Abstract

The coloring behavior of santalin, a natural reddish-brown dye derived from sandalwood, has been investigated in this work for the dyeing of silk fabrics while being heated in MW radiation. Microwave (MW) radiation up to 5 min has been employed to isolate colorant (Santalin) from red sandalwood (Ptrecarpus santalinus) in selected medium, and bio-mordants in competing with salts as chemical-mordants have been included. Statistical analysis was made and dyeing variables were selected for getting dark shades though mordants. MW treatment for 3 min. to both extract and fabric was selected and mild dyeing conditions were optimized statistically to get dark shades. On applying chemical mordants, selected amount of salts of Al+3, Fe+2 and T.A. before and after dyeing, has given good results. Comparatively, selected extracts of plant based sources have shown colorfast shades of high strength. The MW radiation has excellent potential to extract dye form plants using optimum medium through less time and energy, and the application of plant extracts along with sustainable salts have developed colorfast shades.

Keywords:

Amaltas; Anar phali; Central Composite Design; henna; pomegranate; Ptrecarpus santalinus; santalin 1. Introduction

Among the global village, many industries, such as textile, chemical, cosmetic, and pharmaceutical sectors, frequently employ synthetic dye during the finishing of their products [1,2]. Although these dyes give brilliant hues that attract attention, the effluents shed during their processing are dangerous for the environment and human life [3,4]. It is generally accepted that most synthetic dyes contain such intermediates, which can contaminate the environment by decreasing ecosystem parameters [5]. These effluents also affect global health by causing allergic reactions and adverse skin conditions [6]. As a result of the constant addition of colored wastewater, freshwater environments is also polluted and becoming unfit for aquatic life [7]. Among many industries, the textile processing industry is considered a producer of one of the worst environmental pollutants and uses a lot of fuel and chemicals [8]. Most synthetic dyes in textile processing exhibit stability against microbial breakdown and do not biodegrade in aerobic environments [9]. Hence their waste also contaminates air, water, and soil fertility. The need for eco-friendly synthetic dye substitutes has been highlighted by the toxicity of waste and dangerous substances emitted during the manufacturing and use of chemicals [10]. Hence there is a need to spread awareness about the inclusion of nature’s gift particularly natural colorants into our daily life and to force the world stakeholders to search for the natural, sustainable, and easily biodegradable sources of colorants for textiles [11].

Natural dyes have many advantages over synthetic dyes, including being environmentally friendly, renewable, biodegradable, and non-carcinogenic in nature [12]. As a result, they are increasingly being used in textile dyeing. These dyes are generally derived from plant roots, bark, and leaves. Some natural colors come from animals, insects, fungi, bacteria, mineral sources, flowers, and fruits [13]. All natural dyes have anti-bacterial anti-allergic, and antioxidant qualities, due to which these colorants are gaining widespread fame for their frequent use in all walks of life. These colorants give brighter, more attractive, softer, and soothing shades. These exhibit insect-repellent, odor-remover, and flame-retardant properties [14,15]. Along with the many advantages, certain disadvantages have also been found, including low color yield, a lower fastness rating, and non-reproducible hues [16] Scientists use conventional techniques to overcome these limitations but could be more effective at saving resources like money, labor, or energy. Nowadays, researchers use modern techniques for isolating colorants, which include gamma [17], plasma [18], ultrasonic, ultraviolet [19], and microwave radiations [20]. Microwaves increase dye absorption by heating materials exposed to them quickly and steadily. Many textile processes, including drying, finishing, and printing, are feasible with these rays [21]. These rays penetrate the fabric, tuning its surface to increase its substantivity and speed up the dying process. Additionally, through a unique mechanism known as mass transfer kinetics, these rays compel the plant components to collapse, break their barriers, and effectively interact with the solvent through the functional component (pigment). In addition to using less energy and time to produce high yields, this quick and efficient response also uses less solvent [15,22,23].

Mordants are employed in natural dyeing to enhance color qualities and fastness characteristics. Mordants are essential in dyeing with many natural dyes through development/interactions between the fibers, mordant, and dye [24] Many metal salts are used, but Cu, Co, and Cr electrolytes are toxic by nature and should not be used [25]. When combined with natural colorants and fabric dyeing, these toxic additives develop a wide range of colors. However, their effluent load is carcinogenic, which in turn is the cause of soil infertility, deforestation, and destruction of the natural beauty [26]. Now in place of toxic chemicals, the mordanting trend has been changed to use bio-mordants in the natural dyeing process to make the process greener, clean, and pollution-free. These mordants have the potential to completely replace metal salts for the ecological dyeing of textiles to develop new colorfast gamutes [27].

