Optimization of a New Ultrasound-Assisted Extraction Method of Caffeic Acid from the Aerial Parts of Coriandrum sativum by Using Experimental Design and Ultra-Performance Liquid Chromatography

Abstract

:1. Introduction

2. Materials and Methods

2.1. Chemicals and Reagents

2.2. Coriander Sample Preparation

2.3. Extraction of Phenolic Compounds

2.4. Ultra-High Performance Liquid Chromatography (UPLC) Analysis

2.5. Experimental Design

2.6. Data Analysis

3. Results

3.1. Identification of Phenolic Compounds from Coriander

3.2. Optimization of Extraction Conditions by Experimental Design

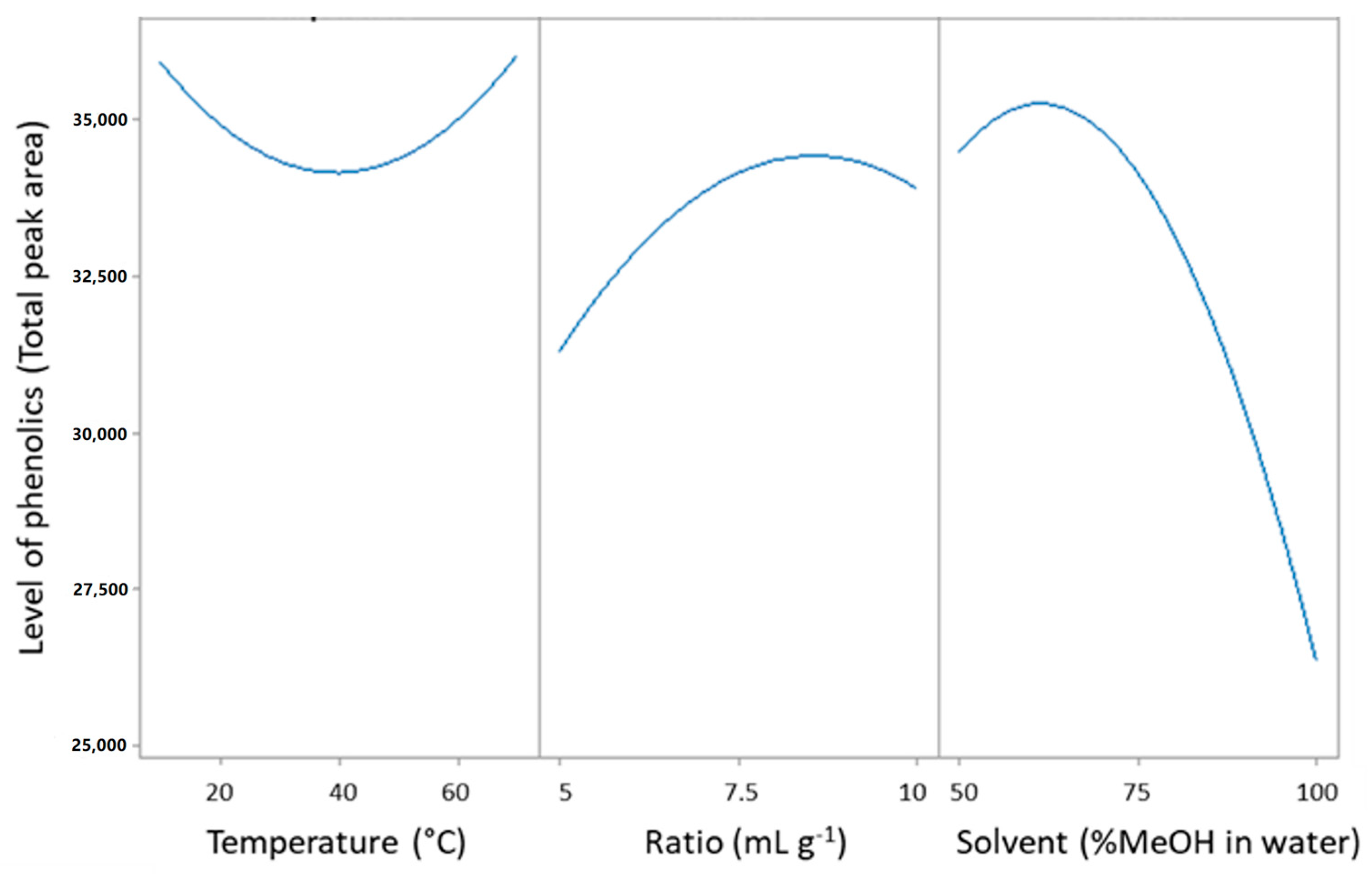

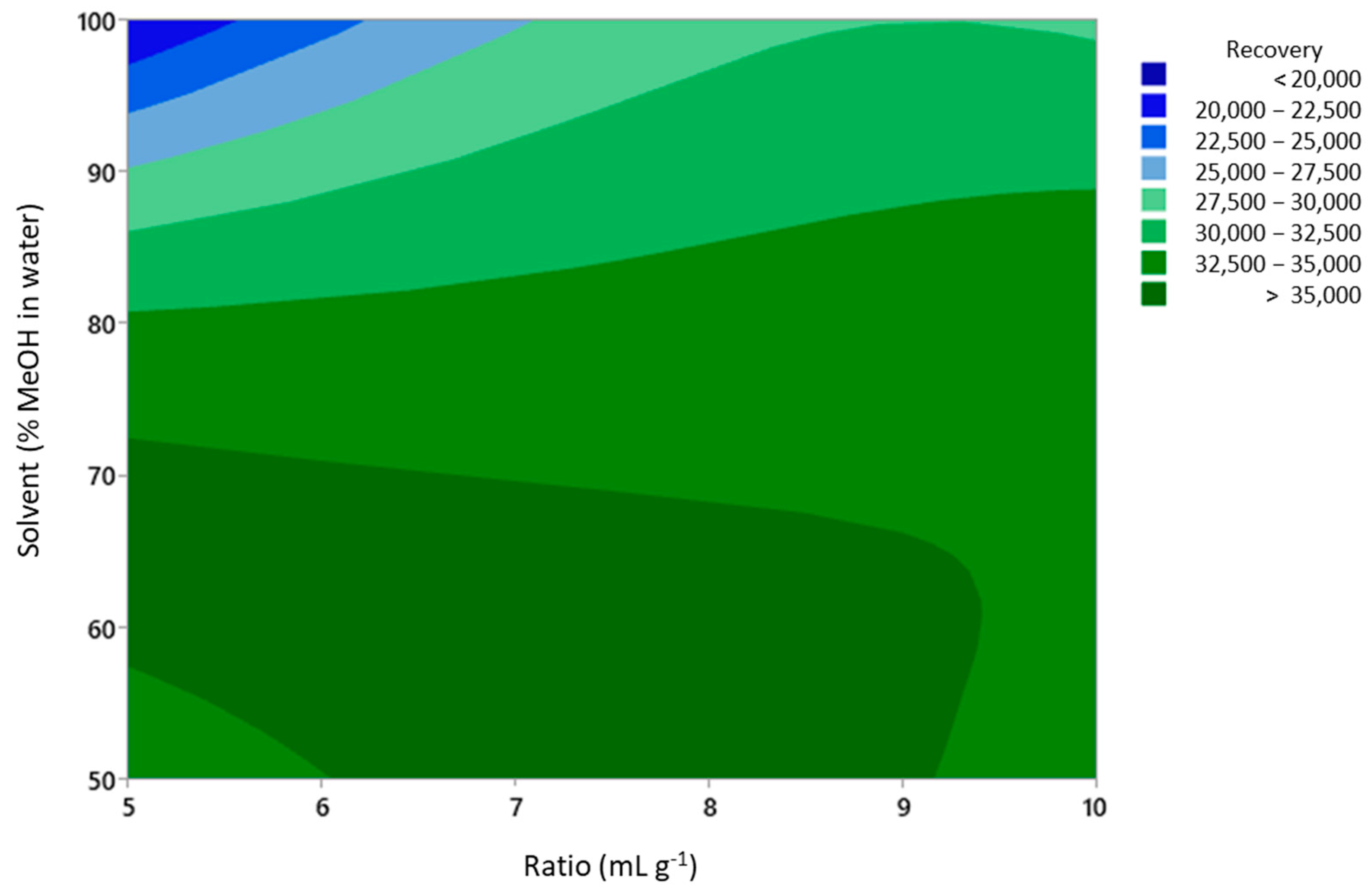

3.3. Effect of Experimental Parameters on the Recovery of Phenolic Compounds

3.4. Optimization of the Response and Verification of the Model

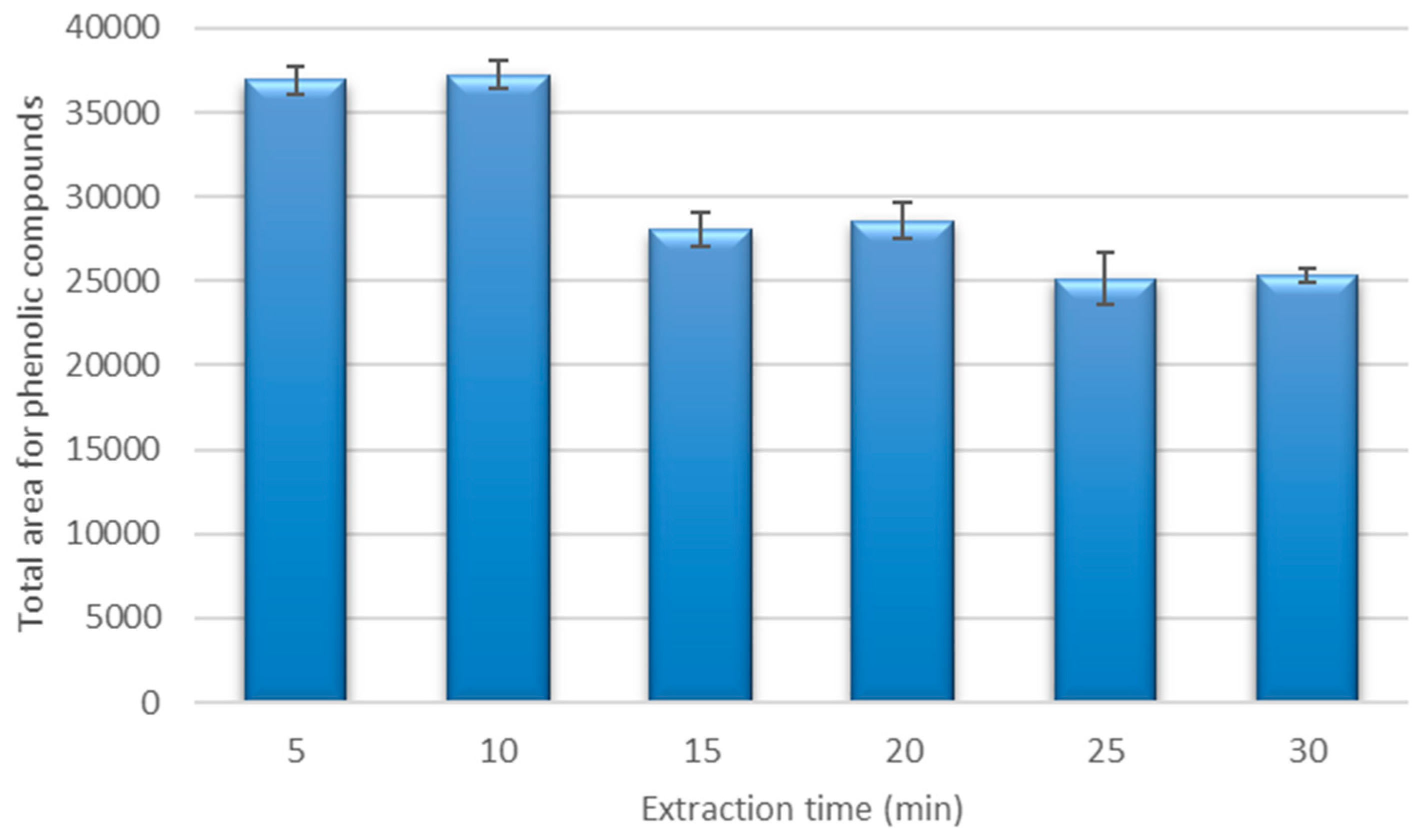

3.5. Extraction Kinetics

3.6. Repeatability and Intermediate Precision of the Method

3.7. Application of the Developed Method to Real Samples

4. Discussion

4.1. Effect of Experimental Parameters on the Recovery of the Phenolic Compounds

4.2. Optimization of the Response and Verification of the Model

4.3. Extraction Kinetic

4.4. Repeatability and Intermediate Precision of the Method

4.5. Application of the Developed Method to Real Samples

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kaur, C.; Kapoor, H.C. Anti-oxidant activity and total phenolic content of some asian vegetables. Int. J. Food Sci. Technol. 2002, 37, 153–161. [Google Scholar] [CrossRef]

