Tang, M.; Billam, M.; Wang, Z.; Theodorakis, C.W.; Kendall, R.J.; Wang, J.-S. Comparative Acute and Combinative Toxicity of Aflatoxin B1 and Fumonisin B1 in Animals and Human Cells. Food Chem. Toxicol. 2006, 44, 868–876. [Google Scholar] [CrossRef] [PubMed]

- Suo, Z.; Niu, X.; Wei, M.; Jin, H.; He, B. Latest Strategies for Rapid and Point of Care Detection of Mycotoxins in Food: A Review. Anal. Chim. Acta 2023, 1246, 340888. [Google Scholar] [CrossRef] [PubMed]

- Dong, S.; Yan, J.; Zhou, S.; Zhou, Q. Mycotoxins Detection Based on Electrochemical Approaches. Electroanalysis 2022, 34, 132–147. [Google Scholar] [CrossRef]

- Lin, X.; Yu, W.; Tong, X.; Li, C.; Duan, N.; Wang, Z.; Wu, S. Application of Nanomaterials for Coping with Mycotoxin Contamination in Food Safety: From Detection to Control. Crit. Rev. Anal. Chem. 2024, 54, 355–388. [Google Scholar] [CrossRef] [PubMed]

- Ma, X.; Li, X.; Zhang, W.; Meng, F.; Wang, X.; Qin, Y.; Zhang, M. Carbon-Based Nanocomposite Smart Sensors for the Rapid Detection of Mycotoxins. Nanomaterials 2021, 11, 2851. [Google Scholar] [CrossRef] [PubMed]

- Goud, K.Y.; Reddy, K.K.; Satyanarayana, M.; Kummari, S.; Gobi, K.V. A Review on Recent Developments in Optical and Electrochemical Aptamer-Based Assays for Mycotoxins Using Advanced Nanomaterials. Microchim. Acta 2020, 187, 29. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.; Li, G.; Wu, D.; Liu, J.; Wu, Y. Recent Advances on Emerging Nanomaterials for Controlling the Mycotoxin Contamination: From Detection to Elimination. Food Front. 2020, 1, 360–381. [Google Scholar] [CrossRef]

- Thurner, F.; Alatraktchi, F.A. Recent Advances in Electrochemical Biosensing of Aflatoxin M1 in Milk—A Mini Review. Microchem. J. 2023, 190, 108594. [Google Scholar] [CrossRef]

- Marimuthu, M.; Arumugam, S.S.; Jiao, T.; Sabarinathan, D.; Li, H.; Chen, Q. Metal Organic Framework Based Sensors for the Detection of Food Contaminants. TrAC Trends Anal. Chem. 2022, 154, 116642. [Google Scholar] [CrossRef]

- Sohrabi, H.; Salahshour Sani, P.; Zolfaghari, R.; Majidi, M.R.; Yoon, Y.; Khataee, A. MOF-Based Mycotoxin Nanosensors for Food Quality and Safety Assessment through Electrochemical and Optical Methods. Molecules 2022, 27, 7511. [Google Scholar] [CrossRef] [PubMed]

- Shrivastava, A.; Sharma, R.K. Biosensors for the Detection of Mycotoxins. Toxin Rev. 2022, 41, 618–638. [Google Scholar] [CrossRef]

- Vidal, J.C.; Bonel, L.; Ezquerra, A.; Hernández, S.; Bertolín, J.R.; Cubel, C.; Castillo, J.R. Electrochemical Affinity Biosensors for Detection of Mycotoxins: A Review. Biosens. Bioelectron. 2013, 49, 146–158. [Google Scholar] [CrossRef] [PubMed]

- Santana Oliveira, I.; da Silva Junior, A.G.; de Andrade, C.A.S.; Lima Oliveira, M.D. Biosensors for Early Detection of Fungi Spoilage and Toxigenic and Mycotoxins in Food. Curr. Opin. Food Sci. 2019, 29, 64–79. [Google Scholar] [CrossRef]