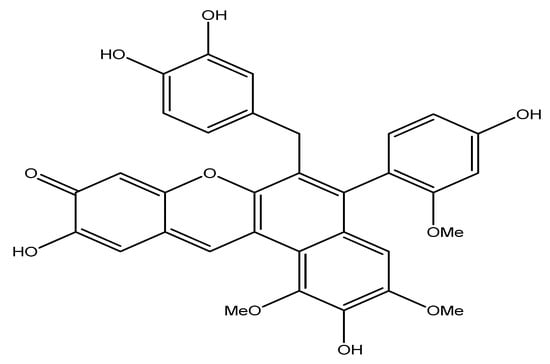

Given the advantages of MW treatment for the isolation of colorants and the application of bio-mordants for getting colorfast shades with acceptable fastness rates, the current study has been undertaken to investigate red sandalwood (Ptrecarpus santalinus) as a source of orange-red colorant for silk [28]. A member of the Fabaceae family, red sandalwood (RSW) is well known for its distinctive timbre, excellent color, and beauty [29]. Its extract treats mental abnormalities, vomiting, eye disorders, and ulcers [30]. In addition to being used as a diaphoresis aid, the heartwood is also known to have antihyperglycemic, antipyretic, anti-inflammatory, anthelmintic, tonic, hemorrhagic, and dysentery properties. Phytochemical examination revealed that santalin (A, B) and deoxysantalin are two complex compounds found in red sandalwood [31]. The heartwood extracts red pigment, specifically santalin (Figure 1), a natural dye (CI Natural Red 22) for bio-colorants for furniture and crafts, food, cosmetics, and textiles [32].

Figure 1.

Santalin (CI Natural Red 22).

Hence, the current study has been aimed to use the central composite design (C.C.D.) to get statistically the significant levels of coloring variables. The study has also been aimed to select the levels of chemical and biological mordants before and after dyeing under specified conditions, as well as to evaluate shade fastness rating by following ISO Standards.

2. Materials and Methodology

2.1. Materials Required

Red sandalwood (Ptrecarpus santalinus), as a source of natural red dye called Santalin (CI Natural Red 22), has been procured from Faisalabad, Pakistan. The powder of 20 mesh size was prepared for extraction and pretreated silk fabric (GSM = 70 g/m2) was obtained from the textiles market in Faisalabad, Pakistan. All the chemicals used during extraction, bio-dyeing, and mordanting will be of local grade (Pakistan-made). For bio-mordanting, turmeric rhizomes, henna leaves, acacia bark, pomegranate rind, Amaltas bark, Pomegranate peel, Anar phali fruit, and Arjun bark were purchased from the local market.

2.2. Extraction and Irradiation Process

To successfully isolate the natural color from red sandalwood powder (RSWP), two extraction media, i.e., aqueous (neutral) and acidic, were used. For an acidic medium, 2 mL of conc. HCl was added in 98 mL water (2% v/v). Then neutral and acidic media was employed to extract the dyes from the plant by boiling 4 g of finely meshed plant powder with 100 mL of water. After dye extraction in the given media, the crude material was filtered by conventional filtering to obtain the pure extract. The silk fabric and the extract were treated with microwave radiation for 1 to 5 min using a high-power microwave irradiator. After this, the treated and untreated extracts were used to dye treated and untreated silk fabric at 80 °C for 65 min, keeping an extract to fabric ratio of 1:30.

2.3. Optimization of Dyeing Variables

Different dyeing parameters, such as the temperature, time, pH of dyeing, and salt concentration, were optimized using a central composite design of 32 experiments with response surface methodology (RSM). To see the effect of temperature, dyeing was carried out at 45, 55, 65, 75, 85, and 95 °C. Similarly, dyeing time was optimized by dyeing fabrics for 35, 45, 55, 65, and 75 min. In another series of experiments, dyeing was performed using dye solutions of different pH values (2, 4, 6, 8 and 10). In contrast, to achieve maximum exhaustion, dyeing was also performed using a range of salt concentrations (0.5–2.5 g/100 mL) of table salt (NaCl). Table 1 describes the trials to select dyeing parameters formulated using the central composite design with response surface methodology.

Table 1.

Selected radiation and dyeing conditions for silk using red sandal powder extracts.

2.4. Shades Improvement Process

New shades have been developed onto silk while dyeing silk with RSW extract at selected conditions before and after mordanting at 80 °C for 45 min by employing a mordant to fabric ratio of 25:1. For this purpose, 0.5–2.5% of electrolytes of metal (Al, Fe) and tannic acid have been used. To make the process worth seeing with better fastness and soothing shades, extracts of plants having potential bio-actives have been employed under the same conditions. For this purpose, extracts were prepared by taking 0.5–2.5 g of each uniform particle size powder with 100 mL water, boiled and filtered. Each filtrate, as per the weight of silk (1 g), was used before and after dyeing at selected conditions.

2.5. Analysis of Fabric

Fourier-transform infrared spectroscopy spectra were scanned using ATR-FTIR (Perkin Elmer, Waltham, MA, USA). The changes in the functional peaks were observed within the range of 400–4000 cm−1. The surface morphology of fabric before and after irradiation was scanned under a scanning electron microscope (SEM), and images were studied at an image power of 1000×. The dyed fabrics were analyzed using Spectra flash SF600 (Data Color, Lucerne, Switzerland) at D65 10° observer to get color depth (K/S) and tonal variations. The color fastness properties were assessed for washing (ISO 105 CO3), light (ISO 105 BO2), and rubbing (ISO 105 X-12), as per ISO Standards.

