1. Introduction

In recent years, concerns about the generation of industrial waste have risen, boosting interest in sustainable production. Thus, technologies have been developed to manufacture high-value-added products from waste. Some of the industries that generate the most waste are related to the production and transformation of food [

1]. In the present work, residues from the wine industry were used as raw materials because they are a natural source of antioxidants and have various compounds that are beneficial for health [

2,

3].

There are several studies on the antioxidant and health-promoting effects of secondary metabolites present in plants, including grapes (and wine). It has been reported that the content of phenolic compounds in grapes contributes to the inhibition of the oxidation of low-density lipoproteins, thus helping prevent cardiovascular diseases [

4,

5]. The edible part of the grape is the pericarp, which is composed of the epicarp (peel or skin), the mesocarp (pulp), and the endocarp (the tissue that surrounds the seeds and is indistinguishable from the pulp and stem) [

6,

7].

The Mexican wine industry includes producers of table grapes, raisins, concentrated grape juice, wine, and grape liqueurs (brandy) [

8]. Wine is the beverage resulting from the complete or partial alcoholic fermentation of grape must in contact or not with pomace [

9]. The must is the juice obtained by squeezing and/or draining and/or pressing the grapes [

10]. The winemaking process comprises several operations, from harvest to clarification. At the time of harvest, the grape cluster is collected and taken to the winery. The grape harvest is carried out when the fruit has reached an adequate maturity, which is determined by measuring the concentration of sugars and acids [

10], and is specific depending on the type of wine [

11,

12]. Once in the winery, the grapes are squeezed; this process involves breaking the skin so that the juice is easily released. The squeezing process favors the natural inoculation of the juice with the yeast attached to the skin, the aeration of the juice, and the subsequent maceration of the solid parts. For white wine vinification, only the must is vatted, whereas for red wine vinification, both the must and the solid parts are vatted in large tanks—preferably made of stainless steel—which allow for control of the fermentation temperature and are equipped with technical devices that facilitate the processes [

13,

14]. During fermentation, control of the aeration and temperature is crucial as these parameters modulate the yeast activity and allow for a uniform fermentation process. Once the desired composition of the wine is reached, it is transferred to other tanks, where it will slowly finish fermenting, and in the case of red vinification, the pomace will be separated [

15,

16].

During the winemaking process, waste is generated, most of which (80–85%) is organic. This waste is made up of the pomace (62%), lees (14%), stems (12%), and sludge (12%). The pomace is produced when grapes are pressed and is composed of the seeds and skin of the fruit, whereas the lees (the remains of yeast and solids) are generated during the wine clarification process. The stems include the branches and leaves of the vine, and finally, the sludge is generated during the wastewater treatment [

17].

The bioactive compounds in the pomace mainly include anthocyanins, catechins, flavonoids, phenolic acids, and stilbenes [

18,

19]. Hence, grape pomace is considered to be a valuable source of phenolic compounds. Moreover, the high content of dietary fiber suggests the possible nutritive value of grape pomace, which could be used as a functional food ingredient [

20,

21]. The use of grape waste as a dietary antioxidant supplement has been proposed [

22]. Furthermore, several studies [

23,

24] have reported that grape pomace has a high phenolic content. During the winemaking process, some phenolic compounds are transferred to the wine; however, they are not exhaustively extracted, and the byproduct (grape pomace) still has a substantial content of polyphenols [

25,

26,

27]. Generally, the industrial recovery of grape pomace is aimed at the extraction of tartaric acid or production of ethanol, and pomace can also be used as a fertilizer, animal feed, compost, biomass, and soil amendment, or simply discarded [

21]. Therefore, grape pomace represents a cheap and natural source for the extraction of phenolic compounds which may be an alternative to solve environmental problems caused by the disposal of this byproduct [

21,

28].

The industrial extraction of bioactive compounds from grape pomace is carried out by maceration [

29]. Some studies have recently demonstrated that non-thermal technologies such as ultrasound may represent effective alternatives to improve polyphenol extraction. Ultrasound application at 20–35 kHz enhances the extraction of polyphenols from red-grape residues [

30]. Although this methodology offers an advantage, the necessary equipment must be implemented to carry it out, which implies extra costs. In addition, it should be considered that this method can also affect the chemical structure of some polyphenols since the high temperatures and pressures generated by the collapse of cavitation bubbles can induce chemical reactions and accelerate some reactions that usually occur during wine aging [

16]. In addition, this method can also affect the chemical structure of some polyphenols and modify their antioxidant activity. The introduction of a new technology on the market requires that it perform at least as well as existing commercial processes. In this sense, a patented MSPD method [patent WO 2014013122 A1, ref. [

31], with modifications, could be applied for the extraction of bioactive compounds from grape pomace. The novelty of this method is the disruption of the sample with a dispersant, the isolation of the analytes on a solid support, and their subsequent elution with the solvent [

32]. The appropriate combination of the dispersant and elution solvent provides adequate recovery percentages and medium selectivity, in addition to having a low cost per extraction and a moderate consumption of organic solvents [

32], which are the method’s main advantages. Nevertheless, matrix solid-phase dispersion (MSPD) can be used for the extraction of polar and phenolic compounds from medicinal plants [

33]. In this work, the MSPD method for the extraction of bioactive compounds from grape pomace and the maceration method of Acuña et al. [

34], with some modifications, were used. The central composite design (CCD) was used to establish the optimal extraction conditions by maceration, whereas the factorial design was applied to identify the optimal extraction conditions by matrix solid-phase dispersion (MSPD).