- Zhou, Q.; Tang, D. Recent Advances in Photoelectrochemical Biosensors for Analysis of Mycotoxins in Food. TrAC Trends Anal. Chem. 2020, 124, 115814. [Google Scholar] [CrossRef]

- Aoulad El Hadj Ali, Y.; Hejji, L.; Ait Lahcen, A.; Pérez-Villarejo, L.; Azzouz, A.; Kim, K.-H. Progress and Prospects in the Green Synthesis of Molecularly Imprinted Polymers for Sorptive Extraction and Sensing Applications toward Emerging Contaminants in Various Sample Matrices. TrAC Trends Anal. Chem. 2024, 170, 117466. [Google Scholar] [CrossRef]

- Gkika, D.A.; Tolkou, A.K.; Lambropoulou, D.A.; Bikiaris, D.N.; Kokkinos, P.; Kalavrouziotis, I.K.; Kyzas, G.Z. Application of Molecularly Imprinted Polymers (MIPs) as Environmental Separation Tools. RSC Appl. Polym. 2024, 2, 127–148. [Google Scholar] [CrossRef]

- Andersson, L.; Sellergren, B.; Mosbach, K. Imprinting of Amino Acid Derivatives in Macroporous Polymers. Tetrahedron Lett. 1984, 25, 5211–5214. [Google Scholar] [CrossRef]

- BelBruno, J.J. Molecularly Imprinted Polymers. Chem. Rev. 2019, 119, 94–119. [Google Scholar] [CrossRef] [PubMed]

- Ayerdurai, V.; Cieplak, M.; Kutner, W. Molecularly Imprinted Polymer-Based Electrochemical Sensors for Food Contaminants Determination. TrAC Trends Anal. Chem. 2023, 158, 116830. [Google Scholar] [CrossRef]

- Hua, Y.; Ahmadi, Y.; Sonne, C.; Kim, K.-H.H. Progress and Challenges in Sensing of Mycotoxins Using Molecularly Imprinted Polymers. Environ. Pollut. 2022, 305, 119218. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Anik Kirgöz, Ü.; Mo, J.-W.; Lu, J.; Nasser Kawde, A.; Muck, A. Glassy Carbon Paste Electrodes. Electrochem. Commun. 2001, 3, 203–208. [Google Scholar] [CrossRef]

- Afsharara, H.; Asadian, E.; Mostafiz, B.; Banan, K.; Bigdeli, S.A.; Hatamabadi, D.; Keshavarz, A.; Hussain, C.M.; Keçili, R.; Ghorbani-Bidkorpeh, F. Molecularly Imprinted Polymer-Modified Carbon Paste Electrodes (MIP-CPE): A Review on Sensitive Electrochemical Sensors for Pharmaceutical Determinations. TrAC Trends Anal. Chem. 2023, 160, 116949. [Google Scholar] [CrossRef]

- Malagutti, M.A.; de Fátima Ulbrich, K.; Winiarski, J.P.; Paes, V.Z.C.; Geshev, J.; Jost, C.L.; Maduro de Campos, C.E. Mechanochemical Synthesis of γ-CoTe2 Nanocrystals and Their Application for Determination of Ferulic Acid. Mater. Today Commun. 2022, 31, 103481. [Google Scholar] [CrossRef]

- de Barros, M.R.; Winiarski, J.P.; de Matos Morawski, F.; Marim, R.G.; Chaves, E.S.; Blacha-Grzechnik, A.; Jost, C.L. A High-Performance Electrochemical Sensor Based on a Mesoporous Silica/Titania Material and Cobalt(II) Phthalocyanine for Sensitive Pentachlorophenol Determination. Microchim. Acta 2022, 189, 269. [Google Scholar] [CrossRef] [PubMed]