3. Results and Discussion

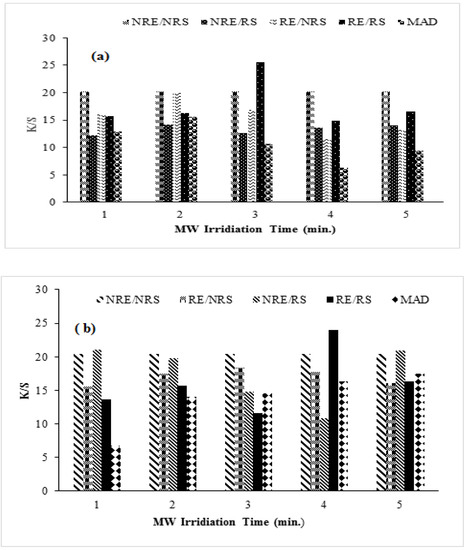

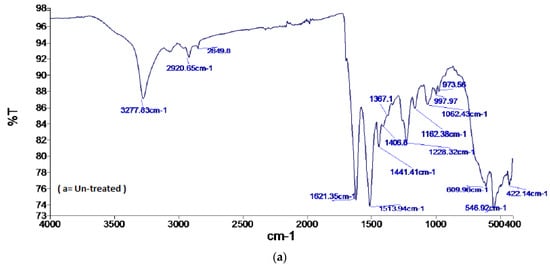

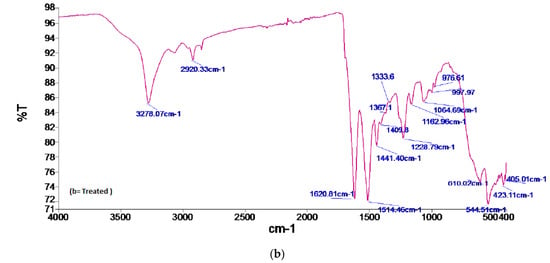

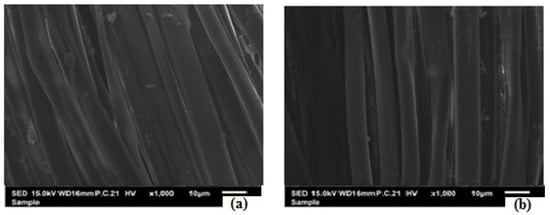

The microwave rays also affect the bio-coloration of silk with plant dyes. Because of its nature, silk fabric, upon surface modification, sorbs colorant up to the maximum extract [33]. Our previous studies show that M.W. causes surface modification of fiber to enhance its sorption attitude without changing its chemical nature [34,35]. These rays also influence the isolation process by special kinetics [36]), where the boundary of plant cells is ruptured [37,38], biomolecules are evolved, and, through interaction with solvent, the mass (colorant) is extracted, which upon dyeing shows maximum yield (K/S = 25.44). The same behavior was observed in our case when before radiation, RSWE extract had given better yield in an aqueous medium (K/S = 25.44) onto silk upon radiation up to 3 min, and the yield was enhanced (K/S = 25.441) using an acidic medium before radiation. However, the yield was almost the same (K/S = 23.98) as that shown by the aqueous medium; however, after radiation, the yield was improved (K/S = 25.44). Tonal expressions in terms of L*, a*, and b* in Table 2 revealed that before radiation, the shade was darker (L* = 38.26) and reddish yellow (a* = 20.43, b* = 29.01) in hue. After radiation of up to 3 min, the shade moved towards brightness, the redder tone was little changed, and the yellower tint was enhanced. On changing the medium from neutral to acidic before the radiation, the shade becomes brighter and more reddish yellow in tone. Still, after treatment for up to 4 min, the shade becomes darker with less reddish and yellow tone. Hence the results drawn in Figure 2a,b show that both silk and RSWE using an aqueous medium should be treated up to 3 min to get a high yield. The structural changes in fabric have been studied via scanning spectral images before and after radiation, where it can be seen that functional peaks of amido linkage as the main functional site of fabric has not altered their positions (Figure 3a,b). This absence of significant change has revealed that MW rays did not alter the chemistry of the functional unit of silk. However, physically modified surfaces in the form of scratches/peeled surfaces (Figure 4a,b) reveal that MW rays have improved the sorption behavior of fabric. Thus, MW rays have another big advantage that these waves have nothing to do with chemical nature of fibers, but only tune the surface physically to uphold maximum volume of the extract.

Table 2.

Central composite design for optimization of dyeing variables using irradiated extract of red sandalwood.

Figure 2.

(a) Utilization of microwave irradiated and un-irradiated aqueous (a) and acidic extract (b) of red sandalwood (RSW) powder for dyeing irradiated and un-irradiated silk fabric.

Figure 3.

FTIR analysis of un irradiated silk fabric (a), irradiated silk fabric (b).