4. Conclusions

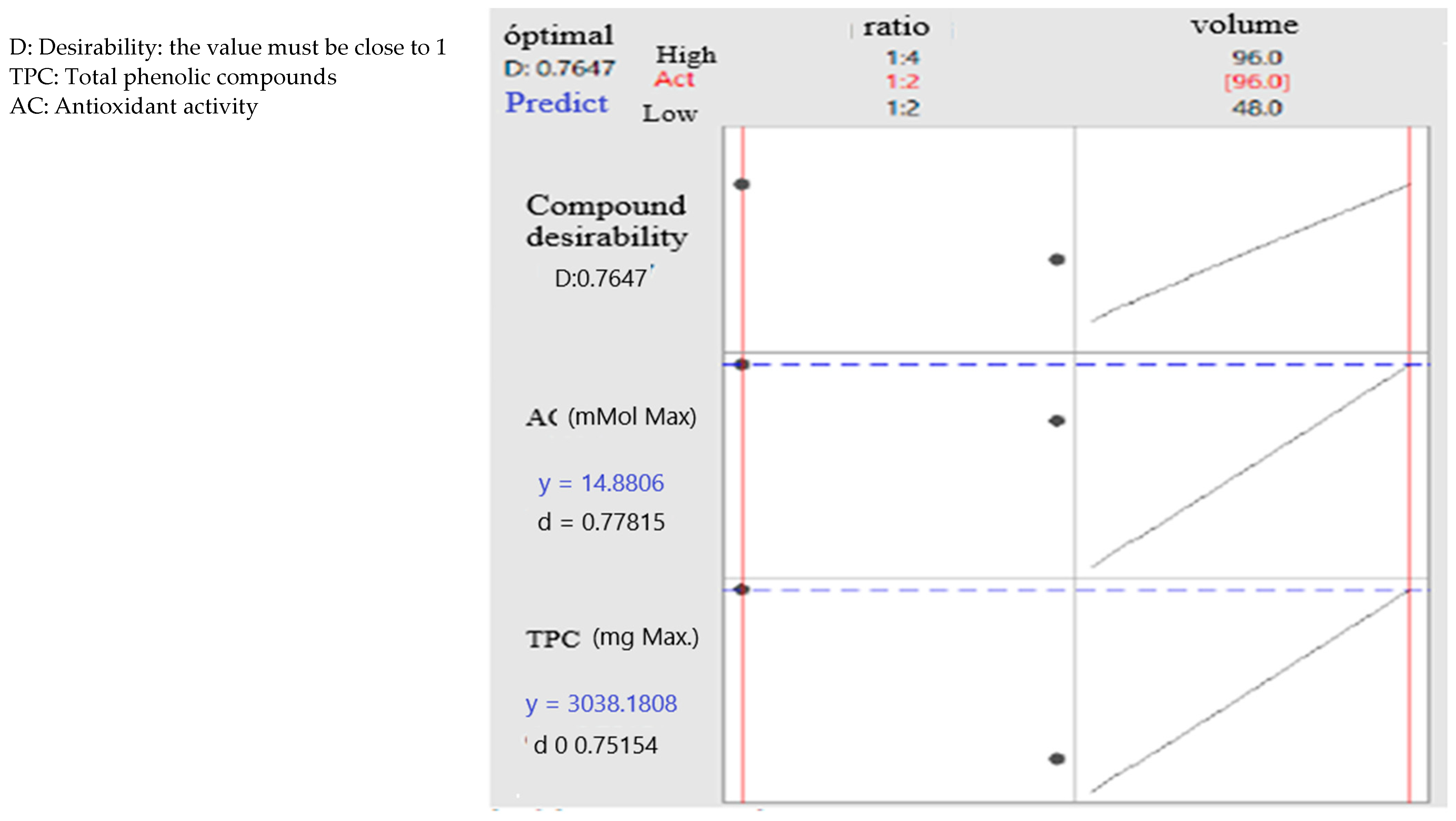

The central composite design allowed us to establish the optimal extraction conditions by maceration, whereas with the factorial design, it was possible to identify the optimal extraction conditions by matrix solid-phase dispersion (MSPD). Through model predictions, we found that the total phenolic content (TPC) and antioxidant capacity (AC) of the extracts were within the prediction intervals at a 95% confidence level. By maceration, the percentage of error between the predicted and the real value for TPC was between −6.09 and 0.25%, whereas for AC, it was between −5.97 and 2.59%. Regarding the MSPD method, the prediction interval at a 95% confidence level for the antioxidant capacity was between 13,181 and 16,580 mMol TE/100 g pomace db, and for the phenolic content, it ranged between 2637.9 and 3438.5 mg GAE/100 g pomace db. However, although the predicted values were higher than those obtained, they were within the prediction interval obtained.

Therefore, the models could be used to predict the response values. Moreover, when the extraction was performed by MSPDSand, greater TPC concentration and AC were obtained. Thus, MSPDSand was chosen for further analysis. The TPC and AC of the extracts demonstrated that Cabernet Sauvignon grape pomace has great potential as a source of antioxidant compounds for food applications. Moreover, the content of bioactive compounds was comparable to that reported for Cabernet Sauvignon grape pomace from other countries. Both the maceration method and MSPD proved to be efficient for the extraction of phenolic compounds from waste from the winemaking process. However, when using the MSPD method, higher values of both TPC and AC were obtained under the optimal conditions. Future research may evaluate the use of other solvents and dispersion materials with this method to obtain bioactive compounds (tannins, anthocyanins, etc.) with different polarities.