- Thangavelu, S.; Balasubramanian, B.; Palanisamy, S.; Shanmugam, V.; Natchiappan, S.; Kalibulla, S.I.; Rathinasamy, B.; Arumugam, V.A. Characterization and phytoconstituents of Petroselinum crispum (Mill) and Coriandrum sativum (Linn) and their impacts on inflammation—An in vitro analysis against human adenocarcinoma cells with molecular docking. S. Afr. J. Bot. 2022, 146, 776–788. [Google Scholar] [CrossRef]

- Kumari, B.; Tiwari, B.K.; Hossain, M.B.; Rai, D.K.; Brunton, N.P. Ultrasound-assisted extraction of polyphenols from potato peels: Profiling and kinetic modelling. Int. J. Food Sci. Technol. 2017, 52, 1432–1439. [Google Scholar] [CrossRef]

- Harborne, J.B. Role of secondary metabolites in chemical defence mechanisms in plants. In Ciba Foundation Symposium 154-Bioactive Compounds from Plants: Bioactive Compounds from Plants: Ciba Foundation Symposium; John Wiley & Sons, Ltd.: Chichester, UK, 2007; Volume 154, pp. 126–139. [Google Scholar]

- Masek, A.; Chrzescijanska, E.; Latos, M. Determination of antioxidant activity of caffeic acid and p-coumaric acid by using electrochemical and spectrophotometric assays. Int. J. Electrochem. Sci. 2016, 11, 10644–10658. [Google Scholar] [CrossRef]

- Dai, J.; Mumper, R.J. Plant phenolics: Extraction, analysis and their antioxidant and anticancer properties. Molecules 2010, 15. [Google Scholar] [CrossRef] [PubMed]

- Mahendra, P.; Bisht, S. Coriandrum sativum: A daily use spice with great medicinal effect. Pharmacogn. J. 2011, 3, 84–88. [Google Scholar] [CrossRef]

- Sahib, N.G.; Anwar, F.; Gilani, A.H.; Hamid, A.A.; Saari, N.; Alkharfy, K.M. Coriander (Coriandrum sativum L.): A potential source of high-value components for functional foods and nutraceuticals-a review. Phyther. Res. 2013, 27, 1439–1456. [Google Scholar] [CrossRef]

- Yashni, G.; Al-Gheethi, A.; Mohamed, R.M.S.R.; Abirama Shanmugan, V.; Abu Bakar, J. Characterization of Coriandrum sativum leaves as a sustainable green biosorbent. Mater. Today Proc. 2021, 47, 1345–1349. [Google Scholar] [CrossRef]

- Wei, J.N.; Liu, Z.H.; Zhao, Y.P.; Zhao, L.L.; Xue, T.K.; Lan, Q.K. Phytochemical and bioactive profile of Coriandrum sativum L. Food Chem. 2019, 286, 260–267. [Google Scholar] [CrossRef]

- Inan, M.; Kirici, S.; Sultan Giray, E.; Turk, M.; Taghikhani, H. Determination of suitable coriander (Coriandrum sativum L.) cultivars for eastern mediterranean region. Turkish J. Field Crops 2014, 19, 1–6. [Google Scholar] [CrossRef]

- Nadeem, M.; Anjum, F.M.; Khan, M.I.; Tehseen, S.; El-Ghorab, A.; Sultan, J.I. Nutritional and medicinal aspects of coriander (Coriandrum sativum L.): A review. Br. Food J. 2013, 115, 743–755. [Google Scholar] [CrossRef]

- Divya, P.; Puthusseri, B.; Neelwarne, B. The effect of plant regulators on the concentration of carotenoids and phenolic compounds in foliage of coriander. LWT 2014, 56, 101–110. [Google Scholar] [CrossRef]

- Prachayasittikul, V.; Prachayasittikul, S.; Ruchirawat, S.; Prachayasittikul, V. Coriander (Coriandrum sativum): A promising functional food toward the well-being. Food Res. Int. 2018, 105, 305–323. [Google Scholar] [CrossRef]