Figure 4.

SEM analysis un irradiated silk fabric (a), irradiated silk fabric (b).

Using optimal radiation conditions, selecting coloring factors that affect the shade’s strength is necessary to select through statistical models, such as a central composite design (CCD). The results presented in Table 3 show that 40 mL of irradiated extract of 6 pH having 3 g/100 mL of salt as an exhausting agent when employed at 75 °C for 55 min has displayed high strength. Statistically, it has been observed that the model is fit (p = 0.000) and linear (p = 0.001), which shows that the selection of the model to study the significance of results on determining dyeing variables after a series of experiments is acceptable and excellent. The role of extract, pH temperature (p = 0.005), and salt (p = 0.035) value are also highly significant for silk dyeing individually. In two joint actions, the role of pH with temperature (p = 0.007) and salt (p = 0.000) and the role of temperature with time (p = 0.000), salt (p = 0.000) are highly significant. Hence, the heating level, extract nature, and salt used for exhausting in two way-interactions is important during silk dyeing with S.W. extract. This is because silk, being proteinous in nature, needs acidic conditions for firm dye fixation. Contact of fabric with colorant for a short time does not initiate kinetics for dyeing, whereas for a long time period, heat, instead of coloration, retarding, or desorption rate, is enhanced. In both cases, after finishing, actual contact behavior is lost, and low yield is observed. Similarly, salt plays a role during the dyeing process. It is added slowly until the end of the process to promote exhaustion of the dye bath to the fabric. Using less salt causes the colorant to exhaust well, whereas, above 3 g, the over exhaustion results in the gathering of molecules in the form of clusters to yield uneven dyeing and on assessing such dyed fabrics with Spectra flash, less color depth is observed. Hence, using selected conditions, the dyeing followed by mordanting should be done to get colorfast gamutes.

Table 3.

Central composite design for optimization of dyeing variables using irradiated extract of red sandalwood.

For polyamide-based fabrics in natural dyeing, it is also essential to treat them with salt or plant extracts [39]. Previously, salts of Al+3, Cu+2, Co+2, Cr+2, Ni+2, Fe+2, and tannic acid (T.A.) were employed. Still, global communities have found that Co, Ni, Cr, and Cu salts are toxic and hazardous. Their excess in water bodies causes infertility in life, severe changes in water quality parameters, and soil infertility [40]. Hence, they must be replaced with eco-friendly, sustainable materials: either salt or plant-bioactive [41]. Our research group has employed plant extracts that have functional bioactives to interact with the amido linkage of silk and -O.H of colorant (Santalin) and very low amounts of electrolytes and tannic acid to develop colorfast shades.

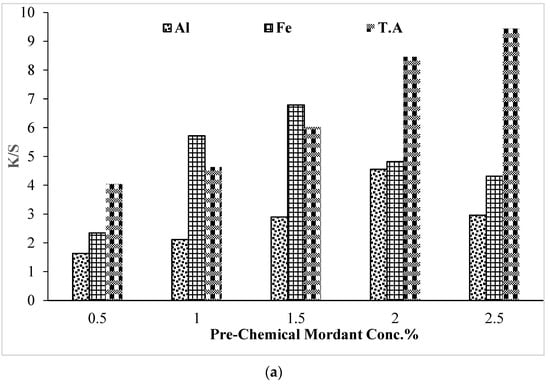

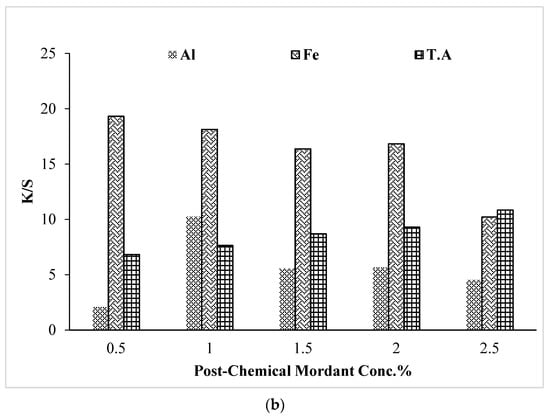

The results shown in Figure 5a,b revealed that before the dyeing of silk, 25 mL from 2% of Al, 1.5% of Fe, 2.5% of T.A. have a high yield. After dyeing, 25 mL of 1% of Al, 0.5% of Fe, and 2.5% of T.A. have also furnished shades of high strength. This is because the metals used can form a dye complex onto the fabric before and after dyeing [42]. Here the treatment of fabric, natural colorant, and its binding site, as well as the reduction in the power of metal or -O.H from tannic acid, play their part via covalent bonding to develop firm and fast shades. Hence, the shades developed at selected conditions using the selected amount of mordant as per the weight of fabric have improved the fastness from poor to good and poor to better.

Figure 5.

(a) Pre-chemical mordant of silk fabric with red sandalwood (RSW) powder at optimized conditions. (b) Post-chemical mordant of silk fabric with red sandalwood (RSW) powder at optimized conditions.