- Alizadeh, T.; Akhoundian, M. Promethazine Determination in Plasma Samples by Using Carbon Paste Electrode Modified with Molecularly Imprinted Polymer (MIP): Coupling of Extraction, Preconcentration and Electrochemical Determination. Electrochim. Acta 2010, 55, 5867–5873. [Google Scholar] [CrossRef]

- Soni, I.; Kudur Jayaprakash, G. A Short Review on the Analysis of the Adsorptive Behavior of Surfactants at Carbon Paste Electrodes for Electrochemical Sensing. J. Mol. Liq. 2023, 388, 122737. [Google Scholar] [CrossRef]

- Mostafiz, B.; Bigdeli, S.A.; Banan, K.; Afsharara, H.; Hatamabadi, D.; Mousavi, P.; Hussain, C.M.; Keçili, R.; Ghorbani-Bidkorbeh, F. Molecularly Imprinted Polymer-Carbon Paste Electrode (MIP-CPE)-Based Sensors for the Sensitive Detection of Organic and Inorganic Environmental Pollutants: A Review. Trends Environ. Anal. Chem. 2021, 32, e00144. [Google Scholar] [CrossRef]

- Nishchaya, K.; Rai, V.K.; Bansode, H. Methacrylic Acid as a Potential Monomer for Molecular Imprinting: A Review of Recent Advances. Results Mater. 2023, 18, 100379. [Google Scholar] [CrossRef]

- Yanti; Nurhayati, T.; Royani, I.; Widayani; Khairurrijal. Synthesis and Characterization of MAA-Based Molecularly-Imprinted Polymer (MIP) with D-Glucose Template. J. Phys. Conf. Ser. 2016, 739, 012143. [Google Scholar] [CrossRef]

- Xie, W.; Chan, C.-M. Surface Analysis of Graphene and Graphite. In Applications and Use of Diamond; IntechOpen: London, UK, 2023. [Google Scholar]

- López, G.P.; Castner, D.G.; Ratner, B.D. XPS O 1s Binding Energies for Polymers Containing Hydroxyl, Ether, Ketone and Ester Groups. Surf. Interface Anal. 1991, 17, 267–272. [Google Scholar] [CrossRef]

- Vasapollo, G.; Sole, R.D.; Mergola, L.; Lazzoi, M.R.; Scardino, A.; Scorrano, S.; Mele, G. Molecularly Imprinted Polymers: Present and Future Prospective. Int. J. Mol. Sci. 2011, 12, 5908–5945. [Google Scholar] [CrossRef] [PubMed]

- Dai, J.; Fidalgo de Cortalezzi, M. Influence of PH, Ionic Strength and Natural Organic Matter Concentration on a MIP-Fluorescent Sensor for the Quantification of DNT in Water. Heliyon 2019, 5, e01922. [Google Scholar] [CrossRef] [PubMed]

- Cheng, J.; Li, Y.; Zhong, J.; Lu, Z.; Wang, G.; Sun, M.; Jiang, Y.; Zou, P.; Wang, X.; Zhao, Q.; et al. Molecularly Imprinted Electrochemical Sensor Based on Biomass Carbon Decorated with MOF-Derived Cr2O3 and Silver Nanoparticles for Selective and Sensitive Detection of Nitrofurazone. Chem. Eng. J. 2020, 398, 125664. [Google Scholar] [CrossRef]

- Güney, S. Electrochemical Synthesis of Molecularly Imprinted Poly(p-Aminobenzene Sulphonic Acid) on Carbon Nanodots Coated Pencil Graphite Electrode for Selective Determination of Folic Acid. J. Electroanal. Chem. 2019, 854, 113518. [Google Scholar] [CrossRef]

- Chen, J.; Xu, Q.; Shu, Y.; Hu, X. Synthesis of a Novel Au Nanoparticles Decorated Ni-MOF/Ni/NiO Nanocomposite and Electrocatalytic Performance for the Detection of Glucose in Human Serum. Talanta 2018, 184, 136–142. [Google Scholar] [CrossRef] [PubMed]