- Silva, F.; Domingues, F.C. Antimicrobial activity of coriander oil and its effectiveness as food preservative. Crit. Rev. Food Sci. Nutr. 2017, 57, 35–47. [Google Scholar] [CrossRef]

- Middleton, E.; Kandaswami, C.; Theoharides, T.C. The effects of plant flavonoids on mammalian cells: Implications for inflammation, heart disease, and cancer. Pharmacol. Rev. 2000, 52, 673–751. [Google Scholar] [PubMed]

- Barros, L.; Dueñas, M.; Dias, M.I.; Sousa, M.J.; Santos-Buelga, C.; Ferreira, I.C.F.R. Phenolic profiles of in vivo and in vitro grown Coriandrum sativum L. Food Chem. 2012, 132, 841–848. [Google Scholar] [CrossRef]

- Meinhart, A.D.; Damin, F.M.; Caldeirão, L.; de Jesus Filho, M.; da Silva, L.C.; da Silva Constant, L.; Teixeira Filho, J.; Wagner, R.; Teixeira Godoy, H. Study of new sources of six chlorogenic acids and caffeic acid. J. Food Compos. Anal. 2019, 82, 103244. [Google Scholar] [CrossRef]

- Alara, O.R.; Abdurahman, N.H.; Ukaegbu, C.I. Extraction of phenolic compounds: A review. Curr. Res. Food Sci. 2021, 4, 200–214. [Google Scholar] [CrossRef]

- Benito-Román, Ó.; Alonso, E.; Cocero, M.J. Ultrasound-assisted extraction of β-glucans from barley. LWT 2013, 50, 57–63. [Google Scholar] [CrossRef]

- Odabaş, H.İ.; Koca, I. Application of response surface methodology for optimizing the recovery of phenolic compounds from hazelnut skin using different extraction methods. Ind. Crops Prod. 2016, 91, 114–124. [Google Scholar] [CrossRef]

- Chemat, F.; Rombaut, N.; Sicaire, A.G.; Meullemiestre, A.; Fabiano-Tixier, A.S.; Abert-Vian, M. Ultrasound assisted extraction of food and natural products. Mechanisms, techniques, combinations, protocols and applications. A review. Ultrason. Sonochem. 2017, 34, 540–560. [Google Scholar] [CrossRef] [PubMed]

- Palma, M.; Barbero, G.F.; PiñEiro, Z.; Liazid, A.; Barroso, C.G.; Rostagno, M.A.; Prado, J.M.; Meireles, M.A.A. Extraction of Natural Products: Principles and Fundamental Aspects; The Royal Society of Chemistry: London, UK, 2013; ISBN 9781849736060. [Google Scholar]

- Carrera, C.; Ruiz-Rodríguez, A.; Palma, M.; Barroso, C.G. Ultrasound-assisted extraction of amino acids from grapes. Ultrason. Sonochem. 2015, 22, 499–505. [Google Scholar] [CrossRef] [PubMed]

- Espada-Bellido, E.; Ferreiro-González, M.; Carrera, C.; Palma, M.; Barroso, C.G.; Barbero, G.F. Optimization of the ultrasound-assisted extraction of anthocyanins and total phenolic compounds in mulberry (Morus nigra) pulp. Food Chem. 2017, 219, 23–32. [Google Scholar] [CrossRef]

- Rostagno, M.A.; Palma, M.; Barroso, C.G. Ultrasound-assisted extraction of soy isoflavones. J. Chromatogr. A 2003, 1012, 119–128. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Q.A.; Fan, X.H.; Li, T.; Zhang, Z.Q.; Liu, Y.K.; Li, X.P. Optimisation of ultrasound extraction for flavonoids from semen astragali complanati and its identification by HPLC-DAD-MS/MS. Int. J. Food Sci. Technol. 2013, 48, 1970–1976. [Google Scholar] [CrossRef]

- Piñeiro, Z.; Guerrero, R.F.; Fernández-Marin, M.I.; Cantos-Villar, E.; Palma, M. Ultrasound-assisted extraction of stilbenoids from grape stems. J. Agric. Food Chem. 2013, 61, 12549–12556. [Google Scholar] [CrossRef] [PubMed]