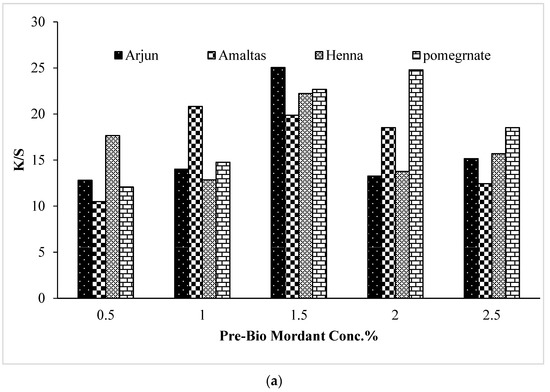

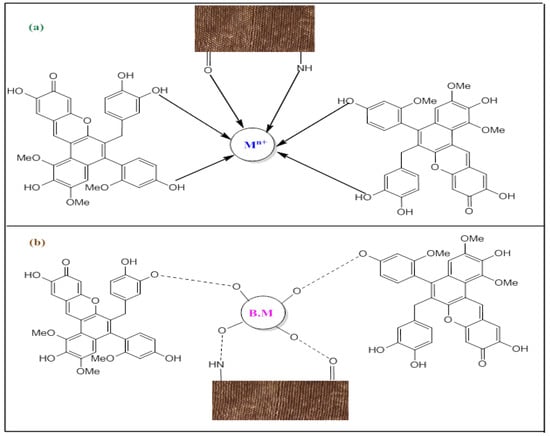

Bio-mordants are the plant’s potent molecules that transfer their functional properties when interacting with matter such as fabrics (cotton, wool, or silk) [43]. These molecules, after extraction, when employed onto fabric before and after dyeing, produce firm and stable shades through extra H-bonding [44]. Additionally, the conjugation present in the molecule also plays a role when the transfer of ions in the system causes special bonding with the functional fabric site (-NHCO = silk/wool; -OH = Cellulose) and colorant functional points (–O.H. or –O.H. and -C=O) to develop soothing and sustainable colorfast shades [45]. In this work, the extracts from henna leaf powder, pomegranate rind, Amaltas bark, and arjun bark have been used before and after the dyeing of silk at selected conditions.

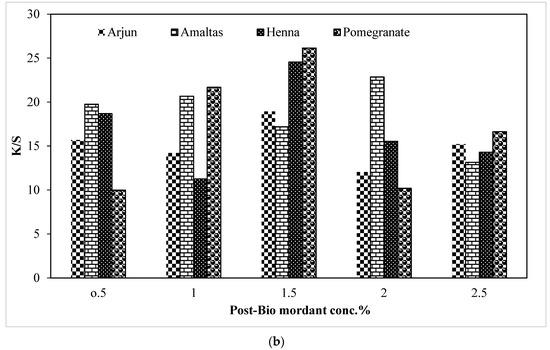

The results shown in Figure 6a,b reveal that, before dyeing, 25 mL from 1% of Amaltas, 1.5% of arjun, 1.5% of henna, and 2% of pomegranate have given high yield and darker reddish yellow shades. After dyeing, 25 mL of 1% of Amaltas, 2% of arjun, 1.5% of henna, and 1.5% of pomegranate have also given high yield. Overall, before dyeing, arjun bark extract (1.5%) containing arjunic acid has developed high strength (K/S = 25.04) and darker shade (L* = 22.3) with a reddish yellow hue (a* = 28.1; b* = 31.9). Similarly, after dyeing (Table 4), the application of 1.5% of pomegranate extract having tannin has developed high strength (K/S = 26.1) and a less red (a* = 12.1) but yellower hue (b* = 29.6). Hence, overall, at selected levels, the application of these anchors before and after dyeing has produced good shades with acceptable results. Additionally, it can be seen that MW rays on the fabric have developed extracts. The metal–dye interaction is shown in Figure 7a,b.

Figure 6.

(a) Pre-bio mordant of silk fabric with red sandalwood (RSW) powder at optimized conditions. (b) Post-bio mordant of silk fabric with red sandalwood (RSW) powder at optimized conditions.

Table 4.

Shade quality parameters of selected fabric dyed with red sandalwood before and after chemical and bio-mordanting.

Figure 7.

Proposed interaction of chemical mordant (a) and bio-mordants (b) for dye using silk fabric.

For dyeing fabric with plant pigments, the main concern is its shade fastness. The colorfastness properties have been assessed at a grey scale after evaluating selected fabric dyed before and after mordanting using electrolytes and plant extracts [46]. The results presented in Table 5 and Table 6 show that before treatment, the colorfastness to light, washing, and rubbing was poor, but after mordanting, the rating was improved from poor to good and excellent. This colorfastness is due to the firm and stable complex developed onto surface-modified fabrics, using salts and adding extra H-bonding using plant extracts. In addition, the surface modification and the nature of colorants and mordants used have played roles in giving darker shades. Hence, the results revealed that by using a specific amount of mordants, the fastness properties of dyed silk fabric could be improved.