- Cruz-Navarro, J.A.; Mendoza-Huizar, L.H.; Salazar-Pereda, V.; Romo-Gómez, C.; Cobos-Murcia, J.Á.; Álvarez-Romero, G.A. A Cu(II)-BTC Metal-Organic Framework Modified Carbon Paste Electrode and Its Application as Electrochemical Sensor for Methanol Determination. J. Electrochem. Soc. 2022, 169, 37509. [Google Scholar] [CrossRef]

- Hernández-García, F.; Sanchez-Mora, A.T.; Serrano-García, J.S.; Amaya-Florez, A.; Ortiz-Frade, L.A.; Alvarez-Romero, G.A.; Cruz-Navarro, J.A.; Morales-Morales, D. Para-Hydroxy Ni(II)-POCOP Pincer Complexes as Modifiers on Carbon Paste Electrodes and Their Application in Methanol Electro-Oxidation in Alkaline Media. Processes 2024, 12, 1466. [Google Scholar] [CrossRef]

- Koventhan, C.; Musuvadhi Babulal, S.; Chen, S.-M.; Lo, A.-Y.; Senthamil Selvan, C. Unveiling the Capability of Novel Cobalt/Barium Stannate Nanoparticles Embedded Functionalized MWCNTs Nanocomposite for Electrochemical Investigation of Antibiotic Drug Nifuroxazide. Mater. Today Chem. 2024, 35, 101896. [Google Scholar] [CrossRef]

- Veerakumar, P.; Koventhan, C.; Chen, S.-M. Copper-Palladium Alloy Nanoparticles Immobilized over Porous Carbon for Voltammetric Determination of Dimetridazole. J. Alloys Compd. 2023, 931, 167474. [Google Scholar] [CrossRef]

- Geleta, G.S. Recent Advances in Electrochemical Sensors Based on Molecularly Imprinted Polymers and Nanomaterials for Detection of Ascorbic Acid, Dopamine, and Uric Acid: A Review. Sens. Bio-Sens. Res. 2024, 43, 100610. [Google Scholar] [CrossRef]

- Faridbod, F.; Zoughi, S.; Alizadeh, T.; Ganjali, M.R. Molecularly Imprinted Conductive Polymers. In Conductive Polymers in Analytical Chemistry; ACS Symposium Series; American Chemical Society: Zurich, Switzerland, 2022; Volume 1405, pp. 10–255. ISBN 9780841297869. [Google Scholar]

- Mocak, J.; Bond, A.M.; Mitchell, S.; Scollary, G. A Statistical Overview of Standard (IUPAC and ACS) and New Procedures for Determining the Limits of Detection and Quantification: Application to Voltammetric and Stripping Techniques. Pure Appl. Chem. 1997, 69, 297–328. [Google Scholar] [CrossRef]

- Singh, A.K.; Lakshmi, G.B.V.S.; Fernandes, M.; Sarkar, T.; Gulati, P.; Singh, R.P.; Solanki, P.R. A Simple Detection Platform Based on Molecularly Imprinted Polymer for AFB1 and FuB1 Mycotoxins. Microchem. J. 2021, 171, 106730. [Google Scholar] [CrossRef]

- Hernández-Hernández, A.A.; Castañeda-Ovando, A.; Mendoza-Huizar, L.H.; Franco-Guzmán, M.; Meneses-Pimentel, K.X.; Galán Vidal, C.A.; Páez-Hernández, M.E.; Álvarez Romero, G.A. A Novel Voltammetric Approach For The Quantification of Aflatoxin B1 Using a Bismuth-Modified Electrode. J. Electrochem. Soc. 2021, 168, 026512. [Google Scholar] [CrossRef]

- Zohdijamil, Z.; Reza Ahmadi Afshar, S.A.; Khazalpour, S.; Hashemi, M. Deep Eutectic Solvent Based Ultrasound Assisted Emulsification Microextraction for Preconcentration and Voltammetric Determination of Aflatoxin B1 in Cereal Samples. Anal. Methods 2021, 13, 946–954. [Google Scholar] [CrossRef] [PubMed]