- Aadil, R.M.; Zeng, X.A.; Wang, M.S.; Liu, Z.W.; Han, Z.; Zhang, Z.H.; Hong, J.; Jabbar, S. A potential of ultrasound on minerals, micro-organisms, phenolic compounds and colouring pigments of grapefruit juice. Int. J. Food Sci. Technol. 2015, 50, 1144–1150. [Google Scholar] [CrossRef]

- Setyaningsih, W.; Saputro, I.E.; Carrera, C.A.; Palma, M. Optimisation of an ultrasound-assisted extraction method for the simultaneous determination of phenolics in rice grains. Food Chem. 2019, 288, 221–227. [Google Scholar] [CrossRef] [PubMed]

- Setyaningsih, W.; Saputro, I.E.; Palma, M.; Barroso, C.G. Pressurized liquid extraction of phenolic compounds from rice (Oryza sativa) grains. Food Chem. 2016, 192, 452–459. [Google Scholar] [CrossRef]

- Yusoff, I.M.; Mat Taher, Z.; Rahmat, Z.; Chua, L.S. A review of ultrasound-assisted extraction for plant bioactive compounds: Phenolics, flavonoids, thymols, saponins and proteins. Food Res. Int. 2022, 157, 111268. [Google Scholar] [CrossRef] [PubMed]

- Wangensteen, H.; Samuelsen, A.B.; Malterud, K.E. Antioxidant activity in extracts from coriander. Food Chem. 2004, 88, 293–297. [Google Scholar] [CrossRef]

- Ivanovic, M.; Razboršek, M.I.; Košir, I.J.; Kolar, M. Response surface methodology: An optimal design applied for maximum ultrasound-assisted extraction efficiency of phenolic acids from Coriandrum sativum L. J. Appl. Bot. Food Qual. 2019, 92, 378–387. [Google Scholar] [CrossRef]

- Sriti, J.; Aidi Wannes, W.; Talou, T.; Ben Jemia, M.; Elyes Kchouk, M.; Marzouk, B. Antioxidant properties and polyphenol contents of different parts of coriander (Coriandrum sativum L.) fruit. Riv. Ital. Delle Sostanze Grasse 2012, 89, 253–262. [Google Scholar]

- Zeković, Z.; Vladić, J.; Vidović, S.; Adamović, D.; Pavlić, B. Optimization of microwave-assisted extraction (MAE) of coriander phenolic antioxidants-response surface methodology approach. J. Sci. Food Agric. 2016, 96, 4613–4622. [Google Scholar] [CrossRef]

- Zeković, Z.; Kaplan, M.; Pavlić, B.; Olgun, E.O.; Vladić, J.; Canli, O.; Vidović, S. Chemical characterization of polyphenols and volatile fraction of coriander (Coriandrum sativum L.) extracts obtained by subcritical water extraction. Ind. Crops Prod. 2016, 87, 54–63. [Google Scholar] [CrossRef]

- Zeković, Z.; Pavlić, B.; Cvetanović, A.; Đurović, S. Supercritical fluid extraction of coriander seeds: Process optimization, chemical profile and antioxidant activity of lipid extracts. Ind. Crops Prod. 2016, 94, 353–362. [Google Scholar] [CrossRef]

- Zeković, Z.; Bušić, A.; Komes, D.; Vladić, J.; Adamović, D.; Pavlić, B. Coriander seeds processing: Sequential extraction of non-polar and polar fractions using supercritical carbon dioxide extraction and ultrasound-assisted extraction. Food Bioprod. Process. 2015, 95, 218–227. [Google Scholar] [CrossRef]

- De Almeida Melo, E.; Mancini Filho, J.; Barbosa Guerra, N. Characterization of antioxidant compounds in aqueous coriander extract (Coriandrum sativum L.). LWT 2005, 38, 15–19. [Google Scholar] [CrossRef]

- Hadjmohammadi, M.; Sharifi, V. Investigation of optimum extraction conditions for determination of quercetin and kaempferol in coriander (Conundrum sativum L.) by using experimental design and HPLC. J. Food Drug Anal. 2009, 17, 7. [Google Scholar] [CrossRef]

- El-Zaeddi, H.; Calín-Sánchez, Á.; Nowicka, P.; Martínez-Tomé, J.; Noguera-Artiaga, L.; Burló, F.; Wojdyło, A.; Carbonell-Barrachina, Á.A. Preharvest treatments with malic, oxalic, and acetylsalicylic acids affect the phenolic composition and antioxidant capacity of coriander, dill and parsley. Food Chem. 2017, 226, 179–186. [Google Scholar] [CrossRef]