Table 5.

Fastness grading of silk fabric dyed with acidic extract of red sandalwood before and after chemical mordanting at selected conditions.

Table 6.

Fastness grading of silk fabric dyed with acidic extract of red sandalwood before and after chemical mordanting at selected conditions.

4. Conclusions

Natural dyes are receiving widespread attention worldwide due to their excellent ayurvedic properties. The purpose of the current study was to evaluate the efficacy of red sandalwood as a source of natural colorant for dying silk fabric, from the perspective of the benefits of having natural dyes. The results show the irradiation of silk and fabric has given good yield under mild conditions by saving time and energy. The results demonstrate that the MW treatment saved time, temperature, extract volume, and salt amount. This technique is more environmentally friendly and sustainable because of the addition of novel bio-mordants. The results show that the MW treatment effectively isolates colorant from red sandalwood extract for silk dyeing.

Author Contributions

Supervisor, S.B.; Co-supervisor, S.A.; Methodology, M.M.; Visualization of data, N.A.; Formal analysis, N.H.; Investigation, F.-u.-R. and M.H. All authors have read and agreed to the published version of the manuscript.

Funding

This join research work has been funded by Department of Chemistry, Riphah International University Faisalabad Campus, Faisalabad, 44000, Pakistan.

Data Availability Statement

The data can be found in the manuscript.

Acknowledgments

The authors are highly grateful to Department of Chemistry, Riphah International University Faisalabad Campus, Faisalabad, for providing the necessary glassware, chemicals and apparatus for smooth running of experiments for this M.Phil Studies. Authors are also thankful to Department of Chemistry, Government College University Faisalabad for facilitating this joint research work of M.Phil. Studies and for smooth running of experiment.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Ardila-Leal, L.D.; Poutou-Piñales, R.A.; Pedroza-Rodríguez, A.M.; Quevedo-Hidalgo, B.E. A brief history of color, the environmental impact of synthetic dyes, and removal by using laccases. Molecules 2021, 26, 3813. [Google Scholar] [CrossRef] [PubMed]

- Elmaaty, T.A.; Abouelenin, S.; Elsisi, H.; Okubayashi, S. Eco-friendly approach for dyeing synthetic fabrics with natural dyes using electron beam irradiation. Fibers Polym. 2022, 23, 759–767. [Google Scholar] [CrossRef]

- Elsahida, K.; Fauzi, A.M.; Sailah, I.; Siregar, I.Z. Sustainability of the use of natural dyes in the textile industry. IOP Conf. Ser. Earth Environ. Sci. 2019, 399, 012065. [Google Scholar] [CrossRef]

- Amutha, K.; Sudhapriya, N. Dyeing of textiles with natural dyes extracted from Terminalia arjuna and Thespesia populnea fruits. Ind. Crops Prod. 2020, 148, 112303. [Google Scholar]

- Slama, H.B.; Chenari, B.A.; Pourhassan, Z.; Alenezi, F.N.; Silini, A.; Cherif-Silini, H.; Belbahri, L. Diversity of synthetic dyes from textile industries, discharge impacts and treatment methods. Appl. Sci. 2021, 11, 6255. [Google Scholar] [CrossRef]

- Manzoor, J.; Sharma, M. Impact of textile dyes on human health and environment. Impact Text. Dyes Pub. Health Environ. 2020, 3, 275–290. [Google Scholar]

- Ayele, A.; Getachew, D.; Kamaraj, M.; Suresh, A. Phycoremediation of synthetic dyes: An effective and eco-friendly algal technology for the dye abatement. J. Chem. 2021, 2021, 9923643. [Google Scholar] [CrossRef]

- Jamee, R.; Siddique, R. Biodegradation of synthetic dyes of textile effluent by microorganisms: An environmentally and economically sustainable approach. Eur. J. Microb. Immun. 2019, 9, 114–118. [Google Scholar] [CrossRef]

- Mehta, M.; Sharma, M.; Pathania, K.; Jena, P.K.; Bhushan, I. Degradation of synthetic dyes using nanoparticles: A mini-review. Environ. Sci. Pollut. Res. 2021, 28, 49434–49446. [Google Scholar] [CrossRef]

- Rafique, M.A.; Jamal, A.; Afzal, G.; Abrar, S.; Kiran, S.; Nosheen, S.; Majeed, T. Photocatalytic mediated remediation of synthetic dyes effluent using zero-valent iron: A comparative study. Desalin. Water Treat. 2021, 237, 284–291. [Google Scholar] [CrossRef]

- Hamdy, D.; Hassabo, A.G.; Othman, H.A. Various natural dyes using plant palette in coloration of natural fabrics. J. Text. Color. Polym. Sci. 2021, 18, 121–141. [Google Scholar] [CrossRef]

- El-Sayed, G.A.; Othman, H.; Hassabo, A.G. An overview on the eco-friendly printing of jute fabrics using natural dyes. J. Text. Color. Polym. Sci. 2021, 18, 239–245. [Google Scholar] [CrossRef]