- Hajian, R.; Ensafi, A.A. Determination of Aflatoxins B1 and B2 by Adsorptive Cathodic Stripping Voltammetry in Groundnut. Food Chem. 2009, 115, 1034–1037. [Google Scholar] [CrossRef]

- Liu, P.; Qi, X.; Zhang, H.; Zheng, Y. Sensitive Electrochemical Immunosensor for Detection of Mycotoxins Aflatoxin B1 Using Disposable Screen-Printed Carbon Electrode. Int. J. Electrochem. Sci. 2021, 16, 21033. [Google Scholar] [CrossRef]

| Electrode | LOD (ng/L) | Sensitivity | Ref. |

|---|---|---|---|

| PANI-MIP@ITO | 0.313 | 0.07 µA (ng/L)−1 cm−2 | [45] |

| Bi film | 11.2 | 0.0132 µA (ng/L)−1 | [46] |

| Au/Deep Euthectic Solvent | 50 | 111.8 µA (ng/L)−1 | [47] |

| Hg drop | 150 | 6.22 µA (ng/L)−1 | [48] |

| Screen Printed CE | 7 | 0.004 µA (ng/L)−1 | [49] |

| MAA-MIP@CPE | 2.31 | 19.83 µA (ng/L)−1 cm−2 0.45 µA (ng/L)−1 | This work |

| Source of Variation | SS | df | SM | F | p |

|---|---|---|---|---|---|

| Between Groups | 0.012227 | 4 | 0.003057 | 1.287921 | 0.338115 |

| Within Groups | 0.023733 | 10 | 0.002373 | ||

| Total | 0.035960 | 14 |

| Results Comparison | Statistical Comparison | |||

|---|---|---|---|---|

| Sample | Standard Addition n = 5 | Calibration Curve Analysis n = 5 | To Vs Tα/2 | |

| Corn | 41.1 ng/L | 41.7 ng/L | 1.51 | 2.30 |

| Wheat | 42.8 ng/L | 43.6 ng/L | 2.02 | 2.30 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hernández-García, F.; Cruz-Navarro, J.A.; García-Serrano, J.; Franco-Guzmán, M.; Islas, G.; Alvarez-Romero, G.A. Development of a Voltammetric Methodology Based on a Methacrylic Molecularly Imprinted Polymer-Modified Carbon-Paste Electrode for the Determination of Aflatoxin B1. Separations 2024, 11, 246. https://doi.org/10.3390/separations11080246

Hernández-García F, Cruz-Navarro JA, García-Serrano J, Franco-Guzmán M, Islas G, Alvarez-Romero GA. Development of a Voltammetric Methodology Based on a Methacrylic Molecularly Imprinted Polymer-Modified Carbon-Paste Electrode for the Determination of Aflatoxin B1. Separations. 2024; 11(8):246. https://doi.org/10.3390/separations11080246

Chicago/Turabian StyleHernández-García, Fabiola, Jesús Antonio Cruz-Navarro, Jesús García-Serrano, Miriam Franco-Guzmán, Gabriela Islas, and Giaan A. Alvarez-Romero. 2024. "Development of a Voltammetric Methodology Based on a Methacrylic Molecularly Imprinted Polymer-Modified Carbon-Paste Electrode for the Determination of Aflatoxin B1" Separations 11, no. 8: 246. https://doi.org/10.3390/separations11080246

APA StyleHernández-García, F., Cruz-Navarro, J. A., García-Serrano, J., Franco-Guzmán, M., Islas, G., & Alvarez-Romero, G. A. (2024). Development of a Voltammetric Methodology Based on a Methacrylic Molecularly Imprinted Polymer-Modified Carbon-Paste Electrode for the Determination of Aflatoxin B1. Separations, 11(8), 246. https://doi.org/10.3390/separations11080246