- Bouafia, M.; Colak, N.; Ayaz, F.A.; Benarfa, A.; Harrat, M.; Gourine, N.; Yousfi, M. The optimization of ultrasonic-assisted extraction of Centaurea sp. antioxidative phenolic compounds using response surface methodology. J. Appl. Res. Med. Aromat. Plants 2021, 25, 100330. [Google Scholar] [CrossRef]

- Palma, M.; Taylor, L.T. Supercritical Fluid Extraction of 5-Hydroxymethyl-2-furaldehyde from Raisins. J. Agric. Food Chem. 2001, 49, 628–632. [Google Scholar] [CrossRef] [PubMed]

- Amiri, S.; Shakeri, A.; Sohrabi, M.R.; Khalajzadeh, S.; Ghasemi, E. Optimization of ultrasonic assisted extraction of fatty acids from Aesculus hippocastanum fruit by response surface methodology. Food Chem. 2019, 271, 762–766. [Google Scholar] [CrossRef]

- Dziri, S.; Hassen, I.; Fatnassi, S.; Mrabet, Y.; Casabianca, H.; Hanchi, B.; Hosni, K. Phenolic constituents, antioxidant and antimicrobial activities of rosy garlic (Allium roseum var. odoratissimum). J. Funct. Foods 2012, 4, 423–432. [Google Scholar] [CrossRef]

- Spigno, G.; Tramelli, L.; De Faveri, D.M. Effects of extraction time, temperature and solvent on concentration and antioxidant activity of grape marc phenolics. J. Food Eng. 2007, 81, 200–208. [Google Scholar] [CrossRef]

- Luthria, D.L. Influence of experimental conditions on the extraction of phenolic compounds from parsley (Petroselinum crispum) flakes using a pressurized liquid extractor. Food Chem. 2008, 107, 745–752. [Google Scholar] [CrossRef]

- Alberti, A.; Zielinski, A.A.F.; Zardo, D.M.; Demiate, I.M.; Nogueira, A.; Mafra, L.I. Optimisation of the extraction of phenolic compounds from apples using response surface methodology. Food Chem. 2014, 149, 151–158. [Google Scholar] [CrossRef]

- Vuong, Q.V.; Goldsmith, C.D.; Dang, T.T.; Nguyen, V.T.; Bhuyan, D.J.; Sadeqzadeh, E.; Scarlett, C.J.; Bowyer, M.C. Optimisation of ultrasound-assisted extraction conditions for phenolic content and antioxidant capacity from Euphorbia tirucalli using response surface methodology. Antioxidants 2014, 3, 604–617. [Google Scholar] [CrossRef]

- Teofilović, B.; Grujić-Letić, N.; Goločorbin-Kon, S.; Stojanović, S.; Vastag, G.; Gadžurić, S. Experimental and chemometric study of antioxidant capacity of basil (Ocimum basilicum) extracts. Ind. Crops Prod. 2017, 100, 176–182. [Google Scholar] [CrossRef]

- AOAC International. Appendix F: Guidelines for Standard Method Performance Requirements. AOAC Official Methods of Analysis. 2016. Available online: https://www.scirp.org/(S(351jmbntvnsjt1aadkposzje))/reference/ReferencesPapers.aspx?ReferenceID=2613575 (accessed on 10 January 2023).

- Stipcovich, T.; Barbero, G.F.; Ferreiro-González, M.; Palma, M.; Barroso, C.G. Fast analysis of capsaicinoids in Naga Jolokia extracts (Capsicum chinense) by high-performance liquid chromatography using fused core columns. Food Chem. 2018, 239, 217–224. [Google Scholar] [CrossRef]

| Independent Variables | Units | Symbols | Coded Levels | ||

|---|---|---|---|---|---|

| −1 | 0 | 1 | |||

| Methanol in water | (%) | X1 | 50 | 75 | 100 |

| Temperature | (°C) | X2 | 10 | 40 | 70 |

| Liquid-to-solid ratio | (mL∙g−1) | X3 | 5.0 | 7.5 | 10.0 |

| Run Order | X1 Methanol (%) | X2 Temperature (°C) | X3 LS Ratio (mL∙g−1) | Experimental Area (µv × s) | Predicted Area (µv × s) | Relative Error of Prediction (%) |