- Sk, S.; Mia, R.; Haque, M.; Shamim, A.M. Review on extraction and application of natural dyes. Text. Leather Rev. 2021, 4, 218–233. [Google Scholar]

- Chuk, N.; Šala, M.; Gorjanc, M. Development of antibacterial and U.V. protective cotton fabrics using plant food waste and alien invasive plant extracts as reducing agents for the in-situ synthesis of silver nanoparticles. Cellulose 2021, 28, 3215–3233. [Google Scholar]

- Buyukakinci, Y.B.; Guzel, E.T.; Karadag, R. Organic cotton fabric dyed with dyer’s oak and barberry dye by microwave irradiation and conventional methods. Ind. Text. 2021, 72, 30–38. [Google Scholar] [CrossRef]

- Agrawal, A.; Chopra, S. Sustainable dyeing of selected natural and synthetic fabrics using waste teak leaves (Tectona Grandis L.). Res. J. Text. Appar. 2020, 24, 357–374. [Google Scholar] [CrossRef]

- El-Kader, A.; Gafar, S.M. Effect of gamma radiation on a natural pigment and its possible use as a label dosimeter. J. Radioanal. Nucl. Chem. 2022, 331, 461–467. [Google Scholar] [CrossRef]

- Haji, A. Natural dyeing of wool with Henna and yarrow enhanced by plasma treatment and optimized with response surface methodology. J. Text. Inst. 2020, 111, 467–475. [Google Scholar] [CrossRef]

- Rather, L.J.; Zhou, Q.; Ali, A.; Haque, Q.M.R.; Li, Q. Valorization of agro-industrial waste from peanuts for sustainable natural dye production: Focus on adsorption mechanisms, ultraviolet protection, and antimicrobial properties of dyed wool fabric. Food Sci. Technol. 2021, 1, 427–442. [Google Scholar] [CrossRef]

- Zhang, Y.; Islam, S.U.; Rather, L.J.; Li, Q. Recent advances in the surface modification strategies to improve functional finishing of cotton with natural colourants—A review. J. Clean. Prod. 2022, 335, 130313. [Google Scholar] [CrossRef]

- Karadag, R.; Buyukakinci, B.Y.; Torgan, E. Extraction and natural cotton dyeing of valonia oak and anatolian buckthorn by microwave irradiation. J. Nat. Fiber 2022, 19, 159–172. [Google Scholar] [CrossRef]

- Gala, S.; Sumarno, S.; Mahfud, M. Comparison of microwave and conventional extraction methods for natural dyes in wood waste of mahogany (Swietenia mahagoni). J. Appl. Eng. Sci. 2020, 18, 618–623. [Google Scholar] [CrossRef]

- Guzik, P.; Kulawik, P.; Zając, M.; Migdał, W. Microwave applications in the food industry: An overview of recent developments. Crit. Rev. Food Sci. Nutr. 2022, 62, 7989–8008. [Google Scholar] [CrossRef] [PubMed]

- Hosseinnezhad, M.; Gharanjig, K.; Jafari, R.; Imani, H. Green dyeing of woolen yarns with weld and madder natural dyes in the presences of biomordant. Prog. Color Color. Coat. 2021, 14, 35–45. [Google Scholar]

- Rosyida, A.; Masykuri, M. Minimisation of pollution in the cotton fabric dyeing process with natural dyes by the selection of mordant type. Res. J. Text. Appar. 2021, 26, 41–56. [Google Scholar] [CrossRef]

- Safapour, S.; Rather, L.J. Assessment of colorimetric and fastness properties of prangos ferulacea (jashir) dyed wool yarns in conjunction with mixed metal mordant combinations via reflectance spectroscopy. J. Nat. Fibers 2022, 20, 2134267. [Google Scholar] [CrossRef]

- Shahmoradi, G.F.; Moghaddam, M.K.; Tehrani, M. Comparison of the effect of metal mordants and bio-mordants on the colorimetric and antibacterial properties of natural dyes on cotton fabric. Color. Technol. 2021, 137, 689–698. [Google Scholar] [CrossRef]

- Sinnur, H.D.; Verma, D.K.; Kar, T.R.; Samanta, A.K. Effect of dyeing process variables on colour yield and colour fastness properties for cotton khadi fabric dyed with de-oiled red sandal wood waste. J. Inst. Eng. 2021, 102, 273–292. [Google Scholar] [CrossRef]

- Singhee, D.; Chatterjee, I.; Samanta, A.K. Multiple re-cycled dyeing of silk with de-oiled red sandalwood waste using different mordants to achieve dark shades and improved colour fastness. Man-Made Text. Ind. 2022, 50, 84–89. [Google Scholar]

- Khan, A.A.; Adeel, S.; Azeem, M.; Iqbal, N. Exploring natural colorant behavior of husk of durum (Triticum durum Desf.) and bread (Triticum aestivum L.) wheat species for sustainable cotton fabric dyeing. Enviorn. Sci. Pollut. Res. 2021, 28, 51632–51641. [Google Scholar] [CrossRef]

- Gong, K.; Rather, L.J.; Zhou, Q.; Wang, W.; Li, Q. Natural dyeing of merino wool fibers with Cinnamomum camphora leaves extract with mordants of biological origin: A greener approach of textile coloration. J. Text. Inst. 2022, 111, 1038–1046. [Google Scholar] [CrossRef]

- Bhavsar, P.; Fontana, G.; Tonin, C.; Patrucco, A.; Zoccola, M. Superheated water hydrolyses of waste silkworm pupae protein hydrolysate: A novel application for natural dyeing of silk fabric. Dyes Pigment. 2020, 183, 108678. [Google Scholar] [CrossRef]

- Adeel, S.; Zuber, M.A.; Hussaan, M.; Amin, N.; Ozomay, M. Sustainable Extraction of Colourant from Harmal Seeds (Peganum harmala) for Dyeing of Bio-Mordanted Wool Fabric. Sustainability 2022, 14, 12226. [Google Scholar] [CrossRef]

- Syafaatullah, A.Q.; Mahfud, M. Optimization extraction of Indigofera tinctoria L. using microwave-assisted extraction. Conf. Ser. Mater. Sci. Eng. 2021, 1053, 012131. [Google Scholar] [CrossRef]

- El-Apasery, M.A.; Hussein, A.M.; El-Din, N.M.N.; Saleh, M.O.; El-Adasy, A.B.A. Microwave-assisted dyeing of wool fabrics with natural dyes as eco-friendly dyeing method: Part I. Dyeing performance and fastness properties. Egyp. J. Chem. 2021, 64, 3751–3759. [Google Scholar]

- Yameen, M.; Adeel, S.; Nasreen, H.; Ghaffar, A.; Ahmad, T.; Inayat, A. Sustainable eco-friendly extraction of yellow natural dye from haar singhar (Nyctanthes arbor-tritis) for bio coloration of cotton fabric. Environ. Sci. Pollut. Res. 2022, 29, 83810–83823. [Google Scholar] [CrossRef]

- da Silva, R.C.; de Aguiar, S.B.; da Cunha, P.L.R.; de Paula, R.C.M.; Feitosa, J.P. Effect of microwave on the synthesis of polyacrylamide-g-chitosan gel for azo dye removal. React. Funct. Polym. 2020, 148, 104491. [Google Scholar] [CrossRef]

- Habib, N.; Ali, A.; Adeel, S.; Aftab, M.; Inayat, A. Assessment of wild Turmeric–based eco-friendly yellow natural bio-colorant for dyeing of wool fabric. Environ. Sci. Pollut. Res. 2023, 30, 4570–4581. [Google Scholar] [CrossRef]

- Vargas, S.; Santamaria-Holek, I.; Rodríguez, R. Photocurrent oscillations in natural dyes-based DSSCs with different mordant and assistants: Their role in oscillations and color stability. Mater. Chem. Phys. 2022, 286, 126163. [Google Scholar] [CrossRef]

- Adeel, S.; Kiran, S.; Alam, M.; Farooq, T.; Amin, N.; Gulzar, T. Alkanna tinctoria-based sustainable alkanin natural colorant for eco-dyeing of wool. Environ. Sci. Pollut. Res. 2022, 1–8. [Google Scholar] [CrossRef]

- Ennaceur, S.; Bouaziz, A.; Gargoubi, S.; Mnif, W.; Dridi, D. Enhanced Natural Dyeing and Antibacterial Properties of Cotton by Physical and Chemical Pretreatments. Processes 2022, 10, 2263. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhou, Q.; Rather, L.J.; Li, Q. Agricultural waste of Eriobotrya japonica L. (Loquat) seeds and flora leaves as source of natural dye and bio-mordant for coloration and bio-functional finishing of wool textile. Ind. Crops Prod. 2021, 169, 113633. [Google Scholar] [CrossRef]

- Hosseinnezhad, M.; Gharanjig, K.; Imani, H.; Razani, N. Green dyeing of wool yarns with yellow and black myrobalan extract as bio-mordant with natural dyes. J. Nat. Fiber 2022, 19, 3893–3915. [Google Scholar] [CrossRef]

- Jabar, J.M.; Owokotomo, I.A.; Ogunsade, A.F. Sustainable dyeing of cotton fabric with mangiferin: Roles of microwave-rays and bio-mordants on fabric colorimetric and fastness properties. Sustain. Chem. Pharm. 2022, 29, 100822. [Google Scholar] [CrossRef]

- Botteri, L.; Miljković, A.; Glogar, M.I. Influence of cotton pre-treatment on dyeing with onion and pomegranate peel extracts. Molecules 2022, 27, 4547. [Google Scholar] [CrossRef]

- Özomay, M.; Akalın, M. Optimization of fastness properties with gray relational analysis method in dyeing of hemp fabric with natural and classic mordant. J. Nat. Fibers 2022, 19, 2914–2928. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).