|---|---|---|---|---|---|---|

| 1 | 50 | 40 | 10 | 33,370.5 | 31,955.8 | −4.3 |

| 2 | 50 | 70 | 7.5 | 36,889.7 | 37,165.9 | 0.7 |

| 3 | 100 | 40 | 5 | 19,821.3 | 21,235.9 | 6.9 |

| 4 | 100 | 40 | 10 | 29,546.6 | 28,421.9 | −3.9 |

| 5 | 75 | 10 | 5 | 33,530.6 | 32,392.2 | −3.5 |

| 6 | 75 | 10 | 10 | 34,979.8 | 36,380.8 | 3.9 |

| 7 | 50 | 40 | 5 | 32,833.2 | 33,957.9 | 3.4 |

| 8 | 75 | 70 | 10 | 33,958.5 | 35,096.9 | 3.3 |

| 9 | 75 | 40 | 7.5 | 34,846.4 | 34,165.4 | −2.0 |

| 10 | 75 | 70 | 5 | 35,302.5 | 33,901.6 | −4.0 |

| 11 | 100 | 70 | 7.5 | 27,464.7 | 27,451.0 | 0.0 |

| 12 | 75 | 40 | 7.5 | 35,045.7 | 34,165.4 | −2.5 |

| 13 | 75 | 40 | 7.5 | 32,604.2 | 34,165.4 | 4.7 |

| 14 | 50 | 10 | 7.5 | 35,452.5 | 35,466.2 | 0.0 |

| 15 | 100 | 10 | 7.5 | 29,201.4 | 28,925.2 | −1.0 |

| Average of absolute relative errors (%) | 3.8 | |||||

| Variable | X1 | X2 | X3 | X12 | X22 | X32 | X1X2 | X1X3 | X2X3 | Lack of Fit |

|---|---|---|---|---|---|---|---|---|---|---|

| p-value | 0.002 | 0.934 | 0.103 | 0.011 | 0.116 | 0.168 | 0.427 | 0.054 | 0.481 | 0.308 |

| Caffeic Acid | Isoquercitrin | Q-3-O-Glucuronide | Rutin | |

|---|---|---|---|---|

| Sample 1 | 3927 ± 208 | 276.2 ± 6.6 | 3077 ± 73 | 406 ± 13 |

| Sample 2 | 2879 ± 138 | 183.3 ± 5.7 | 2134 ± 13 | 335 ± 13 |

| Sample 3 | 4261 ± 136 | 89.7 ± 1.3 | 3782 ± 39 | 340 ± 17 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Messaoudene, L.; Palma, M.; Carrera, C.A.; Setyaningsih, W.; Hazzit, M.; Djebbar, R. Optimization of a New Ultrasound-Assisted Extraction Method of Caffeic Acid from the Aerial Parts of Coriandrum sativum by Using Experimental Design and Ultra-Performance Liquid Chromatography. Separations 2023, 10, 106. https://doi.org/10.3390/separations10020106

Messaoudene L, Palma M, Carrera CA, Setyaningsih W, Hazzit M, Djebbar R. Optimization of a New Ultrasound-Assisted Extraction Method of Caffeic Acid from the Aerial Parts of Coriandrum sativum by Using Experimental Design and Ultra-Performance Liquid Chromatography. Separations. 2023; 10(2):106. https://doi.org/10.3390/separations10020106

Chicago/Turabian StyleMessaoudene, Lynda, Miguel Palma, Ceferino A. Carrera, Widiastuti Setyaningsih, Mohamed Hazzit, and Réda Djebbar. 2023. "Optimization of a New Ultrasound-Assisted Extraction Method of Caffeic Acid from the Aerial Parts of Coriandrum sativum by Using Experimental Design and Ultra-Performance Liquid Chromatography" Separations 10, no. 2: 106. https://doi.org/10.3390/separations10020106

APA StyleMessaoudene, L., Palma, M., Carrera, C. A., Setyaningsih, W., Hazzit, M., & Djebbar, R. (2023). Optimization of a New Ultrasound-Assisted Extraction Method of Caffeic Acid from the Aerial Parts of Coriandrum sativum by Using Experimental Design and Ultra-Performance Liquid Chromatography. Separations, 10(2), 106. https://doi.org/10.3390/separations10020106